Fleck 6600, 6665, 6700, 6765 Service Manual

6600, 6665,

6700, 6765

6665

6700

6600 – 6665 – 6700 – 6765

6600 – 6665 – 6700 – 6765

E

N

G

L

I

S

H

EN

FR

DE

ES

NL

1 www.fleck-orderguide.com

SERVICE MANUAL ..................................... 1

MANUEL D’UTILISATION ........................ 34

BEDIENUNGSANLEITUNG ...................... 66

MANUAL DE USO .................................... 98

IT

MANUALE DI USO ................................. 130

HANDLEIDING VOOR GEBRUIK ........... 162

6600 – 6665 – 6700 – 6765

E

N

G

L

I

S

H

TABLE OF CONTENTS

1- VALVE SPECIFICATION ......................................................3

2- GENERAL ADVICE .............................................................4

3- INSTALLATION INSTRUCTIONS .......................................5

4- VALVE OPERATION ............................................................6

5- BASIC PROGRAMMING MODE ....................................... 12

6- ADVANCED PROGRAMMING MODE .............................. 14

7- TROUBLESHOOTING ...................................................... 32

8- POWER HEAD 6600 / 6665 ........................................194

9- POWER HEAD 6700 / 6765 ........................................195

10- VALVE BODY ..................................................................196

11- METER & ACCESSORIES .............................................197

12- DIMENSIONS ................................................................ 198

13- WIRING DIAGRAM .........................................................199

2 www.fleck-orderguide.com

6600 – 6665 – 6700 – 6765

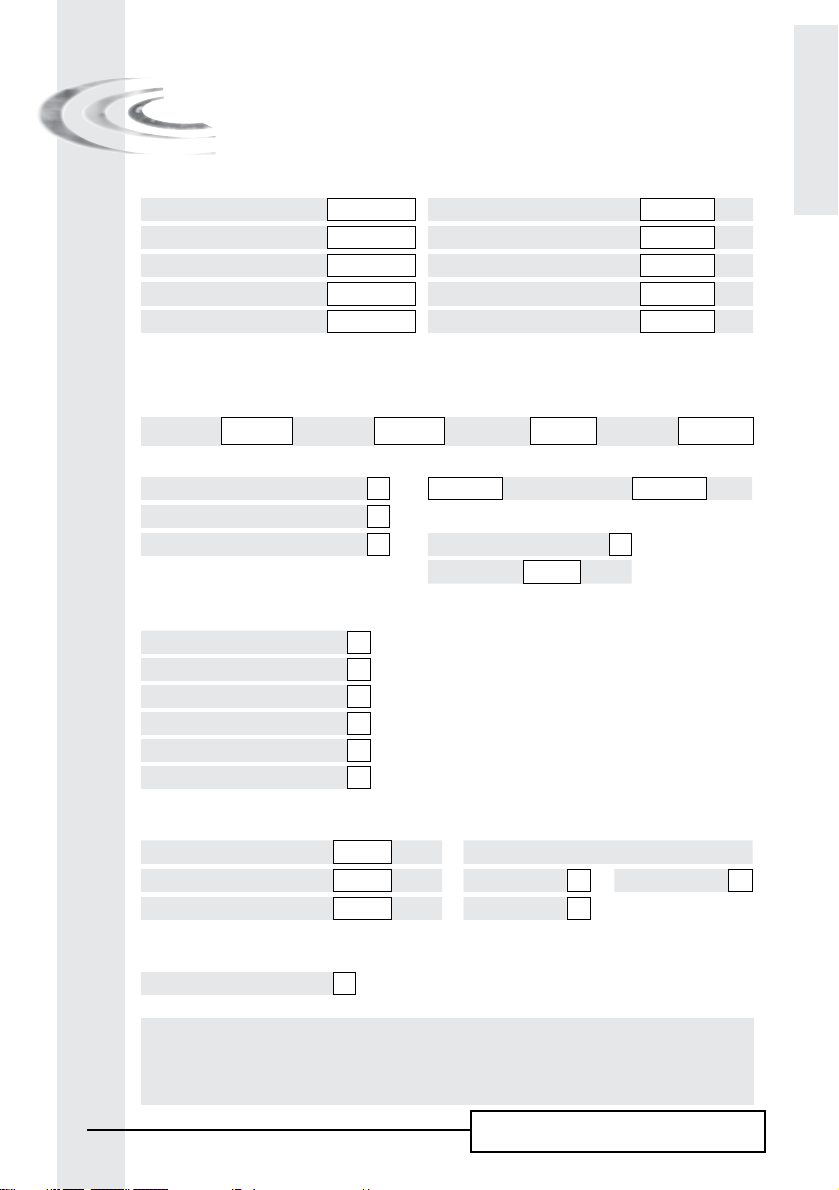

1 - VALVE SPECIFICATION

Installation N° System capacity

Valve serial N°

Tank size

Resin type

Resin volume

Inlet water hardness

Water hardness after mixing valve

Brine tank size

Quantity of salt per regeneration

VALVE TECHNICAL CHARACTERISTICS

VALVE TYPE

6600/1600 6665/1600 6700/1600 6765/1600

TRIGGERING SET REGENERATION

Meter immediate Days

Meter delayed

Timeclock 2 A.M.

REGENERATION TIME

or

a.m./p.m.

REGENERATION CYCLES ACCORDING TO PISTON TYPE

Cycle 1

Cycle 2

Cycle 3

Cycle 4

Cycle 5 (6 cycles valve only)

Cycle 6 (6 cycles valve only)

m

3

°tH

°tH

°tH

litres

Litre

E

N

G

L

I

S

H

Kg

HYDRAULIC SETTINGS

Injector size Pressure regulator

Drain line flow control (DLFC)

Brine line flow control (BLFC) GPM Without

VOLTAGE

24V/50- 60Hz with transformer

Valves complying european regulations:

- Nr. 2004/108/CE, “Electromagnetic compatibility”

- Nr. 2006/95/CE, “Low voltage”

- Nr. D.M. 174/04, Italian regulation

3

GPM 1,4 bar (20 PSI) 2,1 bar (30 PSI)

6600 – 6665 – 6700 – 6765

E

N

G

L

I

S

H

2.1 MANUFACTURER

2 - GENERAL ADVICE

IT IS STRICTLY FORBIDDEN FOR NOT QUALIFIED PERSONAL, TO ACCEDE TO SYSTEM’S INTERNAL PARTS TO

PERFORM ANY KIND OF TECHNICAL ACTION.

Pentair Manufacturing Italy Srl

Via Masaccio, 13

56010 Lugnano di Vicopisano (PI) – Italy

2.2 WARNINGS

The manufacturer will not be held liable for any damages to people or properties resulting from an improper use of

the device not compliant with the following instructions.

Whenever this guide doesn’t clarify all doubts about installation, service or maintenance, please contact the technical

support of the company that has installed the device.

Device installation must be done by a qualified technician according to the current standards and regulations, using

tools compliant with a device safety use and referring to that technician also for device maintenance.

In case of out of order or malfunction, before performing any kind of action on the device, please ensure to have

disconnected the transformer from the power source, to shut off inlet water supply to the valve and to drain water

pressure opening a tap down-line of the valve.

2.3 INTENDED USE

The device is intended for residential, commercial or light industry environment (ref. EN 50081-1) use only and it is

purpose-built for treatment and softening of water coming from supply network.

2.4 TECHNICAL DATA

Transformer: 230Vac, 50/60Hz, 15VA, Class II.

Controller: 24Vac, 50/60Hz, 5W, Class III.

The device must only be used with the transformer provided in order to guarantee safety voltage supply.

2.5 WATER PRESSION

A minimum of 1,4 bar of water pressure is required for the regeneration valve to operate effectively. Do not exceed

8,5 bar; if you face this case, you should install a pressure regulator upstream the system.

2.6 ELECTRICAL CONNECTION

An uninterrupted current supply is required. Please make sure that your voltage supply is compatible with your unit

before installation. If the electrical cable is damaged, it must imperatively be replaced by a qualified personal.

2.7 ExISTING PLUMBING

Existing plumbing should be in a good shape and free from limescale. In doubt, it is preferable to replace it. The installation of a pre filter is always advised.

2.8 BY-PASS

Always provide a by pass valve for the installation, if the unit is not equipped with one.

2.9 WATER TEMPERATURES

Water temperature is not to exceed 43°C, and the unit cannot be subjected to freezing conditions.

2.10 DISINFECTION OF WATER CONDITIONERS

The materials of construction of the modern water conditioner will not support bacterial growth, nor will these

materials contaminate a water supply. In addition, during normal use, a conditioner may become fouled with organic

matter, or in some cases with bacteria from the water supply. This may result in an off-taste or odor in the water.

Thus, your conditioner may need to be disinfected after installation. Some conditioners will require periodic disinfection during their normal life. Consult your installing dealer for more information on disinfecting your conditioner.

2.11 ENVIRONMENTAL CONDITIONS

• Indoor Use Only

• Altitude up to 2000m

• Temperature from 5°C to 40°C

• Maximum relative humidity 80% for temperatures up to 31°C decreasing linearly to 50% relative humidity at 40°C

• Mains supply voltage fluctuations up to ±10% of the nominal voltage

4

6600 – 6665 – 6700 – 6765

3 - INSTALLATION INSTRUCTIONS

3.1 Install the softener pressure vessel(s) in a chosen place on a flat firm surface.

3.2 During cold weather, it is recommended to bring the valve back to room temperature before operating.

3.3 All plumbing for water inlet, distribution and drain lines should be done correctly in accordance with legislation

in force at the time of installation. Install without tension or bending stresses.

3.4 The distribution tube should be cut flush with the top of the tank. Slightly bevel the ridge in order to avoid

deterioration of the seal whilst fitting the valve.

3.5 Lubricate the distribution tube joint and the joint with a 100% Silicon lubricant. Never use other types of

greases that may damage the valve.

3.6 All soldering on main plumbing and to the drain line should be done before fitting the valve. Failing to do so can

generate irreversible damages.

3.7 Use Teflon ® tape if necessary in order to seal between the drain fitting and the outlet flow control.

3.8 On units with by-pass, place in by-pass position. Turn on the main water supply. Open a cold water tap nearby

and let run a few minutes or until the system is free from foreign material (usually solder) that may have

resulted from the installation. Once clean, close the water tap.

3.9 Place the by-pass in service position and let water flow into the mineral tank. When water flow stops, slowly

open a cold water tap nearby and let run until the air is purged from the unit.

3.10 Plug the valve to a power source. Check that the valve is in service position

3.11 Fill approximately 25mm of water above the grid plate, (if used). Otherwise, fill to the top of the air check in

the brine tank. Do not add salt to the brine tank at this time.

3.12 Initiate a manual regeneration, bring the valve into « brine draw and slow rinse position » in order to draw

water from the brine tank until the blockage of the air check; the water level will be approximately in the middle

of the air check.

3.13 Open a cold water tap and let the water run in order to drain the air out of the circuit.

3.14 Bring the valve in brine refill position and let it get back to service position automatically.

3.15 Now you can add salt to the brine tank, the valve will operate automatically.

E

N

G

L

I

S

H

5

6600 – 6665 – 6700 – 6765

E

N

G

L

4 - VALVE OPERATION

I

S

H

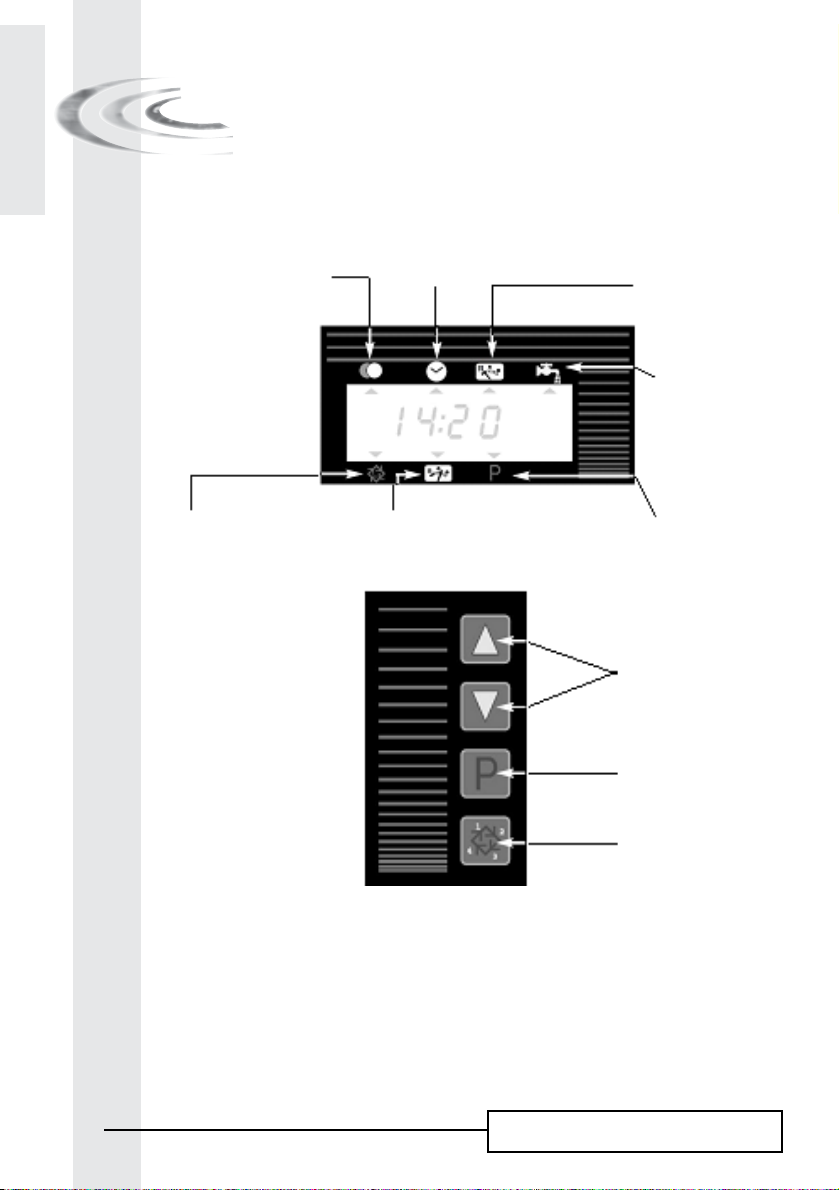

4.1 VALVE 6600 PRESENTATION

Service Indicator

Valve in service : arrow on Regeneration

tonight : flashing arrow

Regeneration indicator:

Arrow on

Time of day display indicator time

of day display: arrow on

Volume remaining

display indicator : Arrow on

Reserve indicator :

Volume remaining at or below the

reserve: flashing arrow

Flow indicator :

Arrow flashes with water

flow

Program display indicator :

Arrow on

Up and Down set button

Program button

Extra cycle button

6

6600 – 6665 – 6700 – 6765

4 - VALVE OPERATION

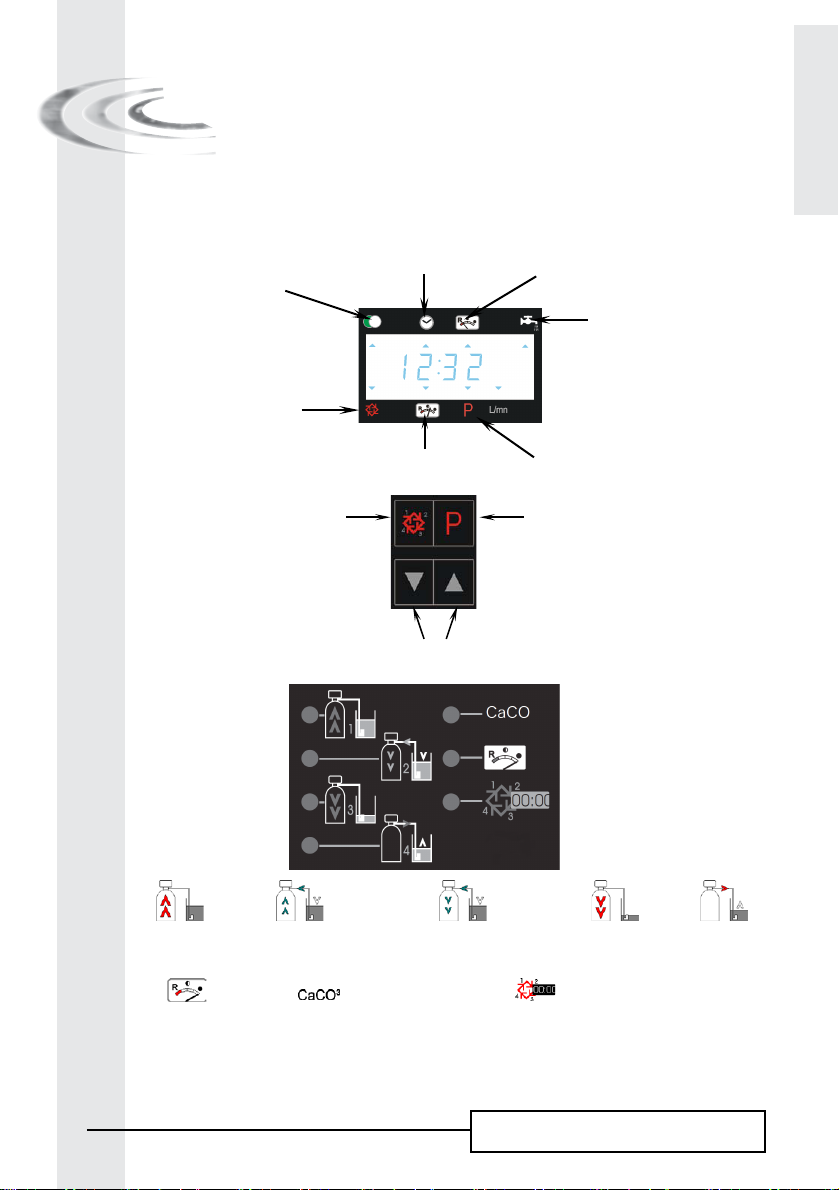

4.2 VALVE 6700 PRESENTATION

E

N

G

L

I

S

H

Service Indicator:

Valve in service : arrow on

Regeneration tonight: flashing arrow

Regeneration indicator: Arrow on

Extra cycle button

Time of day display indicator

Time of day display: arrow on

Volume remaining display indicator:

Arrow on

Up and Down set

button

Reserve indicator

Volume remaining at or below the reserve : flashing

arrow

Flow indicator

Arrow flashes with water flow

Program display indicator: Arrow on

Program button

Backwash

Valve capacity

Brine draw/slow rinse

Up flow

Hardness Regeneration time

Brine draw/slow rinse

Down Flow

Rapid rinse Brine refill

Note: during programming and during regeneration, the red led next to the appropriate symbol turns on

7

6600 – 6665 – 6700 – 6765

E

N

G

L

4 - VALVE OPERATION

I

S

H

4.3 BUTTON FUNCTION

4.3.1 ExTRA CYCLE BUTTON

Pressing this button will initiate a manual regeneration.

1. With timeclock or meter delayed regeneration, an extra regeneration will occur at the set regeneration time.

Press this button for 5 seconds, a regeneration will force to occur immediately.

2. With meter immediate regeneration, an extra regeneration will occur immediately.

4.3.2 PROGRAM BUTTON:

This button is used by the installer during the valve programming. It is used to enter the programming modes,

and to go from one setting to the next one.

4.3.3 SET BUTTON: AND

This button is used to set the current time of day, adjust the parameter value during the valve programming and

the time remaining in a regeneration cycle.

8

6600 – 6665 – 6700 – 6765

4 - VALVE OPERATION

4.4 OPERATION DURING SERVICE

E

N

G

L

I

S

H

4.4.1 METERED VALVE

In service the time of day alternates being viewed with the volume remaining. The water flow through the

unit is indicated by the meter arrow

counts down with the consumption of treated water.

(1)

under the pictogram

4.4.1A METER DELAYED REGENERATION

When the volume remaining reaches the reserve capacity (calculated by the electronics), the reserve arrow

flashes as an indication. The regeneration will initiate at the pre-set regeneration time.

When the reserve capacity is exhausted, the display will show a succession of dash and the regeneration will

initiate at the pre-set regeneration time.

(2)

under the pictogram

(1)

that flashes in a direct relationship to flow rate. The volume remaining

(2)

4.4.1B METER IMMEDIATE REGENERATION

When the volume remaining reaches zero, the regeneration starts immediately.

4.4.1C 6 CYCLES MODE (SPECIAL MODE USED FOR “WATERFALL

SYSTEMS DVGW”)

This valve is in immediate and upflow regeneration,with chlorination and “pause-vacancy” position. The

particularity of the “pause-vacancy” position :

•Whenthereisnotaflowratedetectedfor4daysrunning:

- the valve initiates a regeneration and returns in service

•Whenthereisnotstillaflowratedetectedfornext4daysrunning:

- the valve initiates a regeneration and stops at the “pause-vacancy” position

- the valve will end the regeneration and return in service only when there will be a flow rate

detected.

4.4.1D VARIABLE BRINING MODE (ONLY METER DELAYED UP

FLOW)

The valve will determine that a regeneration is required when the volume remaining drops to the reserve

capacity. The regeneration will begin immediately at the set regeneration time. The volume of the brine

depends on the volume of the softened water consummate; therefore the time of the brine refill is calculated

by the electronic.

9

6600 – 6665 – 6700 – 6765

E

N

G

L

4 - VALVE OPERATION

I

S

H

4.4.2 TIMECLOCK VALVE

In service, the time of day is viewed all the time. The valve operates normally until the pre-set number of days

since the last regeneration is reached. Once this occurs, regeneration will start immediately at the pre-set

regeneration time.

4.4.3 VALVE WITH REGENERATION DAY OVERRIDE

When the valve has reached its set days since regeneration override value, the regeneration will initiate

immediately or delayed at the pre-set regeneration time regardless of the volume remaining.

10

6600 – 6665 – 6700 – 6765

4 - VALVE OPERATION

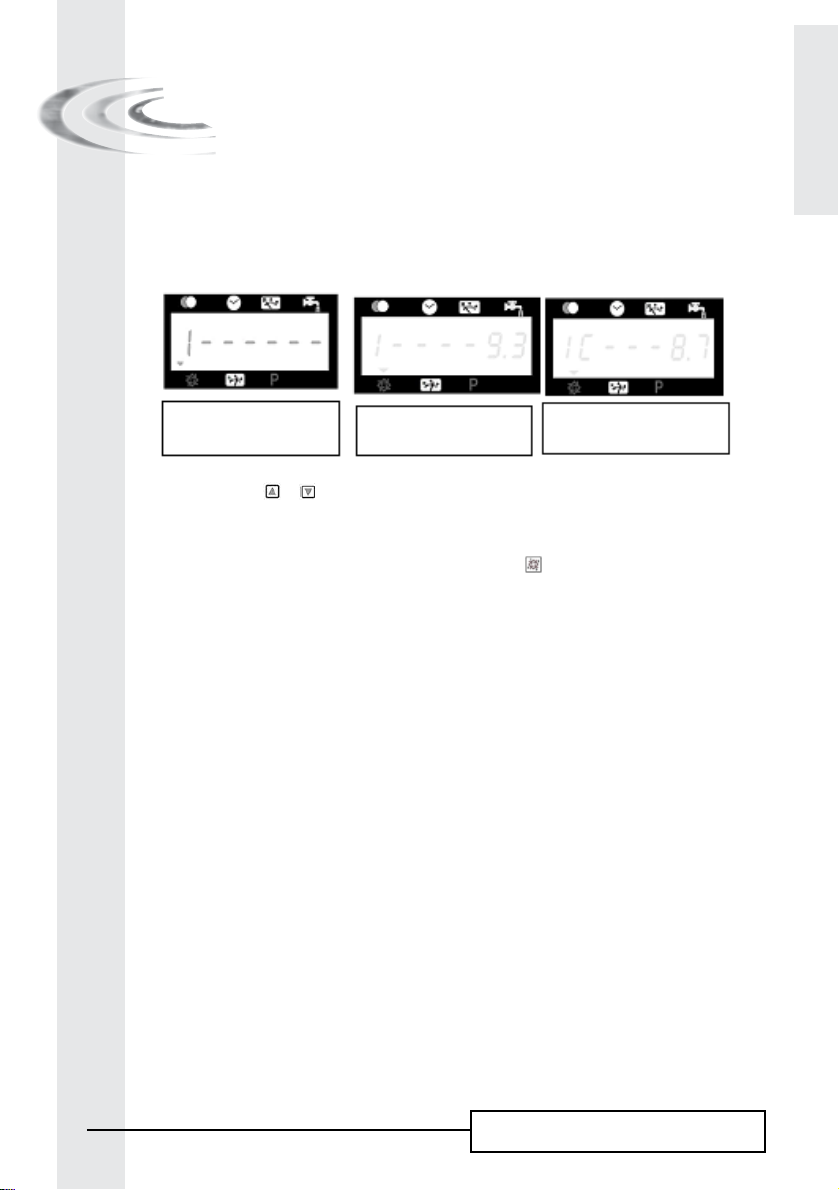

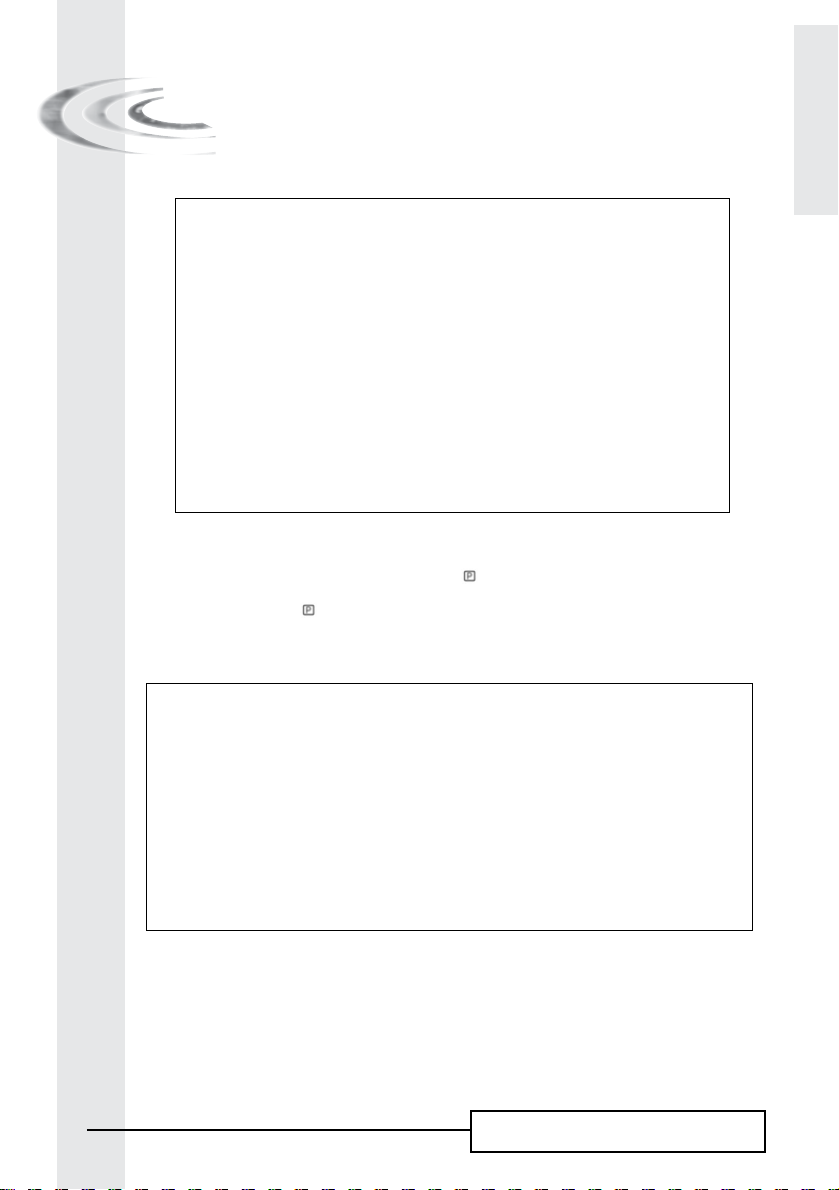

4.5 OPERATION DURING REGENERATION

In regeneration, the valve displays what regeneration cycle has been reached and the time remaining in that

cycle. The time remaining is in minutes and tenth of minutes. Once the cycle time reaches zero, the valve

drives to the next cycle.

E

N

G

L

I

S

H

The valve is advancing to

cycle 1, number 1 is flashing

Pressing the button or during regeneration cycle will adjust the remaining time. The regeneration cycle

programming will not be changed.

The valve is in cycle 1, 9,3 min

remaining in that cycle

For valves with chlorinator,the letter C

indicates its functioning

4.6 ADVANCE TO THE NExT REGENERATION CYCLE

To advance to the next regeneration cycle position, push the button . This action won’t have any effect if

the valve is advancing to the next cycle.

4.7 OPERATION DURING A POWER FAILURE

During a power failure all displays turn off and the regeneration cycles are delayed. The electronics continues

to operate normally until the line power is restored or until the capacitors stored energy is empty.

1. I If the capacitor isn’t fully discharged during the power failure, the electronics continues to operate

normally without the loss of data until the line power is restored.

2. If the capacitor is discharged during the power failure, the electronics stores the current time of day, the

remaining, the regeneration cycle status and the various diagnostic displays. To indicate this type of failure,

the time of day will flash to inform that this display and the volume remaining may be incorrect.

11

6600 – 6665 – 6700 – 6765

E

N

G

L

I

5 - BASIC PROGRAMMING MODE

6600 / 6665

S

H

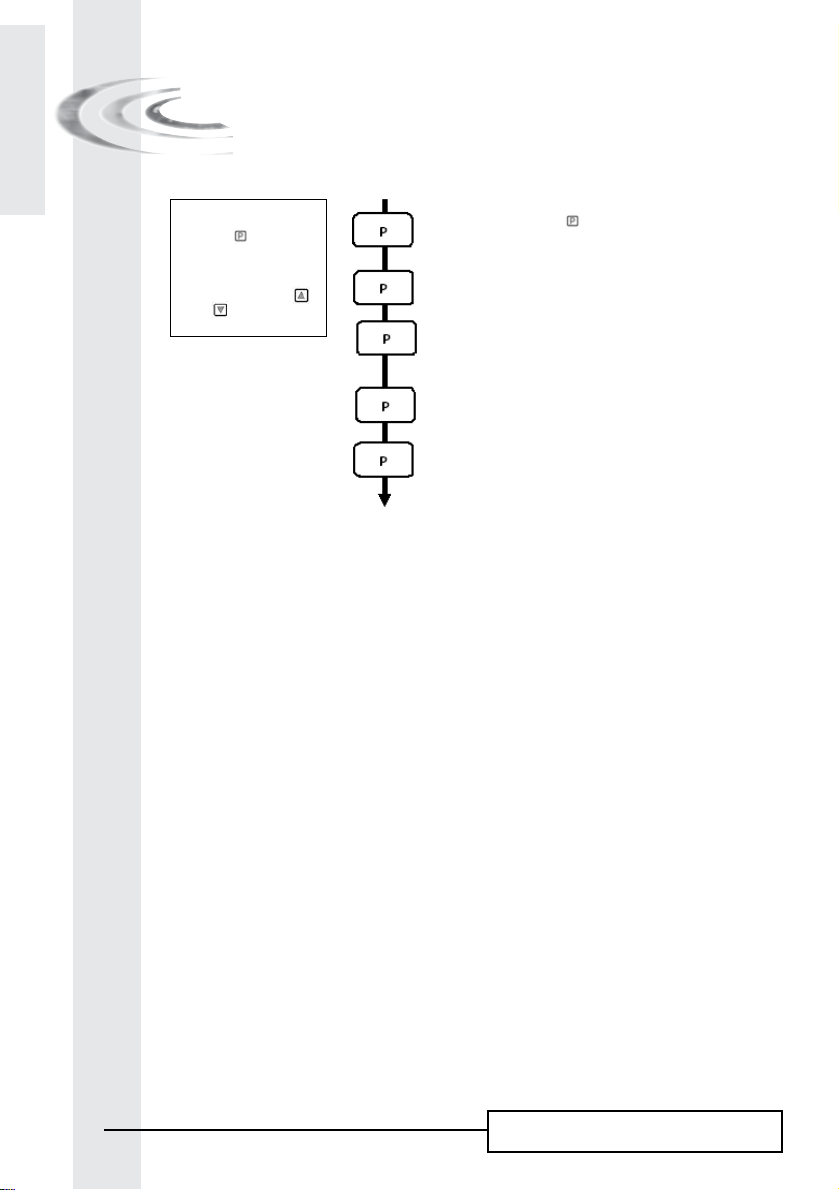

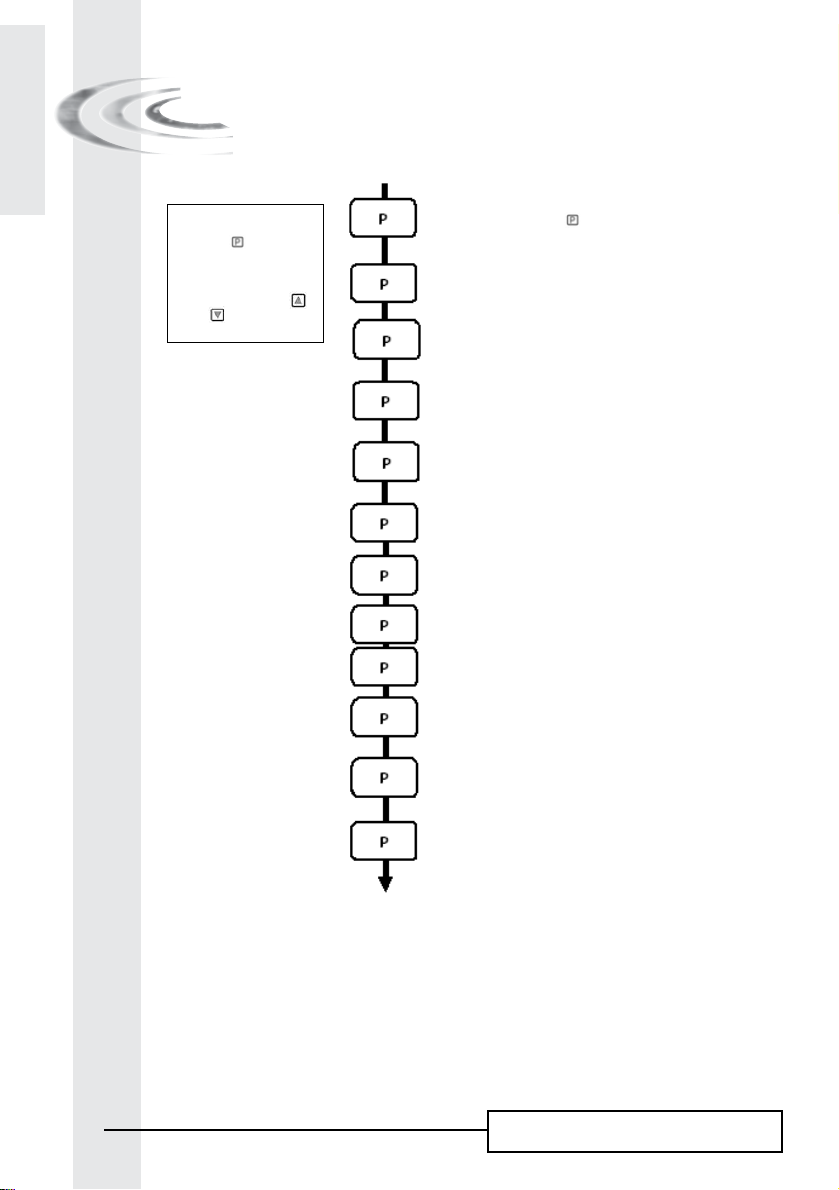

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

The valve is in service position. To enter in the basic programming

mode, push and hold the button for 5 seconds.

5.1. Water Hardness in °tH

Not viewed in timeclock regeneration mode

Ex.: 30 °tH [H - - - -30]

5.2. Water Hardness after mixing valve in °tH

Not viewed in timeclock regeneration mode

Ex.: 6 °tH [P - - - -6]

5.3. Regeneration time

Not viewed in immediate regeneration mode

Ex.: 02:00 [- - 2:00 -]

Basic programming mode exit.

The valve returns in normal operation.

12

6600 – 6665 – 6700 – 6765

5 - BASIC PROGRAMMING MODE

6600 / 6665

This level includes the functioning parameters of the softener related to the site conditions.

E

N

G

L

I

S

H

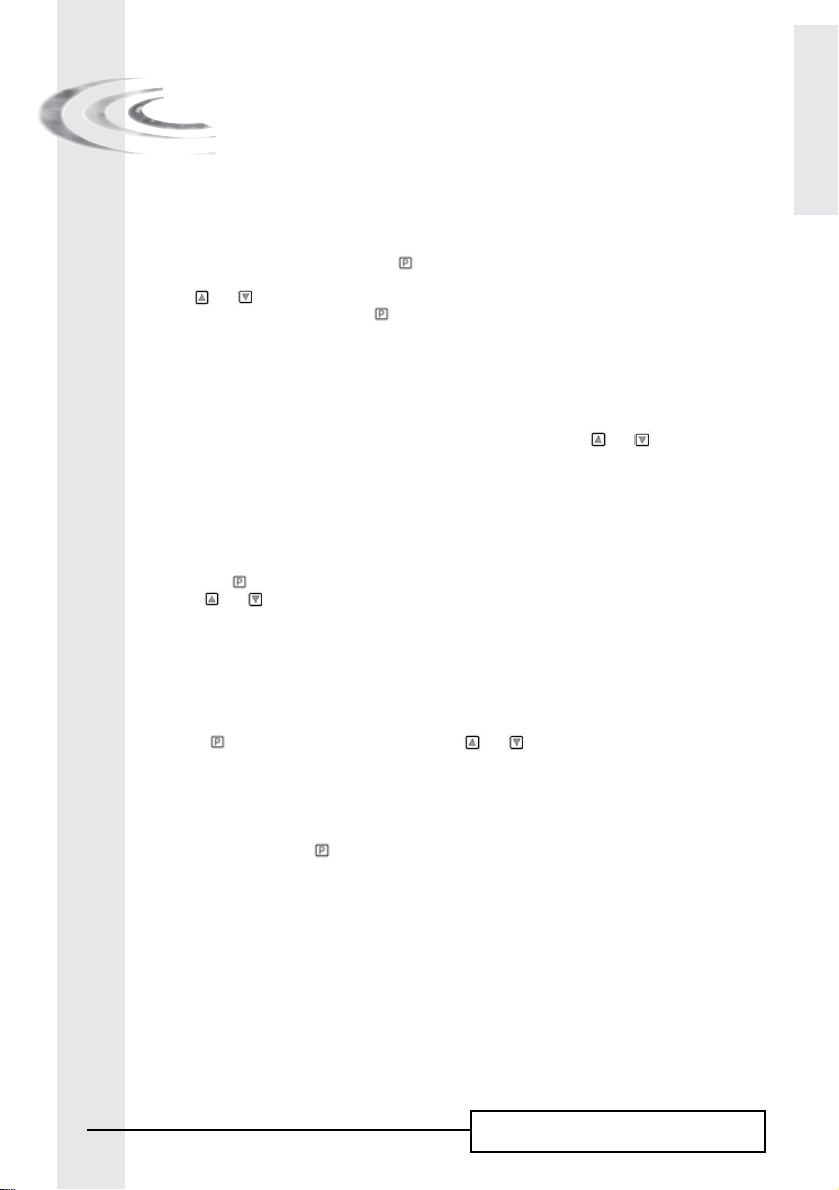

ENTERING BASIC PROGRAMMING MODE

A- The valve is in service position. Press the button for 5 seconds. The program arrow turns on and the

first display viewed is used to set the inlet water hardness.

B- The

and set buttons are used to set the parameter values of different displays.

C- Passing to the next display, push the

Note: depending on the current programming, certain displays will not be viewed or set.

button.

5.1 WATER HARDNESS

Not viewed in timeclock regeneration mode or when the volume override is activated.

The unit of measure used for the parameter is °tH(1). Adjust the value with the and set buttons.

Ex.: Hardness 30 °tH

(1)

[H - - - - 30]

5.2 WATER HARDNESS AFTER THE MIxING VALVE (P)

Not viewed in timeclock regeneration mode, with the volume override activated, or in US format, or if 8 set

(2)

on 1

.

Press button. The letter “P” identifies this parameter. The unit of measure is the °tH(1). Adjust the value

with the

Ex.: Hardness after the mixing valve 6 °tH

and set buttons.

(1)

: [P - - - - 6]

5.3 REGENERATION TIME

Not viewed in meter immediate regeneration mode.

Press the button. Set the regeneration time with the and set buttons.

Ex.: Regeneration at 2:00 A.M. [--2:00--]

ExITING BASIC PROGRAMMING MODE

Press once again the button. the electronics returns in service.

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format -see point 6.17.

(2) See point 6.24

13

6600 – 6665 – 6700 – 6765

E

N

G

L

I

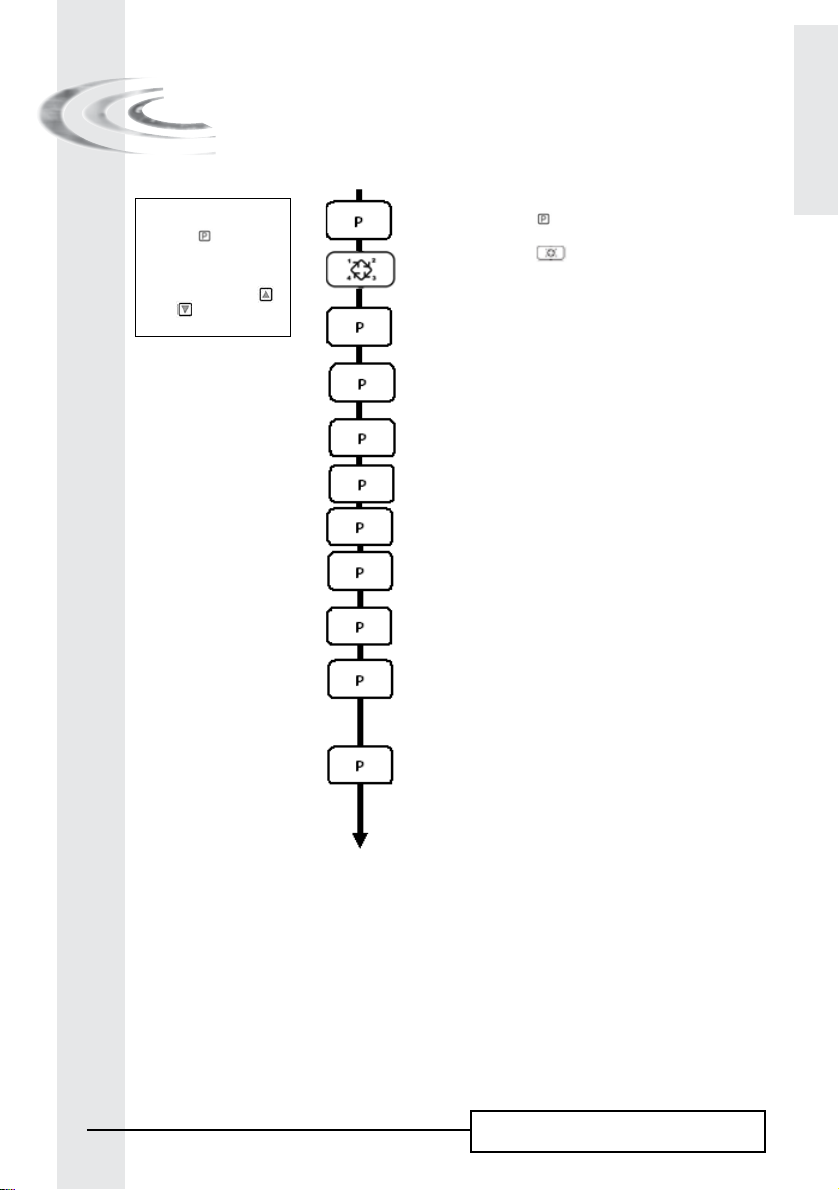

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

S

H

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

The valve is in service position set at 12:01. To enter in the complete

level, push and hold the button for 5 seconds.

The board will show first all parameters of the basic programming

mode, and then following settings:

6.1. Flow rate (Fr) in l/min

Ex.: 8,6 l/mn not adjustable [Fr - - 8.6]

6.2. Days since the last regeneration (d)

Ex.: 2 days not adjustable [d - - - - 2]

6.3. Prior service volume used in litre (1)

Ex.: 3483 l not adjustable [E - -3483]

6.4. Reserve capacity (rc) in litre (1)

Ex.: 852 l not adjustable [rc - - 852]

6.5. Previous days water usage (Pd) in litre (1)

Ex.: 284 l not adjustable [Pd - -28.4]

6.6. System capacity in m3 °tH (c)

Ex.: 100 m3 °tH [C- - - 100]

6.7. Cycle #1 :

Ex.: 6 minutes [1 - - - 6.0]

6.8. Cycle #2 : [2 - - 60.0]

Ex.: 60 minutes

6.9. Cycle #3 : [3 - - 10.0]

Ex.: 10 minutes

6.10. Cycle #4 : [4 - - 12.0]

Ex.: 12 minutes

6.11. Cycle #5 [5 - -OFF]

Only for 6 cycles mode

6.12. Cycle #6 [6 - -OFF]

Only for 6 cycles mode

Note : not viewed if cycle #5 is set on OFF.

(1)

(1)

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

14

6600 – 6665 – 6700 – 6765

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

6.13. Chlorine cell activation (J)

Ex.: - Chlorination activated during the cycle 1 [J - - - - -1]

- No chlorination [J- - -OFF]

6.14 Chlorine cell power on duration

Ex: 20 mn [Jd- - - 20]

6.15. Regeneration day override (A)

Ex.: - Override every 7 days [A - - - - 7]

- Cancel setting [A - -OFF]

Note: in timeclock regeneration, never

cancel this setting.

E

N

G

L

I

S

H

6.16. Volume override (b) in litre

Ex.: - Regenerate every 2000 l [b- - 2000]

6.17. Display format (U)

Ex.: - Litre format [U - - - - - 2]

- Cubic meter format [U - - - - - 4]

6.18. Valve Type (o)

Ex.: Valve 6600/6665/6665 6 cycles [o - - - - - 1]

6.19. Regeneration type (7)

Ex.: - Timeclock [7 - - - - - 1]

- Meter immediate [7 - - - - - 2]

- Meter delayed [7 - - - - - 3]

- Variable Brining [7 - - - - - 4]

- 6 cycles [7 - - - - - 7]

6.20. Volume of resin

(only available with variable brining mode)

Ex. : 15 litres [7r - - - 15.0]

6.21. Salt setting

(only available with variable brining mode)

Ex.: 120 g of salt/litre of resine [7d - - 120]

(1)

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

15

6600 – 6665 – 6700 – 6765

E

N

G

L

I

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

S

H

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

6.22. BLFC size (only available with variable brining mode)

See the label on the injector housing [7b - -X.XX]

6.23. Flow meter size (F)

Ex.: Standard 3/4” [F - - - - - 1]

6.24. Mixing valve location (8)

Ex.: - No mixing valve [8 - - - - - 1]

- Mixing valve before flow meter [8 - - - - - 2]

- Mixing valve after flow meter [8 - - - - - 3]

6.25. System type (9)

Ex.: - System type #4 : single electronic [9 - - - - - 4]

6.26. Program lockout (Pl)

Ex.: - Cancel lockout [Pl - - - OFF]

- Lockout active [Pl - - - - ON]

Advanced programming mode exit.

The valve returns in normal operation

16

6600 – 6665 – 6700 – 6765

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

Setting up the valve during manufacturing of the softener requires access to the advanced programming.

This level includes the functioning parameters of the softener related to actual system configuration.

E

N

G

L

I

S

H

ENTERING ADVANCED PROGRAMMING MODE

A- Set valve at 12:01, press the button for 5 seconds. The program arrow turns on and the first display

viewed is used to set the inlet water hardness. Then press the

B- The

and set buttons are used to set the parameter values of different displays.

C- Passing to the next display, push the

Note: depending on the current programming, certain displays will not be viewed or set.

button.

button for 5 seconds.

6.1 FLOW RATE (Fr) (1):

Not viewed in timeclock regeneration mode.

Press the button .This display is identified by the letters “Fr”. This first display is the current flow rate of

treated water. The unit of measure used depends on the display format chosen

Ex.: 8,6 l/min [Fr - - - 8.6]

.

(1)

6.2 DAYS SINCE THE LAST REGENERATION (d):

Press the button .This parameter is identified by the letter “d”. This display shows the number of days

recorded since the last regeneration. This display is used as an aid in the valve maintenance and is not an

option setting.

Ex.: 2 days [d - - - - - 2]

6.3 PRIOR SERVICE VOLUME USED (E):

Not viewed in timeclock regeneration mode.

Press the button . This display is identified by the letter “E”. This display shows the amount of water

used since the last regeneration. This display is used as an aid in the valve maintenance and is not an option

setting.

The unit of measure used depends on the display format chosen(1).

Ex.: 58,6 m

3 (1)

[E - - - 58.6]

6.4 RESERVE CAPACITY (rc):

Not viewed in timeclock or immediate regeneration mode.

Press the button . This parameter is identified by the letters “rc”. This display shows the reserve capacity

calculated by the electronic for the present day. This display is used as an aid in the valve maintenance and is

not an option setting. The unit of measure used depends on the display format chosen

Ex.: 24,6 m

3(1)

[rc - - 24.6]

.

(1)

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

17

6600 – 6665 – 6700 – 6765

E

N

G

L

I

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

S

H

6.5 PREVIOUS DAYS WATER USAGE (Pd):

Not viewed in timeclock regeneration mode.

Press the button. This display is identified by the letters “Pd”. This display shows the previous days water

usage recorded. This display is used as an aid in the valve maintenance and is not an option setting. The unit of

measure used depends on the display format chosen

Ex.: 28,4 m3(1) [Pd - - 28.4]

.

(1)

6.6 SYSTEM CAPACITY

Press the button . The unit of measure used depends on the display format chosen

set the capacity of the softener. If required, the electronics will calculate a reserve. Adjust the value with the

and set buttons.

Ex.: Capacity 1200 m3° tH

(1)

: [- - - -1200]

. This display is used to

(1)

6.7 REGENERATION CYCLE PROGRAMMING

to

The cycle 6 will not be viewed if the cycle 5 is cancelled [5 --- O F F ].

6.12 Press the button . The next displays are part of a series of option settings used to program the regeneration

cycles. Up to 6 cycles can be programmed. Each display is used to set the duration time (in minute) of that

cycle in the regeneration.

The first display in the series is regeneration cycle 1, example: Backwash

Ex.: - Cycle 1 (Backwash): 8 minutes [1 - - - 8.0]

- Cycle 4 (Brine refill): 8.4 minutes (8 min and 24 s.) [4 - - - 8.4]

6.13 CHLORINE CELL ACTIVATION (J):

Press the button . This display is identified by the letter “J”. This display is used to activate the chlorine

function during cycle 1.

Ex.: - No chlorinator installed [J- - - OFF]

- Chlorinator to turn on during the cycle 1 [J- - - - - -1]

6.14 CHLORINE CELL POWER DURATION

Press the button . This display is identified by the letter “dJ”. This display is used to set the chlorine cell

power on duration.

Note: During a regeneration with the chlorine cell set, for example cycle 2, the regeneration display

will show: [2C - - 38.2]

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

18

6600 – 6665 – 6700 – 6765

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

6.15 REGENERATION DAY OVERRIDE (A)

In timeclock regeneration mode, a value must be set.

Press the button .This parameter is identified by the letter “A”. This option is used to set the regeneration

day override option setting. This override setting determines the maximum amount of time (in days) the

softener can be in service without a regeneration, regardless of the volume of water used or the lack of a

sensor signal. The regeneration begins at the set regeneration time.

Ex.: - Override every 7 days [A - - - - - 7]

- Option cancelled [A - - - OFF]

E

N

G

L

I

S

H

6.16 VOLUME OVERRIDE (b)

Not viewed in time clock regeneration mode.

Press the button . This display is identified by the letter “b”. The volume override option is used to set the

maximum amount of water that can be used before a regeneration cycle is called for.

This option is typically used to bypass standard reserve or capacity calculations made by the electronics.

When this feature is used with meter delayed regeneration systems, it will be up to the installer to determine

a reserve capacity and subtract it from the calculated full capacity. The unit of measure depends on the

display format chosen

Ex.: Override every 2.6 m3(1) [b - - 2600]

(1)

.

6.17 DISPLAY FORMAT (U)

Press the button . This display is identified by the letter “U”. One of five following display

formats can be used. The current format used is the cubic meter (U4): the volume is in cubic

3

meter (m

), the flow rate in litre per minute (l/min), 24 hours timekeeping format, water hardness in French

degrees or °tH degrees and the sys-tem capacity in °tH degrees cubic meter (°tH x m

The format used for small volume is the litre (U2): the volume is in litre (l), the flow rate in litre per minute (l/

min), 24 hours timekeeping format, water hardness in French degrees or °Th degrees and the system capacity

in °tH degrees cubic meter (°tH x m

Ex.: - US format (not used) [U - - - - - 1]

- Litre format [U - - - - - 2]

- Standard metric (not used) [U - - - - - 3]

- Cubic meter format [U - - - - - 4]

Note: for further information, please contact our technical support.

3

).

6.18 VALVE TYPE (o)

Press the button. This parameter is identified by the letter “o”. This display is used to set the type of

valve used. The only possible settings are #1 and #2 for 6600 and 6700 valve family.

Ex.: - 6600 / 6665 [o - - - - - 1]

- 6700 / 6765 [o - - - - - 2]

3

).

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

19

6600 – 6665 – 6700 – 6765

E

N

G

L

I

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

S

H

6.19 REGENERATION TYPE (7)

Press the button . This display is identified by the number “7”. This option is used to set the regeneration

type. There are several possible option settings:

- Timeclock: the electronics determines that regeneration is required when the set regeneration time has been

reached. The regeneration day override setting (see point 2.10) determines the number of days between two

regenerations.

[7 - - - - - 1]

- Meter immediate: the electronics determines that a regeneration is required when the available volume of

softened water drops to zero. The regeneration begins immediately. [7 - - - - - 2]

- Meter delayed: the electronics determines that a regeneration is required when the available volume of

softened water drops to the reserve capacity. The regeneration begins immediately at the set regeneration

time only when the service flow has not been detected. With service flow, the regeneration will be delayed

in two 10 minute sections. After then if there is always a flow, the regeneration begins immediately. There

will be not a delay if the reserve capacity is zero. [7 - - - - - 3]

- Meter delayed variable brining: Only available for UF valve.

The electronics displays and initiates regeneration as in meter delayed mode. In variable brining mode the first

cycle is brine refill, and second one is vacancy. All other cycles follow standard order. Electronic calculates first

cycle duration considering previous water usage and uses setting 7r, 7d & 7b. [7 - - - - - 4]

- Meter Immediate with vacation mode (6 cycles mode): only available for UF valve.

The electronics displays and initiates regeneration as in meter immediate mode. However the electronics

requires a day override setting. However a day override setting is required and cycles sequence is different. The

regeneration cycles are following: brine draw, vacancy, slow rinse, backwash, rapid rinse, brine refill. The valve

will stay in vacancy if there hasn’t been any consumption between the 2 last regenerations. The electronics will

switch to the next cycle if flow usage is detected. [7 - - - - - 7]

Note: for the following options, please contact our technical support.

- Sensor immediate regeneration [7 - - - - - 5]

- Sensor delayed regeneration [7 - - - - - 6]

6.20 VOLUME OF RESIN (7r)

Press the button. This display is available only with variable brining mode. This display is identified by “7r”.

This parameter is used to set volume of resine. [7r - - 15.0]

6.21 SALT SETTING (7d)

Press the button. This display is available only with variable brining mode. This display is identified by

“7d”. This parameter is used to set salt ratio. [7d - - 120]

6.22 BLFC SIIZE (7b)

Press the button. This display is available only with variable brining mode. This display is identified by

“7b”. This parameter is used to set the BLFC size. [7b - - 0.25]

20

6600 – 6665 – 6700 – 6765

6 - ADVANCED PROGRAMMING MODE

6600 / 6665

6.23 FLOW METER SIZE (F)

Not viewed in timeclock regeneration mode.

Press the button. This parameter is identified by the letter “F”. This option is used to set the flow meter size.

Seven settings are possible. The only possible setting is #1 for 6600/6700 valve family:

Standard 3/4” [F - - - - - 1]

E

N

G

L

I

S

H

6.24 MIxING VALVE LOCATION (8)

Not viewed in timeclock regeneration mode.

Press the button. This display is identified by the number “8”. This option is used to indicate where the

mixing valve is located. Three settings are possible:

No mixing valve [8 - - - - - 1]

Mixing valve before flow meter [8 - - - - - 2]

Mixing valve after flow meter [8 - - - - - 3]

6.25 SYSTEM TYPE (9)

With 6600/6700 valve family, the only possible setting is 4. [9 - - - - - 4]

6.26 PROGRAM LOCKOUT (PL)

Press the button. This display is identified by the letters “Pl”. This display is used to prevent certain

programming displays from being viewed or set. Two settings are available:

Protection cancelled [Pl - - - OFF]

Protection active [Pl - - - - On]

The program lockout can be cancelled by pressing the button

ATTENTION: press the button for 25 seconds when the program lockout is not activated will erase

all previous display setting; the electronic will reset to default values. The electronic programming

will have to be completely redone.

for 25 seconds.

ExITING THE ADVANCED PROGRAMMING MODE

Press again the button, the electronic comes back in service.

Note: for further information, please contact our technical support.

21

6600 – 6665 – 6700 – 6765

E

N

G

L

I

7 - BASIC PROGRAMMING MODE

6700 / 6765

S

H

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

The valve is in service position. To enter in the basic programming

mode, push and hold the button for 5 seconds.

7.1. Water Hardness in °tH

Not viewed in timeclock regeneration mode

Ex.: 30 °tH [H - - - -30]

7.2. Water Hardness after mixing valve in °tH

Not viewed in timeclock regeneration mode

Ex.: 8 °tH [P - - - -8]

7.3. System capacity in m3 °tH

Not viewed in timeclock regeneration mode

Ex.: 60 m3 °tH [- - - -60]

7.4. Regeneration time

Not viewed in immediate regeneration mode

Ex.: 2:00 AM [ - -2:00 -]

Regeneration cycle time setting

7.5. Cycle #1

Ex.: 10 minutes [1 - - 10.0]

7.6. Cycle #2

Ex.: 60 minutes [1 - - 60.0]

7.7. Cycle #3

Ex.: 10 minutes [1 - - 10.0]

7.8. Cycle #4

Ex.: 12 minutes [1 - - 12.0]

7.9. Cycle #5

Only for 6 cycles mode

Ex.: Not used [5 - - OFF]

7.10. Cycle #6

Only for 6 cycles mode

Ex.: Not used [6 - - OFF]

Note: not viewed if cycle #5 is set on OFF]

22

Basic programming mode exit.

The valve returns in normal operation.

6600 – 6665 – 6700 – 6765

7 - BASIC PROGRAMMING MODE

6700 / 6765

This level includes the functioning parameters of the softener related to the site conditions.

E

N

G

L

I

S

H

ENTERING BASIC PROGRAMMING MODE

A- The valve is in service position. Press the button for 5 seconds. The program arrow turns on and the first

display viewed is used to set the inlet water hardness.

B- The

and set buttons are used to set the parameter values of different displays.

C- Passing to the next display, push the

Note: depending on the current programming, certain displays will not be viewed or set.

button.

7.1 WATER HARDNESS

Not viewed in timeclock regeneration mode or when the volume override is activated.

The unit of measure used for the parameter is °tH

Ex.: Hardness 30 °tH(1) [H - - - - 30]

(1)

. Adjust the value with the and set buttons.

7.2 WATER HARDNESS AFTER THE MIxING VALVE (P)

Not viewed in timeclock regeneration mode, with the volume override activated, or in US format, or if 8 set

(2)

on 1

.

Press button. The letter “P” identifies this parameter. The unit of measure is the °tH(1). Adjust the value

with the

Ex.: Hardness after the mixing valve 6 °tH(

and set buttons.

1)

: [P - - - - 6]

7.3 SYSTEM CAPACITY

Press the button . The red led next to the symbol turns on. The unit of measure used depends on the

display format chosen(1). This display is used to set the capacity of the softener. If required, the electronics

will calculate a reserve. Adjust the value with the

Ex.: Capacity 1200 m3° tH

(1)

: [- - - -1200]

and set buttons.

7.4 REGENERATION TIME

Not viewed in meter immediate regeneration mode.

Press the button. Set the regeneration time with the and set buttons.

Ex.: Regeneration at 2:00 A.M. [--2:00--]

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

23

6600 – 6665 – 6700 – 6765

E

N

G

L

I

S

H

7.5 REGENERATION CYCLE PROGRAMMING

7 - BASIC PROGRAMMING MODE

6700 / 6765

to

The cycle 6 will not be viewed if the cycle 5 is cancelled [5 --- O F F ]

7.10 Press the button . The next displays are part of a series of option settings used to program the regeneration

cycles. Up to 6 cycles can be programmed. A led identifies only the 4 first cycles. Each display is used to set

the duration time (in minute) of each regeneration cycle.

The first display in the series is regeneration cycle 1, example: Backwash

Ex.: - Cycle 1 (Backwash): 8 minutes [1 - - - 8.0]

- Cycle 4 (Brine refill): 8.4 minutes (8 min and 24 s.) [4 - - - 8.4]

ExITING BASIC PROGRAMMING MODE

Press once again the button. the electronics returns in service.

24

6600 – 6665 – 6700 – 6765

8 - ADVANCED PROGRAMMING MODE

6700 / 6765

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

The valve is in service position. To enter in the advanced programming

mode, push and hold the button for 5 seconds.

Then depress the button

You are in the advanced programming mode.

8.1. Flow rate (Fr) in l/min

Not viewed in timeclock regeneration mode

Ex.: 8,6 l/min not adjustable [Fr - - 8.6]

8.2. Days since the last regeneration (d)

Not viewed in timeclock regeneration mode

Ex.: 2 days not adjustable [d - - - - 2]

8.3. Prior service volume used in litre

Ex.: 3483 l not adjustable [E - -3483]

8.4. Reserve capacity (rc) in litre

Ex.: 852 l not adjustable [rc - - 852]

8.5. Previous days water usage (Pd) in litre

Ex.: 284 l not adjustable [Pd - -284]

8.6. Chlorine cell activation (J)

Ex.: - Chlorinating activated during the cycle 1 [J - - 1]

- No chloration [J - - OFF]

8.7. Chlorine cell power on duration

Ex.: 20 mn [Jd- - - 20]

8.8. Regeneration day override (A)

Ex.: - Override every 7 days [A - - - - 7]

- Cancelled setting [A - -OFF]

Note: in timeclock regeneration, never

cancel this setting.

8.9. Volume override (b) in litre

Ex.: Regenerate every 5000 litres [b- - 5000]

Note: if b is set, water hardness and system capacity are not viewed.

for 5 seconds.

(1)

(1)

(1)

(1)

E

N

G

L

I

S

H

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17).

25

6600 – 6665 – 6700 – 6765

E

N

G

L

I

8 - ADVANCED PROGRAMMING MODE

6700 / 6765

S

H

Note :

1. Push the button once

per display.

2. Option settings may be

changed by pushing the

and set buttons

8.10. Display format (U)

Ex.: - US format (gallon) [U - - - - 1]

- Litre format [U - - - - 2]

- Standard metric [U - - - - 3]

- Cubic meter format [U - - - - 4]

Note: if this parameter is changed, the programming comes

immediately back to the level 1 and directly followed by the level 2.

8.11. Valve type (o)

Ex.: 6700 [o - - - - 2]

8.12. Regeneration type (7)

Ex.: - Timeclock [7 - - - - 1]

- Meter immediate [7 - - - - 2]

- Meter delayed [7 - - - - 3]

- 6 cycles mode [7 - - - - 7]

8.13. Flow meter size (F)

Ex.: - Standard 3/8’’ [F - - - - 0]

- Standard 3/4’’ [F - - - - 1]

8.14 Mixing valve location (8)

Ex.: - No mixing valve [8 - - - - 1]

- Mixing valve before flow meter [8 - - - - 2]

- Mixing valve after flow meter [8 - - - - 3]

8.15. System type (9)

Ex.: System #4-One alone electronic [9 - - - - 4]

8.16. Program lockout (PL)

Ex.: - Cancelled lockout [PL- -OFF]

- Lockout active [PL - - On]

Advanced programming mode exit.

The valve returns in normal operation

26

6600 – 6665 – 6700 – 6765

8 - ADVANCED PROGRAMMING MODE

6700 / 6765

Settings and displays can be viewed

or reset with active lockout

In service:

- Time of day

- Volume remaining

In programming level 1

- Water hardness

- Water hardness after mixing valve (P)

- Regeneration time

In programming level 2

- Flow rate (Fr)

- Days since the last regeneration (d)

- Prior service volume used (E)

- Reserve capacity (rc)

- Previous days water usage (Pd)

No possibility to view the other parameters if lockout is activated

The program lockout can be cancelled by depressing the button for 25 seconds.

CAUTION: depressing the button for 25 seconds when the program lockout is not activated will erase all

previous display settings; the electronic will reset to default values. The electronic programming will have to

be completely redone.

E

N

G

L

I

S

H

27

Installer note:

1. Reserve capacity calculation: in meter delayed regeneration mode, the electronic

automatically calculates its reserve capacity based on daily water usage.

2. System capacity and water hardness will not be viewed or set when timeclock regeneration is programmed; when

volume override is set the system capacity will not be viewed.

3. The regeneration time will not be viewed or set with the metered immediate regeneration mode.

4. Voltage range for reliable operation of the electronic:

Voltage: 24V +/- 10% Frequency: 50 Hz (or 60 Hz without transformer)

6600 – 6665 – 6700 – 6765

E

N

G

L

I

8 - ADVANCED PROGRAMMING MODE

6700 / 6765

S

H

Setting up the valve during manufacturing of the softener requires access to the advanced programming.

This level includes the functioning parameters of the softener related to actual system configuration.

ENTERING ADVANCED PROGRAMMING MODE

A- Set valve at 12:01, press the button for 5 seconds. The program arrow turns on and the first display

viewed is used to set the inlet water hardness.

B- The

and set buttons are used to set the parameter values of different displays.

C- Passing to the next display, push the

Note: depending on the current programming, certain displays will not be viewed or set.

8.1 FLOW RATE (Fr)

Not viewed in timeclock regeneration mode.

Press the button .This display is identified by the letters “Fr”. This first display is the current flow rate of

treated water. The unit of measure used depends on the display format chosen

Ex.: 8,6 l/min [Fr - - - 8.6]

(1)

:

button.

.

(1)

8.2 DAYS SINCE THE LAST REGENERATION (d):

Press the button .This parameter is identified by the letter “d”. This display shows the number of days

recorded since the last regeneration. This display is used as an aid in the valve maintenance and is not an option

setting.

Ex.: 2 Tage [d - - - - - 2]

8.3 PRIOR SERVICE VOLUME USED (E):

Not viewed in timeclock regeneration mode.

Press the button. This display is identified by the letter “E”. This display shows the amount of water used

since the last regeneration. This display is used as an aid in the valve maintenance and is not an option setting.

The unit of measure used depends on the display format chosen(1).

Ex.: 58,6 m

3 (1)

[E - - - 58.6]

8.4 RESERVE CAPACITY (rc):

Not viewed in timeclock or immediate regeneration mode.

Press the button. This parameter is identified by the letters “rc”. This display shows the reserve capacity

calculated by the electronic for the present day. This display is used as an aid in the valve maintenance and is

not an option setting. The unit of measure used depends on the display format chosen

Ex.: 24,6 m3

(1)

[rc - - 24.6]

(1).

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17)

28

6600 – 6665 – 6700 – 6765

8 - ADVANCED PROGRAMMING MODE

6700 / 6765

8.5 PREVIOUS DAYS WATER USAGE (Pd):

Not viewed in timeclock regeneration mode.

Press the button . This display is identified by the letters “Pd”. This display shows the previous days

water usage recorded. This display is used as an aid in the valve maintenance and is not an option setting.

The unit of measure used depends on the display format chosen

Ex.: 28,4 m

(1)

[Pd - - 28.4]

3

(1)

.

E

N

G

L

I

S

H

8.6 CHLORINE CELL ACTIVATION (J):

Press the button. This display is identified by the letter “J”. This display is used to activate the chlorine

function during cycle 1.

Ex.: - No chlorinator installed [J- - - OFF]

- Chlorinator to turn on during the cycle 1 [J- - - - - -1]

8.7 CHLORINE CELL POWER DURATION

Press the button. This display is identified by the letter “dJ”. This display is used to set

Chlorine cell power on duration.

Note: During a regeneration with the chlorine cell set, for example cycle 2, the regeneration display

will show: [2C - - 38.2]

8.8 REGENERATION DAY OVERRIDE (A)

In timeclock regeneration mode, a value must be set.

Press the button.This parameter is identified by the letter “A”. This option is used to set the regeneration

day override option setting. This override setting determines the maximum amount of time (in days) the

softener can be in service without a regeneration, regardless of the volume of water used or the lack of a

sensor signal. The regeneration begins at the set regeneration time.

Ex.: - Override every 7 days [A - - - - - 7]

- Option cancelled [A - - - OFF]

8.9 VOLUME OVERRIDE (b)

Not viewed in timeclock regeneration mode.

Press the button . This display is identified by the letter “b”. The volume override option is used to set the

maximum amount of water that can be used before a regeneration cycle is called for.

This option is typically used to bypass standard reserve or capacity calculations made by the electronics.

When this feature is used with meter delayed regeneration systems, it will be up to the installer to determine

a reserve capacity and subtract it from the calculated full capacity. The unit of measure depends on the

display format chosen(1).

Ex.: Override every 2.6 m

3 (1)

[b - - 2600]

(1) The unit of measure depends on the display format chosen.

All examples above are based on the cubic meter format (see point 6.17)

29

6600 – 6665 – 6700 – 6765

Loading...

Loading...