Page 1

TELESCOPIC DOWNDRAFT VENT SYSTEM

HD0 and HD6 Vent models

HBD600I and HBD1200E Blower models

SYSTÈME DE VENTILATION TÉLESCOPIQUE

À ASPIRATION DESCENDANTE

Modèles de systèmes de ventilation HD0 et HD6

Modèles de ventilateurs HBD600I et HBD1200E

INSTALLATION GUIDE / USER GUIDE

GUIDE D’INSTALLATION / GUIDE D’UTILISATION

US CA

Page 2

English Page 1 – 34

Français

Page 37 – 70

Page 3

CONTENTS

Introduction 3

Safety and warnings 4

Venting requirements 6

Electrical requirements 7

Installation instructions 8

Operating instructions 25

Cleaning and maintenance 26

Troubleshooting 27

Parts and accessories 29

Wiring diagram 30

Limited Warranty 32

EN

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this user guide may

not be available in all markets and are

subject to change at any time. For current

details about model and specification

availability in your country, please go to our

website www.fisherpaykel.com or contact

your local Fisher & Paykel dealer.

Registration

Register your product with us so we can

provide you with the best service possible.

To register your product visit our website:

www.fisherpaykel.com

1

Page 4

Page 5

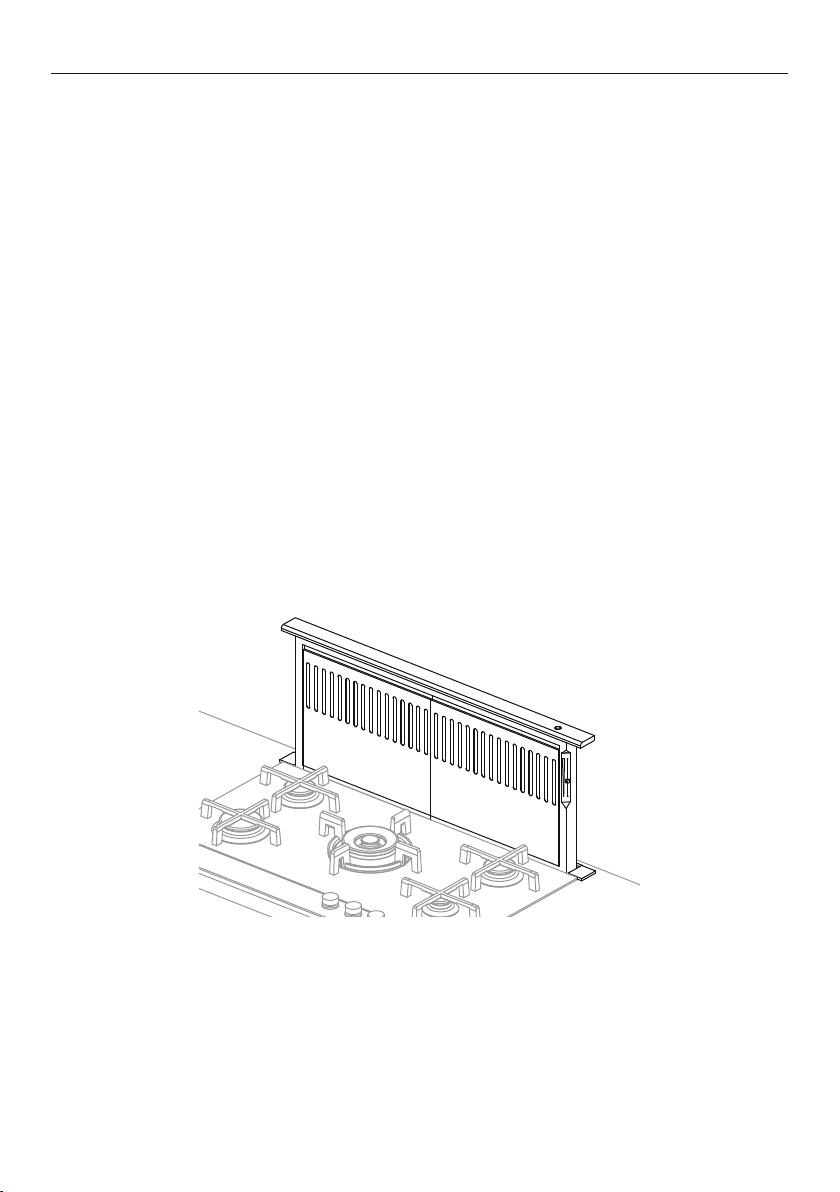

INTRODUCTION

Thank you for purchasing a Fisher & Paykel product. This Installation and Use and Care

Guide contains valuable information on how to properly install, operate and maintain

your new Downdraft Vent System for years of safe and enjoyable service.

To serve you better, please fill out and submit your Product Registration by visiting our

website at www.fisherpaykel.com and selecting ‘Customer Care’ on the home page and

then select ‘Product Registration’. In addition, keep this manual handy, as it will help

answer questions that may arise as you use your new appliance.

For your convenience, product questions can be answered by a Fisher & Paykel Customer

Care Representative by phone: 1-888-936-7872, or email: support@fisherpaykel.com

Note: write the Model, Code and Serial Numbers on this page for references.

Vent Model Number________________ Code_________ Serial Number_______________

Blower Model Number______________ Code_________ Serial Number_______________

Note: inspect the product to verify that there is no shipping damage. If any damage is

detected, call the shipper and initiate a damage claim. Fisher & Paykel is not responsible

for shipping damage where Fisher & Paykel is not the shipper.

DO NOT discard any packing material (box, pallet, straps) until the unit has been

inspected.

EN

3

Page 6

Page 7

SAFETY AND WARNINGS

– Sufficient air is needed for proper combustion and exhausting of gases

through the flue (chimney) of fuel burning equipment to prevent back drafting.

Follow the heating equipment manufacturer’s guideline and safety standards

such as those published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

– When cutting or drilling into wall or ceiling, do not damage electrical wiring

and other hidden utilities.

– Ducted fans must always be vented to the outdoors.

– This appliance must be grounded

●

CAUTION: To reduce risk of fire and to properly exhaust air, be sure to duct air

outside – Do not vent exhaust air into spaces within walls or ceilings or into attics,

crawl spaces, or garages.

●

WARNING: To reduce the risk of fire, use only metal ductwork.

●

NOTE: Suitable for use with solid state speed controls.

●

CAUTION: To reduce the risk of fire and electric shock, install this appliance only

withremote blower models rated maximum 2.8A, and are suitable for use with solid

state speed controls.

●

WARNING: To reduce the risk of a range top grease fire:

– Never leave surface units unattended at high settings. Boilovers cause smoking

and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

– Always turn hood ON when cooking at high heat or when flambéing food

(ie Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

– Clean ventilating fans frequently. Grease should not be allowed to accumulate

onfan or filter.

– Use proper pan size. Always use cookware appropriate for the size of the

●

●

●

surfaceelement.

WARNING: To reduce the risk of injury to persons in the event of a range top grease

fire, observe the following*:

– SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then

turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go

out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

– NEVER PICK UP A FLAMING PAN – You may be burned.

– DO NOT USE WATER, including wet dishcloths or towels – a violent steam

explosion will result.

– Use an extinguisher ONLY if:

– You know you have a Class ABC extinguisher, and you already know how

to operate it.

– The fire is small and contained in the area where it started.

– The fire department is being called.

– You can fight the fire with your back to an exit.

WARNING: Unplug or disconnect the appliance from the power supply before

servicing or cleaning.

WARNING: All wall and floor openings where the vent hood is installed must be sealed.

EN

READ AND SAVE THESE INSTRUCTIONS

* Based on “Kitchen Firesafety Tips” published by NFPA.

5

Page 8

Page 9

Page 10

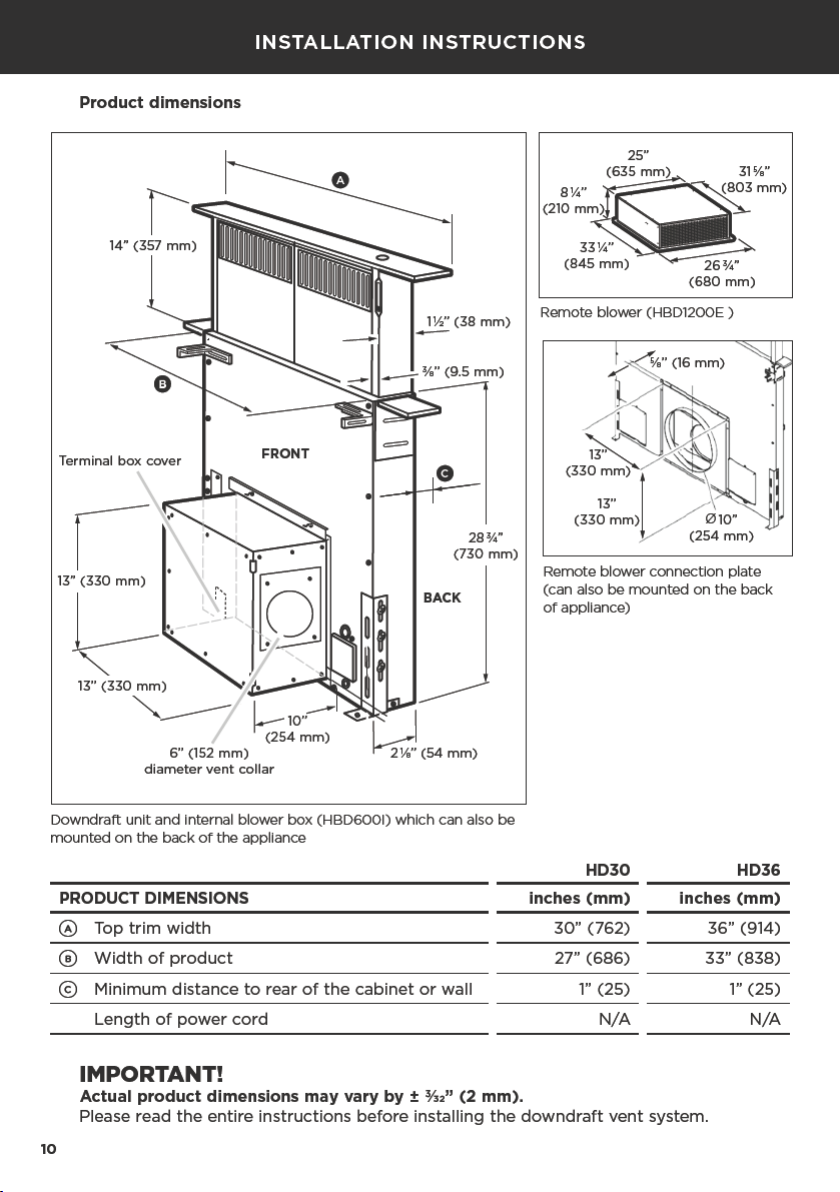

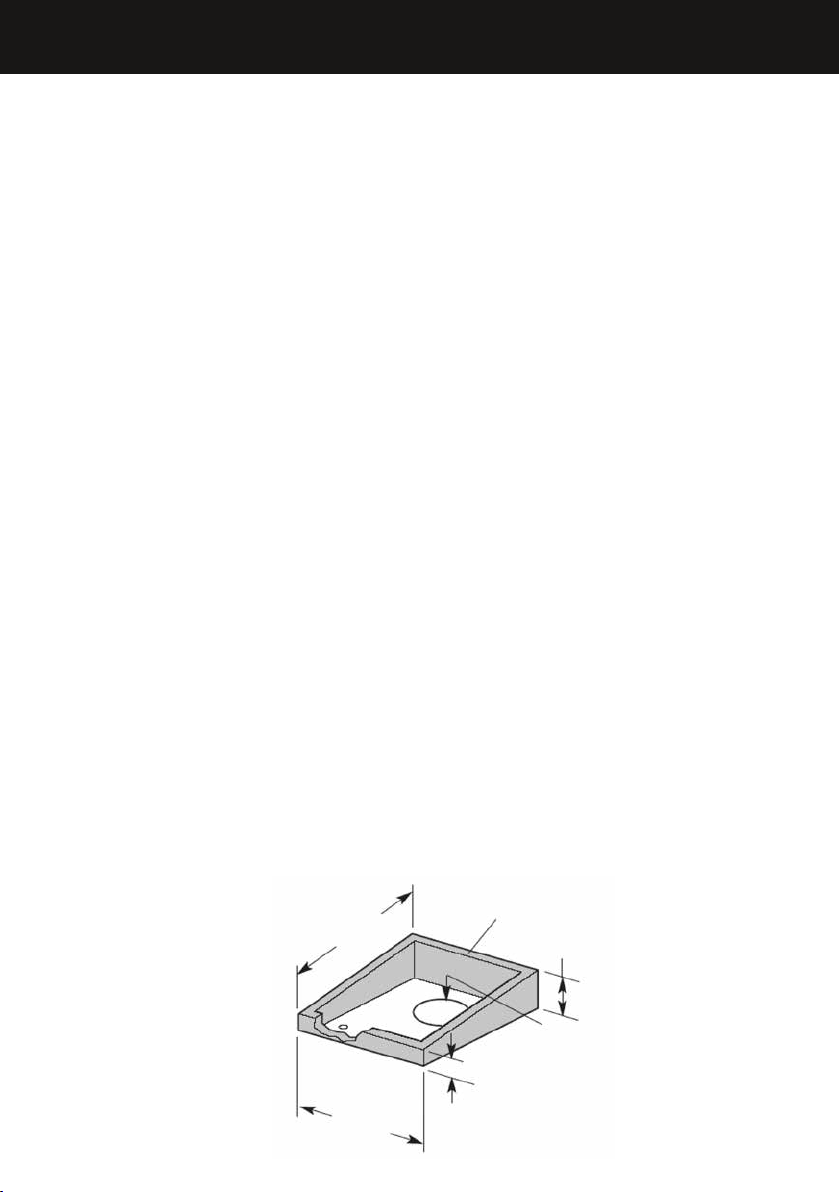

INSTALLATION INSTRUCTIONS

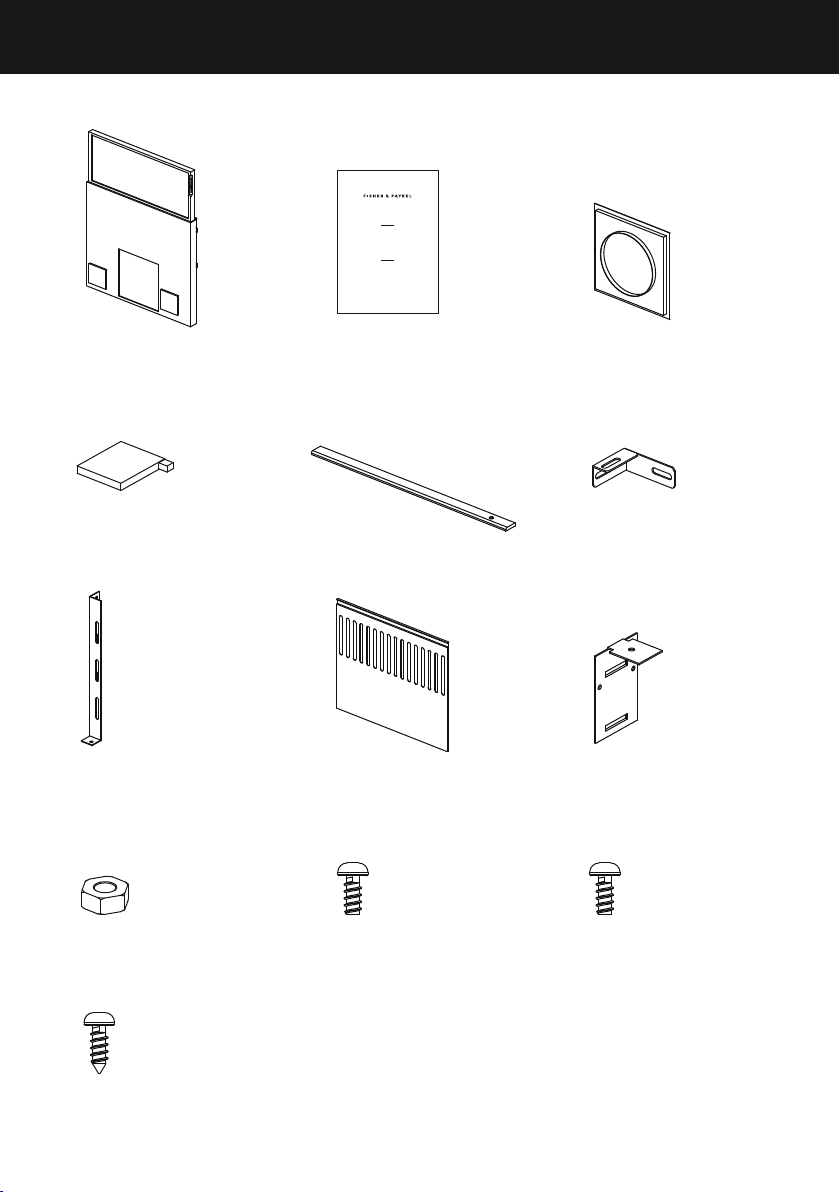

Downdraft unit contents of packaging

TELESCOPC DOWNDRAFT VENT SYSTEM

HD0 and D36 V nt m des

HBD00 and HD 200E l we mod ls

SYSTÈME DE VENTILATION TÉLESCOP QUE

À ASP RATION DESCENDANTE

Mdè s de ys èm s de e ta i n HD30 t HD 6

odl s de en lt us HB 600 et BD 20E

NSTALAT ON GUI E / USER GUDE

GUIDE D NSTA LATON / GUDE D’ TI I ATON

US CA

Downdraft unit

(1)

End cap

(2)

Support leg

mounting bracket

(2)

Installation instructions

User guide manual

(1)

Top trim

(1)

Grease filter

(2)

10” (254mm) remote

blower connection plate

(1)

Under counter

mounting bracket

(2)

Over counter

mounting bracket

(2)

⁄” (7mm) nut

(2)

⁄” (15mm)

Self tapping screw

(6)

8

⁄” (5mm) screw

(2)

⁄” (8mm) screw

(6)

Page 11

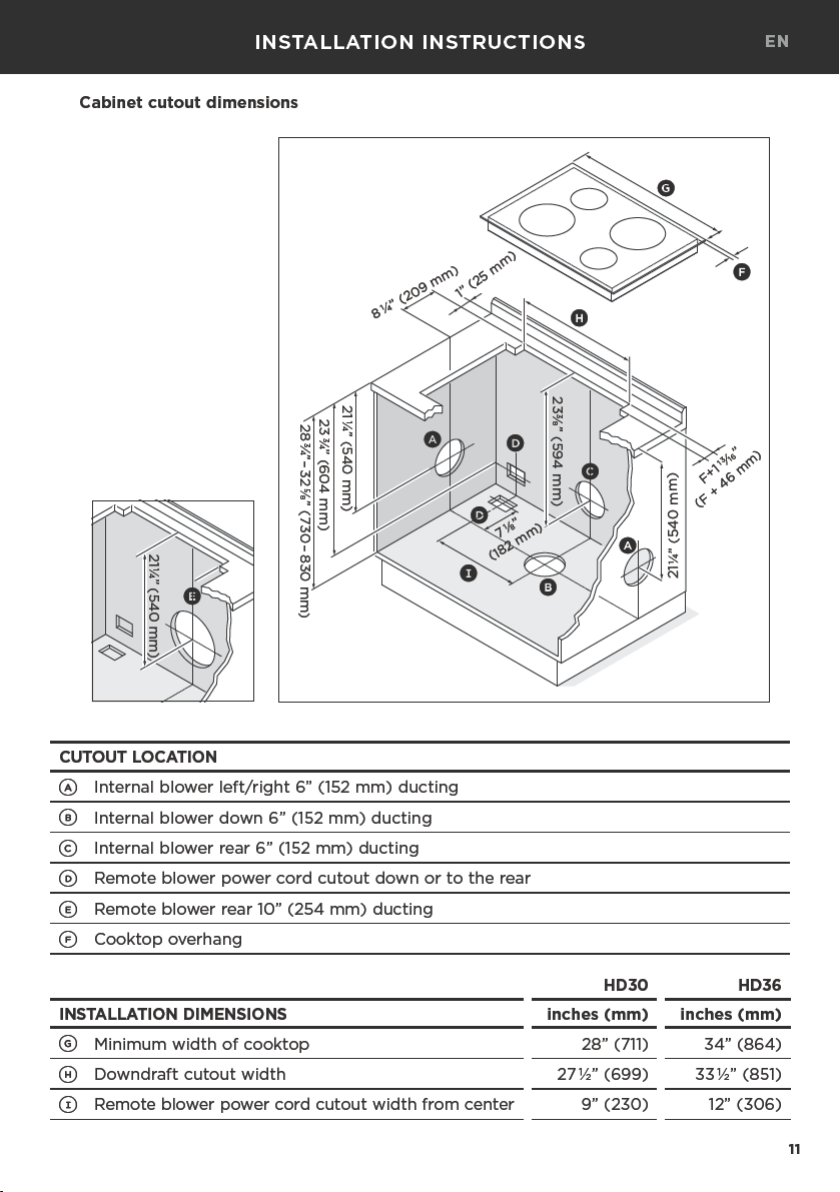

INSTALLATION INSTRUCTIONS

Internal blower (HBD600I) contents of packaging

EN

Internal blower box

(1)

Remote blower (HBD1200E) contents of packaging

Remote blower

(1)

6” (152mm) diameter

back draft damper

(1)

Duct collar plate

(1)

9

Page 12

Page 13

Page 14

INSTALLATION INSTRUCTIONS

WARNING!

To reduce the risk of fire, use only metal ductwork. Do not use flexible plastic ducting.

CAUTION!

To reduce risk of fire and to properly exhaust air, be sure to duct air outside – Do not vent

exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

Compatible blowers with the downdraft vent system

●

Internal blower model HBD600I.

●

Remote blower model HBD1200E or Remote Blower Models max 2.8 A.

●

This downdraft unit may only be used in connection with the above Fisher & Paykel

internal or remote blowers.

Compatible cooktops with the downdraft vent system

The Downdraft Vent System is meant to be installed with residential use cooktops,

cooktops/oven combinations, freestanding ranges WITHOUT backguards and range

tops. This product is not recommended for use with ranges which may require

additional space behind the range for oven venting OR with freestanding ranges WITH

backguards. Always consult all product installation instructions for correct dimensions

and clearances.

IMPORTANT!

Make certain any cooktop installed is appropriate for use with a downdraft vent system.

Venting requirements

Attention should be given to ensure that any applicable regulations concerning the

discharge of exhaust air are fulfilled.

For optimal efficiency use the shortest and straightest duct route possible and use

rigid or semi-rigid ducting for reduced noise and increased airflow. For best results,

internal blowers should use 6” (152 mm) round ducting and remote blowers should

use 10”(254mm) round ducting. Flexible metal ducting should only be used as a last

resort (ie in difficult installations) and if used ensure that it is straight and smooth and

extended as much as possible.

Make sure there is proper clearance within the wall or floor for exhaust duct before

making cutouts. Do not cut a joist or stud unless absolutely necessary. If a joist or stud

must be cut, then a supporting frame must be constructed.

CAUTION!

To reduce the risk of fire and electric shock, install this appliance only withremote

blower models rated maximum 2.8A, and are suitable for use with solid state speed

controls.

12

Page 15

INSTALLATION INSTRUCTIONS

Plan the ductwork

The internal blower can be mounted to the front or back of the downdraft unit and be

ducted in multiple directions: left, right, down, forward or backwards. The remote blower

can be ducted downwards from the front or back of the downdraft unit.

In the event of installations where the blower is located on the back of the downdraft unit,

it is advised to leave an access door or opening to reach the bottom of the downdraft

unit, as well as where the wiring box and blower is located should service be needed.

Calculate the duct run length

The ductwork length should not exceed 55 equivalent feet (16.7 m) for 6” (152 mm)

round duct, or 75equivalent feet (22.9m) for 10” (254mm) round duct. Calculate the

length of the ductwork by adding the equivalent feet listed in the table below for each

piece of duct in the complete system. If flexible metal ductwork is used, each foot

(312mm) of flexible metal ductwork is equivalent to two feet (617mm) of straight metal

ductwork when calculating the duct run length.

For best results the size of the ductwork should be uniform and use no more than

three 90°elbows. Make sure that there is a minimum of 24” (607mm) of straight

duct between elbows if more than one is used. Round duct is recommended instead

of rectangular duct especially if elbows are needed. Rectangular duct should be

transitioned to minimum 6” (152mm) round for internal blowers and 10” (254 mm)

round for remote blowers as soon as possible.

EN

EQUIVALENT LENGTH EXAMPLE CALCULATION

45° elbow 5 feet (1.5m) 9 feet straight duct 9 feet (2.8m)

90° elbow 7 feet (2.1m) 2 x 90° elbows 14 feet (4.3m)

90° flat elbow 12 feet (3.7m) Wall cap 0 feet (0.0m)

Wall cap 0 feet (0.0m) Complete system 23 feet (7.0m)

13

Page 16

INSTALLATION INSTRUCTIONS

WARNING!

●

This appliance is heavy and requires two persons for unpacking and installation.

●

Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards.

IMPORTANT!

●

Wear gloves to protect against sharp edges.

●

When planning the cutout for the downdraft unit:

– Draw both the cooktop and downdraft unit cutouts on the countertop before

making any cuts.

– Check that there is enough room in the cabinet for both the cooktop and

the downdraft unit. Failure to follow these warnings could result in damage

●

1

to the countertop.

To avoid damage to motor bearings and impellers, keep drywall spray, construction

dust, etc. away from the blower.

The manufacturer is not liable for any damage caused by not following these instructions.

Preparing for installation

Before installing your downdraft vent system:

●

Please read the instructions carefully.

●

Unpack the downdraft unit and place on a flat protected surface.

●

Ensure the voltage (V) and the frequency (Hz) indicated on the serial plate match

the voltage and frequency of the installation site.

●

Check that the area around the installation area is clear of any electrical cables and

pipesetc.

●

Be aware of kitchen cabinets and splash backs in the area of the downdraft vent

system and the cooktop. Ensure that the area where the downdraft unit rises is

free of obstacles. Also be aware performance may be reduced by strong drafts

from windows or doors etc.

●

The downdraft unit surfaces can be damaged during installation if grazed or

knocked by tools. Please take care to protect the surfaces during installation.

●

Temporarily mark the center of the cooktop according to the information given

in the ‘Installation instructions – Cabinet cutout dimensions’ section.

●

The downdraft unit is installed directly behind the cooktop. For easiest installation,

install the downdraft vent system first, then the cooktop.

●

Remove any cardboard packaging from within the blower impeller.

14

Page 17

INSTALLATION INSTRUCTIONS

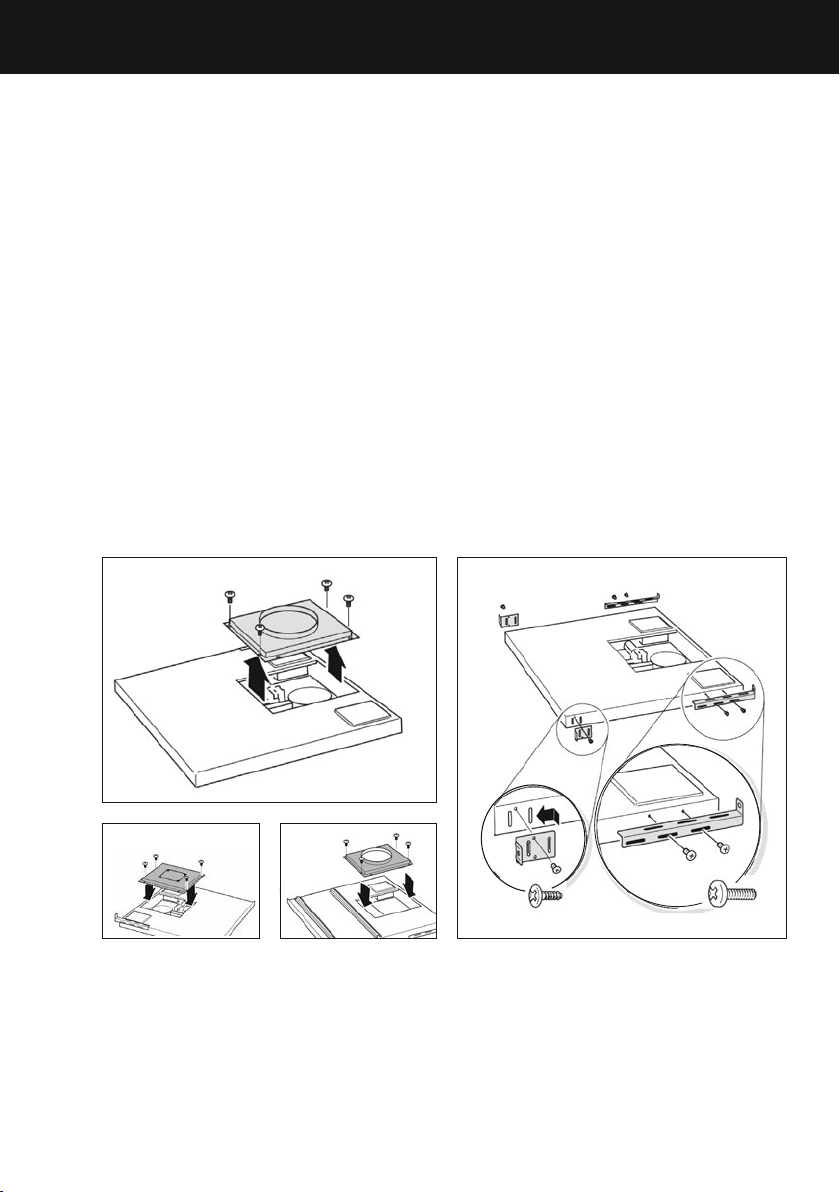

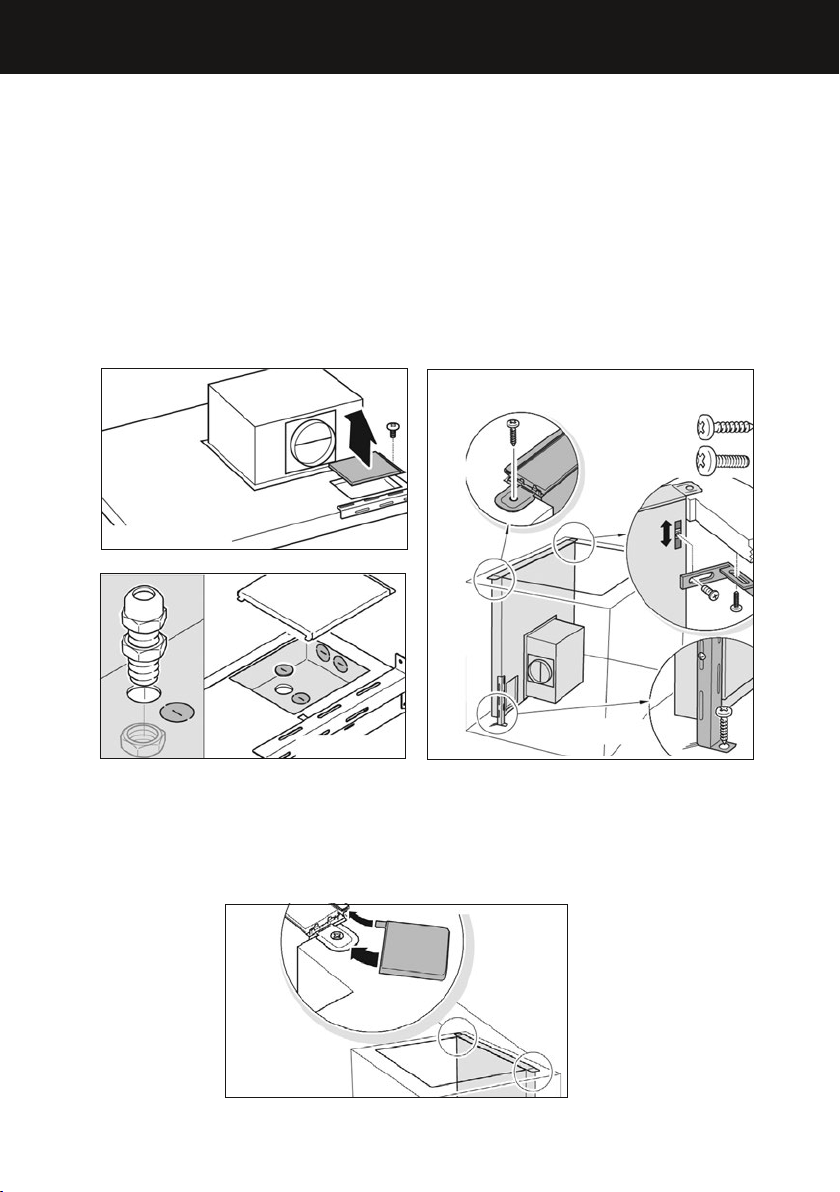

Prepare the downdraft unit for the intended blower

2

Internal blower

●

Remove the 10” (254 mm) blower connection plate from the front of the downdraft

unit Fig.1.

●

Attach the over counter mounting brackets in place with the two ⁄” (5mm) screws

provided Fig.2.

●

Screw the support leg mounting brackets to the side of the downdraft unit using two

⁄” (8mm) screws each, do not fully tighten the screws. The brackets are different

for the right and the left side. Attach them with mounting clip (A) pointing up.

Remote blower

●

The downdraft unit comes ready for installation with the 10” (254 mm) remote blower

connection plate installed on the front of downdraft unit and the cover plate installed

onto the back.

●

To connect the remote blower to the back of the downdraft unit swap the plates over

(see Fig. 3 and 4).

●

Attach the over counter mounting brackets in place with the two ⁄” (5mm) screws

provided Fig.2.

●

Screw the support leg mounting brackets to the side of the downdraft unit using two

⁄” (8mm) screws each, do not fully tighten the screws. The brackets are different

for the right and the left side. Attach them with mounting clip (A) pointing up.

EN

Fig.1

Fig.3

FRONT

Fig.4

Fig.2

2 x

FRONT

A

4 x

15

Page 18

INSTALLATION INSTRUCTIONS

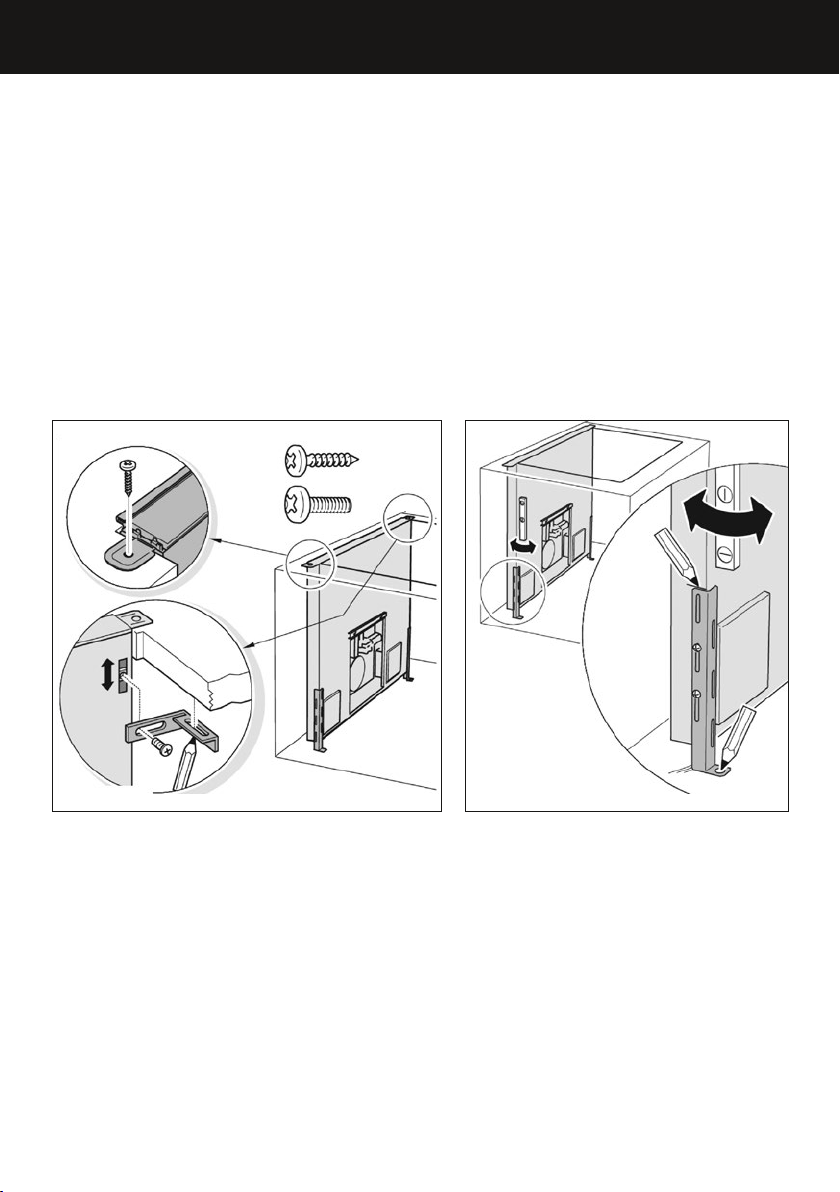

Temporarily insert the downdraft into the cabinet

3

●

With the assistance of another person, lift the downdraft unit into the prepared cutout

in the cabinet. The over counter mounting brackets should rest on the countertop.

●

Secure the downdraft unit to the countertop with two ⁄” (15mm) screws.

●

Install the under counter mounting brackets underneath the countertop for additional

support. First, loosely screw the brackets into the sliding nuts in the downdraft

unit using ⁄” (5mm) screws and push them up under the countertop. Pre-drill

the mounting holes into the countertop from underneath. Check that the mounting

screws are the proper length and will not extend through the countertop surface

when tightened. Failure to follow these instructions could result in damage to the

countertop surface Fig.5.

●

Level and align the downdraft unit in the cabinet. Push the support leg mounting

bracket on each side down against the cabinet floor. Mark the top edge of the

mounting bracket on the downdraft unit and the mounting holes on the cabinet

floorFig.6.

Fig.5 Fig.6

2 x

2 x

Remove the downdraft from the cabinet

4

●

Remove the screws from the countertop and lift the downdraft unit back out of

thecabinet.

●

Pre-drill the marked mounting holes in the cabinet floor.

●

Tighten the support leg mounting brackets on the unit at the pre-marked positions

●

Place the downdraft unit on a flat protected surface to prevent damage in order to

install the blower.

Install the internal or remote blower

5

●

For internal blower installation refer to page 17.

●

For remote blower installation refer to page 18.

Note: this downdraft unit may only be used in connection with Fisher & Paykel

internal or remoteblowers.

16

Page 19

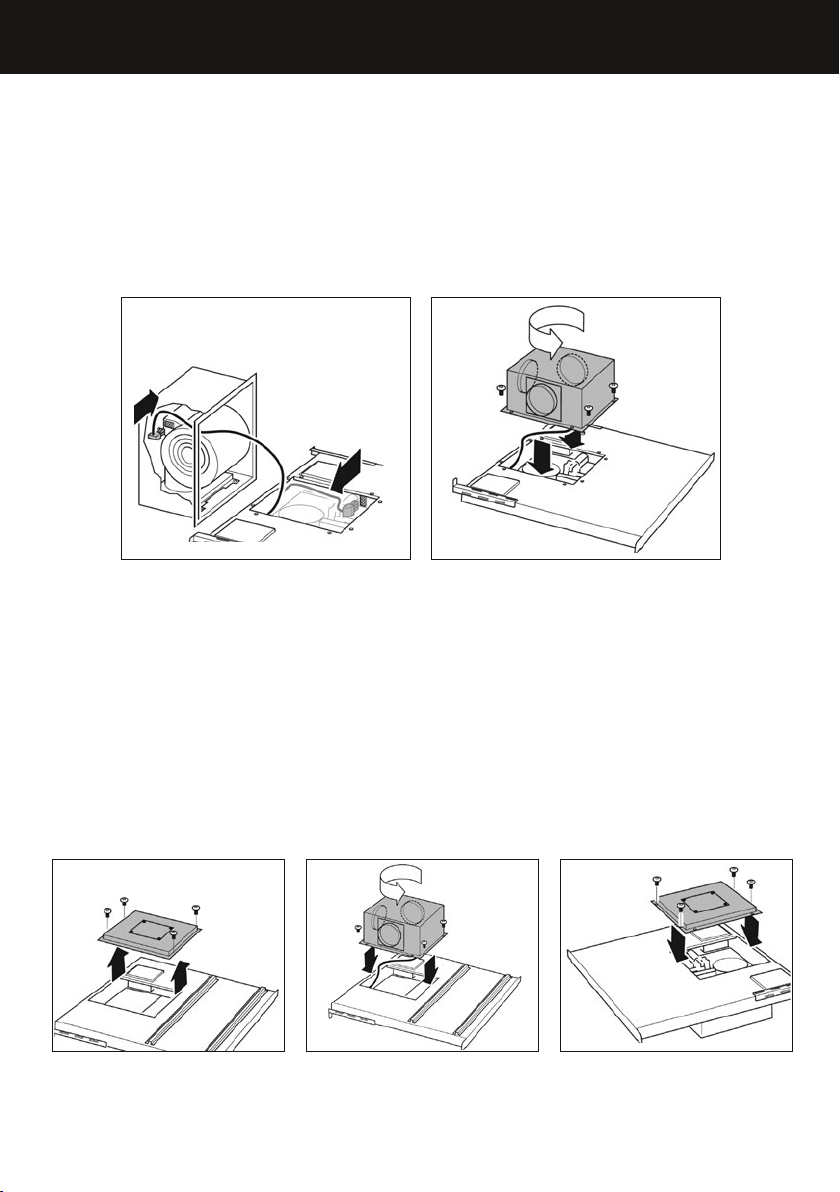

INSTALLATION INSTRUCTIONS

Internal blower installation in one of the following three options:

Option 1: Internal blower, front installation for venting left, right or down

●

Disconnect the cable from inside the downdraft unit. Plug in that same cable

from the downdraft unit into the internal blower Fig.7.

●

Turn the venting collar on the internal blower box to the desired direction – left,

right ordown.

●

Mount the internal blower box to the housing using four screws Fig.8.

●

Continue to the ‘Prepare for electrical connection’ section on page 20.

Fig.8Fig.7

Option 2: Internal blower, back installation for venting left, right or down

●

The internal blower box can also be installed on the back of the downdraft unit

to accommodate the installation of a cooking range, range top or wall oven /

cooktop in front of the downdraft unit.

●

Remove the large cover on the back of the downdraft unit Fig.9.

●

Turn the venting collar on the blower box to the desired direction – left, right or

down. Disconnect the cable from inside the downdraft unit. Plug in that same

cable from the downdraft unit into the internal blower and mount the blower box

to the housing using four screws Fig.10.

●

When finished, mount the previously removed cover onto the front of the

downdraft unit Fig.11.

●

Continue to the ‘Prepare for electrical connection’ section on page 20.

EN

FRONT

Fig.9

Fig.10

BACK

BACK

Fig.11

FRONT

17

Page 20

Page 21

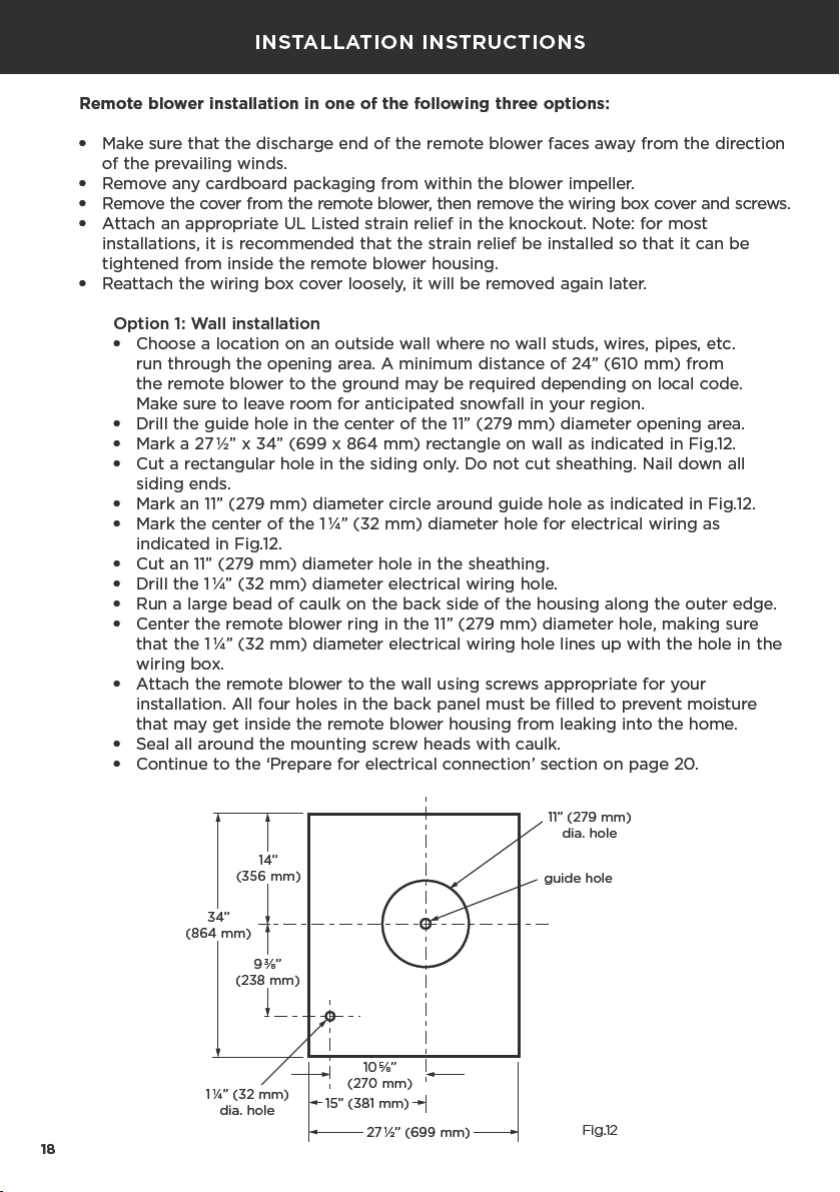

INSTALLATION INSTRUCTIONS

Option 2: Sloped roof installation

(For flat roof installations see Option 3)

●

Choose location on the rear slope of the roof that minimizes vent run.

Avoid obstacles such as TV leads, electric lines, etc. If the remote blower top

is level with the roof peak, it will not be seen from the street. Remember this

location as you work from the inside of the roof space.

●

Mark a point half way between the rafters and drill a guide hole at this point.

●

From the outside, using the guide hole as a starting point, mark the rectangular

cut-out as indicated in Fig.12. Remove ONLY the roof shingles in THIS AREA.

●

Mark an 11” (279mm) diameter circle around guide hole as indicated in Fig.12.

●

Mark the center of the 1¼” (32mm) diameter hole for electrical wiring as

indicated in Fig.12.

●

Cut out the roof boards along the 11” (279mm) diameter circle.

●

Drill the 1¼” (32mm) diameter electrical wiring hole.

●

Remove the roofing nails from the upper two-thirds of the shingles to allow the

back flashing sheet on the remote blower housing to fit under them.

●

Center the remote blower ring in the 11” (279mm) diameter hole, making sure that the

1¼” (32 mm) diameter electrical wiring hole lines up with the hole in the wiring box.

●

Attach the remote blower to roof or frame using screws appropriate for your

installation. All four holes in the back panel must be filled to prevent moisture

that may get inside the remote blower housing from leaking into the home.

●

Seal all the shingles around the remote blower housing, flashing sheet, and

mounting screw heads or frame with roofing cement. The top and side flanges

of the back plate may be covered with trim. It is recommended that electrical

connection be made and checked first. Do not block the vent grill opening at

the bottom of the trim. Doing so will decrease blower performance.

●

Continue to the ‘Prepare for electrical connection’ section on page 20.

EN

Option 3: Flat roof installation

●

Locate the 11” (279 mm) diameter hole between rafters.

●

Build a sloping base that will mount the remote blower at a minimum pitch of

2½” (64mm) see Fig.13 for an example showing 5” (127mm) pitch.

●

Weatherproof the base as required.

●

Locate the base so that the remote blower’s vent aligns with the 11” (279 mm)

diameter hole and the blower sits evenly on the base with no gaps.

Note: Make sure that the discharge end of the remote blower faces away

from the direction of prevailing winds.

●

Use dimensions from Fig.12 to locate the 1¼” (32mm) diameter wiring hole.

●

Continue from point 8 from the previous ‘sloped roof installation’ section.

33¼”

(845mm)

discharge side

of blower

26¾”

(679mm)

2” x 4” (51mm x 102mm)

11” (279mm)

dia. hole

2” (51mm)

Fig.13

7” (178mm)

19

Page 22

INSTALLATION INSTRUCTIONS

Prepare for electrical connection

6

Downdraft unit

●

Remove the cover of the terminal box from the downdraft unit Fig.14.

●

Decide whether the power source should enter the downdraft unit from below or

from the back and remove the respective knock out. Install a UL listed strain relief or

conduit fitting (not included) in the knock out Fig.15.

●

If the downdraft unit is being installed with a remote blower, remove the knock out

for the control cable.

●

With the assistance of another person, lift the downdraft unit into the prepared cutout

in the cabinet. The over counter mounting brackets should rest on the countertop.

●

Secure the downdraft unit to the floor and countertop with screws into the previously

drilled holes Fig.16.

Fig.14

Fig.16

6 x

2 x

FRONT

FRONT

Fig.15

●

Push the end caps into place on the downdraft unit on top of the counter and lock

them in place Fig.17.

Fig.17

20

Page 23

INSTALLATION INSTRUCTIONS

Electrical connection

7

WARNING!

●

Electrical wiring must be done by qualified person(s) in accordance with all applicable

codes and standards and the unit must be grounded.

●

This downdraft unit may only be used in connection with Fisher & Paykel internal or

remote blowers.

●

Unplug or disconnect the appliance from the power supply before servicing or cleaning.

Electrical requirements

A 120 volt, 60 Hz AC-only electrical supply is required on a separate 15 amp circuit,

fused on both sides of the line. A time-delay fuse or circuit breaker is recommended.

The fuse must be sized per local codes in accordance with the electrical rating of this

downdraft unit as specified on the serial/rating plate located inside the downdraft unit

near the field wiring compartment.

This downdraft unit must be connected with copper wire only. Wire sizes must conform

to the requirements of the National Electrical Code, ANSI/NFPA 70 -latest edition, and all

local codes and ordinances. Wire size and connections must conform with the rating of

the appliance. Copies of the standard listed above can be obtained from:

National Fire Protection Association

Battery March Park

Quincy, Massachusetts 02269

This appliance should be connected directly to the fuse disconnect (or circuit breaker)

through flexible, armored or non-metallic sheathed copper cable. Allow some slack

in the cable so the appliance can be moved if servicing is ever necessary. A UL Listed

strain relief or ½”(12.7mm) conduit connector must be provided at each end of the

power supply cable (at the appliance and at the junction box).

EN

When making the electrical connection, cut a 1¼” (32mm) hole in the wall. A hole cut

through wood must be sanded until smooth. A hole through metal must have a grommet.

Note: suitable for use with solid state speed controls.

21

Page 24

INSTALLATION INSTRUCTIONS

Downdraft unit internal blower electrical connection

●

Connect (L1/live) wire from the power supply

cable into the right terminal Fig.19.

●

Connect the green (ground) wire from the power

supply cable into the middle terminal Fig.19.

●

Connect the (neutral) wire from the power supply

cable into the left terminal Fig.19.

●

Ensure that the terminal screws are tightly

holding all wires in place.

●

Replace the cover of the terminal box Fig.18.

Fig.18

Home power

supply cable

Remote blower

control cable

Home power

supply cable

Internal

wiring

GND (ground)

BLUE

BROWN

LIGHT BLUE N (neutral)

GREEN -YELLOW

Ground Screws

Fig.19

WHITE

BLACK

BLUE

BROWN L1 (live)

Downdraft wiring

BROWN

GREEN -YELLOW

Ground Screws

Fig.20

L1 (live)BROWN

N (neutral)BLUE

BROWN L1 (live)

LIGHT BLUE N (neutral)

GREEN -YELLOW GND (ground)

Downdraft wiring

Downdraft unit remote blower electrical connection

●

Connect the power supply cable into the box as described in the ‘Downdraft unit

internal blower electrical connection’ section (above).

●

To use a remote blower, install a control cable between the downdraft unit and

the remote blower. See the ‘Remote blower electrical connection’ on next page.

●

Additional knock outs should be used for the remote blower wiring.

●

Install a suitable UL listed strain relief or conduit fitting (not included) into the

knock out.

●

Connect the remote blower wiring into the downdraft unit: N (neutral) into the

right terminal, L1 (live) into the left terminal and the green (ground) wire goes

into the ground terminal Fig.20.

●

Ensure that the terminal screws are tightly holding all wires in place.

●

The remote blower will be connected to the additional control cable

●

Replace the cover of the terminal box Fig.18.

Internal

wiring

WHITE

BLUE

BLACK

BROWN

22

Page 25

Page 26

Page 27

OPERATING INSTRUCTIONS

The downdraft vent system is designed to remove smoke, cooking vapors and odors

from the cooktop area. For best results, the downdraft vent system should be operating

before cooking is started and should continue to operate for several minutes after

cooking is complete. If using large pots, place them on the rear burner to ensure proper

ventilation, a higher fan setting may be required.

The flame sensing ignition on some gas cooktops may be affected by the downdraft

by dispersing the flame away from the spark igniter. This may cause the spark to keep

running while trying to reignite the burner that is already lit. To resolve this, and improve

burner performance, decrease the fan speed or increase the burner setting, or both.

Controls

EN

A

B

CONTROL PANEL FEATURES

Power On/Off Push the power button on the top trim, the downdraft unit

A

Blower speed Slide the control slider on the right-hand side of the

B

will rise. The blower will begin to vent immediately if the

blower control slider is set to an ‘On’ position.

Push the power button on the top trim, the blower will turn

off and the downdraft unit will lower to the closed position.

downdraft unit to adjust the blower motor speed.

25

Page 28

CLEANING AND MAINTENANCE

WARNING!

Unplug or disconnect the appliance from the power supply before servicing or cleaning.

IMPORTANT!

●

Never use abrasive or oil based cleaners.

●

Wear gloves to protect against sharp edges.

Maintenance

The downdraft vent system should be cleaned regularly using a mild, liquid detergent

and a clean soft cloth to avoid a build-up of grease occurring. Avoid the use of corrosive

chemicals, abrasive cleaning products, hard brushes and steel wool pads. Grease

deposits are corrosive which can cause damage to your downdraft vent system.

Note: in areas of high humidity or coastal environments, cleaning should be carried out

more frequently.

Grease filters

●

Depending on use, and at least once a month, the aluminum grease filters should be

removed and cleaned with hot soapy water or in a dishwasher. Please note that contact

with other items in the dishwasher may cause surface scratching.

●

If washed in a dishwasher, the filter should be placed in an upright position to prevent

food from falling on them.

●

After cleaning and drying, refit the filters.

Removing the grease filters:

Place fingertips in the groove at the top

1

for the filters.

Press down on the filters far enough for

2

the tab at the top of the filters to clear.

Pull forward to release the filter from its

3

groove.

Reverse these instructions when refitting

4

the filters.

Remote blower

Disconnect the power supply and lock out the service panel before cleaning or servicing.

To clean, remove the cover and vacuum the blower and housing, being carefulnot

to damage the blower impeller. The motor is permanently lubricated, do notoil or

disassemble.

26

Page 29

TROUBLESHOOTING

Spills

IMPORTANT!

If a spill occurs on the cooktop that allows liquids to seep inside the downdraft unit,

you must turn the downdraft vent system off immediately. It is possible to cause

damage to the downdraft unit if water is allowed inside the downdraft unit while it

is operating.

●

Immediately turn off the downdraft vent system at the speed control

located on the right-hand side of the downdraft unit.

●

Turn off the power supply to the downdraft vent system at the circuit

breaker box or fuse box.

●

Allow plenty of time for the downdraft unit to dry naturally. Do not open the

downdraft unit to remove the water.

If the downdraft vent system does not operate

●

Check that a circuit breaker has not tripped or a household fuse blown.

●

Check that the grease filters are properly installed.

●

Check the downdraft unit fuse located under the power board.

Note: this downdraft unit is designed with a microswitch behind the center of each

grease filter. These microswitches prevent the blower and the unit-raising and

lowering mechanism from operating when either of the grease filters is removed. It is

very important to make sure that the grease filters are properly and firmly in place. If

the unit does not operate after replacing the grease filters, make sure the filters are

properly installed and are making firmcontact with the microswitches.

EN

27

Page 30

Page 31

PARTS AND ACCESSORIES

ITEM REFERENCE NUMBER

Internal blower HBD600I

Remote blower model HBD1200E

Filter HD30 290317

Filter HD36 290334

EN

29

Page 32

Downdraft unit wiring diagram

WIRING DIAGRAM

30

Page 33

Page 34

LIMITED WARRANTY

When you purchase any new Fisher & Paykel ventilation product for personal or

consumer use you automatically receive a two year limited warranty covering parts and

labor for servicing within the 48 mainland United States, Hawaii, Washington DC and

Canada. In Alaska the limited warranty is the same except that you must pay to ship the

product to the service shop or the service technician’s travel to your home. Products for

use in Canada must be purchased through the Canadian distribution channel to ensure

regulatory compliance.

If the product is installed in a motor vehicle, boat or similar mobile facility, you receive

the same two year limited warranty, but you must bring the vehicle, boat or mobile

facility containing the product to the service shop at your expense or pay the service

technician’s travel to the location of the product.

There is no warranty for commercial purchase or use.

Fisher & Paykel undertakes to:

Repair without cost, with limited exceptions described herein, to the owner either

for material or labor any part of the product, the serial number of which appears

on the product, which is found to be defective during the term of the two year

limited warranty.

In Alaska, you must pay to ship the product to the service shop or for the service

technician’s travel to your home. If the product is installed in a motor vehicle, boat or

similar mobile facility, you must bring it to the service shop at your expense or pay for

the service technician’s travel to the location of the product. If we are unable to repair

a defective part of the product after a reasonable number of attempts, at our option

we may replace the part or the product, or we may provide you a full refund of the

purchase price of the product (not including installation or other charges).

This warranty extends to the original purchaser and any succeeding owner of the

product during the term of the warranty for products purchased for ordinary singlefamily home use.

All service under this limited warranty shall be provided by Fisher & Paykel or its

Authorized Service Agent during normal business hours.

How long does this limited warranty last?

Our liability under the two year limited warranty expires two years from the date of

purchase of the product by the first consumer.

Our liability under any implied warranties, including the implied warranty of

merchantability (an unwritten warranty that the product is fit for ordinary use) expires

two years (or such longer period as required by applicable law) from the date of

purchase of the product by the first consumer. Some States do not allow limitations

on how long an implied warranty lasts, so this limit on implied warranties may not

apply to you. Fisher & Paykel will honor any warranty required by the law of the

particular country or state in which the product is sold.

32

Page 35

LIMITED WARRANTY

This limited warranty does not cover:

Service calls that are not related to any defect in the product. The cost of a service

A

call will be charged if the problem is not found to be a defect of the product.

For example:

Correcting faulty installation of the product.

1

Instructing you how to use the product.

2

Replacing house fuses, resetting circuit breakers, correcting house wiring or

3

plumbing, or replacing light bulbs.

Correcting fault(s) caused by the user.

4

Changing the set-up of the product.

5

Unauthorized modifications of the product.

6

Noise or vibration that is considered normal, for example, fan sounds/noises or

7

user warning beeps.

Correcting damage caused by pests, for example, rats, cockroaches, etc.

8

Defects caused by factors other than:

b

Normal domestic use or

1

Use in accordance with the product’s user guide.

2

Defects to the product caused by accident, neglect, misuse, fire, flood or ‘act of God’.

c

The cost of repairs carried out by non-authorized repairers or the cost of correcting

d

such unauthorized repairs.

Travel fees and associated charges incurred when the product is installed in a location with

e

limited or restricted access (eg airplane flights, ferry charges, isolated geographic areas).

Normal recommended maintenance as set out in the product’s user guide.

f

Filter replacement except in the case of faulty parts or materials within the filter cartridge.

g

Damage (including water damage) caused by faulty installation, plumbing or wiring.

h

EN

This product has been designed for use in a normal domestic (residential) environment.

This product is not designed for commercial use (whatsoever). Any commercial use by

a customer will terminate this product’s limited warranty.

If you have an installation problem contact your dealer or installer. You are responsible

for providing adequate electrical, exhausting and other connection facilities.

Fisher & Paykel will not be responsible for consequential or incidental damages

(including, without limitation, the cost of repairing or replacing other property damaged

if the product is defective or any of your expenses caused if the product is defective).

Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

33

Page 36

LIMITED WARRANTY

How to get service

Please read your user guide. If you then have any questions about operating the

product, need the name of your local Fisher & Paykel Authorized Service Agent, or

believe the product is defective and wish service under this limited warranty,

please contact your dealer or call us at:

USA and Canada

TOLL FREE 1.888.9.FNP.USA (1.888.936.7872)

or use the link at: www.fisherpaykel.com/locator/servicer/

You may be required to provide reasonable proof of the date of purchase

of the product before the product will be serviced under this limited warranty.

No other warranties

This limited warranty is the complete and exclusive agreement between you and

Fisher & Paykel regarding any defect in the product and no other express warranty

has been made or will be made on behalf of Fisher & Paykel. None of our employees

(or our Authorized Service Agents) are authorized to make any addition or modification

to this limited warranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concerning this limited warranty, or need to make a claim under

this warranty, please call us at the above number, or write to:

Fisher & Paykel Appliances, Inc.

695 Town Center Drive, Suite 180

Costa Mesa

CA 92626

This limited warranty gives you specific legal rights, and you may also have other rights

which vary from country to country and from state to state.

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer

Suburb

Town

Country

34

Page 37

Page 38

Page 39

TABLE DES MATIÈRES

Introduction 39

Consignes de sécurité et mises en garde 40

Exigences relatives à l’évacuation 42

Exigences électriques 43

Instructions d’installation 44

Instructions d’utilisation 61

Nettoyage et entretien 62

Dépannage 63

Pièces et accessoires 65

Schéma de câblage 66

Garantie limitée 68

FR

IMPORTANT!

CONSERVEZ CES INSTRUCTIONS

Les modèles illustrés dans ce guide d’utilisation

peuvent ne pas être disponibles dans tous les

pays et sont sujets à modifications sans préavis.

Pour les plus récentes informations sur la

disponibilité des modèles et des caractéristiques

dans votre pays, veuillez visiter notre site Web

www.fisherpaykel.com ou contacter votre

détaillant Fisher& Paykel local.

Enregistrement

Enregistrez votre produit afin que nous

puissions vous offrir un service de la

meilleure qualité possible.

Pour enregistrer votre produit, visitez

notre site Web : www.fisherpaykel.com

37

Page 40

Page 41

INTRODUCTION

Nous vous remercions d’avoir acheté ce produit Fisher&Paykel. Ce Guide d’installation,

d’utilisation et d’entretien contient des informations très utiles sur la façon adéquate

d’installer, de faire fonctionner et d’effectuer l’entretien de votre nouveau système

de ventilation à aspiration descendante, qui vous permettront d’en profiter en toute

sécurité pendant de nombreuses années.

Veuillez enregistrer votre produit pour bénéficier d’un meilleur service. Sur notre site

Web www.fisherpaykel.com, sélectionnez ‘Customer Care’ (‘Service à la clientèle’) dans

la page d’accueil, puis sélectionnez ‘Product Registration’ (‘Enregistrement de produit’).

De plus, conservez ce manuel à portée de main pour obtenir des réponses aux questions

qui peuvent survenir pendant l’utilisation de votre nouvel appareil.

Si vous avez des questions au sujet de notre produit, communiquez avec un

représentant du service à la clientèle de Fisher & Paykel par téléphone: 1-888-936-7872,

ou par courriel: support@fisherpaykel.com

Remarque: veuillez noter le numéro de modèle, le code et le numéro de série sur cette

page pour référence ultérieure.

Numéro de modèle du système de ventilation____________________________________

Code__________________________ Numéro de série___________________________

Numéro de modèle du ventilateur______________________________________________

FR

Code__________________________ Numéro de série___________________________

Remarque: inspectez le produit pour vous assurer qu’aucun dommage n’a été causé lors

de l’expédition. En cas de dommage, communiquez avec l’expéditeur pour effectuer une

demande d’indemnisation. Fisher& Paykel n’est pas responsable des dommages causés

lors de l’expédition dans les cas où Fisher& Paykel n’est pas l’expéditeur.

NE METTEZ PAS au rebut les matériaux d’emballage (boîte, palette, sangles) avant

d’avoir terminé l’inspection de l’appareil.

39

Page 42

Page 43

CONSIGNES DE SÉCURITÉ ET MISES EN GARDE

– Pour éviter le refoulement d’air, une quantité d’air suffisante est nécessaire

pour assurer une bonne combustion et l’évacuation des gaz à travers le carneau

(cheminée) de l’appareil. Suivez les consignes du fabricant de l’appareil de cuisson

ainsi que les normes de sécurité comme celles publiées par la National Fire

Protection Association (NFPA) et la American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), ainsi que les normes locales.

– Au moment de couper ou percer le mur ou le plafond, veillez à ne pas

endommager le câblage électrique ou les conduites qui y sont dissimulés.

– Les ventilateurs avec conduits doivent toujours évacuer l’air vers l’extérieur.

– Cet appareil doit être mis à la terre

●

ATTENTION: Pour réduire les risques d’incendie et évacuer l’air adéquatement,

assurez-vous d’évacuer l’air vers l’extérieur– N’évacuez pas l’air dans les murs,

plafonds, greniers, vides sanitaires ou garages.

●

MISE EN GARDE: Pour réduire les risques d’incendie, utilisez uniquement des conduits

en métal.

●

REMARQUE: Convient à l’utilisation avec des dispositifs de contrôle de vitesse à semiconducteurs.

●

ATTENTION: Pour réduire les risques d’incendie et de choc électrique, installez cet

appareil uniquement avec des modèles de ventilateurs à distance d’un maximum de 2,8A,

qu’il est possible d’utiliser avec des dispositifs de contrôle de vitesse à semi-conducteurs.

●

MISE EN GARDE: Pour réduire les risques de feu de graisse sur la cuisinière:

– Ne laissez jamais les éléments de surface sans surveillance lors de l’utilisation de

réglages élevés. Les débordements produisent de la fumée et des déversements

de matières grasses qui peuvent s’enflammer. Chauffez les huiles lentement, à feu

doux ou moyen.

– Allumez toujours la hotte lorsque vous cuisinez à feu vif ou faites flamber des

aliments (par ex.: crêpes Suzette, cerise jubilé, steak au poivre flambé).

– Nettoyez fréquemment les ventilateurs. Ne laissez jamais la graisse s’accumuler

sur le ventilateur ou le filtre.

– Utilisez des récipients de taille appropriée. Utilisez toujours des plats de cuisson

●

●

●

adaptés à la taille de l’élément de surface.

MISE EN GARDE: Pour réduire les risques de blessures en cas de feu de graisse sur la

cuisinière, respectez ces consignes*:

– ÉTOUFFEZ LES FLAMMES avec un couvercle hermétique, une plaque à biscuits

ou un plateau métallique, puis éteignez le brûleur. FAITES ATTENTION DE NE PAS

VOUS BRÛLER. Si les flammes ne s’éteignent pas immédiatement, ÉVACUEZ LA

PIÈCE ET APPELEZ LE SERVICE D’INCENDIE.

– NE PRENEZ JAMAIS UN RÉCIPIENT QUI EST EN FLAMMES– vous pourriez vous brûler.

– N’UTILISEZ PAS DE L’EAU, ni de linges ou serviettes humides, car cela pourrait

causer une violente explosion de vapeur.

– Utilisez un extincteur UNIQUEMENT si:

– Vous savez qu’il s’agit d’un extincteur de classe ABC et vous savez vous en

servir.

– Le feu est peu important et localisé dans la zone où il a commencé.

– Vous avez appelé le service d’incendie.

– Vous pouvez combattre le feu en ayant le dos tourné vers une sortie.

MISE EN GARDE: Débranchez ou déconnectez l’appareil de l’alimentation électrique

avant de procéder à l’entretien ou au nettoyage.

MISE EN GARDE: Toutes les ouvertures dans le mur et le plancher doivent être scellées

aux endroits où la hotte de ventilation est installée.

FR

LISEZ ET CONSERVEZ CES INSTRUCTIONS

* Tirés des conseils sur la sécurité en matière d’incendie de cuisine de la NFPA.

41

Page 44

Page 45

Page 46

INSTRUCTIONS D’INSTALLATION

Unité d’aspiration descendante– Contenu de l’emballage

TELESCOPC DOWNDRAFT VENT SYSTEM

HD0 and D36 V nt m des

HBD00 and HD 200E l we mod ls

SYSTÈME DE VENTILATION TÉLESCOP QUE

À ASP RATION DESCENDANTE

Mdè s de ys èm s de e ta i n HD30 t HD 6

odl s de en lt us HB 600 et BD 20E

NSTALAT ON GUI E / USER GUDE

GUIDE D NSTA LATON / GUDE D’ TI I ATON

US CA

Unité d’aspiration

descendante

(1)

Capuchon d’extrémité

(2)

Pièce de fixation avec

patte de soutien

(2)

Instructions d’installation

Guide d’utilisation

(1)

Garniture supérieure

(1)

Filtre à graisses

(2)

Plaque de raccordement

de 10po (254mm) pour

ventilateur à distance

(1)

Pièce de fixation pour

dessous de comptoir

(2)

Pièce de fixation pour

dessus de comptoir

(2)

Écrou de ⁄po (7mm)

(2)

Vis autotaraudeuse

de ⁄po (15mm)

(6)

44

Vis de ⁄po (5mm)

(2)

Vis de ⁄po (8mm)

(6)

Page 47

INSTRUCTIONS D’INSTALLATION

Ventilateur interne (HBD600I)– Contenu de l’emballage

FR

Boîtier de ventilateur

interne

(1)

Ventilateur à distance (HBD1200E)– Contenu de l’emballage

Ventilateur à distance

(1)

Clapet anti-refoulement

d’air de 6po (152mm)

de diamètre

(1)

Plaque avec collet

pour conduit

(1)

45

Page 48

Page 49

Page 50

INSTRUCTIONS D’INSTALLATION

MISE EN GARDE!

Pour réduire les risques d’incendie, utilisez uniquement des conduits en métal.

N’utilisez pas de conduits en plastique flexible.

ATTENTION!

Pour réduire les risques d’incendie et évacuer l’air adéquatement, assurez-vous

d’évacuer l’air vers l’extérieur– N’évacuez pas l’air dans les murs, plafonds, greniers,

vides sanitaires ou garages.

Ventilateurs compatibles avec le système de ventilation à aspiration descendante

●

Modèle de ventilateur interne HBD600I.

●

Modèle de ventilateur à distance HBD1200E ou modèles de ventilateur à distance d’un

maximum de 2,8 A.

●

Cette unité d’aspiration descendante peut être utilisée uniquement avec un ventilateur

Fisher & Paykel interne ou à distance indiqué ci-dessus.

Surfaces de cuisson compatibles avec le système de ventilation à aspiration descendante

Le système de ventilation à aspiration descendante est conçu pour être installé avec

ces appareils à usage résidentiel: surfaces de cuisson, combinaisons de surfaces de

cuisson/fours, cuisinières non encastrées SANS dosseret et tables de cuisson. Il n’est

pas recommandé d’utiliser ce produit avec des cuisinières qui pourraient nécessiter un

espace supplémentaire à l’arrière pour l’évacuation OU des cuisinières non encastrées

AVEC dosseret. Consultez toutes les instructions d’installation du produit pour connaître

les dimensions et mesures de dégagement adéquates.

IMPORTANT!

Assurez-vous qu’il soit possible d’utiliser la surface de cuisson installée avec un

système de ventilation à aspiration descendante.

Exigences relatives à l’évacuation

Veuillez porter une attention particulière à assurer la conformité à toutes les

réglementations relatives à l’évacuation de l’air.

Pour une efficacité optimale, utilisez le trajet de conduit le plus court et le plus droit

possible, ainsi qu’un conduit rigide ou semi-rigide afin d’atténuer le bruit et augmenter

la circulation d’air. Pour de meilleurs résultats, raccordez les ventilateurs internes à un

conduit circulaire de 6po (152mm) et les ventilateurs à distance à un conduit circulaire

de 10po (254mm). Un conduit en métal flexible doit uniquement être utilisé en dernier

recours (dans des installations difficiles); en pareil cas, veillez à ce qu’il soit aussi droit,

lisse et allongé que possible.

Avant de découper les ouvertures, assurez-vous qu’il y ait suffisamment d’espace

pour le conduit d’évacuation dans le mur ou le plancher. Ne découpez pas de solive

ou de montant, à moins que cela ne soit absolument nécessaire. S’il est nécessaire de

découper une solive ou un montant, vous devrez construire une structure de soutien.

ATTENTION!

Pour réduire les risques d’incendie et de choc électrique, installez cet appareil

uniquement avec des modèles de ventilateurs à distance d’un maximum de 2,8A, qu’il

est possible d’utiliser avec des dispositifs de contrôle de vitesse à semi-conducteurs.

48

Page 51

INSTRUCTIONS D’INSTALLATION

Planifiez le trajet de conduit

Le ventilateur interne peut être installé à l’avant ou l’arrière de l’unité d’aspiration

descendante, avec un conduit orienté dans l’une de ces directions: gauche, droite, bas,

avant ou arrière. Le ventilateur à distance peut être raccordé à un conduit orienté vers le

bas, à partir de l’avant ou l’arrière de l’unité d’aspiration descendante.

Dans les installations où le ventilateur est situé à l’arrière de l’unité d’aspiration

descendante, il est recommandé de prévoir une porte ou ouverture d’accès

permettant d’atteindre la partie inférieure de l’unité d’aspiration descendante ainsi que

l’emplacement du boîtier de câblage et du ventilateur, en cas de réparation.

Calculez la longueur de conduit

La longueur de conduit ne doit pas dépasser 55 pieds équivalents (16,7 m) pour

les conduits circulaires de 6 po (152 mm) ou 75 pieds équivalents (22,9 m) pour les

conduits circulaires de 10 po (254 mm). Calculez la longueur de conduit en ajoutant la

valeur en pieds équivalents indiquée dans le tableau ci-dessous pour chaque section de

conduit du système complet. Lors de l’utilisation d’un conduit en métal flexible, chaque

pied (312 mm) de conduit en métal flexible équivaut à deux pieds (617 mm) de conduit

en métal droit pour le calcul de longueur du conduit.

Pour de meilleurs résultats, utilisez un conduit de taille uniforme avec un maximum de

trois coudes à 90°. Un minimum de 24po (607mm) de conduit droit est requis entre

les coudes, lorsque plusieurs coudes sont utilisés. Il est recommandé d’installer un

conduit circulaire plutôt qu’un conduit rectangulaire, plus particulièrement si des coudes

sont nécessaires. Les conduits rectangulaires doivent être convertis le plus rapidement

possible au format circulaire d’un minimum de 6po (152mm) pour les ventilateurs

internes et de 10po (254mm) pour les ventilateurs à distance.

FR

LONGUEUR ÉQUIVALENTE EXEMPLE DE CALCUL

Coude à 45° 5pi (1,5m) Conduit droit de 9pi 9pi (2,8m)

Coude à 90° 7pi (2,1m) 2coudes à 90° 14pi (4,3m)

Coude plat à 90° 12pi (3,7m) Capuchon mural 0pi (0,0m)

Capuchon mural 0pi (0,0m) Système complet 23pi (7,0m)

49

Page 52

INSTRUCTIONS D’INSTALLATION

MISE EN GARDE!

●

Cet appareil est lourd. Il doit être déballé et installé par deux personnes.

●

L’installation et le câblage électrique doivent être réalisés par une ou plusieurs

personne(s) qualifiée(s), en conformité avec tous les codes et toutes les normes

applicables.

IMPORTANT!

●

Portez des gants pour vous protéger des rebords tranchants.

●

Pour vous préparer à découper l’ouverture de l’unité d’aspiration descendante:

– Dessinez les ouvertures pour la surface de cuisson et l’unité d’aspiration

descendante sur le comptoir avant d’effectuer les coupes.

– Vérifiez qu’il y a suffisamment d’espace dans l’armoire pour la surface de cuisson

et l’unité d’aspiration descendante. Le fait de ne pas respecter ces consignes

●

1

peut entraîner des dommages au comptoir.

Pour éviter d’endommager les roulements du moteur et les ailettes, gardez les

vaporisateurs à cloison sèche, poussières de construction, etc. à distance du

ventilateur.

Le fabricant n’est pas responsable des dommages résultant du non-respect de ces

instructions.

Préparation pour l’installation

Avant d’installer votre système de ventilation à aspiration descendante:

●

Veuillez lire attentivement les instructions.

●

Déballez l’unité d’aspiration descendante et placez-la sur une surface plane protégée.

●

Assurez-vous que la tension (V) et la fréquence (Hz) indiquées sur la plaque

signalétique correspondent à la tension et la fréquence sur le site d’installation.

●

Vérifiez que la section à proximité de la zone d’installation ne contient aucun câble

électrique, tuyau, etc.

●

Tenez compte de l’emplacement des armoires et dosserets dans la zone d’installation

du système de ventilation à aspiration descendante et de la surface de cuisson.

Veillez à ce que la zone d’élévation de l’unité d’aspiration descendante soit exempte

d’obstacles. Veuillez également noter que l’efficacité de l’appareil peut être

compromise par les courants d’air forts provenant des fenêtres, portes, etc.

●

Les surfaces de l’unité d’aspiration descendante peuvent être endommagées pendant

l’installation en cas de frottement ou contact avec un outil. Veuillez vous assurer de

protéger les surfaces pendant l’installation.

●

Marquez temporairement le centre de la surface de cuisson conformément aux

informations indiquées dans la section ‘Instructions d’installation– Dimensions de

l’ouverture’.

●

L’unité d’aspiration descendante est installée directement derrière la surface de

cuisson. Pour faciliter l’installation, installez d’abord le système de ventilation à

aspiration descendante, puis la surface de cuisson.

●

Retirez l’emballage en carton de l’ailette du ventilateur.

50

Page 53

INSTRUCTIONS D’INSTALLATION

Préparez l’unité d’aspiration descendante pour le ventilateur utilisé

2

Ventilateur interne

●

Retirez la plaque de raccordement de 10po (254mm) pour ventilateur de la partie

avant de l’unité d’aspiration descendante (Fig.1).

●

Installez les pièces de fixation pour dessus de comptoir à l’aide des deux vis de ⁄po

(5mm) fournies (Fig.2).

●

Vissez les pièces de fixation avec patte de soutien sur le côté de l’unité

d’aspiration descendante à l’aide de deux vis de ⁄po (8mm) chacune, sans

serrer complètement les vis. Les pièces de fixation des côtés gauche et droit sont

différentes. Installez-les avec le clip de fixation (A) vers le haut.

Ventilateur à distance

●

L’unité d’aspiration descendante est prête à l’installation, avec la plaque de

raccordement de 10po (254mm) pour ventilateur à distance installée à l’avant et la

plaque de recouvrement installée à l’arrière.

●

Pour raccorder le ventilateur à distance à la partie arrière de l’unité d’aspiration

descendante, changez les plaques (voir Fig.3 et 4).

●

Installez les pièces de fixation pour dessus de comptoir à l’aide des deux vis de ⁄po

(5mm) fournies (Fig.2).

●

Vissez les pièces de fixation avec patte de soutien sur le côté de l’unité

d’aspiration descendante à l’aide de deux vis de ⁄po (8mm) chacune, sans

serrer complètement les vis. Les pièces de fixation des côtés gauche et droit sont

différentes. Installez-les avec le clip de fixation (A) vers le haut.

FR

Fig.1

Fig.3

Fig.2

AVAN T

AVAN T

A

Fig.4

2 x

4 x

51

Page 54

INSTRUCTIONS D’INSTALLATION

Insérez temporairement l’unité d’aspiration descendante dans l’armoire

3

●

Avec l’aide d’une autre personne, soulevez l’unité d’aspiration descendante dans

l’ouverture que vous avez préparée dans l’armoire. Les pièces de fixation pour dessus

de comptoir doivent reposer sur le comptoir.

●

Fixez l’unité d’aspiration descendante au comptoir à l’aide de deux vis de ⁄po (15mm).

●

Installez les pièces de fixation pour dessous de comptoir afin de procurer un

soutien supplémentaire. Commencez par visser sans serrer les pièces de fixation

dans les écrous coulissants de l’unité d’aspiration descendante à l’aide des vis de

⁄po (5mm), puis poussez-les vers le haut, sous le comptoir. Percez les trous de

montage dans le comptoir, par le dessous. Vérifiez que les vis de montage sont

d’une longueur adéquate et qu’elles ne passeront pas au travers de la surface du

comptoir lorsqu’elles seront serrées. Le fait de ne pas respecter ces instructions peut

entraîner des dommages à la surface du comptoir (Fig.5).

●

Mettez de niveau et alignez l’unité d’aspiration descendante dans l’armoire. Poussez

la pièce de fixation avec patte de soutien de chaque côté, contre le fond de

l’armoire. Marquez le rebord supérieur de la pièce de fixation sur l’unité d’aspiration

descendante et les trous de montage sur le fond de l’armoire (Fig.6).

Fig.5 Fig.6

2 x

2 x

Retirez l’unité d’aspiration descendante de l’armoire

4

●

Retirez les vis du comptoir et soulevez l’unité d’aspiration descendante pour la sortir

de l’armoire.

●

Percez les trous de montage marqués dans le fond de l’armoire.

●

Serrez les pièces de fixation avec patte de soutien sur l’unité, aux positions marquées

préalablement.

●

Placez l’unité d’aspiration descendante sur une surface plane protégée pour éviter de

l’endommager pendant l’installation du ventilateur.

Installez le ventilateur interne ou à distance

5

●

Pour l’installation du ventilateur interne, reportez-vous à la page53.

●

Pour l’installation du ventilateur à distance, reportez-vous à la page54.

Remarque: cette unité d’aspiration descendante peut être utilisée uniquement avec

52

un ventilateur Fisher & Paykel interne ou à distance.

Page 55

INSTRUCTIONS D’INSTALLATION

Installation du ventilateur interne à l’aide d’une des trois options suivantes:

Option1: Ventilateur interne, installation par l’avant pour évacuation vers la

gauche, la droite ou le bas

●

Déconnectez le câble à l’intérieur de l’unité d’aspiration descendante. Branchez

ce même câble de l’unité d’aspiration descendante au ventilateur interne (Fig.7).

●

Tournez le collet de conduit du boîtier de ventilateur interne dans la direction

souhaitée: vers la gauche, la droite ou le bas.

●

Installez le boîtier de ventilateur interne sur le compartiment à l’aide de quatre

vis (Fig.8).

●

Poursuivez à la section ‘Préparation pour le raccordement électrique’ à la page56.

Fig.8Fig.7

FR

AVAN T

Option2: Ventilateur interne, installation par l’arrière pour évacuation vers la

gauche, la droite ou le bas

●

Le boîtier de ventilateur interne peut également être installé à l’arrière de l’unité

d’aspiration descendante pour permettre l’installation d’une cuisinière ou d’un

four mural/une surface de cuisson devant l’unité d’aspiration descendante.

●

Retirez le grand couvercle situé à l’arrière de l’unité d’aspiration descendante

(Fig.9).

●

Tournez le collet de conduit du boîtier de ventilateur dans la direction souhaitée:

vers la gauche, la droite ou le bas. Déconnectez le câble à l’intérieur de l’unité

d’aspiration descendante. Branchez ce même câble de l’unité d’aspiration

descendante au ventilateur interne et installez le boîtier de ventilateur sur le

compartiment à l’aide de quatre vis (Fig.10).

●

Lorsque vous terminez, installez le couvercle retiré précédemment sur le devant

de l’unité d’aspiration descendante (Fig.11).

●

Poursuivez à la section ‘Préparation pour le raccordement électrique’ à la page56.

Fig.9

ARRIÈRE

Fig.10

Fig.11

ARRIÈRE

AVAN T

53

Page 56

Page 57

INSTRUCTIONS D’INSTALLATION

Option2: Installation sur un toit incliné

(Pour les installations sur un toit plat, voir l’Option3)

●

Choisissez l’emplacement sur la pente arrière du toit, en veillant à minimiser la

longueur de conduit. Évitez les obstacles tels que les câbles de télévision, lignes

électriques, etc. Si le dessus du ventilateur à distance est de niveau avec le

faîte du toit, il ne sera pas visible de la rue. Assurez-vous de pouvoir situer cet

emplacement lorsque vous travaillerez à partir de l’intérieur du toit.

●

Marquez un point à mi-chemin entre les chevrons et percez un trou de guidage à

cet endroit.

●

Depuis l’extérieur, utilisez le trou de guidage comme point de départ pour marquer

l’ouverture rectangulaire, comme indiqué dans la Fig.12. Retirez UNIQUEMENT le

bardeau dans CETTE ZONE.

●

Marquez un cercle de 11po (279mm) de diamètre autour du trou de guidage,

comme indiqué dans la Fig.12.

●

Marquez le centre du trou de 1¼po (32mm) de diamètre pour le câblage

électrique, comme indiqué dans la Fig.12.

●

Découpez les panneaux-toiture le long du cercle de 11po (279mm) de diamètre.

●

Percez le trou de 1¼po (32mm) de diamètre pour le câblage électrique.

●

Retirez les clous de toiture des deux tiers supérieurs des bardeaux afin de pouvoir

insérer sous ces derniers le revêtement pour solin du ventilateur à distance.

●

Centrez l’anneau du ventilateur à distance dans l’ouverture de 11po (279mm) de

diamètre, en vous assurant que le trou de 1¼po (32mm) de diamètre pour le

câblage électrique soit aligné avec le trou dans le boîtier de câblage.

●

Fixez le ventilateur à distance au toit ou à la charpente à l’aide de vis appropriées

pour votre installation. Bouchez les quatre trous dans le panneau arrière

pour éviter que l’humidité puisse pénétrer dans la maison en s’infiltrant par le

compartiment du ventilateur à distance.

●

Scellez tous les bardeaux autour du compartiment de ventilateur à distance, le

revêtement pour solin et les têtes de vis de montage ou la charpente à l’aide de

goudron de toiture. La bride supérieure et les brides latérales de la plaque arrière

pourraient comporter une garniture. Il est recommandé de commencer par effectuer

et vérifier le raccordement électrique. Ne bloquez pas l’ouverture de la grille

d’évacuation dans le bas de la garniture. Cela réduirait l’efficacité du ventilateur.

●

Poursuivez à la section ‘Préparation pour le raccordement électrique’ à la page56.

Option3: Installation sur un toit plat

●

Localisez l’ouverture de 11po (279mm) de diamètre entre les chevrons.

●

Construisez une base inclinée pour l’installation du ventilateur à distance, avec

une pente minimale de 2½po (64mm); voir Fig.13 pour un exemple avec une

pente de 5po (127mm).

●

Étanchéifiez la base, tel que nécessaire.

●

Placez la base de manière à ce que

l’évent du ventilateur à distance soit

aligné avec l’ouverture de 11po (279mm)

de diamètre, en veillant à ce que le

ventilateur repose uniformément sur

la base, sans espacement. Remarque:

Assurez-vous que l’extrémité d’évacuation

du ventilateur à distance soit à l’opposé

de la direction des vents dominants.

●

Utilisez les dimensions indiquées dans

la Fig.12 pour localiser le trou de 1¼po

(32mm) de diamètre pour le câblage.

●

Poursuivez à partir du point8 de la

section précédente, ‘Installation sur un

toit incliné’.

33¼po

(845mm)

Côté d’évacuation

du ventilateur

26¾po

(679mm)

2po x 4po

(51mm x 102mm)

Trou de 11po

2po (51mm)

(279mm)

de diamètre

Fig.13

FR

7po

(178mm)

55

Page 58

INSTRUCTIONS D’INSTALLATION

Préparation pour le raccordement électrique

6

Unité d’aspiration descendante

●

Retirez le couvercle de la boîte de jonction de l’unité d’aspiration descendante (Fig.14).

●

Choisissez la position de raccordement de la source d’alimentation à l’unité

d’aspiration descendante (à partir du dessous ou de l’arrière), puis retirez l’alvéole

défonçable correspondante. Installez un protecteur de cordon homologué UL ou un

raccord de conduit (non compris) dans l’alvéole défonçable (Fig.15).

●

Si l’unité d’aspiration descendante est installée avec un ventilateur à distance, retirez

l’alvéole défonçable pour le câble de commande.

●

Avec l’aide d’une autre personne, soulevez l’unité d’aspiration descendante dans

l’ouverture que vous avez préparée dans l’armoire. Les pièces de fixation pour dessus

de comptoir doivent reposer sur le comptoir.

●

Fixez l’unité d’aspiration descendante au plancher et au comptoir en insérant les vis

dans les trous percés précédemment (Fig.16).

Fig.14

Fig.16

6 x

2 x

AVAN T

AVAN T

Fig.15

●

Installez les capuchons d’extrémité de l’unité d’aspiration descendante sur le dessus

du comptoir, puis verrouillez-les en place (Fig.17).

Fig.17

56

Page 59

INSTRUCTIONS D’INSTALLATION

Raccordement électrique

7

MISE EN GARDE!

●

Le câblage électrique doit être réalisé par une ou plusieurs personne(s) qualifiée(s),

en conformité avec tous les codes et toutes les normes applicables, en veillant à ce

que l’appareil soit mis à la terre.

●

Cette unité d’aspiration descendante peut être utilisée uniquement avec un ventilateur

Fisher & Paykel interne ou à distance.

●

Débranchez ou déconnectez l’appareil de l’alimentation électrique avant de procéder

à l’entretien ou au nettoyage.

Exigences électriques

Cet appareil ne doit être utilisé qu’avec une alimentation électrique de 120VCA/60Hz,

sur un circuit de 15ampères distinct, avec fusible aux deux extrémités du câble

électrique. Nous vous recommandons d’utiliser un fusible à fusion lente ou un

disjoncteur. Le fusible doit répondre aux exigences des codes locaux et être conforme

aux caractéristiques électriques de cette unité d’aspiration descendante, indiquées sur

la plaque signalétique/de numéro de série apposée à l’intérieur de l’unité d’aspiration

descendante, près du compartiment de câblage.

Cette unité d’aspiration descendante doit être raccordée uniquement à l’aide de fil

de cuivre. Les calibres de fil doivent être conformes aux exigences de la norme ANSI/

NFPA70 de la dernière édition du Code national de l’électricité, ainsi qu’à tous les

codes et règlements locaux en vigueur. Le calibre de fil et les raccordements doivent

être conformes aux caractéristiques de l’appareil. Des copies de la norme mentionnée

ci-dessus peuvent être obtenues de:

National Fire Protection Association

Battery March Park

Quincy, Massachusetts 02269

FR

Cet appareil doit être raccordé directement au sectionneur à fusibles (ou au disjoncteur)

au moyen d’un câble de cuivre flexible à armature ou gaine non métallique. Prévoyez

une longueur de câble suffisante pour qu’il soit possible de déplacer l’appareil en cas de

réparation. Un protecteur de cordon homologué UL ou un raccord de conduit de ½po

(12,7mm) doit être utilisé à chaque extrémité du câble d’alimentation électrique (au

niveau de l’appareil et de la boîte de jonction).

Pour effectuer le raccordement électrique, découpez un trou de 1¼po (32mm) dans le

mur. Si le trou est découpé dans le bois, vous devrez le sabler jusqu’à ce qu’il soit lisse.

Si le trou est découpé dans le métal, il devra comporter un œillet.

Remarque: convient à l’utilisation avec des dispositifs de contrôle de vitesse à semiconducteurs.

57

Page 60

INSTRUCTIONS D’INSTALLATION

Raccordement électrique du ventilateur interne de l’unité d’aspiration descendante

●

Connectez le (L1/sous tension) du câble

d’alimentation électrique à la borne de droite (Fig.19).

●

Connectez le fil vert (terre) du câble d’alimentation

électrique à la borne du centre (Fig.19).

●

Connectez le (neutre) du câble d’alimentation

électrique à la borne de gauche (Fig.19).

●

Veillez à ce que les vis de borne maintiennent

solidement tous les fils en place.

●

Réinstallez le couvercle de la boîte de jonction (Fig.18).

Fig.18

58

Câble d’alimentation

de la maison

Câble de contrôle du

ventilateur à distance

Câble d’alimentation

de la maison

Vis de mise à la terre

Fig.19

BRUN

BLEU

)

n

o

i

s

n

e

t

s

u

o

s

(

1

GND (terre)

L

BRUN

BLEU CLAIR N (neutre)

VERT – JAUNE

Câblage de l’unité

d’aspiration descendante

Câblage

interne

BLANC

BLUE

NOIR

BRUN

VERT – JAUNE

Vis de mise à la terre

Fig.20

)

n

o

i

s

n

e

t

s

u

o

s

(

1

L

BRUN

N (neutre)BLEU

Câblage

)

n

o

interne

i

s

n

e

t

s

u

o

s

(

1

BLANC

L

BLUE

BRUN

BLEU CLAIR N (neutre)

VERT – JAUNE GND (terre)

Câblage de l’unité

d’aspiration descendante

NOIR

BRUN

Raccordement électrique du ventilateur à distance de l’unité d’aspiration descendante

●

Connectez le câble d’alimentation électrique à la boîte de jonction de la manière

décrite dans la section ‘Raccordement électrique du ventilateur interne de l’unité

d’aspiration descendante’ (ci-dessus).

●

Pour utiliser un ventilateur à distance, installez un câble de contrôle entre

l’unité d’aspiration descendante et le ventilateur à distance. Consultez la section

‘Raccordement électrique du ventilateur à distance’ à la page suivante.

●

Des alvéoles défonçables supplémentaires doivent être utilisées pour le câblage

du ventilateur à distance.

●

Installez un protecteur de cordon homologué UL ou un raccord de conduit

adéquat (non compris) dans l’alvéole défonçable.

●

Connectez le câblage du ventilateur à distance à l’unité d’aspiration descendante:

N (neutre) à la borne de droite, L1 (sous tension) à la borne de gauche et le fil

vert (terre) à la borne de mise à la terre (Fig.20).

●

Veillez à ce que les vis de borne maintiennent solidement tous les fils en place.

●

Le ventilateur à distance sera raccordé au câble de contrôle supplémentaire.

●

Réinstallez le couvercle de la boîte de jonction (Fig.18).

Page 61

Page 62

Page 63

INSTRUCTIONS D’UTILISATION

Le système de ventilation à aspiration descendante est conçu pour éliminer la fumée,

les vapeurs de cuisson et les odeurs de la zone de votre surface de cuisson. Pour de

meilleurs résultats, il est recommandé de démarrer le système de ventilation à aspiration

descendante avant de commencer la cuisson, puis de le laisser fonctionner plusieurs

minutes après avoir terminé. Si vous utilisez de grandes casseroles, placez-les sur le

brûleur arrière pour assurer une ventilation adéquate; un réglage de ventilateur plus

élevé pourrait être requis.

Le dispositif d’allumage avec détection de flamme de certaines surfaces de cuisson au

gaz pourrait être affecté par l’aspiration descendante, qui risque de disperser la flamme

en l’éloignant du dispositif d’allumage par étincelle. Le dispositif pourrait alors continuer

de produire une étincelle pour tenter de rallumer le brûleur déjà allumé. Pour résoudre

ce problème et améliorer les performances du brûleur, réduisez la vitesse du ventilateur,

augmentez le réglage du brûleur ou essayez ces deux solutions en même temps.

Commandes

FR

FONCTIONNALITÉS DU PANNEAU DE COMMANDE

Mise en marche/

A

arrêt

Vitesse du

B

ventilateur

Appuyez sur la touche d’alimentation de la garniture

supérieure pour activer l’élévation de l’unité d’aspiration

descendante. Le ventilateur commencera à fonctionner

immédiatement si le curseur de contrôle du ventilateur est

réglé à la position ‘On’.

Appuyez sur la touche d’alimentation de la garniture

supérieure; le ventilateur s’éteindra et l’unité d’aspiration

descendante s’abaissera à la position fermée.

Utilisez le curseur de contrôle sur le côté droit de l’unité

d’aspiration descendante pour régler la vitesse de moteur du

ventilateur.

A

B

61

Page 64

NETTOYAGE ET ENTRETIEN

MISE EN GARDE!

Débranchez ou déconnectez l’appareil de l’alimentation électrique avant de procéder

à l’entretien ou au nettoyage.

IMPORTANT!

●

N’utilisez jamais de nettoyants abrasifs ou à base d’huile.

●

Portez des gants pour vous protéger des rebords tranchants.

Entretien

Le système de ventilation à aspiration descendante doit être nettoyé régulièrement

à l’aide d’un détergent liquide doux et d’un chiffon doux et propre pour éviter

l’accumulation de dépôts de graisse. Évitez d’utiliser des produits chimiques corrosifs,

des produits de nettoyage abrasifs, des brosses rigides et des tampons de laine

d’acier. Les dépôts de graisse sont corrosifs et peuvent endommager votre système

de ventilation à aspiration descendante.

Remarque: dans les régions où l’humidité est élevée ou les environnements côtiers,

le nettoyage doit être effectué plus fréquemment.

Filtres à graisses

●

Selon la fréquence d’utilisation, et au moins une fois par mois, vous devez retirer les

filtres à graisses en aluminium pour les nettoyer avec de l’eau savonneuse et chaude

ou dans un lave-vaisselle. Veuillez noter que le contact avec d’autres articles dans le

lave-vaisselle pourrait égratigner leur surface.

●

Si vous les lavez au lave-vaisselle, vous devez placer les filtres dans une position

verticale pour éviter que des aliments se déposent sur ceux-ci.

●

Après le nettoyage et le séchage, réinstallez les filtres.

Retrait des filtres à graisses: