Page 1

Full Circle Upright Bass Pickup

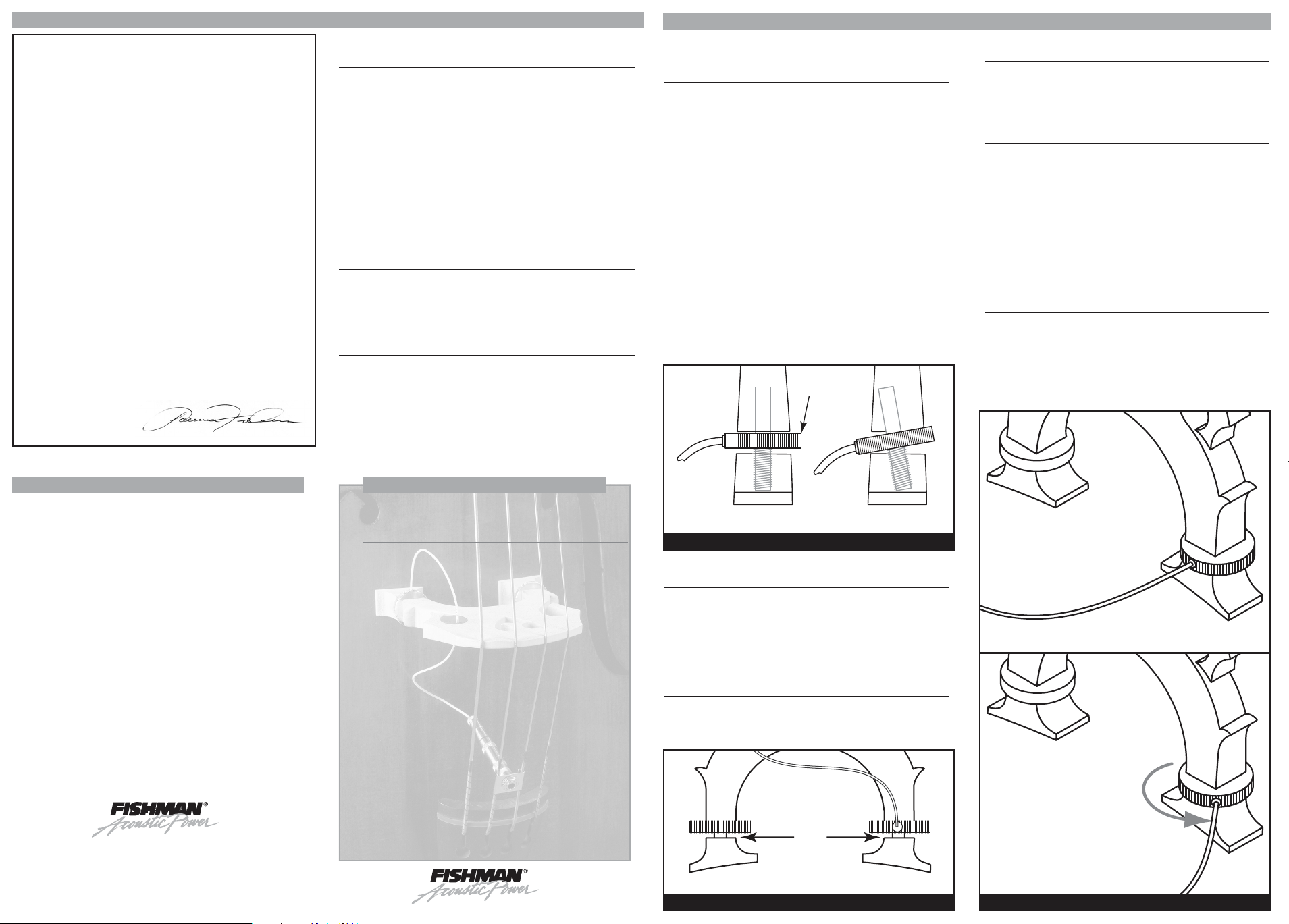

Hot Side

Good Bad

Gap

FF uu ll ll CC ii rr cc ll ee UU pp rr ii gg hh tt BB aa ss ss PP ii cc kk uu pp

Fellow Bassist,

Thank you for choosing the Full Circle pickup. It is the culmination

of many years of transducer design and has special significance for

me. Back in 1979 before I made my first pickup, I was a gigging jazz

bassist. I was frustrated with the transducer technology of the day.

The bass pickups at that time sounded primitive and could not

compete with the volume level of the ever-present Rhodes electric

piano. So I got to work on a bass pickup. My primary goal was simply

to make a clean sounding, feedback-free upright pickup for myself

that could keep up with the Rhodes. The outcome of that experiment

was the BP-100 bass pickup. And so Fishman Transducers was born.

Who knew?

Fast forward over twenty years and 75,000 (!) BP-100s later. The

Rhodes is extinct and the world has witnessed tremendous

advancements in acoustic amplification technology. We bassists now

have before us options that come closer than ever to true acoustic

tone. Our Full Circle upright pickup meets the challenge of this new

era of acoustic amplification head-on.

Plug in the Full Circle and the sound of your upright is all there.

Whether it’s big, fat and punchy pizz, full voiced arco or rockin' slap,

you’ll hear all the acoustic qualities, dynamics, and nuances of your

bass, only louder. Once you plug in the Full Circle, you will find that it

just might be the last upright bass pickup you ever buy.

- Larry Fishman

Description

Encased within a sturdy aluminum height adjuster wheel, the

Full Circle pickup offers accurate, transparent sound and

dependable performance. The pickup’s unique position within

the leg of a bass bridge achieves an amplified sound with fast

attack, lots of body resonance and good resistance to

feedback. Unlike many other bass pickups that add their own

signature sound, the Full Circle has little coloration. Plug in the

Full Circle and you’ll hear the sound of the bass, not the

pickup. The Full Circle is a quick retro-fit on many instruments

with height adjustment wheels.

It is our wish that you are completely satisfied with this

product. If you have any comments or questions, we would

like to hear from you. You may reach Our Customer Service

department at tech@fishman.com or call 978-988-9665.

1/4 - 20 Format:

6mm Format:

RReeppllaacceess wwhheeeellss wwiitthh 11//44 -- 2200 tthhrreeaaddss

RReeppllaacceess wwhheeeellss wwiitthh 66mmmm tthhrreeaaddss

Retro-fit the Full Circle

to a bridge with installed wheels

Although it is preferable to have a repair-person install the pickup, it is also

possible for the player to retro-fit the Full Circle to a bridge with installed

wheels. Attempt only if you have experience setting up your own bridge and

sound post. The pickup replaces the wheel on the E string side of the bridge.

A matching wheel (without the pickup) is also included for the G string side.

Before you install the pickup, confirm that the threads in the bridge (1/4-20

or 6mm) will match those on the Full Circle.

Important!

Before you install the Full circle, confirm that the wheels you are about to replace

are lined up well in the legs. The wheels must be parallel and the posts

perpendicular to the cuts in the legs or the Full Circle may become mechanically

unstable on the instrument. (illustration A)

Fishman Transducers will not be responsible for damages to the pickup or

the instrument due to improperly installed wheels!

The pickup is ‘hot’ on the flat face of the wheel; on the side with the nonthreaded post. For good performance it is crucial that the hot side of the

pickup lays absolutely flat with no gaps or voids where it contacts the bridge.

If necessary, sand the wood flat where it contacts the wheel before you install

bridge on the bass. (illustration A)

When you install the pickup, remove the RCA plug from the backside of the

output jack. Replace the plug after the pickup is in place.

Height Adjustment

Remove the RCA plug from the back of the output jack so the white wire does

not wrap around the leg as you turn the wheel. Turn both wheels equal

amounts for good contact with the pickup. To prolong the life of the pickup,

do not pinch the white wire where it joins the wheel.

Plugging In

The Full Circle performs well plugged directly into most bass amps. But note

that for the most accurate sound, the Full Circle works best into an “ultra

high impedance” (1-10 Mega-Ohm) preamp input. These days many bass

amps, active D.I.s and even some newer mixers have very high impedance

inputs, but many don’t.

If your amplified sound is not as full and deep as you’d expect, you may have

an “impedance mismatch”. We suggest you bolster the pickup with an

impedance matching preamp, such as a Fishman Pro-EQ Platinum Bass, ProEQ II or B II. An Impedance matching preamp will strengthen the pickup,

expand its low frequency response and guarantee consistent sound with

whatever gear you plug into downstream.

Tonal Adjustments (Illustration C)

Turn the wheel so the wire is perpendicular to the leg and the pickup will have

an open, resonant response.

Turn the wheel 45 degrees so the wire faces one of the corners and the tone

will be somewhat drier and more focused, with less output.

Please take the time to experiment and find the wheel position that best suits

your instrument and playing style.

L IMITED W ARRANTY

The FISHMAN Full Circle Upright Bass Pickup is warranted to function for a period of

One (1) Year from the date of purchase. If the unit fails to function properly within the

warranty period, free repair and the option of replacement or refund in the event that

FISHMAN is unable to make repair are FISHMAN’s only obligations. This warranty does

not cover any consequential damages or damage to the unit due to misuse, accident, or

neglect. FISHMAN retains the right to make such determination on the basis of factory

inspection. Products returned to FISHMAN for repair or replacement must be shipped in

accordance with the Return Policy, as follows. This warranty remains valid only if repairs

are performed by FISHMAN. This warranty gives you specific legal rights and you may

also have other rights which may vary from state to state.

Return Policy

To return products to FISHMAN TRANSDUCERS, you must follow these steps...

1. Call FISHMAN TRANSDUCERS at 978-988-9199 for a Return Authorization Number

(“RAN”).

2. Enclose a copy of the original Bill of Sale as evidence of the date of purchase, with

the product in its original packaging and a protective carton or mailer.

3. FISHMAN TRANSDUCERS’ technicians will determine whether the item is covered by

warranty or if it instead has been damaged by improper customer installation or other

causes not related to defects in material or workmanship.

4. Warranty repairs or replacements will be sent automatically free of charge.

5. If FISHMAN TRANSDUCERS determines the item is not covered by warranty, we will

notify you of the repair or replacement cost and wait for your authorization to proceed.

340-D Fordham Road Wilmington MA 01887 USA

FISHMAN T RANSDUCERS

Phone 978-988-9199 • Fax 978-988-0770

www.fishman.com

009-015-006 • 6-20-03Rev 1

Installation Guide

Installation Guide

Full Circle

Upright Bass Pickup

1/4 - 20 Format:

6mm Format:

RReeppllaacceess wwhheeeellss wwii tthh 11//44 -- 2200 tthhrreeaaddss

RReeppllaacceess wwhheeeellss wwii tthh 66mmmm tthhrr eeaaddss

Illustration A

Setup

Once the wheels are mounted and the bass is tuned up, thread the white wire

through one of the wing holes in the bridge and hold it in place with one of

the neoprene plugs from the kit. (Illustration B)

Fasten the output jack behind the bridge and between two adjacent pairs of

strings. Then fasten the RCA plug into the back of the output jack.

Mind the Gap!

For good pickup performance, leave a slight gap between the threaded side

of the wheel and the wood. If you close the gap, the amplified sound will

become choked and muted. (Illustration B)

Illustration B

Open, resonant response.

Drier, more focused response.

Illustration C

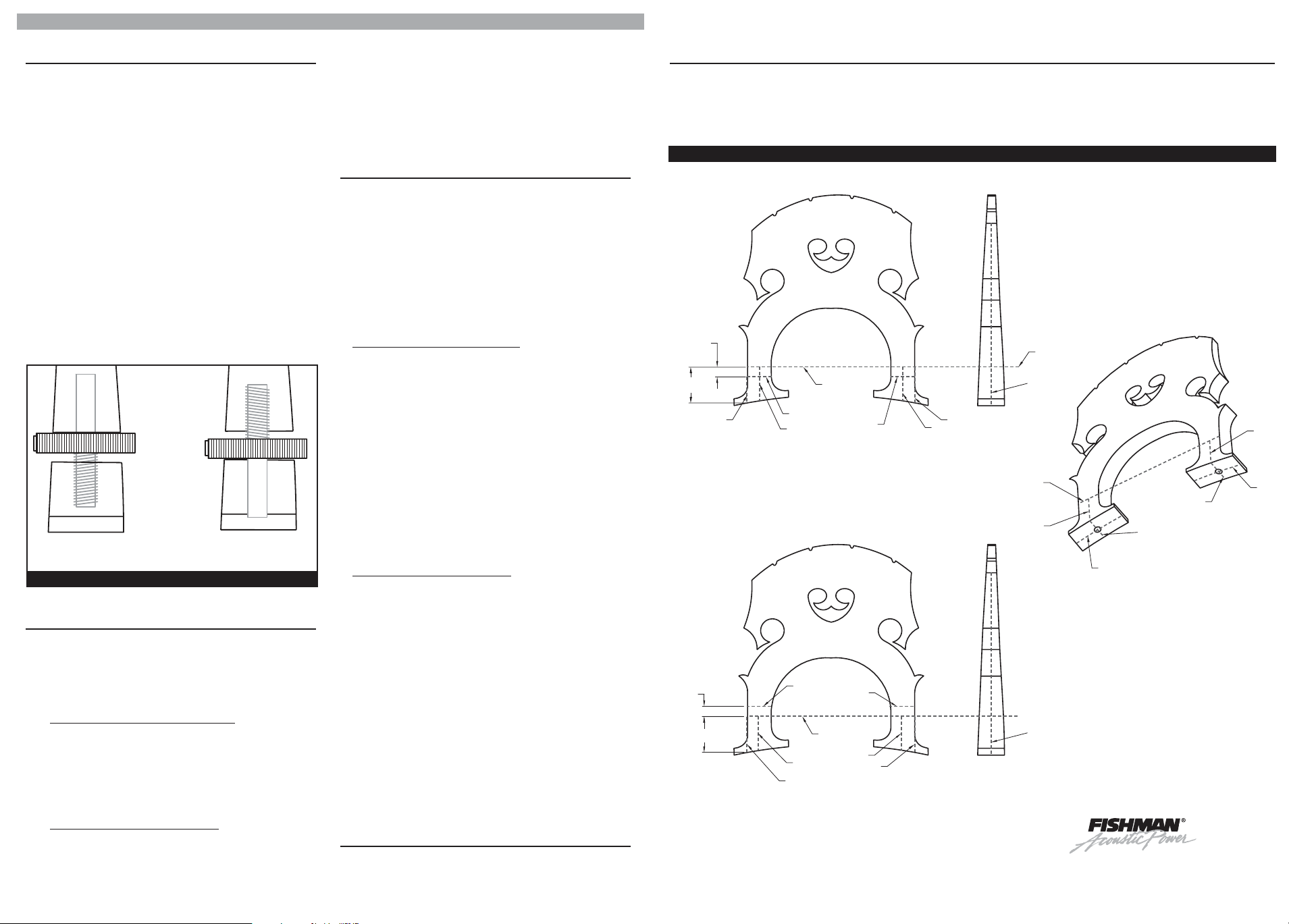

Page 2

Threads into Feet

Threads into Legs

3/8"

(9.5 mm)

No Less Than

1 - 1/4" (31.75 mm)

3/8"

(9.5 mm)

No Less Than

21/32"" (16.66 mm)

Line A

Line C

Line D

Line B

C

D

A

B

Line F

Line A

Line C

Line D

Line B

C

D

A

Line F

B

Line D

Line G

Line E

E

G

D

Full Circle Upright Bass Pickup

Threads Down Threads Up

Fit the Full Circle to a Bridge Without Wheels

Warning! Only a professional repair-person should attempt this installation.

If you have not installed wheels before, please practice on a scrap bridge.

Fishman will not be responsible for damages due to improper installation.

Preliminary

NOTE: In this method we describe how to center the wheels precisely within the

taper of the bridge. We like the way the pickup performs when it is exactly

centered in the leg.

Many repair-people prefer to install the wheels perpendicular to the tailpiece

side of the bridge and parallel to the top of the instrument. This is also

acceptable, but the pickup’s performance may be somewhat less predictable.

Fit the bridge to the bass before you install the wheels. Note that the wheel with

the white wire belongs under the E string.

We’ve had a lot of people ask if there is a tonal difference between “threads up”

or “threads down” position for the pickup. The answer is yes, there is a subtle

difference:

When you mount the Full Circle “threads down”, the hot side of the pickup

faces the strings. This translates to more defined articulation and attack, with

a slight emphasis on the ‘string’ sound. (Illustration D)

When you mount the Full Circle “threads up”, the hot side of the pickup faces

the body of the bass. You’ll get a bit more woody acoustic tone this way, with

a rounded attack and less “edge” . (Illustration D)

Illustration D

Layout the Bridge Refer to Illustration E

The pickup will work best when the wheel is precisely centered in the leg. To

do this, carefully layout the appropriate lines ahead of time. You will be

drawing lines on the side of the bridge that faces the fingerboard.

1. Use the line implied by the outside of each leg to make parallel vertical lines

down to each foot. (line A)

Option 1: Threads down into the feet:

Make a mark on each leg no less than 1-1/4” (31.75 mm) from the

bottom of line A.

Line up a straight edge on the marks and pencil in a horizontal line on

each leg (line B).

To accommodate the thickness of the wheel, make a parallel set of lines

(line C) 3/8” (9.5mm) below line B.

Option 2: Threads up into the legs

Make a mark on each leg no less than 21/32” (16.66 mm) from the

bottom of line A.

Use a straight edge on the marks and pencil in a horizontal line on each

leg (line B).

To accommodate the thickness of the wheel, make a parallel set of lines

(line C) 3/8" (9.5mm) above line B.

2. Find the center of line B on the face of each leg. From these points make

perpendicular lines down to the foot (“D”). Continue across the bottom of

the foot. (“E”)

3. Turn the bridge sideways make a vertical line, centered through the taper of

the bridge (line F). Go back to line B and continue it across the thickness of

the bridge, perpendicular to line F (both legs).

4. Finally, center a line (G) across the bottom length of each foot.

Setup

Once the wheels are mounted and the bass is tuned up, thread the white wire through one of the wing holes in the bridge and hold it in place with one of the

neoprene plugs from the kit. (illustration B)

Fasten the output jack behind the bridge and between two adjacent pairs of strings. Then fasten the RCA plug into the back of the output jack.

Illustration E

Drill the Legs and Cut off the Feet

Precision is crucial here. Use a drill press and a band saw or table saw for

these procedures.

Make a jig that will allow you to clamp the bridge and align your layout marks

for the drill. Two pieces of 3/4” Plywood or MDF fastened at 90 degrees will

do the job. You will use a countersink, a #9 (5mm) drill bit and the appropriate

tap for this procedure (1/4-20 or 6mm). To simplify the job, we recommend

that you use a so called “extension” tap with a long reduced diameter shank.

Your drill jig should hold the bridge firmly. Line up the bridge (and shim if

necessary) so that lines D & F are centered with and parallel to the drill bit.

Double sided carpet tape makes an excellent temporary clamp for the bridge

while you drill.

Option 1:Threads down (into feet)

Start each hole with a single flute countersink. Drill the holes for the posts

with a #9 (5 mm) tap drill. Drill to a depth of no less than 1-3/4” (44.45

mm).

If you have an “extension tap”, use it now to tap the threads to a depth of

1” (25.4 mm) into the feet. If you don’t have an extension tap, wait until

you cut off the feet to tap out the threads. In these cases, start the tap from

the top of the foot.

Before you cut off the feet, line up the “B” lines on the legs so they are

parallel to the saw blade. Place the side of the bridge that faces the tailpiece

down towards the table. Line F must be perpendicular to the blade or the

wheels will not align properly. If necessary, shim up the bridge to make line

B parallel and line F perpendicular to the saw blade. Double sided carpet

tape makes an excellent temporary clamp while you cut.

After you cut off the feet, enlarge the holes in the legs to 1/4” (6.4mm)

diameter.

Option 2: Threads up (into legs)

Start a hole in one foot with a single flute countersink. Then use a #9 (5

mm) tap drill to plunge the hole in one leg to a depth of at least 2” (50.8

mm).

With the bridge still held in position from the first hole, enlarge it to 1/4”

(6.4mm) diameter, to a depth of 1” (25.4mm). Repeat this entire procedure

for the other leg.

Tap the appropriate threads into the legs. If you have an “extension tap”,

you will be able to thread all the way into the bottom of the hole. If you don’t

have an “extension tap”, the threads won’t reach completely into the legs.

This is not a problem; you can go back and finish tapping the threads after

you cut off the feet. But try to at least get the tap started into the upper part

of the legs. This will ensure good thread alignment when you finish tapping

after the feet are cut off.

Before you cut off the feet, line up the “B” lines on the legs so they are

parallel to the saw blade. Place the side of the bridge that faces the tailpiece

down towards the table. Line F must be perpendicular to the blade or the

wheels will not align properly. If necessary, shim up the bridge. Double

sided carpet tape makes an excellent temporary clamp while you cut.

Fit the Wheels

Once you have cut off the feet, fit the wheels with the bridge off of the bass.

The hot side of the pickup should lay absolutely flat against the bridge, with no

gaps or voids. If necessary, sand the wood flat at the contact point and/or

increase the depth/diameter of hole before installing the bridge on the bass.

(illustration A)

F

ISHMANTRANSDUCERSINC

340-D Fordham Road Wilmington MA 01887 USA

Phone 978-988-9199 • Fax 978-988-0770

www.fishman.com

.

Loading...

Loading...