Page 1

r

5112204

Elevator

User Manual

eated by EBCCW 00:06

C

Created by EBCCW 96:05Created by EBCCW 00:06Created by EBCCW 96:05Created by EBCCW 00:06

Page 2

Created by EBCCW 96:05Created by EBCCW 00:06

Page 3

© Flexlink Components AB 2010

Elevator

User Manual

All Rights Reserved

No part of this program and manual may be used, reproduced, stored or

transmitted in any form or by any means without the written permission of

FlexLink Components AB. The contents of this manual are for informational

use only. All information and specifications contained in this document

have been carefully checked to the best efforts of FlexLink Components

AB, and are believed to be true and accurate as of time of publishing.

However, due to continued efforts in product development FlexLink

Components AB reserves the right to modify products and its manuals

without notice.

FlexLink Components AB assumes no responsibility or liability on any

errors or inaccuracies in this program or documentation. Any kind of

material damages or other indirect consequences resulting from any

FlexLink Components AB´s product part, documentation discrepancies

and errors or non-anticipated program behavior are limited to the value of

appropriate products purchased from FlexLink Components AB. The

products are delivered to the customer at th e ’as is’ state and revision level

they are on the moment of purchasing, and are declared in detail in the

license agreements between FlexLink Components AB and user. User

accepts and is obliged to follow the guidelines stated in the separate

license agreement needed in using any parts of this product package.

Created by EBCCW 00:06

5112204

Page 4

5112204

Page 5

Preface 1

1 Safety 3

1.1 System information 3

1.2 Important safety conditions 4

1.3 Description of safety provisions 6

1.4 Safety measures to be taken 13

1.5 Explanation of symbols 13

2 Technical specification 15

2.1 Technical data 16

2.2 Ordering information 17

2.3 Operating conditions 19

3 Introduction function and components 20

3.1 Purpose of use 20

3.2 Description of the Elevator 21

3.3 Working principle 33

4 Unload the elevator 34

Created by EBCCW 00:06

5112204

i

Page 6

4.1 Preparation 34

4.2 Unloading instructions 35

5 Installation and adjustment 38

5.1 Provisions to be provided 38

5.2 Mechanical assembly 39

5.3 Electrical installation and controls 41

5.4 Test run 43

5.5 Adjustment 44

5.6 Check / Shadow run 56

6 Instructions for use 58

6.1 Handling 58

6.2 Manual operation 59

7 Technical maintenance 60

7.1 Check and control procedures 60

7.2 Maintenance procedures 61

7.3 Troubleshooting 63

ii

5112204

Page 7

7.4 Maintenance schedule elevator 64

8 Put out of commission 65

8.1 Disconnect the power sources 65

8.2 Disassemble 65

8.3 Transport 66

8.4 Reuse 66

9 Recommended spare parts 67

9.1 Mechanical 67

9.2 Electrical 72

10 Supplier’s information 92

Created by EBCCW 00:06

5112204

iii

Page 8

iv

5112204

Page 9

Preface

Preface

Purpose of this manual

The purpose of this manual is to describe a number of o perations th at a re

intended for the user concerned. Here it becomes clear how the user can

work as well and as safely as possible. By making use of clear illustrations

and texts FlexLink wants to achieve a simple and safe way of working with

the Elevator . This docu ment cont ains rema rks that point o ut a risky or sp ecific situation to the user . In man y ca ses this situation is provided with one

of the symbols given below.

General warning for danger!

.

Warning for electrical voltage!

.

Attention, this is an important notice!

.

Compliance with the operations described in this document is important in

order to prevent dangerous situations and unnecessary damage to the Elevator. Care fully keep this document! It is recommended to keep one copy

near the machine and one copy with your technical documentation.

Structure of the manual

The user’s manual has been composed in such a way, that a number of operations can quickly and easily be found. This manual will not describe operations that are not meant for the user . It does, however , indicate what the

user must do when carrying out a certain operation, for example calling in

technical staff. The user’s manual has been divided into sections. These

sections describe, among other things, the safety and the operation of the

Elevator. FlexLink would like to point out to the user that section Safety is

to be read carefully.

Created by EBCCW 00:06

5112204

1

Page 10

Preface

Requirements of the user

The Elevator may be operated by any adult person who has become acquainted with section Safety. If the user is not technically qualified, he or

she may not carry out any maintenance or repair activities on the elevator.

. Note! Maintenance activities on the elevator may only be carried

out by a technically qualified person.

. NB: Technically qualified employees means: employees that

have followed an adequate training for carrying out the activitie s

involved and have a good ability to read and understand the

English language.

2

5112204

Page 11

Safety

1 Safety

The Elevator has been designed in such a way, that it can be used and

maintained in a safe way . This holds for the application, the circumst ances

and the instructions described in the manual. Any person working with or

on this machine should study the manual and follow the instructions. It is

the responsibility of the employer to make sure that the employee is familiar

with and follows these instructions.

The company or the country in which the machine is used ma y r eq uire extra safety measures. This particularly applies to the working conditions.

This manual does not describe how these are to be complied with. In case

of doubt, consult your government or safety officer!

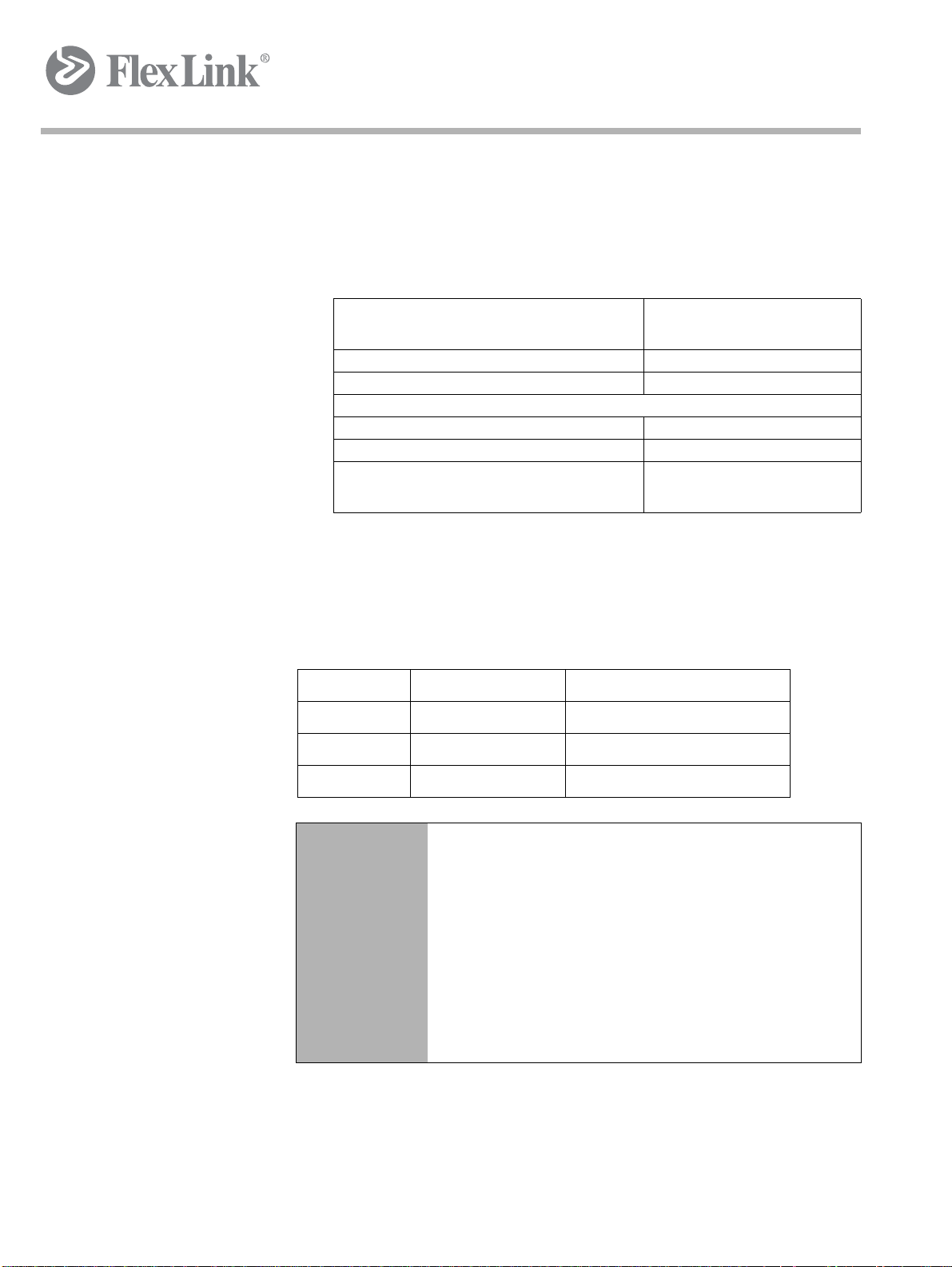

1.1 System information

The project number and/or general drawing number shall always be specified when communicating with FlexLink with respect to the elevator.

Project number See machine nameplate

Supplier FlexLink Engineering Polska

Sp. z.o.o

ul. Za Motelem 2c

62-080 Sady, Poland

Machine type: Elevator

Date of manufacture See machine nameplate

Gen. drwg. no. See machine nameplate

Created by EBCCW 00:06

5112204

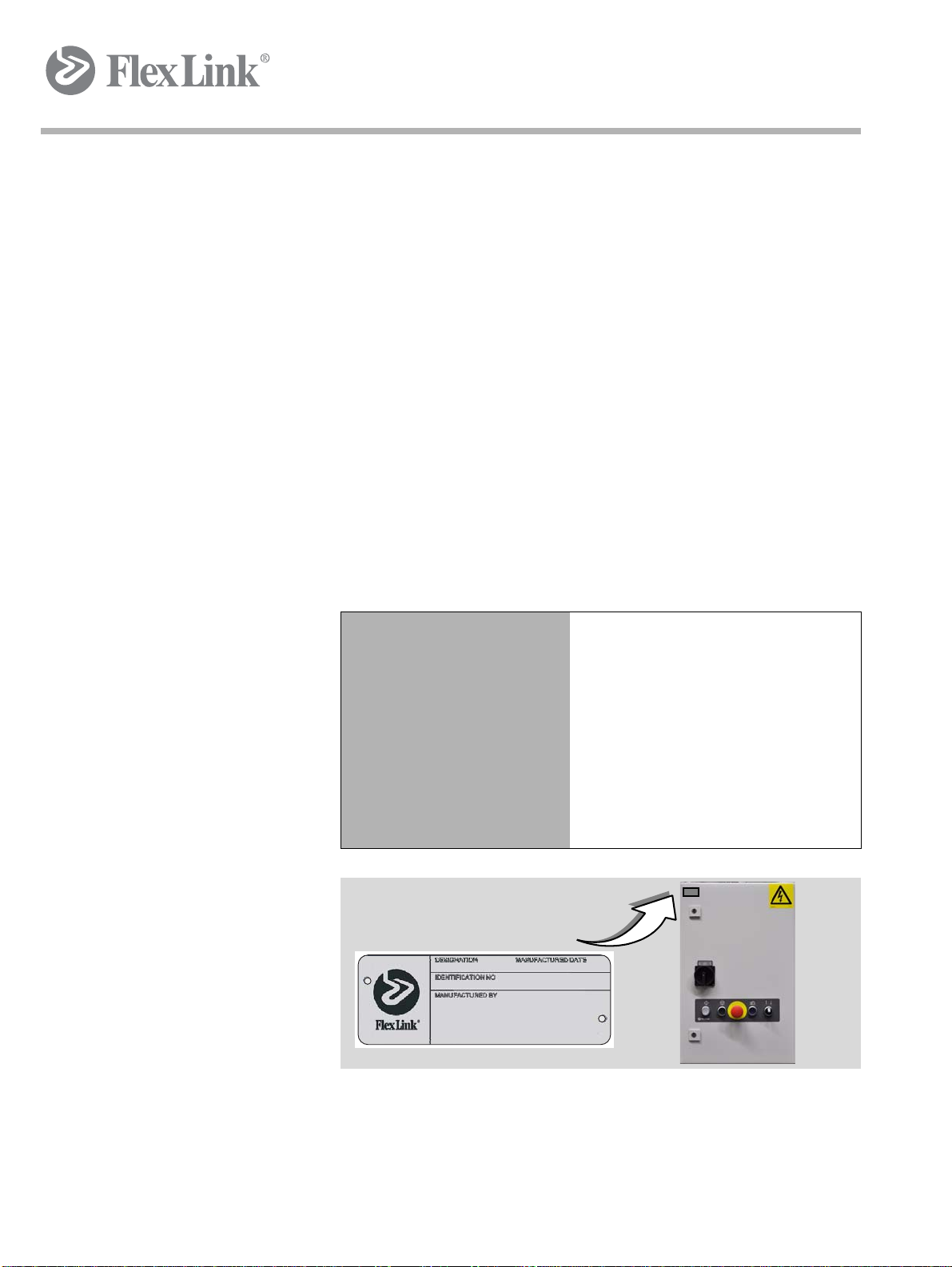

Figure 1 Machine nameplate

The machine nameplate is located on the electrical cabinet a s shown in the

figure above.

3

Page 12

Safety

1.2 Important safety conditions

At the moment that the elevator is going to be operated by a user, the following safety conditions must be met:

• Make sure that children or animals have no access to the machine

and its surrounding area by, for example, screening off the elevator with a fence.

• Only persons who have read and understood the operating instructions are allowed to operate, maintain and clean the machine.

• Do not reach into the machine while it is running or on. Even if the

machine is not running, it can be ‘on’, which means star t operating

automatically.

• Safety provisions, such as side plating, bottom plating, emergency stops and detectors may not be removed or deactivated wh ile

the elevator is running.

• Provide good ambient lighting to enable the opera tor to work well

and orderly with the elevator.

1.2.1 General

. • Incorrect use of the equipment can cau se pe rso n al inju ry.

• Do not stand or climb on the equipment.

• Do not wear clothing or other articles that can fasten in the machine.

• Follow the instructions in this user manual when transporting the

machine. FlexLink Components AB must approve all modifications or changes to this machine.

• Only use recommended spare parts.

• Only authorised personnel may open electrical units.

• FlexLink is not responsible for damage if service on the equipment is not performed in accordance with this user manual.

4

5112204

Page 13

1.2.2 Service technicians

. Service technicians must have:

• Sufficient knowledge for reading technical information

• Ability to comprehend technical drawings

• Basic knowledge of mechanics

• Sufficient knowledge in the use of hand tools

1.2.3 Electricians

. Electricians must have:

• Experience from similar installations

Safety

• Sufficient knowledge to work from drawings and wiring diag ra ms

• Knowledge of local safety regulations for electrical power and automation

To avoid risks, only experienced personnel with technical knowledge and

experience may perform repair work on the machine's electronics components.

1.2.4 Operators

. To correctly use the equipment, operators must have appropriate training

and/or experience.

Created by EBCCW 00:06

5112204

5

Page 14

Safety

1.3 Description of safety provisions

As a standard the Elevator is not provided with control and an y safety pr ovisions. Before putting the Elevator into operation some safety provisions

are to be taken care of. The purpose of these safety p rovisions is to protect

the user, the product and the Elevator against undesired situations (damage). Without these safety provisions FlexLink cannot give a guarantee on

any damage caused in absence of these safety provisions.

The table below gives a general description of the safety provisions required. Here it should be noted that only technically qualified employees

are allowed to work on the settings of the safety provisions!

Control Remark

Emergency stop switch Each Elevator is to be provided with one or more emerge ncy stop switches

that can be operated within reach of the user.

The switch must have the standard red colour.

The emergency stop switch must make sure that the input and output

tracks are switched off simultaneously.

Motor protection The technical specification of the Elevator is, among other things, geared

to the load given in the order confirmation.

Should the Elevator (motor) be overloaded for certain reasons, this should

be detected. Without this protection there is a chance that the Motor or

other components of the Elevator will be damaged.

6

5112204

Page 15

Safety

. Note! If it cannot be made sure that there will be no product on

the machine that exceeds the minimum or maximum dimensions

(see technical specification), the detector described below must

be installed on the Elevator.

Height / width

detector

The product that is put into the Elevator may not get stuck as a result of a too

high / wide or twisted product.

In order to ensure that products fit in the Elevator and will not get stuck, the

input of the Elevator can be checked for height / width.

This detection must take place well before the Elevator prior to putting the

product on the Elevator.

The maximum dimensions of the product are given in the technical

specification.

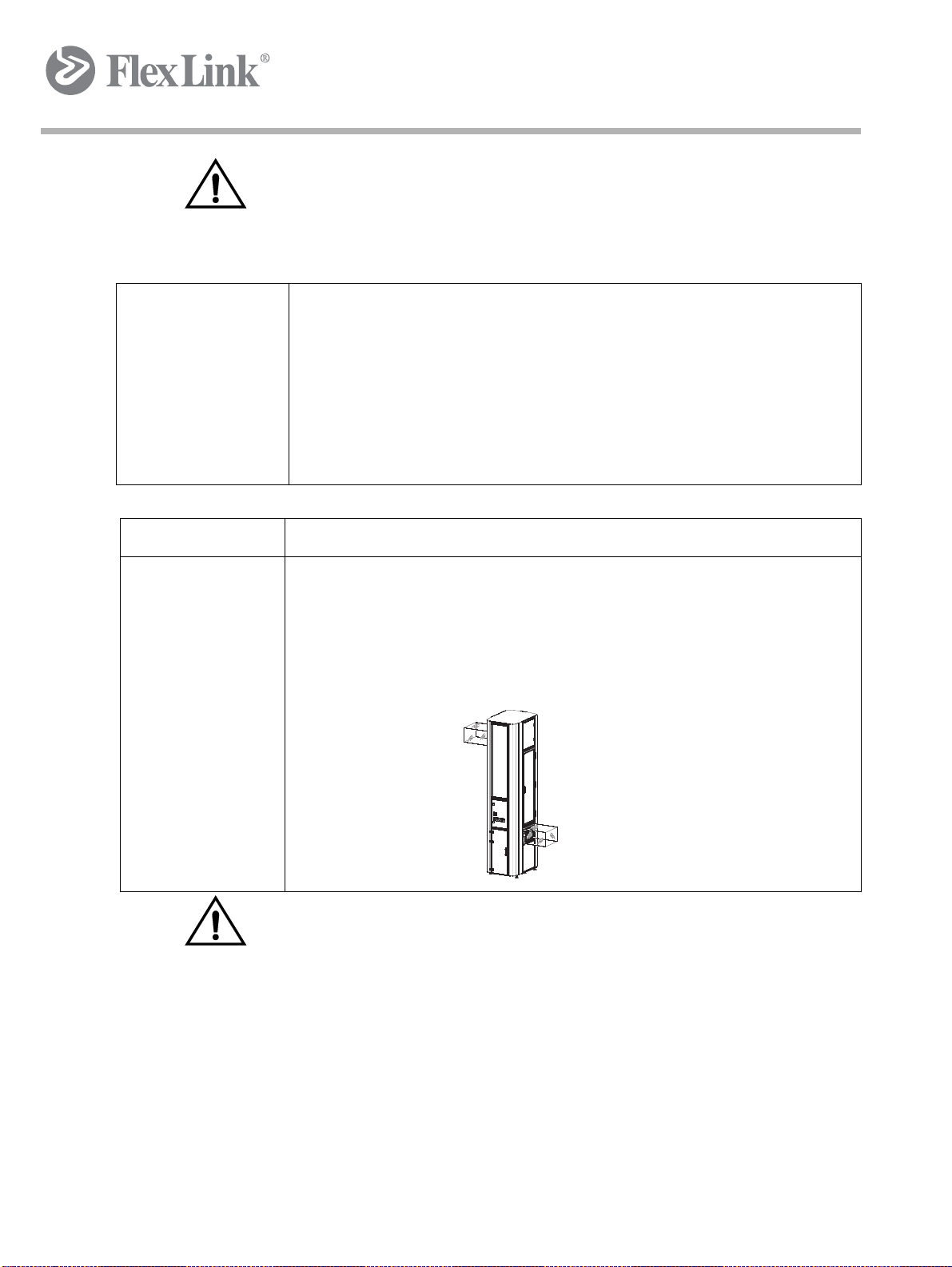

Mechanical Remark

Transition guard At the transition between the Elevator and a connected conveyor a gua rd must

have been placed, so that persons are kept at a reaching distance from the

transition.

Do not use the Elevator as a platform for maintenance work or in the production,

use equipment intended for these purposes.

Created by EBCCW 00:06

. . Note! Only technically qualified employees are allowed to

change the settings of the safety provisions.

5112204

7

Page 16

Safety

Safety

system

Line main cabinet

Safety

system

Door

switch

M

Vertical

motion

ES

M

Horizontal

motion

Motor supply voltage (VAC)

24V

DC

Line global

emergency

switch loop

Elevator

ES

Emergency

switch loop

Comm.

interface

ES

Permanent

I/O

24V

DC

Safe

I/O

Safe motor

supply voltage (V

AC

)

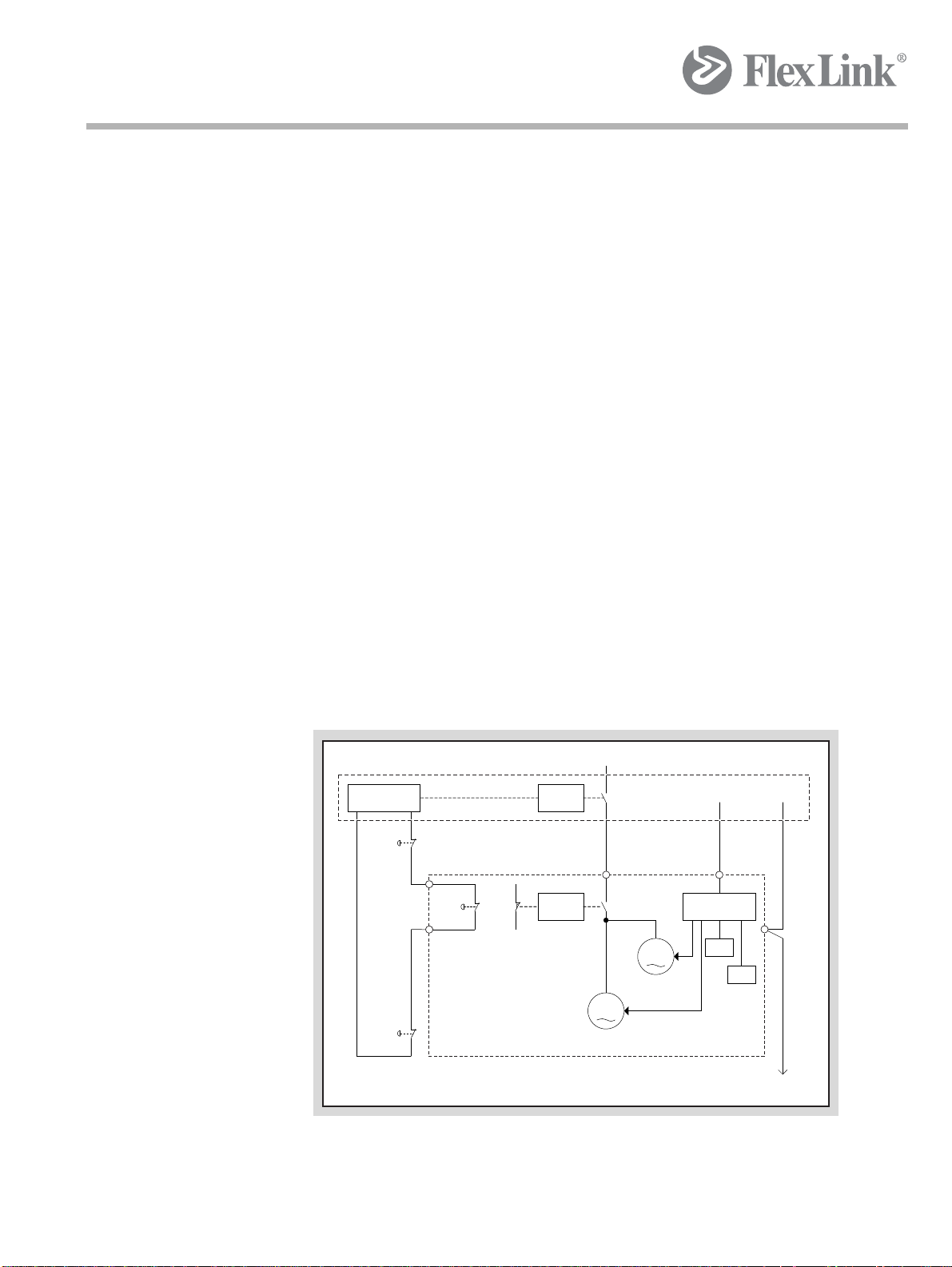

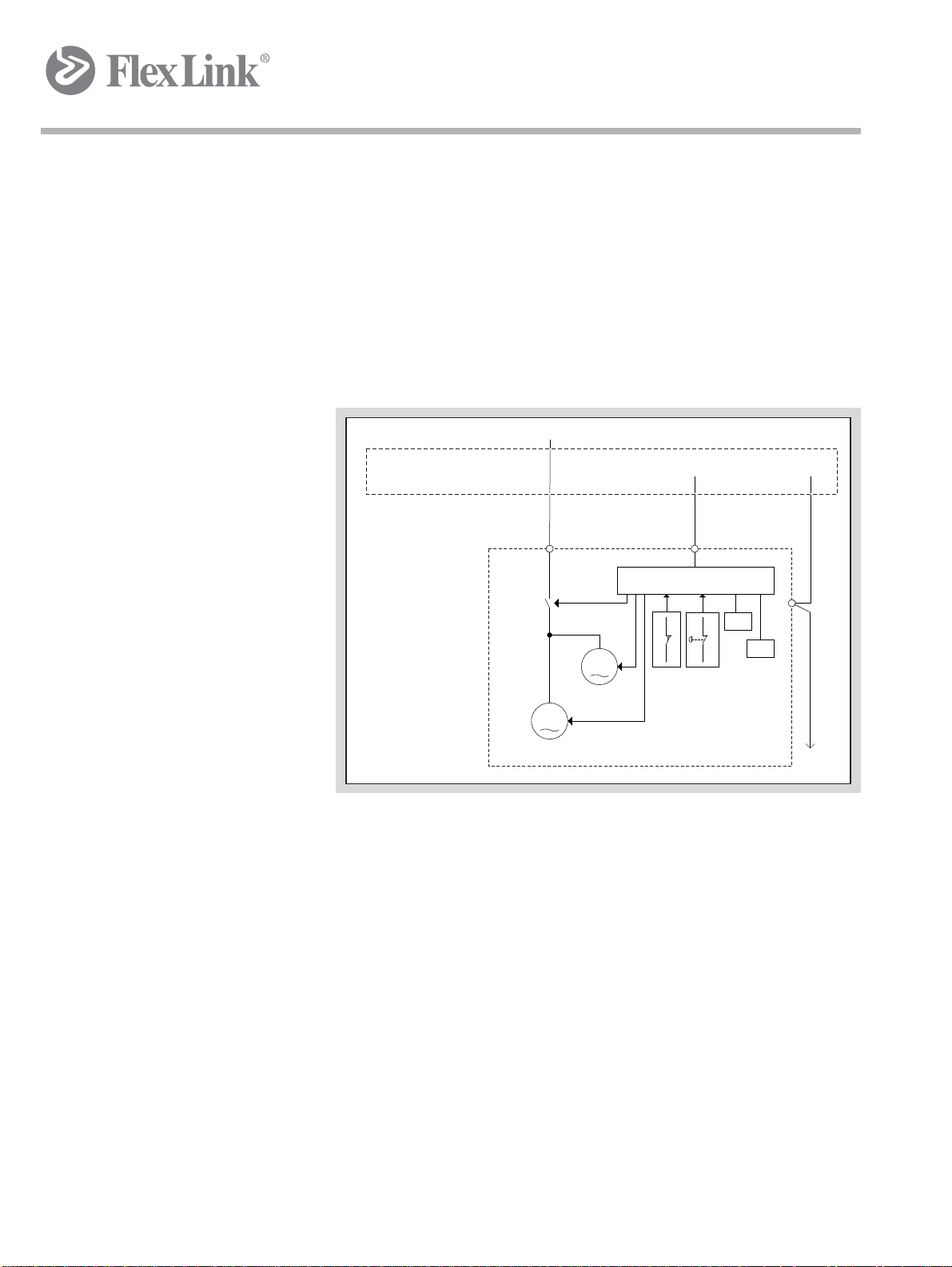

1.3.1 Safety system architecture

The safety system architecture varies depending on elevator version.

Elevators require motor supply voltage and permanen t 24V DC power supply for communication devices. Motor supply voltage depends on version

(50 Hz version: 400 V AC, 60 Hz version: 480 V AC).

Safe 24V DC (disconnected at emergency) is not used although the elevator provides means for passing on the power.

1.3.1.1 Profibus/DeviceNet versions

Emergency switch

The purpose of the safeguard is to be part of the line global emergency

safety system and affect the motor power supply to the elevator.

In case of emergency, the motor power supply to elevator shall be disconnected (stop category 0, EN60204-1).

Door switch

The elevator is equipped with a service door for access inside . Opening the

door results in a elevator internal disconnection to motors (stop category 0,

EN60204-1).

Figure 2 Profibus or DeviceNet version

8

5112204

Page 17

Safety

Line main cabinet

Door

switch

M

Vertical

motion

ES

M

Horizontal

motion

24V

DC

Elevator

Safety comm. interface

Permanent

I/O

24V

DC

Safe

I/O

Motor supply voltage (VAC)

1.3.1.2 Profisafe versions

Emergency switch and door switch

Safety fieldbus protocols provide flexibility in safety architecture.

The emergency switch and door switch are connected to safe inputs of the

communication interface inside the control box of elevator.

Safety outputs of the communication in terface disconnect s the motor power supply internally in the elevator.

Created by EBCCW 00:06

5112204

Figure 3 Profisafe version

9

Page 18

Safety

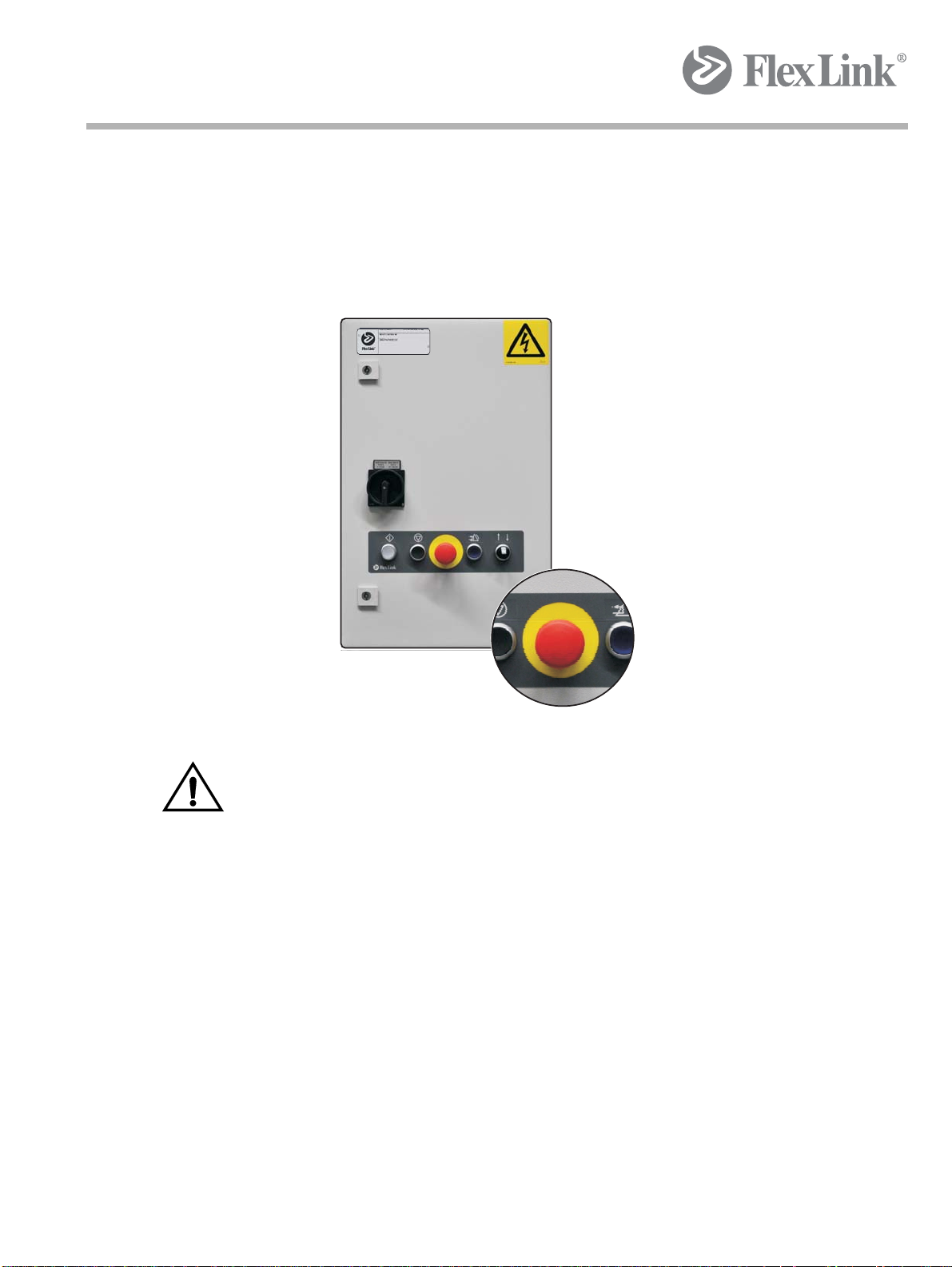

1.3.2 Emergency stops

If personal safety is endangered or if there is a risk for equ ipment damage,

the emergency stop button must be immediately pressed.

An emergency stop button is mounted on the front of the electrical cabinet.

Figure 4 Location of emergency stop button

. The emergency stop device does not disconnect power to the ma-

chine.

For more detailed information about th e emerge ncy stop function, see the

application manual.

10

5112204

Page 19

1.3.3 Guards

. The elevator consists of moving parts that can cause injury.

Feed-in and feed-out areas around the elevator are unprotected; they must

be protected by, for example, the installation of tunnels or similar devices.

The elevator may not be operated if the door switch is inoperable or if a st ationary guard is improperly fitted.

Stationary guards

The elevator is protected by stationary guards of clear PC a nd alu minium.

Openable guard

The elevator is equipped with a service door for accessing the interior . This

door is equipped with a door switch. If the door is opened dur ing operation,

power to elevator motors is disconnected (stop category 0 according to EN

60204-1).

Safety

. Stop the elevator before opening the door. Do not open the door for

the purpose of stopping the elevator.

The door switch does not disconnect power to the machine.

1.3.4 Noise level

. The noise level produced by the elevator is under 70 dB(A).

1.3.5 Electrical cabinet

. The voltage in the electrical cabinet is 400 V or 480 V, depending on ver-

sion. Ensure that the electrical cabinet is closed and locked after working

in the electrical cabinet.

Never bypass the safety system.

The electrical cabinet can only be opened using a tool.

Before working in the electrical cabinet, the main switch to the motor must

be turned off and locked. The key is retained by the service technician until

work is finished.

Created by EBCCW 00:06

5112204

11

Page 20

Safety

Examples of service work include:

• Disconnection of wiring

• Replacement of motors, etc.

• Service work in the electrical cabinet, terminal boxes, etc.

• Service work performed on the machine that cannot be seen from

the electrical cabinet.

For adjustment of photo-electric cells, inductive sensors, etc., power is required:

- Stop the machine and wait until the moving p arts have come

to a complete stop.

- Ensure that "Start" is turned off.

- Open the elevator door.

- Make adjustment.

Verify adjustments using manual operation of the elevator with the door

closed (see Handling

on page 58).

12

5112204

Page 21

Safety

1.4 Safety measures to be taken

For a safe operation of the Elevator a number of safety measures are to be

taken. These include the following measures:

• Clean floor surface - With a clean floor surface the operator will

not be hindered while operating the Elevator. This can prevent

tripping or slipping, so that the operator does not unexpectedly

come into contact with the Elevator.

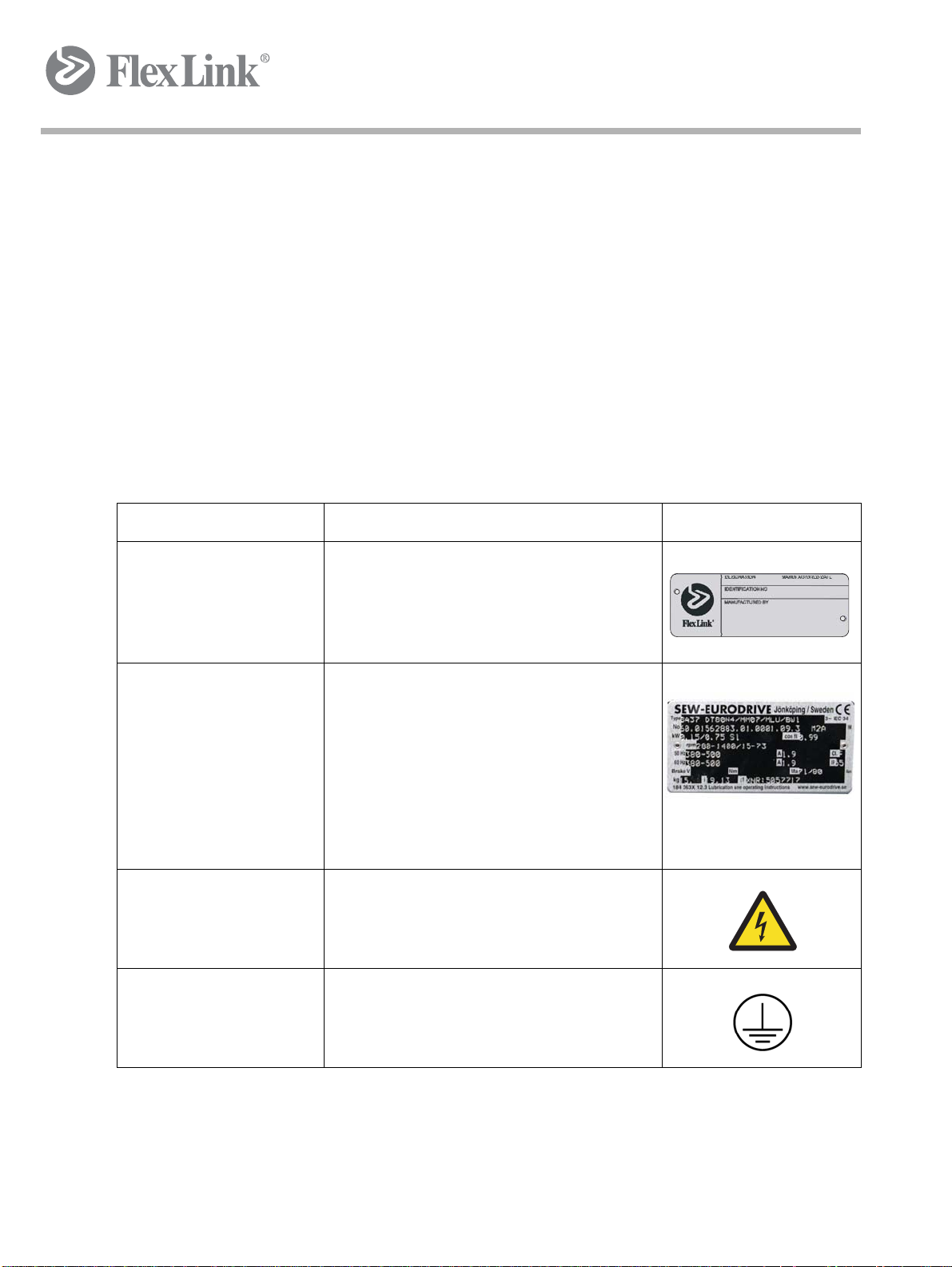

1.5 Explanation of symbols

Just like in the manual, symbols are used that have been placed on the Elevator in order to point the attention of the user to cert ain situations or pr ovide certain information on components of the Elevator.

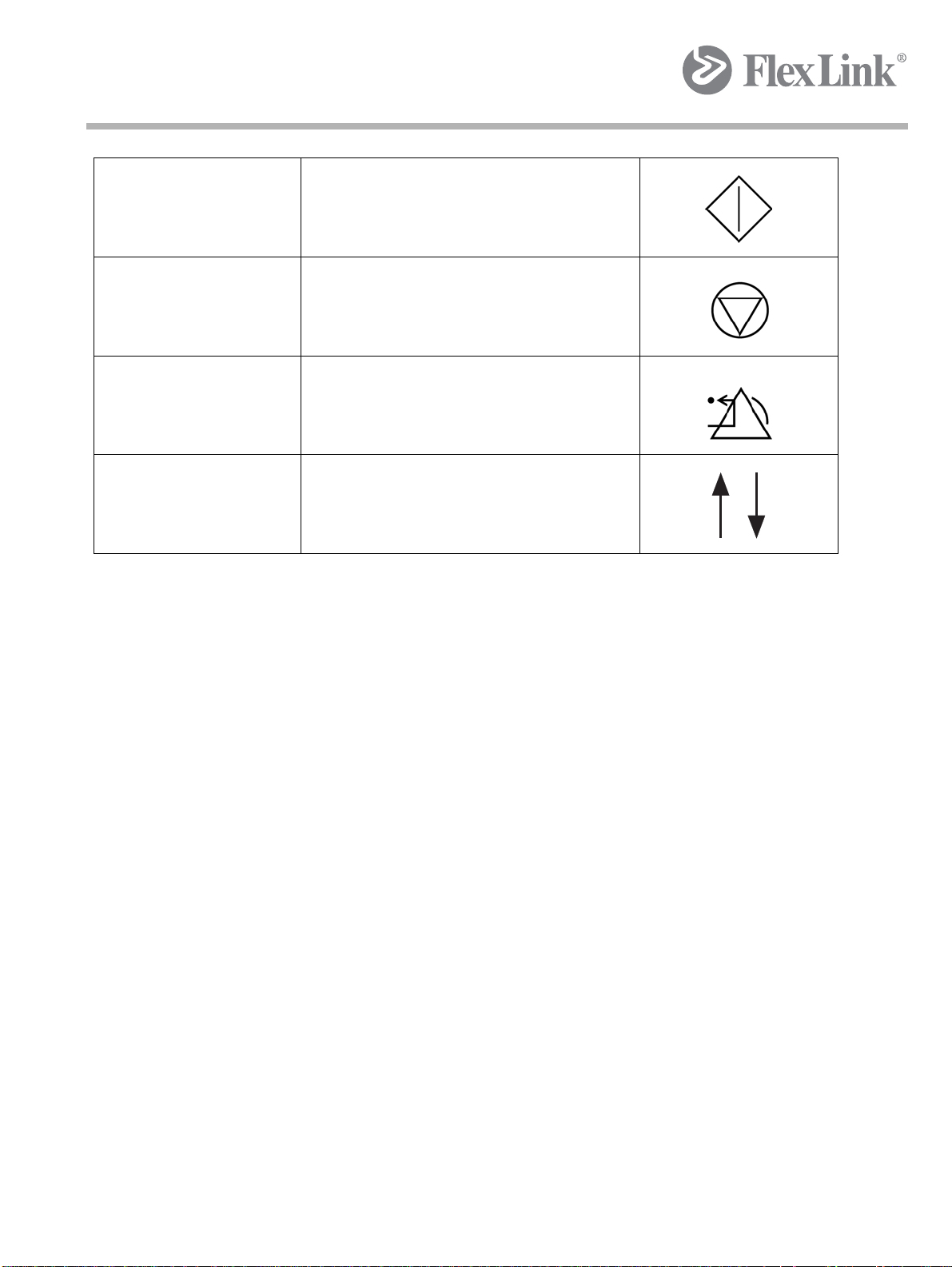

No. Description Picture

1.Type plate Elevator This contains the name and the address of

the Manufacture. Apart from that the

declaration of incorporation, series or type

indication, serial number and the year of

construction of the Elevator.

2.Type plate motor This contains the name and the address of

the motor supplier. Apart from that the CEmark, kind of motor oil, series or type

indication, serial number and the year of

construction of the motor.

3. Risk for electric shock Placed on control box.

4. Protective earth According to IEC 60417. Placed below

control box. Points out where to connect

equipotential bonding conductors.

Created by EBCCW 00:06

5112204

13

Page 22

Safety

5. Start According to IEC 60417. Pictogram at

pushbutton on control box door.

6. Stop According to IEC 60417. Pictogram at

pushbutton on control box door.

7. Alarm reset According to IEC 60417. Pictogram at

pushbutton on control box door.

8. Up/Down According to IEC 60417. Pictogram at

pushbutton on control box door.

14

5112204

Page 23

Technical specification

2 Technical specification

Complete turn-key version.

In feed and discharge protections are not included.

Cycle time 13- 16 sec (low elevator)

18- 24 sec (high elevator)

Max weight* *

Max product height 400 mm

A number of pallets can be elevated at the same time.

Conveyor length Max. length 550/640 mm

Conveyor speed 15 m/min

Electrical environment 50 Hz: 400 V AC

60 Hz: 480 V AC

ESD version elevators are available.

Cabinet for Profibus, Profisafe or Device Net communication for Line control.

*) Maximum product weights are as follows:

Type Max. load/level Max. total load in elevator

X85/XK/XT 30 Kg 30 Kg

RTI 15 Kg 100 Kg

DAS 80 85 Kg 85 Kg

Dimensions LxBxH: See appendix.

Weight Low elevator: ~ 300 kg (Depending of configuration)

Weight High elevator: ~ 400 kg (Depending of configuration)

Electrical

specifications

Pneumatic

system

Supply: 3 phase + neutral + PE, 400 V AC, 50 Hz, 24 V DC

Max. power: 1 kW N/A

N/A

Created by EBCCW 00:06

5112204

Capacity Products per minute: See application.

Max. speed: See application.

15

Page 24

Technical specification

A

A

A-A

745

435

1018

75 30±

1754

75 30±

A-A

745

435

1018

75 30±

A

A

3394

A-A

75 30±

1754

A

A

833

604

1356

A-A

745

435

1018

Pallet width 240-320

Pallet width 400-640

A-A

833

604

1356

A-A

745

435

1018

Pallet width 240-320

Pallet width 400-640

A

A

3394

75 30±

XT

X85/XK

2.1 Technical data

Figure 5 Elevator description

16

5112204

Page 25

Technical specification

2.2 Ordering information

Example of strings obtained from the configurator:

AC D EF GHIJ

X85 - 200 - ABCD - E - 900 - 2800 - 50 - PB - AS0

Table 1: X85 High elevator with Profibus

AB CDE F G H

I J

XT - 400 - 150 - AB - E - 400 - 1200 - 50 - PS - AS2

Table 2: XT low elevator, pallet width 400, Profisafe

AC D EF GHIJ

X85 - 200 - ABCD - E - 900 - 2800 - 50 - DN - AS0

Table 3: X85 High elevator with Device net

Created by EBCCW 00:06

5112204

17

Page 26

Technical specification

E

A

B

D

C

F

E

F

Input Variable

A- Platform: X85

XK

XT

B- Pallet width: 240

320

400

480

640

C- Product height: 1-400 mm

D- In feed and discharge positions: A

B

C

D

E- Door positions: E= Left

F= Right

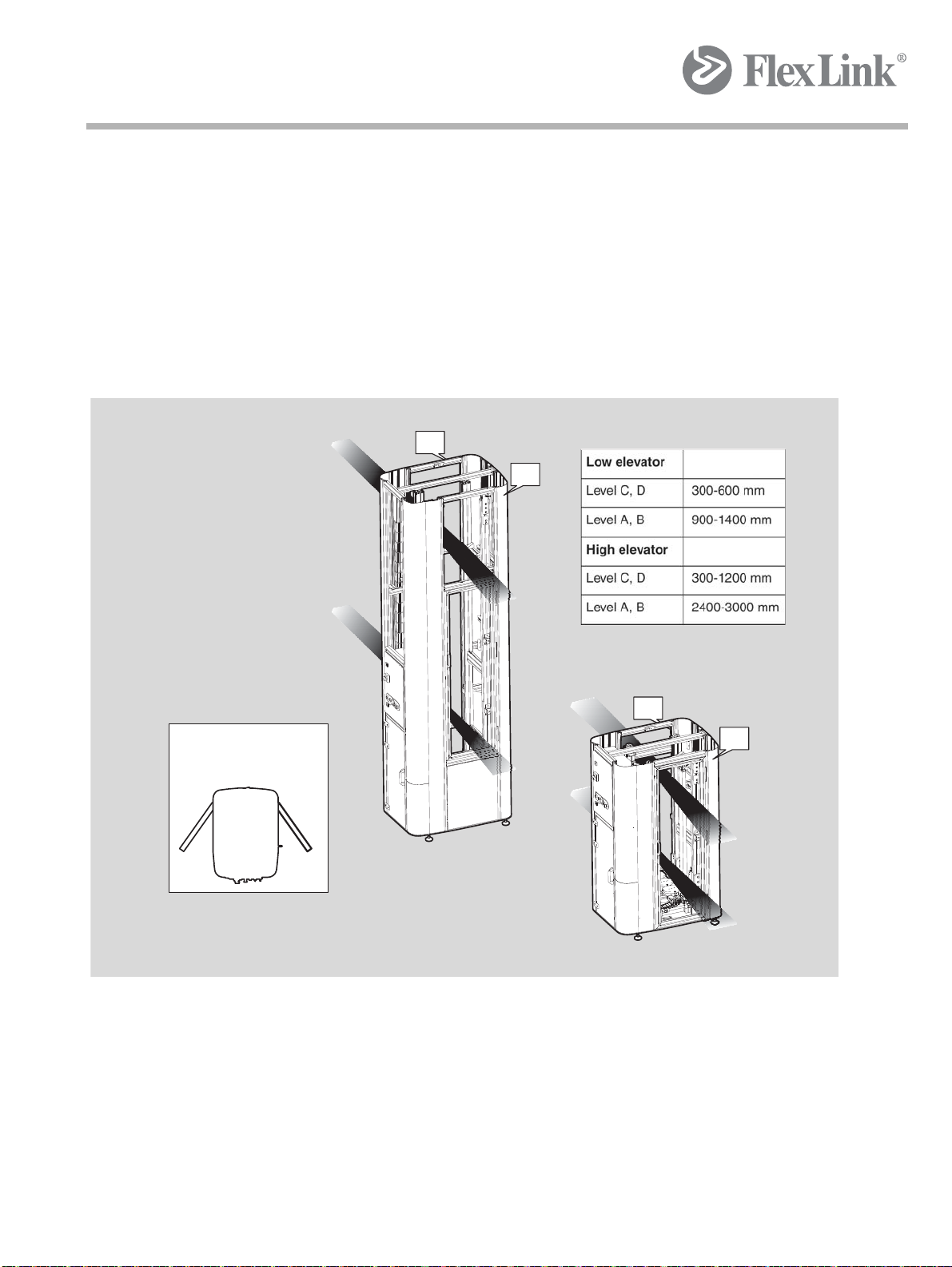

F- Lower height: Low elevator 300-600 mm

High elevator 300-1200 mm

G- Upper height: Low elevator 900-1400 mm

High elevator 2400-3000 mm

H- Drive unit version 50 Hz, European

60 Hz, American

I- Fieldbus: PB: Profibus

PS: Profisafe

DN: Device net

J- ESD version: Standard: AS0

Conductive: AS2

For more information please contact your local FlexLink of fice.

18

5112204

Page 27

Technical specification

2.3 Operating conditions

The circumstances under which the Elevator can be ap plied partly depend

on the materials selected. FlexLink has defined a number of parameters

within which the Elevator would be allowed to function. Should th e Elevator

still be applied beyond these limiting values, FlexLink cannot guarantee the

good functioning of the Elevator.

Ambient temperature (in operation) -20°C to +60°C

Relative air humidity (RH) 30% to 95%, not condensing

Lighting Normal ambient lighting

As a standard no lighting is installed on the Elevator and this can neither

be installed as an option. Normal ambient lighting is sufficient to work safely

with the Elevator. The Elevator is not intended for use in the open air and

besides the Elevator is not suitable for an envir onment with a risk of explo sion.

For use under deviating circumstances you may contact the supplier of the

Elevator.

Created by EBCCW 00:06

5112204

19

Page 28

Introduction function and components

E

A

B

C

D

A

B

D

C

Height

(Top of chain)

F

E

F

E, F

Available door positions

To p

View

Right

Left

3 Introduction function and

components

3.1 Purpose of use

The elevator changes the elevation of products in a flow, such as boxes or

pallets, according to the principle of first in/first out.

20

5112204

Page 29

Introduction function and components

3.2 Description of the Elevator

The elevator primarily consists of two main units:

• Control system

• Mechanical lifting device

Control system

Created by EBCCW 00:06

5112204

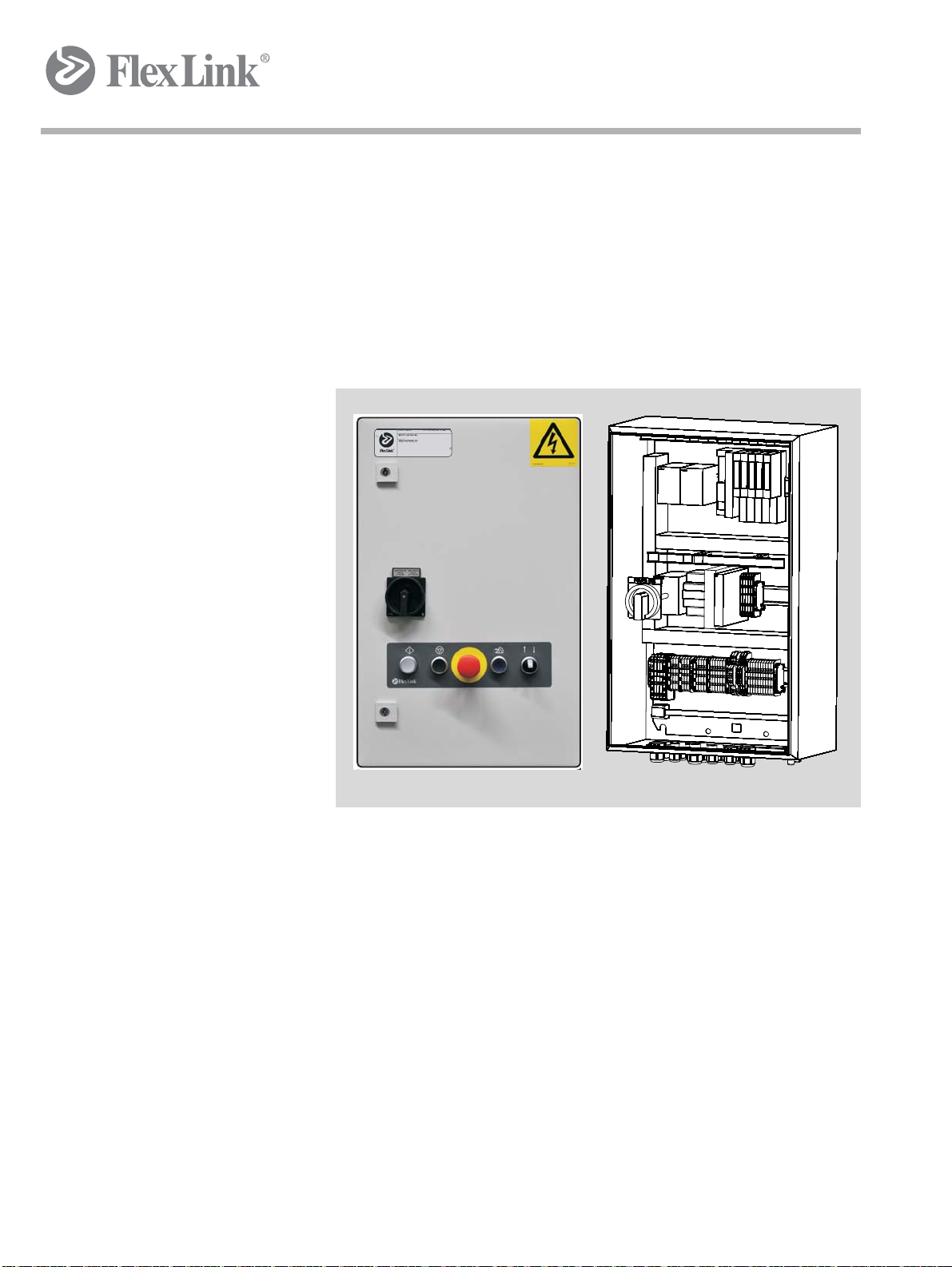

Figure 6 Electrical cabinet

Central intelligence and distributed I/O

The elevator is to be controlled by a Line co ntroller and do not itself contai n

any intelligence such as PLC. The Line controller (PLC/PC/etcetera) controls the elevator through the integrated communication interface in the

control box.

21

Page 30

Introduction function and components

Safety system

Profibus and DeviceNet versions includes an autonomous safety system

for the door switch, disconnecting the power suply to the motors through

the safety relay and main contactors.

For Profisafe versions the door switch and emergency switch are connected to safety inputs of the communication interface. Main contactors are

connected to safety outputs of the communication interface.

For Profibus and DeviceNet versions the conductors of emergency switch

is connected to a terminal group. This terminal group is integrated into the

line global emergency stop safety system by integrator.

The red knob of emergency switch is delivered in pla stic bag a s th e el evator emergency switch functionality is not guaranteed before it is appropriately integrated into the line's safety system by the integrator.

Drives

The horizontal drive is with fixed speed controlled by a device including

contactor and motor protection.

The vertical drive is frequency controlled by a frequency converter placed

on the motor itself.

For standard versions the motor contr ol is discrete: On/Off, Up/Down, High

speed/Low speed. Spee ds are preset in hardware of motor.

For advanced versions a second communication interface provides advanced control of the motor. Speed and ramp times can be controlled by

software in Line controller . Motor current value and error codes can be provided by the motor to the Line controller.

22

5112204

Page 31

Introduction function and components

Mechanical lifting device

For RTI elevators (Paternoster), the lifting device consists of a number of

carriers attached to a roller chain. These ar e powered by a Movimot bra ke

motor mounted in the lower part of the elevator. Feed-in and discharge devices are required for feeding in and feeding out pallets. These are not included with the elevator.

For XT/X85/XK elevators, the lifting device consist of a short conveyer with

separate drives for feeding in and feeding out p allets (see the figure below).

Vertical movement of the lifting device is powered by a drive chain to a Movimot brake motor, mounted in the lower part of the elevator.

Figure 7 Lifting device

Elevator function is controlled by a number of photo-electric cells and inductive

sensors.

The photo-electric cells check that product feed-in is correct and that the

product is correctly positioned for discharge. For XT elevators, this check

is made by inductive sensors.

Inductive sensors control the lowering of the lifting speed and stopping of

the lifting movement.

The machine is of the stand-alone design and can be combined with conveyers. Feed-in and discharge can be single or multiple.

Maximum product size is dependent on product stability and the dimensions of the elevator.

RTI elevators do not include feed-in or discharge devices at the top.

Created by EBCCW 00:06

5112204

23

Page 32

Introduction function and components

3.2.1 Components

3.2.1.1 Electrical cabinet

The electrical cabinet is fitted in the front of elevator. The door is equipped

with the required means of maneuvering (pushbuttons/lamp s) and module

electrical main switch.

The main switch do not disconnect 24 V DC power supply to module.

24

Figure 8 Electrical cabinet

The through-puts in the bottom of box is accord ing to module version, see

electrical drawings. In the bottom is also the fast-connectors for fieldbus

positioned.

Inside the electrical cabinet is the module safety system, fieldbus communication interface, circuit breakers, etcetera.

The safety system design depends on version. Profibus and DeviceNet

versions include a safety relay to which the door is connected. Profisafe

version do not contain any safety relay. Common for all versions is that motor supply voltage is disconnected at emergency stop through main contactors.

In the bottom of cabinet is an earth rail for cables. There is also one earth

terminal for each terminal group.

5112204

Page 33

Introduction function and components

The fieldbus cable is connected by fast connectors as mentioned above,

see electrical documentation. If the module contains several communication interfaces, such as the advanced versions with field distributor, there

is still only one connection point for fieldbus.

Outside and below the electrical cabinet is the connection point for equipotential bonding, see electrical documentation.

. .

Warning: The voltage is 400 V AC (or 480 V AC).

Warning: The voltage in the field distributor is 400 V . There is risk

for serious injury due to electrocution. Immediately seek the care

of a physician if an accident occurs. After the main switch of field

distributor is turned off, voltage is still high in the field distributor.

Warning: Check that the electrical cabine t is closed and locked

after working in the electrical cabinet.

Warning: Never bypass the safety system.

Created by EBCCW 00:06

5112204

25

Page 34

Introduction function and components

3.2.1.2 Field distributor

The field distributor, used in advanced versions, is the communication interface of the adjustable speed drive for the vertical motion.

26

Figure 9 Field distributor

5112204

Page 35

Introduction function and components

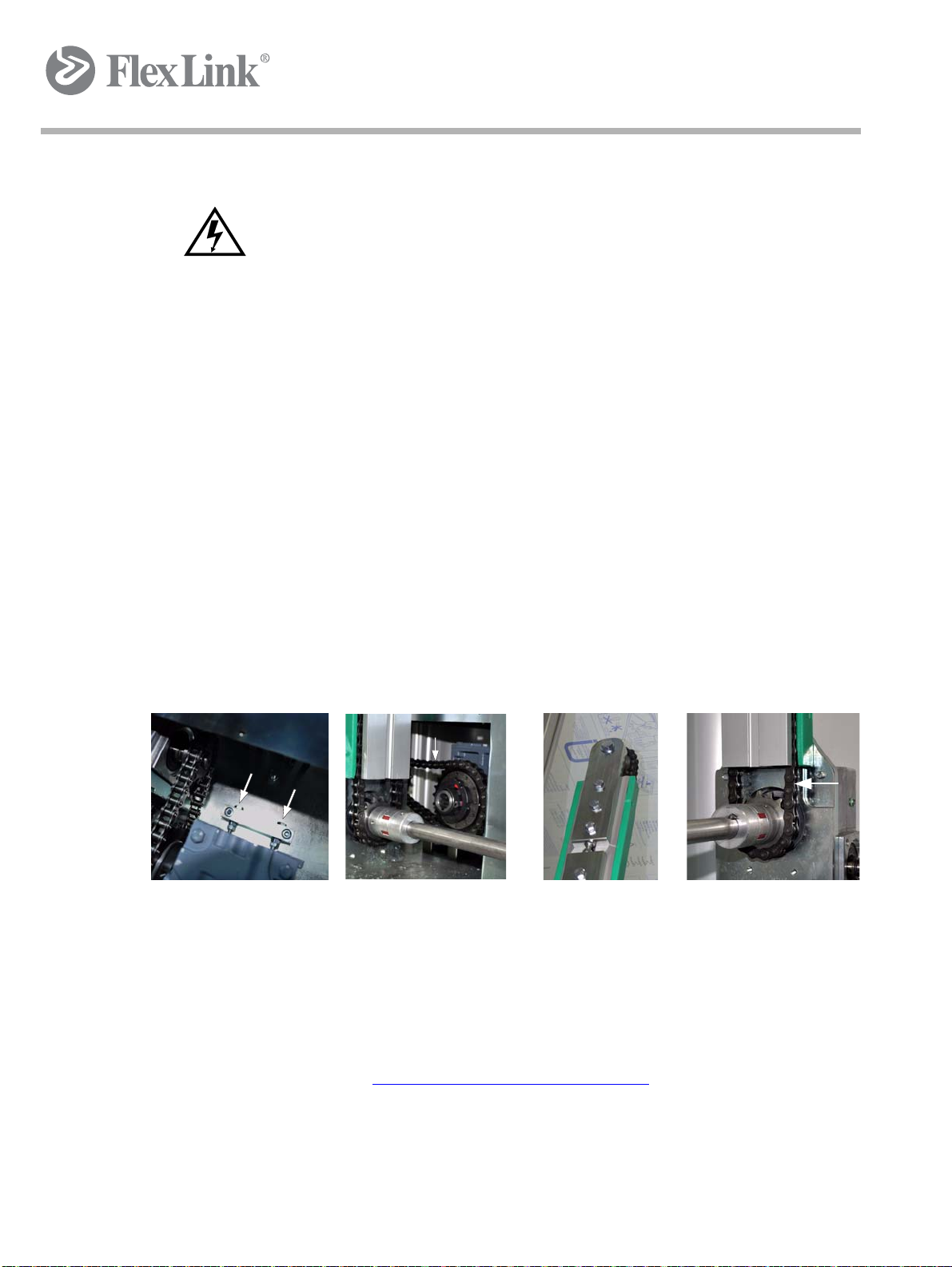

3.2.1.3 Motor

Figure 10 Adjustable speed drive (motor with frequency inverter)

An adjustable speed drive powers the elevator 's lif ting motion, ver tical m otion, via roller chain/gears. The drive p ackage is moun ted in the lowe r pa rt

of the elevator.

Created by EBCCW 00:06

5112204

27

Page 36

Introduction function and components

3.2.1.4 Guards

The elevator consists or moving parts that can cause injury. Feed-in and

discharge are covered by stationary and openable guards. The elevator

may not be operated if the door switch is inoperable or if a stationary guard

is improperly fitted.

Stationary guards

The elevator is protected by stationary guards of clear PC and aluminium.

These guards must be correctly fitted when the elevator is in service. The

stationary guards must be in place when the power is on.

Openable guard

The elevator is equipped with a service door for accessing the interior . This

door is equipped with a door switch. If the door is opened during operation,

power to the elevator motors is disconnected (stop category 0 according to

EN 60204-1). The door switch is a p art of the safety system and may under

no circumstances be by passed or in any other way made inoperable. Once

the door is closed, the elevator can be reset and started.

. Warning: Stop the elevator b efore opening the door. Do not o pen

the door for the purpose of stopping the elevator.

Figure 11 Safety switch, door

28

5112204

Page 37

Introduction function and components

Elevator module

Vertical motion

Horizontal

motion

Discharge conveyor

Not part of module

In-feed conveyor

Not part of module

Possible conveyor motors placed inside elevator , not p art of Elevator module, are not affected by the door switch.

Figure 12 Elevator module

. Warning: Stop the elevator before op ening the door. Do not open

the door for the purpose of stopping the elevator.

5112204

Created by EBCCW 00:06

29

Page 38

Introduction function and components

XT

Inductive lift cage

position sensor

X85/XK

Photo-electric lift cage

position sensor

X85/XK

Reflector of photo-electric

lift cage position sensor

3.2.1.5 Sensors

3.2.1.5.1 Lift cage

30

Figure 13 Photo-electric cells

Photo-electric or inductive sensors, depending on version, are used for detecting that product is positioned in the lift cage.

The photo-electric sensor type is retro-reflective, thus the light beam is reflected by a reflector on the opposite side of conveyor back to sensor, making the detection of product less sensitive to colour differences of product.

The stop position of conveyed item, due to sensor position, is such that the

conveyed item does not reach to the end of lift cage convey or.

RTI elevator version

For RTI elevators, photo-electric cells are used, mounted at fixed positions

in the elevator frame.

5112204

Page 39

3.2.1.5.2 Vertical motion

Vertical motion

position sensors

Lifting interlock sensor

Lifting interlock sensor

reflector

Introduction function and components

Figure 14 Inductive sensors

Vertical motion sensors

Inductive sensors are used at stop positions and low-speed stretches of the

vertical motion.

Interlocking sensors

Retro-reflective photo-electric sensors are mounted in the upper part of

frame with reflectors mounted on the bottom plate of elevator. Their purpose is to interlock vertical motion if obstacle is detected.

Created by EBCCW 00:06

5112204

31

Page 40

Introduction function and components

3.2.1.5.3 Limit switches

This does not apply to RTI units. These should be protected by the application.

32

Figure 15 Limit switches

The limit switches are located in the upper and lower parts of the frame and

are activated in the event of excessive lifting device travel.

The upper limit switch interlock the vertical motion upwards electrically and

vice versa for the lower limit switch. Thus, activating the lower limit switch

still allows upward motion.

Mechanical dampers serve as protectio n after the limit switch es .

To assure correct operation of the elevator, ensure that the switches are

correctly positioned and are activated in the intended direction of travel.

5112204

Page 41

Introduction function and components

E

A

B

C

D

A

B

D

C

Height

(Top of chain)

F

E

F

E, F

Available door positions

To p

View

Right

Left

3.3 Working principle

The purpose of the elevator is to transport produ cts / goods ve rtically to

bridge a difference of height or to function as buffer zone.

5112204

Figure 16 Principle sketch elevator

In most cases the Elevator is integrate d in a system. The input / output sid e

of the Elevator is determined by the application.

33

Created by EBCCW 00:06

Page 42

Unload the elevator

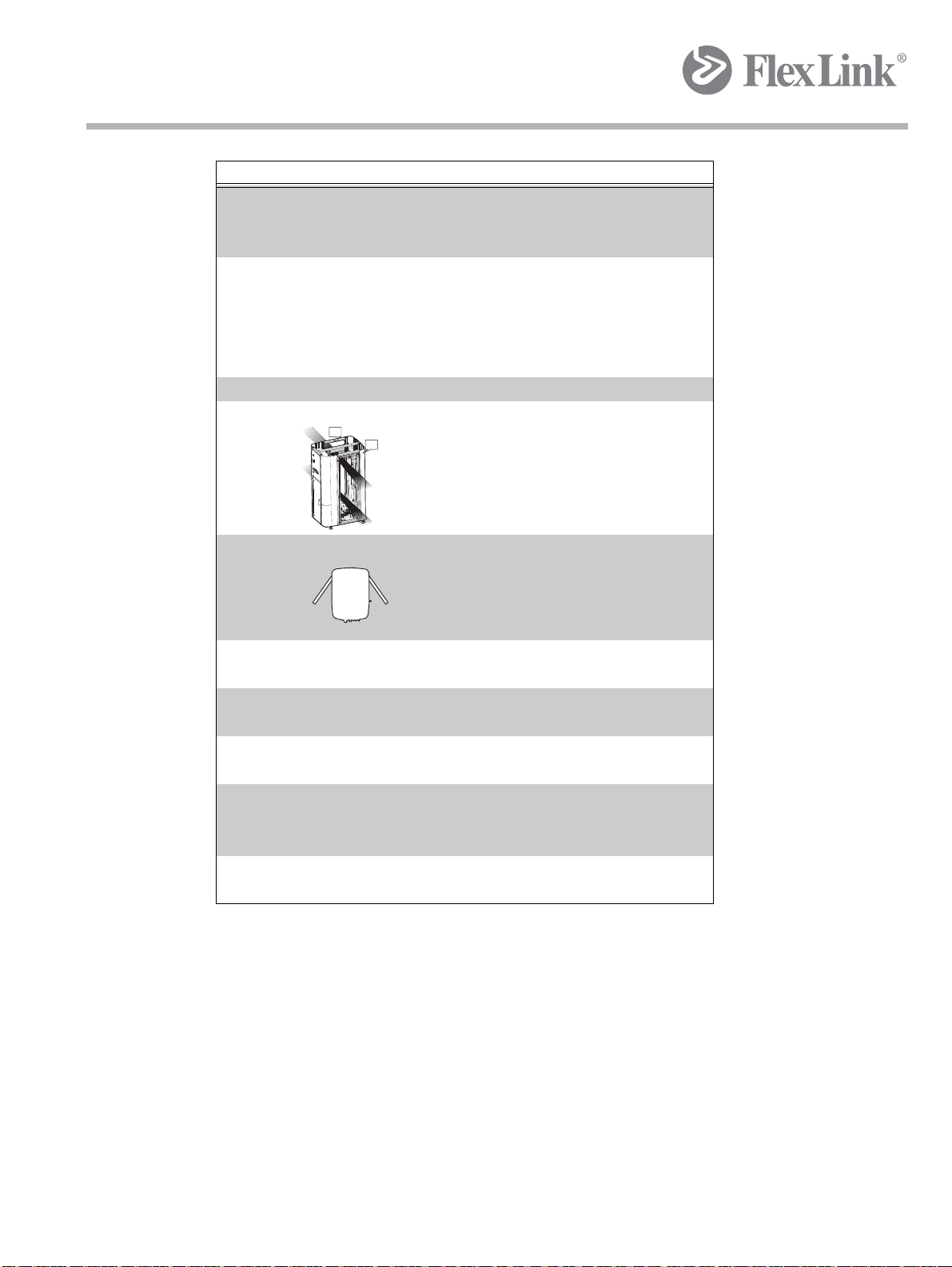

4 Unload the elevator

4.1 Preparation

This section describes the steps that are required for unloading the Elevator. It is recommended to make use of the d evices described. When using

this or another device, this device is expected to be provided with a quality

mark.

. Note! The operations concerned are to be carried out calmly in

order to be able to carefully monitor any movement of the

Elevator.

Before starting the unloading a good prep aration is required . The appropriate devices must be available. Apart from that the first transport check is

an important part of the unloading, as in case of damage this shou ld be

mentioned on the delivery note in relation to guarantee and the like.

The first transport check after arrival of the Elevator a transpor t check is to

be carried out. The check can be carried out at the moment the Elevator

has been unloaded from the container o r the truck. The technical specification gives the dimensions to be checked. Is the elevator delivered undamaged and is it the correct Elevator?

Machine serial number type plate

. Note! Any damage is to be mentioned on the delivery note and

should immediately be reported to the supplier . This with respect

to the guarantee of the machine.

34

5112204

Page 43

Unload the elevator

4.2 Unloading instructions

Before starting unloading, all fastening means (securing belts, screws, etc.)

that secure the Elevator unto the means of transport must be removed.

Subsequently check whether the transport supports are still connected well

to the Elevator. After this the unloading procedure may be started.

4.2.1 Erecting the Elevator See Erecting the Elevator on page 37

When putting upright, just like when moving the Elevator, make sure that

the floor is level and clean and has sufficient carrying capacity. At the moment the Elevator is on the correct place it can be put upright. Dependent

on the situation the Elevator can be put upright using a hoist, a cran e o r a

forklift truck.

Device(s)

Hoist Crane Open-end spanner

. Note! Make sure when putting upright there is enough space /

height to put the Elevator upright!

Hoist

• The hoisting device is to be fastened to the top of the Elevator .

While hoisting the hoist should be well fixed and may not ride/shif t

away unexpectedly.

• After having mounted the adjusting feet the Elevator can be put

upright. Now the hoisting device can calmly hoist the Elevator in

the upright position.

Created by EBCCW 00:06

5112204

35

Page 44

Unload the elevator

. Note! Be careful that the Elevator does not tip at the moment it

almost has been hoisted in the upright po sition. Make sure there

are no persons near the Elevator!

. Note! Carry out these operations calmly in order to be able to

carefully monitor any movement of the Elevator.

. Note! It is forbidden to walk under the Elevator during putting

upright.

. Note! Make sure that while putting upright there are no

unauthorised persons or people that ar e no t su pp osed to be

there near the Elevator.

36

5112204

Page 45

Unload the elevator

1

2

3

4

Created by EBCCW 00:06

5112204

Figure 17 Erecting the Elevator

37

Page 46

Installation and adjustment

Connecting track

Elevator

Connecting track

Input/output

without

connecting track

5 Installation and adjustment

This section deals with the operations to have the elevator function well

within a (transport) system. First section 1.2 on page 4, in which the provisions to be taken care of are given, should be studied car efully . section 1.3

on page 6 is particularly im portant for the elevators that are deliver ed to the

end user not fully assembled.

5.1 Provisions to be provided

Make sure before integrating that the surround ings are clean and free from

obstacles and the mounting surface is clean and level. Besides, it shou ld

be repeated that the operations are to be carried out in a calm and controlled way!

After having placed the elevator in the correct position, the elevator is to be

fastened to the mounting surface by using the holes in the adjusting feet.

The elevator has an input and output and these a re to be connecte d to the

connecting tracks. Correct adjustment determines the quality of the system.

Figure 18 In feed and discharge

38

5112204

Page 47

Installation and adjustment

Air vents

5.2 Mechanical assembly

5.2.1 Integration in a (transport) system

The elevator is a machine that is integrated in a system of conveyors. This

means that an input and output are to be connected to it. If the elevator is

to be fitted into an existing situation, this usually give s more problems than

in a completely new situation. In both cases one should aim at optimum

functioning.

5.2.2 Floor construction

Below a number of items are given which should be paid attention to during

integrating a elevator as floor construction.

Tools

Opend end spanner Ring spanner Plastic hammer

• Before placing the elevator first make sure that it is placed on the

right place and at the right height. For setting the correct height

the adjusting feet mounted under the elevator can be used.

• Now that the correct height has been established, the connectin g

tracks at the lower and upper ends of the elevator can be adjusted. A special sliding bridge or roller bridge may be needed for a

safe transfer of products.

• After the elevator has been well integrated in the system, the elevator can be attached to the floor surface. This can be don e by anchoring the adjusting feet firmly to the floor or/and connect

through the holes shown in the picture.

• At installation, dismount transport protections and replace them

with air vents.

For more information, see the separate manual from gear box

manufacture.

NB: The quality of integration in the system is coresp on sib l e fo r

the good functioning of the elevator. Therefore make sure this is

done properly!

Created by EBCCW 00:06

5112204

39

Page 48

Installation and adjustment

5.2.3 Validation

No. Component Remark Checked

1. Lower end Has the lower end the correct height. For the cor rect height we

refer to the technical specification.

2. Upper end Has the upper end the correct height. For the correct height we

refer to the technical specification.

3. Elevator Is there enough sp ace aroun d the elevator to allow working on

it.

4. Fastening /

foundation

Has the elevator been fastened well so that the elevator is

standing steadily and does not move to the left or to the right.

Yes / No

Yes / No

Yes / No

Yes / No

40

5112204

Page 49

Installation and adjustment

400 V AC

24 V DC

ES-loop

Fieldbus

Equipotential bonding

Module

A001

5.3 Electrical installation and controls

5.3.1 Electrical installation

During this phase all necessary cabling is connected to elevator and application code software for controlling the elevator is downloaded to the line

controller (IPC/PLC) as well as the fieldbus hardware configuration.

Reference to the electrical documentation for the version in question.

5112204

Created by EBCCW 00:06

Figure 19 Cabling example

Cabling:

• Power supply

• Fieldbus

• Safety

• Equipotential bonding

41

Page 50

Installation and adjustment

Action Remark

Power on - Motor supply

Voltage check Check equipotential bonding.

Safety check Check that safety system is working properly.

5.3.2 Validation

The purpose of the validation phase is to prepare the elevator for test run.

The validation is performed with empty elevator. No products in elevator.

Reference to electrical documentation.

(Version dependent. 50 Hz: 400 V AC, 60 Hz: 480 V AC)

- 24 V DC

Check voltages. Turn elevator control box circuit breakers

on.

- Service door can be opened and cause motor power

supply disconnection. Closing the door enables safety

reset.

- Emergency switch activation cause motor power supply

disconnection. Deactivating the switch enables safety

reset.

Where disconnections are made is version dependent.

Manual sensor I/O-check Important: Service door must be open preventing motions.

Make sure all sensor signals reach the communica tio n

interface in control box. The sensors are activated

manually. (Inductive sensors are activated with metal.)

Limit switches are excluded.

Maneuver interface check Important: Service door must be open preventing motions.

Make sure all push button signals reach the communication

interface in control box.

42

5112204

Page 51

5.4 Test run

The purpose is to check functionality. T esting is performed by running man ually with an empty elevator without products.

Adjustment for making the lift cage stop exactly in horizontal line with connecting tracks is performed in a later stage.

Action Remark

Manual mode check Elevator can be set to manual mode enabling

vertical motion up/down.

Installation and adjustment

Vertical motion and end

positions

Run elevator carefully towards end-position.

Listen for noise and vibrations.

a. Check that elevator is running high-speed

outside the low-speed areas.

b. Check ramp-down to low speed while

inside low-speed areas.

c. Check that when stopped in end position,

the stop and low speed sensors are still

activated.

Limit switch check Disconnect stop position sensors by

unscrewing the sensor cable in the sensor

end.

The elevator will pass the stop sensor. It will

probably loose the low speed sensor which

may cause it to switch to high speed.

Check that limit switch interlocks the

corresponding motion direction.

Re-connect stop position sensors.

Interlocking sensor check Check that if any of these sensors are

activated vertical motion in both directions is

interlocked.

See Adjustment

on

page 53

See Limit switches

on page 54

See Adjustment on

page 53

Created by EBCCW 00:06

5112204

43

Page 52

Installation and adjustment

Reset button

5.5 Adjustment

5.5.1 Electrical cabinet

The electrical cabinet contains several items which needs correct settings

before usage:

• Contactor (for horizontal drive)

• Communication interface

. 5.5.1.1 Adjustment

For designations of contactor and communication interface see electrical

documentation.

Contactor for horizontal drive

The contactor includes motor prote ction which must be ad justed to the rated current of motor.

Before adjustment make sure the device is not activated.

44

Figure 20 Contactor for horizontal drive

5112204

Page 53

Installation and adjustment

Instruction

1 Activate the reset button for more than 6 s to reach the operating

mode "Parameterization" - the green LED PWR flashes once. The

LEDs are switched off at intervals of 2 s for 0.3 s in the operating

mode "Parameterization" to differentiate from other operating

conditions.

2 Set the rated current of the drive with the 240° potentiometer, for

value see below. The four LEDs display the set current.

Current setting = 0.41 A: PWR=0, ERR=0, L=1, R=0.

3 Store the value by pressing the reset button again (retentive area

of the memory).

4 Actuate the Reset key for more than 2 s (and less than 6 s) to

display the set current for 3 s.

Communication interface

Integrator responsibility due to situation.

5.5.2 Field distributor

Apply to advanced elevator versions. Reference to electrical document.

Created by EBCCW 00:06

5112204

Figure 21 Field distributor

45

Page 54

Installation and adjustment

Adress (dip switches)

5.5.2.1 Adjustments

Figure 22 Terminal box cover

• Switch off power supply prior to removing/installing the terminal-

• Ensure before startup that all protective covers have been fitted

Necessary settings:

• Address (dip switches)

For more information see manufacturer manual.

box cover.

correctly.

46

5112204

Page 55

Installation and adjustment

5.5.3 Vertical motion drive

Figure 23 Adjustable speed drive (motor with frequency inverter)

The motor is frequency controlled with the frequency converter integrated

on the motor.

The converter requires settings according to application.

The drive powers the elevator's lifting motion, via roller chain/gears. The

drive package is mounted in the lower part of th e elevator.

5.5.3.1 Adjustments

Reference to electrical documentation.

Reference to manufacturer manual.

Settings are made on the inside of frequency converter top cover.

• Switch off power supply prior to removing/installing the terminalbox cover.

• Ensure before startup that all protective covers have been fitted

correctly.

Created by EBCCW 00:06

5112204

47

Page 56

Installation and adjustment

f1

t1

f2

S1, S2

Figure 24 Frequency controlled

Standard elevator settings

Potentiometers:

• Nominal speed (f1)

• Low speed (f2)

• Acceleration (t1)

• Dip switch (S1, S2)

• Address and PWM frequency

Advanced elevator settings

Potentiometers:

• Nominal speed (f1)

• Acceleration (f2)

• Dip switch (S1, S2)

• Address and PWM frequency

48

For more information, see manufacture manual.

5112204

Page 57

Adjustment procedure, See section 7.2.2 on page 61

Adjustable screws

5-10 mm

2-3 mm

Installation and adjustment

Figure 25 Drive and drift chain adjustment

5.5.4 Connecting tracks

Elevator lift cage conveyor speed see Technical specification on page 15

The optimal speed of the connecting tracks is equal to elevator lift cage

conveyor speed as this prevents product twisting and wear of the high friction conveyor plates.

The speed difference may not exceed 15%.

If speed difference is unavoidable, an increasing speed is preferred.

5.5.5 Guards

The elevator consists or moving parts that can cause injury. Feed-in and

feed-out are covered by stationary and openable guard s. The elevator may

not be operated if the door switch is inoperable or if a stationary guard is

improperly fitted.

Created by EBCCW 00:06

5112204

49

Page 58

Installation and adjustment

5.5.5.1 Stationary guards

The elevator is protected by stationary guards of clear PC and aluminium.

These guards must be correctly fitted when the elevator is in service. The

stationary guards must be in place when the power is on.

5.5.5.2 Openable guard

The elevator is equipped with a service door for accessing the interior . This

door is equipped with a door switch.

5.5.5.3 Adjustment

To be positioned in line according to figure below.

Figure 26 Safety switch, door

. Warning: Stop the elevator b efore opening the door. Do not o pen

the door for the purpose of stopping the elevator.

50

5112204

Page 59

Installation and adjustment

XT

Inductive lift cage

position sensor

X85/XK

Photo-electric lift cage

position sensor

X85/XK

Reflector of photo-electric

lift cage position sensor

5.5.6 Sensors

5.5.6.1 Lift cage

5112204

Figure 27 Photo-electric cells

Photo-electric or inductive sensors, depending on version, are used for detecting that product is positioned in the lift cage.

The photo-electric sensor type is retro-reflective, thus the light beam is reflected by a reflector on the opposite side of conveyor back to sensor, making the detection of product less sensitive to colour differences of product.

The stop position of conveyed item, due to sensor position, is such that the

conveyed item does not reach to the end of lift cage conveyor.

51

Created by EBCCW 00:06

Page 60

Installation and adjustment

Vertical motion

position sensors

Lifting interlock sensor

Lifting interlock sensor

reflector

5.5.6.1.1 Adjustments

Photo-electric sensor

Adjust the sensor angle towards the reflector.

Adjust the reflector angle making the light beam from sensor hit the reflector 90 degrees against reflective surface.

The LED of sensor confirms reflection by reflector with not obstacles between. Any obstacle between should cause the LED to fall.

If anything blocks the signal between the sensor and reflector, the LED indicator shall turn off.

Inductive sensor

Adjust the vertical distance between sensor and sensor flag on pallet.

5.5.6.2 Vertical motion

52

Figure 28 Inductive sensors

Inductive sensors are used at stop positions and low-speed stretches of the

vertical motion.

Retro-reflective photo-electric senso r s are mo un te d in th e up per part of

frame with reflectors mounted on the bottom plate of elevator. Their purpose is to interlock vertical motion if obstacle is detected.

5112204

Page 61

5.5.6.2.1 Adjustment

Reflector

Interlocking

Low speed

area

Low

speed

Up

Reflector

Interlocking

Low speed

area

Low

speed

Down

Vertical motion

Lift cage

sensor flag

Vertical motion sensors

Installation and adjustment

Figure 29 Vertical motion sensors

The low speed and stop sensors for up and down must be adjusted in relation to motion speed and flag length.

The distance between low speed sensor and corresponding stop sensor is

affected by:

• Flag length. Distance between sensors may not exceed flag

length on lift cage. If not fulfilled, the lift cage will loose the low

speed sensor, thus accelerating to high speed the moments before reaching stop sensor.

• Motion speed/ramp time.

1 The combination of high speed, ramp time and distance between

sensors should be such that the lift cage successfully ramps down

to low speed before reaching stop sensor.

2 The combination of low speed and ramp time should be such that

the lift cage successfully ramps down to stop on the stop sensor

when the stop sensor is activated.

Created by EBCCW 00:06

5112204

53

Page 62

Installation and adjustment

Interlocking sensors

The light beam of the photo-electric sensor should hit the reflector. The lift

cage should not act as obstacle at any height.

5.5.6.2.2 Adjustment

The sensor is adjusted so that the XT conveyers stops within the area, limited by the two photo-electric laser cells (WL9L).

5.5.6.3 Limit switches

This does not apply to RTI units. These should be protected by the application.

54

Figure 30 Limit switches

The limit switches are located in the upper and lower parts of the frame and

are activated in the event of excessive lifting device travel.

Mechanical dampers serve as protectio n after the limit switch es .

To assure correct operation of the elevator, ensure that the switches are

correctly positioned and are activated in the intended direction of travel.

5112204

Page 63

Installation and adjustment

5.5.6.3.1 Adjustment

The limit switches are positioned so that they are activated af ter the upp er

and lower feed-in and discharge positions and be fore the dampers (see the

figure 30).

Created by EBCCW 00:06

5112204

55

Page 64

Installation and adjustment

5.6 Check / Shadow run

In this paragraph the elevator will be checked in a semiloaded condition

with all safety provisions activated. If during the shadow run irregular

sounds or other anomalies occur or if the elevator does not meet the specification or if with a test of ALL products some of th ese do not fit on the track

or get stuck or slip, the machine may not be tested further and advice

should be obtained.

Carry out the check

First the elevator is to be put into operation in order to carry out the checks

required. The elevator will run with semiload while the specified products

are transported through the elevator. If no unusual situations occur, the

check of the elevator and the associated safety provisions can be started.

Check elevator

Below a check table is set up with respect to how the elevator can be

checked for a number of items.

Checklist

No. Check Remarks

1. Does excessive noise occur. Yes / No This may occur because the tension of the

chain is not correct, lifting device are loose or a

sprocket wheel is not aligned well (see

Troubleshooting

list’).

2. There is a ticking sound. Yes / No This may occur because the tension of the

chain is not correct, lifting device are loose or a

sprocket wheel is not aligned well (see

Troubleshooting

list’).

3. Are the lifting device strongly

moving at any place in the

elevator.

4. Are lifting de vice touching the

frame, the guide, the guard or

anything else.

Ye s / No This m ay oc cu r as th er e ar e som e loos e lifting

device (see Troubleshooting

‘troubleshooting list’)

Yes / No Adjust the lifting device.

on page 63. ‘troubleshooting

on page 63. ‘troubleshooting

on page 63.

5. Do all products fit on the

track.

56

Y es / No Check in the technical specification whether the

product dimensions are correct.

5112204

Page 65

Installation and adjustment

6. Are there any products that

do not run over the

transitions uninterruptedly.

7. Is the product correctly

supplied / discharged at the

input / output track.

8. Is the product properly

transported through the

elevator.

9. Can any irregularities be

found in the chain guide.

Yes / No Check the setting of the transition distance or

the transition roller. See section 5.2.2 on page

39 ‘integration elevator’.

Yes / No The system designer has determined this and

will have guidelines with respect to this and

know how to adjust an incorrect output.

Yes / No The product may not move on the track. If so,

contact the supplier

Yes / No The lifting device may not get stuck anywhere

or find resistance, otherwise this is to be

reworked or improved

Created by EBCCW 00:06

5112204

57

Page 66

Instructions for use

6 Instructions for use

6.1 Handling

The control box contains pushbuttons and indica tions (lamps ) to star t/stop/

jog/alarm och to reset alarms. Pictograms are used for describing purpose

of pushbuttons and indications; Start, Stop, Reset, Jog up/down.

Pushbutton and lamp overview

"Start" is used for starting the module

" Stop" is used for stopping the module normally. The elevator can be

stopped normally in two ways, quickly or controlled. A quick stop is executed when the stop-button is activated more than one time per second. A

quick stop will cause the elevator to stop immediately (as quick as possible). A controlled stop is executed if the stop-button is activated once per

second and cause the elevator to finish the motions in progress before it

stops.

"Alarm reset" is used for resetting alarms.

"Jog up/down" is used for manually adjusting the lift cage's vertical position.

58

Start procedure

Before the elevator can be started all alarms must be reset. Press "Start"

to start. The "Start"-indication will start flashing slowly (1 Hz) a certain time,

ca 2 seconds, before the flash turns into steady light. At fixed light the elevator is started and in production.

Production

When the elevator is in production it receives products from connecting

tracks, elevates to correct vertical level, sends the product to receiving conveyor and returns to home position.

5112204

Page 67

Instructions for use

Stop procedure

Quick stop instruction: Press several times during one second. The elevator will stop immediately/quickly. It will not finish motions in progress.

Controlled stop instruction: Press once per second. The elevator will finish

ongoing motions before stopping. While stopping, the "Start"-indication

flash quickly (2 Hz). When the elevator is stopped the "Start"-indication is

off.

Emergency stop

Emergency stop must not be used for normal stop. It should be used in

case of emergency. Emergency stopping may cause the whole line to

emergency stop. An emergency stop of the elevator disconnect parts of the

electric power. A certain amount of manual labour may be required to get

the elevator back into normal run.

Opening door as stop

The door must not be used for normal stop. It should be used in case of

emergency or when the elevator already is normally stopped. Opening the

door during production will have the same effect on elevator as an emergency stop. See above.

Alarm

During normal state the "Reset" -indication has steady light. At the occasion of alarm the indication will start flashing until alarm is reset. Press "Re-

set" in order to reset alarm. The flashing turns into steady light if a larms are

reset.

6.2 Manual operation

The elevator's vertical motion can be manually adjusted in stopped state.

Alarms must be reset. Stop the eleva tor, wait until it is stopped and adjust

the lift cage's vertical position up/down using the 3-position switch. The motion is interlocked to avoid running past the up-and down-sensors. If the elevator is run upwards it will stop automatically when the up-sensor is activated, which is an advantage when verifying an adjusted sensor-position,

checking that lift cage and adjacent conveyor are in level thus making the

transition smooth. The motion downwa rds is not affected by the up-se nsor .

Occasionally it is necessary to run past the up-and down-sensors, for example at a crash-situation. In order to realize a run past the up-and downsensors keep "Stop"-button pressed.

Created by EBCCW 00:06

5112204

Manual operation, upward direction: Turn the switch to the left.

Manual operation, downward direction: Turn the switch to the right.

To return to operation in automatic mode: Leave the switch in neutral position and press "Start"-button.

59

Page 68

Technical maintenance

7 Technical maintenance

Technical main te na nc e is an imp o rtant part of this manual. Go od ma int e nance will lead to cost reduction, because defects can be timely recognised

and solved. This section starts with a troubleshooting list, subsequently a

maintenance schedule is set up in section 7.2 on page 61 describes different maintenance activities.

During carrying out any activities on the elevator make sure that the main

switch has been switched off, so that there is no voltage on the machine.

7.1 Check and control procedures

7.1.1 Daily maintenance

• Check for abnormal sound/heat

• Check for dust and particles (especially on sensors)

7.1.2 Monthly maintenance

• Check function of the emergency stop device.

• Check chain tension and lubrication.

• Check the roller chain guides.

• Check drive chain for wear and tension.

• Check the bearings.

7.1.3 Maintenance performed every third month

• Check threaded fasteners.

• Check that the elevator is running smoothly.

• Check attachment of the carriers.

• Check that the chain, cog belt and carriers/lifting device are free

from damage.

60

5112204

Page 69

Technical maintenance

Adjustable screws

5-10 mm

2-3 mm

7.2 Maintenance procedures

. Disconnect the power when performing maintenance on the elevator.

A clearly visible sign must be displayed, indicating that work is underway.

If you have questions related to maintenance, contact FlexLink.

7.2.1 Cleaning

Periodic cleaning keeps the elevator in ser vice and extends its service life.

Do not employ high pressure cleaning on drive ends, chains and electrical

components. Cleaning behind guards is conducted with a damp cloth or

sponge.

7.2.2 Roller chain

Chains/cog belt replaced as necessary.

After replacement, ensure that the cog belt/chain is correctly tensioned.

The drive chain is

correctly tensioned

when it does not

flutter during

operation.

Chain tensioning is

conducted at the top

of the elevator; the

lower sprocket wheel

and drive shaft shall

move freely after

tensioning

Once the chain is

correctly tensioned,

the chain should be

possible to depress

2–3 mm between the

lower sprocket wheel

and the chain guide.

Created by EBCCW 00:06

5112204

See Recommended spare parts

on page 67.

61

Page 70

Technical maintenance

7.2.3 Motor

For standard elevators without field distributor the main switch of the cabinet needs to be switched off and locked prior to motor replacement.

• Turn off electrical main switch of module located on control box

door.

• Check no voltage in motor.

• Replace motor electrically and mechanically.

• Set all DIP switches and thumb wheels in the cover of the motor

according to replaced motor.

• Connect the internal cables on the terminal block acco rd ing to ei ther the electrical documentation or the replaced motor.

The vertical drive for advanced versions is connected to the field distributor

through a fast connector cable to facilitate service.

• Turn off the switch on the field distributor and lock it prior to disconnecting the fast connector to the motor.

• Set all DIP switches and thumb wheels in the cover of the motor

so that they are the same positions

as the one to be replaced.

• Connect the internal cables on the terminal block acco rd ing to ei ther the electrical documentation or the replaced motor.

• Plug in the connector and tighten it before turning on the power

switch.

To assure trouble-free operation, the motor and gears must be maintained

according to manufacturer's user manual.

For more information, see manufacturer manual.

7.2.4 Chain guide profile

The chain guide profile shall be replaced as necessary.

See Recommended spare parts

on page 67.

62

5112204

Page 71

Technical maintenance

7.3 Troubleshooting

If in doubt concerning the troubleshooting procedures below, contact FlexLink.

Troubleshooting guide

Symptom Cause Corrective action

The elevator does

not start

Products fasten/

have fastened

Peripheral equipment is not

connected. Power not on,

emergency stop button pressed,

door not closed, no signal from

peripheral equipment or circuit

breaker tripped.

No products to discharge Wait for products to arrive.

Foreign matter on photo-electric

cells

Photo-electric cell faulty, out of

position or dirty

Only personnel with technical

knowledge or equivalent sufficient

experience may conduct the

following actions.

• Check circuit-breakers.

• Check that peripheral equipment has started.

• Check that the power is on.

• Check that the emergency stop

button is not pressed.

• Check that the door switch is

activated.

• Press "Reset".

• Check that peripheral equipment produces signals.

• Press "Start".

Clean photo-electric cells.

Only personnel with technical

knowledge or equivalent sufficient

experience may perform the

following actions.

1 Clean photo-electric cells.

2 Adjust photo-electric cells.

3 Check photo-electric cells'

position and operation, and

that they are connected.

Created by EBCCW 00:06

5112204

63

Page 72

Technical maintenance

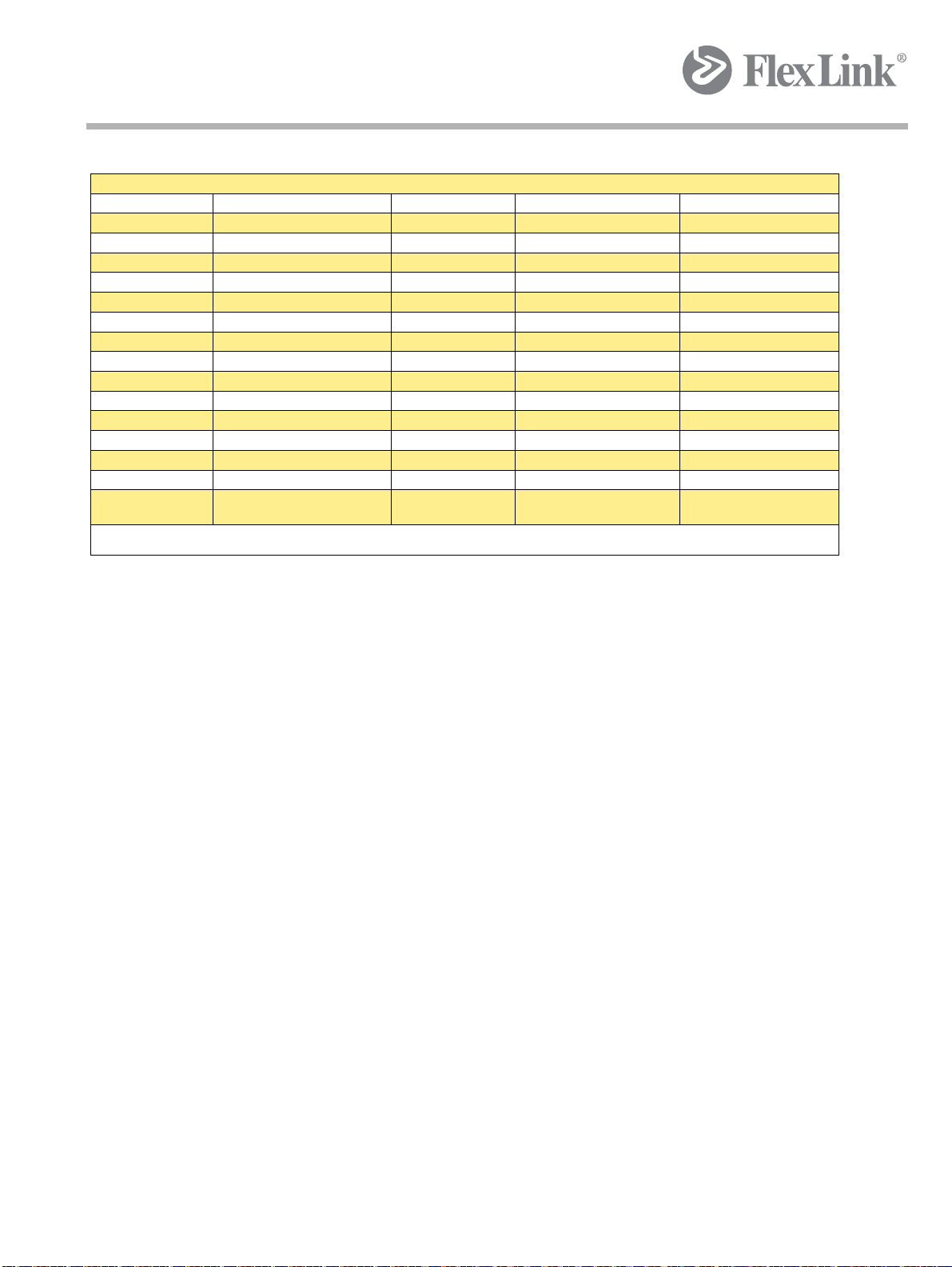

7.4 Maintenance schedule elevator

The elevator requires relatively little maintenance. S till some maintenance

activities are to be carried out. Below there is a maintenance schedule with

an interval that is referred to normal operating conditions in an organisation

with one shift without excessive accumulation of dirt caused by the products or the environment conditions. The user has to apply an appropriate

maintenance schedule dependent on the individual operating conditions.

It is very important for the proper functioning of the elevator that maintenance is done correctly and timely. Improper, insufficient or not documented maintenance will void any warranty.

No. Execution Interval Remark

1. Clean elevator Monthly Regular cleaning depends on product and

environment

2. Check the elevator for broken

or missing parts, replace if

Daily It is the task of the operator to check this daily (see

user’s manual)

necessary

3. Check the chain tension Monthly See section 7.2.2 on page 61

4. Check the sprocket wheel

and alignment. Replace or

align if necessary

5. Check the guide rails for

Monthly Faulty alignment of the gear may cause permanent

wear or make the chain derail and can so cause

serious stoppages

Monthly Replace guides

dents, damages and

connection

6. Check the drive for oil

leakage and annoying noise

7. Check whether the Moto r is

fastened well to the elevator.

Tighten the bolt s if necessary

8. Check the oil level in the gear

Monthly Repair or replace if necessary. See the

troubleshooting list

Monthly Drive vibrations can make the bolts loosen by

vibration, the faulty alignment of the drive can bend

the shaft and the chain may derail.

Monthly

boxes, fill up if necessary

9. Change the oil in the Gear

box

In accordance with the gear boxes specification of

the manufacturer!

. Note! During carrying out any activities on the elevator make

sure that the main switch has been switched off, so that there is

no voltage on the machine.

64

5112204

Page 73

Put out of commission

8 Put out of commission

Place the elevator on a pallet or p allets with specially cu t supports and with

the electrical cabinet upwards. Secure the elevator with straps. The eleva tor must be well protected and strapped during transport.

At the moment a elevator is put out of operation for some reason, a number

of steps are to be taken in order to avoid da ngerous situations. This section

clearly indicates how one should proceed in a number of cases with respect to uncoupling, dismounting, transport and reuse of materials coming

from the elevator

8.1 Disconnect the power sources

Prior to starting the dismounting, the voltage is to be cut of f from the power

source. First the main switch is to be switched off before the power source

can be disconnected.

. Danger: First switch off the main switch before the power source

may be disconnected.

8.2 Disassemble

While dismounting the machine, the regulations for waste processing applicable on the place and at the time of the dismantling are to be complied

with. The machine only contains commonly known materials. At the time of

assembling the elevator there were processing possibilities for this and no

particular risks were known for persons involved in dism antling. The disassembly of the elevator generally requires few operations. The elevator can

be disposed of in the same way as it was delivered.

. Note! At the time of assembling the elevator there were

processing possibilities for this and no particular risks were

known for persons involved in dismantling.

Created by EBCCW 00:06

5112204

65

Page 74

Put out of commission

8.3 Transport

While transporting the elevator a number of safety measur es are to be t aken.

Use the tools / aids indicated in section. If not, it is assumed that the tool /

device used instead is safe and provided with a quality mark.

Carry out the transport operations calmly in order to be able to carefully

monitor any movement of the elevator.

. Note! Vertical or horizontal movement depends on the height of

the elevator. It is recommended to move a elevator higher than

2400 mm in a horizontal position!

8.4 Reuse

No fixed rules have been made up for reuse of the elevator, because the

elevator does not contain any hazardous subst ances. At the time of assembling the elevator there were processing possibilities for this and no particular risks were known for persons involved in the reuse.

. Note! Putting the elevator out of operation with all operations

involved may only be done by technically qualified personnel.

66

5112204

Page 75

Recommended spare parts

2

1

19

9 Recommended spare parts

9.1 Mechanical

Created by EBCCW 00:06

5112204

67

Page 76

Recommended spare parts

17

14

Only XT

15

12

68

5112204

Page 77

8B

10B

11

4B

4A

20

13

16

5, 6, 7

8A, 10A

3

11

10B

9

13

18

Recommended spare parts

Created by EBCCW 00:06

5112204

69

Page 78

Recommended spare parts

Group

Drive unit 1 Motors:

Pos

2 Field distributor 5057737 Z6 PROFIBUS SEW

3 Roller chain 08-B1 LAMDA FlexLink or local

4A

4B

5 Roller chain 5045327 08-B1 FlexLink or local

6 Carrier link 5986156 08-B1 Special

7 Chain lock 5045326 08-B1 FlexLink or local

Part Part no. Designation Comments Supplier

XT 640

XT 480-240

XK/X85

XK/X85

RTI

Gear box 5111425

5111464

5111919

5111545

5111569

5111684

5111424

K37DT80K4MM07BMG

W30DT80K4MM05BMG

W30DT80K4MM05BMG

W30DT80K4MM05BMG

K37DT80N4MM07BMG

BS 50A0U

BS 50 A0O- DP

Contact FlexLink

(All with KPF6 1.5 M)

50 Hz, 54-541 rpm

50 Hz, 27-137 rpm

50 Hz, 43-213 rpm (EU)

60 Hz, 43-259 rpm (US)

50 Hz, 35-176 rpm

SEW

supplier

Benzlers

supplier

FlexLink

supplier

8A

8B

9 Guide profile 5986013 FlexLink

10A

10B

11

Lifting

device

Sensors

Sensors 16 Reflector 5110995 PL 30A SICK

12 (Applies to XT, X85 and XK variants)

13 Inductive sensor 5058574 IQ10 SICK

14 Inductive sensor 5111460 NBN40-L2-E2-V1 Applies only to XT

15 Photo-electric

17 Reflector 5111135 SICK

Bearings 5052978

5058259

Sprocket wheel 5986022

5986183

Coupling element

For spare mechanical parts, see FlexLink catalogue 5147 or www.flexlink.com.

5059929 MHL 15-p3336 (Does not apply to XT) SICK

cell

6202-2 Z/C3

6204- 2 RSH/C3

ROTEX GS 19 98 SH A GS FlexLink or local

Top

Bottom

Top

Bottom

pallets

SKF

FlexLink or local

supplier

supplier

SICK

70

5112204

Page 79

Recommended spare parts

Group

Switches

Pos

Part Part no. Designation Comments Supplier

18 Photo-electric

laser cell

19 Door switch 5112509 PSEN 1.1p-22, 504222 Pilz

20 Limit switch 5059096 XCKP 2118 P16

5111749 WL9L-P430 SICK

TELE-MECANIQUE

Created by EBCCW 00:06

5112204

71

Page 80

Recommended spare parts

9.2 Electrical

Spare parts list Kit 5112499

Des Name Manufacturer Manufacturer item nr Comment

W320 Cable U.I. Lapp 1119 404 4G2.5

W321 Cable U.I. Lapp 1119 107 7G0.75

W322 Cable U.I. Lapp 1119 802 2x0.75

W323 Cable U.I. Lapp 1119 802 2x0.75

W330 Cable U.I. Lapp 1119 304 4G1.5

W360 Cable Murr Electronic 7000-08061-2210150

W430 Cable Murr Electronic 7000-88001-2200300

W431 Cable Murr Electronic 7000-88001-2200300

W432 Cable Murr Electronic 7000-88001-2200300

W433 Cable Murr Electronic 7000-88001-2200300

W434 Cable Murr Electronic 7000-88261-2200300

W435

W436 Cable Murr Electronic 7000-88241-2200300

W437 Cable Murr Electronic 7000-88241-2200300