Page 1

Appendixes

PO

X45

XS

XL

A. Installation of plastic slide rail and support rail

About slide rail

The slide rail is attached to the sides of the conveyor

beam to reduce chain friction where the chain w ould otherwise be in direct contact with the beam profile. It is v ery

im

portant that the slide rail is installed properly, so that

the chain can run without disruption.

When the conveyor is to be mounted high above

g

round leve l, it might be easier to mount the slide rail onto

a convey or section while the conve yor beam is still on the

floor. If doing so, leave an extra end, approximately

300 mm longer than the beam, so that it can be cut off

a

nd adjusted when the beam is finally installed.

Characteristics

Slide rails are available in several materials, each with

ferent characteristics:

dif

The coefficient of friction is normally closer to the lower

v

alue at startup of a new conveyor. It will increase as the

contact surfaces are wearing in. Lubricants will reduce

the coefficient of friction.

Considerations when selecting slide rail

Each of the slide rails has its own characteristics and is

suitable for different types of applications.

Slide rails made of HDPE or PA-PE are suitable for

mo

st standard applications. PA-PE has higher wear

resistance but should not be used in wet environments.

In environments where high resistance to chemicals

is

important, PVDF slide rails are recommended.

Hardened steel slide rails in combination

slide rails in bends can be a good combination where

larger particles such as chip occur.

UHMW-PE has the highest wear resistance and can

be

recommended in applications with accumulation,

transport of heavy parts, high speed, abrasive particles

or requirements on low dust generation.

Horizontal plain bends

The contact pressure between the chain and the slide r ail

is v

ery high in the inner bend of horizontal plain bends. It

is important to use the PVDF slide at this location if the

speed is high as there will be increased temperatures

that may cause melting of other slide r ails. This, howe ver ,

will result in somewhat higher wear on the chain.

with PVDF

XLP

X85

X85P

XH

XK

XKP

X180

X300

GR

CS

XT

XC

XF

XD

FST

XLX

X85X

X180X

X300X

GRX

CSX

ELV

CTL

TR

APX

IDX

A. Installation of plastic slide rail and support rail 459

Page 2

A. Installation of plastic slide rail and support rail (continued)

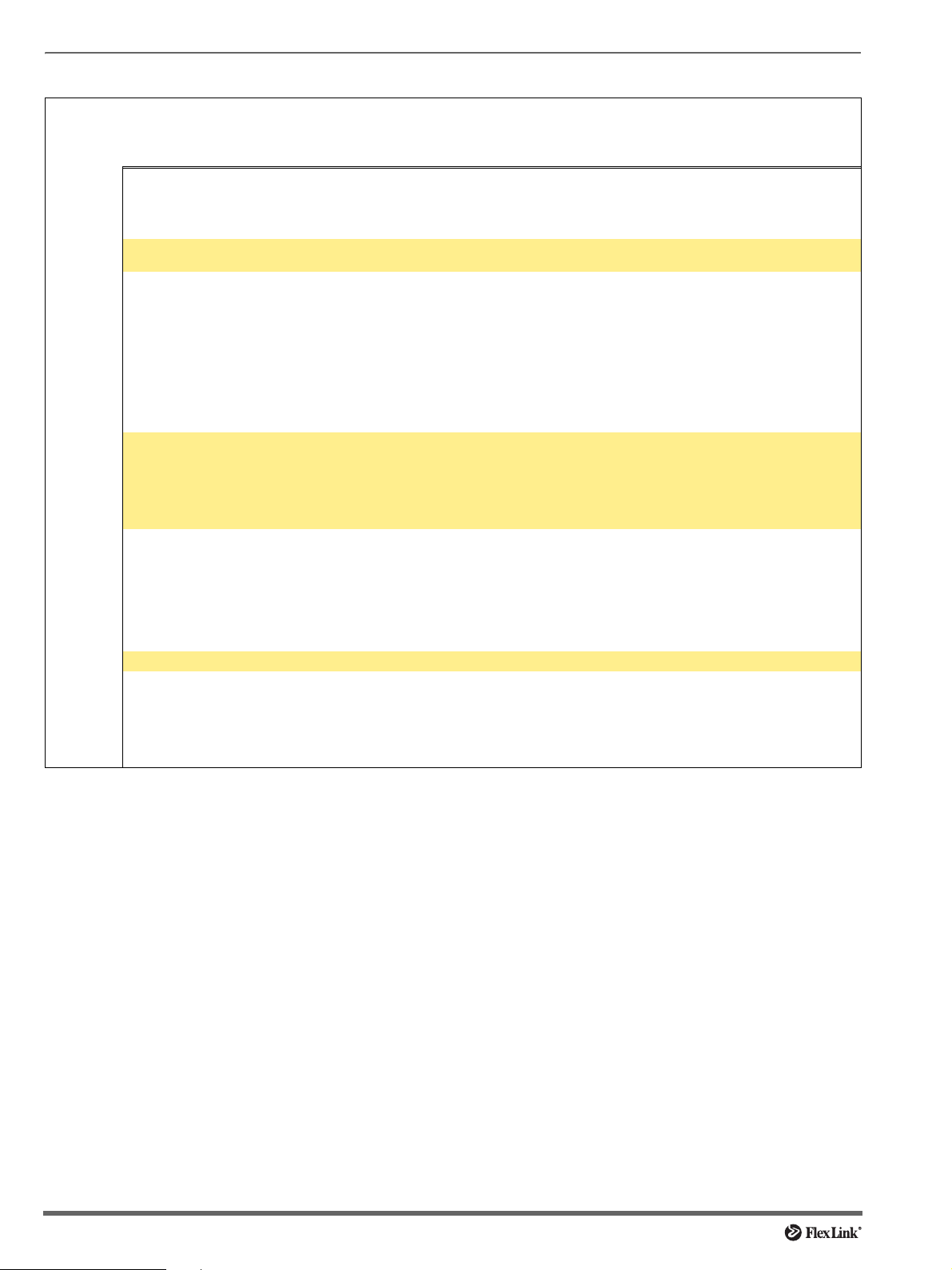

Example of available slide rail types

Slide rail

type

Material HDPE

Friction

coefficient

Application

information

Advantages Good standard

Disadvantages

Colour Black Natural white Grey White Black Natural Natural

Suitable

application

areas

XSCR 25

XLCR 25

XBCR 25

High density polyethylene

0,1–0,25 0,15–0,35 0,1–0,30 0,1–0,25 0,15–0,30 0,15–0,35 0,15–0,35

–40 to +60 °C

Standard applications

Easy to mount

Poor resistance

to solvents

(petroleum,

white spirit)

Limited temperature range

Wear out at

heavy accumula

tion

All industries

Medium speed

Medium load

XSCR 25 P

XLCR 25 P

XWCR 25 P

PVDF

Polyvinylidene

fluoride

–40 to +100 °C

High resistance

to chemicals

(see table in the

Product cata

logue)

Accumulation

Transport of

heavy parts

High speed

Abrasive particles

Chemical and

heat resistant

Low elongation

More resistant to

chemicals

Higher friction

More difficult to

mount

-

Greasy environments

Water (washing

machines)

Chemicals

High load

Heat resistant

XLCR 25 H XSCR 25 U

PA-PE

Polyamide-polyethylene

–40 to +80 °C

Accumulation

Transport of

heavy parts

-

High speed

Abrasive nonmetal particles

Good wear and

heat resistance

Should not be

used in wet

applications

High speed

High load

XLCR 25 U

XKCR 25 U

XWCR 25 U

XBCR 3/6 UA

UHMW-PE

Ultra-high

molecular weight

polyethylene

–40 to +60 °C

High wear resistance

Clean environment

Low dust and

particle generation

Easy to mount

Low wear out

Minimum of particles

Limited temperature range

Higher elongation

All types of clean

production

XLCR 25 E

XBCR 25 E

XBCR 25 EB

XBCR 3 EA

UHMW-PE

Carbon filled

ultra-high molecular weight polyethylene

–40 to +60 °C

Reduces static

electricity

Relatively low

dust and particle

generation

High conductivity

Fast discharge

Easy to mount

Some particle

generation may

occur

Environments

sensitive to static

electricity

XLCR 3 TA XKCR 3 TH

SS

Stainless steel

Abrasive particles

High resistance

to chemicals

No elongation

High resistance

to chemicals and

abrasive parti

cles.

Heat resistant

Low wear out

Difficult to

mount, with only

straight lengths

High friction

Generates particles in dry environments

High load

Heat/cold

XKCR W.. TH

-Hardened steel

Abrasive particles such as

metal chips from

milling and grind

ing processes

No elongation

Very high resistance to abrasive

-

particles

Heat resistant

Low wear out

Special mounting procedure

High friction

Generates particles in dry environments

Aggressive particles

High load

Heat/cold

-

460 A. Installation of plastic slide rail and support rail

Page 3

A. Installation of plastic slide rail and support rail (continued)

J

Attaching the slide rail in straight sections

Tools required

Slide rail installation tool:

XS-XL X85,

X180/X300

XLMR 140 XBMR 170 XMMR 140 XHMR 200 XKMR 200

Procedure

1 Start at an idler end unit.

Separate the top and bot

tom flange of the slide rail

at the end of the rail and

press it into place.

2 Make sure that you

mount the slide rail so

that it snaps on to the

beam. The different typ es

of slide rail do not look

alike, so check which

flange should be on top.

3 Use the slide rail mount-

ing tool to press the slide

rail into place. One end of

the tool is used when

slide rail is mounted onto

only one side of the

beam, and the other end

is used when you mount

slide rail onto the second

side.

4 Do not forget to mount

slide rails both under

neath and on the upper

side of the beam (unless

top running chain only)

XM XH XK

-

-

Joining slide rails

Tools required

Cutting pliers

Procedure

1 Cut both slide rail ends in

a 45° angle. The begin

ning of a new slide rail

section (in the direction of

travel) m ust be cut back a

small angle.

2 Allow a space of approxi-

mately 10 mm between

two slide rail ends. The

arrow indicates travel

direction.

3 Do not place two slide rail

joints opposite each

other. Ma ke sure there is

a distance of at least

100

mm between them to

make the chain run

smoother.

This does not apply to slide rail that begin s by an idler

unit or after a drive unit, where joints are alw ays par

allel.

Comments

• Try to let the slide rail run in as many continuous

lengths as possible, except in circumstances stated

below:

• It is recommended to use short slide rails (2–3 m)

where chemicals may have an effect on the slide rail

composition.

• It is important to cut the slide rail and allow f or elongation in high load areas. Cutting is required in wheel

bends (see below), by idler units and where the con

veyor will be heavily loaded, especially by the drive

units. This prevents the slide rail from stretching out

and entering into the drive unit, which may block the

chain.

• Never join slide rail in horizontal or vertical bends,

since forces are higher on the slide rail in these sec

tions. Instead, place the joint before the bend.

• Avoid joining slide r ails on top of conveyor beam

joints.

PO

X45

XS

XL

XLP

-

X85

X85P

XH

XK

XKP

X180

X300

GR

CS

-

XT

XC

XF

XD

FST

XLX

-

X85X

X180X

X300X

GRX

-

CSX

ELV

A. Installation of plastic slide rail and support rail 461

CTL

TR

APX

IDX

Page 4

A. Installation of plastic slide rail and support rail (continued)

Mounting slide rail in wheel bends

Tools required

Cutting pliers

Before wheel bend

1 Cut the slide rail end at a

45° angle.

2 The slide rail must be

longer than the conveyor

beam itself, and there

should be a 10 mm dis

tance between the slide

rail and the wheel of the

bend. Make sure that the

end of the slide rail is not

bent up or down.

-

After wheel bend

3 Cut the slide rail at a 45°

angle with a short back

cut. The slide rail must be

longer than the conveyor

beam itself, and there

should be a 2 mm dis

tance between the slide

rail and the wheel of the

bend.

4 In the outer bend, make

sure that the slide rail is

properly connected to the

conveyor beam profile.

Horizontal plain bends

In plain bends with small radii, the slide rail for the inner

bend should be cut so that it is only 10 mm wide in the

bend. This is to prevent an uneven slide r ail surface.

Stretch the rail while mounting.

-

Important

Plain bends with small radii should be avoided, if at all

possible. Always consult FlexLink Systems for design

assistance.

462 A. Installation of plastic slide rail and support rail

Page 5

A. Installation of plastic slide rail and support rail (continued)

Arrow indicates direction

of travel

PO

Mounting support rail in plain bends

The friction in plain bends can be significantly reduced b y

using support rails in the inner beam profile.

Tools required

Soft hammer

Knife

Drill 4,2 mm

Clamp

Screwdriver

Sheet metal screws ISO 7049 4,2×9,5

Procedure

1 Drill two holes (4,2 mm) in

the beam at the entry and

exit of the bend. Drill

additional holes every

200–300 mm.

2 Cut both ends of the rail

at a 45° angle.

7 Fix with BSS ST 4,2×9,5

sheet metal screws

(never use scre ws longer

than 9,5 mm).

Anchoring the slide rail

The beginning of each slide rail section must be fixed to

the beam, since the chain will cause the slide rail to be

pushed forward. Slide rail which moves into a wheel bend

or a drive unit can block the chain completely.

There are two diff er ent me th od s for fixing slide rail to

the conveyor beam, using aluminium rivets or plastic

screws. Either method can be used, but the riveting

method is more secure if the conveyor will run with high

operational speed or be heavily loaded.

Tools required

Hand drill

Drill fixture for slide rail:

Part #3924774 (drill diameter 3,2 mm): XS*

Part #3920500 (drill diameter 4,2 mm): XS**-XL-X85/XM-XH-XKX180/X300

* Rivet method only

**Plastic screw method only

Countersink

X45

XS

XL

XLP

X85

X85P

XH

XK

XKP

X180

X300

GR

CS

XT

3 Press the support rail into

place at one end of the

bend. It is important that it

is mounted against the

bottom flange of the

beam.

4 Make sure that the rail

starts exactly at the joint

between the bend and

the straight conveyor

beam.

5 Press the rest of the sup-

port rail in place.

6 Clamp the rail.

Procedure – drilling

1 Drill two holes near the

beginning of each slide

rail section. Use the drill

fixture to ensure cleancut holes and the correct

location of the holes.

The holes must be at the

leading edge of the joint

piece, in the direction of

travel, to hold the slide rail

in place when the con

veyor is in use . Use a well

sharpened drill bit.

2 Use a countersink to

deburr and countersink

the holes. Also make sure

that there are no metal fil

ings left underneath the

slide rail.

XC

XF

XD

FST

XLX

X85X

-

X180X

X300X

GRX

-

CSX

ELV

CTL

TR

APX

IDX

A. Installation of plastic slide rail and support rail 463

Page 6

A. Installation of plastic slide rail and support rail (continued)

Wrong

Correct

Slide rail in conveyor beam section XLCH 5 V

1 When using articulated

beam section XLCH 5 V,

the slide rail must be

mounted across the

entire beam section, and

cut off at the beginning of

the following beam sec

-

tion.

Anchoring slide rails using aluminium rivets

Tools required

Rivet crimping pliers

XS: Part #3924776,

XL-X85/XM-XH-XK-X180/X300: Part #5051395

or

Rivet crimping clamp

XS: Part #3924770

XL-X85/XM-XH-XK-X180/X300: Part #3923005

Aluminium rivets:

XS: XLAH 3×6

XL-XM-XH: XLAH 4×6

XK-X180/X300: XLAH 4×7 (brown colour)

Procedure

1 Insert rivets in the holes,

using rivet crimping pliers

or a rivet crimping clamp.

For type of rivet, see

above.

2 If working space is lim-

ited, the rivet crimping

clamp might be easier to

use. The two crimping

tools perform the same

task, but the pliers are

more efficient and easier

to use.

3 Check that the rivets do

not protrude over t he su r

face of the slide rail.

Check both top and

underneath surface of

slide rail for protruding

metal.

-

Anchoring slide rail using plastic screws

Tools required

Pliers/screwdriver

Knife

Hammer

Plastic screws: XS-XL-X85/XM-XH-

Procedure

1 Press or screw the

screws into the holes

using a pair of pliers or a

screwdriver.

2 Cut off the screw heads

by using a knife and a

hammer. Cut should be

made awa y from the joint,

in the direction of chain

travel.

3 Make sure the slide rail

surface is smooth and

that screws do not pro

trude over the surface of

the slide rail. If the sur

face should be uneven,

file the edges smooth.

Check both top and

underneath surface of

slide rail for protruding

plastic or metal.

4 Keep a distance of

approximately 30 mm

between screws and idle r

unit. This is in case the

idler unit has to be

removed after conveyor

system assembly.

X180/X300:

XLAG 5

-

-

XK:

XWAG 5

4 Keep a distance of

approximately 30 mm

between rivets and idler

unit. This is in case the

idler unit has to be

removed after conveyor

system assembly.

464 A. Installation of plastic slide rail and support rail

Page 7

A. Installation of plastic slide rail and support rail (continued)

PO

Slide rail installation – conveyor beam XKCB N

Conve y or beam Type XKCB N has additional flanges f or

slide rail “inside” the beam. Attaching slide rail to these

flanges is slightly different from the standard procedure.

This also applies to XK plain bends (see next page).

Tools required

Cutting pliers

Hammer

Screwdriver

Clamp

Knife

Drill 4,2 mm

Drill fixture Part #3920500

Plastic screws XWAG 5

Procedure

1 Cut the slide rail at a 45°

angle.

7 Use a clamp to press the

slide rail on to the beam

flange where the type N

beam begins.

8 Drill one additional hole in

each slide rail at the

beginning of the type N

beam section.

9 Install the chain as shown

in the picture.

X45

XS

XL

XLP

X85

X85P

XH

XK

XKP

X180

X300

GR

2 Mount slide rail on the

lower flange of the con

veyor beam.

3 Drill holes for plastic

XWAG 5 screws.

4 Use a screwdriver to

insert the screws. Cut off

the screw heads using a

knife and a hammer. File

off protruding edges.

5 On the upper flange of

the slide rail, use the drill

fixture to drill two holes in

the slide rail before it

enters the XKCB N beam.

CS

-

XT

XC

XF

XD

FST

XLX

X85X

X180X

X300X

GRX

CSX

ELV

CTL

6 Use a screwdriver to

insert the screws. Cut off

the screw heads using a

knife and a hammer. File

off protruding edges.

TR

APX

IDX

A. Installation of plastic slide rail and support rail 465

Page 8

A. Installation of plastic slide rail and support rail (continued)

Installation of slide rail in XK plain bends

Plain bends increase the tension in the chain and cause

higher stress on the slide rail. It is therefore recom

mended that slide rail be used on both the upper and

lower flanges in XK horizontal plain bends. Start by

installing the lower slide rail.

Tools required

Cutting pliers

Knife

Hammer

Screw driver

Drill 4,2 mm

Drill fixture (Part #3920500)

Plastic screws XWAG 5

Procedure

1 Mount slide rail on the

lower flange of the con

vey or beam. Cut the slide

rail at a slight angle, to

ensure a smooth entry of

the chain.

-

Installation of slide rail in X180/X300 plain bends

The centre beam in X180/X300 plain bend s has an ad ditional pair of flanges for slide r ail inside the beam, similar

to the XK beam type N. Installation is similar to that

described for slide rail in XK plain bends.

Note

For the slide rail in side th e bea m (i nner ben d o nly), p lastic screws must be used for anchoring.

Plastic screw XLAG 5 or aluminium rivet XLAH 4×7

can be used for the upper slide rails.

2 Temporarily install a

piece of upper slide rail.

Use the drill fixture to drill

holes in the slide rail on

the upper and lower

flange. Use a drill bit that

is long enough to drill

through both flanges.

3 Anchor the lower slide rail

to the beam using

XWAG

5 plastic screws.

4 Cut off all screw heads.

File off protruding edges.

5 Remove and discard the

temporary piece of upper

slide rail and install the

full length of upper slide

rail. Test the chain track.

466 A. Installation of plastic slide rail and support rail

Loading...

Loading...