Page 1

NASHVILLE SERIES PICKUPS

INSTALLATION GUIDE

www.fishman.com

Read Me First!

If you are unfamiliar with these products, please pay

close attention to the dimensional requirements for

installation. Failure to do so can result in permanent

damage to the pickup.

Installation of this product is a straightforward

procedure, but we recommend this job only if you

are an experienced repair technician.

Do not modify

0.050”

0.050”

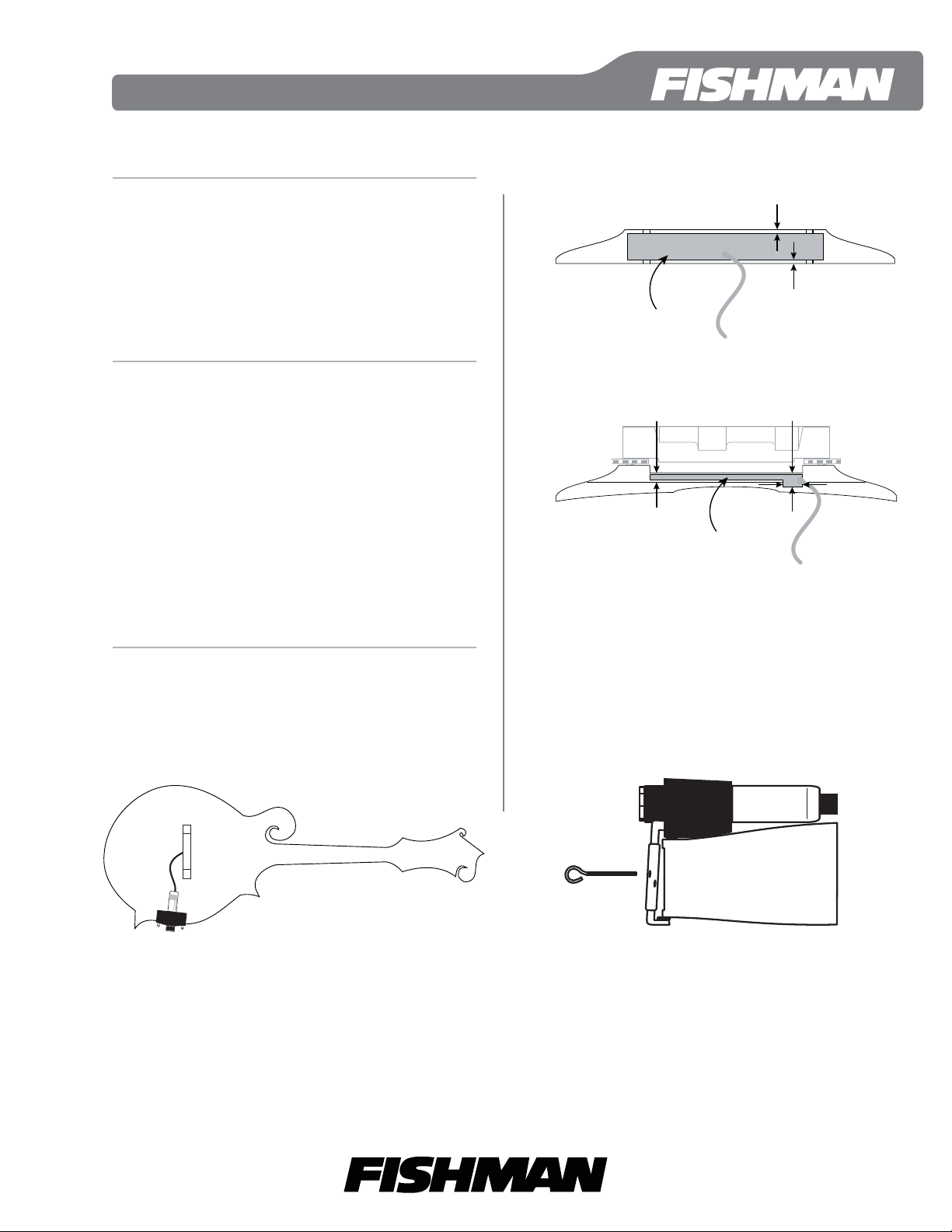

M-300 and M-400

The Nashville Series fl at-top and two piece archtop

mandolin pickups feature a piezo-ceramic element preinstalled in the bridge. Use your preferred

method for bridge fi tting.

For the fl at-top model (M-400), up to .050” may

be removed from either the top or bottom of the

bridge (Figure 1).

For the archtop model (M-300), be sure to observe

the “Do not modify” area of the bridge base

(Figure 2).

Special care must be taken not to damage the

pickup wire when tooling the bridge blank.

Installing The Jack

After fi tting the pickup, place the jack in a com-

fortable location (Figure 3) and tighten it with the

enclosed turnbuckle key (Figure 4). Be careful not to

scratch the side of your instrument.

Figure 1. M-400

0.100”

Figure 2. M-300

0.250”

0.180”

Do not modify

www.fi shman.com

Figure 4.Figure 3.

Page 2

www.fishman.com

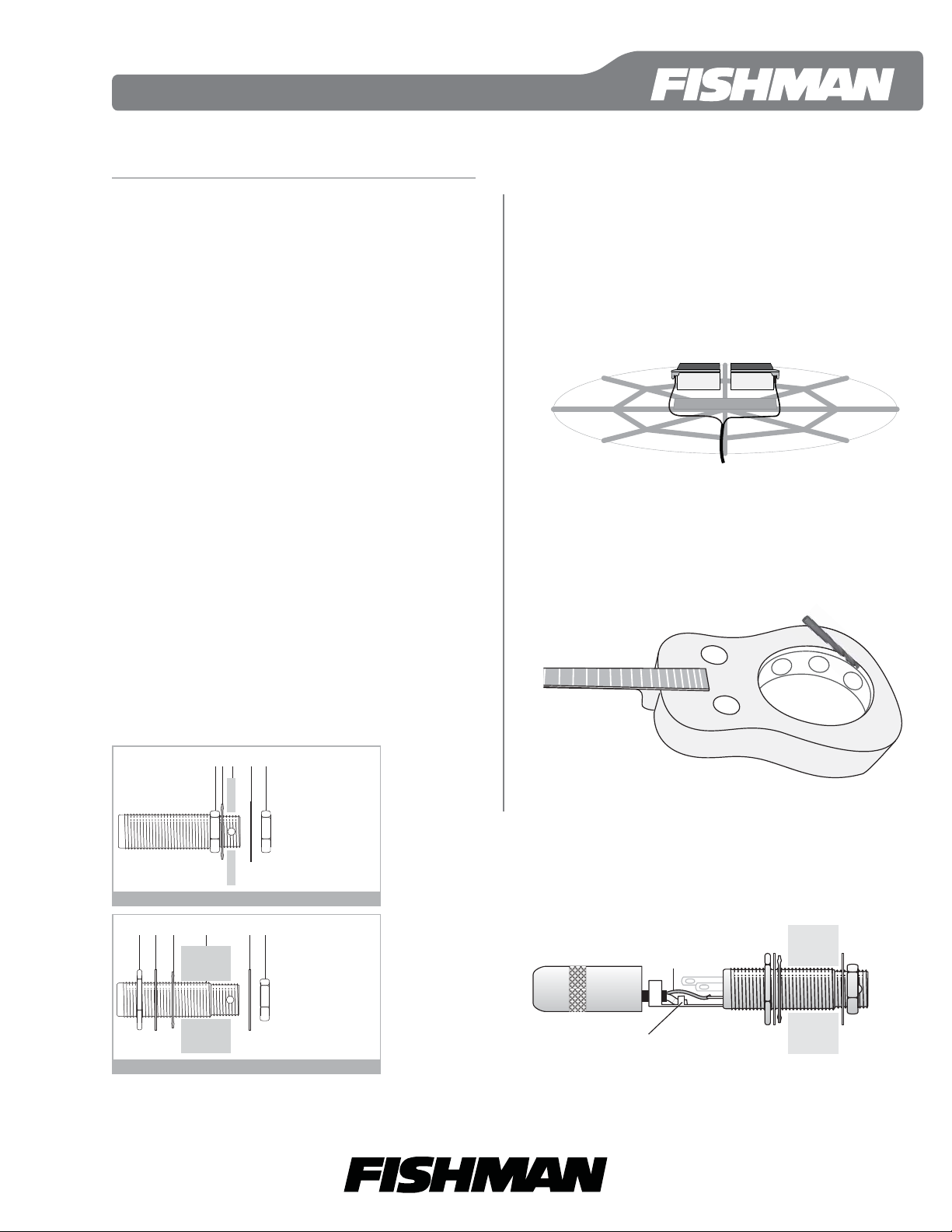

Spider-Style Resophonic

The Nashville Series resophonic pickup for spider-

style bridges features a piezo-ceramic element

preinstalled in the saddles. The saddles should fi t

tightly into the saddle slot in the spider bridge as

shown (Figure 1).

Fit the saddles by your preferred method, with the

maple side towards the cone, and the top notched

for string spacing. Both the top and bottom of these

saddles can be adjusted for proper fi t and playability.

Take special care not to damage the wires leading

from the pickup during adjustment.

Drill a hole for the jack in your preferred location,

usually in the treble side of the lower bout for metal

bodied instruments, or in the endblock, centered

below the tailpiece, for wooden bodied instruments.

Metal Bodied Instruments (sidemount location):

Use a center punch at the chosen location and use

a sharp 3/8” (9.5mm) drill.

Wooden Bodied Instruments (endblock location):

Drill a 3/16” (4.8mm) hole and enlarge it to 15/32”

(12mm) with a 15/32” tapered reamer. Note that if

the instrument has a ring (“soundwell”) inside the

sound chamber, you may have to drill through it to

accommodate the jack.

Drill a 3/16” hole in the corner edge of the

soundwell near or under the tail piece so that it is

hidden when you reinstall the coverplate (Figure 2).

Pass the pickup wire through and wire the pickup

leads to the jack as shown (Figure 3).

Install the jack hardware (Figure 4) in the chosen

location.

Figure 1.

12 3 4 5

1 - 3/8” Nut

2 - 3/8” Star Washer

3 - Guitar Body

4 - 3/8” Dress Washer

5 - 3/8” Nut

Metal Body Instrument Jack Location

612 3 4 5

1 - 15/32” Nut

2 - 15/32” Washer

3 - 15/32” Star Washer

4 - Guitar Endblock

5 - 3/8” Dress Washer

6 - 3/8” Nut

Wooden Body Instrument Jack Location

Figure 4.

Figure 2.

Pickup Signal

to Tip

Shield to

Sleeve

Figure 3.

514-300-004 Rev C 4-10

www.fi shman.com

Loading...

Loading...