Page 1

FULL CIRCLE

INSTALLATION GUIDE

www.fishman.com

Read Me First!

Installation of this product is a simple procedure,

but we recommend this job only if you are an

experienced repair technician.

Requirements

The Full Circle is available in either ¼-20 or 6mm

thread format. Before you install the pickup,

confi rm that the threads in the bridge will match

those on the Full Circle.

Installation

Observe the following

precautions!

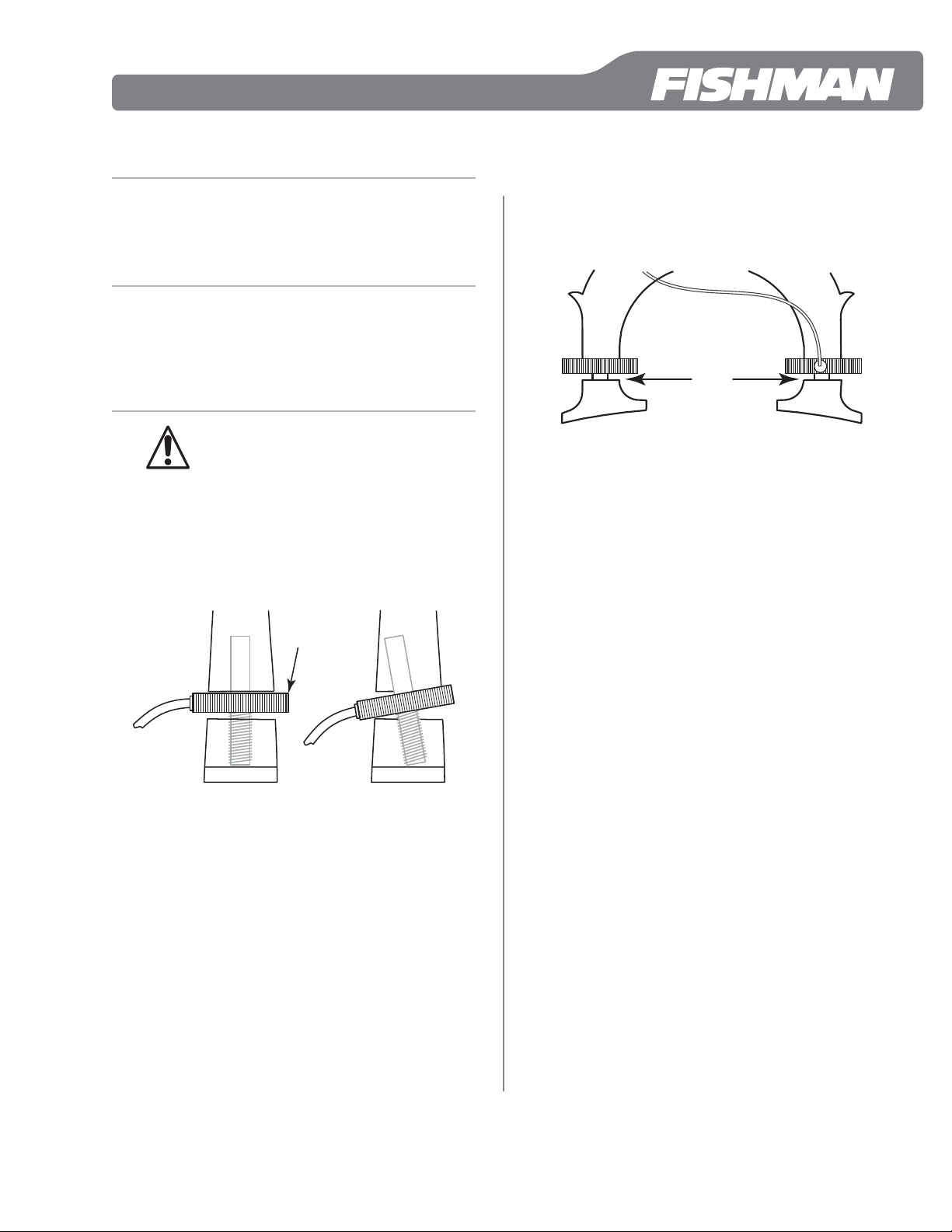

• Before you install the Full Circle, confi rm

that the wheels you are about to replace are

lined up well in the legs. The wheels must

be parallel and the posts perpendicular to

the cuts in the legs or the Full Circle may

become mechanically unstable on the

instrument (fi gure 1).

Hot Side

Setup

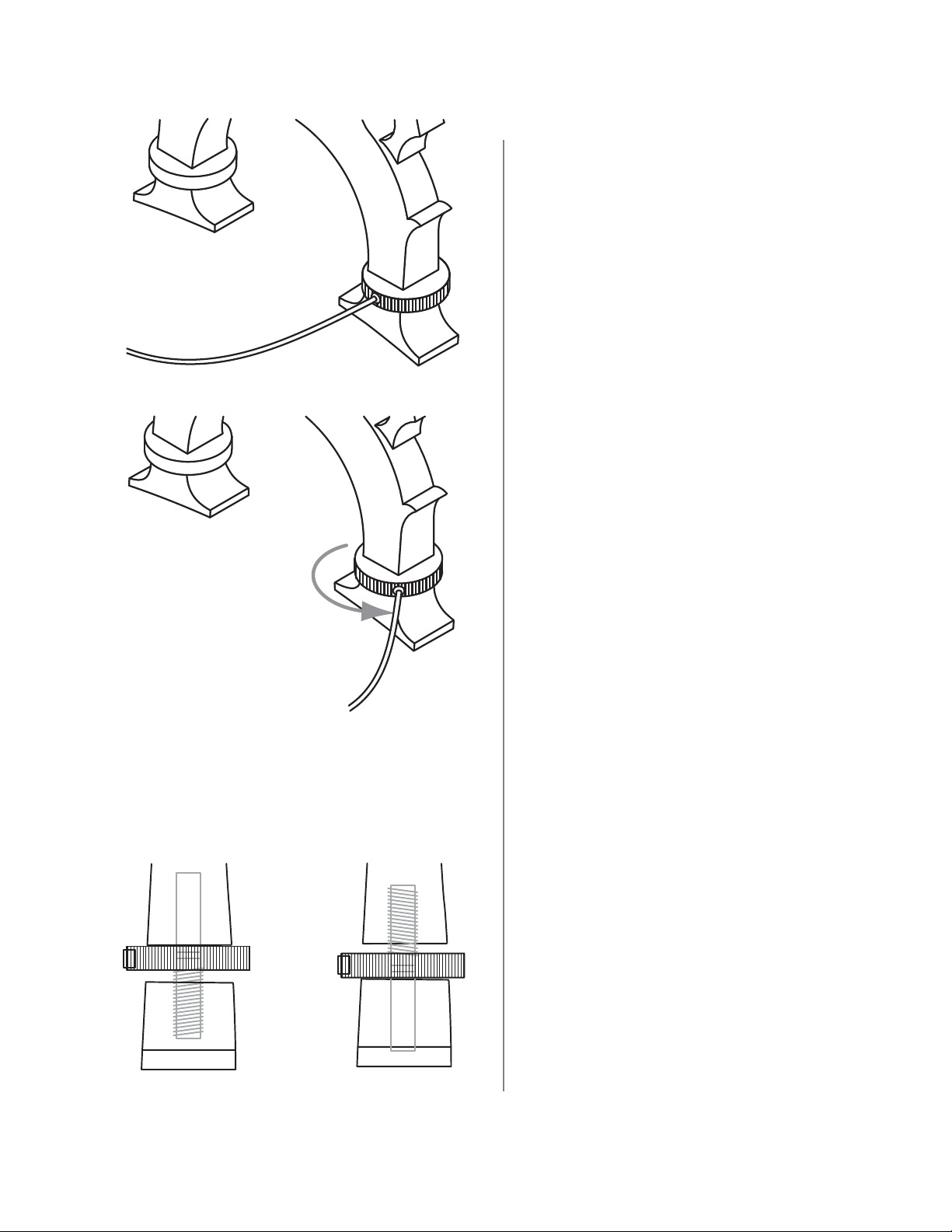

Once the wheels are mounted and the bass is tuned

up, thread the white wire through one of the wing

holes in the bridge and hold it in place with one of

the neoprene plugs from the kit (fi gure 2).

Gap

Figure 2

Fasten the output jack behind the bridge and

between two adjacent pairs of strings. Then fasten

the RCA plug into the back of the output jack.

Mind the gap!

For good pickup performance, leave a slight gap

between the threaded side of the wheel and the

wood. If you close the gap, the amplifi ed sound will

become choked and muted (fi gure 2).

Height adjustment

Remove the RCA plug from the back of the output

jack so the white wire does not wrap around the

leg as you turn the wheel. Turn both wheels equal

amounts for good contact with the pickup. To prolong the life of the pickup, do not pinch the white

wire where it joins the wheel.

Good Bad

Figure 1

• Fishman Transducers will not be responsible

for damages to the pickup or the instrument

due to improperly installed wheels!

Retro-fi t the Full Circle to a bridge with

installed wheels

The pickup is “hot” on the fl at face of the wheel:

on the side with the non-threaded post. For good

performance it is crucial that the hot side of the

pickup lies absolutely fl at with no gaps or voids

where it contacts the bridge. If necessary, sand the

wood fl at where it contacts the wheel before you

install bridge on the bass (fi gure 1).

When you install the pickup, remove the RCA plug

from the back side of the output jack. Replace the

plug after the pickup is in place.

Tonal adjustments (fi gure 3)

Turn the wheel so the wire is perpendicular to the

leg and the pickup will have an open, resonant

response.

Turn the wheel 45 degrees so the wire faces one of

the corners and the tone will be somewhat drier and

more focused, with less output.

Fit the Full Circle to a bridge without

wheels

For maximum reliability and performance, the

wheels should be centered precisely within the

taper of the bridge.

Fit the bridge to the bass before you install the

wheels. Note that the wheel with the white wire

belongs under the E string.

There is a subtle tonal difference between “threads

up” and “threads down” position for the pickup.

1

Page 2

Open, resonant response.

Drier, more focused response.

Figure 3

When you mount the Full Circle “threads down,” the

hot side of the pickup faces the strings. This translates to more defi ned articulation and attack, with a

slight emphasis on the “string” sound (fi gure 4).

Threads Down Threads Up

Figure 4

When you mount the Full Circle “threads up,” the

hot side of the pickup faces the body of the bass.

You’ll get a bit more woody acoustic tone this way,

with a rounded attack and less “edge” (fi gure 4).

Lay out the bridge (fi gure 5)

The pickup will work best when the wheel is precisely

centered in the leg. To do this, carefully lay out the

appropriate lines ahead of time. You will be drawing

lines on the side of the bridge that faces the

fi ngerboard.

1. Use the line implied by the outside of each leg to

make parallel vertical lines down to each foot (line A

Option 1: threads down into the feet:

Make a mark on each leg no less than 1 ¼”

(31.75mm) from the bottom of line A.

Line up a straight edge on the marks and pencil in a

horizontal line on each leg (line B).

To accommodate the thickness of the wheel, make a

parallel set of lines (line C) 3⁄8” (9.5mm) below line B.

Option 2: threads up into the legs

Make a mark on each leg no less than 21⁄32”

(16.66mm) from the bottom of line A. Use a straight

edge on the marks and pencil in a horizontal line on

each leg (line B).

To accommodate the thickness of the wheel, make

a parallel set of lines (line C) 3⁄8” (9.5mm) above

line B.

2. Find the center of line B on the face of each leg.

From these points make perpendicular lines down

to the foot (D). Continue across the bottom of the

foot (E).

3. Turn the bridge sideways and make a vertical line,

centered through the taper of the bridge (line F). Go

back to line B and continue it across the thickness of

the bridge, perpendicular to line F (both legs).

4. Finally, center a line (G) across the bottom length

of each foot.

Drill the legs and cut off the feet

Precision is crucial here. Use a drill press and a band

saw or table saw for these procedures.

Make a jig that will allow you to clamp the bridge

and align your layout marks for the drill. Two pieces

of ¾” Plywood or MDF fastened at 90° will do the

job. You will use a countersink, a #9 (5mm) drill bit

and the appropriate tap for this procedure (¼-20 or

6mm). To simplify the job, we recommend that you

use a so-called “extension” tap with a long reduced

diameter shank.

Your drill jig should hold the bridge fi rmly. Line

up the bridge (and shim if necessary) so that lines

D and F are centered with and parallel to the drill

bit. Double sided carpet tape makes an excellent

temporary clamp for the bridge while you drill.

).

2

Page 3

3/8”

(9.5 mm)

No Less Than

1 ¼” (31.75 mm)

Line A

Line C

Line D

Line B

C

Line F

D

B

A

Threads into Feet

3/8”

(9.5 mm)

No Less Than

21/32” (16.66 mm)

Line C

Line D

Line A

Line B

C

D

A

Line F

Threads into Legs

D

Line D

B

E

Line E

Line G

G

Figure 5

Option 1: threads down (into feet)

Start each hole with a single fl ute countersink. Drill

the holes for the posts with a #9 (5mm) tap drill. Drill

to a depth of no less than 1 ¾” (44.45mm).

If you have an “extension tap,” use it now to tap the

threads to a depth of 1” (25.4mm) into the feet. If

you don’t have an extension tap, wait until you cut

off the feet to tap out the threads. In these cases,

start the tap from the top of the foot.

Before you cut off the feet, line up the “B” lines on

the legs so they are parallel to the saw blade. Place

the side of the bridge that faces the tailpiece down

towards the table. Line F must be perpendicular to

the blade or the wheels will not align properly. If

necessary, shim up the bridge to make line B parallel

and line F perpendicular to the saw blade. Double

sided carpet tape makes an excellent temporary

clamp while you cut.

After you cut off the feet, enlarge the holes in the

legs to ¼” (6.4mm) diameter.

Option 2: threads up (into legs)

Start a hole in one foot with a single fl ute countersink. Then use a #9 (5mm) tap drill to plunge the

hole in one leg to a depth of at least 2” (50.8mm).

With the bridge still held in position from the fi rst

hole, enlarge it to ¼” (6.4mm) diameter, to a depth

of 1” (25.4mm). Repeat this entire procedure for the

other leg.

Tap the appropriate threads into the legs. If you have

an “extension tap,” you will be able to thread all the

way into the bottom of the hole. If you don’t have an

“extension tap,” the threads won’t reach completely

into the legs. This is not a problem; you can go back

and fi nish tapping the threads after you cut off the

feet. But try to at least get the tap started into the

upper part of the legs. This will ensure good thread

alignment when you fi nish tapping after the feet are

cut off.

Before you cut off the feet, line up the “B” lines on

the legs so they are parallel to the saw blade. Place

the side of the bridge that faces the tailpiece down

towards the table. Line F must be perpendicular to

the blade or the wheels will not align properly. If

necessary, shim up the bridge. Double sided carpet

tape makes an excellent temporary clamp while you cut.

Fit the wheels

Once you have cut off the feet, fi t the wheels with

the bridge off of the bass. The hot side of the pickup

should lay absolutely fl at against the bridge, with no

gaps or voids. If necessary, sand the wood fl at at the

contact point and/or increase the depth/diameter of

hole before installing the bridge on the bass (fi gure 1).

Setup

Once the wheels are mounted and the bass is tuned

up, thread the white wire through one of the wing

holes in the bridge and hold it in place with one of

the neoprene plugs from the kit (fi gure 2).

Fasten the output jack behind the bridge and

between two adjacent pairs of strings. Then fasten

the RCA plug into the back of the output jack.

www.fi shman.com

514-300-111 Rev A 5-09

Loading...

Loading...