Page 1

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 1/12 FJn

Index

2006-05-19

1. AGS-system layout.................................................................................................................................2

1.1 Integrator responsibility.....................................................................................................................2

2. Placing components................................................................................................................................4

2.1 Using non-standard Guide unit cables..............................................................................................5

3. Guide unit supply....................................................................................................................................6

3.1 Connectors........................................................................................................................................6

4. Zone supply ............................................................................................................................................7

5. Safety information.................................................................................................................................10

6. Installing the guide rail to the Guide units.............................................................................................10

7. Feedback functionality – Track width setting........................................................................................11

8. Fault handling .......................................................................................................................................12

Archived

This document is found at www.flexlink.com: Technical library/Functions/Automatic guiding

system.

3928587_03.DOC

Page 2

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 2/12 FJn

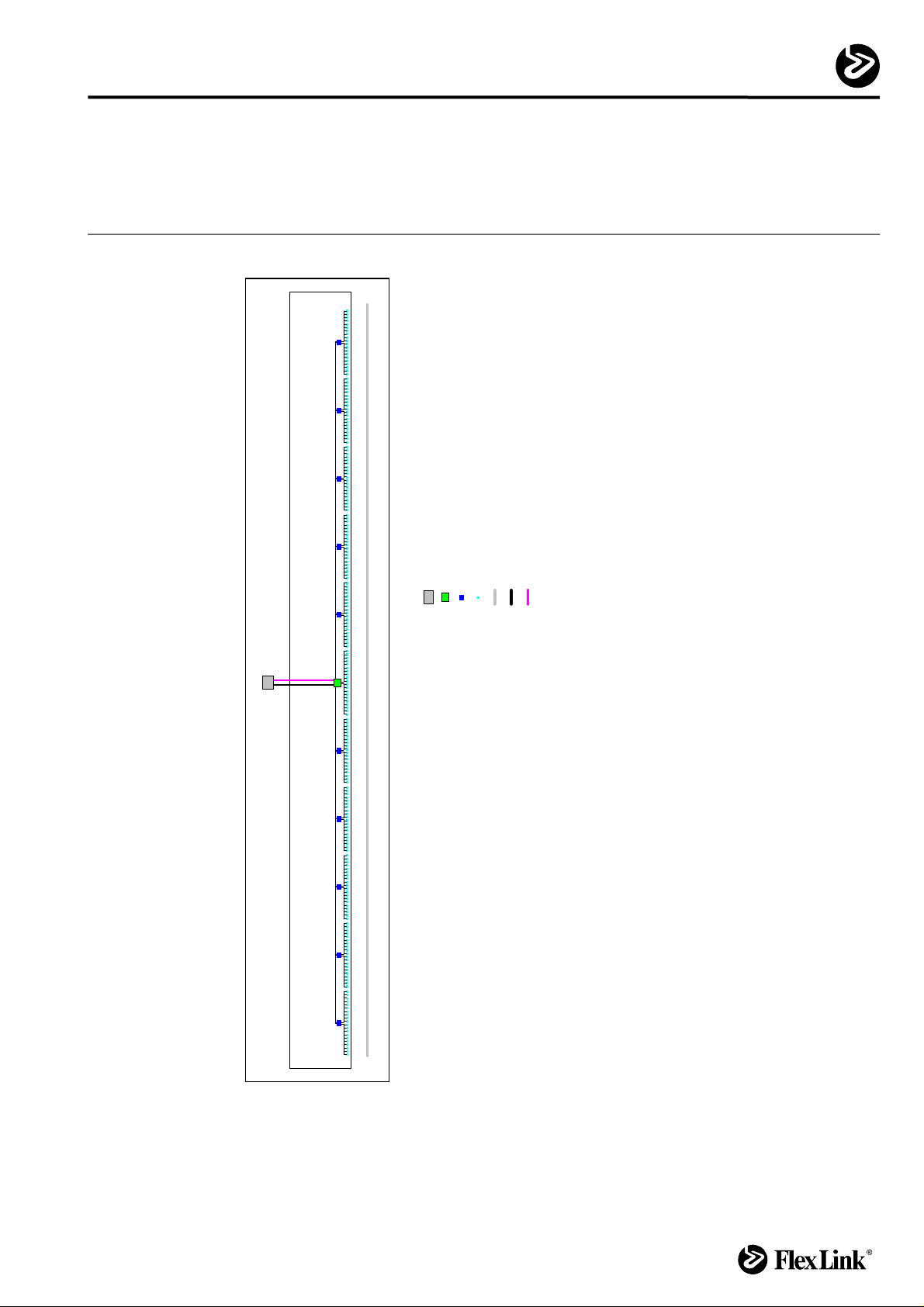

1. AGS-system layout

The AGS-system contains the following parts:

1. Control box;

2. Guide units;

3. Guide unit cables;

4. Junction box;

5. Zone supply cables.

The points 4 and 5 are used when the number of Guide units are higher than the Control

box itself can control.

The default distance between Guide units is 1 meter. This may be changed depending on

application.

See picture next page.

For more information see document "Controls overview".

2006-05-19

1.1 Integrator responsibility

Some parts of installation is application depending and part of the integrator’s

responsibility:

Archived

1. Box mounting frames;

2. Wire ways;

3. Zone supply conductors (see chapter “4. Zone supply”)

3928587_03.DOC

Page 3

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 3/12 FJn

2006-05-19

Conveyor system's control cabinet

Junction box

Control box

Guide unit

Conveyor

Power cable

Communication cable

Legend

Archived

AGS

Conveyor system

3928587_03.DOC

- 1 Control box

Data

- Max. 5 Junction boxes in both

directions

- Max. 10 Guide units in both

directions for each box

Page 4

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 4/12 FJn

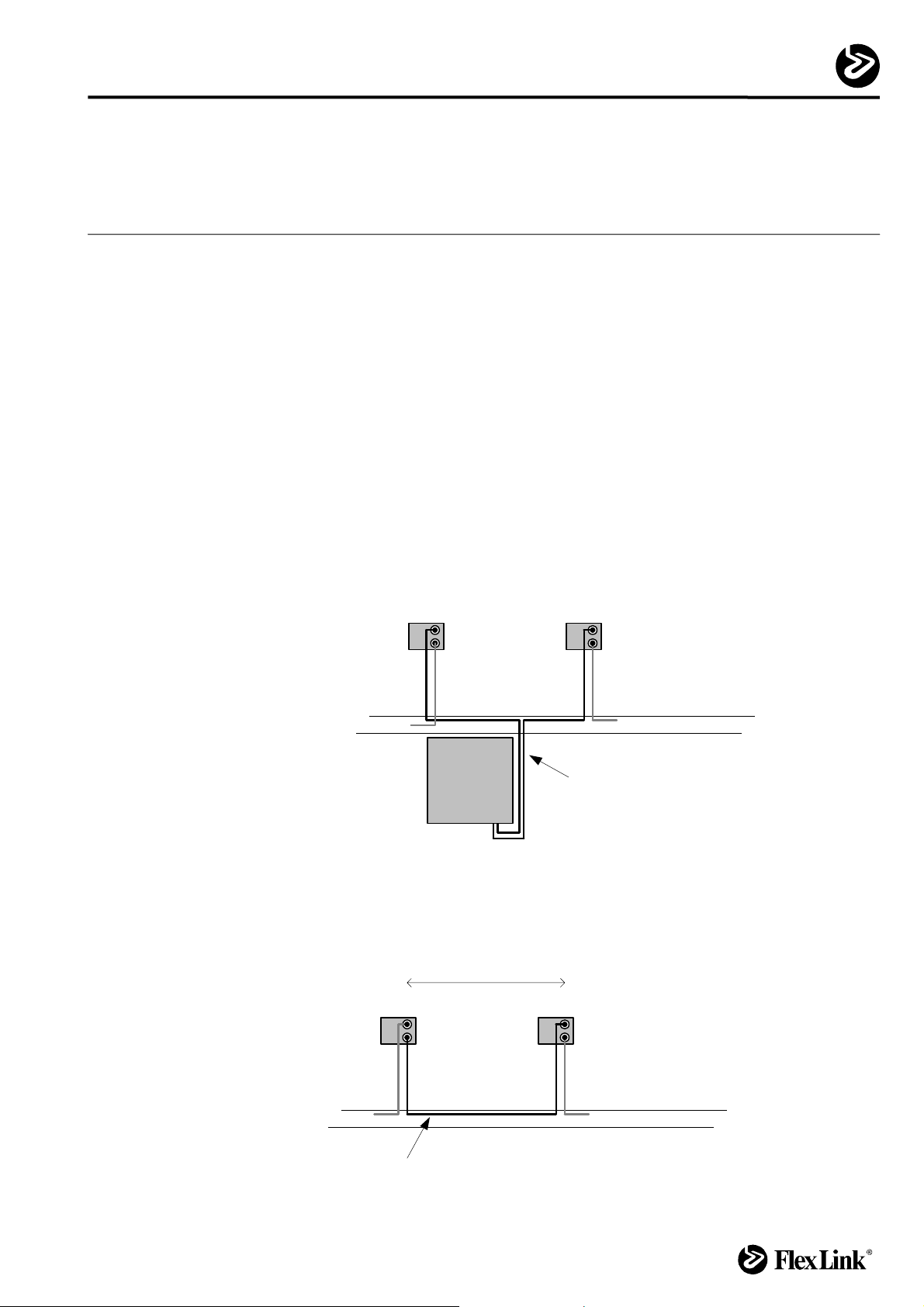

2. Placing components

General information:

• The cable between Guide units is a factory-made cable with fixed length (2 or 3 m)

connectors in both ends which affects the placing of components.

• Maximum 5 Junction boxes can be connected in each direction from the Control

box.

• Maximum 10 or 6 (depending on cable length) Guide units can be connected in

each direction from Control box/Junction box.

Instructions:

• Adjust the distance between the Control box or Junction box and the Guide unit so

that the Guide unit cable reaches between the Control box or Junction box and the

Guide unit.

2006-05-19

Guide unit

Wiring way

Box

Guide unit cable

Archived

• Place the Guide units so that the cable reaches between the Guide units.

Distance

Guide unit

Wiring way

Guide unit cable

3928587_03.DOC

Page 5

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 5/12 FJn

• The Control box and the Junction box are equipped with two horizontal XCBL 44

beams with T-slots attached to the backside. This makes it easy to mount the

Control box and the Junction box to other FlexLink structural beams.

2006-05-19

Archived

2.1 Using non-standard Guide unit cables

The standard length of Guide unit cable is 2 m for basic version and 3 m for heavy version.

If for any reason longer cables are required, the total cable length from the box to the last

Guide unit of that group is not allowed to exceed 20 meters.

Connectors for customized cable (Manufacturer Wieland):

• Female 96.031.4053.1 (screw connection)

• Male 96.032.4053.1 (screw connection)

For more information – www.gesis.com.

3928587_03.DOC

Page 6

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 6/12 FJn

3. Guide unit supply

The Guide unit cable is a factory-made cable with fixed length and connectors in both

ends.

The Control box, Junction box and the Guide unit are equipped with same type of

connectors.

WARNING! Disconnect electrical power by switching off the main switch of the Control box

before any electrical installation is started. Lock the switch with a padlock until the

installation is finished.

• Start by plugging the Guide unit cable into the Control box or Junction box,

thereafter into the Guide unit.

• Proceed by connecting the rest of Guide units controlled by the same Control or

Junction box.

Guide unit

2006-05-19

3.1 Connectors

Box

1. 2. 3.

Archived

When connecting two connectors the catch must say "click". The Guide units otherwise

risk to malfunction.

For disconnection see picture below.

3928587_03.DOC

Page 7

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 7/12 FJn

4. Zone supply

Up to five Junction boxes can be connected in both directions from a Control box.

The Zone supply conductor runs from the Control box and through the Junction boxes.

The conductor cable area must be 2.5mm

Zone supply conductor and wiring way.

Note: Preferably U.I. Lapp, Ölflex 110, 5G2.5, 1119 405, is selected for european

installations.

WARNING! Disconnect electrical power by switching off the main switch of the Control box

before any electrical installation is started. Lock the switch with a padlock until the

installation is finished.

• Run the conductor from the Control box and connect it to nearest Junction box.

• Continue to run conductors between the rest of Junction boxes.

2

. The integrator is responsible for the choice of

2006-05-19

Cable area = 2.5mm

Archived

Junction boxControl box

2

3928587_03.DOC

Page 8

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 8/12 FJn

European installation

2006-05-19

Archived

3928587_03.DOC

Page 9

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 9/12 FJn

US installation

2006-05-19

Archived

3928587_03.DOC

Page 10

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 10/12 FJn

5. Safety information

It is important to secure that products on the conveyor can not fall down on personal and

cause personal injury. Fall protection may need to be added below the conveyor. This is

specifically important where conveyors are running overhead a gangway. There is a risk

that the customer runs the system adjusted for the wrong product, this might increase the

risk of falling products. It is the integrators responsibility to install protections.

6. Installing the guide rail to the Guide units

Attach all Guide units to the conveyor. It is very important that the Guide units are parallel

to each other (see picture below). A and B must be equal.

Check that all Guide units are in outer position, this is the way they are delivered. Install

the guide rails adjusted for the widest product.

When the power supply is installed, run the system in and out and check that everything

runs smooth. Built in tensions can stop the system.

If a curve is made of segments placed at the same level it is important that the ends of the

segments never comes in contact with each other (see picture below). Check the whole

stroke of the guide unit!

Archived

A

B

2006-05-19

AA>0

3928587_03.DOC

Page 11

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 11/12 FJn

7. Feedback functionality – Track width setting

2006-05-19

7.1 System overview

The home position sensor (1) and the pulse sensor (2) shall be connected to the field bus

interface in the Control box with a cable (not included in delivery). The cable must have M8

3-pin connector towards the sensors.

The pulse sensor (2) is a magnetic sensor that counts pulses while the screw (3) is

rotating. The home position sensor (1) is a inductive sensor that detects when the sliding

element (4) is in end position.

7.2 Synchronization

If, by any reason the Guide units in a line are in different positions the line has to be

synchronized. When the command “synchronize” is chosen the unit starts to move out.

After reaching the home position sensor (1) the unit continues to move another 20

seconds*. If needed repeat this sequence until all Guide units are in outer position.

*The Guide unit can run against mechanical stop. This will make a humming sound but will

not damage the motor inside.

Archived

For controls information see document "Software user guide".

3928587_03.DOC

Page 12

Specification

Unit/Dept. Document type Date

APD/Research & Development

Issued by Document number Page Approved by

Assembly Instruction

Fredrik Johansson 3928587-03 12/12 FJn

8. Fault handling

No. Error description Check Possible reasons Action

1 Guide unit not moving a. Check automatic fuses

b. Check relay One relay should pull when running.

c. Total cable length Cable length too long. The total cable length from box through Guide units is not allowed to

d. Number of Guide units connected The total number of Guide units should not exceed 10 in each

e. Are the guide rails attached to the

Guide units without any stress?

2 Guide unit moving the wrong direction a. Connectors Loose Guide unit connector Secure that connectors are connected correctly.

Conveyor not horizontal.

Guide units not parallell to each

other.

2006-05-19

exceed 20 meters.

direction.

Check conveyor with water level.

Check Guide units with scale and composing stick.

Archived

3928587_03.DOC

Loading...

Loading...