Page 1

8050179

X65 Function modules

User Documentation

Created by EBCCW 96:05Created by EBCCW 00:06Created by EBCCW 96:05Created by EBCCW 00:06

Created by EBCCW 00:06

Page 2

Created by EBCCW 96:05Created by EBCCW 00:06

Page 3

8050179

X65 Function modules

Created by EBCCW 96:05Created by EBCCW 00:06Created by EBCCW 96:05Created by EBCCW 00:06

Created by EBCCW 00:06

Page 4

Created by EBCCW 96:05Created by EBCCW 00:06

Page 5

© Flexlink AB 2013

X65 Function modules

User Documentation

All Rights Reserved

No part of this program and manual may be used, reproduced, stored or

transmitted in any form or by any means without the written permission of

FlexLink Components AB. The contents of this manual are for informational

use only. All information and specifications contained in this document

have been carefully checked to the best efforts of FlexLink Components

AB, and are believed to be true and accurate as of time of publishing.

However, due to continued efforts in product development FlexLink

Components AB reserves the right to modify products and its manuals

without notice.

FlexLink Components AB assumes no responsibility or liability on any

errors or inaccuracies in this program or documentation. Any kind of

material damages or other indirect consequences resulting from any

FlexLink Components AB´s product part, documentation discrepancies

and errors or non-anticipated program behavior are limited to the value of

appropriate products purchased from FlexLink Components AB. The

products are delivered to the customer at the ’as is’ state and revision level

they are on the moment of purchasing, and are declared in detail in the

license agreements between FlexLink Components AB and user. User

accepts and is obliged to follow the guidelines stated in the separate

license agreement needed in using any parts of this product package.

8050179

Created by EBCCW 00:06

Page 6

8050179

Page 7

Preface 1

1 Safety 3

1.1 System information 3

1.2 The most important safety conditions 4

1.3 Description of safety provisions 6

1.4 Safety information 7

1.5 Intended use 7

2 Technical specification 8

2.1 Operating conditions 8

2.2 Ordering information 9

3 Functions 10

3.1 Function description for Divert modules 10

3.2 Function description for Merge modules 15

3.3 Function description for Divert and Merge modules 45° 19

3.4 Function description for Divert and Merge module 90° 24

4 Unload the X65 function modules 29

4.1 Preparation 29

8050179

Created by EBCCW 00:06

4.2 Unloading instructions 30

5 Mounting, installation, adjustment 31

0

Page 8

5.1 Recommended tools 31

5.2 Basic value, Torque for dimension 31

6 Put out of commission 35

6.1 Disconnect the power sources 35

6.2 Disassemble 35

6.3 Reuse 35

7 Recommended spare parts 36

8 Drawings 37

8.1 Pneumatic drawing 37

9 Supplier’s information 39

1

8050179

Page 9

Preface

Preface

Purpose of this manual

The purpose of this manual is to describe a number of operations that are

intended for the user concerned. Here it becomes clear how the user can

work as well and as safely as possible. By making use of clear illustrations

and texts FlexLink wants to achieve a simple and safe way of working with

the X65 function modules. This document contains remarks that point out

a risky or specific situation to the user. In many cases this situation is provided with one of the symbols given below.

General warning for danger!

.

Warning for electrical voltage!

.

Attention, this is an important notice!

.

Compliance with the operations described in this document is important in

order to prevent dangerous situations and unnecessary damage to the X65

system. Carefully keep this document! It is recommended to keep one copy

near the conveyor system and one copy with your technical documentation.

Structure of the manual

The user’s manual has been composed in such a way, that a number of operations can quickly and easily be found. This manual will not describe operations that are not meant for the user. It does, however , indicate what the

user must do when carrying out a certain operation, for example calling in

technical staff. FlexLink would like to point out to the user that section 1

Safety is to be read carefully.

8050179

Created by EBCCW 00:06

1

Page 10

Requirements of the user

The X65 Conveyor system may be operated by any adult person who has

become acquainted with section 1 Safety . If the user is not technically qualified, he or she may not carry out any maintenance or repair activities on

the system.

. Note! Maintenance activities on the system may only be carried

out by a technically qualified person.

. NB: Technically qualified employees means: employees that

have followed an adequate training for carrying out the activities

involved and have a good ability to read and understand the

English language.

Preface

2

8050179

Page 11

Safety

1 Safety

The X65 function modules has been designed in such a way , that it can be

used and maintained in a safe way. This holds for the application, the circumstances and the instructions described in the manual. Any person

working with or on this system should study the manual and follow the instructions. It is the responsibility of the employer to make sure that the employee is familiar with and follows these instructions.

The company or the country in which the system is used may require extra

safety measures. This particularly applies to the working conditions. This

manual does not describe how these are to be complied with. In case of

doubt, consult your government or safety officer!

1.1 System information

The project number and/or general drawing number shall always be specified when communicating with FlexLink with respect to the module.

Project number See module nameplate

Module type: Module

Date of manufacture See module nameplate

Identification. no. See module nameplate

Figure 1 Module nameplate

8050179

Created by EBCCW 00:06

The modules nameplate is located on the module beam.

3

Page 12

1.2 The most important safety conditions

At the moment that the X65 system is going to be operated by a user, the

following safety conditions must be met:

• Only persons who have read and understood the operating instructions are allowed to operate, maintain and clean the system.

• Provide good ambient lighting to enable the operator to work well

and orderly with the system.

1.2.1 General

. • Incorrect use of the equipment can cause personal injury.

• Do not wear clothing or other articles that can fasten.

• Follow the instructions in this user manual when transporting the

machine. FlexLink Components AB must approve all modifications or changes to this system.

Safety

• Only use recommended spare parts.

• Only authorised personnel may open electrical units.

• FlexLink is not responsible for damage if service on the equipment is not performed in accordance with this user manual.

1.2.2 Service technicians

. Service technicians must have:

• Sufficient knowledge for reading technical information

• Ability to comprehend technical drawings

• Basic knowledge of mechanics

• Sufficient knowledge in the use of hand tools

4

8050179

Page 13

Safety

1.2.3 Electricians

. Electricians must have:

• Experience from similar installations

• Sufficient knowledge to work from drawings and wiring diagrams

• Knowledge of local safety regulations for electrical power and automation

To avoid risks, only experienced personnel with technical knowledge and

experience may perform repair work on the electronics components.

1.2.4 Operators

. To correctly use the equipment, operators must have appropriate training

and/or experience.

8050179

Created by EBCCW 00:06

5

Page 14

1.3 Description of safety provisions

Before putting the system into operation some safety provisions are to be

taken care of. The purpose of these safety provisions is to protect the user ,

the product and the system against undesired situations (damage). Without

these safety provisions FlexLink cannot give a guarantee on any damage

caused in absence of these safety provisions.

The table below gives a general description of the safety provisions required. Here it should be noted that only technically qualified employees

are allowed to work on the settings of the safety provisions!

. . . 1.3.1 Noise level

. The noise level produced by the X65 conveyor system is under 70 dB(A).

Safety

1.3.2 Power supply

. Power such as electrical, pneumatic, etc.

Never bypass the safety system.

Before working on powered components (i.e. motors), pneumatic activators of power supply the main switch must be turned off and locked. The

key is retained by the service technician until work is finished.

Examples of service work include:

• Disconnection of wiring/tubing

• Replacement of components, i.e. motors, etc.

• Service work performed on the machine that cannot be seen from

the electrical cabinet.

For adjustment of photo-electric cells, inductive sensors, etc., power is required:

- Stop the system and wait until the moving parts have come to

a complete stop.

6

8050179

Page 15

Safety

1.4 Safety information

For a safe operation of the conveyor system a number of safety measures

are to be taken. These include the following measures:

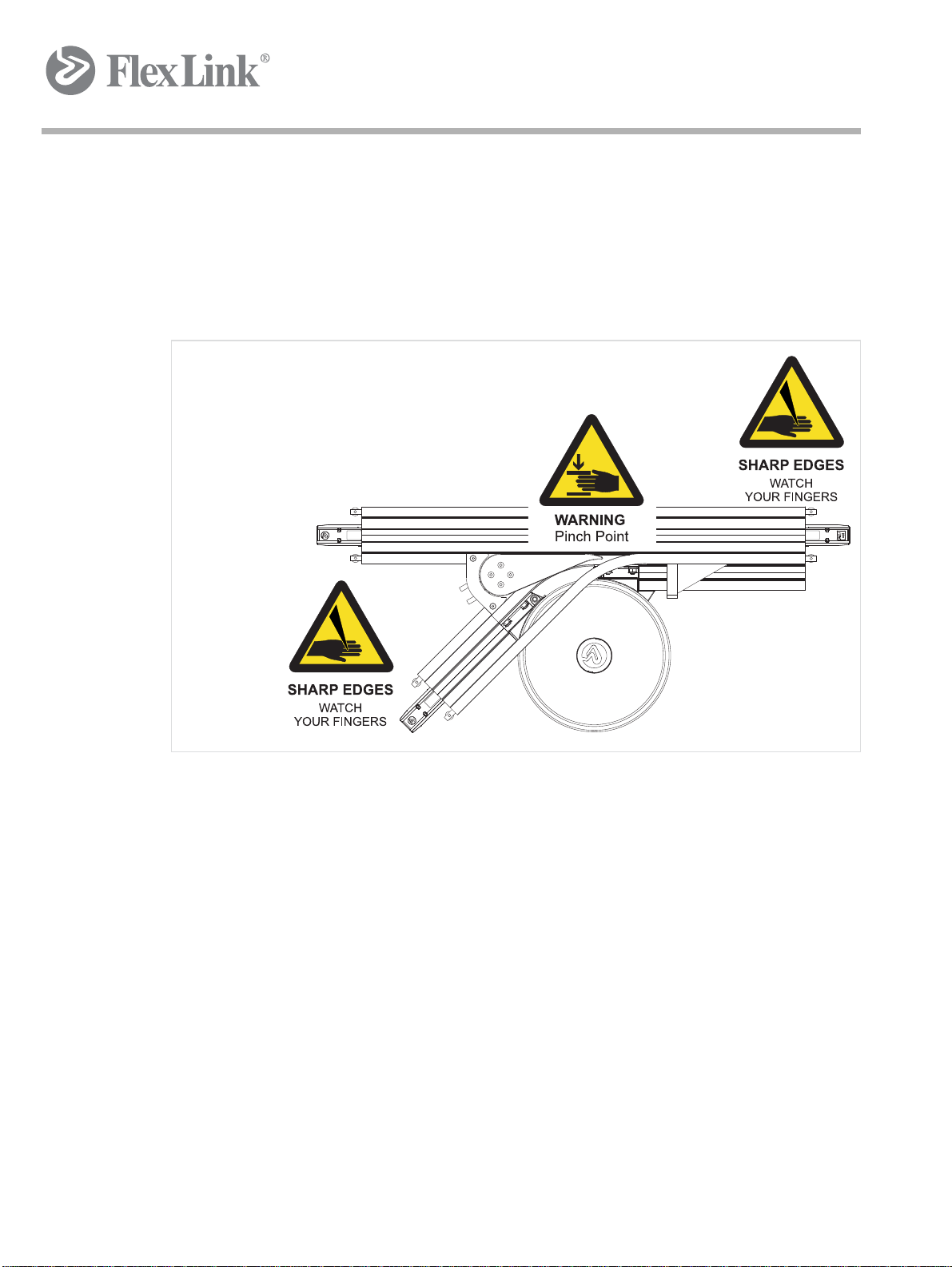

1.4.1 Power supply must be disconnected during installation (air and voltage).

8050179

Figure 2 Sharp edges

1.5 Intended use

The X65 function modules are intended to be used with the X65 pallets,

XLPP 100x128. All other use is the responsibility of the user.

7

Created by EBCCW 00:06

Page 16

Technical specification

2 Technical specification

2.1 Operating conditions

The circumstances under which the X65 conveyor system can be applied

partly depend on the materials selected. FlexLink has defined a number of

parameters within which the system would be allowed to function. Should

the system still be applied beyond these limiting values, FlexLink cannot

guarantee the good functioning of it.

Ambient temperature (in operation) -20° to +35°C

During transport / storage 5 to +40°C

Relative air humidity (RH) 10% to 95%, not condensing

Lighting Normal ambient lighting

Height Up to max. 2000 m above sea

level

8

8050179

Page 17

Technical specification

2.2 Ordering information

XLUT 45 D, XLUT 45 M, XLUT 45 C, XLUT 90 D, XLUT 90 M and XLUT 90 C.

Question Choices Description code

Right/Left

Sensors

Photo eyes

RFID

Right/Left Right/Left

Yes/No S/N

Yes/No PE-2/N

Yes/No RF/N

Configuration example

One of the six above mentioned modules has to be chosen first. Then the

questions in the configurator have to be answered.

Example of configurator string: Left-S-PE-2-RF

The choice sensor "Yes" includes sensors and brackets for indicating:

• Pallet in stop position.

The choice sensor "No" includes:

• Sensor bracket for pallet in stop position.

8050179

Sensors and brackets that always are included:

• Position of arm (in diverter and combined divert/merge modules).

The choice photoeyes "Yes" includes:

• Photoeyes

• Brackets for photoeyes (8050137).

• Reflectors (8050114)

The choice photoeyes "No" includes no brackets or reflectors.

The choice RFID "Yes" includes:

• Read/write head (5058152).

• Read/write head bracket (8050112).

9

Created by EBCCW 00:06

Page 18

3 Functions

3.1 Function description for Divert modules

The diverter function gives the opportunity to split highway flow to two

streams (satellite & highway), in a fully controlled way. The function is

equipped with all needed parts to setup and run it, including set of sensors

(not mandatory), RFID read/write head (not mandatory), fasteners and

pneumatic actuators.

Excluded parts:

• Chain

• Slide rails for chain and guide rails

• Tubes for pneumatic circuit

Functions

• Pallets

• Cables (for sensors and RFID r/w head)

3.1.1 Diverters

Diverters are used to split a flow of pallets from one line into two. The lines

can be in 45° or 90° angle.

DL DLDR DR

45°45°

The Diverter is an active unit with one infeed and two outfeed conveyors.

There are four different variants of the Diverter.

• Diverter, 45°, Left

• Diverter, 45°, Right

• Diverter, 90°, Left

90° 90°

10

• Diverter, 90°, Right

8050179

Page 19

Initiators

B1 Pre-stop highway

B2 and B3 sensing pallet route

B4 and B5 position of diverter arm

B6 RFID head

Actuators

A1 Pre-stop. Single acting

A2 Arm. Double acting

Interfaces

B1-B5 M12-connector, 3-pin

B6 RFID, 4-pin (ASI)

A1 Ø 6 mm pneumatic hose

A2 Ø 6 mm pneumatic hose

B2

B4

Functions

B3

B5

A2

A1

B6

B1

8050179

Figure 3 XLUT 45 D (also valid for XLUT 90 D)

Principle of operation

Diverting pallet to satellite:

A pallet on Highway is approaching. Sensor B1 is activated which actuates

stop A1 which stops the pallet, if function is occupied.

Sensor B2 and B3 supervise the function area. If both sensors gives low

signal the area is empty.

Straight passing through:

A pallet on Highway is approaching. The pallet activates sensor B1 which

actuates stop A1 which stops the pallet if function is occupied.

Sensor B2 and B3 supervise the function area. If both sensors gives low

signal the area is empty.

11

Created by EBCCW 00:06

Page 20

Function occupied

Before a pallet is let into the function the previous flow must be finished, the

arm to be in right position and downstream receiver be ready to receive.

Example: Previous flow was on satellite. Pallet enters on highway to go

straight. Stop A1 block the flow , then wait until B2 and B3 do not detect any

pallets. Thereafter diverter change arm position. When downstream High

way is ready to receive, then pallet on highway is released by stop A1.

Diverter arm

The position of the diverter arm A2 is indicated by sensors B4 and B5.

Sensors

The primary function of in position sensor (B1) is to detect pallet placed in

specific position. Additionally the sensor is placed in the way it can actuate

stop (open/blocking) before pallet gets into contact with the stop up to conveyor speed 20 m/min.

Functions

-

RFID

The RFID head B6 can be used to read/write RFID tag data on pallet. The

data can be used to take flow decisions at crossings, for example at stop

A1.

12

8050179

Page 21

3.1.2 Cylinder details

Cylinder A1 "Pre-stop"

Type: Single acting with two ports.

Function:

• Pressurized: Releases the pallet flow

• No pressure: Blocks the pallet flow

For safety reasons, the pallet stop is blocking the

flow in case of a pressure drop, preventing pallets

from travelling uncontrolled along the conveyor.

The stop should not re-block the flow while a pallet

puck is in a position where it could be clamped.

Functions

Cylinder A1

It is recommended to re-block the flow after each

pallet.

Cylinder A2 "Arm"

Type: Double acting

Function: Change the flow through the module.

Cylinder A2

8050179

Created by EBCCW 00:06

13

Page 22

3.1.3 Sensor details

Sensor B1 "Pre-stop"

Type: Proximity switch, inductive

Position: Placed together with Pre-stop.

Function: Detects the initiator plate of the pallet

before the pallet is stopped and stays active until

the pallet leaves the stop.

The reason why the pallet is detected by the

sensor before the pallet hits the stop, is to

enhance the efficiency of the pallet flow. As the

pallet is detected in advance, the controller has

time to take a decision whether or not the pallet

should be stopped. If it should pass, the stop

changes state to ”Release flow” before the pallet

reaches it.

Functions

Sensor B1

Sensor B2 and B3 "Sensing pallet route"

Type: Photo eye.

Function: Detects if there is a pallet in the merging

area. A new pallet must not be released from any

of the stop positions before the merging area is

clear.

Sensor B4 and B5 "Arm"

Type: Cylinder sensor

Position: Placed on the arm cylinder.

Function: Detects the arm position.

Sensor B2 and B3

14

Sensor B4 and B5

8050179

Page 23

Functions

3.2 Function description for Merge modules

The merging function gives the opportunity to merge two flows of pallets

(satellite to highway) in a fully controlled way . The function is equipped with

all needed parts to setup and run it, including set of sensors (not mandatory), fasteners and pneumatic actuators.

Excluded parts:

• Chain

• Slide rails for chain and guide rails

• Tubes for pneumatic circuit

• Pallets

• Cables (for sensors)

3.2.1 Mergers

Mergers are used to combine the flow from two lines into one. The lines can

be in 45° or 90° angle.

ML MLMR MR

45°45°

90° 90°

The Merger is an active unit with two infeed and one outfeed conveyor.

There are four different variants of the merger.

• Merger, 45°, Left

• Merger, 45°, Right

• Merger, 90°, Left

• Merger, 90°, Right

8050179

Created by EBCCW 00:06

15

Page 24

Initiators

B1 Pre-stop highway

B2 Pre-stop satellite

B3 and B4 Sensing pallet route

Actuators

A1 Pre-stop. Single acting

A2 Pre-stop. Single acting

Interfaces

B1-B4 M12-connector, 3-pin

A1 Ø 6 mm pneumatic hose

A2 Ø 6 mm pneumatic hose

B3

A2

Functions

A1

B2

Figure 4 XLUT 45 M (also valid for XLUT 90 M)

B4

Principle of operation

Merging a satellite pallet

A pallet on Satellite is approaching. Sensor B2 is activated which actuates

stop A2 which stops the pallet, if function is occupied.

Sensor B3 and B4 supervise the function area. If both sensors gives low

signal the area is empty.

Straight passing through:

A pallet on Highway is approaching. The pallet activates sensor B1 which

actuates stop A1 which stops the pallet if function is occupied.

Sensor B3 and B4 supervise the function area. If both sensors gives low

signal the area is empty.

B1

16

8050179

Page 25

Functions

Function occupied

Before a pallet is let into the function the previous flow must be finished and

the downstream receiver be ready to receive. Example: Previous flow was

straight. Pallet enters on Satellite to be merged. Stop A2 block the flow

,

then wait until B3 and B4 do not detect any pallets. When downstream

Highway is ready to receive, then pallet on Satellite is released by stop A2.

Sensors

The primary function of in position sensors (B1, B2) is to detect pallet

placed in specific position.

Additionally the sensors are placed in the way

they can actuate stop (open/blocking) before pallet gets into contact with

the stop up to conveyor speed 20 m/min.

3.2.2 Cylinder details

Cylinder A1 and A2 "Pre-stop"

Type: Single acting with two ports.

Function:

• Pressurized: Releases the pallet flow

• No pressure: Blocks the pallet flow

For safety reasons, the pallet stop is blocking the

flow in case of a pressure drop, preventing pallets

from travelling uncontrolled along the conveyor.

The stop should not re-block the flow while a pallet

puck is in a position where it could be clamped.

It is recommended to re-block the flow after each

pallet.

Cylinder A1 and A2

8050179

Created by EBCCW 00:06

17

Page 26

3.2.3 Sensor details

Sensor B1 and B2 "Pre-stop"

Type: Proximity switch, inductive

Position: Placed together with Pre-stop.

Function: Detects the initiator plate of the pallet

before the pallet is stopped and stays active until

the pallet leaves the stop.

The reason why the pallet is detected by the

sensor before the pallet hits the stop, is to

enhance the efficiency of the pallet flow. As the

pallet is detected in advance, the controller has

time to take a decision whether or not the pallet

should be stopped. If it should pass, the stop

changes state to ”Release flow” before the pallet

reaches it.

Functions

Sensor B1 and B2

Sensor B3 and B4 "Sensing pallet route"

Type: Photo eye.

Function: Detects if there is a pallet in the merging

area. A new pallet must not be released from any

of the stop positions before the merging area is

clear.

Sensor B3 and B4

18

8050179

Page 27

Functions

3.3 Function description for Divert and Merge

modules 45°

The combiner function gives the opportunity to split and join highway to satellite/ satellite to highway flows in a fully controlled way. The function is

equipped with all needed parts to setup and run it, including set of sensors

(not mandatory), RFID read/write head (not mandatory), fasteners and

pneumatic actuators.

Excluded parts:

• Chain

• Slide rails for chain and guide rails

• Tubes for pneumatic circuit

• Pallets

• Cables (for sensors), RFID r/w head

3.3.1 Combined Diverter/Mergers

A Combined diverter/merger is used to create a sub line for example to

guide pucks out and in on a satellite conveyor from the main conveyor

CL

45°

CR

45°

.

This function has the behaviour from both the diverter and the merger. The

prioritized order can be predetermined or decided dynamically from a line

controller.

There are two variants of the 45° Combined Diverter/Merger.

• Combined Diverter/Merger, 45°, Left

• Combined Diverter/Merger, 45°, Right

8050179

Created by EBCCW 00:06

19

Page 28

Initiators

B1 Pre-stop highway

B2 Pre-stop satellite

B3 and B4 Sensing pallet route

B5 and B6 position of diverter arm

B7 RFID head

Actuators

A1 and A2 Pre-stop. Single acting

A3 Arm. Double acting

B4

B5

Functions

B6

A3

Interfaces

B1-B6 M12-connector, 3-pin

B7 RFID 4-pin (ASI)

A1 Ø 6 mm pneumatic hose

A2 Ø 6 mm pneumatic hose

A3 Ø 6 mm pneumatic hose

Figure 5 XLUT 45 C

Principle of operation

Merging a satellite pallet:

A pallet on Satellite (M) is approaching. Sensor B2 is activated which actuates stop A2 which stops the pallet, if function is occupied. Sensor B3 and

B4 supervise the function area. If both sensors gives low signal the area is

empty.

Diverting pallet to satellite:

B2

M

A2

B3

A1

B7

B1

20

A pallet on Highway is approaching. Sensor B1 is activated which actuates

stop A1 which stops the pallet, if function is occupied.

Sensor B3 and B4 supervise the function area. If both sensors gives low

signal the area is empty.

8050179

Page 29

Functions

Straight passing through:

A pallet on Highway is approaching. The pallet activates sensor B1 which

actuates stop A1 which stops the pallet if function is occupied. Sensor B3

and B4 supervise the function area. If both sensors gives low signal the

area is empty.

Function occupied:

Before a pallet is let into the function the previous flow must be finished, the

arm to be in right position and downstream receiver be ready to receive.

Example: Previous flow was straight. Pallet enters on Satellite (M) to be

merged. Stop A1 block the flow , then wait until B3 and B4 do not detect any

pallets. When downstream Highway is ready to receive, then pallet on Satellite (M) is released by stop A2.

Sensors:

The primary function of in position sensors (B1, B2) is to detect pallet

placed in specific position. Additionally the sensors are placed in the way

they can actuate stop (open/blocking) before pallet gets into contact with

the stop up to conveyor speed 20 m/min.

RFID:

The RFID head B7 can be used to read/write RFID tag data on pallet. The

data can be used to take flow decisions at crossings, for example at stop

A1

8050179

Created by EBCCW 00:06

21

Page 30

3.3.2 Cylinder details

Cylinder A1 and A2 "Pre-stop"

Type: Single acting with two ports.

Function:

• Pressurized: Releases the pallet flow

• No pressure: Blocks the pallet flow

For safety reasons, the pallet stop is blocking the

flow in case of a pressure drop, preventing pallets

from travelling uncontrolled along the conveyor.

The stop should not re-block the flow while a pallet

puck is in a position where it could be clamped.

Functions

Cylinder A1 and A2

It is recommended to re-block the flow after each

pallet.

Cylinder A3 "Arm"

Type: Double acting

Function: Change the flow through the module.

Cylinder A3

22

8050179

Page 31

3.3.3 Sensor details

Sensor B1 and B2 "Pre-stop"

Type: Proximity switch, inductive

Position: Placed together with Pre-stop.

Function: Detects the initiator plate of the pallet

before the pallet is stopped and stays active until

the pallet leaves the stop.

The reason why the pallet is detected by the

sensor before the pallet hits the stop, is to

enhance the efficiency of the pallet flow. As the

pallet is detected in advance, the controller has

time to take a decision whether or not the pallet

should be stopped. If it should pass, the stop

changes state to ”Release flow” before the pallet

reaches it.

Functions

Sensor B1 and B2

Sensor B3 and B4 "Sensing pallet route"

Type: Photo eye.

Function: Detects if there is a pallet in the merging

area. A new pallet must not be released from any

of the stop positions before the merging area is

clear.

Sensor B5 and B6 "Arm"

Type: Cylinder sensor

Position: Placed on the arm cylinder.

Function: Detects the arm position.

Sensor B3 and B4

8050179

Created by EBCCW 00:06

Sensor B5 and B6

23

Page 32

3.4 Function description for Divert and Merge module 90°

The combiner function gives the opportunity to split and join highway to satellite/ satellite to highway flows in a fully controlled way. The function is

equipped with all needed parts to setup and run it, including set of sensors

(not mandatory), RFID read/write head (not mandatory), fasteners and

pneumatic actuators.

Excluded parts:

• Chain

• Slide rails for chain and guide rails

• Tubes for pneumatic circuit

• Pallets

• Cables (for sensors), RFID r/w head

Functions

3.4.1 Combined Diverter/mergers

A combined diverter/merger are used to create a sub line for example to

guide pucks out and in on a satellite conveyor from the main conveyor

They can also be used as "shortcuts".

CL

90°

Example where two 90° CL are used to make a "shortcut".

This function has the behaviour from both the diverter and the merger. The

prioritized order can be predetermined or decided dynamically from a line

controller.

There are two variants of the 90° Combined Diverter/Merger.

• Combined Diverter/Merger, 90°, Left

CL

90°

CR

90°

.

24

• Combined Diverter/Merger, 90°, Right

8050179

Page 33

Initiators

B1 Pre-stop highway

B2 Pre-stop satellite

B3 and B4 Sensing pallet route

B5 and B6 position of diverter arm

B7 RFID head

Actuators

A1 and A2 Pre-stop. Single acting

A3 Arm. Double acting

Interfaces

B1-B6 M12-connector, 3-pin

B7 RFID 4-pin (ASI)

A1 Ø 6 mm pneumatic hose

A2 Ø 6 mm pneumatic hose

A3 Ø 6 mm pneumatic hose

M

B2

A2

B4

B3

B5

Functions

B6

A3

A1

B7

B1

8050179

Figure 6 XLUT 90 C

Principle of operation

Merging a satellite pallet:

A pallet on Satellite (M) is approaching. Sensor B2 is activated which actuates stop A2 which stops the pallet, if function is occupied. Sensor B3 and

B4 supervise the function area. If both sensors give low signal the area is

empty.

Diverting pallet to satellite:

A pallet on Highway is approaching. Sensor B1 is activated which actuates

stop A1 which stops the pallet, if function is occupied.

Sensor B3 and B4 supervise the function area. If both sensors give low sig-

nal the area is empty.

25

Created by EBCCW 00:06

Page 34

Straight passing through:

A pallet on Highway is approaching. The pallet activates sensor B1 which

actuates stop A1 which stops the pallet if function is occupied. Sensor B3

and B4 supervise the function area. If both sensors give low signal the area

is empty.

Function occupied:

Before a pallet is let into the function the previous flow must be finished, the

arm to be in right position and downstream receiver be ready to receive.

Example: Previous flow was straight. Pallet enters on Satellite (M) to be

merged. Stop A1 block the flow , then wait until B3 and B4 do not detect any

pallets. When downstream Highway is ready to receive, then pallet on Satellite (M) is released by stop A2.

Sensors:

The primary function of in position sensors (B1, B2) is to detect pallet

placed in specific position. Additionally the sensors are placed in the way

they can actuate stop (open/blocking) before pallet gets into contact with

the stop up to conveyor speed 20 m/min.

Functions

RFID:

The RFID head B7 can be used to read/write RFID tag data on pallet. The

data can be used to take flow decisions at crossings, for example at stop

A1.

26

8050179

Page 35

3.4.2 Cylinder details

Cylinder A1 and A2 "Pre-stop"

Type: Single acting with two ports.

Function:

• Pressurized: Releases the pallet flow

• No pressure: Blocks the pallet flow

For safety reasons, the pallet stop is blocking the

flow in case of a pressure drop, preventing pallets

from travelling uncontrolled along the conveyor.

Functions

The stop should not re-block the flow while a pallet

puck is in a position where it could be clamped.

It is recommended to re-block the flow after each

pallet.

Cylinder A3 "Arm"

Type: Double acting

Function: Change the flow through the module.

Cylinder A1 and A2

Cylinder A3

8050179

Created by EBCCW 00:06

27

Page 36

3.4.3 Sensor details

Sensor B1 and B2 "Pre-stop"

Type: Proximity switch, inductive

Position: Placed together with Pre-stop.

Function: Detects the initiator plate of the pallet

before the pallet is stopped and stays active until

the pallet leaves the stop.

The reason why the pallet is detected by the

sensor before the pallet hits the stop, is to

enhance the efficiency of the pallet flow. As the

pallet is detected in advance, the controller has

time to take a decision whether or not the pallet

should be stopped. If it should pass, the stop

changes state to ”Release flow” before the pallet

reaches it.

Functions

Sensor B1 and B2

Sensor B3 and B4 "Sensing pallet route"

Type: Photo eye.

Function: Detects if there is a pallet in the merging

area. A new pallet must not be released from any

of the stop positions before the merging area is

clear.

Sensor B5 and B6 "Arm"

Type: Cylinder sensor

Position: Placed on the arm cylinder.

Function: Detects the arm position.

Sensor B3 and B4

28

Sensor B5 and B6

8050179

Page 37

Unload the X65 function modules

4 Unload the X65 function modules

4.1 Preparation

This section describes the steps that are required for unloading the modules for the X65 system. It is recommended to make use of the devices described. When using this or another device this device is expected to be

provided with a quality mark.

. Note! The operations concerned are to be carried out calmly in

order to be able to carefully monitor any movement of the X65

module.

Before starting the unloading a good preparation is required. The appropriate devices must be available. Apart from that the first transport check is

an important part of the unloading, as in case of damage this should be

mentioned on the delivery note in relation to guarantee and the like.

After arrival of the modules a transport check is to be carried out. The check

can be carried out at the moment the module has been unloaded from the

container or the truck. The technical specification gives the dimensions to

be checked. Is the module delivered undamaged and is it the correct module?

Figure 7 Module serial number type plate with configurator string

. Note! Any damage is to be mentioned on the delivery note and

should immediately be reported to the supplier. This with respect

to the guarantee of the module.

8050179

Created by EBCCW 00:06

29

Page 38

Unload the X65 function modules

4.2 Unloading instructions

Before starting unloading, all fastening means (securing belts, screws, etc.)

that secure the module into the means of transport must be removed. Subsequently check whether the transport supports are still connected well to

the module. After this the unloading procedure may be started.

4.2.1 Introduction

4.2.1.1 Accessories and spare parts

Spare parts for the X65 modules can also be ordered. See Recommended

spare parts on page 36

4.2.1.2 Ordering process

Every X65 module has its own unique order code which can be found in

each module description. The various options available for each module

are shown in the order code and all the parameters have to be specified

when ordering.

It is important to know that by ordering for example a conveyor module, you

do not automatically get a support module. This has to be ordered separately.

4.2.1.3 Shipment

Modules are delivered in std eur pallet 1200x800.

30

8050179

Page 39

Mounting, installation, adjustment

. . 5 Mounting, installation, adjustment

This section deals with the operations to have the modules function well

within a (transport) system. First section 1.2 on page 4, in which the provisions to be taken care of are given, should be studied carefully . section 1.3

on page 6 is particularly important for the modules that are delivered to the

end user not fully assembled.

5.1 Recommended tools

Figure 8 Tools

5.2 Basic value, Torque for dimension

Basic value, Torque for dimension

M5 M6 M8 M10

24,5 Nm / 217 lb.in.9 Nm / 80 lb. in.4 Nm / 35 lb. in.

Figure 9 Basic value

Make sure before integrating (section 1.4 on page 7) that the surroundings

are clean and free from obstacles and the mounting surface is clean and

level. Besides, it should be repeated that the operations are to be carried

out in a calm and controlled way!

After having placed the modules in the correct position, the modules is to

be fastened to the mounting surface by using the holes in the adjusting

feet.

45 Nm / 398 lb.in.

8050179

Created by EBCCW 00:06

31

Page 40

SAFETY

Mounting, installation, adjustment

5.2.1 Mounting instruction, XLUT 45 D and XLUT 90 D

HEAVY WEIGHT

10 - 25 kg

X6

WARNING

The system must not be

operated without safety

equipment properly

mounted.

6-8 Nm≈

WARNING

At installation, maintenance

and service, make sure the

motor is shut off.

WARNING

Pinch Point

CAUTION

Due to heavy weight - 2

person lift, or mechanical

lift equipment.

32

8050179

Page 41

SAFETY

Mounting, installation, adjustment

5.2.2 Mounting instruction, XLUT 45 M and XLUT 90 M

HEAVY WEIGHT

10 - 25 kg

WARNING

The system must not be

operated without safety

equipment properly

mounted.

X6

6-8 Nm≈

WARNING

At installation, maintenance

and service, make sure the

motor is shut off.

WARNING

Pinch Point

CAUTION

Due to heavy weight - 2

person lift, or mechanical

lift equipment.

8050179

Created by EBCCW 00:06

33

Page 42

SAFETY

Mounting, installation, adjustment

5.2.3 Mounting instructions, XLUT 45 C and XLUT 90 C

HEAVY WEIGHT

10 - 25 kg

WARNING

The system must not be

operated without safety

equipment properly

mounted.

X8

6-8 Nm≈

WARNING

At installation, maintenance

and service, make sure the

motor is shut off.

WARNING

Pinch Point

CAUTION

Due to heavy weight - 2

person lift, or mechanical

lift equipment.

34

8050179

Page 43

Put out of commission

6 Put out of commission

At the moment a module is put out of operation for some reason, a number

of steps are to be taken in order to avoid dangerous situations. This section

clearly indicates how one should proceed in a number of cases with respect to uncoupling, dismounting, transport and reuse of materials coming

from the elevator

6.1 Disconnect the power sources

Prior to starting the dismounting, the voltage is to be cut off from the power

source. First the main switch is to be switched off before the power source

can be disconnected.

. Danger: First switch off the main switch before the power source

may be disconnected.

6.2 Disassemble

While dismounting the machine, the regulations for waste processing applicable on the place and at the time of the dismantling are to be complied

with. The machine only contains commonly known materials. At the time of

assembling the module there were processing possibilities for this and no

particular risks were known for persons involved in dismantling. The disassembly of the module generally requires few operations. The module can

be disposed of in the same way as it was delivered.

. Note! At the time of assembling the modules there were

processing possibilities for this and no particular risks were

known for persons involved in dismantling.

Dust, dirt and liquides can accumulate in different cavities in the

module. Use appropriate personal protection during disassembly .

6.3 Reuse

No fixed rules have been made up for reuse of the modules, because the

module does not contain any hazardous substances. At the time of assembling the module there were processing possibilities for this and no particular risks were known for persons involved in the reuse.

. Note! Putting the module out of operation with all operations

8050179

Created by EBCCW 00:06

involved may only be done by technically qualified personnel.

35

Page 44

7 Recommended spare parts

Recommended spare parts

Description Std name Manufacturer Type External

order no

FlexLink

order no.

Prestop initiator Sensor SICK IM12-08NPS-ZC1 7900045 5058572

Sensor bracket for

Prestop initiator

Photoeye for

Sensor

FlexLink - - XLPB 12 H

bracket

Sensor SICK MHL 15-P3336 1026129 5058929

sensing pallet route

Bracket for photoeye Bracket FlexLink - - 8050137

Reflector Reflector FlexLink - - 8050114

Sensor for position

Sensor Festo SIEN-M8B-PS-S-L - 5115023

of diverter arm

Connector M8 - M12 Connector Murr 7000-42201-

- 5113472

0000000

RFID reader/writer RFID r/w IFM

- DTA100 5058152

Electronic

36

8050179

Page 45

8 Drawings

8.1 Pneumatic drawing

Applies to Diverter and Combined divert/merge.

0,6 MPa

Drawings

8.1.1 XLUT 45 D and XLUT 90 D

Pallet pre-stop

PUN-6x1

2

14 12

4

513

14 12

Arm

4

513

PUN-6x1

2

8050179

Created by EBCCW 00:06

37

Page 46

8.1.2 XLUT 45 M and XLUT 90 M

Drawings

Pallet pre-stop

PUN-6x1

2

14 12

8.1.3 XLUT 45 C and XLUT 90 C

4

1

5

3

14 12

Pallet pre-stop

PUN-6x1

2

4

1

5

3

38

Pallet pre-stop

PUN-6x1 PUN-6x1 PUN-6x1

2

14 12

4

513

Pallet pre-stop

2

14 12

4

513

Arm

2

14 12

4

513

8050179

Page 47

Supplier’s information

9 Supplier’s information

This manual goes together with the module of the type mentioned on the

order and on the title page of this manual. This document was drawn up by:

FlexLink Components AB

Date: 2013/03/11

Copyright: FlexLink Sweden, 2013

The machine was produced by:

Flexlink Components AB Tel: +46 (0)31-337 31 00

SE-415 50 Göteborg Fax: +46 (0)31-337 31 95

Sweden E-mail: info@FlexLink.se

www.FlexLink.com

. Note! In case of failures please contact the system integrator.

8050179

Created by EBCCW 00:06

39

Page 48

Supplier’s information

EC Declaration of Incorporation

Partly complied machinery

FlexLink Components AB

SE-41550 Göteborg

Sweden

We hereby declare that the following equipment is intended to be incorporated into a FlexLink conveyor system and thereby forming a machine. Operation is prohibited until it has been determined that the machine in which

these products are incorporated, has been declared in conformity with the

Machinery Directive 2006/42/EC, together with amendments which have

entered into force as of the date of issue of this declaration, with particular

reference to the essential health and safety requirements in connection

with the design, construction and manufacture of the below specified

equipment.

Function modules X65

- XLUT 45 D and XLUT 90 D

- XLUT 45 M and XLUT 90 M

- XLUT 45 C and XLUT 90 C

According to 2004/108/EC Electromagnetic Compatibility Directive (EMC),

the listed device is not independently operable product, but intended as

part of a given fixed installation. Compliance of the directive requires the

correct installation of the product, the observance of specific installation

notes and product documentation.

40

8050179

Loading...

Loading...