Page 1

Conveyor maintenance manual

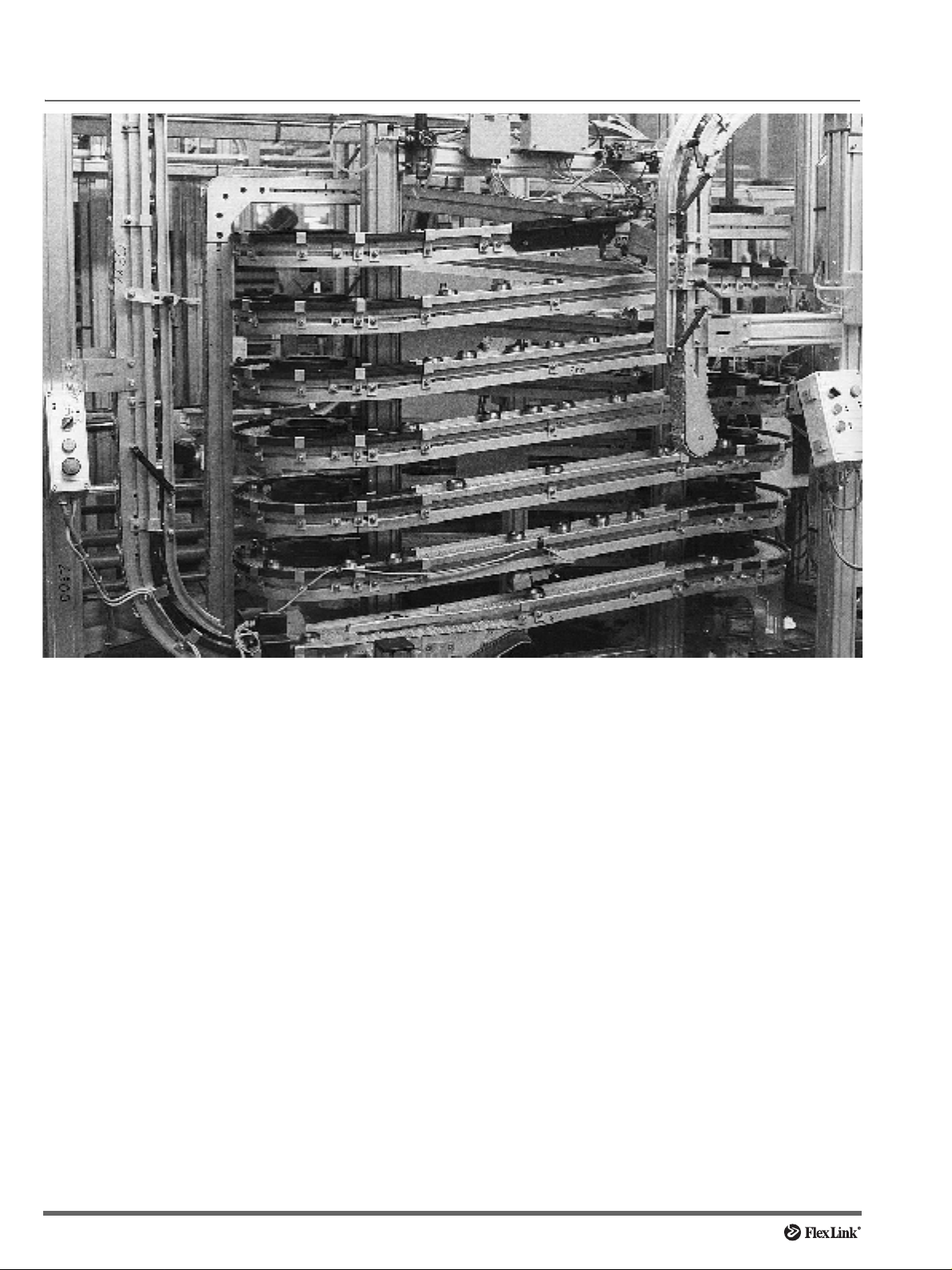

FlexLink conveyors XS, XL, XM, XH, XK, XB

Contents

General safety and design considerations................. 2

Introduction ........................................................... 2

Maintenance............................................................... 4

System maintenance............................................. 4

Maintenance instructions ...................................... 4

Introduction to drive units...................................... 5

Slip clutch adjustment........................................... 6

Inspection – drive units ......................................... 8

Inspection – conveyor chains................................ 9

Inspection – slide rails, beams, idlers, bends...... 11

Inspection – safety devices................................. 12

Replacement of worn parts – conveyor chain..... 13

Replacement of worn parts – slide rails.............. 14

Anchoring slide rail.............................................. 15

Troubleshooting ....................................................... 17

Checklist/maintenance schedule.............................. 18

System dismantling and disposal............................. 19

Important safety precautions............................... 19

1

Page 2

General safety and design considerations

Introduction

Critical factor

To achieve an operational installation which is reasonably safe for all people involved in its use and maintenance, it is necessary to consider certain aspects. This is

done when designing a conveyor system. The chain is

generally the critical factor to consider with guarding.

Safeguarding

All pinch and shear points as well as other exposed moving parts that present a hazard to people at their workstations or their passageways must be safeguarded.

Overhead conv eyors must be guarded to pre vent objects

falling. Cleated conveyor chains are more hazardous in

creating more pinch and shear points than plain convey or

chains.

Safeguarding can be achieved by:

•Location

Location of the hazardous area away from the area

occupied by personnel, wherever possible.

•Guards

Mechanical barriers preventing entry into the hazard-

ous areas or protecting against falling objects.

• Control devices

Machine controls which prevent the interruption of

hazardous operations/conditions.

• Warnings

Instructions, warning labels, or sound/light signals

which alert to hazardous conditions.

Safeguarding should be designed to minimize discomf ort

or difficulties to the operator. Bypassing or o verriding the

safeguarding during operation should be difficult.

Warning labels etc. should only be used when all

other means of safeguarding will impair the function of

the installation or are not cost effective.

The degree of safeguarding required should be iden-

tified during the implementation of the essential safety

requirement during the design process.

2

General safety and design considerations

Page 3

Introduction (continued)

Special considerations

When correctly applied, the FlexLink family of components are safe to use and maintain. It is however necessary for those responsible for design, installation,

operation and maintenance of the FlexLink installation to

be aware of certain areas where special attention is

required.

All drive units with slip clutch

• Before adjusting the slip clutch it is necessary to

remove all objects from the chain to remove any

remaining chain tension.

• Adjustment should be conducted in accordance with

the maintenance procedures.

• All drive units, except the direct drive units, are fitted

with transmission chain covers . these covers m ust be

fitted before unit is operated.

Note

The slip clutch is not a personnel safety device, but a

device to protect the conveyor equipment.

End drive units

• The chain slack (catenary) of the end drive units must

be maintained during the system lifetime.

• If side plates are fitted, the chain must be shortened if

the chain becomes visible below the level of the side

plates.

• The opening between the links when they turn round

the end roller could be a risk. Drive ends should not

be accessible during conveyor operation wherever

possible.

For coupled drive units, safety protection should be

applied to the connecting shaft.

Intermediate drive units

• The area near the guides for the return loop of the

chain should not be accessible during conveyor operation.

Catenary drive unit

• The ‘bridge’ area where the chain goes down into the

drive should not be accessible during conveyor operation.

Horizontal bend drive unit

• The drive wheel and the transmission chain should

not be accessible during the conveyor operation.

Idler units

• The opening between the links when they turn round

the idler roller could be a risk. Idler ends should not be

accessible during conve yor operation where ver possible.

Wheel bends

• Guarding may be required at wheel bends depending

upon location of bends and load applied to the conveyor.

Cleated chains

• Any application incorporating cleated chains requires

careful safety consideration. Pinch and shear points

are generated throughout the assembly of the incorporated components. Therefore generous guarding

should always be emplo yed to fully protect within user

operating limitations.

• There is a higher risk of product damage when using

cleated chains. Special attention must be given to

operator access in the event of products becoming

trapped or similar.

Maintenance

The maintenance routine of FlexLink conveyors should

also include procedures to ensure that the guarding

remains securely fastened and effective (if not interlocked via control system etc.).

FlexLink components are continuously reviewed to

improve performance either by design modification or

material upgrade. In all these reviews user safety is our

primary consideration.

All associated technical data are retained at the man-

ufacturers address.

Control system

Before operating or completing any maintenance on control system, read the associated section as supplied with

the equipment documentation.

If there are any questions as to the safe operating pro-

cedures of the equipment supplied, please contact FlexLink Systems immediately.

General safety and design considerations

3

Page 4

Maintenance

System maintenance

Introduction

The following section is designed to offer assistance for

your planned maintenance schedule. It may become evident that the suggested maintenance intervals can be

extended to accommodate your local en vironmental conditions.

Maintenance of the FlexLink conveyor systems

should only be carried out by competent persons, who

are familiar with FlexLink equipment. If there is an y doubt

as to the most suitable procedure for maintenance, consult your FlexLink supplier.

Non FlexLink equipment

Equipment and components which are not from the FlexLink family of products should be maintained and serviced in accordance with their respective manufacturer’s

instructions.

Maintenance instructions

Safety considerations

Before starting any maintenance on your FlexLink equipment, the following saf ety instructions must be observed:

• All electricity must be switched off.

• Make sure that the motor switch is also switched off

and locked in the “off” position.

• Pneumatic and/or hydraulic power must be disconnected and any pressure accumulation released.

• Products being transported should, if possible, be

removed from the conveyor chain.

• Staff affected must be informed that maintenance

work is being undertaken.

Warning

Do not climb onto the equipment.

Warranty/guarantee

FlexLink conv e yors are covered by warranty/guarantees

as identified within the trading terms issued for each

country. Check the warranty conditions for your system

before submitting claims etc. If you are in any doubt as to

what warranty is applicable to your system, consult your

supplying agent or FlexLink Systems direct.

Introduction

This maintenance manual contains directions for the

standard components sold through the FlexLink main

catalogue, for conveyor systems XS, XL, XM, XH, XK,

and XB unless otherwise stated. For non-FlexLink components, such as motors, pneumatic equipment, control

systems etc., the manufacturer’s maintenance instructions apply. In general, maintenance instructions are not

given for equipment which the customer has chosen and

specified for fitting to the installation.

The instructions supplied should be followed to

ensure that the installation runs with a high degree of

safety and to minimize the risk of breakdowns which can

adversely affect the production.

The installation must be used for the transport of

goods in accordance with system specification or within

design criteria as outlined in the general catalogue. If a

fault occurs on the installation which cannot be rectified

with the help of the instructions in the manual, or if unexpected conditions occur during servicing, contact your

FlexLink retailer or FlexLink maintenance personnel.

Spare/replacement parts

If there is a demand for spare parts, contact FlexLink

Systems or your supplying agent.

Checklist/maintenance schedule

A suggested maintenance schedule is shown on

page 18.

Important

Consult your system documentation for any special

maintenance required for your specific installation.

4

Maintenance

Page 5

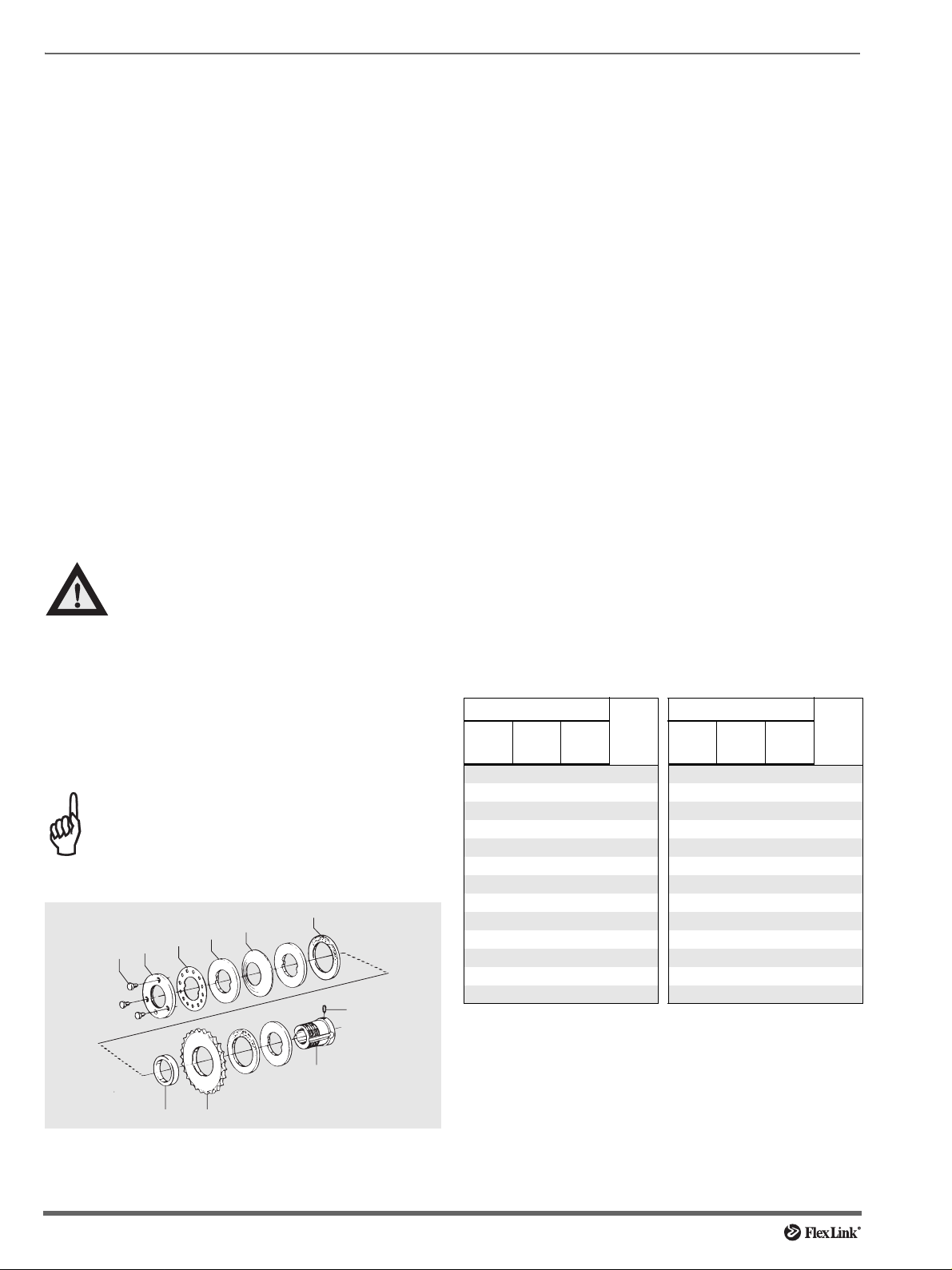

Introduction to drive units

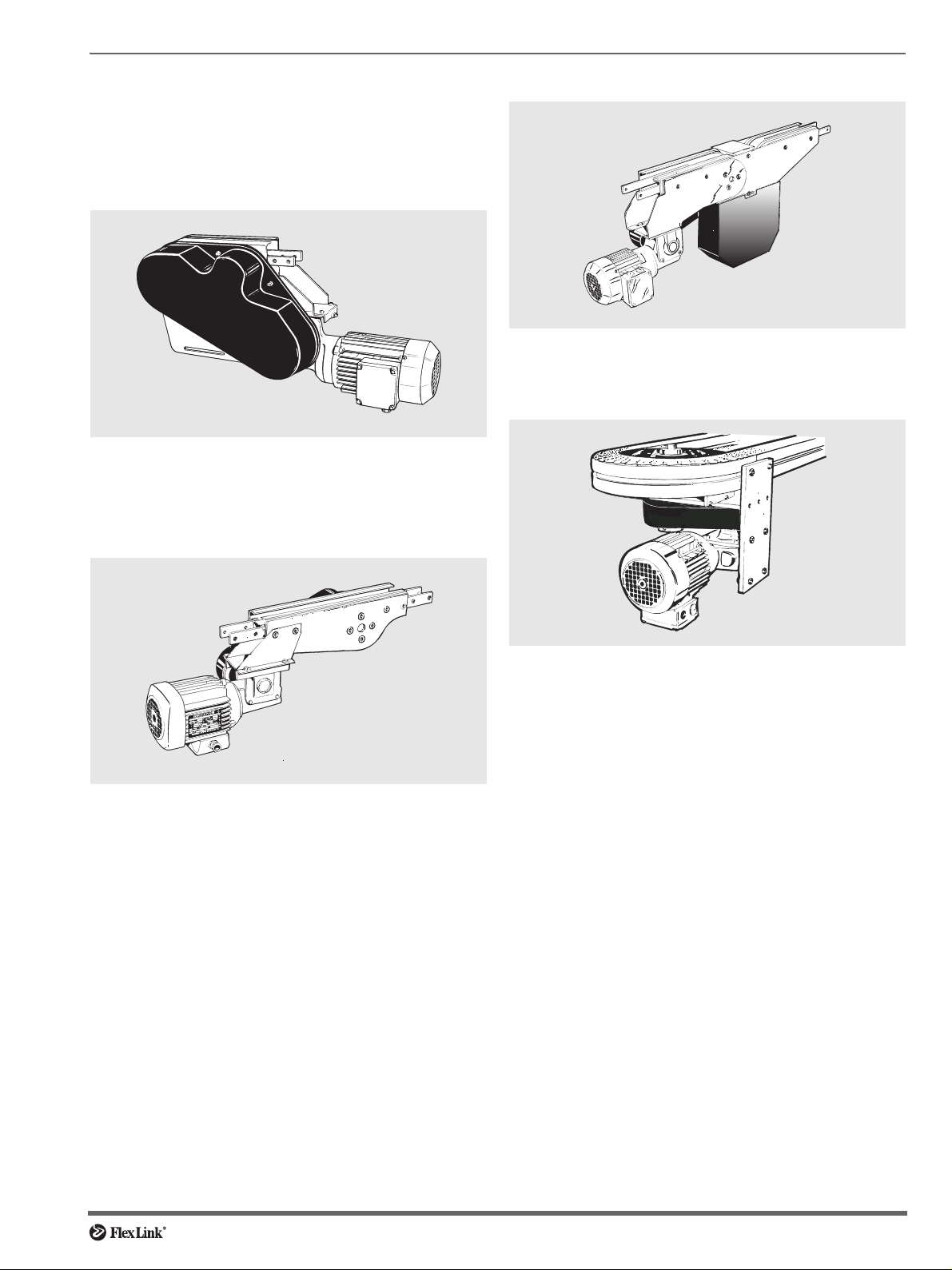

Four types

There are four different types of drive unit: end drive

units, intermediate drive units, catenary drive units and

horizontal bend drive units.

End drive units

End drive unit with return chain, located at the ‘pulling’

end of the conveyor. End drive units are either transmission chain types (see picture) or direct drive types.

Intermediate drive units

Catenary drive units

Catenary drive unit without return chain, located at an

intermediate position along the conveyor.

Horizontal bend drive units

Intermediate drive unit located at an intermediate position along the conveyor.

Horizontal bend drive unit for driving endless conveyors

without return chain.

Chain transmission

The drive units are normally fitted with roller chain transmission. Some end drive units come with direct drive.

Note

The roller chain transmission has chain guards and gearing protection. These guards should always be in position

when the conveyor is in operation.

Maintenance

5

Page 6

Slip clutch adjustment

Old and new versions

The slip clutch is available in two versions. Shipping of

the new version began in 2001. Adjustment of both versions are described here.

Introduction

The slip clutch on the drive unit is a safety device which

allows the chain to stop if the load becomes excessiv e. It

has two purposes:

• Prevent damage to conveyor

• Prevent damage to the products on the conveyor

Where a slip clutch is fitted, it must be adjusted so that it

does not slip whenever the drive unit is started under full

load. The installation is carried out as follows:

Preparations for adjustment

1 Stop the conveyor.

2 Ensure that the conveyor can not be started acciden-

tally. For example: unplug the electric power plug.

3 Remove any load on the conveyor.

Caution:

If you try to adjust the slip clutch when

there is still load on the conveyor, the

accumulated tension in the chain can

cause severe injuries when you release

the clutch.

Slip clutch should not be adjusted until

1 Motor direction is confirmed

2 Conveyor is fully assembled

Important:

The slip clutch is not a personal safety

device. It is primarily intended to protect the

equipment.

Clutch adjustment, old type

9

5

6

7

8

4

10

2 Unscrew the three screws (8) so that the outer ring (7)

can be rotated freely.

3 Hand-tighten the outer ring (7) to stop (no tools!).

4 Look for the desired maximum traction force in the

table to the right and determine the X value for that

force.

5 Positive X-value: (If the X value is negative (X≤0)

ignore step 5 and go to step 6.) Turn the outer ring (7)

counter-clockwise the number of divisions given by

the table, i.e. the X value. One division is defined as

the angle (30°) between adjacent holes in the stop

ring (6). Check that screws (8) align with the holes in

the stop ring (6).

6 Negative X-value: (If the X value is positive (X≥0)

ignore step 6 and go to step 7.) Turn the outer ring (7)

clockwise with a hook wrench, the number of divisions

given by the table, i.e. the X value. One division is

defined as the angle (30°) between adjacent holes in

the stop ring (6). Check that screws (8) align with the

holes in the stop ring (6).

7 Tighten the three screws (8) to stop. Use 10 mm

wrench

Clutch adjustment table, old type

F

is the desired maximum traction force applied to the

max

chain by the drive unit. The clutch will start slipping at

forces above F

max.

Note

The values in the table are approximate and apply to

factory-new slip clutches.

Traction force F

XSXLXM

XH

XW

450 450 100 19 1200 1200 1400 6

475 475 200 18 1300 1500 5

1000 1200 8 2500 –5

1100 1300 7

(N) X (div.) Traction force F

max

XK XMXHXW XK

525 300 17 1400 1600 4

575 400 16 1525 1700 3

625 500 15 1800 2

675 600 14 1900 1

725 700 13 2000 0

775 800 12 2100 –1

825 900 11 2200 –2

875 1000 10 2300 –3

925 1100 9 2400 –4

(N) X (div.)

max

3

2

1 Remove the transmission cover.

6

1

Maintenance

Page 7

Slip clutch adjustment (continued)

Clutch adjustment, new type

3

1 Remove the drive unit protection cover.

2 Use an Allen key , 3 mm, to loosen the scre w (1) on the

slip clutch so that the adjustment nut (2) can be freely

rotated.

3 Turn the adjustment nut (2) clockwise with a hook

spanner until the arrow on the nut is aligned with the

desired F

value (3). See the follo wing table f or cor-

max

rect values.

Note: On delivery, the clutch is always set to “0”.

4 Tighten the screw (1).

5 Re-install the drive unit protection cover.

2

1

Traction force, F

No.

0 300 300 300 600

1 400 400 400 800

2 500 500 500 1000

3 700 700 1150

4 800 800 1300

51550

6 1050 1050 1700

7

8 1250 1250 2000

9

10 1400 2200

11

12 1500 2400

13

14 1650 2500

XS

XL

Standard and direct drives 1/2”:

Slip clutches marked 3904324,

5052769, 3925774, 5052827

XM, XH

XK, XB

(N)

max

XT XK H

Standard drives 5/8”:

Slip clutches marked

3925071, 5052772

Clutch adjustment table, new type

is the desired maximum traction force applied to the

F

max

chain by the drive unit. The clutch will start slipping at

forces above F

max.

Hook spanner

Maintenance

7

Page 8

Inspection – drive units

Roller chain transmission

The roller chain transmission should be checked and

lubricated after 50, 250, 500 hours of operation, and then

every 500 hours.

If the roller chain transmission is not fitted with a chain

tensioner the chain tension should be checked on this

occasion.

At the same time as the roller chain tension is

checked, the chain must also be lubricated with a suitable chain spray or similar.

If the transmission is fitted with a chain tensioner,

lubrication should only be carried out at the stated intervals. The condition of the chain tensioner must be

checked at the same time as the lubricating is done.

Note

The discs in the slip clutch must be kept free from oil and

grease.

Worm gear motor and geared motor

The worm gear or geared motor is checked in accordance with the instructions from the relevant supplier.

Guide for the conveyor chain

The purpose of the guide for the conveyor chain is to

guide the return chain correctly into the drive unit.

Fully enclosed drive units do not have guides. On

these, no slack is permitted at the drive unit since the

conveyor chain is being controlled all the time. Special

attention must be given to chain elongation in conv e y ors

of this configuration.

If guides are fitted they can be of two different types:

• Loose disposable guides in plastic.

Replaceable chain guides

• Guides integrated into the ends of the drive unit...

Chain guides integrated into ends.

General checks on drive unit

Carry out a general inspection of the drive unit.

• Check particularly that the protective covers for the

roller chains are complete and firmly in place.

• Replace damaged/worn parts.

8

Maintenance

Page 9

Inspection – conveyor chains

Conveyor chains

The most common types of conveyor chains are:

• Plain conveyor chains.

.

Plain conveyor chain

• Chain with cleats for inclined or vertical conve yor sections. The cleats are generally spread over the chain

at a predetermined distance.

Cleated, friction and wedge chains

Cleated chains, friction chains and wedge chains, or

other special chains should be inspected regularly, and

any defective links replaced or cleaned.

Warning

Only warm water (50°C), with soap if necessary , ma y be

used for cleaning conveyor chains.

• Check the guards on cleated chain conveyors.

Checking the tension of conveyor chain

The chain is made of elastic material. The chain eventually stretches as the material creeps. The extent of the

stretch depends on the traction force in the chain. The

stretch shows itself as slack on the return side of the

drive unit.

The tension of the conve yor chain should be check ed

after 50, 250, 500 hours of operation and thereafter every

500 hours.

In operation there will be some slack in the conveyor

chain. How much slack is acceptable depends on the

length of the convey or chain. The most suitable places to

check the slack in the chain are at intermediate or end

drive units.

Cleated chain

• Chain with flexible cleats for vertical wedge conveyors.

Chain with flexible cleats

• Chain with friction surface for conveyors with an

incline up to 30°. The friction surfaces are normally

distributed over the chain at a predetermined distance.

Chain with friction surface

Maintenance

9

Page 10

Inspection – conveyor chains (continued)

Important:

The chain should therefore be pre-tensioned while the

conveyor is stationary, but must never be so tight that

there is no slack during operation. There should be no

appreciable slack on the chain when the conveyor is stationary. This can, however, vary depending on the total

length of the chain. If there is too much slack, there will be

excessive wear on the chain guides and the chain. This

could be a risk for injury.

If the slack on the conveyor chain is unacceptably

high, it must be shortened by splitting the chain and

removing the necessary number of links. See “Shortening conveyor chains” on page 10.

If the conveyor has a guided drive unit with no chain

slack take up , the elongation of the chain has to be monitored even more carefully, to ensure a trouble free operation.

Beam section for chain installation

• by removing the side plates of the drive or idler end

unit in closed systems.

• at a wheel bend by removing the outer curve.

• at a convey or beam section for liftable chain (if there is

any).

Instructions

1 Make the conveyor chain accessible at some of the

overhead positions.

2 Remove the steel pin (1) from the pivot (2). Use the

pin insertion tool (see figure).

3 Remove the necessary number of links.

The conveyor chain must show some slack during

operation.

The conveyor chain does not need to show any slack

when the conveyor chain is stationary.

Shortening conveyor chains

The most suitable place to shorten the chain is at the

drive unit.

Alternatively:

• at a beam section for chain installation which has

detachable sections.

Chain joint components

Note. With cleated or friction chains, pay attention to

the divisions between the links.

4 Join the chain together with a new pivot.

Note. The old pivot should not be re-used. When the

chain is divided, a new pivot must always be fitted.

5 Insert the steel pin using the pin insertion tool.

6 After inserting the steel pin, check that it is centered

and that the chain easily bends in the fitted link.

10

Usage of pin insertion tool

Maintenance

Page 11

Inspection – slide rails, beams, idlers, bends

25

100

Checking slide rails

The condition of the slide rails is fundamental to the functioning of the installation. It is therefore essential that

these are in good condition.

Checking the slide rail with the conveyor chain in place

The slide rail must be checked after every 250 hours’

operation. Carry on the checking on a stationary conveyor with the chain in place.

• Check the fastening points on the slide rail.

• Check the joints on the slide rail.

4

5

25

10

50

Correct configuration of joints

• Check that there is a gap between the slide rails and

that the joints are correctly fitted.

• Check that the joints are not deformed.

Checking the slide rail, conveyor chain removed

At least once a year or after ev ery 2 000 hours’ operation,

the chain should be removed from the beam, and the

slide rail carefully checked for wear and fastening.

Plain bends should be checked after e very 500 hours’

operation, since these are subjected to higher loads.

• Carry out the same checks as were carried out during

“Checking slide rails with the conv eyor chain in place”.

• Check the slide rail for wear and tear.

Note

Check in particular the inner slide rail in plain bends,

since the stresses here are particularly high.

• Check the slide rails for scratches and notches.

• Replace the slide rail and fasteners if necessary, see

“Replacing slide rails” on page 14.

Wash the conveyor chain.

Conveyor beams, idler ends, and bends

The convey or beams themselves do not normally require

any regular inspection. Be observant for damage arising

from external factors, warping or deformation. Deformation can cause the conveyor chain to jam, resulting in

uneven running.

Idler ends and wheel bends do not normally require

any special inspections, but they should be checked

when the slide rails are inspected.

Large radius plain bends may hav e inner support rails

fitted to the beam. Ensure that these rails (if fitted) are not

worn, paying particular attention to the “lead-in” area.

Deformed joints

• Check that the slide rail has not been broken off.

Replace the slide rail if necessary, see “Replacing the

slide rail”, beginning on page 14.

Maintenance

Inner support rails

11

Page 12

Inspection – safety devices

Protective and safety devices

Safety devices should be checked at regular intervals.

• Check the chain guard for roller chain transmission.

This guard must always be in place when the conveyor is in motion.

• Check the protective cover on the cleated chain conveyor return chain.

• Drive units type H, have a slac k protection for the conveyor chain. Chec k that the slack protection plates are

in place, and that the chain does not slacken enough

to hang below the plates.

• Check the protective cover for the conveyor chain on

intermediate drive units and catenary drive units.

• There may be other types of guard which are specific

to your installation, and these must also be checked.

See the system documentation.

Chain guard for roller chain transmission

Slack protection plate for drive unit type H

12

Maintenance

Page 13

Replacement of worn parts – conveyor chain

Removal of conveyor chain

1 Ensure that the power to the drive motor is discon-

nected.

2 Disengage the motor; there are various methods

depending on the type of drive unit:

— Detach the slip clutch.

— Remove the roller chain.

— Disengage the gear from the drive wheel.

3 Split the chain by removing the steel pin from the

pivot. Use the special tool for insertion/removal.

4 Pull out the chain.

Sample for checking conveyor chain space

2 Put the new conveyor chain in place. Check that the

chain direction corresponds to the convey or direction.

Pin insertion/removal tool

Fitting the conveyor chain

1 Run a sample (approx. 0.3 m) of conveyor chain

through the installation in the direction of the conveyor. Check that the chain moves easily and correctly through the bends and idler ends. Check at the

same time that there is enough space for the chain.

The conveyor chain direction

Note

Be careful that the first link of the conveyor chain does

not damage the slide rails.

Immediately investigate the reasons f or any jamming and

take immediate action.

3 Shorten the conveyor chain to the right length. Fit the

pivot and the steel pin, using the special pin insertion/removal tool.

After fitting, check that the steel pin is centered and

that the chain can easily bend in the fitted link.

4 Check that the slack is not e xcessiv e . See “Chec king

the tension of conveyor chain” on page 9.

Maintenance

13

Page 14

Replacement of worn parts – slide rails

XLMR 140

40

0

0

Replacing slide rails

It is very important to assemble slide rails correctly to

ensure smooth system operation.

Follow the illustrated instructions on the following

pages carefully. Observe the following points:

• Single-cut pliers are suitable tools for cutting the slide

rails.

Single cut pliers

• Use mounting tool for slide rail XLMR 140,

XMMR 140, XHMR 200, or XKMR 200.

XMMR 1

XHMR 20

XKMR 20

1

2

Mounting tool for slide rail

• Use drill fixture 3920500. The distance between

anchor points must be 50 mm.

• Use a high quality drill bit to avoid forming a shoulder ,

preferably one which is intended for drilling aluminium.

• Use XLAH 4×6/XLAH 3×6 rivets.

When fitting the slide rails with rivets, the fitting instructions on page 15 must be followed.

• The joints on the slide rails must have a distance of

100 mm between them. The joints should be laid out

as in the picture with a gap of approx. 10 mm between

the rails.

• Joints may not be positioned in bends, or in the transition between two sections of beams.

• The slide rails should normally be approximately 5 m

long on a straight conve yor beam. In a bend, the maximum length of slide rail should be 3 m.

• The joints should be positioned a minimum of 500 mm

before an idler end unit, drive unit or vertical bend.

The slide rail must overlap the recess in the idler end

and drive unit.

• The inner slide rail after a wheel bend must be cut so

that the cut surface is parallel to the wheel. In front of

the wheel bend, the slide rail will normally be cut at

45°.

Note

Check the final slide rails visually, as well as running a

section of conveyor chain through the installation.

An alternative to the aluminium rivets, is to use the plastic

screws XLAG 5 (XW A G 5 for XK). See page 16 f or fitting

instructions. The holes for the plastic screws are

threaded with a tap.

∅

Drill fixture 3920500

14

Maintenance

Page 15

Anchoring slide rail

Fixing slide rail to the conveyor beam

Hand drill

Drill fixture for slide rail 4,2 mm (XS: 3,2 mm)

Countersink

The beginning of each slide rail section must be fixed to

the beam, since the chain will cause the slide rail to be

pushed forward. Slide rail which mo ves into a wheel bend

or a drive unit can block the chain completely.

There are two different methods f or fixing slide rail to

the conveyor beam: using aluminium rivets or plastic

screws. Either method can be used, but the riveting

method is more secure if the conveyor will run with high

operational speed or be heavily loaded.

wrong

correct

Method 1: Using aluminium rivets

Rivet crimping pliers/rivet crimping clamp

Aluminium rivets

Mounting:

1 Insert rivets in the holes, using rivet crimping pliers or

a rivet crimping clamp. For type of rivet, see table on

previous page.

3 Check that the rivets do not protrude over the surf ace

of the slide rail.

Check both top and underneath surface of slide rail for

protruding metal.

4 Keep a distance of appro ximately 30 mm between riv-

ets and idler unit. This is in case the idler unit has to

be removed after conveyor system assembly.

2 If working space is limited, the rivet crimping clamp

might be easier to use. The two crimping tools per-

form the same task, but the pliers are more efficient

and easier to use.

Maintenance

15

Page 16

Anchoring slide rail (continued)

Method 2: Using plastic screws

Pliers/screwdriver

Knife

Hammer

Plastic screws XLAG 5

An alternative to aluminium rivets is to use plastic screws

XLAG 5:

Mounting:

3 Make sure the slide rail surface is smooth and that

screws do not protrude over the surface of the slide

rail. If the surface should be uneven, file the edges

smooth.

Check both top and underneath surface of slide rail for

protruding plastic or metal.

1 Press or screw the screws into the holes using a pair

of pliers or a screwdriver.

2 Cut off the screw heads by using a knife and a ham-

mer. The cut should be made away from the joint, in

the direction of chain travel.

4 Keep a distance of approximately 30 mm between

screws and idler unit. This is in case the idler unit has

to be removed after conveyor system assembly.

16

Maintenance

Page 17

Troubleshooting

Jerky running

Cause Corrective action

Damaged or badly fitted

slide rail

Wrongly adjusted slip

clutch

Worn transmission parts Check/replace transmission chain, chain

Conveyor chain is too

tight/loose

Dirty conveyor Clean conveyor chain/slide rail. Lubri-

Inspect and replace as necessary.

Check and adjust slip clutch.

drive sprocket.

Tension conveyor chain correctly.

cate with silicone based lubricant.

Drive unit is running, conveyor chain is not

Cause Corrective action

Wrongly adjusted slip

clutch

Friction discs in slip clutch

are worn or contaminated

Damaged/badly fitted slide

rail

T ransmission products are

not fitted

Check adjustment of slip clutch.

Check and replace if necessary.

Check the free running of the conveyor

chain.

Check and fit.

Motor overheating on drive unit

Cause Corrective action

Overloaded conveyor Remove products from conv eyor and test

Gearbox leaking oil Check output shaft seal and area around

Dirty conveyor Clean the conveyor chain with warm

run.

Check actual conveyor load against rec-

ommended loading.

motor/gearbox interface.

water (50°).

Noise

Cause Corrective action

Worn or damaged bear-

ings in drive unit

Damaged/badly fitted slide

rail

Excessive conve yor speed Lower speed.

Incorrect conveyor chain

tension

Check/replace drive unit.

Check the free running of the conveyor

chain, especially in slide rail joints.

Check actual load against recommended

loading.

Lengthen/shorten conveyor chain.

Abnormal wear on plastic parts

Cause Corrective action

Overloaded conveyor Remove products from conveyor

Ambient temperature too high Check against recommended

Chemicals in the environment are

affecting plastic parts

Damage due to ingress of contaminate

Particles, swarf etc. Remove source of contamination.

and test run.

Check the free running of the con-

veyor chain.

Check actual conveyor load

against recommended loading.

temperature for conveyor.

Check in FlexLink main catalogue

(section TR) for listing of incompatible chemicals.

Clean the system.

Troubleshooting

17

Page 18

Checklist/maintenance schedule

No. General checks Number of operating hours/time interval See page

1. Check roller chain, sprocket, chain tension and lubrication of drive unit

2. Check/adjustment of slip clutch Every 1 000 hours Page 6

3. Check conveyor chain guides in drive units and idler

ends

4. Check tension of conveyor chain 5 0 250 500 Then every 500 hours Page 9

5. Check slide rails Every 250 hours Page 11

6. Check slide rails, conveyor chain removed. Every 2 000 hours, or at least once a year Page 11

7. Check slide rails in plain bends. Every 500 hours Page 11

8. Check safety and security devices At least once a year Page 12

50 250 500 Then every 500 hours Page 8

Every 1 000 hours Page 8

18

Checklist/maintenance schedule

Page 19

System dismantling and disposal

Important safety precautions

Dismantling

Dismantling of the FlexLink conveyor system should be

carried out by competent persons, who are familiar with

the equipment being decommissioned.

In the absence of detailed information, every care

should be taken to ensure that all items are securely

retained during the decommissioning process. This is to

ensure that the equipment remains stable and will not fall

if left unattended.

If pneumatics or hydraulics are to be decommissioned, special attention should be given for the safe

release of any accumulated pressure from within the circuitry. All reservoirs/accumulators must be depressurised prior to removal.

If there are any doubts as to the most suitable procedure for decommissioning, then consult the equipment

supplier.

Conveyor system XS, XL, XM, XH, XK, and XB

To dismantle a FlexLink conv eyor the following tools are

required.

Ring spanners /10 mm and 13 mm size

Allen keys

Pin insertion tool XS/XL = XLMJ 4

Pin insertion tool XM = XMMJ 6

Pin insertion tool XH = XHMJ 6

Pin punch XK = XKMJ 8

Hammer

Drill to remove slide rail rivets

1 Remove any remaining product from the conveyor

system.

2 Switch off all electrical power and disconnect all pneu-

matic and hydraulic feeds, including accumulators.

Ensure that system is safe by shutting down all feed

supplies or removing electrical fuses.

3 Remove the black transmission cover from drive unit

to expose slip clutch and transmission drive chain.

4 The locking effect of the slip clutch can be remov ed by

removing the transmission chain or by releasing the

slip clutch (section in maintenance and service refers

to slip clutch adjustment).

5 Remove the motor gear unit from the conveyor drive

assembly . The motor gear unit may be fitted with an oil

breather. Ensure that the oil from the gearbo x cannot

leak into the surrounding area when decommis-

sioned. Oil should be drained from the gearbox and

disposed of in accordance with local environmental

regulations.

6 Remove guide rails and guide rail brackets etc.

7 Split the conveyor chain using the pin insertion tool

and remove the conv eyor chain. If remo ving conv eyor

chain from over head conveyor special attention

should be given when removing the last few metres.

The weight of the removed chain accelerates the

removal from the conveyor beams and can cause

injury when the last links exit the extrusion. The chain

should always be removed in the conveyor working

direction.

8 Unscrew the inner grub screws from the drive unit

connector strips and remove drive end from the conveyor. Repeat for idler end unit.

9 Remove the slide rail on all sides of the conveyor

extrusion. Remove the slide rail retaining fixings by

drilling away the rivets or plastic screws and pulling

away the slide rail from the aluminium extrusion profile.

10 Dismantle the conveyor extrusions from the support

brackets . This should be done in a systematic manner, removing conveyor section by section. Where

extrusions are joined by connecting strips, first

untighten the retaining grub screws from the connection strips. It may be necessary to release the clamp

effect of the connector piece by giving a sharp tap

with a hammer.

11 Dismantle the conveyor support system into separate

components.

12 Sort different materials ready for disposal. Include a

list of the materials.

If other equipment is to be dismantled simultaneously

with the FlexLink conveyor, attention should also be

given to the interaction of the other equipment to the

FlexLink conveyor. Pneumatic equipment should be

removed from the conv eyor before dismantling. Hydr aulic

equipment should also first be removed to assist dismantling and handling of the conveyor components during

dismantling and disposal.

System dismantling and disposal

19

Loading...

Loading...