Page 1

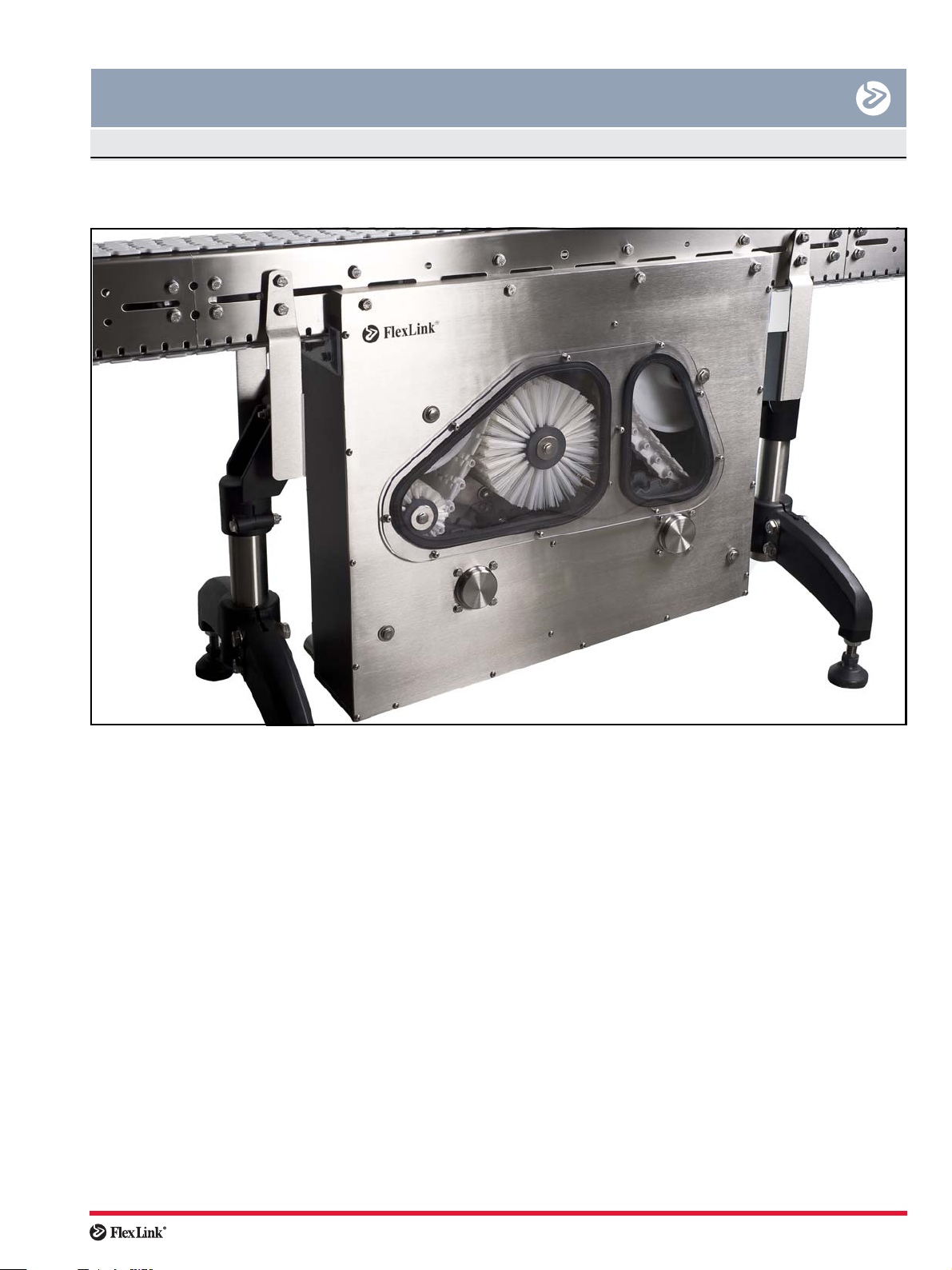

Chain washer and dryer unit

A FlexLink standard solution 5620EN-1

Inline chain washer and dryer unit

The chain washing unit is designed to run continu-

ously when working with production lines that have a

high degree of product spillage. The result is a

cleaner and dryer chain that allows longer

production runs without the need for CIP or routine

maintenance.

The chain cleaner prevents product build up on the chain

and allows continuous fault free running of the line with

the need to stop the conveyor and remove the chain to

clean by hand.

Supplied as a complete unit the washer/dryer can quickly

be integrated into new conveyor lines or upgraded to

existing conveyor lines in order to improve performance

and reliability.

Standard features

• Robust – the system is robust and designed to operate within harsh environment where spillages on the

conveyor are highly likely.

• Compact – the unit will take up the smallest footprint

possible.

• Clean – clean design with sloping faces and minimum

areas for fluid or dirt to build up.

• Safe – fully guarded design.

• Simple installation – mount to conveyors using

standard fittings.

Technical bulletin 5620EN-1 1

Page 2

Chain washer and dryer unit

System information

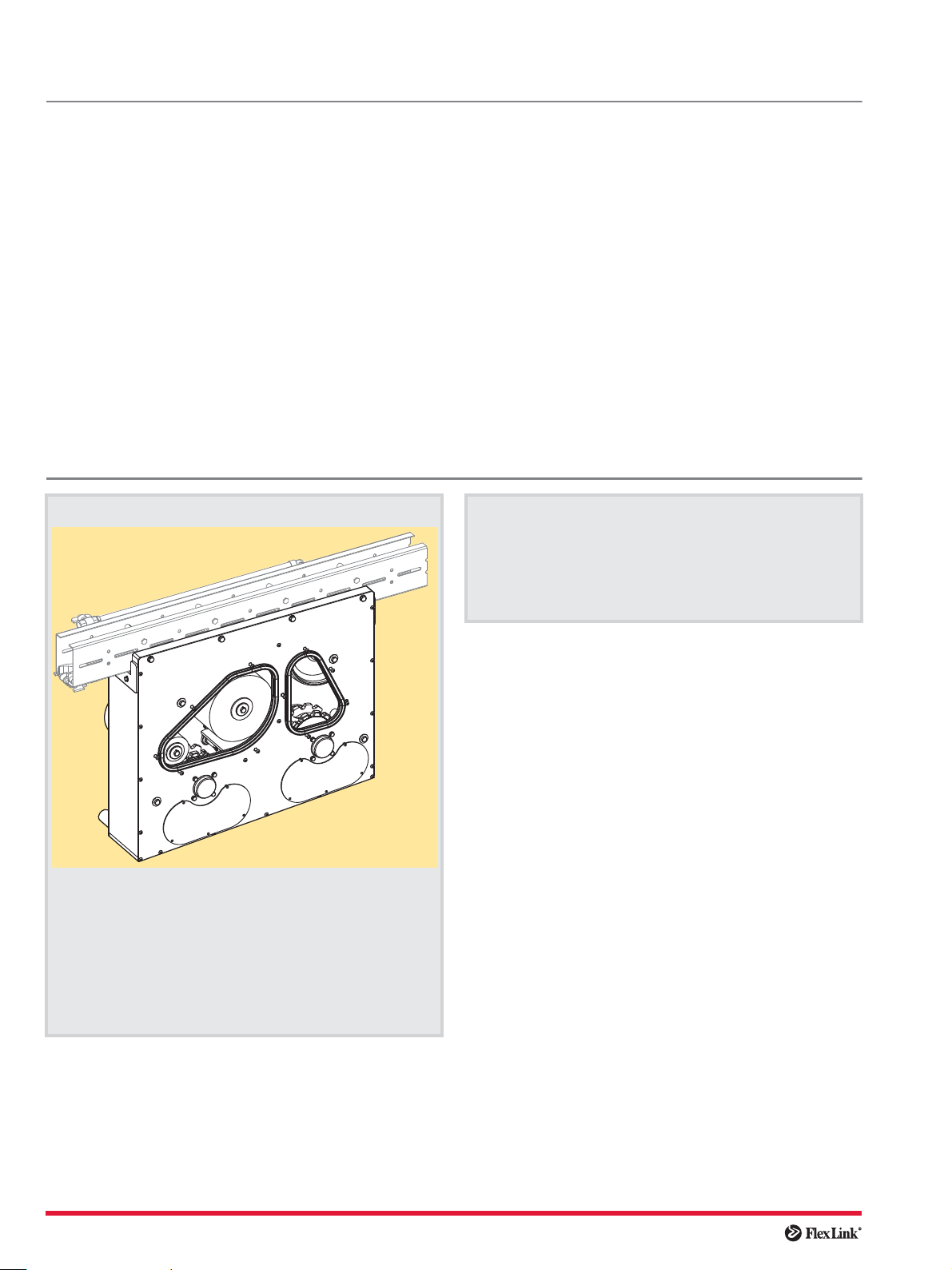

The washer/dryer unit is available for aluminium con-

veyor systems XS, XL, X85, XH and XK, and stainless

systems XLX and X85X.

Technical specification

Minimum top of chain height ............. 700 mm

Maximum conveyor length ................. 3m

Maximum conveyor speed ................. 50 m/min

Operating requirements

Water supply

Connection of water/cleaning system is made by G ½''

internal thread connection. Max/Min flow rate required is

11–13,5 l/min.

Chain washer and dryer unit

Chain washer and dryer unit

Air attachment

Connection of air system is made by G ½'' internal thread

connection. Air system requirements 6 Bar with a

flow rate of 200 m3/h.

Drainage/ Drying Vacuum

Vacuum attachment is made by ∅32 hose connection.

Vacuum requirements are 23,5 kPa minimum with a vacuum of 2×56 l/second.

Spare parts

Air nozzle large

Air nozzle small

Spray nozzle

Brush ∅80

Brush ∅180

8043200

8042711

8042716

8042673

8042672

Chain washer and dryer unit

Conveyor system XS

Conveyor system XL

Conveyor system XLX

Conveyor system X85

Conveyor system X85X

Conveyor system XH

Conveyor system XK

Note. 1 m long beam section

Note!

The chain washing unit cannot be used with an

enclosed or guided type of conveyor drive unit.

2 Technical bulletin 5620EN-1

8042679

8042663

8042664

8042665

8042666

8042667

8042668

Loading...

Loading...