Fleck 9100TS Upflow Service Manual

FLECK 9100TS UPFLOW

SERVICE MANUAL

waterpurification.pentair.com

TABLE OF CONTENTS

WARNING:

JOB SPECIFICATION SHEET .................................................... 2

HOW TO USE THIS MANUAL .................................................... 2

EQUIPMENT CONFIGURATION ................................................ 2

SAFETY INFORMATION ............................................................ 3

INSTALLATION INSTRUCTIONS ............................................... 3

CONTROLLER FEATURES ........................................................ 6

INITIAL STARTUP INSTRUCTIONS .......................................... 7

USER PROGRAMMING ............................................................. 8

PROGRAMMING MODE ............................................................ 11

AUTOMATIC CLEANING CYCLE ............................................... 15

DISINFECTION OF WATER CONDITIONING SYSTEMS ............ 15

WIRING DIAGRAMS .................................................................. 16

POWERHEAD ASSEMBLY......................................................... 17

9100 CONTROL VALVE ASSEMBLY .......................................... 18

9100 SECOND TANK ASSEMBLY ............................................. 19

TURBINE METER ASSEMBLY - P/N 60626 ............................. 20

PADDLE METER ASSEMBLY -P/N 60086-50 ........................... 20

1" METER ASSEMBLY - P/N 60622 .......................................... 21

BYPASS VALVE ASSEMBLY (METAL) ........................................ 22

BYPASS VALVE ASSEMBLY (PLASTIC) ..................................... 22

SAFETY BRINE VALVE .............................................................. 23

PROBE KIT ............................................................................... 24

TROUBLESHOOTING ................................................................ 25

9000/9100 METER FLOW DATA ................................................ 26

9000/9100 INJECTOR FLOW DATA (

1600 SERIES INJECTORS) ....................................................... 27

9100 CONTROL DIMENSIONS.................................................. 28

WATER CONDITIONER FLOW DIAGRAMS ............................... 29

SERVICE ASSEMBLIES ............................................................ 31

JOB SPECIFICATION SHEET

Job No: _____________________________________________

Model No: ___________________________________________

Water Test: __________________________________________

Capacity Per Unit: _____________________________________

Mineral Tank

Size: ____________ Diameter: ___________Height: _________

Brine Tank Size and Salt Setting per Regeneration: _________

9100TS Control Valve Specifications:

1. Regeneration Program Setting:

a. Brine and Slow Rinse: ______________________ Minutes

b. Backwash: _______________________________ Minutes

c. Rapid Rinse: _____________________________ Minutes

d. Brine Tank Refill: _________________________ Minutes

2. Drain Line Flow Control: _________________________ gpm

3. Brine Refill Rate: _______________________________ gpm

4. Injector Size: ______________________________________

HOW TO USE THIS MANUAL

This installation manual is designed to guide the installer

through the process of installing and starting water

conditioning systems featuring the 9100TS controller.

This manual is a reference and will not include every system

installation situation. The person installing this equipment

should have:

• Training in the 9100TS control and the 9000/9100 valve.

• Knowledge of water conditioning and how to determine

proper control settings.

• Adequate plumbing skills.

EQUIPMENT CONFIGURATION

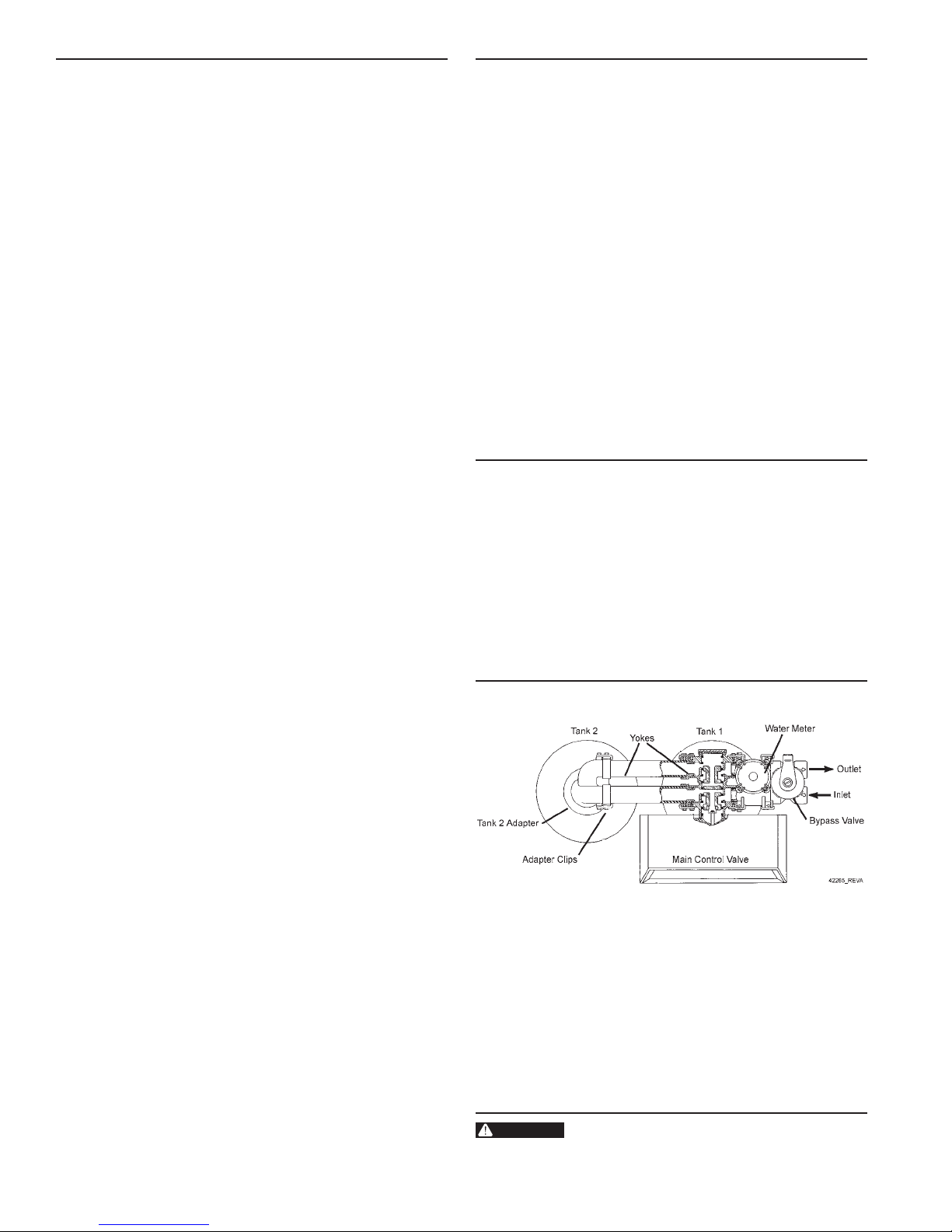

9100TS Configuration

Figure 1

CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals known to the

State of California to cause cancer or birth

defects or other reproductive harm.

SAFETY INFORMATION

General Warnings And Safety Information

Electrical

• There are no user-serviceable parts in the AC adapter,

motor, or controller. In the event of a failure, these items

should be completely replaced.

• All electrical connections must be completed according to

local codes.

• Use only the power transformer supplied with this water

conditioning system.

• The power outlet must be grounded and always on.

• To disconnect power, unplug the AC adapter from its

power source.

Mechanical

• Do not use petroleum based lubricants such as Vaseline,

oils, or hydrocarbon based lubricants. Use only 100%

silicone lubricants.

• All plastic connections should be hand tightened. PTFE

tape may be used on connections that do not use an

O-ring seal. Do not use pliers or pipe wrenches.

• All plumbing must be completed according to local codes.

• Use only lead-free solder and flux, as required by

federal and state codes, when installing soldered copper

plumbing.

• The drain line must be a minimum of 1/2-inch diameter.

Use 3/4-inch pipe if the pipe length is greater than 20 feet

(6 m).

• Do not support the weight of the system on the control

valve fittings, plumbing, or the bypass.

General

• Observe all warnings that appear in this manual.

• This system is not intended to be used for treating water

that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

• Keep the unit in the upright position. Do not turn on side,

upside down, or drop. Turning the tank upside down will

cause media to enter the valve.

• Operating water temperature is between 35°F (1°F) and

100°F (38°C).

• Operating water pressure range : 20 to 125 psi (1.38 to

8.27 bar).

• Use only salts designed for water softening. Acceptable

salt type is sodium chloride pellet salt.

• Follow state and local codes for water testing.

• When filling media tank, do not open water valve

completely. Fill tank slowly to prevent media from exiting

the tank.

• Always make modifications to house plumbing first.

Connect to valve last.

• Plastic parts and O-rings may be damaged by heat and

solvents. When constructing plumbing connections allow

heated parts to cool and protect parts from solvents.

Location Selection

Location of a water treatment system is important. The

following conditions are required:

• Level platform or floor.

• Ambient temperatures over 35°F (1°C) and below 120°F

(49°C).

• Constant electrical supply to operate the controller.

• Total minimum pipe run to water heater of ten feet (three

meters) to prevent backup of hot water into system.

• Local drain or tub for discharge as close as possible.

• Water line connections with shutoff or bypass valves.

• Must meet any local and state codes for site of

installation.

• Valve is designed for minor plumbing misalignments. Do

not support weight of system on the plumbing.

• Room to access equipment for maintenance and adding

salt.

INSTALLATION INSTRUCTIONS

Things You Need to Know

• When the controller is first plugged in, it may display a

flashing hourglass and the message Err 3, this means

that the controller is rotating to the home position.

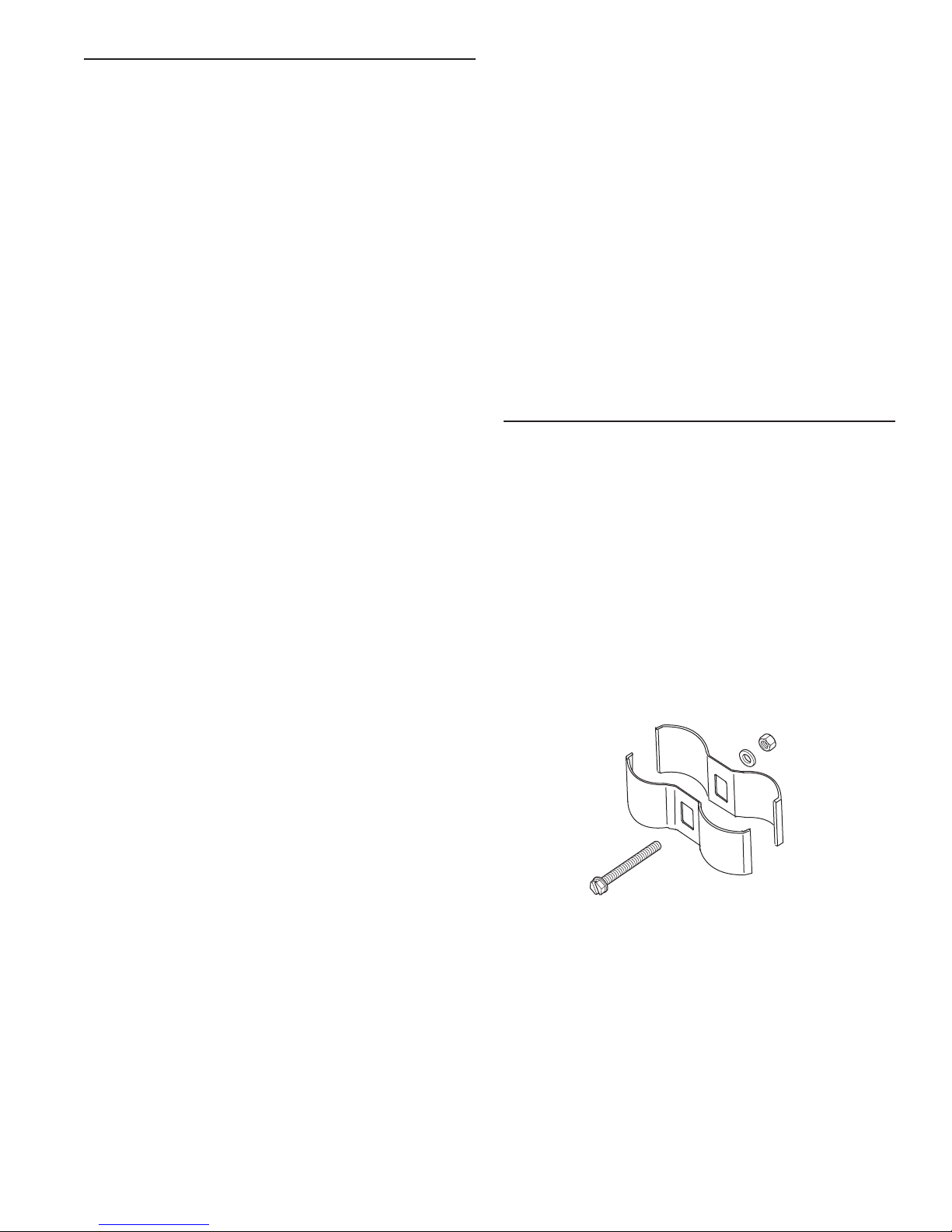

Grounding the Plumbing

It is important that the plumbing system be electrically

grounded. When a water softener is installed, a non-metallic

bypass valve may interrupt the grounding. To maintain

continuity, a grounding strap can be purchased at a hardware

store (Figure 2). When it is installed the strap will connect the

plumbing into the softener to the plumbing out of the softener.

If you have other water treating equipment such as a

chlorinator, sediment filter, neutralizer, iron filter, or taste

and odor filter they should be installed upstream of the water

softener.

Figure 2

FLECK 9100TS Upflow • 3

B

INSTALLATION INSTRUCTIONS continued

WARNING:

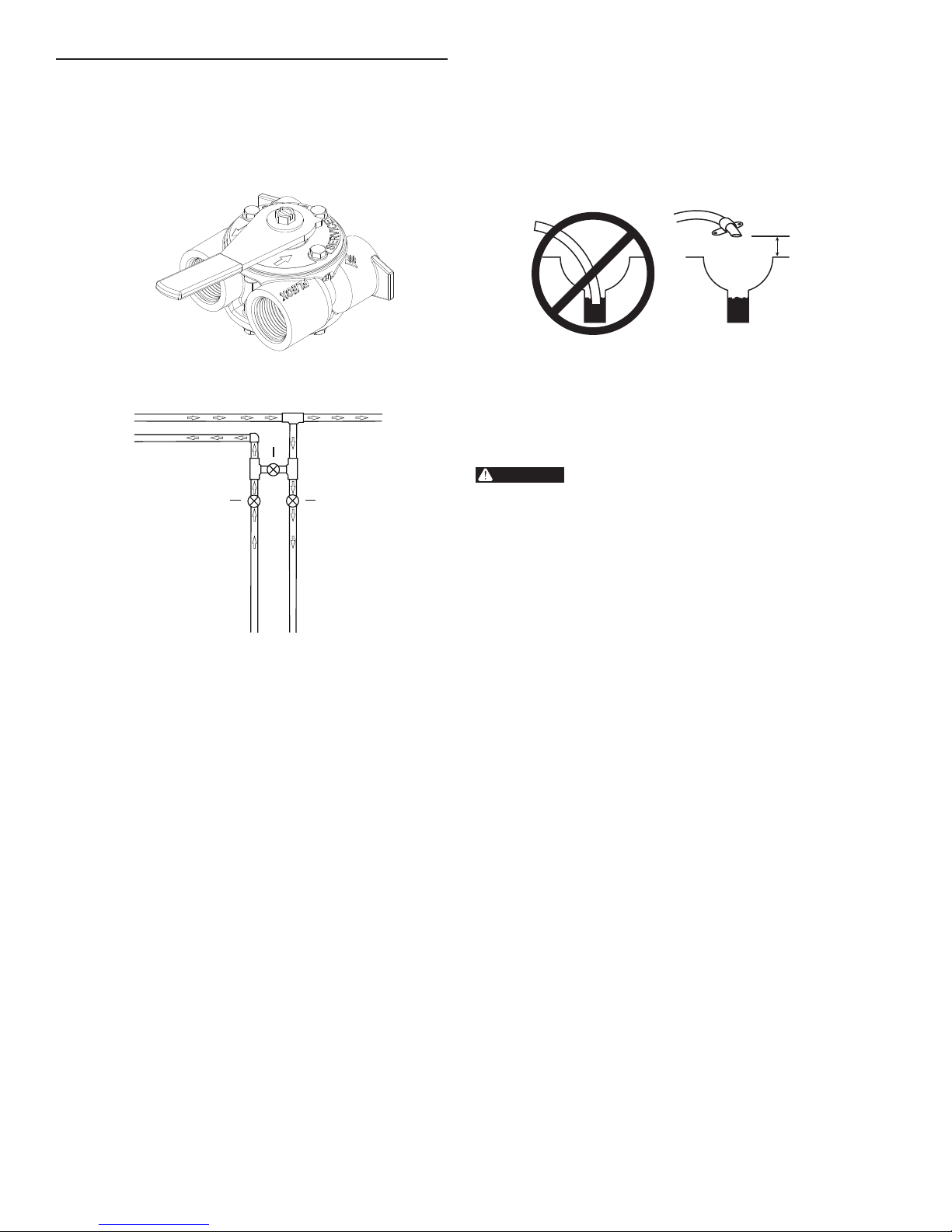

Bypass Valve

A bypass valve system should be installed on all water

conditioning systems. Bypass valves isolate the conditioner

from the water system and allow unconditioned water to be

used. Service or routine maintenance procedures may also

require that the system is bypassed. Figures 3 and 4 show the

two common bypass methods.

Figure 3 Bypass Valve

2

1

3

3. Where the drain line is elevated but empties into a drain

below the level of the control valve, form a 7-inch (18-cm)

loop at the far end of the line so that the bottom of the loop

is level with the drain line connection. This will provide

an adequate siphon trap. Where the drain empties into an

overhead sewer line, a sink-type trap must be used.

Secure the end of the drain line to prevent it from moving.

INCORRECT

Construct air gap as shown or purchase air

gap device as used with clothes washers.

CORRECT

1" AIR GAP

Figure 5 Drain Line Connection

NOTE: Waste connections or drain outlets should be designed

and constructed to provide for connection to the

sanitary waste system through an air gap of two pipe

diameters or one inch (22 mm) whichever is larger.

Never insert drain line directly into a drain,

sewer line, or trap (Figure 5 Drain Line

Connection). Always allow an air gap between

the drain line and the wastewater to prevent

the possibility of sewage being back-siphoned

into the softener.

Figure 4 Manual Bypass

If this unit includes a bypass valve (Figure 3), it can be used by

itself or with a manual bypass (Figure 4).

Manual Bypass In Service Position

• Valves 1 and 3 open

• Valve 2 closed

Bypassed Position

• Valve 2 open

• Valves 1 and 3 closed

Drain Line Connection

NOTE: Standard commercial practices are expressed here.

1. The unit should be above and not more than 20 feet

2. The drain line may be elevated up to 6 feet (1.8 m) providing

Local codes may require changes to the following

suggestions. Check with local authorities before

installing a system.

(6.1 m) from the drain. Use an appropriate adapter fitting

to connect plastic tubing to the drain line connection of the

control valve.

the run does not exceed 15 feet (4.6 m) and water pressure

at the softener is not less than 40 psi (2.76 bar). Elevation

can increase by 2 feet (61 cm) for each additional 10 psi (.69

bar) of water pressure at the drain connector.

General Installation Notes

1. Place the softener tanks where you want to install the unit.

NOTE: Be sure the tanks are level and on a firm base.

2. During cold weather it is recommended that the installer

warm the valve to room temperature before operating.

3. Perform all plumbing according to local plumbing codes.

— Use a 1/2" minimum pipe size for the drain.

4. Lubricate the distributor O-ring seal and tank O-ring seal.

Place the main control valve on one tank and the tank

adapter on the second tank.

NOTE: If required, solder copper tubing for tank

interconnection before assembling on the main

control valve and tank adapter. Maintain a

minimum of 1" distance between tanks on final

assembly.

5. Solder joints near the drain must be done before connecting

the Drain Line Flow Control fitting (DLFC).Leave at least

6" (152 mm) between the DLFC and solder joints when

soldering pipes that are connected on the DLFC. Failure to

do this could cause interior damage to DLFC.

6. Use only plumber tape on the drain fitting.

7. Be sure the floor under the salt storage tank is clean and

level.

8. Place approximately 1" (25 mm) of water above the grid

plate of the salt storage tank before filling with salt. Add

salt to brine tank so that salt level is above the brine well

air check.

9. Make all electrical connections according to codes. Plug the

valve into an approved power source.

10. Tank one has control valve and tank two has adapter.

11. Look on the right side of the control valve, it has indicators

showing which position the control valve is in during

Regeneration and which tank is In Service.

FLECK 9100TS Upflow

4 •

INSTALLATION INSTRUCTIONS continued

WARNING:

Brine Line Connection

The brine line from the brine tube connects to the valve. Make

certain the connections are hand tightened. Be sure that the

salt line is secure and free from air leaks. Even a small leak

may cause the salt line to drain out, and the softener will not

draw salt from the tank. This may also introduce air into the

valve causing problems with valve operation.

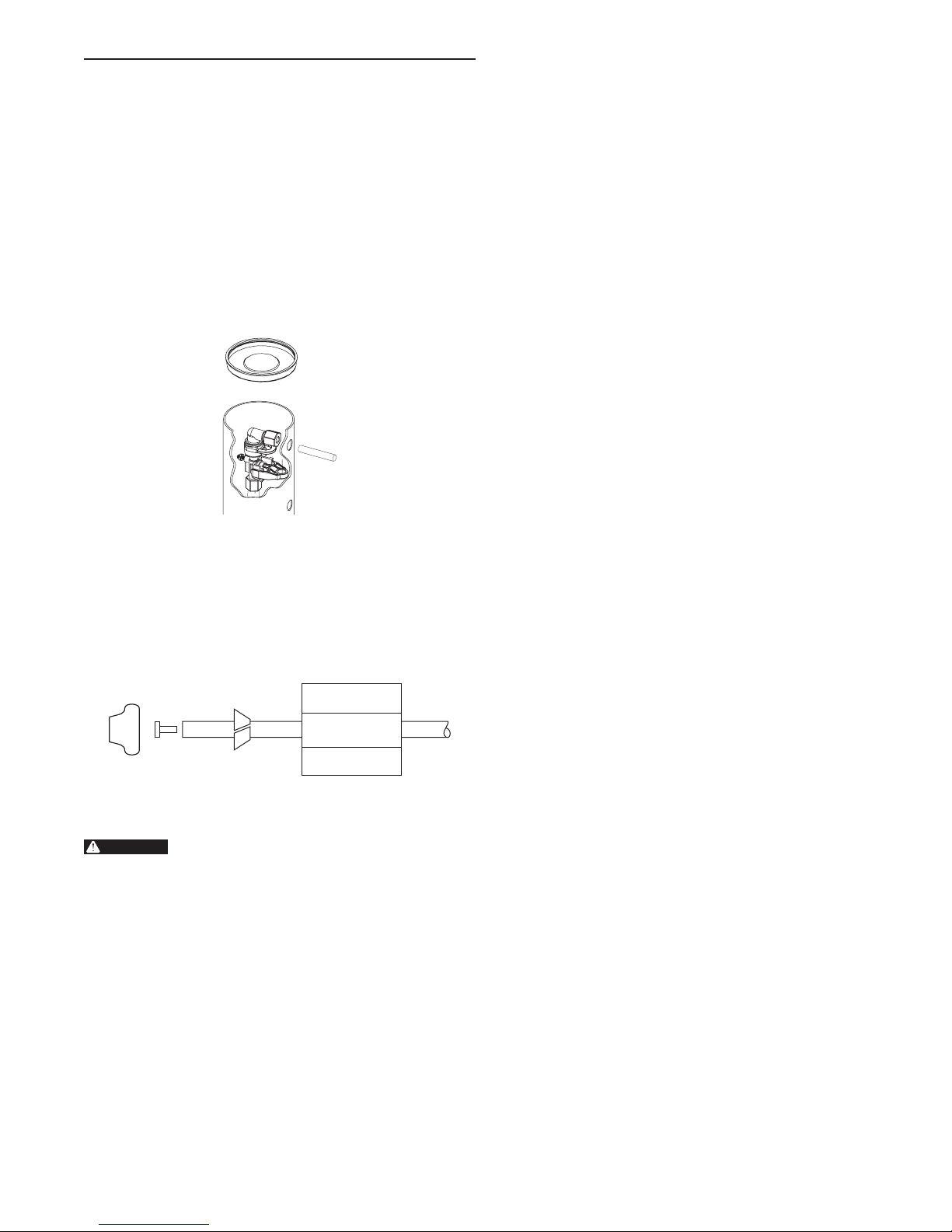

To install the brine line:

1. Inside the salt tank, remove the cap from the large cylinder

to gain access to the connection.

2. Be sure the brass insert is in the end of the brine tubing.

Insert the tubing through the opening in the tank.

3. Push the tubing into the plastic nut. Slowly unscrew the nut

until the tubing moves into the connection. The tubing will

hit bottom.

9100TS Control Operation

Power Loss Memory Retention

The 9100TS control features battery-free Time of Day and Day

of Week retention during temporary loss of power. A super

capacitor is designed to keep time for 8 to 24 hours depending

on the installation. If the super capacitor is exhausted the

9100TS control will display four dashes (- - : - - ) immediately

upon power up. The Time of Day and Day of Week must be

reset.

All other programmed parameters are stored in the static

memory and are retained.

Figure 6

NOTE: Once the tubing has been pushed into the nut it cannot

4. Hand tighten the nut until the connection is tight.

5. Make compression fitting connection between brine line

be pulled out. The nut will need to be removed. See

Figure 6 for correct assembly.

and valve (Figure 7).

Figure 7

Electrical Connection

This valve and control are for dry location use

only unless used with a Listed Class 2 power

supply suitable for outdoor use.

The controller operates on 24-volt alternating current power

supply. This requires use of the supplied AC adapter included

with your system.

AC Adapter

Make sure power source matches the rating printed on the AC

adapter.

NOTE: The power source should be constant. Be certain

the AC adapter is not on a switched outlet. Power

interruptions longer than 8 hours may cause the

controller to lose the time setting. When power is

restored, the time setting must then be re-entered.

FLECK 9100TS Upflow • 5

CONTROLLER FEATURES

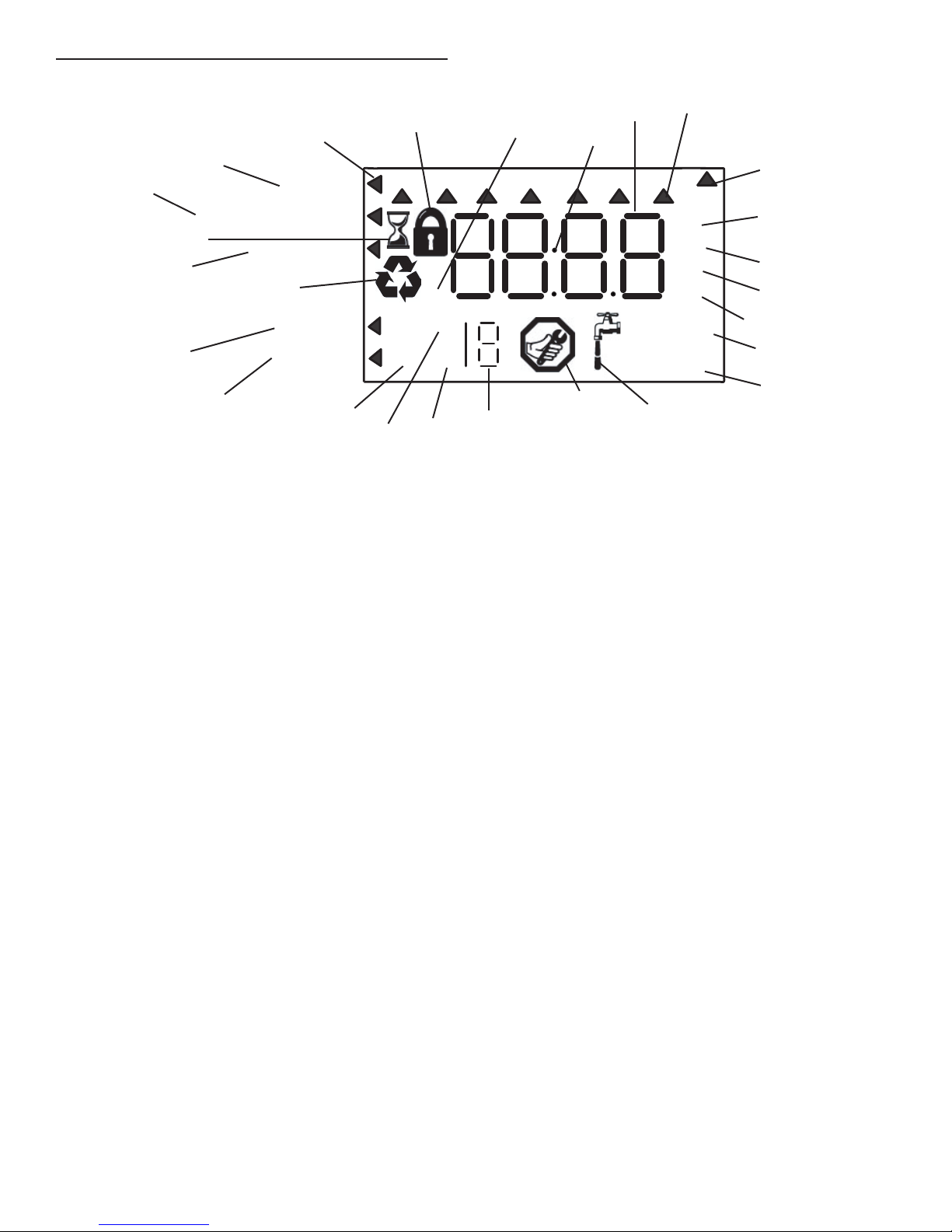

Display Icons & Cursors

14

13

Regeneration Time

15

Salt Amount

12

16

Time/Day

11

9

10

7

2

8

SU MO TU WE TH FR SA DAYS

PM

MIN

g/L

KGx2

1

3

4

5

Capacity

26

25

NOTE: In normal operation and during programming, only a

1. This cursor is displayed when the days between

2. One of these cursors is displayed to indicate which day will

3. "PM" indicates that the time displayed is between 12:00

4. When "MIN" is displayed, the value entered is in minute

5. When g/L is displayed, the value for regenerant amount

6. When "Kg" is displayed, the value entered is in kilograms or

7. Four digits used to display the time or program value. Also

8. Colon used as part of the time display.

9. Locked/unlocked indicator. In Level I Programming this

10. When "x2" is displayed, a second regeneration has been

11. The recycle sign is displayed (flashing) when a regeneration

12. The display cursor is next to "SALT AMOUNT" when

13. The display cursor is next to "REGENERATION TIME" when

14. The display cursor is next to "TIME/DAY" when

15. The hourglass is displayed when the motor is running. The

16. These cursors appear next to the item that is currently

6 •

few of the icons are actually displayed.

regeneration are being programmed (used with .5 to 30 day

regeneration programming).

be programmed into the controller.

noon and 12:00 midnight (there is no AM indicator). PM

indicator is not used if clock mode is set to 24-hour.

increments.

entered is in grams/Liter of resin.

kilograins.

used for error codes.

is displayed when the current parameter is locked-out.

It is also used in Level II Programming to indicate if

the displayed parameter is locked (icon flashes) when

controller is in Level I.

called for.

at the next time of regeneration has been called for. Also

displayed (continuous) when in regeneration.

programming the amount of regenerant.

programming the time of regeneration and the days of

regeneration.

programming the current time and day.

piston should be moving.

displayed.

FLECK 9100TS Upflow

Hardness

24

C

23

H

22

6

x100P

Lbs/ft

3

17

18

20

21

17. X100 multiplier for large values.

3

18. When Lbs/ft

entered is in pounds/cubic foot of resin.

19. Faucet is displayed when the current flow rate is displayed.

Control may show the faucet and "0", indicating no flow.

20. Maintenance interval display turns on if the months in

service exceed the value programmed in P11.

21. Displays the tank in service during normal operating mode.

Used with #22, #23 and #24 in programming mode or

regeneration.

22. History Values (H). The number displayed by #21 identifies

which history value is currently displayed.

23. Parameter (P). Displayed only in Level II Programming.

The number displayed by #21 identifies which parameter is

currently displayed.

24. Cycle (C). The number displayed by #21 is the current cycle

in the regeneration sequence.

25. Hardness setting.

26. Capacity display—shows estimated system capacity.

is displayed the value for regenerant amount

19

CONTROLLER FEATURES continued INITIAL STARTUP INSTRUCTIONS

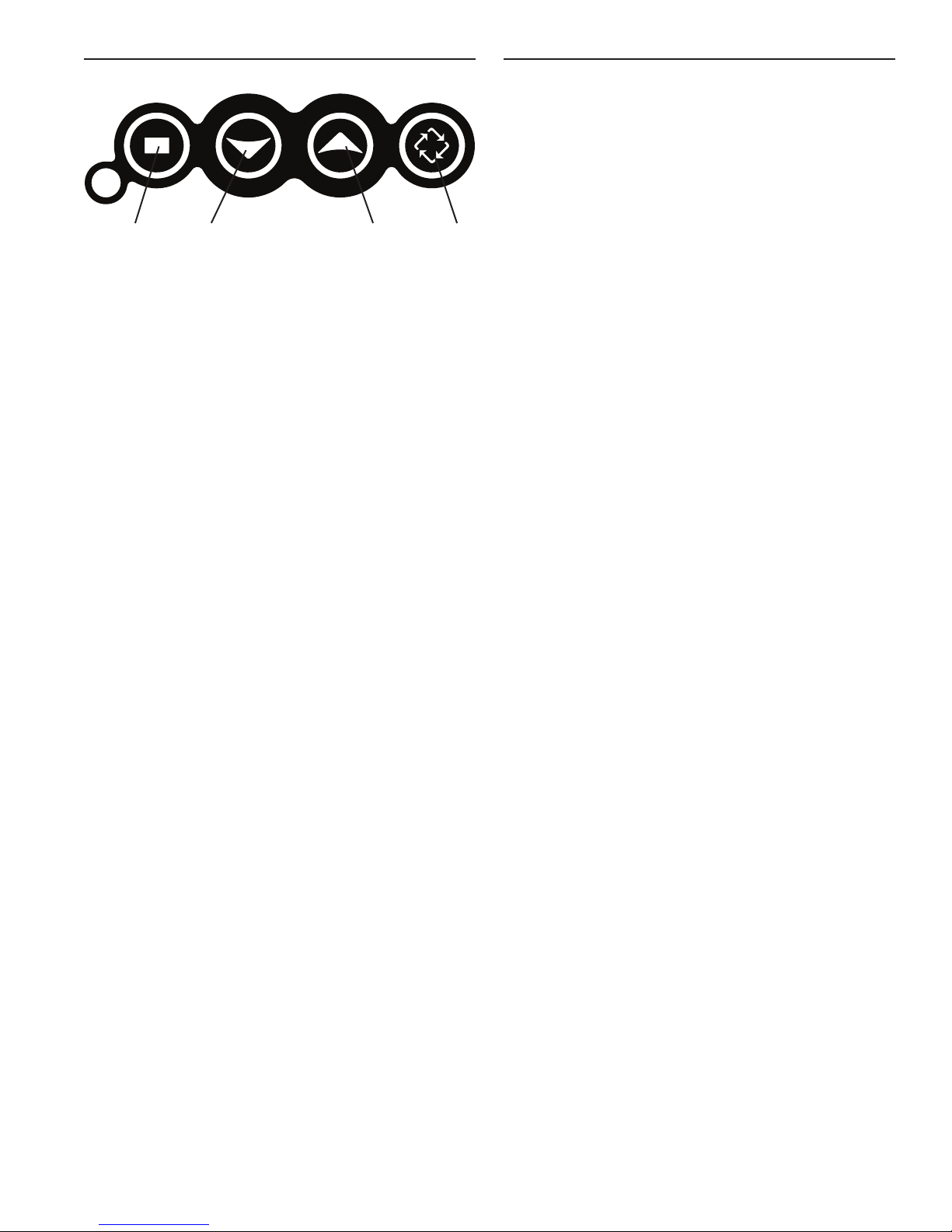

Keypad - Buttons

1 2 3 4

Figure 8

1. SET. Used to accept a setting that normally becomes stored

in memory. Also used together with the arrow buttons.

2. DOWN arrow. Generally used to scroll down or decrement

through a group of choices.

3. UP arrow. Generally used to scroll up or increment through

a group of choices.

4. REGENERATE. Used to command the controller to

regenerate. Also used to change the lock mode.

NOTE: If a button is not pushed for thirty seconds, the

controller returns to normal operation mode.

Pushing the Regenerate button immediately returns

the controller to normal operation except when

the controller is in regeneration mode or Level II

Programming mode.

After you have performed the installation steps, the conditioner

will need to be placed into operation for the first time.

NOTE: The controller will be shipped in the service (treated

water) position. Do not move the piston before

performing the following steps.

The incoming supply water should be turned off.

Power-up The Control

1. Plug the transformer into a non-switched outlet. The

display will show 9100. If this is the first time the control is

powered up the display will show "_.__".

NOTE: err3 will be displayed if the control does not detect

the valve at the home position and that the motor

is turned on. As soon as it detects the valve at the

home position, the motor will be turned off and error

will disappear. The piston will move to service if not

already in service. These movements may take up to

five minutes.

Program the Controller

2. Program the Controller for initial operation using the User

Programming Guide (See Quick Start on page 8 or Step-byStep Instructions on pages 9-10).

Remove Air From Tank 1

3. Press and hold the REGEN button for three seconds. The

controller will enter regeneration mode.

4. Press both SET and UP buttons to advance to backwash

(Cycle 2).

5. Open the incoming water supply valve slowly to the quarter

open position.

6. Allow water to run down the drain until air exits the tank.

When water flows steady from the drain, open inlet valve

fully. Allow to run until water is clear in drain.

7. Hold SET and UP buttons for three seconds to cancel

regeneration.

Remove Air From Tank 2

8. Close inlet water supply valve.

9. Press and hold the REGEN button for three seconds. The

controller will enter regeneration mode.

10. Press both SET and UP buttons to advance to backwash

(Cycle 2).

11. Repeat steps 5 and 6 above.

12. Allow the controller to finish regeneration on its own. This

will fill the brine tank.

FLECK 9100TS Upflow • 7

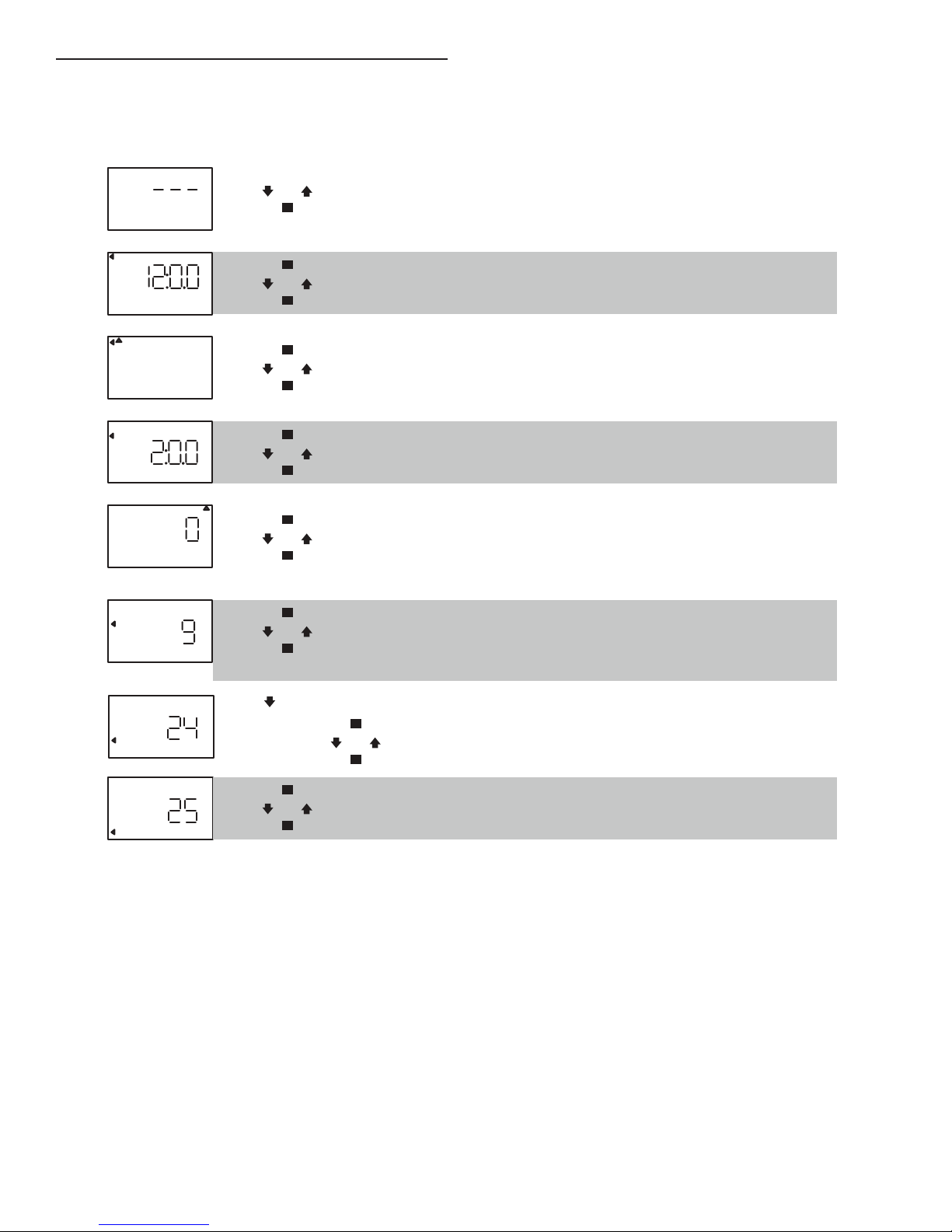

Regeneration Time

Screen Buttons to Description Range

Control programming is complete

Regeneration Time

Regeneration Time

Regeneration Time

Regeneration Time

Regeneration Time

USER PROGRAMMING

Level I Programming - 9100TS

Press

SU MO TU WE TH FR SA DAYS

Time/Day

PM

Lbs/ft

KG

then

press

press

then

press

press

then

press

press

then

press

press

then

press

press

then

3

press

press

to override

press

then

press

or

or

or

or

or

or

press

then

or

press

or

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Regeneration Time

Salt Amount

Capacity

Hardness

SU MO TU WE TH FR SA DAYS

Time/Day

Regeneration Time

Salt Amount

Capacity

Hardness

P0 Resin Volume

Select correct resin volume.

Default is 1 cubic foot/30 liters.

P1 Time of Day (12 hr)

Set to me of day.

Note: Seng includes PM indicator.

P2 Day of Week

Set to actual day of the week.

P3 Time of Regeneraon

Set to desired me of regeneraon.

P4 Days Override

Leave at 0 to disable

or

Set to desired days between

regeneraon.

Default is 0 days.

P6 Salt Dosage

Set to desired dosage

lbs per cubic feet of resin

Default is 9 lbs/ / 110 gm/l.

3

P7 Capacity

Capacity calculated by control

Use to OVERRIDE calculated capacity.

P8 Hardness

Set to actual water hardness

in grains per gallon / ppm.

Cubic Feet:

0.75 to 2.00

Liters:

20 to 60

Days: 0 (Disable)

0.5 to 30

3

Lbs/ :

3 to 15

gm/l:

50 to 200

NOTE: The regen icon may begin flashing after the control

displays err3 or after the time is reset following a

power outage. This indicates that a regeneration will

occur at the next scheduled regeneration based on

metered water usage during the error condition or

power outage.

8 • FLECK 9100TS Upflow

USER PROGRAMMING continued

Regen

Time & Da

SU MO TU WE TH FR SA DAYS

Regen

FR

Regen

SU MO TU WE TH FR SA DAYS

Regen

SU MO TU WE TH FR SA DAYS

Figure 11

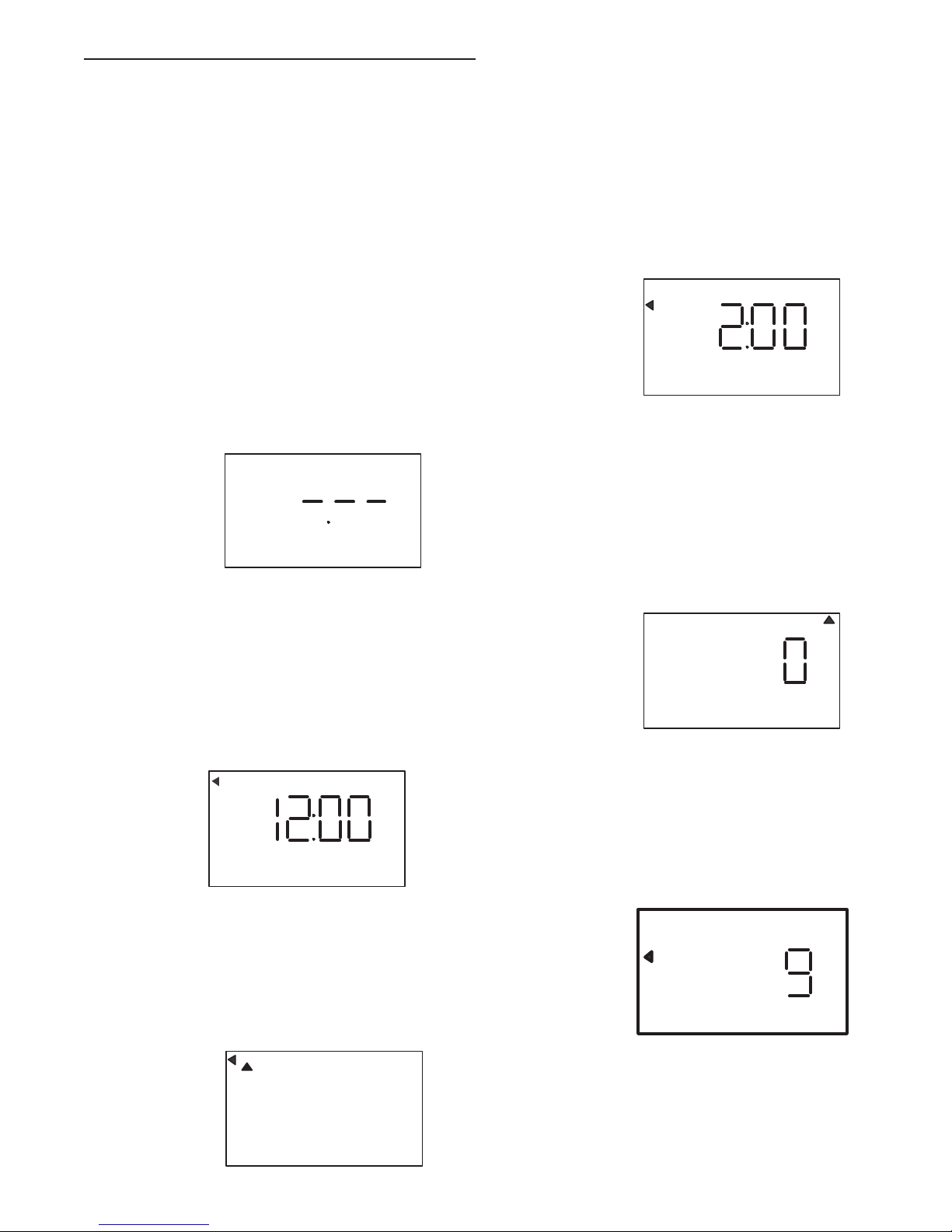

Step-by-Step Instructions

Step 1: Program System Size

This step may have been performed by your system’s OEM

manufacturer. In this case, proceed to step 2.

NOTE: Capacity is the result of the amount of media in the

tank and the salt setting. The default capacity will be

changed by selecting a different regenerant setting.

• Input system size – media volume – in cubic feet (liters).

• Use UP and DOWN buttons to scroll through resin volume

choices.

• Choose the nearest volume to your actual system size.

• Press SET to accept the system size you’ve selected.

NOTE: If the controller was incorrectly set to the wrong

size, press the DOWN button and SET button for five

seconds to display resin volume in "HO". Press and

hold the SET button for five seconds to reset the

controller. Use the UP or DOWN buttons to increment

the display to the correct resin volume. Press SET.

SU MO TU WE TH FR SA DAYS

Time & Day

Time & Day

Salt

Capacity

Hardness

Figure 9

Step 4: Set Regen Time

• 2:00 (AM) is the default time of regeneration. To accept

this time, press the DOWN button to move to step 5.

• To change the regen time, press SET – causing “2:00” to

flash.

• Use the UP and DOWN buttons to advance to the desired

regen time.

• Press SET to accept the time and advance to the next

parameter.

Time & Day

Time & Day

Salt

Capacity

Hardness

Figure 12

Step 5: Set Calendar Override

• Set number of days for calendar override.

• “0” days (disabled) is the default for calendar override.

• Days can be adjusted from ½ (.5) to 30 days.

• To change, press SET to make the “0” flash.

• Use the UP and DOWN buttons to change to the number

of days desired. Press SET to accept the regen frequency,

and advance to the next cycle.

Step 2: Program Time of Day

• While “12:00” is blinking, set the correct time of day.

• Use the UP and DOWN buttons to scroll to the correct

time of day.

• “PM” is indicated, “AM” is not indicated.

• Press SET to accept the correct time of day and advance

to the next parameter.

y

Capacity

Hardness

Figure 10

Step 3: Set Day of Week

• Press SET to make the arrow under “SU” flash.

• Use the UP and DOWN buttons to advance the arrow until

it is under the correct day of week.

• Press SET to accept and advance to the next parameter.

SU MO TU WE TH

Time & Day

Time & Day

Capacity

Hardness

Salt

SA DAYS

Time & Day

Time & Day

Salt

Capacity

Hardness

Figure 13

Step 6: Amount of Regenerant used per Regeneration

• Set desired regenerant amount.

• Default setting is 9 lbs/cubic feet (120 gm/l).

• To change salt setting, press the SET button and use the

UP and DOWN buttons to change to the desired setting.

• Press SET to accept the setting and advance to the next

parameter.

SU MO TU WE TH FR SA DAYS

Time/Day

Regeneration Time

Salt Amount

Capacity

Hardness

Lbs/ft

3

Figure 14

Step 7: Estimated Capacity

• System capacity is displayed in total kilograins or

kilograms of hardness removed before a regeneration is

necessary.

FLECK 9100TS Upflow • 9

Regen

SU MO TU WE TH FR SA DAYS

Regen

SU MO TU WE TH FR SA DAYS

USER PROGRAMMING continued

• Value is derived from the system’s resin volume input and

salt amount input.

• To override capacity on the control, press SET to make the

default capacity flash. Use the UP and DOWN buttons to

increment to the desired capacity.

• Press SET to accept the setting and advance to the next

parameter.

Time & Day

Time & Day

Salt

KG

Capacity

Hardness

Figure 15

Step 8: Enter Hardness

• Enter inlet water hardness at installation site.

• Default hardness setting is 10 grains (170 ppm).

• To change hardness, press SET to make the setting flash.

Use the UP and DOWN buttons to scroll to the desired

hardness.

• Press SET to accept the entered hardness value.

• The control will return you to the normal operation mode.

Initial programming is now complete. The control will return

to normal operation mode if a button is not pushed for 30

seconds.

Time & Day

Time & Day

Backwash Time

Figure 17

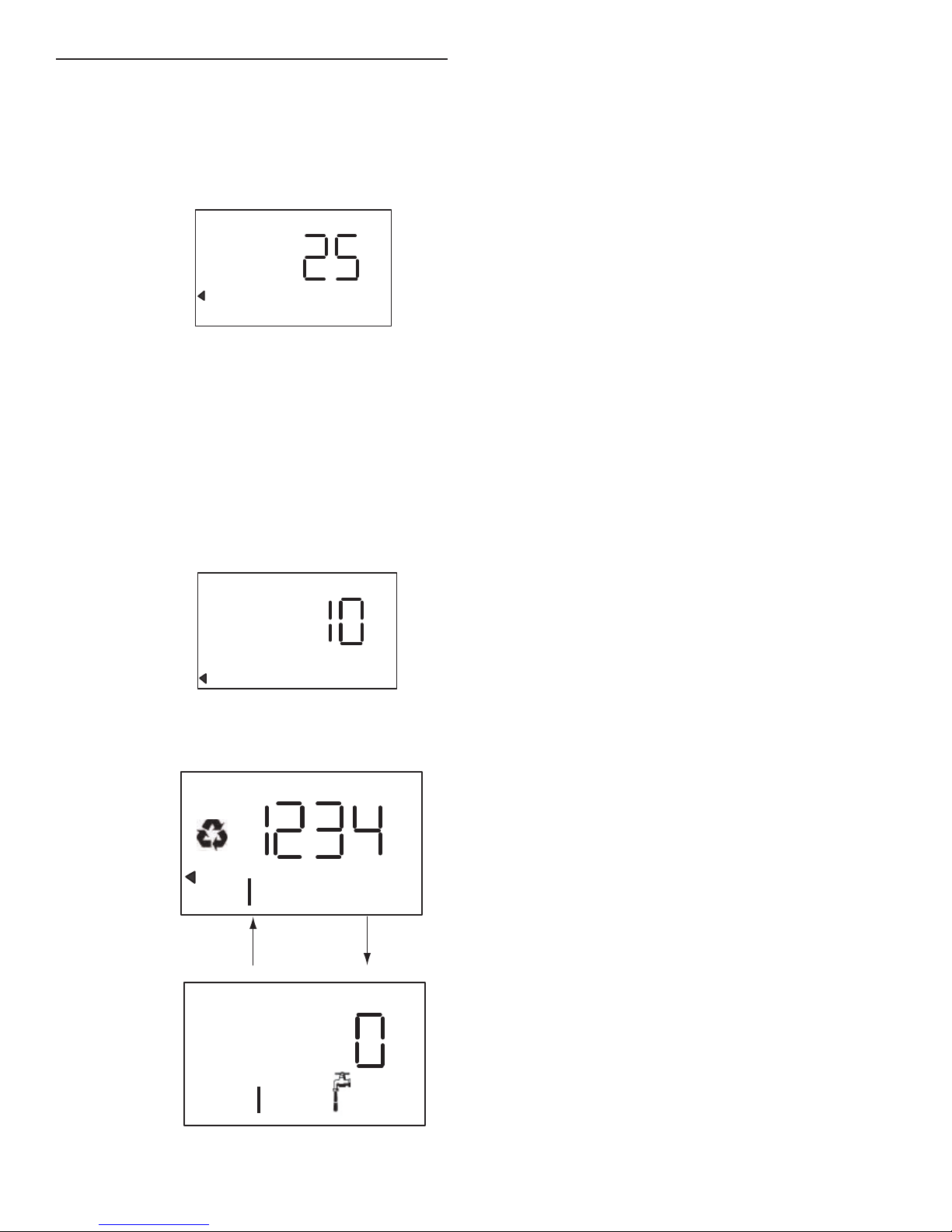

The display shows the number of the tank in service (small

digit next to CPH position). The display also alternates between

Capacity Remaining and Flow Rate (faucet icon) for the tank in

service.

NOTE: The Regen icon is steady on when in regeneration.

NOTE: The faucet icon is displayed when there is flow. The

display will show the faucet icon when the flow rate is

displayed, even if the flow rate is zero. The faucet icon

will turn off when the capacity is displayed.

Capacity

Hardness

In Service Display

Time & Day

Regen Time & Day

Salt Amount

Capacity

Hardness

Time & Day

Regen Time & Day

Salt Amount

Capacity

Hardness

Figure 16

SU MO TU WE TH FR SA DAYS

SU MO TU WE TH FR SA DAYS

10 • FLECK 9100TS Upflow

Loading...

Loading...