Page 1

RESOPHONIC AND NATIONAL® BISCUIT

INSTALLATION GUIDE

www.fishman.com

Read Me First!

Installation of this product is a simple procedure,

but we recommend this job only if you are an

experienced repair technician.

Requirements

The Resophonic guitar pickup is suitable for

installation on most single cone resonator guitars

with biscuit or spider cones.

The National® Style Resophonic guitar pickup is

suitable for single cone National® brand biscuit

bridge assemblies only.

Installation

Observe the following

precaution!

• Handle the pickup carefully! Mishandling

may damage the pickup, producing ground

hum or intermittent signal.

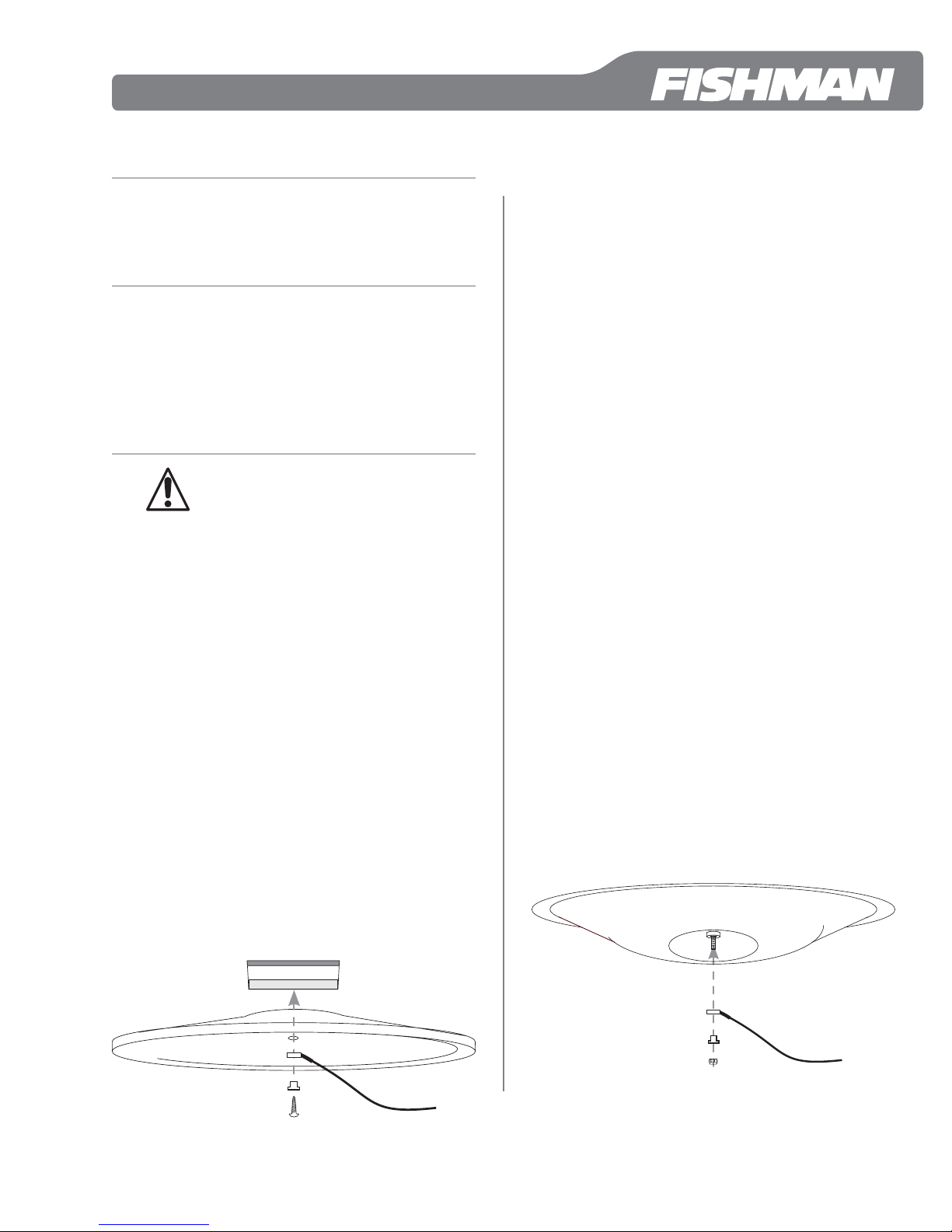

Resophonic pickup installation

Installation for biscuit style instruments

The pickup is held against the center of the cone

with the wood screw that normally holds the biscuit

to the cone.

1. Remove the original screw from the biscuit and

swap it with the longer wood screw that is supplied

with the kit.

2. Notice that the heat-shrink tubing on the end of

the pickup is bent to one side. Do not attempt to

unbend it! If you do so you may damage the pickup.

Position the pickup so the bend in the heat-shrink

tubing faces away from the cone.

3. Place the shoulder washer into the pickup and the

screw into the shoulder washer.

4. Fasten the pickup assembly to the cone / biscuit.

Tighten the screw until snug and then another 1⁄8

turn tighter.

Biscuit Bridge

Installation for spider style instruments

For the pickup to operate properly it is critical that

the spider and cone are preloaded with the correct

pressure.

1. Remove the strings and the plate that protects the

cone assembly. Calibrate the spider / cone pressure

by loosening the screw that holds the cone to the

spider until the screw head no longer touches the

spider frame. Tighten the screw until the head just

touches the spider and then tighten one full turn

more. The spider/cone is now preloaded for

optimum bass response without buzzes or rattles.

2. If the end of the screw is long enough to accept

the pickup and locknut, go on to the next step. If it

is not long enough you will need to replace it with a

longer screw and go back to step 1. We include

replacements for both SAE 4-40 and 3mm screws

plus matching locknuts in the hardware kit. Choose

the screw that matches the threaded slug in the

center of the cone assembly.

3. Notice that the heat-shrink tubing on the end of

the pickup is bent to one side. Do not attempt to

unbend it! If you do so you may damage the pickup.

Position the pickup so the bend in the heat-shrink

tubing faces away from the cone.

4. Place the pickup, then the shoulder washer on the

screw and start to thread the locknut. You must hold

the head of the screw stationary (with the screwdriver) as you tighten the locknut or you will change

the crucial preloaded pressure on the spider and

cone. If the screw accidentally turns as you tighten

the locknut, then you must go back to step #1 and

re-calibrate the cone and spider.

5. Tighten the nut until it is snug against the pickup

and then 1⁄8 turn tighter.

6. When the installation is completed, plug the instrument into an amplifi er and slowly turn the screw

counter-clockwise until you hear the strongest signal.

Cone

Machine

Screw

Pickup

Shoulder Washer

Screw

Cone

Pickup

Shoulder Washer

Locknut

1

Page 2

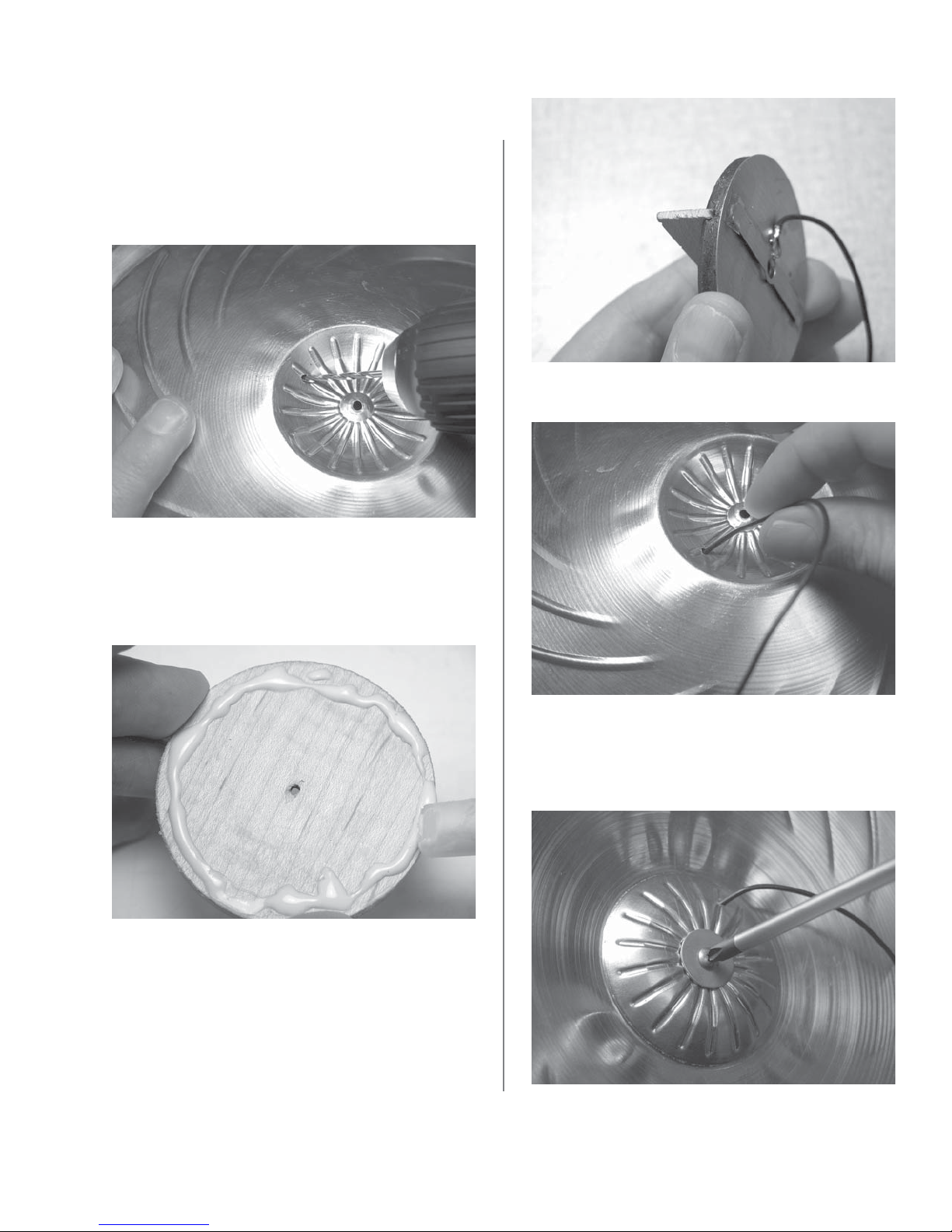

National® Style Resophonic pickup

installation

1. Remove the strings and the cover plate. Unscrew

the biscuit from the cone.

2. Drill a .094” (2.4mm) hole in the cupped side of

the cone, about 3⁄8” (9.5mm) below the rim. Remove

any burrs from the hole.

3. Examine the bottom surface of the biscuit with a

straightedge. If the biscuit is warped sand it fl at.

4. Clean off any dust or debris from the bottom of

the biscuit and apply a thin bead of woodworking

glue around the edge.

7. Thread the pickup wire through the hole you

drilled earlier.

5. Line up the ends of the saddle with the notches in

the brass disc, on the side of the disc opposite the

pickup element.

6. Affi x the biscuit to the disc and wipe off any

excess glue. Double-check the alignment between

the notches in the disc and the ends of the saddle.

Clamp for several minutes.

8. Fasten the biscuit/pickup assembly to the cone.

Tighten this screw just enough to prevent the biscuit

assembly from freely rotating on top of the cone. Do

not over tighten the screw or you may short out the

pickup!

9. Remove the barrel from the jack and thread the

pickup wire through it.

2

Page 3

Wiring Options

Passive pickup

Solder the center wire to the Tip terminal and

the shield wire to the Sleeve terminal. Fasten the

shielding cap to the jack.

Pickup Signal

to Tip

Shield to

Sleeve

Active pickup

Thread the pickup wire through the strain relief hole

at the end of the circuit board. Solder the signal wire

to the “IN” pad and the shield wire to the “G” pad.

Be careful not to burn the solder pads! If the pads

are overheated, they may lift off the circuit board.

Fasten the shielding cap to the jack.

Pickup Shield

to Ground (“G”)

G

+

PJ FISHMAN

REV. 2.3

IN

-

Pickup Signal

to “IN”

R

Jack Installation

Where to locate jack

Metal body instrument

For a metal instrument with a stick that runs the

length of the body into the tailblock, we recommend

that you place the jack on the treble side lower bout.

Use a center punch at the chosen location and use

a sharp

use a drill press and clamp the instrument securely

to prevent the drill from wandering or distorting the

shape of the hole.

3

⁄8” (9.5mm) brad-point drill. For best results,

Wooden body instrument

For most wooden instruments, locate the jack at the

endblock, centered below the tailpiece. Drill a 3⁄16”

(4.8mm) hole and enlarge it to

15

⁄32” tapered reamer. Note that if the instrument

15

⁄32” (12mm) with a

has a ring (“soundwell”) inside the sound chamber,

you may have to drill through it to accommodate

the jack.

23

1

1. 15⁄32” Nut; 2. 15⁄32” Washer; 3. 15⁄32” Star Washer;

4. Guitar Endblock; 5.

3

⁄8” Dress Washer; 6. 3⁄8” Nut

456

Battery Installation

You may locate the battery bag on any fl at surface

inside the instrument.

1. Clean the area where you will mount the bag with

mineral spirits. Let the area dry before continuing.

2. Peel off the plastic fi lm from the Velcro patch and

attach the bag at the chosen location.

3. Carefully separate the bag from the Velcro patch.

To set the adhesive, burnish the entire area of the

patch, especially the edges.

4. Install a 9V alkaline or lithium battery. Tuck the

battery into the bag and re-attach to the Velcro

patch. The adhesive under the Velcro patch requires

24 hours to achieve a full bond, so take care to not

stress the adhesive if you remove the battery bag

after the initial installation.

Complete the Installation

1. 3⁄8” Nut; 2. 3⁄8” Star Washer;

3. Guitar Body; 4.

Washer; 5.

3

⁄8” Nut

3

⁄8” Dress

23 4 51

www.fi shman.com

Reassemble the instrument and tune to pitch.

514-300-117 Rev A 5-09

Loading...

Loading...