Fisher & Paykel Intuitive DEIX2, Intuitive DGIX2, DE27CW1 Installation Instructions And User Manual

Page 1

DEIX2, DGIX2

Secadora de ropa Intuitive™

Instructivo de instalación

y guía del usuario US CA (ES)

Installation instructions

and user guide

US CA (EN)

Intuitive™ clothes dryer

Page 2

2

The Governor of California is required to publish a list of substances known to the

state of California to cause cancer or reproductive harm and requires business to

warn customers of potential exposures to such substances.

Gas appliances contain or produce substances, which can cause death, or serious

illness and which are known to the State of California to cause cancer, birth defects,

or other reproductive harm. To reduce the risk from substances in fuel or from

fuel combustion, make sure this appliance is installed, operated, and maintained

according to the manufacturers instructions.

English Page 2 – 56

Español Pág 57 – 110

WARNING: For your safety the

information in this manual must be

followed to minimize the risk of fire or

explosion or to prevent property

damage, personal injury or death.

—Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Clear the room, building or area of all

occupants.

• Immediately call y our gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

—Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

Page 3

3

Contents

Dryer Safety

5

Important Safety Instructions

6

Warranty 8

Installation Instructions

9

Installer Responsibilities, Location Requirements 10

Dimensions 12

Mobile Home Installation 13

Exhausting 14

Alternative Installation for Close Clearances 18

Exhaust Venting 19

Installation 20

Grounding Instructions 22

Electrical Requirements 23

Gas Requirements 29

Level Machine, Final Installation Checklist 32

Features

33

Operating Instructions

34

Fabric Type

Heavy, Mixed, Casual, Dry and Wear 37

Light, Air Dry 38

How Dry?

Autosensing, Dryness Levels 39

Display Screen

40

All About the Options Button

40

Progress Screen

41

The Options

Wrinkle Free, Time Dry 42

End of Cycle Beeps, Reminders, Cycle Tips, Troubleshooting 43

Lifecycles™

Family Allergy, Towels, Shirts, Lingerie 44

Special Freshen Up, Warm Up, Dry Clean 44

Bulky Blankets, Jeans, Comforter 45

Using Your Dryer

Sorting, Loading 46

Lint Bucket 47

Lidlock

Power failure 48

Care Labels

49

Cleaning

50

If your Intuitive™ Dryer Beeps for Help

51

Trouble Shooting

52

Limited Warranty

54

US

CA

Page 4

4

Thank you for buying a Fisher & Paykel Intuitive™ dryer.

We hope you enjoy using the Intuitive™ dryer as much as we have enjoyed designing it. We’ve

developed this dryer to treat your clothes with the utmost care, drying them gently so they

will look better for longer. We know you’ll enjoy the benefits of its easy loading drum, reverse

tumbling and lint removal system.

Please take the time to read this User Guide carefully. It will help you to operate and maintain

your new Intuitive™ dryer.

Your safety, and the safety of others is very important. Located on your dryer and throughout this

guide are safety messages and instructions; it is important that you understand and follow them.

Page 5

5

Dryer Safety

Symbols

Symbols will be used in this Guide to highlight when extra care is required. Abide by these at

all times to ensure you and your family are not harmed while operating your dryer.

It is important to always act with caution and use common sense when operating your dryer.

Use only as per instructed by the User Guide.

DANGER

This is the safety alert symbol. This symbol alerts you to hazards that can kill

or hurt you and others.

The safety alert symbol and the word DANGER or WARNING will precede all

safety messages. These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will identify the hazard, tell you how to reduce the chance of injury,

and tell you what can happen if the instructions are not followed.

WARNING

US

CA

Page 6

6

Important Safety Instructions

WARNING

Electric Shock Hazard

Follow the safety precautions outlined in this User Guide.

Failure to do so can result in death or electric shock.

Safety Precautions

Read all instructions carefully before using this dryer.

Use this dryer only for its intended purpose as described in this User Guide.

To minimize the possibility of electric shock, unplug this dryer from the power supply or

disconnect the dryer at the household distribution panel (by removing the fuse or switching

off the circuit breaker) before attempting any user maintenance or cleaning.

Installations must be performed by a qualified or licensed contractor, plumber or gasfitter

qualified or licensed by the state, province, or region where this appliance is being installed.

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used.

This dryer must be properly grounded to conform with all governing codes and ordinances.

Follow details in Installation Instructions.

Do not install or store the dryer where it will be exposed to water or exposed to the weather.

Connect to a properly protected, rated and sized power supply circuit to avoid electrical overload.

Do not repair or replace any part of the appliance or attempt any servicing, unless specifically

recommended in the published user repair instructions that you understand and have the skills

to carry out.

When disconnecting the dryer, pull by the plug rather than the cord or junction of the cord plug,

to avoid damage to the cord or junction of the cord plug.

Make sure the cord is located so that it will not be stepped on, tripped over or otherwise subject

to stress or damage.

Do not tamper with the controls or the lid lock.

Note: Pressing the POWER button does NOT disconnect the dryer from the power supply, even

though the lights are out.

Do not operate this dryer if it is damaged, malfunctioning, partially disassembled or has missing

or broken parts, including a damaged cord or plug.

This dryer must be directly connected to an approved fixed electrical outlet. It cannot be

plugged into an extension cord.

Page 7

7

Important Safety Instructions

WARNING

Fire Hazard

Only dry fabrics that have been washed with water.

Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials. Dry on the Air Dry cycle.

A clothes dryer produces combustible lint and must be

exhausted outdoors. Take care to prevent the accumulation of

lint around the exhaust opening and in the surrounding area.

Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric softener

or product.

Failure to follow these instructions can result in death or

personal injury.

To Reduce the Risk of Fire in a Tumble Dryer the Following Should

be Observed:

Do not place items in a tumble dryer that have previously been cleaned in, washed in, soaked

in, or spot cleaned with flammable liquids or solids. They are a fire or explosion hazard. Highly

flammable substances commonly used in domestic environments include acetone, denatured

alcohol, gasoline, kerosene, some brands of spot removers and dry cleaning solvents, turpentine,

waxes, wax removers, vegetable oil, fish oil, massage oil, and cooking oil.

Do not leave hot oil-affected items in a pile or stack. This can prevent heat from escaping and

can create a fire hazard. Oil-affected items can ignite spontaneously, especially when exposed to

heat sources such as a tumble dryer. The items become warm causing an oxidation reaction in

the oil. This oxidation creates heat. If the heat cannot escape the items can become hot enough

to catch fire.

Do not use heat to dry items containing rubber, foam rubber, plastic or similar materials, (such as

padded bras, bath mats, rugs, bibs, baby pants, plastic bags, pillows etc), as these materials might

melt or burn. Some rubber materials when heated can under certain circumstances produce fire

by spontaneous combustion. Dry only on the AIR DRY cycle.

Unless specifically recommended by their manufacturer, do not use fabric softeners or similar

products in a tumble dryer.

Do not store or use gasoline or other flammable gases and liquids near this or any other appliance.

Keep the area around and underneath your dryer free from the accumulation of combustible

materials such as lint, paper, rags, chemicals etc.

Do not store any items that may burn or melt (such as paper materials, plastics or plastic

containers etc) next to the dryer.

Empty the lint bucket before the lint reaches the top of the transparent section. (usually once

a week).

US

CA

Page 8

8

Important Safety Instructions/Warranty

The dryer must be exhausted to the outside. Carefully follow the venting details in the

Installation Instructions.

Keep the floor around your dryer clean and dry to reduce the possibility of slipping.

If your dryer is running and you want to unload or add clothes, press START/PAUSE and wait

until the machine has unlocked the lid. Do not force it open.

Do not reach into the appliance if the drum is moving.

Close supervision is necessary if this dryer is used by or near children. Do not allow children to

play inside, around or with this dryer or any other appliance.

Never climb on, climb into, or stand on the dryer top, lid or drum.

Undergarments that contain metal reinforcements should not be placed directly in the dryer.

Damage to the dryer can result if the metal reinforcements come loose during drying.

The interior of the appliance and exhaust duct should be cleaned periodically by qualified

service personnel.

Before the appliance is removed from service or discarded remove the lid and the drum door to

the drying compartment.

SAVE THESE INSTRUCTIONS

Warranty

Your dryer has been made to the highest standards. Years of development and rigorous testing

ensure that you have bought a world-class product, in the unlikely event that a problem should

occur, refer to the Warranty section at the back of this Guide (refer to page 54).

If you have a problem with your dryer refer to our troubleshooting section. If your problem

is not referenced, please always contact your Fisher & Paykel Authorized Service Agent or our

Customer Care Center (Toll Free 1 888 9 FNP USA (1 888 9 367 872)) rather than attempting to fix

it yourself.

Page 9

9

Installation Instructions

Read the Important Safety Instructions on pages 6 – 8 before you start

installing the dryer.

Check to make sure you have all the tools and parts necessary to correctly install this appliance.

Tools Required

¼’’ nut driver or socket wrench

Phillips screwdriver

Flat-blade screwdriver

Adjustable wrench 8” or 10” (20cm or 25cm) for gas connections

Pipe joint compound (pipe dope or tape) for gas pipe connections that is resistant to LP Propane,

Butane and Natural Gas (Gas models only)

Level

Caulking gun and compound (for installing new exhaust vent)

Gloves

Safety glasses

Knife

Duct tape

Parts Supplied

2 feet inserts for front feet.

A power supply cord is supplied already connected to the gas dryer (Gas models only)

Check to make sure all parts have been supplied.

Accessories

Mobile Home Installation Kit Part No 395488

Natural Gas to LP Conversion Kit Part No 395489 (Gas models only)

LP to Natural Gas Conversion Kit Part No 395490 (Gas models only)

Kit Element 208V Part No 395500 (Electric models only)

Parts Needed

Check with local codes and read electrical, gas and venting requirements before purchasing parts.

US

CA

Page 10

To the Installer

The correct installation of the dryer is your responsibility.

Be sure you read the following instructions carefully before you start to install the dryer. These

instructions should be left with the home owner for future reference.

It is Your Responsibility to:

Observe all governing codes and ordinances.

Check code requirements. Some codes limit or do not permit installation of clothes dryers in

garages, closets, mobile homes or sleeping quarters. Contact your local building inspector.

Adhere to these installation instructions.

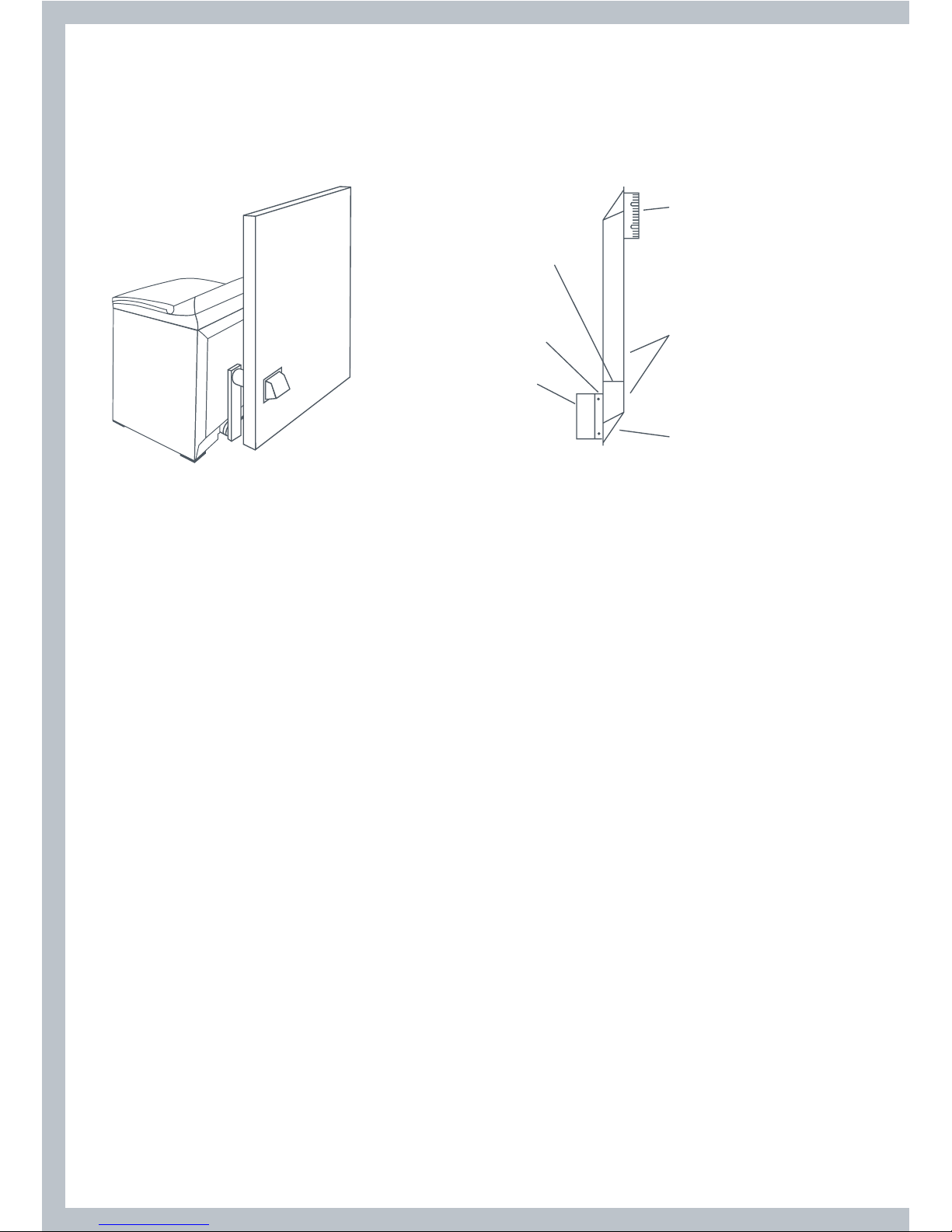

Allow for spacing requirements with side by side installations (refer page 11).

Make sure you have all items necessary for correct installation.

Properly install the dryer.

Contact a qualified installer to ensure that the electrical and gas installation meets all national

and local codes and ordinances. (See page 6).

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as gasoline, away

from the dryer.

Place dryer at least 18 inches (46 cm) above the floor for a

garage installation.

Failure to do so can result in death, explosion, fire, or burns.

The dryer must be installed or stored in an area which is not exposed to water or weather.

It is extremely important that the dryer is installed in a well ventilated location. This dryer must

exhaust air outdoors. Do not install the dryer in any room or closet which does not permit the

free flow of replacement air.

The free area of any opening for the introduction of outside air shall not be less than twice the

area of the dryer exhaust outlet.

Before installing the dryer ensure that there is sufficient height to fully open the lid. Allow

sufficient room behind the dryer for the exhaust. The air intake is at the rear of the dryer. Ensure

that there is a sufficient air passage on each side of the dryer for intake air.

10

Page 11

Location Requirements

The area in which the dryer is located must be

kept clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

A dryer produces combustible lint so the area

around the dryer must be cleaned regularly to

keep it free of lint.

This dryer can only be vented from the rear and

must be exhausted to the outdoors.

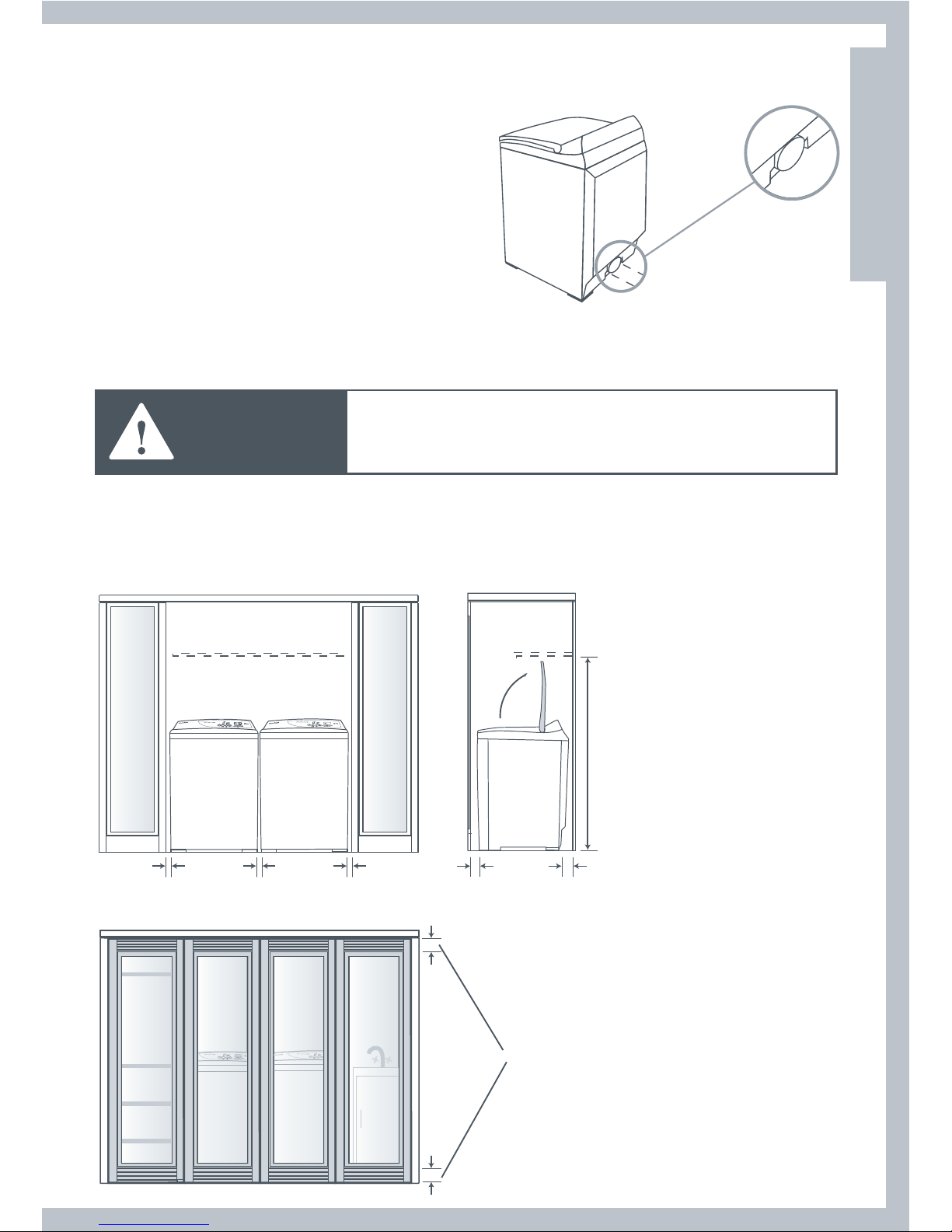

Alcove or Closet Installation

WARNING

When installing a dryer in a closet/alcove it must be

exhausted to the outdoors. No other fuel burning

appliance can be installed in the same closet or alcove.

The top opening area in the door must be a minimum of 48 square inches (310cm

2

) and the

bottom opening area must have a minimum of 24 square inches (155cm

2

). These openings must

never be obstructed (a louvred door with the minimum air opening is acceptable). Minimum

installation clearances are required but more clearance is recommended.

1” (25mm) 1” (25mm) 1” (25mm)

min 2” (50mm) min 3” (76mm)

min 56 /”

(1430mm)

48 sq” (310cm

2

)

total ventation area

72 sq” (465cm

2

)

24 sq” (155cm2)

11

US

CA

Page 12

12

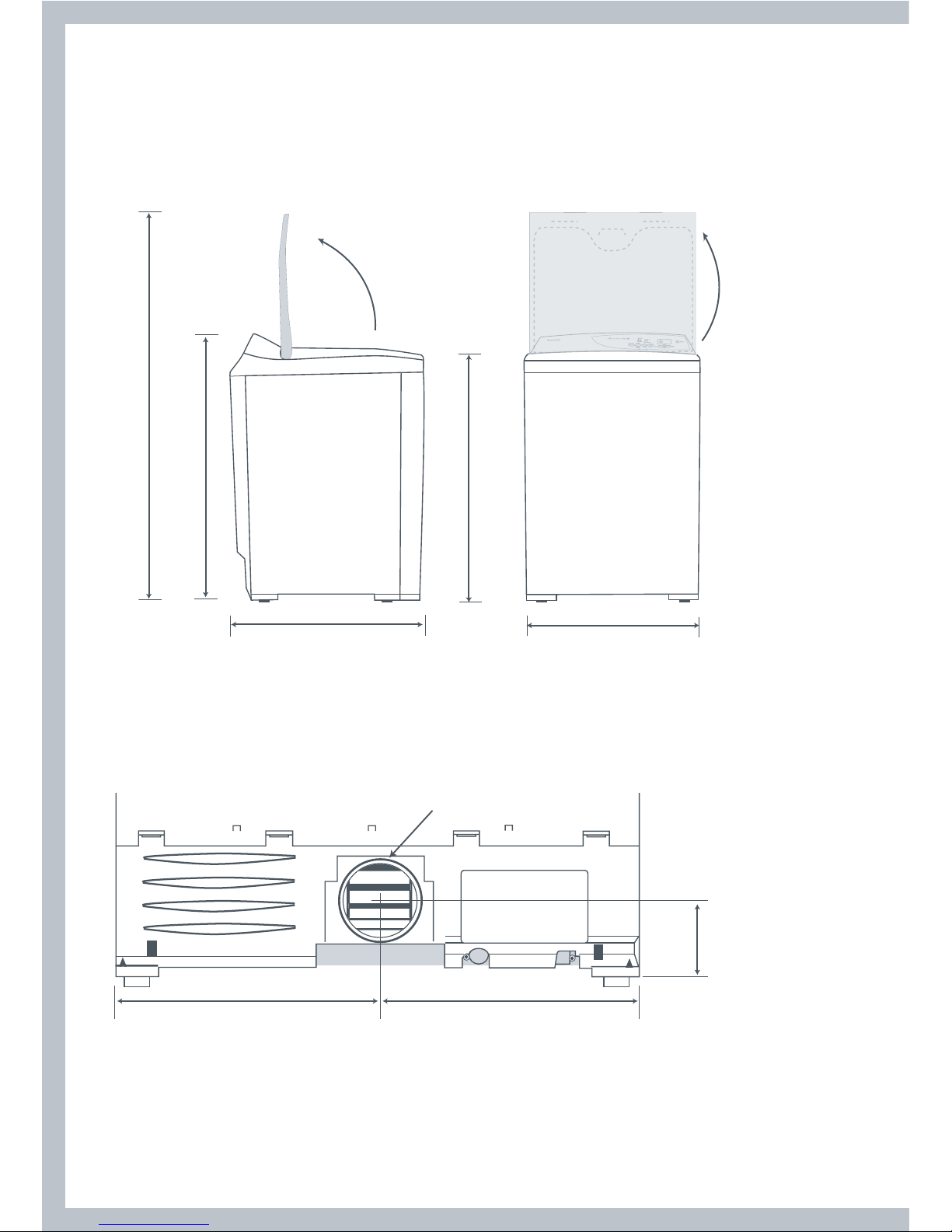

Dimensions

Lid Clearance

Check that there is enough clearance for the lid to fully open.

56” (1422mm)

39 /” – 41 ⁄”

(1010 – 1050mm)

27 ⁄” (700mm)

37” – 37 ⁄”

(925 – 955mm)

27” (685mm)

Exhaust Outlet Location

Exhaust outlet

Does not include

foot height

13 ⁄” (333mm)

13 ⁄” (352mm)

4 ⁄”

(111mm)

Page 13

13

Dimensions

Mobile Home Installation

The installation of the dryer in a mobile home must conform to the Manufactured Home

Construction and Safety Standard Title 24 CFR, Part 3280 {formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24 HUD (Part 280), 1975} for the United States or

Standard CAN/CSA – Z240MH for Canada.

When installing a dryer in a mobile home, provisions for anchoring the dryer to the floor must

be made.

A Mobile Home anchoring installation kit is available with instructions (see Accessories

page 9). Locate in an area that has adequate outside make up air (a minimum of 72 square

inches of unobstructed opening is required).

Mobile home installations must be exhausted to the outdoors with the exhaust duct

termination securely fastened to the mobile home structure, using materials that will not

support combustion.

The exhaust duct must not terminate beneath the mobile home. See the section on exhausting

for more information.

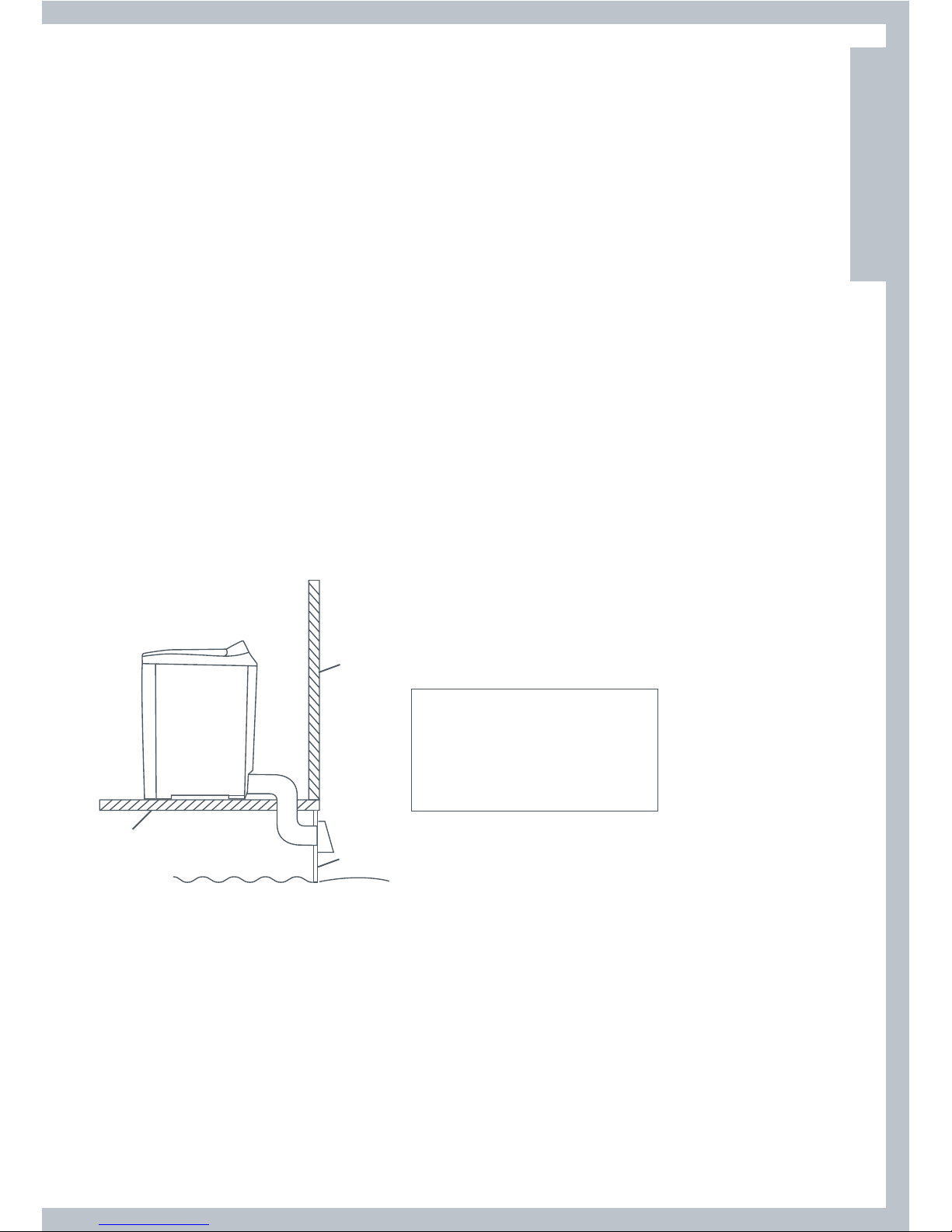

outside

wall

The dryer must be

exhausted outside

floor

enclosed area

skirting

The exhaust vent must be securely

fastened to a non-combustible

portion of the mobile home

structure and must not terminate

beneath the mobile home.

US

CA

Page 14

14

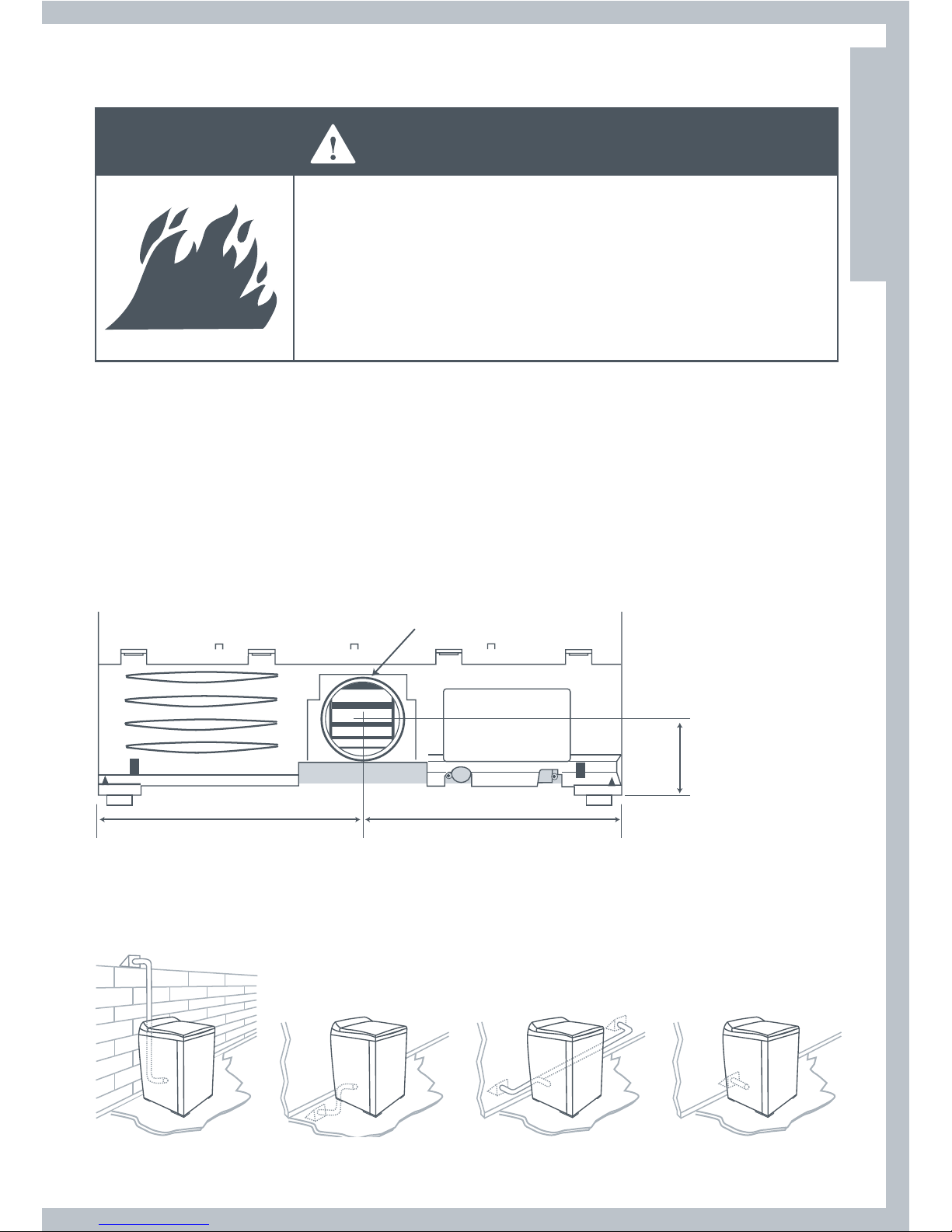

Exhausting

WARNING

Fire Hazard

The dryer must be vented to the outdoors.

Use rigid or thick wall flexible metal exhaust duct.

Do not use a plastic exhaust duct.

Do not use a metal foil exhaust duct.

Failure to follow these instructions can result in death or fire.

The dryer must be exhausted to the outdoors. This will prevent the build up of lint and moisture

in the room in which it is located and reduce the risk of fire.

This appliance must always be vented to the outdoors.

Exhaust ducting products can be purchased from your local Appliance store or Hardware store.

Plastic or metal foil flexible duct can kink, sag, be punctured, reduce airflow, extend drying times

and affect dryer operation.

A minimum of 4 inch (100mm) thick wall flexible metal or rigid galvanised metal duct must be

used. Using ducts larger than 4 inches (100mm) diameter may result in more lint accumulating.

Using straight rigid metal ducting will minimize lint accumulation. Thick wall flexible metal

ducting may be used but care must be exercised to avoid sharp bends which may squash the

duct and cause blockages. Do not use plastic ducting or thin wall flexible metal ducting.

Use duct tape to secure joints. Do not use screws as they collect lint.

Keep ducting as short and straight as possible. Do not exceed the maximum exhaust duct

lengths stated later in these installation instructions.

Do not exhaust the dryer into any other duct, chimney or gas vent, a wall, a ceiling or any

concealed space in a building. Do not exhaust the dryer under a house or mobile home or a

porch, or into a window well or other area that will accumulate lint.

The exhaust duct should end with an exhaust hood with a

swing out damper to prevent back drafts and entry of wild life.

Never use exhaust hoods with a magnetic damper. The hood

should have at least 12 inches (305mm) clearance between the

bottom of the hood and the ground or other obstruction. The

hood opening should point down. Never install a screen over

the exhaust outlet.

12” (305mm)

Page 15

15

Exhausting

To reduce condensation, insulate any ducting which passes through unheated areas.

Slope the duct gently downwards to the hood, to drain condensation and reduce lint build up.

Avoid sag or loops in the duct as they may collect and store water and accumulate lint.

Before using an existing exhaust duct system for a dryer ensure that:

No plastic or other potentially combustible duct or flexible metal foil ducting has been used.

The duct is not pierced, kinked or crushed.

The duct does not exceed the maximum recommended length for the new dryer.

The exhaust hood damper opens and closes freely and with sufficient movement.

Static pressure in the exhaust ducting does not exceed 1 inch (250Pa), or is not less than 0 inches

of water column (ie. negative pressure), when measured with a manometer in the first 6 inches

of the duct, with the dryer running on Air Dry (no heat) setting.

The exhaust duct system meets all relevant local, state and national codes.

All ducting should be inspected and cleaned at least once a year to remove accumulated lint.

Frequently check that the damper on the exhaust hood moves sufficiently and opens and

shuts freely.

Mobile Home Installations

A Mobile Home Installation Kit is available (see Accessories page 9 and notes page 13).

Determine Vent Duct Length

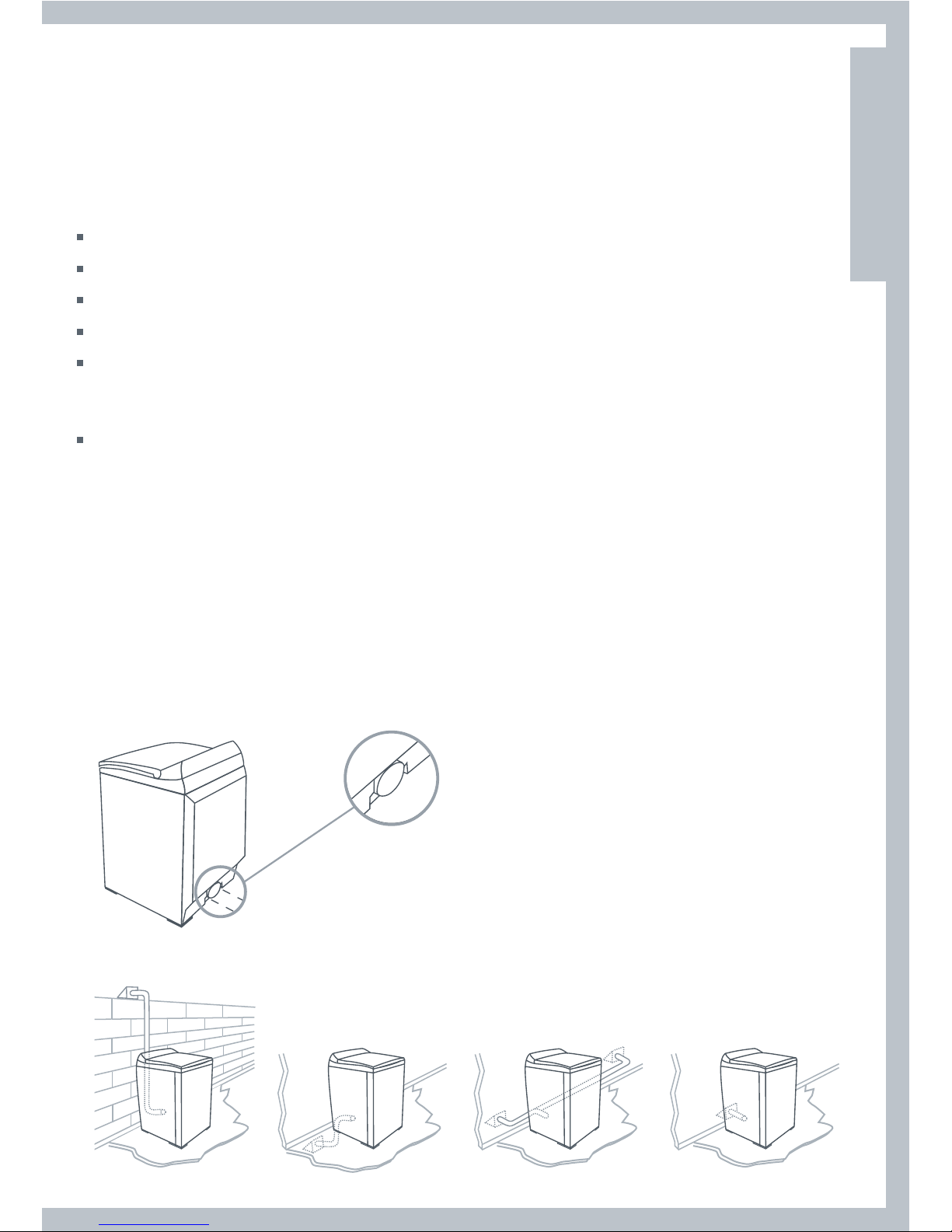

This dryer can only be vented from the rear and must be exhausted to the outdoors.

Different types of vent arrangements are shown below.

US

CA

Page 16

16

Exhausting

Choose a route that will provide the straightest and most direct path outdoors. Plan the

installation to use the fewest number of elbows and turns.

When using elbows (rigid duct) or making turns (thick wall flexible metal duct), allow as much

room as possible. With thick wall flexible metal duct bend duct gradually to avoid kinking and

avoid 90˚ turns.

recommended acceptable

Maximum Length of Exhaust Duct

The maximum length of the exhaust duct system depends upon:

The type of ducts (rigid or thick walled flexible metal).

The number of elbows or bends used.

1

Refer to the exhaust duct length chart that matches your hood type for the maximum duct

lengths you can use. Do not use duct runs longer than specified in the exhaust duct length

charts (refer to next page).

Exhaust duct systems longer than specified will:

Accumulate lint creating a potential fire hazard.

Shorten the life of the dryer.

Reduce performance, resulting in longer drying times and an increased energy usage.

2

Determine the number of elbows/bends you will need.

3

In the column listing the type of metal duct you are using (rigid or thick wall flexible metal), find

the maximum length of metal duct on the same line as the number of elbows/bends to be used

(refer to next page).

Page 17

17

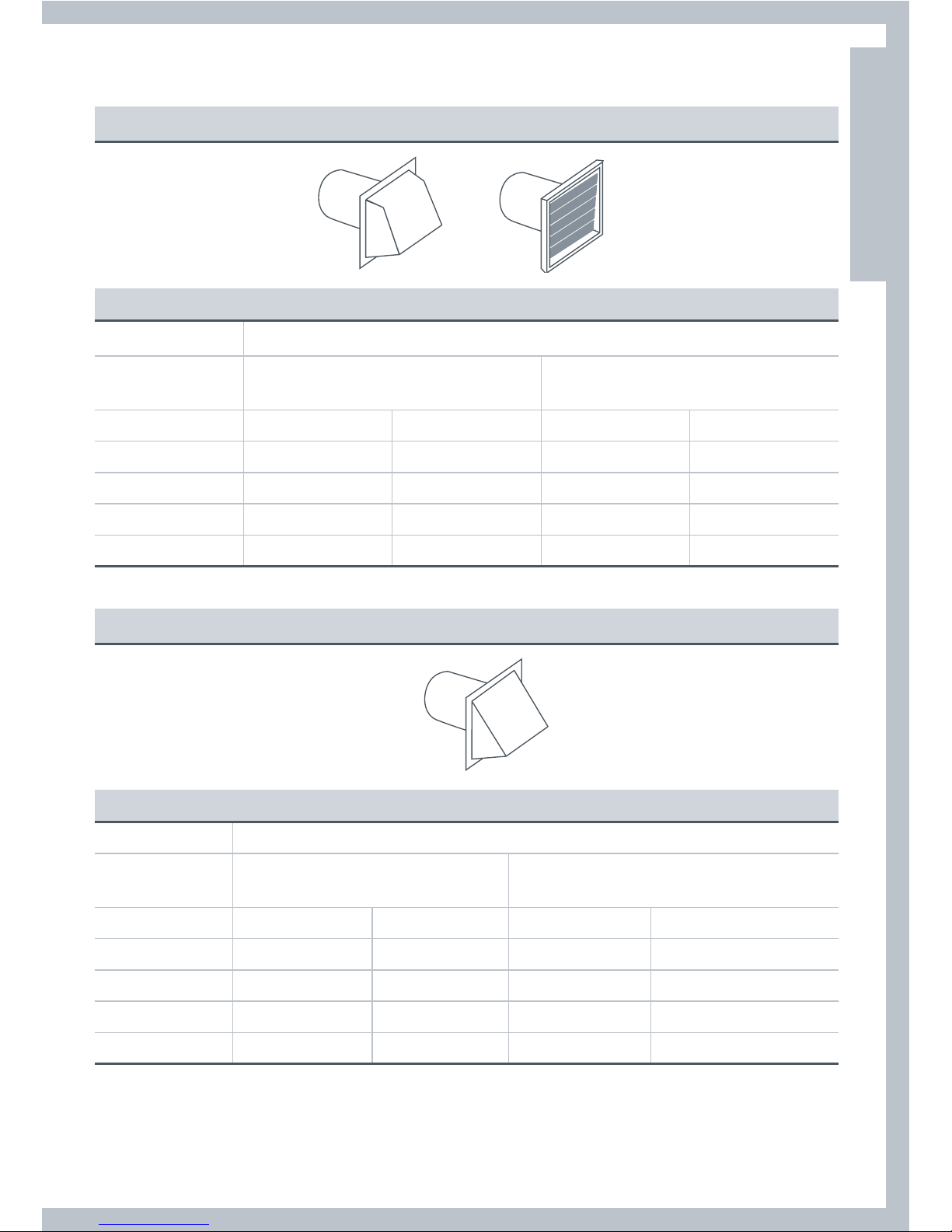

Preferred 4” Hoods

When you have a 4” (10cm) Hood

Maximum length of 4” diameter metal duct.

Number of 90˚

elbows/bends

Rigid

Thick Wall Flexible Metal

(fully extended)

0 64ft 19.5m 36ft 10.9m

1 54ft 16.5m 31ft 9.4m

2 44ft 13.4m 27ft 8.2m

3 35ft 10.6m 25ft 7.6m

4 27ft 8.2m 23ft 7.0m

Acceptable 2 ½”Hood

When you have a 2 ½” (6cm) Hood

Maximum length of 4” diameter metal duct.

Number of 90˚

elbows/bends

Rigid

Thick Wall Flexible Metal

(fully extended)

0 58ft 17.6m 28ft 8.5m

1 48ft 14.6m 23ft 7.0m

2 38ft 11.5m 19ft 5.7m

3 29ft 8.8m 17ft 5.1m

4 21ft 6.4m 15ft 4.5m

For exhaust systems not covered by the exhaust duct length charts (such as multiple unit

hook-ups, plenums, and power-assist fans), call our Customer Care Center:

TOLL FREE 1 888 9 FNP USA (1 888 9 367 872).

Maximum Length of Exhaust Duct

US

CA

Page 18

18

Alternative Installation for Close Clearances

Venting systems come in many varieties. Select the type best for your installation.

A close-clearance installation is shown.

sections separate,

fittings can face

same or opposite

swivel collar

Extra long

band–clamp

for dryer

connection

swivel collar

wall connection

telescoping

sections

beveled edges

allow corner

installations

The maximum length using a 2” x 6” (5cm x 15cm) rectangular duct with two elbows and a

2 ½”(6.3cm) exhaust hood is 8ft (2.4m).

Refer to the venting system kit manufacturers instructions.

Page 19

19

Exhaust Venting

WARNING

Fire Hazard

Use heavy metal exhaust duct.

Do not use a plastic exhaust duct.

Do not use thin metal foil exhaust duct.

Failure to do so can result in death or fire.

1

Read the exhaust section (page 14 – 18) before installing the exhaust system to determine the

maximum allowable exhaust duct length.

Do not use sheet metal screws when assembling ducting. Always use suitable duct tape.

Never use plastic or thin metal foil flexible exhaust material.

2

The exhaust outlet is located close to the center of the rear of the dryer. Make sure you join the

exhaust duct to the dryer with duct tape only. This will prevent lint and dust from escaping from

the dryer and exhaust system.

Exhaust outlet

Does not include

foot height

13 ⁄” (333mm)

13 ⁄” (352mm)

4 ⁄”

(111mm)

3

The exhaust vent can be routed up, down, left, right or straight out the back of the dryer.

Refer to diagram.

US

CA

Page 20

20

Installation

Parts and literature are packaged inside the dryer drum.

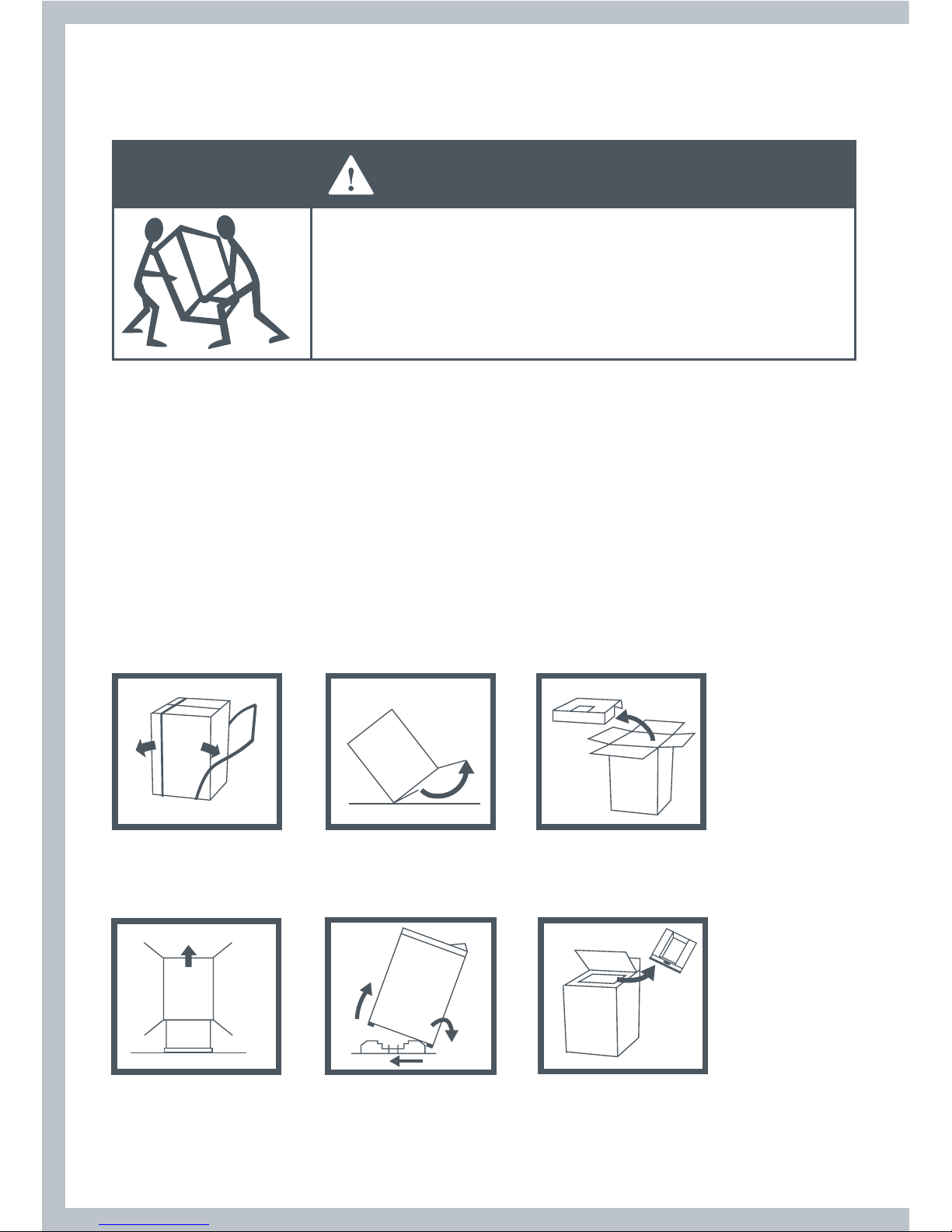

WARNING

Excess Weight Hazard

Use two or more people to move and install the dryer.

Failure to do so can result in back or other injury.

Only remove the packaging at the customer’s premises.

This will ensure the appliance arrives in pristine condition and reduces the risk of damage when

transporting to the customer’s home.

Unpacking

Make sure dryer is in a suitable location for installation.

Consider installing the dryer before the washing machine in a side by side installation, this will

allow better access to electrical and exhaust connections.

Remove Packaging

1. Remove straps.

2. Unfold the bottom flaps

on the carton.

3. Unfold the top flaps on

the carton, remove top

packer.

1.

2. 3.

4. Remove the carton

by lifting it off the

product (do not cut

the carton off ).

5. Remove the basepacker

by tilting the product

back and walking the

product off.

6. Remove the drum packer

and the tape from the

lint collector bucket in

the drum.

Tilt

Walk

off

Slide out

4. 5.

6.

Page 21

21

Installation

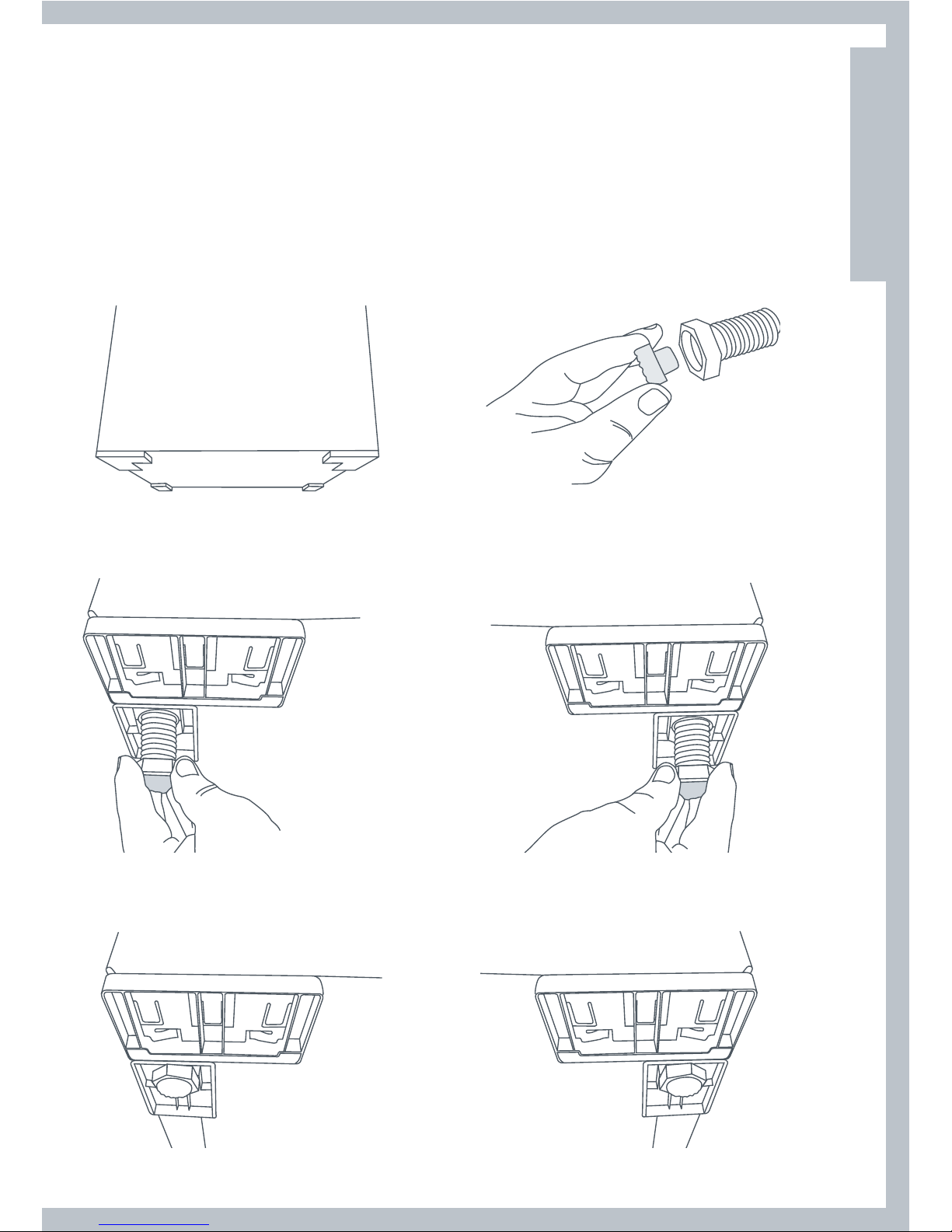

Fitting the Front Feet

Note:

Dryer is usually supplied with feet fitted and protruding the correct distance.

1

Tilt the dryer back using a hand trolley and making sure the trolley and dryer are secure.

2

Fit a rubber insert to each plastic foot as shown.

3

Screw the feet into the foot retainers on the left hand and right hand sides as shown.

4

Screw both feet in so they protrude ½” (12mm) below the bottom of the wall on the foot retainers.

US

CA

Page 22

22

Grounding Instructions for Gas and Electric Dryers

WARNING

Electrical Shock Hazard

Make sure appliance is wired or plugged into a grounded

outlet.

Do not use an adaptor.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire,

or electrical shock.

WARNING

Electrical Shock Hazard

Check with a qualified electrician or serviceperson if you are

in doubt as to whether the appliance is properly grounded.

Do not modify the plug if it will not fit the outlet.

Have the proper outlet installed by a qualified electrician.

Failure to follow these instructions can result in death, fire, or

electrical shock.

Grounding for a Cord-Connected Appliance

This appliance must be grounded. In the event of malfunction or breakdown, grounding will

reduce the risk of electric shock by providing a path of least resistance for electric current.

When this appliance is equipped with a cord having an equipment-grounding conductor and a

grounding plug, the plug must be plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and ordinances, or in their absence, with the

National Electrical Code ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1. Do not cut or

remove the grounding prong from this plug.

WARNING

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with

a qualified electrician or service representative if you are in

doubt as to whether the appliance is properly grounded.

Refer to pages 23 – 28 for wiring details for electric dryers.

Page 23

23

Electrical Requirements for Electric Models Only

WARNING

Electric Shock Hazard

Use a new UL approved 30-ampere power cord or direct wire

cable.

Use a UL approved strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center terminal.

On all four wire installations remove the grounding link and

connect the ground wire to the green ground connecting screw.

Connect remaining 2 supply wires to remaining 2 terminals.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or electrical shock.

Note:

The wiring diagram is located in the control console.

The dryer must be plugged into or connected to an individual branch circuit, do not use an

extension cord.

The power supply must be 220/240V or 208V, 60 Hz approved alternating current electrical

service. The electrical service requirements can be found on the data label that is located on the

splash back. A 30-ampere fuse or circuit breaker is required on each of the lines.

If a power cord is used, the cord must be plugged into a 30-ampere receptacle.

The power cord is NOT provided with U.S. electric model dryers.

This dryer is supplied with the cabinet grounded through the neutral on the terminal block.

If the dryer is to be installed in (1) a new branch circuit installation, (2) a mobile home, (3) a

recreational vehicle, (4) an area where local codes do not permit grounding through the neutral

conductor, the appliance grounding link must be removed and a 4-wire power cord/cable or a

separate grounding wire must be used.

Do not reuse a power supply cord/cable from an old dryer. The power cord/cable electric supply

wiring must be retained at the dryer cabinet with a suitable UL listed strain relief.

208V Requirements

If your power supply is 208V 60 Hz, a new element kit must be fitted by a qualified electrician or

service representative (see Accessories page 9 for kit part number).

US

CA

Page 24

24

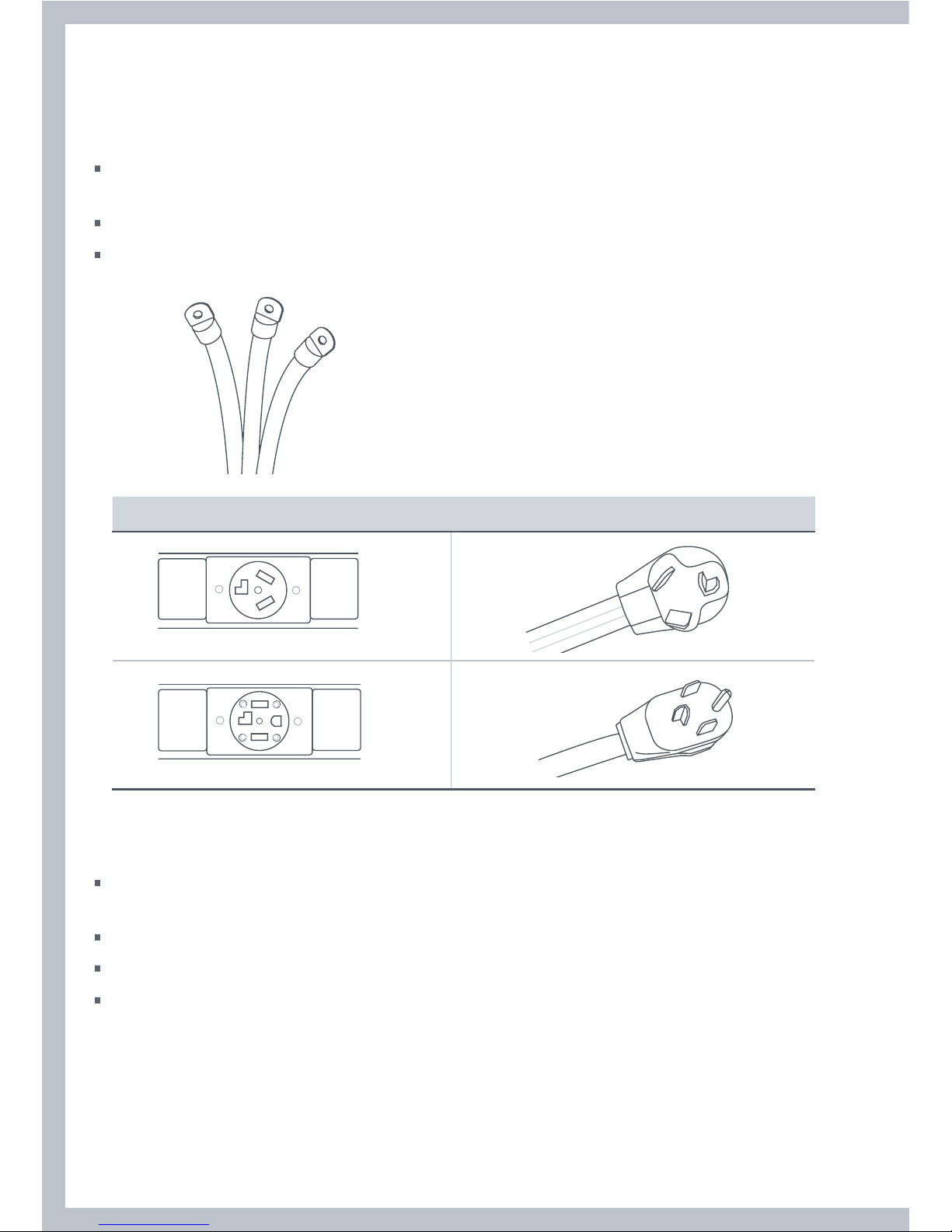

Power Supply Cord Requirements for U.S.A

for Electric Models Only

Only a UL listed power-supply cord kit a suitable length for the installation and rated 120/240 V

min, 30 A and marked with use for clothes dryers shall be used.

This shall have ring terminals to connect to the dryer.

The UL-rated strain relief included with it shall be suitable for a 1 /” (28.5mm) hole.

If your outlet looks like this Choose this power supply cord

Connecting by Direct Wire

Power supply cable must match power supply (4-wire or 3-wire) and be:

Flexible armoured or non-metallic sheathed copper cable (with ground wire). All current-carrying

wires must be insulated.

10 gauge AWG solid copper wire (do not use aluminium wire).

Suitable length for the installation.

A UL approved strain relief must be used.

Grounding for a Direct Wired Appliance

This appliance must be connected to a grounded metal permanent wiring system, or an

equipment grounding conductor must be run with the circuit conductors and connected to the

equipment-grounding terminal on the appliance.

4 wire

3 wire

Page 25

25

Electrical Connections (Electric Models Only)

Please read Electrical requirements and grounding instructions on pages 22 – 23 first.

Electric models of the dryer are manufactured for a 3-wire connection system. The dryer frame

is grounded by a link to the neutral conductor on the dryer terminal block. If local codes do

not permit grounding through the neutral, the grounding link from the terminal block must be

removed and a separate ground wire must be used.

The grounding link on the dryer must be removed for all 4-wire installations including new,

remodelled construction, or mobile homes.

These Electrical Connection instructions provide for installing the dryer in the following situations:

3-wire connection where local codes permit grounding through the neutral.

3-wire connection plus separate grounding connector where local codes do not permit

grounding through the neutral.

4-wire connection.

Each of the above connections can be made with an approved power supply cord or by direct

wiring. Each connection instruction identifies the appropriate Power Supply Cord and covers

requirements for direct wiring.

For 3-Wire Connections by Power Cords

3-wire power supply cord must have three 10 AWG copper wires and match a 3-wire receptacle

of NMEA Type10-30R.

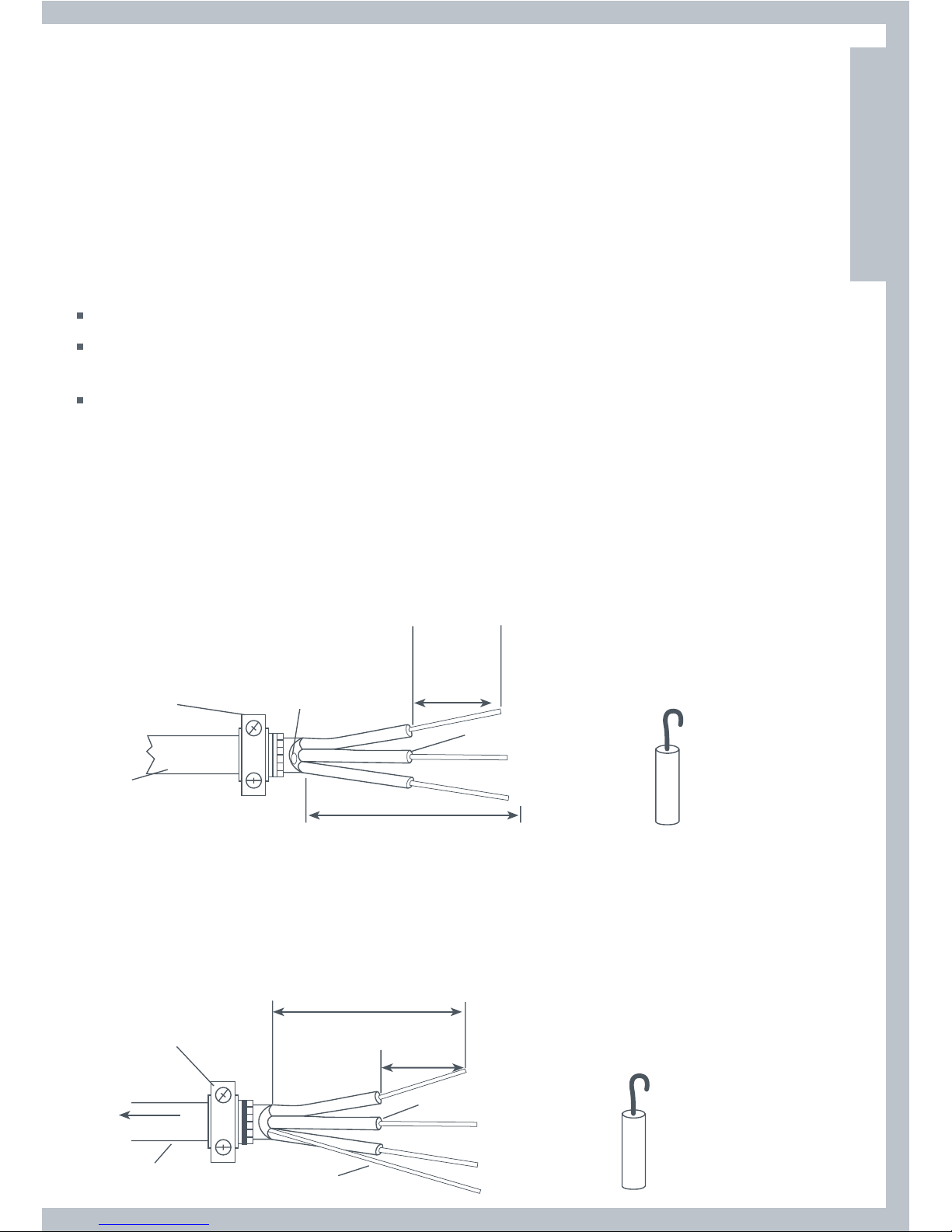

For 3-Wire Connections by Direct Wiring

10-gauge, 3-wire or,

10-gauge, 3-wire with

ground wire (Romex)

to disconnect

box

¾” UL-listed

strain relief

Three-wire with ground

wire: Bare wire cut short.

Wire not used. Dryer is

grounded through neutral

or separate grounding

1” of wires

stripped of

insulation

NEUTRAL wire

(white or center)

4 ¼”

Strip 4 ¼” of outer covering from end

of cable. Strip insulation back 1”. If

using 3-wire cable with ground wire,

cut bare wire even with outer covering.

Shape ends of wire

into a hook.

For 4-Wire Connections by Power Cords

4-wire power supply cord must have four 10 AWG copper wires and match a 4-wire receptacle of

NMEA Type14-30R. The fourth wire (ground conductor) must be identified by a green cover and

the neutral wire by a white cover.

For 4-Wire Connections by Direct Wiring

¾” UL-listed

strain relief

to disconnect

box

10-gauge, 3-wire with ground

wire (Romex)

bare ground wire

NEUTRAL wire

(white or center)

1” of wires

stripped of

insulation

4 ¼”

Strip 4 ¼” of outer covering from end of

cable. Strip insulation back 1”.

Shape ends of wire

into a hook.

US

CA

Page 26

26

3-Wire Connections

For use where local codes permit grounding through the Neutral wire.

Use approved 3-wire Power Supply Cord or a 3-wire Cable for Direct Wiring as described on page 24.

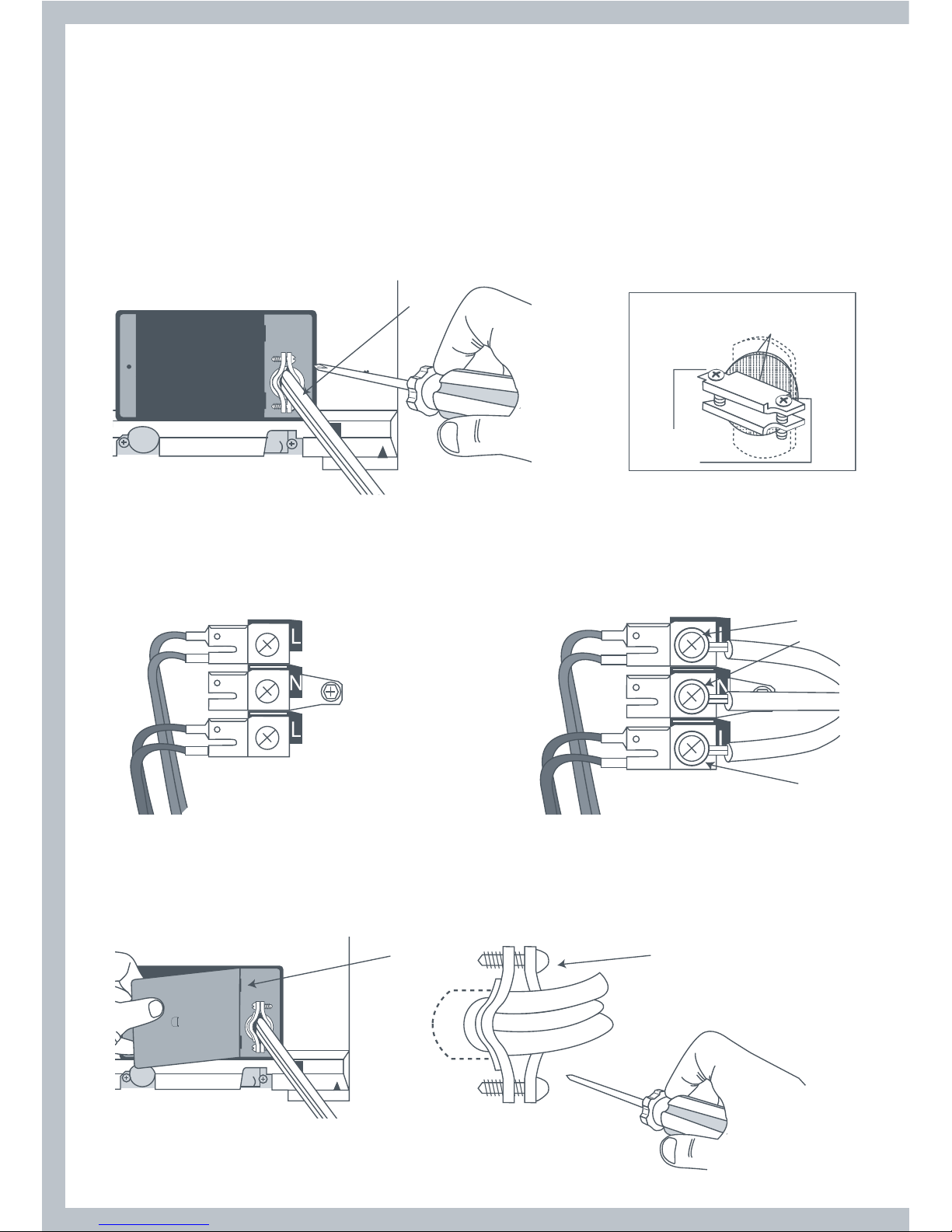

1

Remove the terminal block cover plate.

2

Insert the power cord with a UL listed strain relief through the hole provided in the cabinet near

the terminal block. Do not tighten strain relief screw until wiring connections are complete.

Note: a strain relief must be used.

2

strain relief

clamp sections

strain relief

screws

3

Loosen or remove the center terminal block screw. Connect the neutral wire (center) of the power

supply cord to the center terminal screw of the terminal block. Tighten screw.

4

Connect the other wires to the upper and lower terminal block screws marked with the

letter L. Tighten screws.

4

3

4

5

Refit terminal block cover by inserting the two tabs first on the rear panel of the dryer. Secure

cover with securing screw.

6

Tighten strain relief screws.

56

Page 27

27

3-Wire Connections plus separate grounding connector

For use where local codes do not permit grounding through the Neutral wire.

Use approved 3-wire Power Supply Cord or a 3-wire Cable for Direct Wiring as described on page 25.

A separate 10AWG copper grounding wire is required.

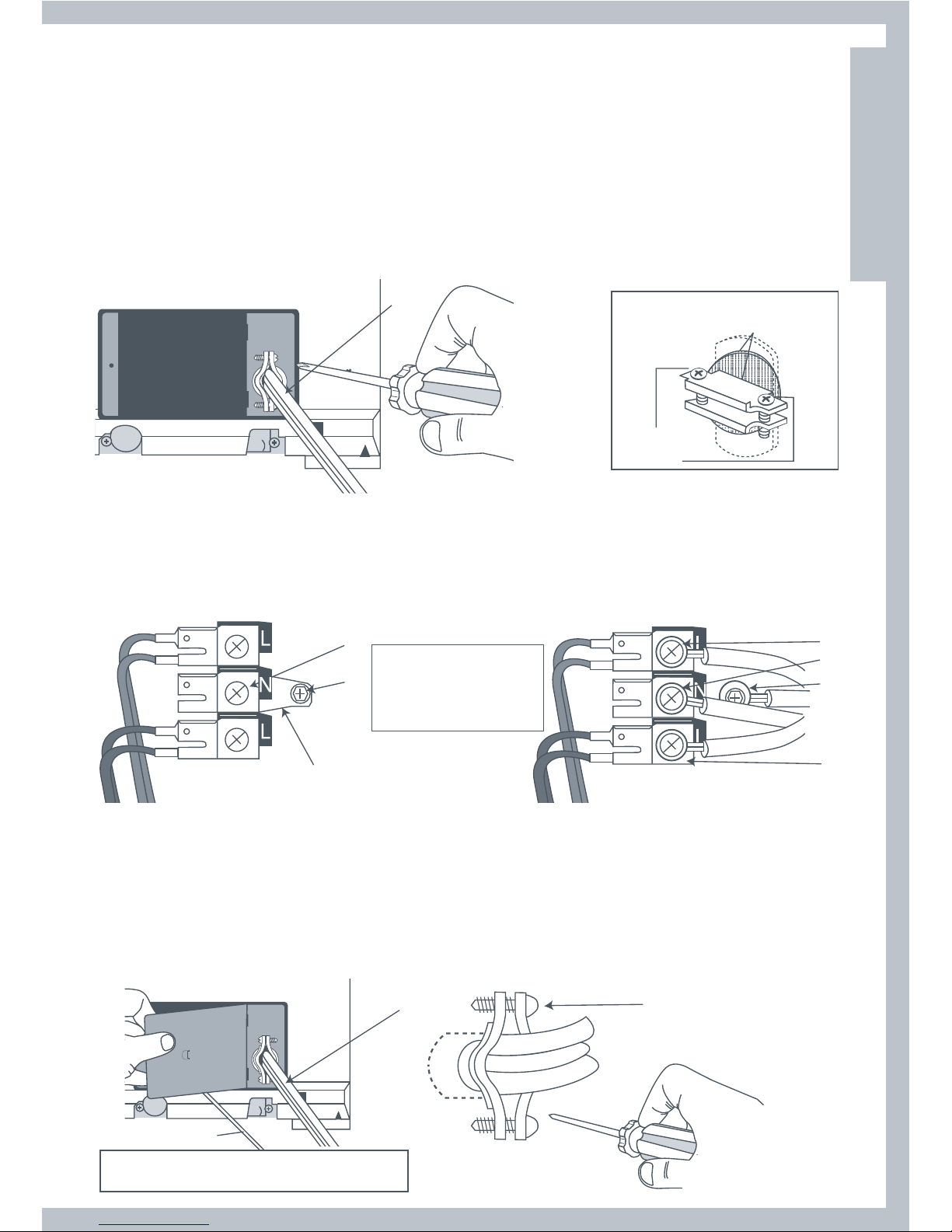

1

Remove the terminal block cover plate.

2

Insert the power supply cable with a UL listed strain relief through the hole provided in the cabinet

near the terminal block. Do not tighten strain relief screw until wiring connections are complete.

Note: a strain relief must be used.

2

strain relief

clamp sections

strain relief

screws

3

Remove center terminal block screw.

4

Remove appliance ground link by removing the ground connector screw (Green screw).

5

Connect a separate copper ground wire (green with yellow stripe) using the ground connector

screw (Green screw). Make sure a ring terminal is used when connecting the ground wire and that

the wire is firmly secured to an adequate grounding path.

3

4

7

6

5

7

Note: If the appliance is

moved back to a 3-wire

installation the ground

link must be refitted.

Remove link

6

Connect the neutral wire (center) of the power supply cord to the center terminal screw of the

terminal block. Tighten screw.

7

Connect the other wires to the upper and lower terminal block screws marked with the

letter L. Tighten screws.

8

Refit terminal block cover by inserting the two tabs first on the rear panel of the dryer and secure

cover with securing screw.

9

Tighten strain relief screws.

It is recommended that a qualified electrician

determine that the ground path is adequate

grounding wire

8

9

US

CA

Page 28

28

4-Wire Connections

Use approved 4-wire Power Supply Cord or a 4-wire Cable for Direct Wiring as described on page 25.

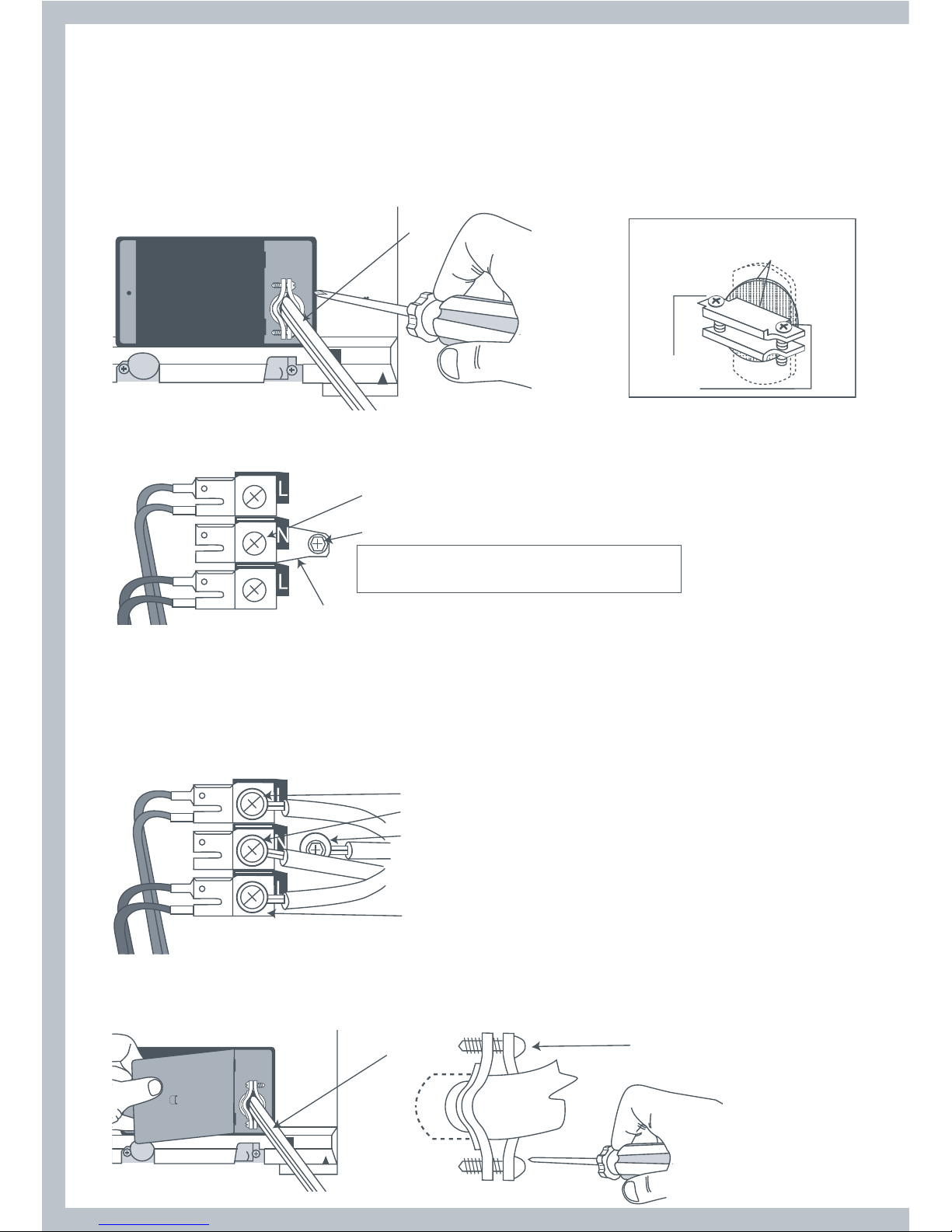

1

Remove the terminal block cover plate.

2

Insert the power supply cable with a UL listed strain relief through the hole provided in the cabinet

near the terminal block. Do not tighten strain relief screw until wiring connections are complete.

Note: a strain relief must be used.

2

strain relief

clamp sections

strain relief

screws

3

Remove center terminal block screw.

4

Remove appliance ground link by removing the ground connector screw (green screw).

3

4

Note: If the appliance is moved back to a 3-wire

installation the ground link must be refitted.

Remove link

5

Connect ground wire (green) of the power supply cord to the ground conductor green screw.

Tighten screw.

6

Connect the neutral wire (white) of the power supply cord to the center terminal screw of the

terminal block. Tighten screw.

7

Connect the red wire and black wire to the upper and lower terminal block screws marked with the

letter L. Tighten screws.

7

6

5

7

8

Refit terminal block cover by inserting the two tabs first on the rear panel of the dryer and secure

cover with securing screw.

9

Tighten Strain Relief screws.

8

9

Page 29

29

Gas Requirements (Gas Models Only)

The installation must conform with Local Codes, or in the absence of Local Codes, to the National

Fuel Gas Code ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code,

CSA B149.1.

WARNING

Explosion Hazard

Installations must be performed by a qualified or licensed

contractor, plumber, or gasfitter qualified or licensed by

the state, province, or region where this appliance is being

installed.

Use a new AGA or CSA approved gas supply line.

Install a shut-off valve in an accessible place.

Only use a gas shut-off valve approved for use within the state,

province, or region where this appliance is being installed.

Securely tighten all gas connections.

If connecting to LP Gas, have a qualified person make sure

gas pressure does not exceed 13” (33 cm) water column.

Failure to follow these instructions can result in death,

explosion, or fire.

Gas type

Your dryer must have the correct burner for the type of gas in your home. Burner information is

located on the rating plate located on the rear of the console. If this information does not agree

with

the type of gas available in your home, contact your local Fisher & Paykel supplier or service

center.

Natural Gas

This dryer is supplied ready for use with Natural Gas.

It is design certified by UL International for LP (Propane or Butane) Gases with the appropriate

conversion.

LP Gas Conversion

If the dryer is to be operated on LP (Liquid Propane or Butane) Gas, the dryer must be converted.

To do so, use only the approved Fisher & Paykel conversion kit listed in Accessories on page 9.

Do not use with a different gas without consulting the serving gas supplier.

The dryer must be converted for safe and proper performance by qualified service or installation

personel.

Conversion kits for Natural and LP Gas are available from your local Fisher & Paykel Dealer (see

Accessories page 9). If other conversions are required, check with your local gas utility for specific

information concerning conversion requirements.

US

CA

Page 30

30

Connecting Gas to Your Dryer (Gas Models Only)

Use compound or thread tape appropriate to the gas type that is to be used (Natural or LP Gas),

on the male threads of all non-flared connections.

Never use an open flame to test for gas leaks.

This dryer will operate satisfactorily up to altitudes of 6500ft (2000m) above sea level at the

BTU rating indicated on the model/serial plate. Burner input adjustments may be required if

operating above this elevation.

The dryer must be disconnected from the gas supply system during any pressure testing.

Gas Ignition

This dryer has an automatic ignition system to ignite the burner. There is no pilot flame burning

in this dryer.

Connecting to the Gas Supply

1

The gas supply line should be ½ inch.

2

An individual manual shut-off valve must be installed on the gas supply line within 6ft (1.8m) of

the dryer, in accordance with the National Fuel Gas Code ANSI Z223.1/NFPA 54 for the United

States or in accordance with the B149.1 Natural Gas and Propane Installation Code for Canada.

3

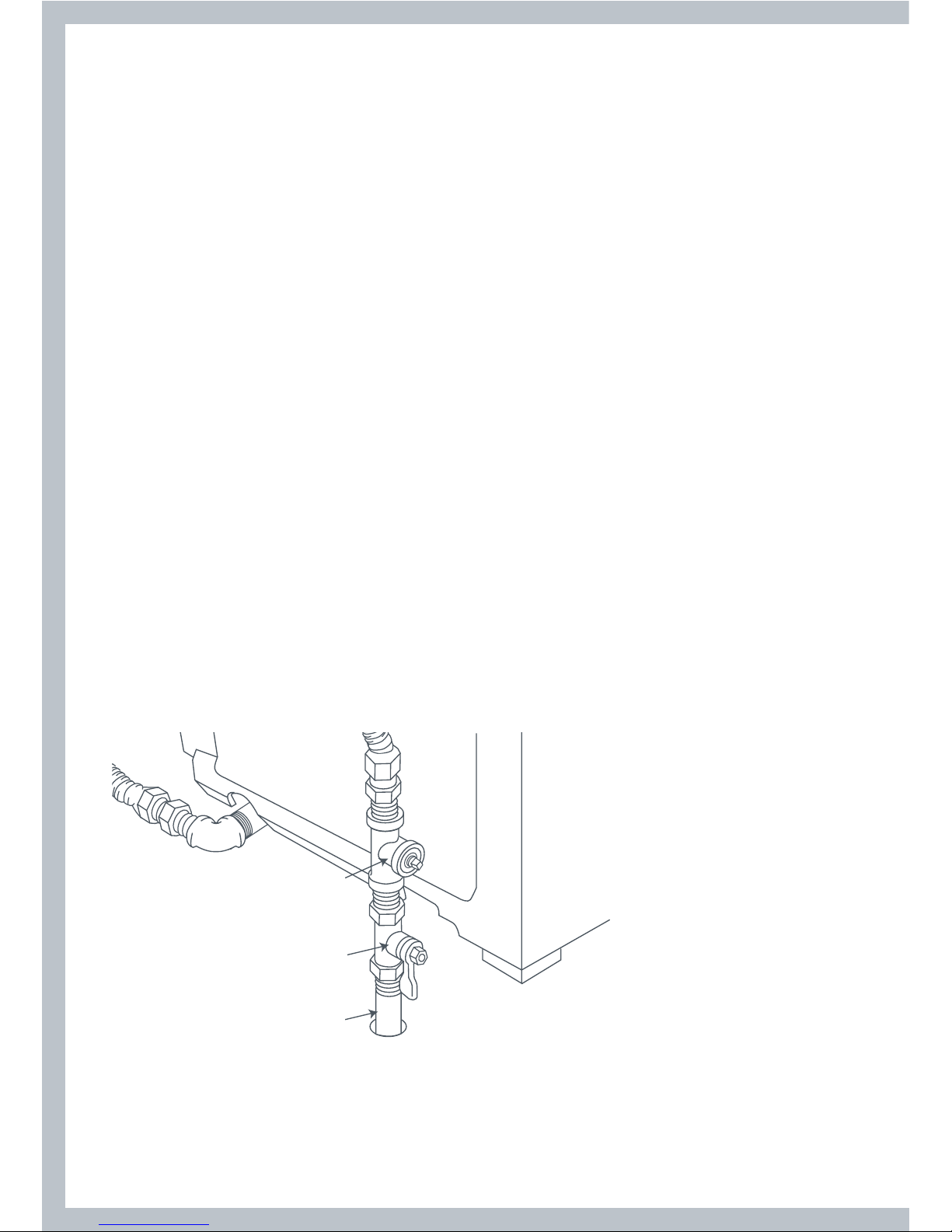

An ⁄ inch NPT plugged tapping must be installed to allow the gas inlet pressure to be checked.

It must be accessible for the test gauge connection and immediately upstream of the gas

connection to the dryer.

⁄” NPT plugged tapping

Gas shut–off valve

⁄” NPT gas supply line

Page 31

31

Connecting Gas to Your Dryer (Gas Models Only)

4

A listed connector in compliance with ANSI Z21.24/CSA6.10 must be used to connect the dryer

to the gas supply.

5

If flexible tubing is used, an elbow should be installed on the pipe at the back of the dryer for

the flexible tube to be connected to. This will minimize damage to the tube when the dryer is

moved back. Use a flexible tubing connection kit that has designed for use on a clothes dryer.

This kit should have the unions necessary to join to the ends of the tubing. Be sure to follow all

instructions supplied with the kit.

6

Copper tubing should not be used for Natural Gas and if used for LP Gas, it must be LP Gas

compatible.

7

Disconnect and discard old flexible tubing.

8

The gas pipe that comes out of the rear of your dryer has on it a ⁄” NPT male thread. Remove

the protective cap and apply sealing compound or tape to the thread. Thread sealant should be

appropriate for the type of gas to be used.

Apply thread

sealant

Remove cap

⁄” NPT pipe thread

Elbow required

for flexible tubing

Completing the Connection

9

Use wrenches to tighten all joints but do not over tighten.

10

Open the gas supply valve and check all joints by brushing on a non-corrosive leak-detecting

solution. Bubbling will indicate a leak. If any leaks are found, close the valve immediately and

correct the leaks. Retest and repeat until no leaks are found.

US

CA

Page 32

32

Level Machine

Check the dryer is level, and make necessary adjustments to the

front levelling feet. The rear levelling feet are self adjusting.

Final Installation Check List

Check that:

No plastic or flexible metal foil is used in the exhaust ducting.

Exhaust is rigid ducting or thick wall flexible metal ducting.

All joints in the ducting are made with duct tape. It must not be connected with screws or other

fastening devices which extend into the inside of the duct.

Ducting is clean and is connected to the dryer.

Inserts are fitted to the two front feet.

Dryer is level across the front.

Additionally for Electric Dryer Models Only, Check:

If installation is 208V, special element kit has been fitted (see page 23).

Dryer is plugged or directly wired into an approved fitting and is properly grounded.

Dryer starts, heats, cools and shuts off.

Customer has been shown how to use the dryer.

Additionally for Gas Dryer Models Only, Check:

Dryer is plugged into an approved fitting and is properly grounded.

All fittings in the gas line are tested for leaks.

Exhaust temperature increases, to confirm ignition has occurred.

– If ignition does not occur initially, it may be due to air in the gas line or low voltage power supply.

– The gas regulator valve may fail to open if the power supply falls below 105 Volts.

– If the gas fails to flow or does not ignite, the dryer will automatically switch off.

Customer has been shown how to use the dryer.

Note:

All dryers have a drum reversal feature to reduce clothes tangle. Throughout the drying cycle

the motor will run for four minutes, then stop and run in the opposite direction for forty seconds

before reversing again.

WARNING!

Electric Shock Hazard

Read and follow the Important safety instructions outlined in this User

Guide before operating this appliance, pages 6 – 8.

Failure to do so can result in death, electric shock, fire or injury to persons.

Close supervision is necessary if this dryer is used by or near children. Do not allow children to

play inside, around or with this dryer or any other appliance.

Page 33

33

Features

Smart Loading

The new ergonomic design of this dryer means less bending.

Simply move clothes from the washer to the dryer with

minimal effort.

Superior Clothes Care

Superior clothes care is accomplished by an efficient high airflow

fan and careful heat control. The Intuitive™ dryer provides the

right heat for temperature sensitive delicate articles while still

efficiently drying more robust regular and denim loads.

Reverse Action Tumbling

The drum reverses regularly, so your clothes dry more evenly

without roping or tangling.

Lint Bucket

The lint filter is automatically scraped clean during the drying

cycle and the lint is deposited into the lint bucket. No touching

or scraping lint any more. Airflow is more efficient as it is never

restricted by a blocked filter.

Perfect with the Fisher & Paykel Intuitive™ Washer

The dryer combined with the Intuitive™ washer’s superior spin

performance and quick cycle times will cut laundry turn around

time by up to one third, reducing the time you spend doing

laundry.

Stainless Steel Drum

Being stainless steel, this drum is not only more hygienic, it’s also

more resilient and easier to keep looking good.

US

CA

Page 34

34

Operating Instructions Control Panel

A. Sorting

Sort clothes of similar types and loads that take similar times to dry.

(Refer to Sorting page 46).

B. Loading

Load clothes no higher than the transparent section of the lint

bucket. (Refer to Loading page 46).

C. Lint Bucket

Check to see if the lint bucket needs emptying. Empty before

the lint reaches the top of the transparent section (refer to Lint

Bucket page 47).

D. Press Power

E. Fabric Type

Choose the fabric type that most represents the items in your load. Your dryer defaults to a MIXED

fabric type, to change it press either the UP or DOWN arrow. A description of each cycle will pop

up on the display screen as you scroll through the lights. (For more information on the cycles refer

to page 37).

If you want to use AIR DRY, press the DOWN arrow until AIR DRY light is lit.

Empty before this

level is reached

D

E GF

Page 35

35

Control Panel

F. How Dry?

Choose how dry you want to dry your clothes, There are 5 dryness settings you can choose

between, EXTRA DRY, EXTRA DRY/DRY, DRY, DAMP/DRY, or DAMP. (Refer to page 39 for

descriptions). Press the HOW DRY button until the setting you want is lit.

G. Start

Press START/PAUSE to start your machine.

H. Display screen

Shows you what options you have selected and/or any Lifecycles™ you may have chosen. The

display screen also shows you the progress of the load as well as displaying messages to help you

with the overall running of your machine.

I. Options Menu

Choose any options you want by scrolling through the OPTIONS MENU. Press the OPTIONS button.

Scroll through the options by using the UP and DOWN arrows. To select an OPTION, press ADJUST.

Once a selection has been made press HOME to return to the main screen (Refer to page 42).

J. Lifecycles™

There are 10 unique Lifecycles™ that have been specifically designed to make drying simpler

and easier.

Family Specials Bulky Items

Allergy Freshen Up Blankets

Towels Warm Up Jeans

Shirts Dry Clean Comforter

Lingerie

(Refer to Lifecycles™ page 44).

H

J

I

US

CA

Page 36

36

Quick Start

WARNING

To reduce the risk of fire, electric shock or personal injury, read the IMPORTANT

SAFETY INSTRUCTIONS before operating this appliance.

WARNING

Fire Hazard

Only dry fabrics that have been washed with water.

Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials. Dry on the Air Dry cycle.

A clothes dryer produces combustible lint and must be

exhausted outdoors. Take care to prevent the accumulation of

lint around the exhaust opening and in the surrounding area.

Failure to follow these instructions can result in death or

personal injury.

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as gasoline, away

from dryer.

No washer can completely remove oil.

Do not dry anything that has ever had gasoline, oil or anything

flammable on it (including cooking oils).

Failure to follow these instructions can result in death or

personal injury.

1

Press POWER

2

Choose your Fabric Type

3

Choose How Dry you want your clothes

4

Press START

1

2 3 4

Page 37

37

Fabric Type

The Intuitive™ dryer is capable of drying many

different fabric types. On the display screen the

FABRIC TYPE button is located next to the POWER

button. Use the UP and DOWN arrows to alter the

fabric type you wish to dry with.

When you turn your Intuitive™ dryer on it will

automatically select the MIXED fabric type. This

setting is suitable for drying your everyday garments,

e.g. t-shirts, trackpants, sweatshirts etc.

To change the FABRIC TYPE, press either the UP or DOWN Arrow.

Select a fabric type that matches the type of load you are drying. Different fabrics have different

drying requirements, so it is important to choose the cycle that best describes the load. For

example if your load contains mainly delicate items it is best you select the LIGHT Fabric Type.

Always follow manufacturer’s care label instructions when drying.

If you are unsure of the temperature to select for a load, it’s best to select a lower heat rather

than a higher heat, e.g. the LIGHT or CASUAL setting instead of the MIXED setting.

There are five FABRIC TYPES programmed into your Intuitive™ dryer as well as an AIR DRY option.

HEAVY

The HEAVY setting has been designed to provide a long, high heat cycle for heavy fabrics and

denims that tend to have thick and bulky seams. This setting dries for longer intervals to ensure

heavy items are fully dry.

MIXED

The MIXED setting has a high heat for drying everyday clothing and linen. This cycle is suitable

for most garments labelled “Tumble Dry”.

CASUAL

The CASUAL setting uses a medium heat for lightweight fabrics. It is ideal for lightweight cottons

and items labelled “ tumble with a medium heat”

DRY AND WEAR

The DRY AND WEAR setting uses a medium heat combined with the selection of the WRINKLE

FREE option. Ideal for any types of garments where you want to wear them straight away. The

Wrinkle Free option is automatically selected so there is no need to iron clothes when you

remove them from your dryer. Once drying is completed, clothes are automatically turned every

5 minutes, without heat, to reduce the likelihood of creases and wrinkles developing. This will

continue for up to 24 hours or until you stop the dryer.

US

CA

Page 38

38

Fabric Type

LIGHT

The LIGHT setting is ideal for delicate or heat sensitive items. Use this setting when care-labels

recommend low heat settings or for garments with a synthetic fiber content, where overheating

could cause damage to fibers.

AIR DRY

The AIR DRY option is for items requiring drying without heat. Perfect for airing clothes or to

freshen up garments that have been packed in a suitcase or drawer.

Press the FABRIC TYPE button DOWN until the AIR DRY light is glowing. A second screen will

automatically pop up, to show AIR DRY time options. Use the ADJUST button to choose the

length of time you wish to dry your load for.

Page 39

39

How Dry?

AUTO SENSING

Autosensing is automatically selected when your

Intuitive™ dryer is turned on. When selected, your

dryer automatically senses the dryness level of the

load and turns off when the clothes are dry. Intuitive’s

internal computer measures the moisture content of

the load using metal sensor bars and together with a

temperature sensor determine when the clothes have

reached the selected dryness level.

For optimum clothes care match the cycle to the load. AUTO SENSING often provides the best

results and leads to lower energy costs than TIME DRY.

There are five different dryness levels to choose from:

EXTRA DRY

DRY/EXTRA DRY

DRY

DAMP/DRY

DAMP

The dryer defaults to the DRY Setting. To change this

press the HOW DRY button until the dryness setting

you want is highlighted. If you choose the DAMP/DRY

or DRY/EXTRA DRY setting two lights will be displayed.

At the end of the cycle if the clothes are still damp or

are too dry next time adjust the dryness level on the

touch pad to meet your personal preferences.

Dryness Level Descriptions

EXTRA DRY

This is mainly for items that you want to store (i.e. place in a drawer, cupboard or wardrobe). By

using this setting you eliminate the possibility of ‘musty smells’ that commonly occur when items

are stored in a damp state.

DRY

Dries clothes to a level where they are considered ‘dry’, so garments can be worn immediately.

DAMP

Dries the clothes to a level where they are considered ‘moist’. It is designed for delicate, lightweight fabrics and articles of clothing which you want to iron-dry.

US

CA

Page 40

40

Display Screen

The display screen on the right hand side of the panel

shows you what the machine is doing during the cycle. The

display screen also shows you the different drying options

available. When you first turn your Intuitive™ dryer on it will

briefly display the message “Welcome to Intuitive”. The main

screen then appears with a big smiley face and tells you the

machine is READY TO DRY, the setting it has defaulted to

and also displays any options/lifecycles you select.

All About the Options Button…

Your Intuitive™ dryer has a menu of drying options you can use. The buttons and the display

screen on the right hand side of the panel are used to select and display the different options.

To Select a Drying Option:

1

Push either the Options UP or Options DOWN arrow. The

Options menu will then be displayed.

2

Scroll through the options by using either the UP or DOWN

arrows. To select an option use the ADJUST button. The

option will be highlighted to show you have selected it.

3

Press HOME, the display will return to the home screen,

where your selected drying option(s) will be displayed.

4

To start your dryer press START/PAUSE.

Note:

If you want to change any of the drying options while your machine is running you will need to

press START/PAUSE before changing an option or setting.

Page 41

41

Progress Screen

During the cycle the display screen shows you the progress of your load by displaying a series of

messages that indicate what stage the dryer is up to. The display screen also scrolls through any

options you may have chosen.

When you first start your dryer the words SENSING Dampness will appear on the screen. During

this period the dryer is sensing the dampness of your load.

Once the dryer has sensed your loads dampness the words

DRYING will appear on the screen. (If you have chosen

AIR DRY the word AIRING will appear). This message is

displayed for the majority of the cycle letting you know it is

in the process of drying your load. The dryer will continue

to display the word DRYING until it senses that your load is

becoming damp.

The word DAMP will appear when the dryer senses that the load is becoming dry. This is the

stage that you can remove delicate garments you wish to hang dry.

The word DAMP/DRY appears when the dryer senses that the clothes are almost dry. It will

continue drying until it reaches the HOW DRY level you have selected. Once it reaches the

dryness setting you have chosen your dryer will progress into COOLING.

You can select an option in the Options menu to remind you to remove your delicates early

(refer to page 43).

The word COOLING will appear when dryer is in the

process of cooling down the dry load. This is where the

load is tumbled with no heat, decreasing the need for

ironing. COOLING will continue until the dryer senses the

clothes have been cooled down sufficiently. The exception

is TIME DRY which has a fixed COOLING period.

US

CA

Page 42

42

The Options

For all the options mentioned below select the OPTIONS

menu (by pressing the UP Options arrow). Use the Options

arrows to scroll through the options until the one you want

is displayed.

Press ADJUST to select it and HOME to return to the main

screen.

1. WRINKLE FREE

The WRINKLE FREE option minimizes the likelihood of creases or wrinkles forming in clothes, if

you are not able to unload the dryer straight away. This option rotates the drum periodically after

the cycle has finished. This tumbling action, combined with blowing cool air through the clothes,

helps garments to remain wrinkle free.

WRINKLE FREE uses very little power and will continue for

up to 24 hours or until the user turns the dryer off. After

completing each tumble Intuitive™ dryer will give an end

of cycle beep to remind you that the load is dry and can

be removed.

Scroll to Option screen 1, press the ADJUST button to

change setting, press HOME to save your setting.

To stop the dryer press either POWER or START/PAUSE.

Intuitive™ dryer will open the drum door and unlock the lid,

so you can remove your clothes.

WRINKLE FREE can be selected on any cycle.

2. TIME DRY

There are three timed cycles. You can choose between

20, 40 and 80 minutes. A COOLING period of 10 minutes

is included in the 80-minute and 40-minute cycle. The 20

minute cycle has a 5-minute COOL DOWN period.

Scroll to Option screen 1, press the ADJUST button to

change setting, press HOME to save your setting.

To select a timed cycle, press the ADJUST button to move to the time you wish to dry for. Your

Intuitive™ dryer will default to 40 minutes.

If you choose to select TIME DRY, please note the dryer will not sense when your clothes are dry.

This may increase the chance of over-drying.

We recommend that you dry your clothes for a slightly shorter time than you think they need, or

check on them regularly (to avoid over-drying).

Page 43

43

The Options

3. END OF CYCLE BEEPS

You can change the number of beeps your Intuitive™ dryer sounds at the end of the cycle. Scroll

to Options screen 3, use the ADJUST button to move to your desired preference. Press HOME to

save your selection.

4. REMINDER – REMOVE DELICATES EARLY

If you wish, your Intuitive™ dryer can remind you to

remove your delicate items while they are still slightly

damp. This can be useful if you have a mixture of light

and heavy fabrics in your load. Your dryer will beep and

display a message when it senses that the load is nearly

dry. You will then be able to remove delicate items and

the rest of the load will continue the cycle.

To activate the reminder, scroll to Options screen 4, press the ADJUST button to select ON, then

press HOME to save your setting.

5. REMINDER – EMPTY LINT BUCKET

This reminder is automatically selected when you receive your dryer. If you do not wish to be

reminded every 5 cycles to remove the lint from the lint bucket you can turn the reminder off.

Scroll to Options screen 5, press the ADJUST button to select OFF, then press HOME to save your

setting (also refer to page 47).

6. REMINDER – ADD SOFTENER SHEETS

If you add fabric softener sheets to your dryer, you can select this option to remind you to add

them at the beginning of each cycle. To activate the reminder, scroll to Options screen 6, press

the ADJUST button to select ON, then press HOME to save your setting.

7. CYCLE TIPS

Cycle tips screens are displayed to help you to remember what each cycle does.

For example, when you select Fabric Type = Mixed, after 1 second a cycle tips screen will appear

with the words “Mixed – High heat for everyday cottons”.

Once you have become familiar with your dryer you may wish to switch these tips off. Scroll to

Options screen 7, press the ADJUST button to select OFF, then press HOME to save your setting.

8. TROUBLE SHOOTING

Your Intuitive™ dryer provides basic Trouble Shooting tips on screen. Scroll to Options screen 8,

press the ADJUST button to select the topic that you require assistance with. The topic will then

be displayed on the screen. Use the Options down arrow to scroll through possible solutions.

For more detailed Trouble Shooting information refer to pages 52 – 53 of this guide, or If Your

Intuitive™ Dryer Beeps For Help, page 51.

US

CA

Page 44

44

Lifecycles™

Your Intuitive™ dryer has a range of special, pre-programmed Lifecycles™ to make doing the laundry

even easier.

Push the LIFECYCLES button.

Use the OPTIONS button to scroll through the 3

Lifecycles™ menus, or you can press the LIFECYCLES

button repeatedly.

Use the ADJUST button to select a lifecycle.

Press HOME to return to the main screen.

L1 Family

ALLERGY

This cycle has been designed to complement the Allergy cycle currently available in the Intuitive™

washer. It is recommended for both allergy sufferers and for piece of mind in times of family illness.

This cycle uses a high heat to ensure that dust mites and bacteria populations are decimated. It has

been designed primarily for sheets and everyday clothing, and is not recommended for garments

that are heat sensitive.

TOWELS

Heavy Fabric Type, Dry/Extra Dry dryness level, with Autosensing.

Specifically designed for towels.

SHIRTS

This cycle has been developed for business and dress shirts. It uses

a medium heat, Autosensing selected, Dry dryness level, with the

WRINKLE FREE option selected to reduce wrinkling.

LINGERIE

This is an extra gentle cycle for delicate fabrics. It has been designed for garments that you previously

may have been reluctant to put into the dryer e.g. lingerie and synthetics. This cycle dries using the

Light Fabric Type setting, Autosensing, the Dry dryness level, and has the WRINKLE FREE option

selected to reduce wrinkling. We recommend placing undergarments in a net bag for extra protection.

L2 Special Items

FRESHEN UP

This cycle tumbles for 20 minutes without heat. It has been designed to freshen clean clothes that

have been stored in a cupboard, drawer or packed in a suitcase.

WARM UP

Warm Up is designed to heat clothes for 20 minutes so that they are warm to the touch. Warm your

pyjamas before bed on a cold night, or warm towels while you are in the shower. The Warm Up

cycle uses a Casual Fabric Type and is not recommended for garments that are heat sensitive.

DRY CLEAN

A cycle specially designed for “In Dryer” dry clean products. This cycle has a medium heat for 40

minutes and has the WRINKLE FREE option selected. Follow the manufacturers instructions for how

to prepare the load. At the end of the cycle remove the dry cleaning product from the machine

and continue to follow the dry cleaning product’s instructions.

Important:

Ensure the dry cleaning product is recommended for use in a domestic dryer.

Page 45

45

Lifecycles™

L3 Bulky Items

BLANKETS

You will need to check the care label to make sure that

the item can be dried in the dryer.

It is a good idea to include 4 – 5 medium sized towels

along with the blanket for cushioning. This will reduce

shrinkage from over tumbling. If you are drying more

than one blanket, ensure that they do not sit higher than

the top of the lint bucket, otherwise there will not be

enough room for them to tumble.

This cycle uses the lowest heat setting, the Light Fabric Type setting and runs with the

Damp/Dry How Dry setting.

On completion, remove the blanket, shake and if needed stretch the blanket back to its original

shape. Place back in the dryer and repeat until the blanket is dry.

Important:

It is important to completely dry the blanket to prevent mildew from forming.

JEANS

This cycle has been designed for drying denims or similar heavyweight items like jeans and

thick towels, which are bulky or have thick seams. The Jeans lifecycle has been tailored to dry

these items. This cycle uses High Heat, the Heavy Fabric Type, and has the WRINKLE FREE

option selected.

COMFORTER

Comforters are very bulky items and can be difficult to dry.

It is important before you put your comforter in the dryer that you check to make sure the

care label says that it can be dried in a clothes dryer.

This cycle uses Autosensing, and dries on the lowest heat setting. The Fabric Type setting used

is Light, How Dry level is Dry/Extra Dry. It is a good idea to check the garment throughout the

cycle to ensure even drying. If the item contains feathers, add a heavy item (e.g. a towel tied in

a knot) to the load to help fluff the comforter.

Ensure the load does not sit higher than the top of the lint bucket before starting the cycle.

US

CA

Page 46

46

Using Your Dryer

Check the care labels inside the garments to determine whether the garment manufacturer

recommends tumble-drying.

Sorting

It is best that you sort your garments before placing them

into the dryer. Sort into loads of similar types, and loads that

take similar times to dry.

Heavier items (e.g. towels, t-shirts and flannel sheets) are

best dried separately from lightweight items (e.g. synthetics,

poly-cotton sheets and shirts). This prevents the possibility of

some items becoming over-dried whilst others are still damp.

It will also help to extend the life of your clothing and linen.

Drying your clothes as soon as the washer has finished will

decrease the chance of wrinkles and the chance of dye

transfer from colored items to white items.

We recommend that articles of clothing with screen-printing

are turned inside out to ensure the screen-printing does

not stick to the drum. Garments with hooks or zippers need

to be fastened and where possible turned inside out. Place

undergarments in a net bag to provide protection from other

items in the load.

Loading

Garments need to be loaded properly to reduce the

likelihood of them wrinkling and to ensure the load is dried

evenly. Make sure there is ample room for the garments to

tumble freely while drying. Load in terms of the space the

garments take up when dry, rather than when they are wet.

The general rule is one wash load = one dryer load.

Only load the dryer up to the top of the transparent

section of the lint bucket. Loading any higher may result in

uneven drying, tangling, wrinkling and the dryer becoming

overloaded.

It is a good idea to dry ‘permanent press’ type garments

together in a separate cycle with the WRINKLE FREE

option turned on. This will help reduce wrinkles and the

need for ironing.

Load no higher

than here

Page 47

47

Using Your Dryer

Lint Bucket

The Intuitive™ dryer’s lint removal system is unique. Unlike

other dryers, the Intuitive™ dryer automatically removes the

lint for you, from the lint screen – all you have to do is tip

the lint out!

The lint filter is hidden behind the lint bucket. As the air

passes through this filter the lint is caught on the fine

mesh. Once the lint is about ⁄” (2mm) thick it comes into

contact with a scraper which deposits it into the bucket.

This process is automatically performed every time lint

builds up on the filter.

Apart from the benefit of not having to scrape the lint

after every cycle, it also means the drying efficiency is not

affected by lint build-up during the drying cycle.

The lint bucket is located inside the dryer on the left-hand

side. You can remove it by gently pulling the handle and

lifting outwards. It slots easily back into place.

This lint bucket does not need to be cleaned as regularly

as other dryer’s lint filters. The lint bucket only needs to

be emptied before the lint reaches the top of the

transparent section.

It is important that you run your dryer with the lint bucket in place at all times.

Empty before this

level is reached

US

CA

Page 48

48

Lid Lock

Your Intuitive™ dryer locks it’s lid at the start of the

drying cycle, providing added safety for you and your

family while it is operating. This lock ensures the lid

cannot be opened while the drum is rotating.

A lidlock symbol (padlock) appears in the corner of the

screen when locked (it disappears when unlocked).

If the lidlock symbol is flashing the lid is in the process

of being unlocked. During this stage, the lid still cannot

be lifted.

The lid must be closed before the drying cycle can start. If START/

PAUS E is pressed with the lid open, the machine will beep and a

message will appear in the display screen Saying “Please close the lid

Press start to continue”, to signal that the lid needs to be closed.

Once the lid has been closed and START/PAUSE is pressed, the LID

LOCK will be activated and the drying cycle will begin.

Power Failure

If the power is cut while your Intuitive™ dryer is operating, the lid will be unlocked. In some

circumstances the drum door may not be automatically opened. If this occurs it is best if the

dryer is not interfered with. When the power is restored the dryer will automatically resume

operating. However if it does not automatically open, first close the lid and start the dryer in the

usual manner, after 5 seconds press START/PAUSE. This will cause Intuitive™ to open correctly

with the lid unlocked.

If it is absolutely necessary to remove some items before power is

restored follow the steps below:

1

Ensure the dryer is disconnected from the power supply.

2

Open the lid (this will already be unlocked).

3

On the left hand side of the dryer there is a thumb tab that appears

when the drum is closed. Press the thumb tab, while rotating the drum

by hand away from you (push the drum towards the back of the dryer).

4

Hold the thumb tab down until the drum starts opening.

5

Keep rotating the drum until it is fully open and it comes to a stop.

6

Now you can remove items from the dryer drum.

7

Close the lid once you have removed desired items.

8

Re-connect the power supply to your dryer.

The drum door will automatically close and the dryer will resume

normal operation when power is restored.

Hold thumb

tab down

Push

Page 49

49

Care Labels

Below is a selection of care label symbols that garment manufacturers use to show how their

garments should be dried. We’ve converted these symbols into the cycles and heat settings

that we recommend you use in the Intuitive™ dryer. By following our recommendations, you can

ensure that your clothes will retain their appearance over time.

Tumble

Dry Symbols

Normal Permanent

Press

Delicate Do not

Tumble Dry

Fabric Type We

Recommend

HEAVY or

MIXED

CASUAL LIGHT

Do not place

in Dryer

Tumble

Dry Symbols

Any Heat High Medium Low No Heat

Fabric Type We

Recommend

Any Cycle

HEAVY or

MIXED

CASUAL LIGHT AIR DRY

Additional Drying

Instructions

Hang to Dry Drip Dry Dry in Shade Dry Flat

Do not place articles with these symbols in the dryer.

US

CA

Page 50

50

Cleaning

Clean your dryer with a soft damp cloth and wipe dry. Do not use

scouring cleaners as they can damage the paint and plastic surfaces.

Removing the Lid

You can remove the lid for cleaning. Open the lid fully, hold one side

with one hand and tap the other side with an upwards motion. To

replace the lid, hold the lid vertically and align both hinges before

clicking back into place.

Pre-Treatment Sprays

Do not use pre-treatment sprays or liquids on or near your dryer as they can damage your

machine’s control panel as well as any of its plastic parts. Damage to your dryer caused by pre-

treatment products will not be covered by your warranty.

Stains