Page 1

QR 6619591

Page 2

Note. The sensor set-up depends on pallet size.

X85 Pallet

Page 3

Function description

The Index station is divided into Pre-stop position and

Process position.

Pre-stop position

The Pre-stop position is relieving the Process position of

the queue-pressure. The RFID-reader of the Pre-stop

identifies the pallet, affecting the ef fi cie ncy as pallets with

other destination quickly pass the Process position.

Process position

The Process position receives one pallet at a time from

the Pre-stop.

If the pallet should be processed, it is caught by the

integrated stop. Thereafter it is located and process is

allowed to start for the first index position.

When processing is finished for the first index position, the

pallet is unlocked simultaneously as the integrated stop is

releasing the flow downstream.

The index sensor detects the next index position (index

position 2) and triggers the index motion to stop th e pa ll e t.

The pallet is located in the second index position, the

index motion is disactivated and processing is allowed to

start for second index position.

When processing is finished, the pallet it unlocated.

Pre-stop

position

Internal positions

Data:

Pre-stop queue pressure limit: 100 kg

Process position accuracy: +/- 0,1 mm

The Exchange time [sec] shown below is cycle time

with process time excluded and is only valid for

125 mm pallet size

Process

position

5 m/min 10 m/min 15 m/min

Position 1 3,5 1,9 1,7

Position 2 2,2 1,3 1,2

Notes:

The station is not equipped with any downstream

maxqueue sensor as the design is only possible with

an overview of the line as a whole.

The sensor configuration is depending on the size of

pallet. Mixed flow with reference to pallet length is not

possible.

X85 Pallet

Page 4

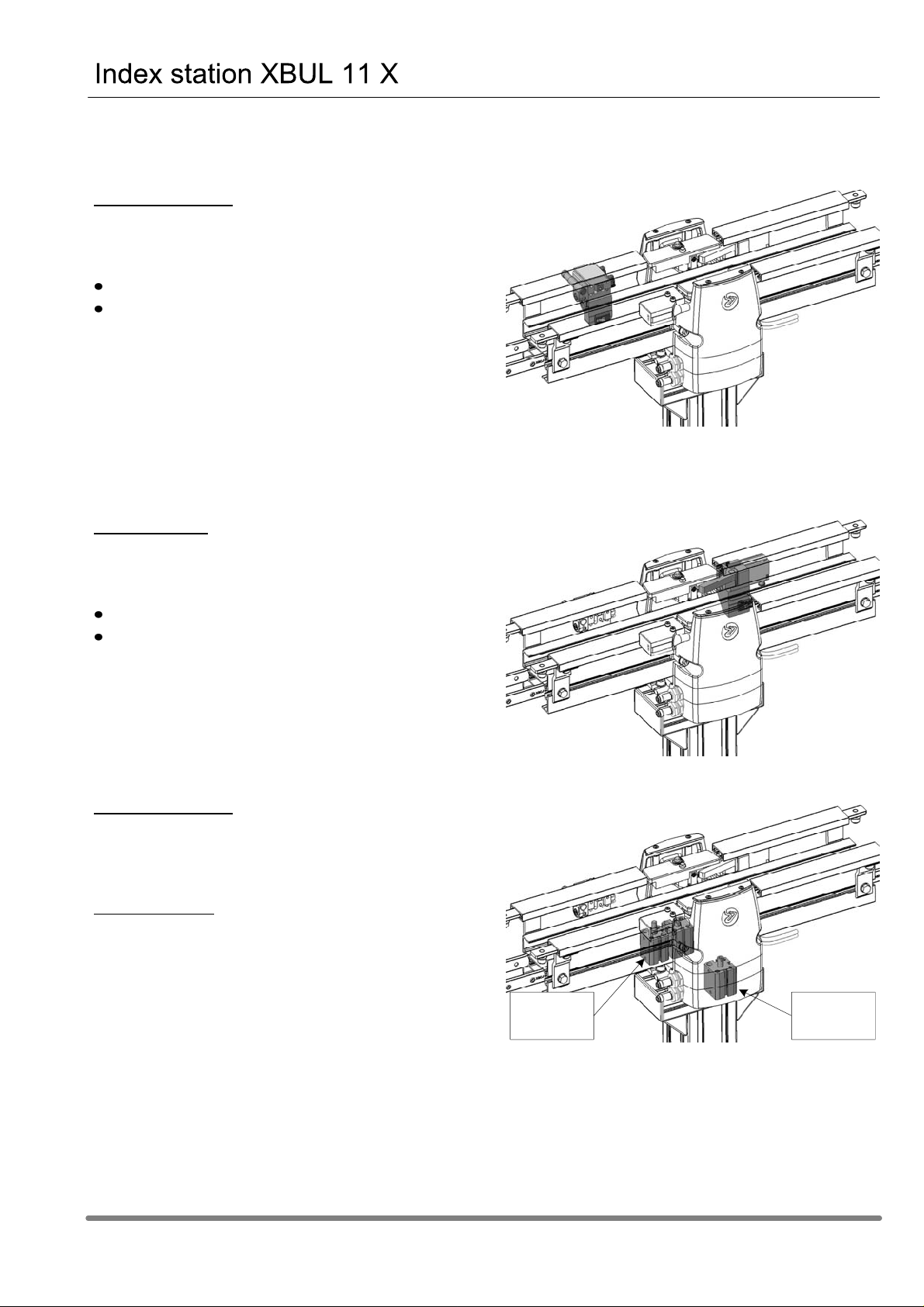

Initiators and actuators

B1

A1

A3

A2

A4 B2*

B3

B10

Initiators

B1 Pre-stop

B2 In position

B3 Index

B4 Locating Up

B5 Locating Down

B10 RFID

* B2's position depends on pallet size.

B2*

B4

B5

Actuators

A1 Pre-stop. Single acting.

A2 Stop. Single acting.

A3 Locating. Double acting.

A4 Index. Double acting.

X85 Pallet

Page 5

Interfaces

Initiators

B1: M12-connector, 3-pin

B2: M12-connector, 3-pin

B3: M12-connector, 3-pin

B4: M12-connector, 3-pin

B5: M12-connector, 3-pin

B10: M12-connector, 4-pin (Asi)

Note: Sensors placed inside the Locating housing are

equipped with sensor cables (with the given connector

type above), reaching outside the housing.

Actuators

Pneumatic cylinders

A1: 6 mm

A2: 6 mm

A3: 6 mm (tubing)

A4: 6 mm

Note: The A3 cylinder, placed inside the Locating housing,

is equipped with tubes (with the given size above),

reaching outside the housing.

X85 Pallet

Page 6

Spare parts

Standard Des. Manufacturer Type Order FlexLink ID

name number

Pallet 160x125 mm

Sensor B1 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor bracket FlexLink XBPB 12 H 5110793

Sensor B2 SICK IQ10-06NPS-KT1 7900209 5058574

Sensor B3 SICK IM08-0 2BPS-ZT1 7900005 5110130

Sensor B4 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor B5 SICK IM12-08NPS-ZC1 7900045 5058572

RFID Reader/Writer B10 IFM DTA100 5058152

Read/Write head bracket FlexLink 5110840

Pallet 160x175 mm

Sensor B1 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor bracket FlexLink XBPB 12 H 5110793

Sensor B2 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor bracket FlexLink XBPB 12 H

Sensor B3 SICK IM08-0 2BPS-ZT1 7900005 5110130

Sensor B4 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor B5 SICK IM12-08NPS-ZC1 7900045 5058572

RFID Reader/Writer B10 IFM DTA100 5058152

Read/Write head bracket FlexLink 5110840

Pallet 160x225 mm

Sensor B1 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor bracket FlexLink XBPB 12 H 5110793

Sensor B2 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor bracket FlexLink XBPB 12 H 5110793

Sensor B3 SICK IM08-0 2BPS-ZT1 7900005 5110130

Sensor B4 SICK IM12-08NPS-ZC1 7900045 5058572

Sensor B5 SICK IM12-08NPS-ZC1 7900045 5058572

RFID Reader/Writer B10 IFM DTA100 5058152

Read/Write head bracket FlexLink 5110840

X85 Pallet

Page 7

Cylinder details

Cylinder A1 ”Pre-stop”

Type: Single acting

Function:

Pressurized: Releases the pallet flow

No pressure: Blocks the pallet flow

For security reasons, the pallet stop is blocking the flow in

case of a pressure drop, preventing pallets from travelling

uncontrolled along the conveyor.

The stop should not re-block the flow while a pallet puck is

in a position where it could be clamped.

It is recommended to re-block the flow after each pallet.

Cylinder A2 ”Stop”

Type: Single acting

Function:

Pressurized: Releases the pallet flow

No pressure: Blocks the pallet flow

Cylinder A1 ”Pre-stop”

For security reasons, the pallet stop is blocking the flow in

case of a pressure drop, preventing pallets from travelling

uncontrolled along the conveyor.

Cylinder A3 ”Locating”

Type: Double acting

Function: Locates the pallet.

Cylinder A4 ”Index”

Type: Double acting

Function:Index the pallet.

There is no sensor attatch to the ”index” cylinder

Note 1: It is recommended that flow control valves are

used, for example Festo GR-QS-6 (193969).

Cylinder A4

”Index”

Cylinder A2 ”stop”

Cylinder A3

”Locating”

Cylinder A3 and A4

X85 Pallet

Page 8

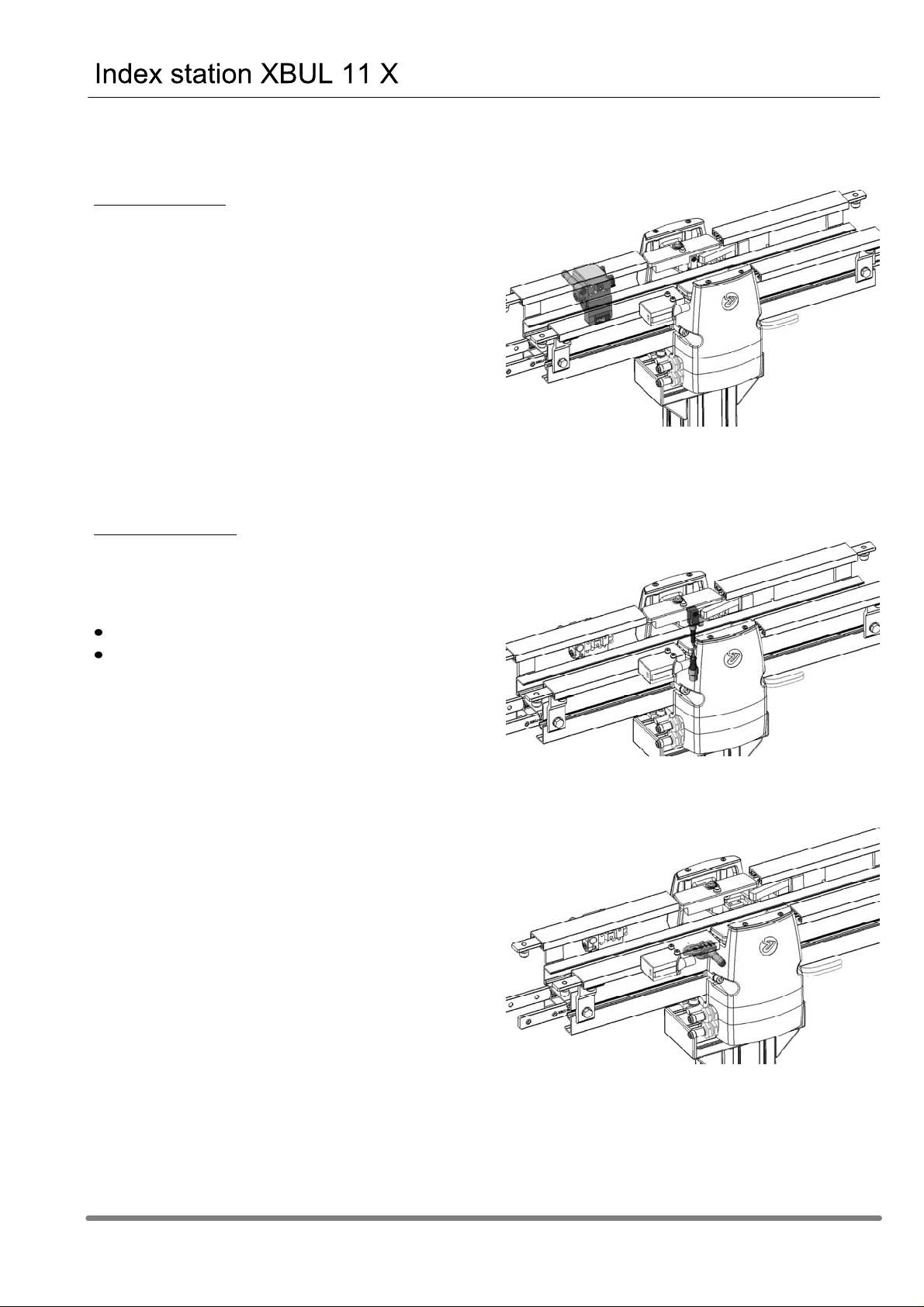

Sensor details

Sensor B1 ”Pre-stop”

Type: Proximity switch, inductive

Position: Placed together with Pre-stop.

Function: Detects the initiator plate of the pallet before the

pallet is stopped and stays active until the pallet leaves

the stop.

The reason why the pallet is detected by the sensor

before the pallet hits the stop, is to enchance the

efficiency of the pallet flow. As the pallet is detected in

advance, the controller has time to take a decision

whether or not the pallet should be stopped. If if should

pass, the stop change state to ”Release flow” before the

pallet reach it.

Sensor B2 ”In position”

Type: Proximity switch, inductive. Model depends on

pallet length.

Sensor B1 ”Pre-stop”

Position: Depends on pallet length.

125: Inside process position, left side

175/225: Before process position, right side

Function: Detects the pallet initiator plate when the pallet

is stopped in the process position.

Sensor B2, 125 mm pallet length

X85 Pallet

Sensor B2, 175/225 mm pallet length

Page 9

Sensor details

Sensor B3 and B4 ”Locating up/down”

Type: Proximity switch, inductive

Function: Activated then the pallet is located/released.

Sensor B3 and B4, Locating up/down

X85 Pallet

Page 10

Mechanical spare parts

No. Flexlink no. Type

C1 5105005 Festo, ADN-25-10-I-P-A

C2 5110079 Igus, WLM-1618-26

C3 5059820 Shaft

C4 5059821 Shaft

C5 5110079 Igus, WLM-1012-16

C6 5059849 Shaft

C7 5105009 Festo, ADN-20-10-A-P-A

C7

C4

C5

Spare parts position balloons

C6

C3

C2

C1

X85 Pallet

Page 11

Pneumatic drawing

X85 Pallet

Loading...

Loading...