Page 1

#52180C3

Fits 1968-1972

Corvette Radiator & Fan Kits

#52181C3

Fits 1970-1982

Chevrolet Corvette C3

Note: Manual transmission preferred; automatic transmission requires a remote cooler. (pt. #4116C3 available)

Note: Always read instructions

and verify kit contents prior to

installation.

Radiator ..................................... 1 ea.

Pre-Mounted Fan ...................... 1 ea.

Bracket, 27-1/2” extension ......... 1ea.

Instruction Sheet ....................... 1 ea.

Flex-a-lite Decal ......................... 1 ea.

*Hardware Kit ............................ 1 ea.

*Wiring Kit ................................. 1 ea.

INSTALLATION INSTRUCTIONS

Removal of Existing Fan, Shroud & Radiator

(Instructions shown are for Rad. / Fan kit #52180C3.

Installation of Rad. / Fan kit #52181C3 should be similar)

BE SURE THE ENGINE IS COOL BEFORE PROCEEDING.1.

* Hardware Kit Includes: top radiator mounting bracket (2ea),

hex bolt 5/16-18 x 1-3/4” (2ea), hex bolt 5/16-18 x 2” (4ea), flat

washer 5/16 (6ea), fender washer 5/16 (2ea), lock nut 5/16

(2ea), rubber spacer 5/16 hole (2ea), T-bolt (4ea), flat washer

1/4 (4ea), lock nut 1/4 (4ea), aluminum spacer block (2ea),

adhesive backed foam strip (4ea), fitting for radiator overflow (1ea)

* Wiring Kit Includes: control module (1ea), red 10 gauge wire (12ft.),

black 10 gauge wire (12ft), red 14 gauge wire (8ft), green 14 gauge

wire (5ft), tie straps (6ea), fuse holder (1ea), 40 amp fuse (1ea), fuse

tap ATO (1ea), fuse tap ATM mini (1ea), rubber probe cap (1ea), temp.

control knob (1ea), blue tap-in electrical connector (1ea), yellow ring

connectors (2ea), yellow butt connectors (4ea), blue female spade

connectors (3ea), yellow female spade connector (4ea), screw 1/420 x 1/2 (2ea)

Disconnect cable from negative post of battery. Battery is located inside the car, behind driver’s seat, within 2.

an enclosure.

Removal of hood is recommended for better access to engine compartment. 3.

Note: Take note of hood and hinge alignment for reinstallation later.

Note: Enlisting the help of other people will greatly reduce the risk of damage to the hood or fenders.

Drain cooling system by first removing fill cap on expansion tank (if equipped) and then loosening the 4.

petcock on the bottom of the radiator on the driver’s side. Allow coolant to drain until finished.

Remove the upper radiator hose from radiator inlet tube and move out of the way.5.

Loosen the alternator bracket to relieve tension on the fan belt, then remove belt.6.

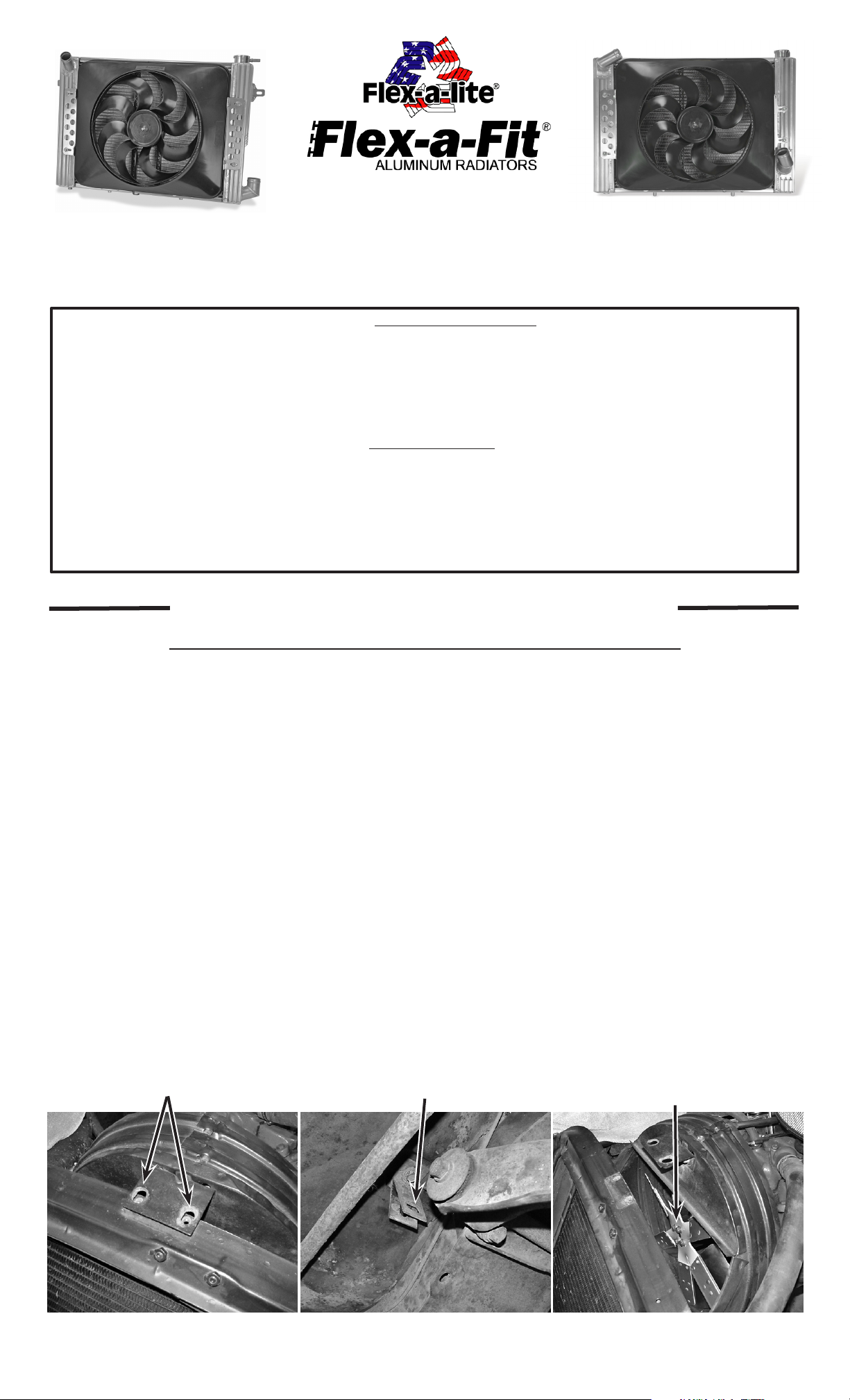

Remove bolts (2ea.) securing top of fan shroud to radiator support. 7. (see Detail A)

From below the vehicle; remove short nut and bolt sets (2ea.) holding shroud mounting flanges to “L” 8.

brackets bolted to lower splash shield plate. (see Detail B)

On stock fan configurations remove clutch and clutch fan. If the factory clutch and clutch fan have been 9.

replaced with a direct drive mechanical fan, slide fan shroud toward engine to reach the front of the

mechanical fan. Reach in between shroud and radiator to access fan mounting bolts. Remove bolts and

then fan. (see Detail C)

Remove bolts 2ea.

Remove nut & bolts 2 sets.

Move shroud toward engine,

then access bolts for removal

(Detail A)

(Detail B)

(Detail C)

Rev. 07-30-12 99181 Page 1 of 6

Page 2

Installation instructions continued from previous page

Remove fan shroud. 10. Note: Rotating the fan shroud will help with removal.

Disconnect the small overflow hose from the barbed fitting attached to filler neck of radiator. 11.

Note: This hose routes back to the Expansion tank.

Remove the lower radiator hose from radiator outlet tube and move out of the way.12.

Disconnect both transmission coolant lines from radiator (if applicable). Cap / plug lines to prevent 13.

transmission fluid from draining out.

Note: For automatic transmission equipped vehicles.

We chose not to install a transmission cooler within our radiator’s side tank. This maximizes the cooling

efficiency of both your engine and transmission. If your vehicle is equipped with an automatic transmission,

you will need to install an aftermarket transmission cooler. We have developed an auxiliary direct fit

transmission cooler kit for the Corvette 68’-82’, part #4116C3.

Flex-a-lite makes a full line of transmission coolers along with customized mounting options.

For more mounting options, call Technical Assistance at: 1-877-767-0554 or FAX: (253) 922-0226.

or visit www.flex-a-lite.com

Remove bolts (2ea.) securing mounting bracket that holds top of radiator. The bracket is located top center 14.

of radiator and attaches to engine side of radiator support. (see Detail D)

Remove radiator from vehicle by carefully lifting up and out parallel with angle of radiator support. 15.

Note: The bottom of the radiator is held in place with studs and rubber grommets that align with brackets

at bottom of radiator support. These grommets will be used with the new radiator. If the grommets are still

attached to the old radiator you will need to remove them and re-seat them back into the lower radiator

support brackets. (see Detail E)

Note: If installing kit #52181C3, verify rubber cushions within lower cradles have remained in place.

Radiator top mounting bracket.

(Detail D)

Bottom bracket with rubber

grommet seated within.

(Detail E)

Remove cap from filler neck of old radiator. 16.

Note: Save cap, it will be used with new radiator.

Remove the long & narrow plate at top of radiator support sandwiched between the top radiator mounting 17.

bracket and radiator support.

Remove foam strips located along both sides of radiator support opening.18.

From below the vehicle, and with weight of the vehicle on the ground, remove bolts (4ea.) securing front 19.

sway bar bushing brackets. Lower front sway bar then remove and discard splash shield plate. Warning:

Removal of sway bar bushing brackets without the front suspension under load could cause injury.

(see Detail F)

With splash shield plate removed, place supplied spacer blocks between vehicle frame and rubber bushing 20.

of sway bar. Reattach sway bar bushing brackets to frame with supplied longer 2” bolts & washers.

(see Detail G) The purpose is to lower the sway bar enough to provide adequate clearance for the new

electric fan assembly. Space blocks are necessary on both #52180C3 and #52181C3 kits

Sway bar bushing

bracket.

(Detail F)

Sway bar bushing bracket

with spacer block.

(Detail G)

Rev. 07-30-12 99181 Page 2 of 6

Page 3

Installation instructions continued from previous page

Installation of Radiator and Fan Kits #52180C3 & #52181C3

Note: If your vehicle is equipped with an automatic transmission, an aftermarket transmission

cooler kit should be installed during new radiator installation.

Find the provided pressure sensitive foam strips (4ea.) and apply to radiator tanks at top and bottom of

machined tank surfaces where radiator will be making contact with radiator support. The foam strips will

help to isolate vibration between radiator tanks and radiator support. (see Detail H)

Note: When installing Rad. / Fan kit #52181C3 into vehicle, replacing a OEM 27-1/2” core, mount supplied

optional bracket to lower right hand corner as shown. This bracket is needed to reach the passenger side

bottom cradle. (see Detail I) Adjust as needed to mount securely.

Carefully lower the radiator / fan assembly into position nesting the protruding studs along the bottom of the 1.

radiator onto the lower brackets and into the grommets cradled within them.

Assemble the “L”-bracket sub-assemblies (2ea.). 2. (see Detail J): Insert “T-bolts” (2ea. per bracket) through

slots then loosely place ¼” washers and locknuts on bolt threads. Place 5/16” washer onto 1-3/4” long bolt

then insert bolt through bracket. On other side of bracket slide rubber spacer onto bolt.

Location of foam strip.

Place foam strip at all four corners.

Place picture

of rad mounted

bracket in this

space

(Detail H)

Gently slide “T-bolts” of “L”-bracket sub-assemblies down channel of radiator end tank. Use the channel 3.

second from front as a starting point. (see Detail K) Do not tighten up “T-bolts” at this time. Insert 1-3/4”

bolt through hole in radiator support, then loosely place fender washer and 5/16” locknut onto bolt threads.

Once “L”-bracket sub-assemblies have been positioned on both sides of radiator, adjust alignment as

necessary and tighten all hardware securing radiator to radiator support. Note: Make sure that the top foam

strips of radiator are being compressed when tightening bracket hardware. (see Detail K)

L-bracket sub-assembly.

“Exploded view”

Top view of L-bracket assembly on

passenger’s side secured to Radiator support.

(Detail I)

(Detail J)

Re-secure the pulley to the water pump, then reinstall fan belt. Reinstallation of pulley to water pump 4.

flange will require shorter replacement bolts. After being tightened, there should be no less than ¼”

of clearance to the water pump. If they are too close, they may cause severe damage to the water

pump upon start-up.

Connect the upper and lower radiator hoses to the new radiator. Make sure they are properly clamped to 5.

the inlet and outlet tubes.

Install the provided pipe-nipple for the coolant overflow hose into filler neck of the radiator. Attach & secure 6.

the small overflow hose onto previously installed pipe-nipple.

Fill radiator / cooling system with vehicle manufacturer recommended coolant until coolant level stabilizes 7.

then attach cap formerly detached from removed radiator. Continue filling cooling system through

expansion tank until “Cold Fill Level” is reached. Replace expansion tank cap and check for leaks before

proceeding.

Note: BE SURE that all moving parts of the engine and electric fan (where applicable) are clear of

each other before proceeding!!

(Detail K)

Rev. 07-30-12 99181 Page 3 of 6

Page 4

Installation instructions continued from previous page

Wiring Diagram

colored

thick black

thick

black

black

Locate a mounting point for the control near inlet side of radiator. Control needs to be placed within 18” of 1.

radiator inlet hose. You may want to mount next to radiator on fender well or the corner of the fan shroud.

Mount control using the screws provided.

Using the yellow butt connectors provided, attach a length of the large diameter (10 AWG) 2. red wire to

the colored motor wire. Attach a length of the large diameter (10 AWG) black wire to the black motor

wire. Once the fan is in place, these will attach to the control module. Tip: Strip an additional 1/8” of

insulation from the motor wires and fold them over to increase the thickness of the wire where it

will slide into the butt connector. If mounting the control module to the fan shroud, the motor wires can

be connected now. If mounting the control somewhere else in the engine compartment, leave enough wire

to reach the control module.

Connect the motor wires to the control module (colored wire to the “M+” terminal and black wire to the “M-” 3.

terminal).

Use the large diameter red (10 AWG) wire to run power directly from the battery positive (+) terminal to 4.

the “B” terminal on the control module. Connect the fuse holder in-line with this wire, as shown, but do not

insert the fuse yet. Use the yellow female spade, ring and butt connectors provided.

Use the large diameter black (10 AWG) wire to run from a clean surface on the engine block or head to the 5.

“G” terminal on the control module. Use the yellow female spade and ring connector provided.

Use the small diameter red wire (14 AWG) to connect the “+” terminal on the control module to a positive 6.

power source. NOTE: Attaching this wire to an ignition-controlled source will shut off the fan when

the engine is turned off. Note: Do Not connect the “+” terminal wire to the ignition switch, ignition

coil, or fuel pump. Attach this wire to an uninterrupted (always hot) power source to allow the fan to

continue running after the engine is shut off. Use the blue female connector and fuse taps (included) if

necessary.

If the vehicle is equipped with air conditioning, a 7. mandatory connection is needed to cycle the fan on and

off with the A/C clutch when the A/C is turned on. Create a connection between the “C” terminal on the

control module and the positive wire that triggers the A/C compressor. Using a voltmeter, determine which

wire coming from the compressor is the positive trigger wire. Use the included 3-way connector and small

diameter green wire (14 AWG) to tap into this wire and send a signal to the “C” terminal on fan control

module.

(Optional) For manual switch operation, use Flex-a-lite p/n 31148. Connect the switch as shown on the 8.

wiring diagram. Connect the “M” terminal on the control module to the “1” terminal on the switch. Connect

the “2” terminal on the switch to a positive 12v power source. Connect terminal “3” on the switch to a good

ground (for switch illumination). NOTE: To prevent thermostatic activation (if only manual switch

operation is desired), omit the lead to the “+” terminal of the control box. “B”, “G”, “M+” and “M-”

must remain connected. If not using a Flex-a-lite manual switch, do not connect a ground wire to

the switch!

Install temp. probe near inlet hose...

(Detail L)

then replace the insulator cap.

Rev. 07-30-12 99181 Page 4 of 6

Page 5

Installation instructions continued from previous page

Use the zip ties provided to secure the wires and prevent them from interfering with fan blades, belts, and 9.

pulleys in the engine compartment. Insert the fuse provided.

Insert the temp. probe through the radiator fins near the upper radiator hose, then install black insulator cap 10.

onto the end of the probe. (see Detail L, on previous page)

Press the control knob (included in wiring kit) onto the control box shaft. Turn the knob clockwise until it 11.

stops.

Reconnect negative (-) battery cable to battery.12.

Start the engine and allow it to idle. Using a hand held thermometer (positioned near the inlet hose) or the 13.

vehicle’s temperature gauge, monitor the temperature. When the coolant temp is slightly above normal (or

desired temp.), turn the knob counter-clockwise just until the fan turns on. From now on, the fan should

activate at this temperature setting. Adjust as necessary to maintain desired temperature.

After electric fan operation has been verified turn vehicle off and allow coolant to return to ambient 14.

temperature. Check coolant levels of reservoir and radiator, topping off as needed.

Note: Visit our website www.flex-a-lite.com to register product

for warranty and review warranty policy.

Limited Radiator Warranty

Flex-a-lite Consolidated warrants its aluminum radiators to be free from defects in materials and workmanship

for a period of one year from the date of purchase at retail by the original purchaser. This warranty is extended

only to the first purchaser of any such radiator at retail. If the Flex-a-lite radiator is used in any racing application,

repaired or altered, this warranty is considered null and void, it also does not cover any radiator repaired or

altered in any way. If products such as transmission cooler or electric fan are attached with cable ties or similar

fasteners that run through the radiator core, the warranty is voided.

This warranty does not cover labor, materials not manufactured by Flex-a-lite, or shipping charges. The retail

purchaser is responsible for the appropriate use and application of the product. This warranty does not cover the

effects of physical or chemical properties of water, steam, or other liquids used in the radiator. Radiators used

without an adequate proportion of premium quality antifreeze/coolant are not covered by this warranty. Flex-a-lite

aluminum radiators require a correct proportion of quality coolant, which contains aluminum corrosion inhibitors in

the formula.

Claims for internal damage of the engine, components, or user’s vehicles are not covered by this warranty. It is

the responsibility of the Flex-a-lite product user to monitor engine operation and have proper detection devices

installed to warn the user of overheating. Specific exemptions to the warranty include tube damage, ballooning

or bursting from excessive engine operating temperature, internal corrosion due to inadequate proportions of

antifreeze/coolant, or damage to radiator resulting from a collision damage.

Flex-a-lite shall not be responsible for damages to its product or injury to persons using the product when

improperly opening radiator pressure caps, burst hoses, etc. Flex-a-lite shall not be responsible for injury or harm

to persons or property caused by persons or vehicles using our products.

The purchaser’s remedy for breach of this warranty, exclusive of all other remedies provided by law, is expressly

limited to repair or replacement of any part or parts. All products returned for warranty consideration must be

returned through the point of purchase with all transportation expenses prepaid. Upon receipt of the product,

Flex-a-lite will examine the product to determine the condition and validity of the claim.

Radiators or products received, which were damaged in shipping, should immediately be reported to the shipping

carrier as damaged, and claims of damage filed accordingly. Contact the transport carrier (UPS, truck line, etc.)

for procedures in filing damage claim with the carrier or their agent. Do not return product damaged in shipping

to Flex-a-lite.

Some states may not allow a limitation on the duration of any implied warranty. The above warranty may not

apply to you. This warranty grants you specific legal rights, and you may have other rights, which vary from state

to state.

The Flex-a-lite Limited Warranty

Flex-a-lite Consolidated, 7009-45th St. Ct. E. Fife, WA 98424, Telephone No. 253-922-2700, warrants to the original purchasing user, that all Flex-a-lite

products to be free of defects in material and workmanship for a period of 365 days (1 year) from date of purchase. Flex-a-lite products failing within

365 days (1 year) from date of purchase may be returned to the factory through the point of purchase, transportation charges prepaid. If, on inspection,

cause of failure is determined to be defective material or workmanship and not by misuse, accidental or improper installation, Flex-a-lite will replace the

product free of charge, transportation prepaid. Flex-a-lite will not be liable for incidental, progressive or consequential damages. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives

you specific legal rights and you may have other rights, which vary from state to state. The Flex-a-lite warranty is in compliance with the Magnuson-Moss

Warranty Act of 1975.

Rev. 07-30-12 99181 Page 5 of 6

Page 6

Troubleshooting the #180 electric fan

Problem

Fan does not turn

on regardless of

temperature.

Fan still does not turn

on.

Fan still does not turn

on.

Possible Cause How to find out

“+” terminal on control

box not connected to

proper source.

Fuse to battery

positive post blown.

Wires to terminals “B”

and “G” aren’t properly

hooked up.

Motor wired

improperly.

Trace wire connected

to the “+” terminal.

Use a voltmeter or

test light to check for

voltage.

Inspect the fuse in the

holder.

Check for power and

ground through lines

hooked to terminals

“B” & “G”.

Check to see that the

blue motor wire runs

to the “M+” terminal

and the black motor

wire runs to the “M-“

terminal on the control

box.

Solution

If there is no power to

the “+” terminal, find

an ignition-switched or

constant 12v. power

source and wire it to

the “+” terminal on the

control box.

Replace fuse.

Hook up wires for

terminals “B” & “G” to

battery and ground

respectively.

Connect wires to

correct terminals.

If motor does not spin

after checking wiring,

call tech support at

1-800-851-1510.

Fan does not come on

until the temperature

is very hot.

Fan was working

properly but suddenly

shut down.

When engine is

started, fan comes on

even though engine is

cold.

Temp. probe not

located in optimum

position.

Temperature set to

high.

Usage of a chassis

ground and/or

alternate source for

power other than

positive terminal on

battery.

Constant (always

“hot”) 12v source

hooked to “C”

terminal.

A/C or defrost turned

on.

Check location of

temp. probe.

Locate temperature

adjusting knob on top

cover of control box.

Trace wire from

terminals “B” and “G”

to find source.

Trace the wire

connected to the “C”

terminal and make

sure it is spliced into

the positive trigger

wire from the A/C

compressor clutch.

Check if defrost

activates a/c or if the

a/c is on.

Temp. probe should

be located nearest the

upper radiator hose.

Turn knob counterclockwise to set the

control box to a lower

temperature.

Move to posts on the

battery.

Splice into the positive

trigger wire to the A/C

clutch and connect

to the “C” terminal on

control box.

Shut off a/c or leave

on as this is normal

operation.

99993-Z

Rev. 07-30-12 99181 Page 6 of 6

Loading...

Loading...