Page 1

BUILT-IN OVEN

OB30SP & OB30DP

models

INSTALLATION GUIDE

US CA

Page 2

SAFETY AND WARNINGS

!

WARNING!

Electric Shock Hazard

Failure to follow this advice may result in

electric shock or death.

• Before carrying out any work on the electrical

section of the appliance, it must be disconnected

from the mains electricity supply.

• Connection to a good earth wiring system is

absolutely essential and mandatory.

• Alterations to the domestic wiring system must

only be made by a qualified electrician.

!

WARNING!

Fire Hazard

Failure to follow this advice may result in

overheating, burning, and injury.

• Do not use adapters, reducers, or branching

devices to connect this appliance to the mains

power supply.

!

WARNING!

Very Heavy

Failure to follow this advice may result in

serious injury.

• Do not attempt to lift this product unassisted.

!

WARNING!

Cut Hazard

Failure to use caution could result in injury.

• Take care – some panel edges are sharp.

WARNING!

To avoid hazard, follow these instructions carefully before installing or using this appliance.

z

Save these instructions for the local inspectors use.

z

Please make this information available to the person installing the appliance — doing so

could reduce your installation costs.

z

This oven is to be installed and connected to the electricity supply only by an

authorized person.

z

If the installation requires alterations to the domestic electrical system, call a qualified

electrician. The electrician should also check that the socket cable section is suitable

forthe electricity drawn by the oven.

z

The oven must be grounded.

z

Installation must comply with your local building and electricity regulations.

z

This appliance must be installed and connected to the mains power supply only by a

suitably qualified person according to these installation instructions and in compliance

with any applicable local building and electricity regulations. Failure to install the

appliance correctly could invalidate any warranty or liability claims.

z

If the power supply cable is damaged, it must be replaced by the manufacturer,

itsservice agent or similarly qualified person in order to avoid a hazard.

z

A circuit breaker is recommended.

z

Do not use adaptors, reducers or branching devices to connect the oven to the mains

electricity supply, as they can cause overheating and burning.

z

Ensure the cavity is completely sealed with no gaps. This is to ensure the oven cooling

system functions correctly.

z

The appliance must not be installed behind a decorative door in order to avoid overheating.

Electrical requirements

z

Connect oven with copper wire only.

z

Do not cut the conduit.

z

A U.L. listed conduit connector must be provided at the junction box.

z

Do not ground to a gas pipe.

z

Do not have a fuse in the grounding or neutral circuit.

z

Fuse both sides of the line.

z

A time delay fuse or circuit breaker is recommended. If using a time delay fuse,

thenfuse both sides of the line.

z

Flexible armored cable from the appliance should be connected directly to the junction box.

z

Connect directly to the fused disconnect (or circuit breaker box) through flexible,

armored or non-metallic sheathed, copper cable (with grounding wire).

z

If codes permit and a separate grounding wire is used, it is recommended that

a qualified electrician determine that the grounding path and wire gauge are in

accordance with local codes.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country,

please go to our website www.fisherpaykel.com or contact your local Fisher&Paykel dealer.

2

Page 3

PARTS SUPPLIED

Screws

Single oven models (2)

Double oven models (4)

Spacers

Single oven models (2)

Double oven models (4)

Long Trim (1)

To be fitted in

a flush installation.

PRIOR TO INSTALLATION

IMPORTANT!

Some environmental factors and cooking habits can cause condensation in and around the oven during use. To protect surrounding cabinetry from possible damage caused by

frequent or excessive condensation, we recommend moisture-proofing the oven cavity.

z

the countertop and oven cavity are square and level, and are the required dimensions.

z

the installation will comply with all clearance requirements and applicable standards and regulations.

z

the isolating switch will be easily accessible to the customer with the oven installed.

z

the electrician provides sufficient free length of power supply cable to reach from the bottom rear of the cavity to at least 1.5 metres in front of the bottom edge of the opening.

z

the cable may enter the cavity from the side, top or bottom, but top entry must be at the rear of the cavity.

z

the oven connection socket (if fitted) is outside the cavity if the oven is flush to the rear wall.

z

the oven will rest on a surface that can support its weight.

z

the height from the floor suits the customer.

z

you consult local building authorities and by-laws if in doubt regarding installation.

AFTER INSTALLATION

IMPORTANT!

Please take extra care not to damage the lower trim of the oven during installation. The trim is important for correct air circulation and allows the

door to open and close without obstruction. The manufacturer does not accept any responsibility for damage resulting from incorrect installation.

z

the oven door(s) can open fully without obstruction.

z

do not seal the oven into the cabinetry with silicone or glue. This makes future servicing difficult. Fisher&Paykel will not cover the costs of

removing the oven, or of damage caused by this removal.

z

the power supply cable does not touch any hot metal parts.

z

the isolating switch is easily accessible to the customer with the oven installed.

z

you complete the ‘Final checklist’ at the end of the installation.

z

if, after following the instructions given, correct performance cannot be achieved, please contact your nearest Fisher&Paykel Authorized Service

Center, Customer Care, or contact us through our local website listed at the end of this document.

3

Page 4

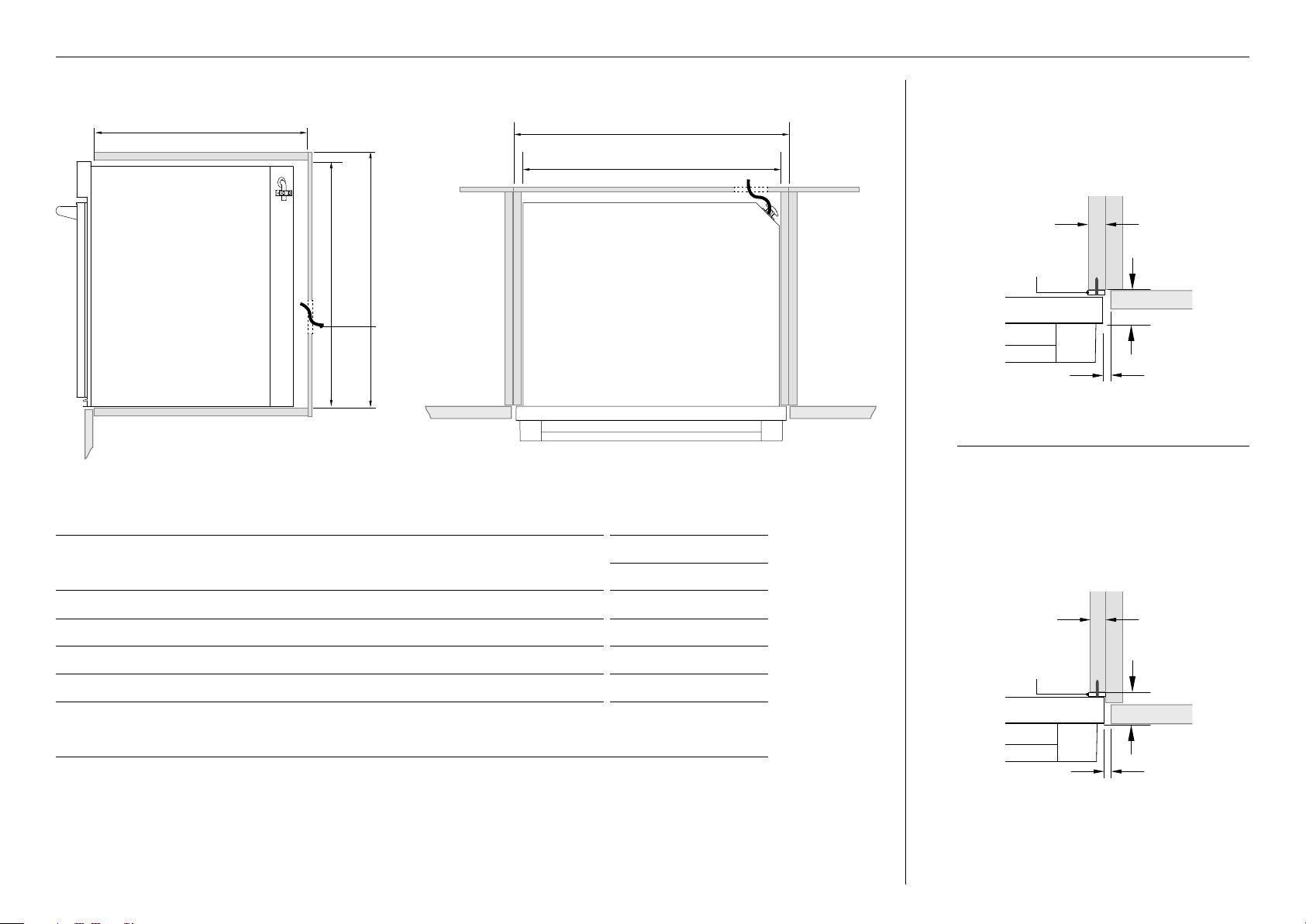

PRODUCT DIMENSIONS — SINGLE OVENS

A

H

B

G

PRODUCT DIMENSIONS

Ed

F

PROFILEFRONT

OB30S

INCHES MM

A Overall height of product 27 1/8 689

B Overall width of product 29 13/16 757

C Overall depth of product (excl. handle and dials) 23 15/16 608

C

PLAN

4

D Depth of oven front and control panel (excl. handle and dials) 1 9/16 39

E Depth of chassis (does not include oven front) 22 3/8 569

F Height of chassis 26 9/16 675

G Depth of door (open) (measured from front of door) 21 5/8 550

H Overall width of chassis 28 5/16 719

Note: If flush installing, you need to replace the lower trim with the supplied long trim at the base of the

oven, and the depth of the control panel D with the fitted spacer is larger than conventional ovens. Ensure

you have created a 1 5/8" (42mm) recess incabinetry.

Page 5

CABINETRY DIMENSIONS — SINGLE OVENS

e b

CABINETRY DIMENSIONS

c d

Electrical

Supply

PROUD INSTALL

a

5/8 – 13/16"

(16-20mm)

spacer

1 – 5/8"

(42mm)

min 1/16"

(2mm)

PLANPROFILE

FLUSH INSTALL

OB30S

INCHES MM

A Minimum inside width of cavity 28 1/2 724

B Overall width of cabinetry 30 1/8 764

C Minimum inside height of cavity 26 13/16 681

D Overall height of cabinetry 27 3/8 693

E Minimum inside depth of cavity

z

Proud install

z

Flush install

22 5/8

24 3/16

575

614

Notes:

If installing a cooktop above the oven, ensure adequate clearance is provided for the cooktop as per the cooktop

manufacturer’sinstructions.

Ensure the cavity is completely sealed with no gaps. This is to ensure the oven cooling system functions correctly.

spacer

5/8 – 13/16"

(16-20mm)

1 – 5/8"

(42mm)

min 1/16"

(2mm)

5

Page 6

PRODUCT DIMENSIONS — DOUBLE OVENS

A

B

ED

F

G

h

i

PRODUCT DIMENSIONS

A Overall height of product 48 1/2 1232

B Overall width of product 29 13/16 757

C Overall depth of product (excl. handle and dials) 23 15/16 608

D Depth of oven front and control panel (excl. handle and dials) 1 9/16 39

C

PLAN

6

E Depth of chassis (does not include oven front) 22 7/16 569

F Height of chassis 47 15/16 1218

G Depth of upper door (open) (measured from front of door) 21 5/8 550

H Depth of lower door (open) (measured from front of door) 20 7/8 530

I Overall width of chassis 28 5/16 719

Note: If flush installing, you need to replace the lower trim with the supplied long trim at the base of the

oven, and the depth of the control panel D with the fitted spacer is larger than conventional ovens. Ensure

you have created a 1 5/8" (42mm) recess incabinetry.

PROFILEFRONT

OB30D

INCHES MM

Page 7

e

c d

Electrical

Supply

CABINETRY DIMENSIONS — DOUBLE OVENS

b

a

PROUD INSTALL

5/8 – 13/16"

(16-20mm)

spacer

1 – 5/8"

(42mm)

min 1/16"

(2mm)

PROFILE PLAN

CABINETRY DIMENSIONS

INCHES MM

OB30D

A Minimum inside width of cavity 28 1/2 724

B Overall width of cabinetry 30 762

C Minimum inside height of cavity 48 3/16 1224

D Overall height of cabinetry 48 11/16 1236

E Minimum inside depth of cavity

z

Proud install

z

Flush install

22 5/8

24 3/16

575

614

Notes:

If installing a cooktop above the oven, ensure adequate clearance is provided for the cooktop as per the cooktop

manufacturer’sinstructions.

Ensure the cavity is completely sealed with no gaps. This is to ensure the oven cooling system functions correctly.

FLUSH INSTALL

spacer

5/8 – 13/16"

(16-20mm)

1 – 5/8"

(42mm)

min 1/16"

(2mm)

7

Page 8

Single model shown for illustration purposes only

IMPORTANT!

z

When you remove the oven from the carton

be careful not to damage the lower trim.

Thetrimisimportant for both ventilation and to

ensure the door opens fully without obstruction.

z

Ensure you remove the Long Trim

from thepackaging.

UNPACKING THE OVEN

Lower trim

Remove the accessories box from

the top of the oven and set aside.

Recycle responsibly.

8

Page 9

REMOVING AND REFITTING THE DOOR(S)

IMPORTANT!

z

Take care, the oven door is heavy.

z

Do not lift the oven door by its handle. Doing so may damage the door.

z

Ensure the oven and the door are cool before you begin to remove the door.

z

Before removing the door, ensure there is a large enough clear, protected surface in the kitchen to rest the door on.

To remove the door(s)

1

2

3

Open the door completely.

Open the hinge locks fully

on both sides

Holding the door on both

sides, lift door back up to 45°

and carefully pull the door out

and away from the hinges.

To refit the door(s)

1

2

3

Holding the door at 45°, carefully

align the hinge tongues with the

hinge slots. Push the door in until

you feel the latches locate into

position on each side.

Open the door completely and

ensure both hinges are secured

by the correct notches.

Rotate the locks up into the

closed position ensuring they rest

inside the slots completely. Note:

Incorrect installation will prevent

door from correctly sealing.

4

Close the oven door ensuring that

when closed, the door is vertical and

parallel to any surrounding cabinetry

9

Page 10

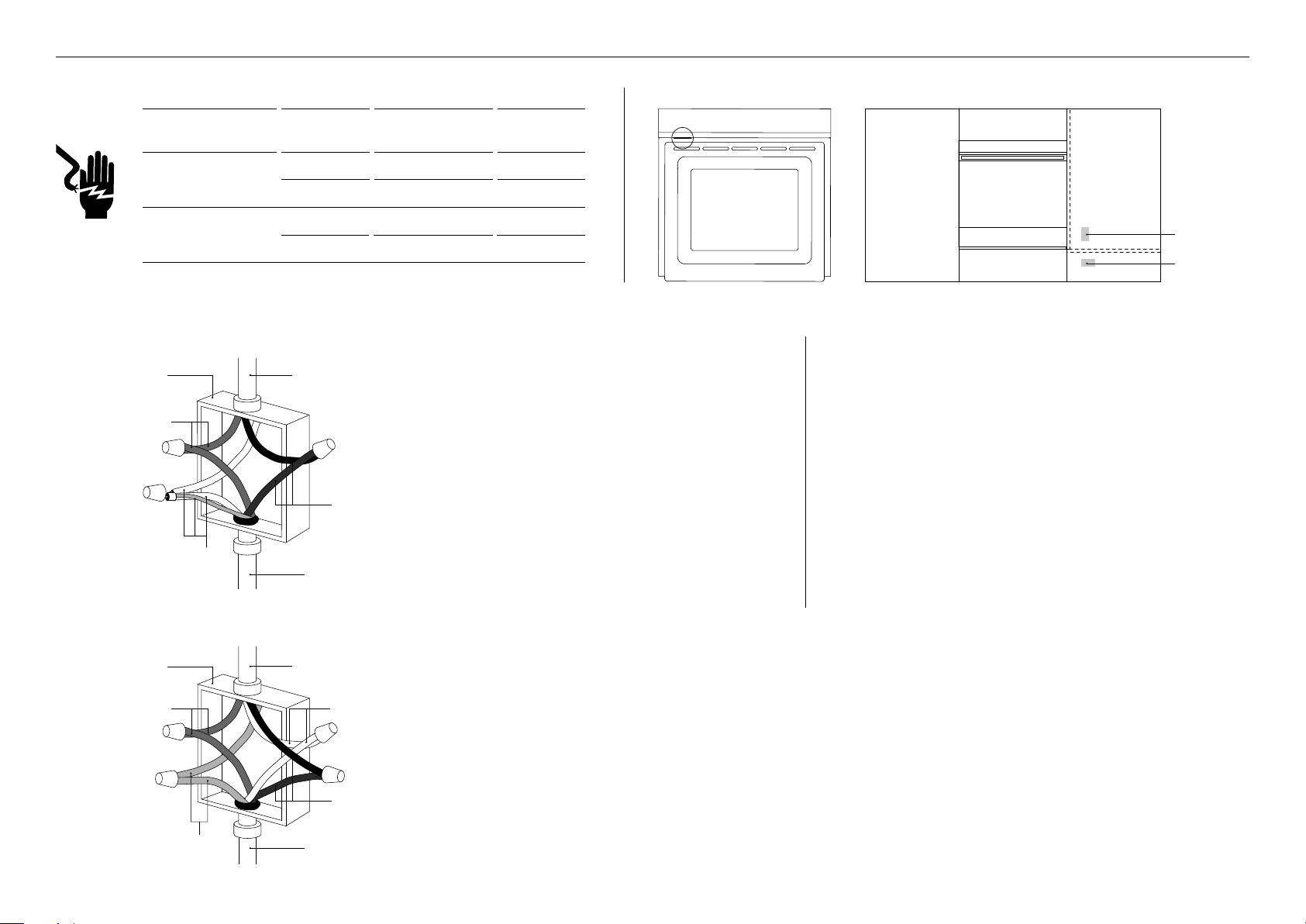

ELECTRICAL CONNECTION TO JUNCTION BOX

MODEL VOLTAGE

OB30 Single 208 V 16.6 A 3.5 kW

OB30 Double 208 V 33.2 A 7.0 kW

Connection methods

box

red

wires

a

white and

green grounding

oven wires –

factory taped

MAX CURRENT

DRAW

MAX LOAD

240 V 19.4 A 4.6 kW

240 V 38.3 A 9.2 kW

If local codes permit connecting the cabinet-grounding

cable from

power supply

conductor to the neutral (white) wire in the junction box:

1 Disconnect the power supply.

2 Remove the junction box cover.

3 Connect the oven cable to the junction box through

the U.L. listed conduitconnector.

4 Connect the two black wires together with

twist-on connectors.

5 Connect the two red wires together with twist-on

black

wires

connectors.

6 Connect electrical connection according to local

codes andordinances.

7 Connect the factory-taped green and white oven cable

U.L.-listed

conduit

connector

wires to the neutral (white) wire in the junction box.

8 Replace the junction box cover.

Nameplate location

Junction box locations

junction box

location for

undercounter

installation

junction box

location for

wall installation

If local codes DO NOT PERMIT connecting the cabinet-grounding

conductor to the neutral (white) wire in junction box:

1 Disconnect the power supply.

2 Remove the junction box cover.

3 Connect the oven cable to the junction box through the U.L.-

listed conduit connector.

4 Connect the two black wires together with twist-on connectors.

5 Connect the two red wires together with twist-on connectors.

6 Connect electrical connection according to local codes and

ordinances.

7 Separate the factory-taped green andwhite oven cable wires.

8 Connect the white oven cable wire to the neutral (white) wire

in junction box.

9 Connect the green grounding oven cable wire to a grounded

wire in the junctionbox.

!0 Replace the junction box cover.

B

10

box

red

wires

green grounding

oven wires –

factory taped

cable from

power supply

white

wires

black

wires

U.L.-listed

conduit

connector

Four-wire electrical system

1 Disconnect the power supply.

2 Remove the junction box cover.

3 Connect the oven cable to the junction box through the U.L.-listed conduit connector.

4 Connect the two black wires together with twist-on connectors.

5 Connect the two red wires together with twist-on connectors.

6 Connect electrical connection according to local codes and ordinances.

7 Separate the green and white oven cablewires.

8 Connect the white oven cable wire to theneutral (white) wire in junction box.

9 Connect the green grounding oven cable wire to the (green) grounding wire in thejunction box.

Do not connect the green grounding wire to the neutral (white) wire in junction box.

!0 Replace the junction box cover.

Page 11

spacer

SECURE THE OVEN TO THE CABINETRY

IMPORTANT!

z

Do not lift the oven by the door handle.

z

Do not over-tighten the screws.

z

Do not seal the oven into the cabinetry with silicone or glue.

This makes future servicing difficult. Fisher & Paykel will not

cover the costs of removing the oven, or of damage caused

by this removal.

1 Position the oven in the prepared cavity.

2 Open the oven door fully.

3 Mark and pre-drill the screw holes.

4 Use the supplied screws to secure the oven to the cabinetry.

Ensure supplied spacer is fitted between oven and cabinetry.

11

Page 12

FLUSH INSTALLATION ONLY — REPLACE THE LOWER TRIM WITH THE SUPPLIED LONG TRIM

Unscrew and remove

the installed lower trim

12

Replace with the

supplied long trim

Page 13

FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

Ensure the oven is level and securely fitted to the cabinetry.

Check the lower trim is undamaged.

Open the oven door slowly until it is fully open and check there is

adequate clearance between the bottom of the door and the lower trim.

This is to ensure correct air circulation. Should the lower trim become damaged,

straighten the trim and ensure the oven door opens fully without obstruction.

Ensure you remove all internal packaging (including the circular yellow packing

retainers holding the accessory box in place).

Ensure all oven vents and openings are clear and free of any obstruction or damage.

IMPORTANT!

Failure to ensure all oven vents are clear may result in poor product performance.

Ensure the isolating switch is accessible by the customer.

TEST OPERATION:

Turn the power to the oven on. The display should light up.

Set the clock following the instructions in the ‘User guide’.

Set the oven to Bake at 120°F (50oC). The light should come on inside the oven cavity

and air should blow out of the vent at the top of the oven. After five minutes, open

the oven door: the air inside should feel warm. Turn the oven off.

Have you demonstrated the basic operation to the customer?

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

13

Page 14

FISHERPAYKEL.COM

The product specifications in this document apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You should

therefore check with your Dealer to ensure this booklet correctly describes the

© Fisher & Paykel Appliances 2019. All rights reserved.

product currently available.

US CA

592096A 10.19

Loading...

Loading...