Page 1

this has been set at the iactory but cau be checked after the correct pressure has been reached.

[ o adjust Jor IT_il_ilTltllT_setting, if ne(2tJed. YoLl wilt need a 7/64" diameter x t 3/4" [2.5 x 45mini

screwdriver.

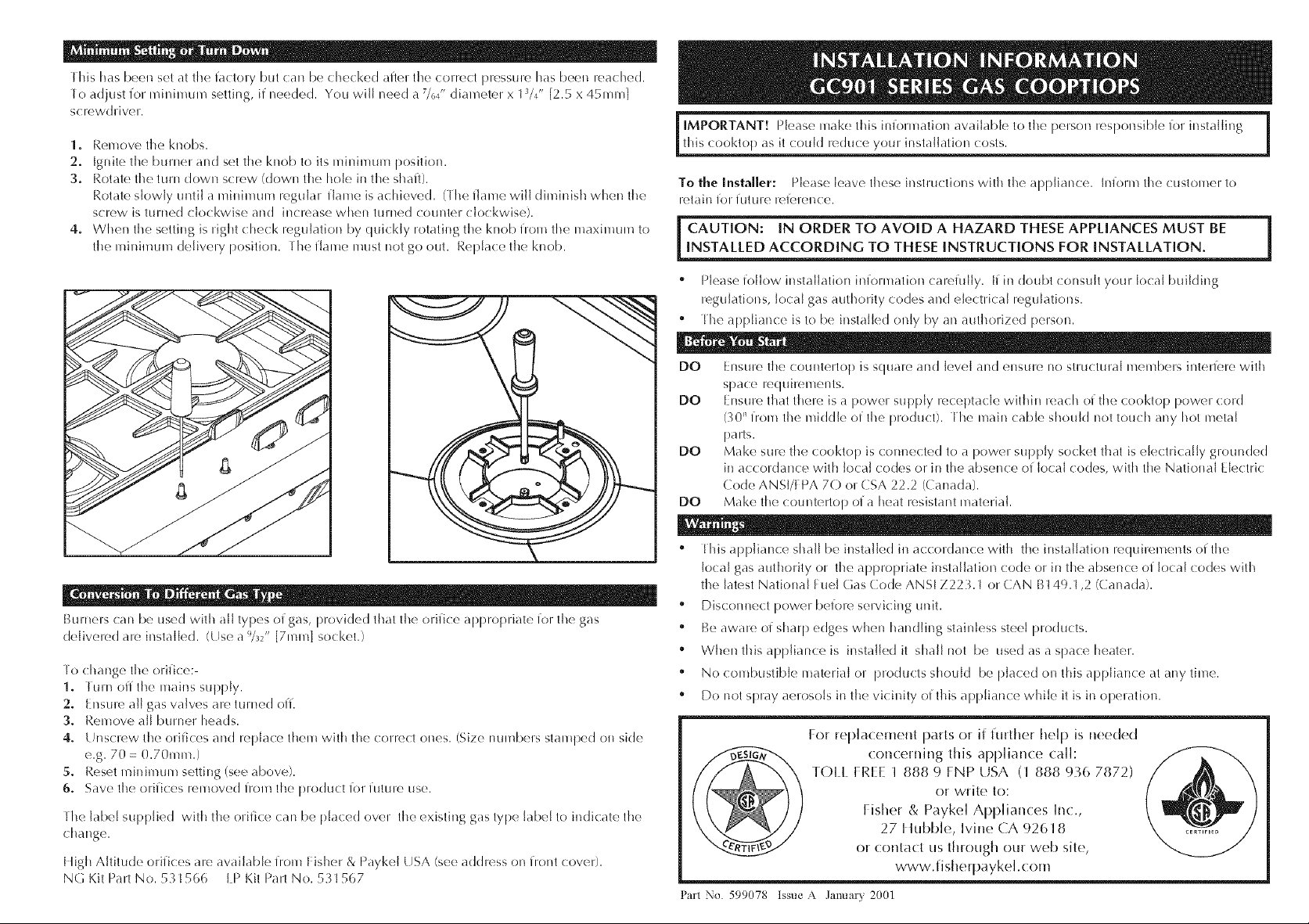

1. Remove the knobs.

2. tguite the burner and set the kuob to its i_]iniimm] position.

3. Rotate theturu down screw (dowu the hole iu the shafl].

Rotate slowly LmtiJa millimLli'q regular lJal'qe is achieved. (the lJal'qe wilt diminish when the

screw is tLlrlletJ ctocl<wise anti increase wheu tLlrlletJ co=inter clockwise).

4. When the settiug is right check regulation by quickly rotatiug the knob item the maxhTltllT_ to

the mh_hT_tlm delivery position. [he flame mtist not go oLlt. Replace the knob.

I IMPORTANT! Pteas_ make tills imormation aw_itabk to th_ I_ rson re,; _onsibte ior installing

,I , i

|

[this cooktop as it cotlJ(J r( (JLIC( yotll installation costs. 1

To the Installer: Please leave these instrLlctions with the apl_iiance, tniorm the customer to

retah_ 1or Jut[ire ie_(?l-el_ce.

j CAUTION" IN ORDER TO AVOID A HAZARD THESE APPLIANCES MUST BE

m i

INSTALLED ACCORDING TO THESE INSTRUCTIONS FOR INSTALLATION.

" Please follow installation information carefully, tf in doubt (onsult your local building

regulations, local gas authority codes and electrical regulations.

° the appliance is to be installed only by an authorized person.

DO Ensure the couutertop is square an(J level an(J ensure no structural members il_terl(_re with

sl)ace req tlh-el'ftel_tS.

DO EItSLII'e that there is a Dower supply receptacle withiu reach of the cooktop power cord

(30" item the middle of the [)ro(Juct). the main cable should not touch any hot metal

[)arts.

DO Make sure the cooktop is conl_ected to a power SUpl_Jy socket that is electrically groLill(Je(J

iu accordauce with local codes or in the absence of local codes, with the National Electric

Code ANSI/FPA 70 or CSA 22.2 ((anada).

DO Make the countertol) of a heat resistant material.

Buruers can be used with all types of gas, provided that the orifice appropriate for the gas

delivered are installed. (Use a _/s2" [7mm] socket.)

1o change the oriike:

1. turn oflthe I'liahls su[)l)ty.

2. Ensure all gas valves are turued off.

3. Remove all buruer heads.

4.. Unscrew the oriiices and replace them with the correct ones. (Size numbers stamped on side

e.g. 70 = 0.70mm.)

5. Reset miuimum settiug (see above).

6. Save the oriii(es rel'liove(J l]om the product lot luture use.

the label SUpl_lied with the orifice can be placed over the existing gas type label to indicate the

change.

t tigh Altitude orifices are available from tisher & Payke[ USA (see address on front cover).

NG Kit Part No. 5_ 1566 [ P Kit Part No. Sgt 567

° [his appliance shall be installed in accordance with the iustaliation requirel'nel_ts of the

local gas authority or the appropriate iustaJJation code or ill the absence of Jot:a[ codes with

the latest National Fuel Gas Code ANSI Z22g. t or CAN Bt4!).t,2 (Canada).

" Disconuect power before serviciug Lmit.

" Be aware of sharp edges when handling stainless steel products.

" When this appliance is installed it shall not be used as a space heater.

" No combustible material or productsshoukJ be placed on this apptiauce at any time.

" Do not spray aerosols in the vicinity of this apidiance while it is in operation.

I or replacement parts or if further hel I) is needed

concerning this appliance (:all:

TOIl IREE I 88891NPUSA (I 888 9¢6 7872)

or write to:

I isher & Paykel Ai)l)liances Inc.,

27 I hlbble, Ivine CA 92618

or contact us through our web site,

www.iisherpaykel.com

Part No. 599078 issue A Jalltlar 3 2001

Page 2

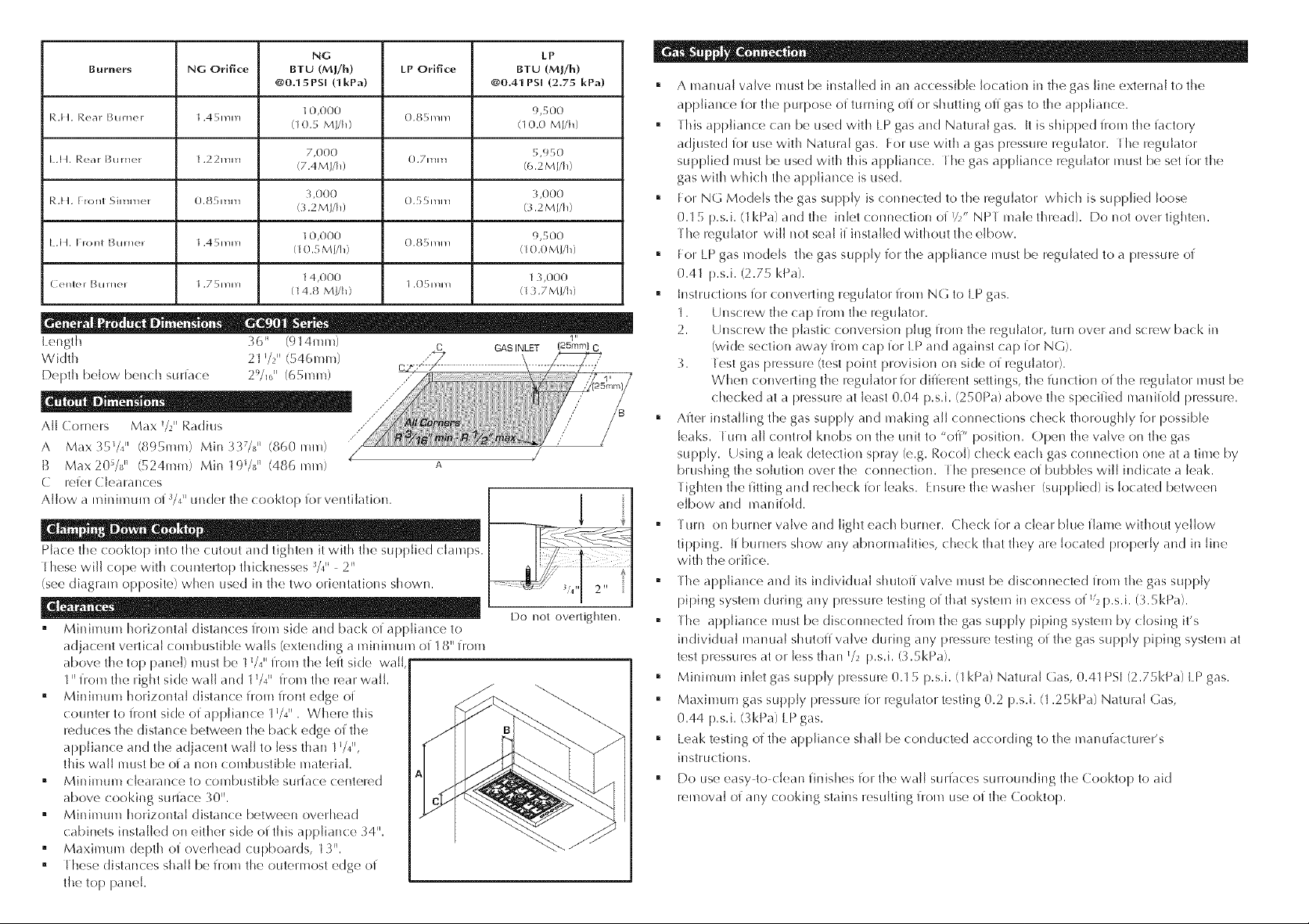

NG LP

Burners NG Orifice BTU (MJ/h) LP Orifice BTU (MJ/E)

JR.[ I. [',}ear Burner 1.45toni I 0,000 0.851_11_1 !),500

I .I I. I',>ear Btllnel 1.22nlm 7,000 0.7me 5,950

I',>.1 I. Fronl Sh11111c,I 0.8r;llln1 3,000 0 r r illn I 3,000

I .I I. I IOlll l_tlfllOf 1,45111nl I 0,000 0,85111111 !),500

(2,nlcq [3tilnc,l 1.75mm I 4,000 1.05HI1_1 I 3,000

@O.+15PSI (] kPa) @O.4+1 PSI (2.75 kPa)

(I 0.5 Mj/h) (I 0.0 Mj/h)

(7.4M j/h) ff,.2Mjlh)

(3.2MWi9 (3.2 MWi9

(l 0,', Ml/h) (l 0,0 Ml/h)

( t 4.8 Mj/h) (l 3.7Mj/h)

t ength g"o" (9 14me) 6ASINLTT s"

Width 21 _/2" (5461_Im)

DelJth below bench suriace 29/16I' (65me)

I D " 0

All COHIeFS Max _/2"Radius

A Max35W' (895mm) Min337/8 '' (860mm1

I:_ Max 2()s/d ' (524mm) Min I !)1/811 (486 I/ll/l) A

C rek'r (tearauces

Allow a minilllulll of 3/,€' under the cooktop ior ventilation.

Place the cooktop into tile CtltO/lt and tighten it with the sUf)l}lied clamps.

these witt cope with countertop thickuesses 3/+ 11 2I1

(see diagram opposite) when used in the two orientations shown.

• Minimum horizontal distances i/om side aud back of appliance to

Do not overtighten.

adjacent vertical combustible walls (extendiug arniuil'nUl'n of t 8IIirom

above the top panel) must be t _/,_"i/om the left side watt

t" irom tile right side watt and l I/311 i/Om the rear watt.

• Miniimml horizontal distauce irom flout edge ot

cotillter to i]ollt side el apIJtiauce I l/311 . Where tiffs

reduces tile (Jistance between tite back edge of the

appliance alld the adjacent watt to tess !halt t _/_",

this watt i'qtlst be of a non combustible material.

" Mininlul'n clearance to combustible suriace centered

above cookiug suriace 3()".

" MhlilllUm horizontal distauce betweelt overhead

cabiltets installed oil either side of this apptiaitce ")4".

• Maximum depth of ow_rhead cupboards, t +}".

• these distallces shall be irom the outerrnost edge of

the top panel.

• A Illauuat valve I'nUSt be iustatted in all accessible location ilt the gels tiue external to the

appliance ior the purpose of turning offer shutting ofigas to the apptiallce.

• this appliance cau be tised witil t Pgas an(J Natural gas. It is shipped from tile iactory

a(Jjuste(J ior use with Natural gas. For use with a gels pressure regulator, the regulator

supplied must be used with this apptiailce, the gels api}tiance regulator mtlst be set ior the

gels with which tile appliance is used.

• For NG Models tite gas supply is conuected to tile regulator which is supplied loose

0.t 5 p.s.i. (I kPa) an(J the inlet coitile(::tioll oi rZ," NP t male thread). Do not over tighten.

the regulator wilt ltOt seat ii installed without tile elbow.

• l:or t P gels models tile gels supply ior the appliance i'iltlst be regulated to a pressure of

0.41 p.s.i. (2.75 kPa).

• tustructions ior convertiug regulator i]om NG to t P gels.

t . t_JltsCI'OWthe celI) iroll} the regulator.

2. t Jltsorew !lie plastic OOlWersioll plug 7roe !lie regtltator, tttrn over and screw back ill

(wide section away 1]'O1"_I cap iOl t P alld against cap iOl" N(-]).

"). lest gels pressure (test point provision oil side oi: regulator).

When COliVertillg the regulator ior diiierellt settiugs, tile itlllctioll Of tile regulator must be

checked at a pressure at least 0.04 p.s.i. (250Pa) above the speciiied mauiiotd pressure.

• After ills!ailing the gels supply and making all connections check thoroughly ior possible

leaks, turn all control kuobs oil the unit to "off _' position. Open the valve oil tile gas

supply. Using a leak detection spray (e.g. Rocot) check each gas connection one at a time by

brushing tile solution over tile connection, the presence of bubbles wilt indicate a leak.

lighten the it!ring alld recheck ior leaks. Ensure the washer (supplied) is located between

elbow alld maliiiotd.

• [ urn oil burner valve aii(J light each buruer. Check iora clear blue itame without yellow

tif)piug, ti burilers show any abnorrnalities, check that they are located properly and ill line

witil the oriiice.

• the apiJtiauce and its iudividuat shutoi] valve i'iltlst be discollllected irol'_l the gas supply

pilling system during auy press!ire testing of that system iu excess of w2p.s.i. (+L5kPa).

• the apptiauce must be disconnected irol'_l tile gas supply pipiug system by ctosiug it's

iudividuat inanuat shutoff valve during any ioressure testing of the gas supply piping system at

test pressures at or tess thau _/2p.s.i. (3.SkPa).

• Mininlum inlet gas supply pressure 0. t 5 p.s.i. (t kPa) Natural (]as, 0.4t PSi (2.75kPa) t P gas.

" Maxiinurn gas supply pressure ior regul<dor testing 0.2 p.s.i. (t .25kPa) Natural Gas,

0.44 p.s.i. (3kPa)t P gas.

• t eak testing el thc, apiJtiance shall be conducted according to tile rnanuiacturer's

instructions.

• Do use easy to clean iinishes ior tile watt SLII'iacos StlHOtllldillg the Cooktop to aid

retrieval of any cooking stains resulting froth use of tile Cooktop.

Loading...

Loading...