Page 1

599116A.03.2003

GC36 GC901,

GC901M

INSTALLATION INFORMATION

2 WARNINGS and SAFETY INFORMATION

3 DIMENSIONS and CLEARANCES

4 INSTALLATION INSTRUCTIONS

INFORMATIONS SUR L’INSTALLATION

8 AVERTISSEMENTS et INFORMATIONS SUR LA SECURITE

9 DIMENSIONS et DEGAGEMENTS

10 INSTRUCTIONS D’INSTALLATION

INFORMACION SOBRE LA INSTALACION

14 ADVERTENCIAS e INFORMACION SOBRE SEGURIDAD

15 DIMENSIONES y DISTANCIAS DE SEPARACION

16 INSTRUCCIONES DE INSTALACION

ES

FR

US

Page 2

WARNINGS AND SAFETY INFORMATION

2

CAUTION!

In order to avoid hazard these products must be

installed according to these instructions.

This product should not be sealed into the bench

with silicone or glue. This will make any future

servicing difficult. Fisher & Paykel will not be liable

for costs associated with releasing such products,

nor for damage incurred as a result.

WARNING

Cut Hazard

Beware of sharp edges.

Use the polystyrene ends

when carrying the product.

Failure to use caution could

result in minor injury or cuts.

IMPORTANT!

This product must be installed by an authorized

person (W

ARNING this product must be installed by

a licensed plumber or gas fitter when within the

Commonwealth of Massachusetts)

Please leave these instructions with the appliance.

Inform the customer to retain for future reference.

This product is supplied with an additional label

containing the model and serial numbers. It may be

affixed to the underside of the product, the inside of

a cupboard or to the User Guide.

US

WARNING

Electrical Shock Hazard

Disconnect power before

servicing the product.

Failure to do so could result in

death or electrical shock.

WARNING!

This appliance shall be installed in accordance with

the installation requirements of the local gas

authority or the appropriate installation code or in the

absence of local codes with the latest National Fuel

Gas Code ANSI Z223.1 or CAN B149.1,2(Canada).

Local building and electrical codes must be adhered to.

When this appliance is installed it shall not be used

as a space heater.

No combustible material or products should be

placed on this appliance at any time.

Do not spray aerosols in the vicinity of this appliance

while it is in operation.

Not to be installed in a bathroom or

bedroom/sleeping quarters.

Flexible appliance connectors shall meet the

requirements of ANSI Z21.24 and State Boards.

They shall not exceed 36 inches in length.

Page 3

DIMENSIONS AND CLEARANCES

3

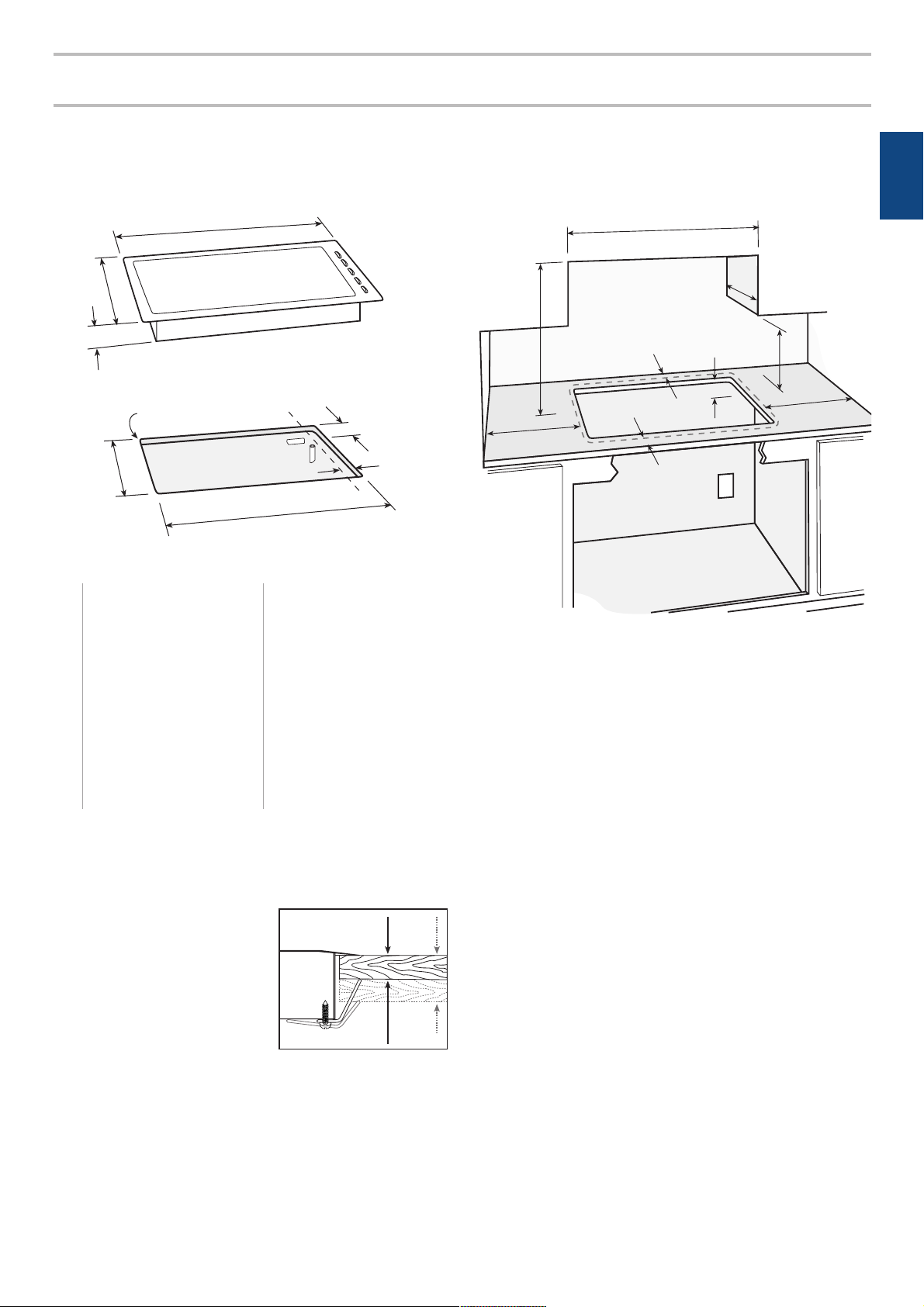

PRODUCT AND CUTOUT DIMENSIONS

GC36 GC901/GC901M

A

36” (914mm) 36” (914mm)

B 21” (533mm) 21

1

/

2

" (546mm)

C 1

5

/

8

" (41.5mm) 2

9

/

16

" (65mm) GC901,

3" (76mm) GC901M

D 19

1

/

2

" (494mm) [18

3

/

8

" - 19

3

/

4

"] 19

1

/

2

" (494mm) [19

1

/

8

" - 20

5

/

8

"]

E 34

1

/

4

" (870mm)

[33

3

/

8

" - 34

3

/

4

"]

34

1

/

4

" (870mm)

[33

7

/

8

" - 35

1

/

4

"]

F R

3

/

8

" (10mm) R

3

/

8

" (10mm)

G 1

3

/

16

" (30mm)

3

/

4

" (20mm)

H 1" (25mm) 1" (25mm)

US

CLAMPING DOWN THE COOKTOP

Place the cooktop into the cutout

and tighten it with the supplied

clamps. These will cope with the

countertop thicknesses

3

/

4

"- 2"

when used in the two orientations

shown.

Do not over tighten.

C

B

A

D

E

H

G

F

manifold

center line

gas inlet

a

b

d

c

e

i

h

g

j

a

36" = Minimum horizontal distance between overhead

cabinets installed on either side of this appliance.

b 30" = Minimum clearance from combustible surface centered

above the cooktop.

c 13" = Maximum overall depth of overhead cabinetry.

d 18" = Minimum clearance from countertop to overhead cabinetry.

e 4" (GC36) or 1

1

/

2

" (GC901 & GC901M) = Minimum clearance

from cooktop to the left side wall.

f 1" = Minimum clearance from cooktop to the right side wall.

g 1

1

/

2

" (GC36) or 1

1

/

4

" (GC901 & GC901M) = Minimum clearance

from cooktop to the rear wall.

h 2

1

/

2

" (GC36) or 1

1

/

4

" (GC901 & GC901M) = Minimum distance

from front edge of counter to front edge of appliance.

Where this reduces the distance between the back edge of the

appliance and the adjacent wall to less than the minimum of

1

1

/

2

" (GC36) or 1

1

/

4

" (GC901 & GC901M), this wall must be of

non combustible material (see note below).

i 2

3

/

8

" (GC36) or 3

5

/

16

" (GC901 & GC901M) = Minimum clearance

below countertop to any combustible surface.

j 30" = Maximum distance to nearest grounded power outlet

from the center of the cooktop.

The power cord must not touch any hot metal sufaces.

f

CLEARANCES

NON COMBUSTIBLE MATERIAL

Recommended non combustible materials are:

1

/

4

" (6mm) flame

retardant millboard covered with not less than No. 28 MSG sheet

steel, 0.015” (0.4mm) stainless steel, 0.024” (0.6mm) aluminium

or 0.020” (0.5mm) copper.

3

/

4

" - 2"

Page 4

INSTALLATION INSTRUCTIONS

4

US

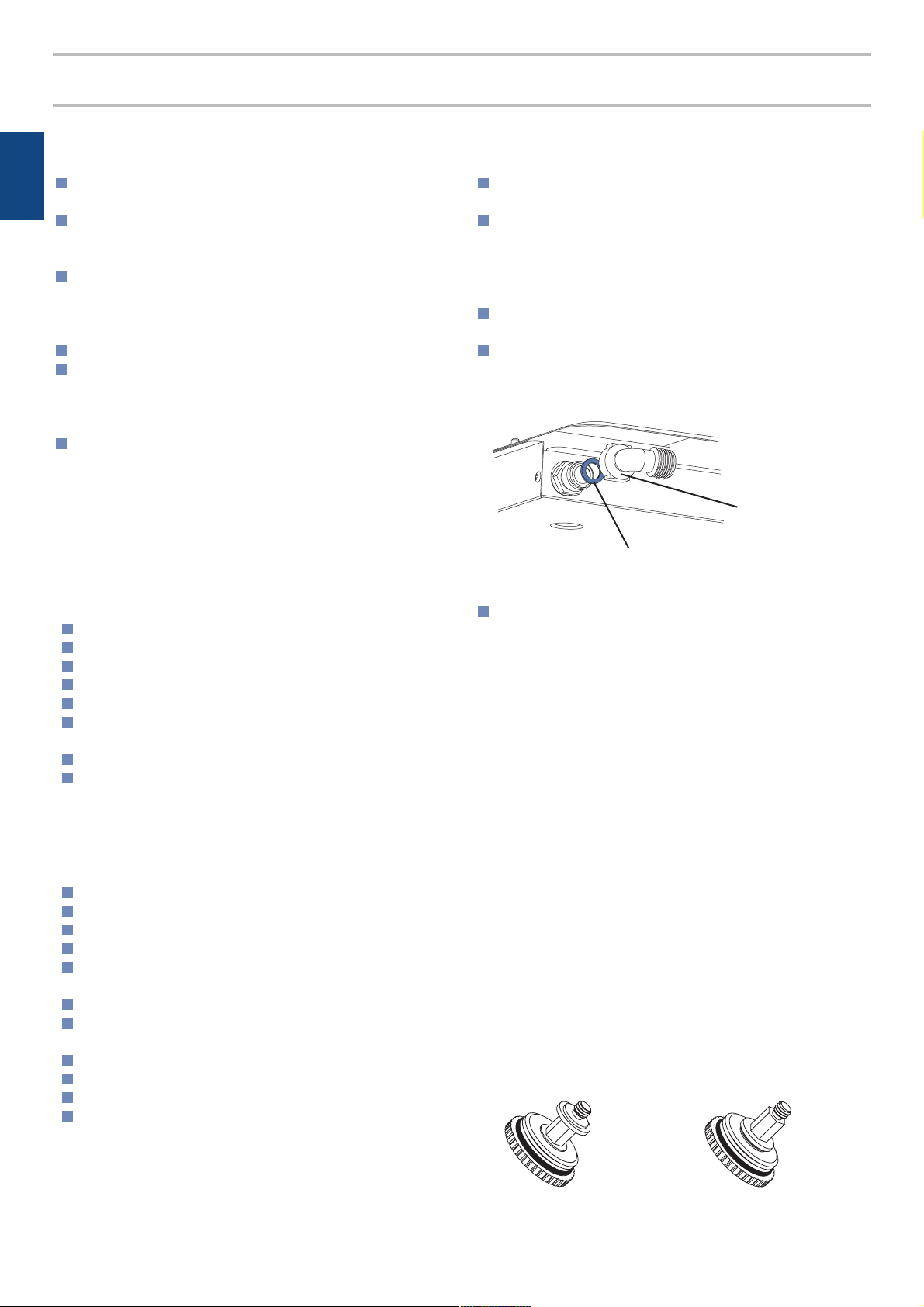

GAS SUPPLY CONNECTION

This appliance can be used with either LP gas or Natural gas and

is factory set for use with Natural gas.

A manual shut-off valve must be installed in an accessible

location in the gas line external to the appliance for the purpose

of turning on or shutting off gas to the appliance. (In

Massachusetts such shutoff devices should be approved by the

Board of State Examiners of Plumbers & Gas Fitters).

Gas connection to the product must use the elbow supplied with

a

1

/

2

" NPT external thread.

Ensure the blue washer (supplied) is located between the

elbow and the product inlet. Failure to use this will cause

a gas leak.

For use with a gas pressure regulator. The regulator supplied

can be set for either LP gas or Natural gas and must be

used with this appliance. It has a

1

/

2

" NPT thread.

CONVERTING THE REGULATOR BETWEEN NG & LP

1 Unscrew the cap from the regulator.

2 Check the orientation of the plastic conversion plug, and if

necessary, unscrew, turn over and screw back in (wide section away

from cap for LP and against cap for NG - see diagram below for

appropriate orientation.

3 Replace regulator cap.

4 Test gas pressure (test point provision on side of regulator).

When converting the regulator for different settings, the function of

the regulator must be checked at a pressure at least 1" WC (0.036

p.s.i.) above the specified manifold pressure.

LP NG

(Note: this diagram is of

GC36 but is similar for

GC901 and GC901M).

Blue Washer

Elbow

TOOLS NEEDED

Phillips No. 2 screwdriver

Plumbing fittings as required

Woodworking tools as required

Shut-off valve

Oil based paint (for sealing cutout)

For LP Conversion

Ø

7

/

64

" x 1

3

/

4

" (Ø2.5 x 45mm) flat screwdriver

9

/

32

" (7mm) box spanner

For GC901M LP Conversion

Ø

7

/

64

" x 1

3

/

4

" (Ø2.5 x 45mm) flat screwdriver

Phillips No. 1 screwdriver

9

/

32

" (7mm) box spanner

13

/

32

" (10mm) ring spanner

PARTS CHECKLIST

Gas Cooktop base unit

Literature pack (includes LPG kit)

Elbow & blue washer (taped to power cord)

Clamping brackets & screws (GC36-on base unit)

Regulator (in Polystyrene)

Burner heads and caps (check polystyrene carefully

before discarding)

3 x Burner grates/trivets (1 x center, 2 x outer)

Accessories pack

BEFORE YOU START

Ensure the countertop is square and level and ensure no

structural members interfere with space requirements.

Ensure that there is a power supply receptacle (110-120V 60Hz)

within reach of the cooktop power cord (30" from the middle of

the product). The main cable should not touch any hot metal parts.

Make sure the cooktop is connected to a power supply socket

that is electrically grounded in accordance with local codes or

in the absence of local codes, with the National Electric Code

ANSI/FPA 70 or CSA 22.2 (Canada).

Make sure the countertop is made of a heat resistant material.

We recommend that the exposed bare wood edges of the

cutout be sealed with an oil based paint or moisture proof

polyurethane to prevent possible damage from moisture

creeping between the cooktop trim and the benchtop.

We recommend using easy-to-clean finishes for the wall

surfaces surrounding the cooktop to aid removal of any cooking

stains resulting from use of the cooktop.

Page 5

INSTALLATION INSTRUCTIONS

5

US

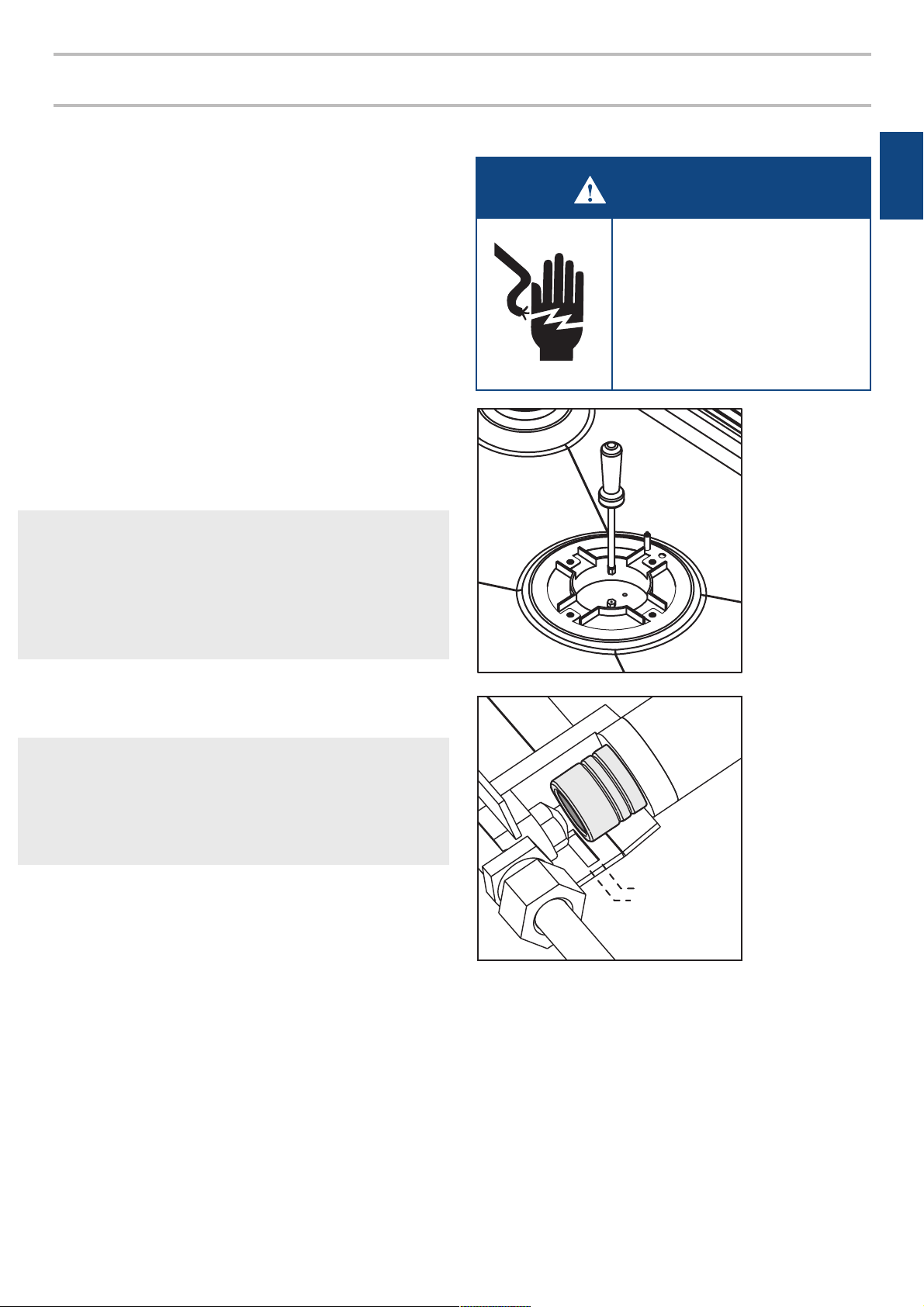

1 Turn off the main electrical supply.

2 Ensure all gas valves are turned off.

3 Remove all trivets and burner heads.

4 Pull off knobs.

5 Remove the 2 screws holding each burner

(3 on the wok burner).

6 Partially lift the hob and unplug the electrode on the mini-

auxiliary burner to allow hob removal. Beware of sharp edges.

7 Unscrew the orifices and replace them with the correct ones.

(size numbers are stamped on the side, eg. 70= 0.70mm)

(see figure 1).

8 Reset the venturi position aligning the end of the venturi tube

with the edge of the slot in the bracket below it. Outermost

position for LPG, innermost for NG (see figure 2). Some fine

adjustment may be required for local conditions.

9 To replace the CG901M hob, repeat steps 3-6 in reverse.

10 Reset the minimum setting. See ‘Minimum Setting’ overleaf.

WARNING

Electrical Shock Hazard

Disconnect power before

servicing the product.

Failure to do so could result in

death or electrical shock.

Changing the

Orifice figure 1

The label supplied with the orifices should be placed over the existing

gas type label to indicate the change.

Venturi Position

figure 2

CG901M onlyCG901M only

CONVERSION TO A DIFFERENT GAS TYPE

Burners can be used with NG or LPG, provided that the injector

orifices appropriate for the gas delivered are installed.

High altitude orifices are available from Fisher & Paykel USA.

GC36 NG Kit Part No. 530463

LP Kit Part No. 530464

GC901/M NG Kit Part No. 531566

LP Kit Part No. 531567

To change the injector orifices, you will need a

9

/

32

" (7mm) box

spanner and a

13

/

32

" (10mm) ring spanner (CG901M only).

NG Venturi Position

LPG Venturi Position

Page 6

INSTALLATION INSTRUCTIONS

6

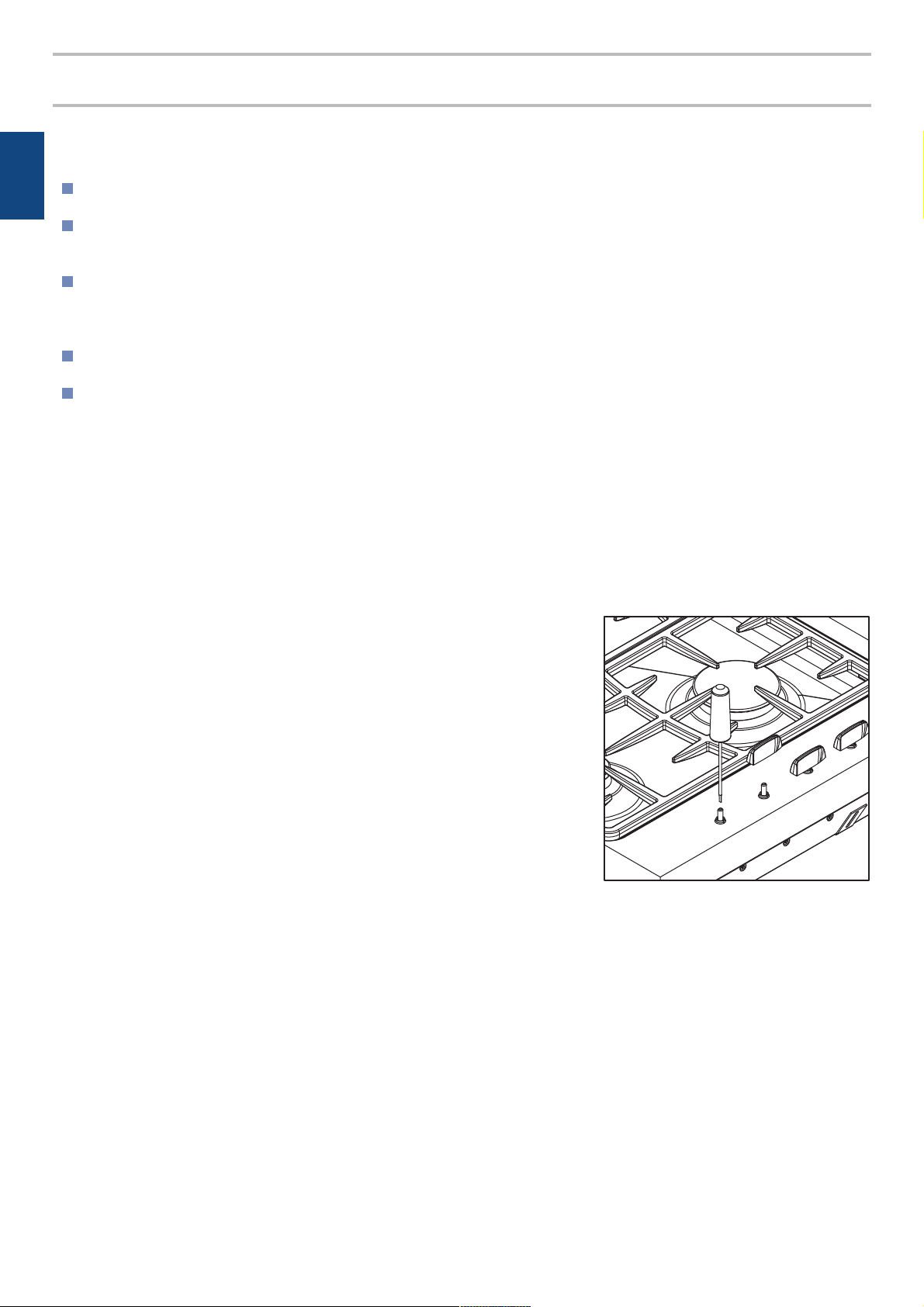

MINIMUM SETTING OR TURNDOWN

This has been set at the factory for NG but can be checked after

the correct pressure has been reached. To adjust for minimum

setting (if applicable), you will need a Ø

7

/

64

" x 1

3

/

4

" (Ø2.5 x

45mm) screwdriver. (A suitable screwdriver is available as

Fisher & Paykel spare part. FB200467).

1 Ignite the burner and set the knob to its minimum position.

2 Remove the knobs.

3 Rotate the turn down screw (down the hole in the spindle)

while holding the shaft. Rotate slowly until a minimum regular

flame is achieved. (The flame will diminish when the screw is

turned clockwise and increase when turned counter clockwise).

4 When the setting is right check regulation by quickly rotating

the knob from the maximum to the minimum delivery position. The

flame must not go out and the autoreignition should not click.

Replace the knob.

US

Minimum setting

adjustment

(Note: this diagram is

of GC901 but is similar

for GC36).

After installing the gas supply and making all connections check

thoroughly for possible leaks.

1 Turn all control knobs on unit to "off" position.

2 Open the valve on the gas supply.

3 Using a leak detection fluid (e.g. Rocol leak detection spray)

check each gas connection one at a time by brushing the solution

over the connection. The presence of bubbles will indicate a leak.

4 If necessary, tighten the fitting and recheck for leaks.

5 Turn on burner valve and light each burner.

6 Check for a clear blue flame without yellow tipping. If burners

show any abnormalities, check that they are located properly and in

line with the injector orifice.

LEAK TESTING

Leak testing of the appliance shall be conducted according to

the manufacturer's instructions.

The appliance and it's individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system in excess of

1

/

2

p.s.i. (3.5kPa).

The appliance must be isolated from the gas supply piping

system by closing it's individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures at or less than

1

/

2

p.s.i.(3.5kPa).

Maximum inlet gas supply pressure 4" W.C. Natural Gas,

11" W.C. LP gas.

Minimum gas supply pressure for regulator testing 5" W.C.

Natural Gas, 12" W.C. LP gas.

See the Product Installation Checklist attached to the product.

Page 7

INSTALLATION INSTRUCTIONS

7

CONTACT DETAILS

A Service Summary is attached to the underside of the product.

For replacement parts or if further help is needed concerning this appliance call:

Toll Free 1 888 9 FNP USA (1 888 936 7872)

or write to:

Fisher & Paykel Appliances Inc.

27 Hubble, Irvine

CA 92618

or contact us through our web site,

www.usa.fisherpaykel.com

US

CHECKING THE GAS TYPE

GC36

Burners NG Orifice NG LP Orifice LP

(mm) BTU (MJ/h)@ (mm) BTU (MJ/h)@

0.15psi (4”H20) 0.41psi (11”H20)

RH Rear 1.3mm 8,000 (8.4 MJ/h) 0.8mm 8,000 (8.4 MJ/h)

LH Rear 1.3mm 8,000 (8.4 MJ/h) 0.8mm 8,000 (8.4 MJ/h)

RH Front Simmer 0.85mm 3,500 (3.47 MJ/h) 0.55mm 4,000 (4.2 MJ/h)

LH Front Wok 1.75mm 12,600 (13.3 MJ/h) 1.05mm 13,000 (13.7 MJ/h)

Center 1.45mm 9,500 (10 MJ/h) 0.85mm 9,500 (10.0 MJ/h)

GC901 / GC901M

Burners NG Orifice NG LP Orifice LP

(mm) BTU (MJ/h)@ (mm) BTU (MJ/h)@

0.15psi (4”H20) 0.41psi (11”H20)

RH Rear 1.3mm 8,000 (8.4 MJ/h) 0.8mm 8,200 (8.7 MJ/h)

LH Rear 1.1mm 5,800 (6.1 MJ/h) 0.7mm 5,700 (6.0 MJ/h)

RH Front Simmer 0.85mm 3,000 (3.2 MJ/h) 0.55mm 3,500 (3.7 MJ/h)

LH Front 1.3mm 8,000 (8.4 MJ/h) 0.8mm 8,200 (8.7 MJ/h)

Center (GC901) 1.75mm 14,000 (14.8 MJ/h) 1.05mm 13,000 (13.7 MJ/h)

Center (GC901M) 2.15mm 20,000 (21.1 MJ/h) 1.22mm 19,000 (20 MJ/h)

Page 8

AVERTISSEMENTS ET INFORMATIONS SUR LA SECURITE

8

ATTENTION !

Pour éviter tout danger, ces produits doivent

impérativement être installés en conformité avec ces

instructions.

Ce produit ne devra pas être collé au plan de travail

avec de la colle ou du silicone au risque de rendre

toute maintenance ultérieure difficile à entreprendre.

Fisher & Paykel ne pourra en aucun cas être tenu

responsable des frais associés avec le retrait de tels

produits et des dommages causés en conséquence.

AVERTISSEMENT

Risque de coupure

Faites attention aux bords

tranchants.

Utilisez les extrémités en

polystyrène lorsque vous

transportez le produit.

Le non respect de cet

avertissement pourrait

entraîner des coupures ou

blessures mineures.

IMPORTANT !

Ce produit doit être installé par une personne

autorisée (A

VERTISSEMENT :

Ce produit doit

impérativement être installé par un plombier ou

installateur de gaz agréé sous licence dans le

Commonwealth du Massachusetts).

Veuillez laisser ces instructions avec l’appareil et

conseiller au client de les garder pour pouvoir s’y

référer ultérieurement.

Ce produit est livré avec une étiquette

supplémentaire sur laquelle le modèle et les

numéros de série sont imprimés. Elle pourra être

collée sous le produit, à l’intérieur d’un placard ou

sur le manuel d’utilisation.

FR

AVERTISSEMENT

Risque d’électrocution

Débranchez la prise avant de

procéder à la maintenance du

produit.

Le non respect de cette

précaution pourrait entraîner

la mort ou une électrocution.

AVERTISSEMENT !

Cet appareil devra être installé en conformité avec

les exigences d’installation de la compagnie du gaz

locale ou avec le code d’installation applicable ou en

l’absence de codes locaux avec le code national

réglementant le gaz et le fioul ANSI Z223.1 ou CAN

B149.1.2 (Canada) le plus récent. Les codes locaux

réglementant l’électricité et la construction devront

être respectés.

Une fois cet appareil installé, il ne devra pas être

utilisé comme appareil de chauffage.

Aucun matériau ou produit combustible ne devra

être placé sur cet appareil à tout moment.

Ne pas vaporiser de bombes aérosols à proximité de

cet appareil pendant qu’il est en marche.

Ne pas l’installer dans une salle de bain ni dans une

chambre à coucher ou quartiers pour dormir.

Les connecteurs flexibles de l’appareil devront

satisfaire aux exigences de ANSI Z21.24 et des

State Boards. Ils ne devront pas dépasser 91 cm de

longueur.

Page 9

DIMENSIONS ET DEGAGEMENTS

9

DIMENSIONS DU PRODUIT ET DE LA DECOUPE

GC36 GC901/GC901M

A

36” (914mm) 36” (914mm)

B 21” (533mm) 21

1

/

2

" (546mm)

C 1

5

/

8

" (41,5mm) 2

9

/

16

" (65mm) GC901,

3" (76mm) GC901M

D 19

1

/

2

" (494mm) [18

3

/

8

" - 19

3

/

4

"] 19

1

/

2

" (494mm) [19

1

/

8

" - 20

5

/

8

"]

E 34

1

/

4

" (870mm)

[33

3

/

8

" - 34

3

/

4

"]

34

1

/

4

" (870mm)

[33

7

/

8

" - 35

1

/

4

"]

F R

3

/

8

" (10mm) R

3

/

8

" (10mm)

G 1

3

/

16

" (30mm)

3

/

4

" (20mm)

H 1" (25mm) 1" (25mm)

FR

FIXATION DE LA PLAQUE DE CUISSON

Placer la plaque de cuisson dans la

découpe et la fixer en position en

utilisant les fixations fournies avec

l’appareil. Elles sont compatibles

avec une épaisseur de contre-plan

de travail de

3

/

4

"- 2" (19mm 50mm) lorsque utilisées dans les

deux orientations indiquées.

Ne pas les serrer excessivement.

C

B

A

D

E

H

G

F

Ligne centrale

d’admission

Orifice d’entrée

du gaz

a

b

d

c

e

i

h

g

j

a 36" (914mm) = distance horizontale minimum entre les meubles

en dessus installés de chaque côté de cet appareil.

b 30" (762mm) = dégagement minimum de la surface

combustible centrée au-dessus de la plaque de cuisson.

c 13" (330mm) = profondeur générale maximum du meuble en

dessus.

d 18" (457mm) = dégagement minimum du contre-plan de travail

au meuble en dessus.

e 4" (101mm) (GC36) ou 1

1

/

2

" (38mm) (GC901 & GC901M) =

dégagement minimum de la plaque de cuisson à la paroi latérale

gauche.

f 1" (25mm) = dégagement minimum de la plaque de cuisson à la

paroi latérale droite.

g 1

1

/

2

" (38mm) (GC36) ou 1

1

/

4

" (31mm) (GC901 & GC901M) =

dégagement minimum de la plaque de cuisson au mur du fond.

h 2

1

/

2

" (63mm ) (GC36) ou 1

1

/

4

" (31mm ) (GC901 & GC901M) =

distance minimum du bord avant du contre-plan au bord avant de

l’appareil. Dans le cas où cela réduit la distance entre le bord

arrière de l’appareil et la paroi adjacente à une valeur inférieure

au minimum de 38mm (GC36) et 31mm (GC901 & GC901M),

cette paroi devra être dans un matériau non combustible (vous

référer à la remarque ci-dessous).

i 2

3

/

8

" (60mm) (GC36) ou 3

5

/

16

" (84mm) (GC901 & GC901M) =

distance minimum sous le contre-plan de travail jusqu’à toute

surface combustible.

j 30" (762mm) = distance maximum jusqu’à la prise de courant

reliée à la terre la plus proche depuis le centre de la plaque de

cuisson. Le cordon d’alimentation ne doit pas toucher une

quelconque surface métallique chaude.

f

DEGAGEMENTS

MATERIAU NON COMBUSTIBLE

Les matériaux non combustibles recommandés sont les suivants :

Carton gris ignifuge

1

/

4

" (6mm) recouvert au minimum d’une tôle

d’acier MSG n° 28, acier inoxydable 0,015” (0,4mm), aluminium

0,024” (0,6mm) ou cuivre 0,020” (0,5mm).

3

/

4

" - 2"

Page 10

INSTRUCTIONS D’INSTALLATION

10

FR

BRANCHEMENT A L’ARRIVEE DU GAZ

Cet appareil peut être utilisé soit avec du gaz combustible liquéfié

(GPL) soit avec du gaz naturel et est réglé à l’usine par défaut

pour être utilisé avec du gaz naturel.

Une soupape de coupure manuelle doit être installée dans un

endroit accessible sur la canalisation de gaz en externe par

rapport à l’appareil pour ouvrir ou fermer l’arrivée du gaz à

l’appareil. (Dans le Massachusetts, les dispositifs de coupure de

ce type devront être approuvés par le Board of State Examiners of

Plumbers & Gas Fitters).

Le raccordement du gaz au produit doit utiliser le coude fourni

avec un pas externe NPT de 12mm (

1

/

2

").

Vérifier que la rondelle bleue (fournie) se situe entre le

coude et l’orifice d’entrée du produit. Si ce n’est pas le

cas, vous risquez de provoquer une fuite de gaz.

Pour les utilisations avec un régulateur de pression du gaz. Le

régulateur fourni peut être réglé soit pour le GPL soit pour le

gaz naturel et doit être utilisé avec cet appareil. Il a un pas

NPT de 12mm (

1

/

2

").

CONVERSION DU REGULATEUR ENTRE LE GAZ

NATUREL ET LE GPL

1 Dévisser le capuchon du régulateur.

2 Vérifier l’orientation de la fiche de conversion en plastique et si

nécessaire, la dévisser, la retourner et la revisser en place

(section large à l’écart du capuchon pour le GPL et contre le

capuchon pour le gaz naturel – vous référer au schéma

ci-dessous pour l’orientation appropriée).

3 Remettre en place la capuchon du régulateur.

4 Tester la pression du gaz (point de test prévu sur le côté du

régulateur). Lors de la conversion du régulateur sur différents

réglages, la fonction du régulateur doit impérativement être

contrôlée à une pression d’au moins 1" WC (0,036 p.s.i.)

au-dessus de la pression d’admission spécifiée.

GPL Gaz naturel

(Remarque : ce schéma

est pour le modèle GC36

mais est similaire aux

modèles GC901 et

GC901M).

Rondelle bleue

Coude

OUTILS NECESSAIRES

Tournevis cruciforme n°2

Raccords de plomberie comme requis

Outils pour travailler le bois comme requis

Soupape de coupure/d’arrêt

Peinture à l’huile (pour vitrifier la découpe)

Pour la conversion au GPL

Tournevis à tête plate Ø

7

/

64

" x 1

3

/

4

" (Ø2,5 x 45mm)

Clé à pipe

9

/

32

" (7mm)

Pour la conversion au GPL du modèle GC901M

Tournevis à tête plate Ø

7

/

64

" x 1

3

/

4

" (Ø2,5 x 45mm)

Tournevis cruciforme n°1

Clé à pipe

9

/

32

" (7mm)

Clé à anneau

3

/

32

" (10mm)

LISTE DE VERIFICATION DES PIECES

Unité de base de la plaque de cuisson au gaz

Documentation (Kit GPL inclus)

Rondelle bleue et coude (rubanés au cordon d’alimentation)

Colliers de fixation et vis (GC36 sur unité de base)

Régulateur (en polystyrène)

Têtes de brûleur et capuchons (vérifier soigneusement le

polystyrène avant de le jeter)

3 x grilles/supports pour brûleur (1 x centre ; 2 à l’extérieur)

Coffret d’accessoires

AVANT DE COMMENCER

Vérifier que le contre-plan de travail est au carré et à niveau et

vérifier qu’aucun élément structurel n’interfère avec les exigences

de place.

Vérifier qu’il y a une prise de courant (110-120V 60Hz) à proximité

du cordon d’alimentation de la plaque de cuisson (762mm du

centre du produit). Le câble principal ne devra pas être en contact

avec une quelconque pièce métallique chaude.

Vérifier que la plaque de cuisson est branchée à une prise de

courant reliée à la masse en conformité avec les codes locaux ou

en l’absence de codes locaux, avec le code national réglementant

l’électricité ANSI/FPA 70 ou CSA 22.2 (Canada).

Vérifier que le contre-plan de travail est fabriqué dans un matériau

résistant à la chaleur.

Nous vous recommandons de vitrifier les bords en bois nu

exposés de la découpe avec une peinture à l’huile ou du

polyuréthane étanche à l’humidité pour empêcher tout

endommagement possible par l’humidité entre le bord de la

plaque de cuisson et le plan de travail.

Nous vous recommandons d’utiliser des finitions faciles à

nettoyer pour les surfaces entourant la plaque de cuisson pour

faciliter le retrait des taches de cuisson résultant de l’utilisation

de la plaque de cuisson.

Page 11

INSTRUCTIONS D’INSTALLATION

11

FR

1 Couper l’arrivée électrique secteur.

2 Vérifier que les soupapes de gaz sont fermées.

3 Retirer toutes les supports et les têtes de brûleur.

4 Retirer les boutons de commande.

5 Retirer les 2 vis maintenant en place chaque brûleur (3 sur le

brûleur à wok).

6 Soulever partiellement la table de cuisson et débrancher

l’électrode sur le mini brûleur auxiliaire pour permettre le retrait

de la table de cuisson. Faire attention aux rebords tranchant.

7 Dévisser les orifices et les remettre en place avec les orifices

appropriés (les numéros des tailles sont estampillés sur le côté,

par ex 70 = 0,70mm) (voir schéma 1).

8 Régler à nouveau la position venturi en alignant l’extrémité du

tuyau venturi avec le rebord de la fente sur l’attache de fixation

dessous. La position la plus à l’extérieur pour le GPL et la

position la plus à l’intérieur pour le gaz naturel (voir schéma 2).

Il est possible que vous ayez besoin de réviser le réglage sur les

conditions locales.

9 Pour remettre en place la table de cuisson GC901M, répéter les

étapes 3 – 6 en sens inverse.

10 Procéder au réglage minimum. Vous référer à la section

Réglage minimum au verso.

Changement de

l’orifice,

schéma 1

L’étiquette livrée avec les orifices devra être placée sur l’étiquette du

type de gaz existant pour indiquer le changement.

Position venturi,

schéma 2

CG901M uniquementCG901M uniquement

CONVERSION SUR UN TYPE DE GAZ DIFFERENT

Les brûleurs peuvent être utilisés avec du gaz naturel ou GPL à

condition que les orifices de l’injecteur appropriés la fourniture du

gaz soient installés.

Des orifices d’altitude élevée sont disponibles auprès de Fisher &

Paykel USA.

GC36 Kit gaz naturel n° de pièce 530463

Kit GPL n° de pièce 530464

GC901/M Kit gaz naturel n° de pièce 531566

Kit GPL n° de pièce 531567

Pour changer les orifices de l’injecteur, vous aurez besoin d’une clé à

pipe

9

/

32

" (7mm) et d’une clé à anneau

13

/

32

" (10mm) (CG901M

uniquement).

Position venturi

gaz naturel

Position venturi GPL

AVERTISSEMENT

Risque d’électrocution

Débranchez la prise avant de

procéder à la maintenance du

produit.

Le non respect de cette

précaution pourrait entraîner

la mort ou une électrocution.

Page 12

INSTRUCTIONS D’INSTALLATION

12

REGLAGE MINIMUM OU RALENTI

Ce réglage a été effectué à l’usine pour le gaz naturel mais peut

être vérifié une fois que la pression correcte est atteinte. Pour tout

ajustement sur le réglage minimum (si applicable), vous aurez

besoin d’un tournevis Ø

7

/

64

" x 1

3

/

4

" (Ø2,5 x 45mm). (Un tournevis

approprié est disponible auprès de Fisher & Paykel, n° de pièce

FB200467).

1 Allumer le brûleur et tourner le bouton de commande sur la

position minimum.

2 Retirer les boutons de commande.

3 Tourner la vis de ralenti (dans le trou dans la broche tout en

tenant la tige. Tourner doucement jusqu’à ce que vous obteniez

une flamme minimale et régulière. (La flamme diminuera

lorsque la vis est tournée dans le sens des aiguilles d’une

montre et augmentera lorsque vous la tournez dans le sens

inverse).

4 Lorsque le réglage est correct, vérifier la régulation en tournant

rapidement le bouton de commande de la position d’arrivée

maximum vers la position d’arrivée minimum. La flamme ne

doit pas s’éteindre et le réallumage automatique ne devra pas

se mettre en marche. Remettre en place le bouton de

commande.

FR

Ajustement du

réglage minimum

(remarque : ce schéma

correspond au GC901

mais est similaire au

GC36)

Après l’installation de la conduite d’arrivée du gaz et après avoir

terminé tous les branchements, vérifier soigneusement l’installation

pour détecter toute éventuelle fuite de gaz.

1 Tourner tous les boutons de commande de l’unité sur la position

off/arrêt.

2 Ouvrir la soupape sur la conduite l’arrivée du gaz.

3 En utilisant un fluide de détection de fuite (par ex bombe de

détection de fuite Rocol), vérifier chaque branchement de gaz,

un à la fois, en vaporisant la solution sur le branchement. La

présence de bulles indiquera une fuite.

4 Si nécessaire, serrer le raccord et vérifier à nouveau qu’il n’y a

pas de fuite.

5 Ouvrir la soupape du brûleur et allumer chaque brûleur.

6 Vérifier que vous avez une flamme bleue transparente sans

bout jaune. Si les brûleurs montrent une quelconque anomalie,

vérifier qu’ils sont bien en place et alignés avec l’orifice de

l’injecteur.

TEST DE DETECTION DE FUITE

Le test de détection de fuite de l’appareil devra être effectué en

conformité avec les instructions du fabriquant.

L’appareil et sa soupape de coupure devront être débranchés

du système de canalisation d’arrivée du gaz pendant tout test

de pression dudit système supérieur à

1

/

2

p.s.i. (3,5kPa).

L’appareil doit être isolé du système de canalisation d’arrivée du

gaz en fermant la soupape de coupure manuelle individuelle

pendant tout test de pression du système de canalisation

d’arrivée du gaz aux pressions de test égales ou inférieures à

1

/

2

p.s.i.(3,5kPa).

Pression maximum d’arrivée du gaz à l’entrée de 4" W.C. pour

le gaz naturel, de 11" W.C. pour le GPL.

Pression minimum d’arrivée du gaz pour le test sur le régulateur

de 5" W.C. pour le gaz naturel, de 12" W.C. pour le GPL.

Vous référer à la liste de vérification de l’installation du produit jointe au produit.

Page 13

INSTRUCTIONS D’INSTALLATION

13

COORDONNEES DU SERVICE CLIENTELE

Un résumé de maintenance est collé sous le produit.

Pour les pièces de rechange ou si vous avez besoin d’assistance pour ce produit,

vous pouvez appeler le numéro suivant :

Numéro gratuit 1 888 9 FNP USA (1 888 936 7872)

ou écrire à l’adresse suivante :

Fisher & Paykel Appliances Inc.

27 Hubble, Irvine

CA 92618

ou nous contacter via notre site Internet,

www.usa.fisherpaykel.com

FR

VERIFICATION DU TYPE DE GAZ

GC36

Brûleurs Orifice gaz Gaz naturel Orifice GPL GPL

naturel (mm) BTU (MJ/h)@ (mm) BTU (MJ/h)@

0,15p.s.i. (4”H20) 0,41p.s.i. (11”H20)

Droit/arrière 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.000 (8,4 MJ/h)

Gauche/arrière 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.000 (8,4 MJ/h)

Droit/avant ; 0,85mm 3.500 (3,47 MJ/h) 0,55mm 4.000 (4,2 MJ/h)

feux doux

Gauche/avant ; 1,75mm 12.600 (13,3 MJ/h) 1,05mm 13.000 (13,7 MJ/h)

wok

Centre 1,45mm 9.500 (10 MJ/h) 0,85mm 9.500 (10,0 MJ/h)

GC901 / GC901M

Brûleurs Orifice gaz Gaz naturel Orifice GPL GPL

naturel (mm) BTU (MJ/h)@ (mm) BTU (MJ/h)@

0,15p.s.i. (4”H20) 0,41p.s.i. (11”H20)

Droit/arrière 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.200 (8,7 MJ/h)

Gauche/arrière 1,1mm 5.800 (6,1 MJ/h) 0,7mm 5.700 (6,0 MJ/h)

Droit/avant ; 0,85mm 3.000 (3,2 MJ/h) 0,55mm 3.500 (3,7 MJ/h)

feux doux

Gauche/avant 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.200 (8,7 MJ/h)

Centre

(GC901) 1,75mm 14.000 (14,8 MJ/h) 1,05mm 13.000 (13,7 MJ/h)

Centre

(GC901M) 2,15mm 20.000 (21,1 MJ/h) 1,22mm 19.000 (20 MJ/h)

Page 14

ADVERTENCIAS E INFORMACION SOBRE SEGURIDAD

14

¡CUIDADO!

Para evitar peligros estos productos deben instalarse

de acuerdo con estas instrucciones.

Este producto no debe sellarse dentro de la mesada

con silicona o goma de pegar. Esto dificultará

cualquier manutención o reparación futura. Fisher &

Paykel no se responsabilizará por costos asociados

con la liberación de tales productos, ni por el daño

incurrido como resultado.

¡ATENCION!

Peligro de cortes

Tenga cuidado con los bordes

filosos.

Utilice los extremos de

poliestireno para acarrear el

producto.

Si no actúa con precaución

puede sufrir heridas o cortes

menores.

¡IMPORTANTE!

Este producto debe ser instalado por una persona

autorizada para ello (A

TENCION

dentro del Estado

de Massachusetts este producto debe ser instalado

por un plomero o gásfiter calificado).

Por favor conserve estas instrucciones junto con el

artefacto. Dígale al cliente que las conserve para

referencia en el futuro.

Este producto se suministra con una etiqueta

adicional que contiene los números del modelo y de

serie. Se la puede adherir al extremo inferior del

producto, al interior de una alacena o a la Guía del

Usuario.

ES

¡ATENCION!

Peligro de electrocución

Desconecte la corriente

eléctrica antes de reparar el

producto.

Si no lo hace puede morir o

electrocutarse.

¡ATENCION!

Este artefacto eléctrico debe ser instalado de

acuerdo con los requisitos de instalación de la

autoridad local de gas, o la norma de instalación

apropiada, o a falta de normas locales siguiendo el

Código Nacional de Gas Combustible ANSI Z223.1 o

CAN B149.1,2 (Canadá) más reciente.

Cuando este artefacto sea instalado no debe ser

utilizado como calefactor de ambientes.

Nunca se deben ubicar sobre este artefacto

materiales o productos combustibles.

No emplee aerosoles cerca de este artefacto

mientras lo esté utilizando.

No se debe instalar en una sala de baño o en

dormitorios.

Los conectores flexibles del artefacto deben cumplir

con los requisitos del ANSI Z21.24 y de las Juntas

Estatales. No pueden exceder las 36 pulgadas de

largo.

Page 15

DIMENSIONES Y DISTANCIAS DE SEPARACION

15

DIMENSIONES DEL PRODUCTO Y DEL CORTE

GC36 GC901/GC901M

A

36” (914mm) 36” (914mm)

B 21” (533mm) 21

1

/

2

" (546mm)

C 1

5

/

8

" (41,5mm) 2

9

/

16

" (65mm) GC901,

3" (76mm) GC901M

D 19

1

/

2

" (494mm) [18

3

/

8

" - 19

3

/

4

"] 19

1

/

2

" (494mm) [19

1

/

8

" - 20

5

/

8

"]

E 34

1

/

4

" (870mm)

[33

3

/

8

" - 34

3

/

4

"]

34

1

/

4

" (870mm)

[33

7

/

8

" - 35

1

/

4

"]

F R

3

/

8

" (10mm) R

3

/

8

" (10mm)

G 1

3

/

16

" (30mm)

3

/

4

" (20mm)

H 1" (25mm) 1" (25mm)

ES

COMO FIJAR EL ANAFE

Ubique el anafe dentro del corte y

ajústelo con los soportes de

fijación suministrados. Estas sirven

para grosores de mesada de

3

/

4

"2" cuando se las utiliza en las dos

orientaciones que se ilustran.

No ajuste demasiado.

C

B

A

D

E

H

G

F

línea central

del múltiple

entrada de gas

a

b

d

c

e

i

h

g

j

a

36" = Distancia horizontal mínima entre alacenas elevadas

instaladas a cada lado de este producto.

b 30" = Separación mínima de superficie combustible centrada

encima del anafe.

c 13" = Profundidad máxima total de alacena elevada.

d 18" = Separación mínima de mesada a alacena elevada.

e 4" (GC36) o 1

1

/

2

" (GC901 y GC901M) = Separación mínima de

anafe a pared izquierda.

f 1" = Separación mínima de anafe a pared derecha.

g 1

1

/

2

" (GC36) o 1

1

/

4

" (GC901 y GC901M) = Separación mínima de

anafe a pared posterior.

h 2

1

/

2

" (GC36) o 1

1

/

4

" (GC901 y GC901M) = Distancia mínima

desde el borde delantero de la mesada al borde delantero del

artefacto. Cuando esto reduce la distancia entre el borde

posterior del artefacto y la pared adyacente a menos del mínimo

de 1

1

/

2

" (GC36) o 1

1

/

4

" (GC901 y GC901M), esta pared debe ser

de material no combustible (vea la nota al pie).

i 2

3

/

8

" (GC36) o 3

5

/

16

" (GC901 y GC901M) = Separación mínima

desde la parte inferior de la mesada a cualquier superficie

combustible.

j 30" = Distancia máxima al tomacorriente a tierra más cercano

desde el centro del anafe.

El cable de alimentación no debe tocar ninguna superficie de

metal caliente.

f

DISTANCIAS DE SEPARACION

MATERIAL NO COMBUSTIBLE

Los materiales no combustibles recomendables son: lámina

aislante de combustión lenta de

1

/

4

" (6mm) recubierta por lo menos

con una lámina de acero MSG No. 28, acero inoxidable de 0,015”

(0,4mm), aluminio de 0,024” (0,6mm), o cobre de 0,020” (0,5mm).

3

/

4

" - 2"

Page 16

INSTRUCCIONES DE INSTALACION

16

ES

CONEXIÓN A ALIMENTACION DE GAS

Este artefacto se puede utilizar tanto con Gas Natural como con

gas LP, y viene configurado de fábrica para ser utilizado con

gas natural.

Para poder abrir o cerrar el paso del gas hacia el artefacto debe

instalarse una válvula de cierre manual en una posición accesible

en la tubería de gas externa al artefacto. (En Massachusetts tales

aparatos de cierre deben ser aprobados por el Board of State

Examiners of Plumbers & Gas Fitters).

La conexión de gas al producto debe utilizar el codo suministrado

con una rosca NPT externa de

1

/

2

".

Asegúrese de que la arandela azul (suministrada) esté

ubicada entre el codo y la boca de entrada del producto.

Si no la utiliza ocasionará una pérdida de gas.

Para ser utilizado con un regulador de presión de gas. El

regulador suministrado puede configurarse para gas LP o

gas natural, y debe utilizarse con este artefacto. Posee una

rosca NPT de

1

/

2

".

COMO CONVERTIR EL REGULADOR A GN Y GAS LP

1 Desenrosque la tapa del regulador.

2 Verifique la orientación del tapón plástico de conversión, y de ser

necesario desenrósquelo, délo vuelta y vuelva a enroscarlo (con la

parte ancha lejos de la tapa para gas LP y contra la tapa para GN:

vea el diagrama de más abajo para la orientación apropiada).

3 Vuelva a colocar la tapa del regulador.

4 Pruebe la presión de gas (se provee un punto de prueba al

costado del regulador). Cuando altere el regulador para diferentes

configuraciones, debe controlarse la función del regulador a una

presión de por lo menos 1" WC (0,036 p.s.i.) por encima de la

presión del múltiple especificada.

GAS LP GN

(Nota: este diagrama

representa al modelo

GC36, pero es similar

para GC901 y GC901M).

Arandela azul

Codo

HERRAMIENTAS NECESARIAS

Destornillador Phillips No. 2

Adaptadores a tuberías según sea necesario

Herramientas para trabajar la madera según se necesite

Válvula de cierre

Pintura al óleo (para sellar el corte)

Para conversión a gas LP

Destornillador plano de Ø

7

/

64

" x 1

3

/

4

" (Ø2,5 x 45mm)

Llave de tubo de

9

/

32

" (7mm)

Para conversión del GC901M a gas LP

Destornillador plano de Ø

7

/

64

" x 1

3

/

4

" (Ø2,5 x 45mm)

Destornillador Phillips No. 1

Llave de tubo de

9

/

32

" (7mm)

Llave de anillo de

13

/

32

" (10mm)

LISTA DE VERIFICACION DE PIEZAS

Unidad base del anafe a gas

Paquete con información (incluye juego gas LP)

Codo y arandela azul (asegurados a cable de alimentación)

Tornillos y soportes de fijación (GC36 – en la unidad base)

Regulador (en poliestireno)

Cabezas y tapas de quemadores (controle el poliestireno

cuidadosamente antes de descartar)

3 rejillas/trípodes (1 central, 2 externas) de quemador)

Paquete de accesorios

ANTES DE EMPEZAR

Asegúrese de que la mesada esté en ángulo recto y nivelada y

asegúrese de que ninguna parte estructural interfiera con los

requerimientos de espacio.

Asegúrese de que haya un receptáculo (110-120V 60Hz) de

suministro eléctrico al alcance del cable de alimentación del

anafe (a 30” del centro del producto). El cable principal no debe

tocar ninguna pieza de metal caliente.

Asegúrese de que el anafe esté conectado a un tomacorriente

eléctrico que esté conectado a tierra de acuerdo con las normas

locales, o a falta de normas locales con el Código Nacional de

Electricidad ANSI/FPA 70 o CSA 22,2 (Canadá).

Asegúrese de que la mesada esté construida de un material

resistente al calor.

Le recomendamos que selle los bordes expuestos de madera del

corte con una pintura al óleo o poliuretano a prueba de humedad

para prevenir posibles daños ocasionados por la humedad que se

deposite entre el borde del anafe y la mesada.

Le recomendamos que utilice terminaciones de fácil limpieza para

las superficies de la pared que rodean al anafe, para ayudar a la

eliminación de cualquier mancha de cocina resultante de la

utilización del anafe.

Page 17

INSTRUCCIONES DE INSTALACION

17

ES

1 Apague el suministro eléctrico principal.

2 Asegúrese de que todas las válvulas de gas estén cerradas.

3 Extraiga todos los trípodes y las cabezas de quemador.

4 Extraiga las perillas.

5 Saque los dos tornillos que sujetan cada quemador (3 en el

quemador para wok).

6 Levante parcialmente la placa superior de metal y desenchufe el

electrodo en el quemador mini-auxiliar para permitir extraer la

placa. Tenga cuidado con los bordes filosos.

7 Desenrosque los orificios y vuelva a colocarlos con los orificios

correctos (los números de tamaño se encuentran impresos al

costado, por ej. 70=0,70mm) (vea el diagrama 1).

8 Vuelva a establecer la posición venturi alineando el extremo del

tubo venturi con el borde de la hendija en el soporte que se

encuentra debajo de él. Posición externa para Gas LP e interna

para GN (vea el diagrama 2). Condiciones locales específicas

pueden precisar un ajuste preciso.

9 Para volver a colocar la placa superior de metal del modelo

GC901M, repita los pasos 3 – 6 en el orden contrario.

10 Vuelva a establecer la calibración mínima. Vea “Calibración

mínima” a vuelta de página.

¡ATENCION!

Peligro de electrocución

Desconecte la corriente

eléctrica antes de reparar el

producto.

Si no lo hace puede morir o

electrocutarse.

Cambiando el

orificio

Diagrama 1

La etiqueta suministrada con los orificios debe ubicarse sobre la

etiqueta de tipo de gas existente para indicar el cambio.

Posición Venturi

Diagrama 2

CG901M solamenteCG901M solamente

CONVERSION A UN TIPO DIFERENTE DE GAS

Los quemadores se pueden utilizar con GN o gas LP, siempre y

cuando se instalen los orificios inyectores apropiados para el gas

suministrado.

Se pueden obtener orificios de gran altura de Fisher & Paykel USA.

GC36 Juego de piezas para GN, No. de Pieza 530463

Juego de piezas para gas LP, No. de Pieza 530464

GC901/M Juego de piezas para GN, No. de Pieza 531566

Juego de piezas para gas LP, No. de Pieza 531567

Para cambiar los orificios inyectores, necesitará una llave de tubo de

9

/

32

" (7mm) y una llave de anillo de

13

/

32

" (10mm) (CG901M

solamente).

Posición Venturi

para GN

Posición Venturi

para gas LP

Page 18

INSTRUCCIONES DE INSTALACION

18

CALIBRACION MINIMA

Esta ha sido configurada de fábrica para GN pero se puede

controlar luego de haber alcanzado la presión correcta. Para ajustar

la calibración mínima (de ser necesario), necesitará un

destornillador de Ø

7

/

64

" x 1

3

/

4

" (Ø2,5 x 45mm) (Fisher & Paykel

dispone de un destornillador apropiado para este uso bajo el

número de pieza FB200467).

1 Encienda el quemador y mueva la perilla hasta su posición

mínima.

2 Extraiga las perillas.

3 Gire el tornillo (en el orificio en el vástago) mientras sujeta el

eje. Gire lentamente hasta alcanzar una llama regular mínima.

(La llama disminuirá cuando se gira el tornillo en la dirección de

las agujas del reloj, y aumentará cuando se gire en la dirección

opuesta).

4 Cuando la calibración sea correcta verifique la regulación

rotando velozmente la perilla de la posición máxima a la

mínima. La llama no debe apagarse y el reencendido

automático no debe chisporrotear. Vuelva a colocar la perilla.

ES

Ajuste de

calibración mínima

(Nota: este diagrama

representa al modelo

GC901, pero es similar

para el modelo GC36).

Luego de instalar el suministro de gas y hacer todas las

conexiones, revise cuidadosamente en busca de posibles pérdidas:

1 Gire todas las perillas de control en la unidad hasta la posición

de apagado.

2 Abra la válvula de alimentación de gas.

3 Utilizando un líquido de detección de pérdidas (por ej. el

vaporizador de detección de pérdidas Rocol) controle cada

conexión de gas de a una por vez cepillando la solución sobre la

conexión. La presencia de burbujas indicará una pérdida.

4 De ser necesario, ajuste el adaptador y vuelva a controlar en

busca de pérdidas.

5 Abra la válvula del quemador y encienda cada quemador.

6 Busque una llama azul claro sin punta amarilla. Si los

quemadores presentan anormalidades, controle que estén

ubicados correctamente y de acuerdo con el orificio de

inyección.

COMPROBACION DE PERDIDA

La comprobación de pérdida del artefacto debe llevarse a cabo

siguiendo las instrucciones del fabricante.

El artefacto y su válvula de cierre individual deben ser

desconectados del sistema de tubería de alimentación de gas

durante cualquier tipo de prueba de presión de ese sistema que

supere

1

/

2

p.s.i. (3,5kPa).

El artefacto debe desconectarse del sistema de tubería de

alimentación de gas cerrando su válvula de cierre manual

individual durante cualquier prueba de presión del sistema de

tubería de alimentación de gas a presiones de prueba de o

menores a

1

/

2

p.s.i.(3,5kPa).

Presión máxima de entrada de alimentación de gas de 4" W.C.

Gas Natural, 11" W.C. gas LP.

Presión mínima de alimentación de gas para prueba del

regulador 5" W.C. de Gas Natural, 12" W.C. gas LP.

Vea la Lista de Verificación de Instalación del Producto adjuntada al producto.

Page 19

INSTRUCCIONES DE INSTALACION

19

COMO CONTACTARSE CON NOSOTROS

En la parte inferior del producto encontrará un resumen de la manutención.

Para piezas de repuesto o si precisa más ayuda en relación a este artefacto, llame gratis al:

1 888 9 FNP USA (1 888 936 7872)

o diríjase por escrito a:

Fisher & Paykel Appliances Inc.

27 Hubble, Irvine

CA 92618

o contáctese con nosotros a través de nuestro sitio en

Internet: www.usa.fisherpaykel.com

ES

CONTROL DEL TIPO DE GAS

GC36

Quemadores Orificio GN GN Orificio Gas LP

(mm) BTU (MJ/h)@ Gas LP

BTU (MJ/h)@

0,15p.s.i. (4”H

2

0) (mm) 0,41p.s.i. (11”H20)

Der. trasero 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.000 (8,4 MJ/h)

Izq. trasero 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.000 (8,4 MJ/h)

Der. delantero 0,85mm 3.500 (3,47 MJ/h) 0,55mm 4.000 (4,2 MJ/h)

de cocción lenta

Izq. delantero 1,75mm 12.600 (13,3 MJ/h) 1,05mm 13.000 (13,7 MJ/h)

para wok

Central 1,45mm 9.500 (10 MJ/h) 0,85mm 9.500 (10,0 MJ/h)

GC901 / GC901M

Quemadores Orificio GN GN Orificio Gas LP

(mm) BTU (MJ/h)@ Gas LP BTU (MJ/h)@

0,15p.s.i. (4”H20) (mm) 0,41p.s.i. (11”H20)

Der. trasero 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.200 (8,7 MJ/h)

Izq. trasero 1,1mm 5.800 (6,1 MJ/h) 0,7mm 5.700 (6,0 MJ/h)

Der. delantero 0,85mm 3.000 (3,2 MJ/h) 0,55mm 3.500 (3,7 MJ/h)

de cocción lenta

Izq. delantero 1,3mm 8.000 (8,4 MJ/h) 0,8mm 8.200 (8,7 MJ/h)

Central

(GC901) 1,75mm 14.000 (14,8 MJ/h) 1,05mm 13.000 (13,7 MJ/h)

Central

(GC901M) 2,15mm 20.000 (21,1 MJ/h) 1,22mm 19.000 (20 MJ/h)

Page 20

Loading...

Loading...