Fisher & Paykel GWL15-96200A, GWL15-96155A, GWL08-96107, IWL16-96203A, IWL12-96154 Installation Instructions Manual

...

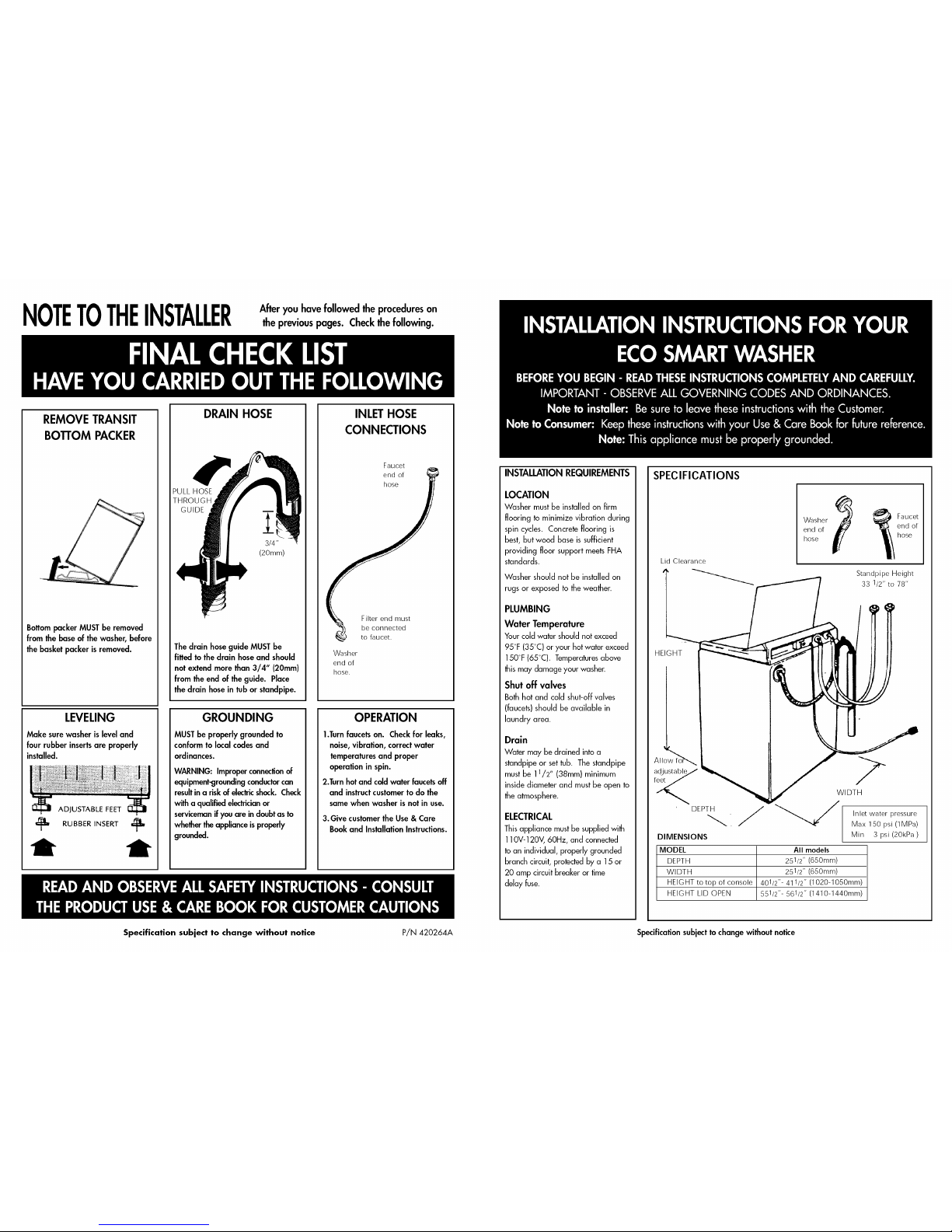

NOTETOTHEINSTALLER

Afteryou havefollowedtheprocedureson

thepreviouspages. Checkthefollowing.

REMOVE TRANSIT

BO'I'rOM PACKER

Bottompacker MUST be removed

from the base of the washer, before

the basket packer is removed.

LEVELING

Make sure washer is level and

four rubber insertsare properly

installed.

ADJUSTABLE FEET

_m RUBBER INSERT _'_

DRAIN HOSE

PULL HOSE

THROUGH

GUIDE m

3/4"

(20mm)

The drain hoseguide MUST be

fitted to the drain hose and should

not extend more than 3/4" (20mm)

from the end of the guide. Place

the drain hose in tub or standpipe.

GROUNDING

MUST be properly grounded to

conform to local codes and

ordinances.

WARNING: Improperconnection of

equipment-groundingconductor can

resultina riskof electricshock. Check

with a qualified electricianor

servicemanif you are in doubt as to

whethertheappliance is properly

grounded.

INLETHOSE

CONNECTIONS

Faucet

end of

hose

Filter end must

be connected

to faucet.

Washer

end of

hose.

OPERATION

1.Turnfaucets on. Check for leaks,

noise, vibration, correct water

temperatures and proper

operation in spin.

2.Turn hot and cold water faucetsoff

and instructcustomer to do the

same when washer is not in use.

3. Give customer the Use & Care

Book and Installation Instructions.

INSTALLATION REQUIREMENTS

LOCATION

Washer must be installed on firm

flooring to minimize vibration during

spin cycles. Concrete flooring is

best, but wood base is sufficient

providing floor support meets FHA

standards.

Washer should not be installed on

rugs or exposed to the weather.

PLUMBING

Water Temperature

Your cold water should not exceed

95°F (35°C) or your hot water exceed

150°F (65°C). Temperaturesabove

this may damage your washer.

Shut off valves

Both hot and cold shut-off valves

(faucets) should be available in

laundry area.

Drain

Water may be drained into a

standpipe or set tub. The standpipe

must be 11/2" (38mm) minimum

inside diameter and must be open to

the atmosphere.

ELECTRICAL

This appliance must be supplied with

110V-120V, 60Hz, and connected

to an individual, properly grounded

branch circuit, protected by a 15 or

20 amp circuit breaker or time

delay fuse.

SPECIFICATIONS

Lid Clearance

Washer

end of

hose

_ Faucet

end of

hose

Standpipe Height

33 1/2" to 78"

HEIGHT

! I

Allowfo_

adjustablee//

DEPTH

DIMENSIONS

WIDTH

/

Inlet water pressure /

Max 150 psi (1MPa)

J

Min 3 psi (20kPa)

MODEL All models

DEPTH 251/2" (650mm)

WIDTH 251/2" (650mm)

HEIGHT to top of console 401/2"- 411/2" (1020-1050mm)

HEIGHT LID OPEN 551/2 "- 561/2" (1410-1440mm)

Specification subject to change without notice P/N 420264A Specificationsubject to change without notice

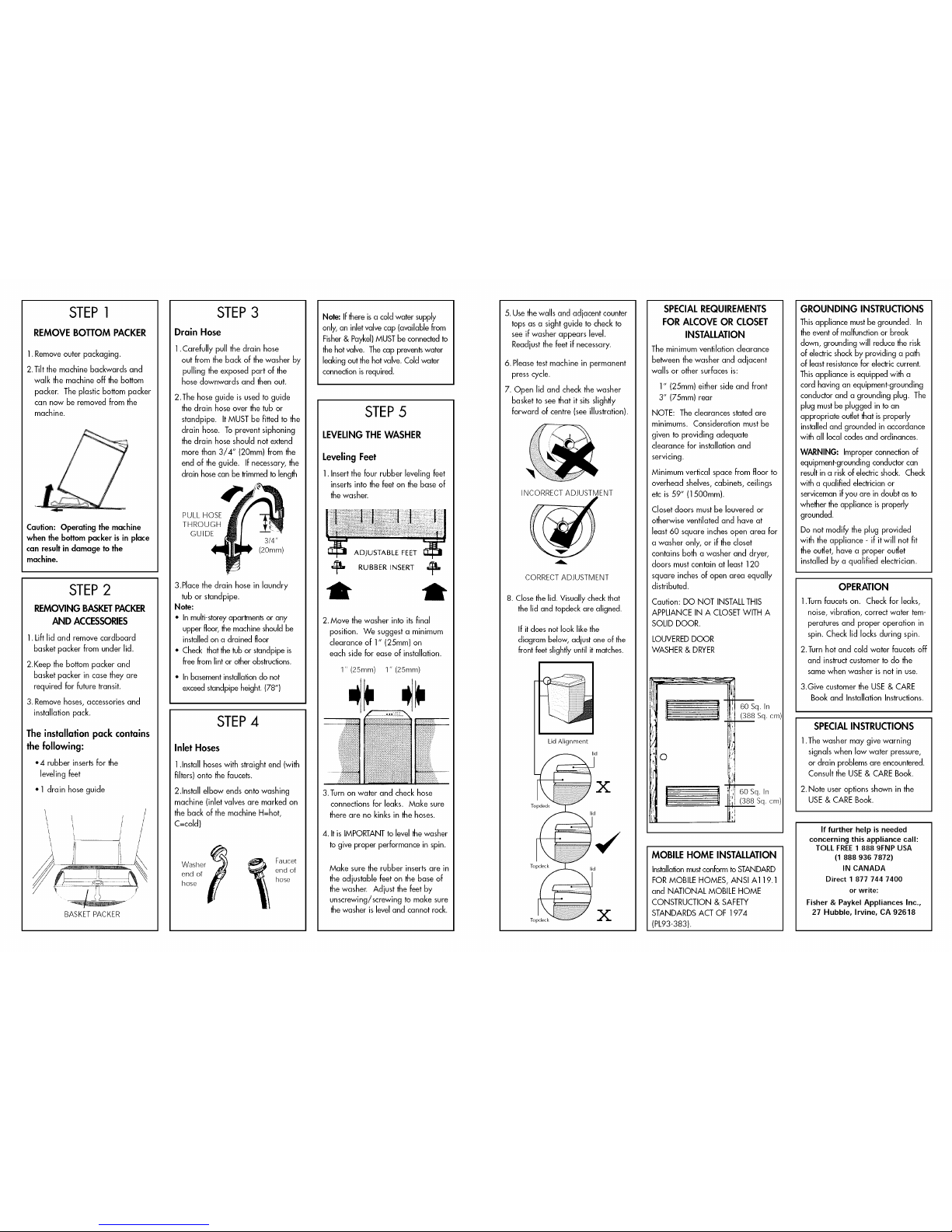

STEP1

REMOVE BOTTOM PACKER

1.Remove outer packaging.

2.Tilt the machine backwards and

walk the machine off the bottom

packer. The plastic bottom packer

can now be removed from the

machine.

Caution: Operating the machine

when the bottom packer is in place

can result in damage to the

machine.

STEP2

REMOVING BASKETPACKER

AND ACCESSORIES

1.Lift lid and remove cardboard

basket packer from under lid.

2.Keep the bottom packer and

basket packer in case they are

required for future transit.

3. Remove hoses, accessories and

installation pack.

The installation pack contains

the following:

*4 rubberinsertsfor the

levelingfeet

• 1 drain hoseguide

\ /

/ ' /

! t J /

BASKETPACKER

STEP3

Drain Hose

1.Carefully pull the drain hose

out from the back of the washer by

pulling the exposed part of the

hose downwards and then out.

2.The hose guide is used to guide

the drain hose over the tub or

standpipe. It MUST be fitted to the

drain hose. To prevent siphoning

the drain hose should not extend

more than 3/4" (20mm) from the

end of the guide. If necessary, the

drain hosecan be trimmed to length

PULL HOSE

THROUGH

GUIDE

3/4"

(20ram)

3.Place the drain hose in laundry

tub or standpipe.

Note:

• In multi-storeyapartments or any

upper floor, the machine should be

installed on a drained floor

• Check that the tub or standpipe is

free from lint or other obstructions.

• In basementinstallationdo not

exceed standpipe height. (78")

STEP4

Inlet Hoses

1.Install hoses with straight end (with

filters) onto the faucets.

2.Install elbow ends onto washing

machine (inlet valves are marked on

the back of the machine H=hot,

C=cold)

Washer

end or

hose

Faucet

end of

hose

Note: If there is a cold water supply

only, an inlet valve cap (available from

Fisher& Paykel)MUST be connected to

the hot valve. Thecap preventswater

leaking out the hot valve. Cold water

connection is required.

STEP5

LEVELING THE WASHER

Leveling Feet

1. Insert the four rubber leveling feet

inserts into the feet on the base of

the washer.

ADJUSTABLE FEET

RUBBER INSERT

2.Move the washer into its final

position. We suggest a minimum

clearance of 1" (25mm) on

each side for ease of installation.

1" (25mm) 1" (25ram)

3.Turn on water and check hose

connections for leaks. Make sure

there are no kinks in the hoses.

4. It is IMPORTANTto level the washer

to give proper performance in spin.

Make sure the rubber inserts are in

the adjustable feet on the base of

the washer. Adjust the feet by

unscrewing/screwing to make sure

the washer is level and cannot rock.

5. Use the walls and adjacent counter

tops as a sight guide to check to

see if washer appears level.

Readjust the feet if necessary.

6. Pleasetest machine in permanent

press cycle.

7. Open lid and check the washer

basket to see that it sits slightly

forward of centre (see illustration).

INCORRECTADJUSTMENT

CORRECT ADJUSTMENT

8. Close the lid. Visually check that

the lid and topdeck are aligned.

If it does not look like the

diagram below, adjust one of the

front feet slightly until it matches.

Lid Alignment

lid

SPECIAL REQUIREMENTS

FOR ALCOVE OR CLOSET

INSTALLATION

The minimum ventilation clearance

between the washer and adjacent

walls or other surfaces is:

I" (25mm) either side and front

3" (75mm) rear

NOTE: The clearances stated are

minimums. Consideration must be

given to providing adequate

clearance for installation and

servicing.

Minimum vertical space from floor to

overhead shelves,cabinets, ceilings

etc is 59" (1500mm).

Closet doors must be Iouvered or

otherwise ventilated and have at

least 60 square inches open area for

a washer only, or if the closet

contains both a washer and dryer,

doors must contain at least 120

square inches of open area equally

distributed.

Caution: DO NOT INSTALLTHIS

APPLIANCE IN A CLOSETWITH A

SOLID DOOR.

LOUVEREDDOOR

WASHER & DRYER

i !-

/,

'10

!r

! !

60 Sq. In

(388 Sq. cm,

60 Sq. In

(388 Sq. cm)

MOBILE HOME INSTALLATION

Installationmustconform to STANDARD

FOR MOBILE HOMES, ANSI A119.1

and NATIONAL MOBILE HOME

CONSTRUCTION & SAFETY

STANDARDS ACT OF 1974

(PL93-383).

GROUNDING INSTRUCTIONS

This appliance must be grounded. In

the event of malfunction or break

down, grounding will reduce the risk

of electric shock by providing a path

of least resistancefor electric current.

This appliance is equipped with a

cord having an equipment-grounding

conductor and a grounding plug. The

plug mustbe plugged in to an

appropriate outletthat is properly

installed and grounded in accordance

with all local codes and ordinances.

WARNING: Improper connection of

equipment-grounding conductor can

resultin a risk of electricshock. Check

with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded.

Do not modify the plug provided

with the appliance - if it will not fit

the outlet, have a proper outlet

installed by a qualified electrician.

OPERATION

1.Turn faucets on. Check for leaks,

noise, vibration, correct water tem-

peratures and proper operation in

spin. Check lid locks during spin.

2.Turn hot and cold water faucets off

and instruct customer to do the

same when washer is not in use.

3.Give customer the USE & CARE

Book and Installation Instructions.

SPECIAL INSTRUCTIONS

1.The washer may give warning

signals when low water pressure,

or drain problems are encountered.

Consult the USE & CARE Book.

2. Note user options shown in the

USE& CARE Book.

If further help is needed

concerning this appliance call:

TOLL FREE 1 888 9FNP USA

(1 888 936 7872)

IN CANADA

Direct 1 877 744 7400

or write:

Fisher & Paykel Appliances Inc.,

27 Hubble, Irvine, CA 92618

Loading...

Loading...