Fisher & Paykel Dryer Installation Instructions Manual

\

Dryer

installation instructions and

User Guide US CA

Secadora

Instrucciones de Instalaci6n y

Guia del Usuario ES

New Zealand f_,L_stralla USA Canada Eur,- pe Asia P,sclfic

_\_ _g_o.RNING: For your safety the iaf_rmat_oa ia

th_s manual must be fo[h_wed to miaimize the risk

of fire or exp_osioa or to preve_lt property damage,

perso=a[ bliury or death°

-- Do aot store or use gasohne or other _ammaWe vapors

aad liquids b_ the vida_ty of aay other app[iaaceo

-- WHAT TO DO IIFYOU SMELL GAS

÷ Do aot try to _ight aay app_iaaceo

° Do _mt touch aay dectricaJ switch} d.o aot use aay

phoae ir:_your: bui_di_lgo

÷ CJear the room, bui_diag or area of a[[ occupaatso

° Immediately call your gas supplier _}om a _dghbor's

* i[f you caanot reach your g_s supplier, ca[_ the fire

--i[asta[[atioa aad service mast be performed by a

qualified b_sta[[er, service ageacy or the gas supp[iero

Y}e 6ove_>o_' of CaIifo_'_da to pLsbIisb a !ist of sLsbsta_'ces k_"ow_'tto the state of

([a/ifo_'tia to ca_,sse ca_'_ce_'0_' _'ep_'od_sctive ha_'m a_d _'eq<si_'es b_{sieesses to wa_e

<:Llstome_s of pote_ tia[ e)4pos_'es to s/,_<:}'_s_bsta_"ces

(_as app[ a_'ces co_ta[_" o_' p_'od .see s_sbsta_"ces, w}_[ h ca_ <a_sse deat}b o_' scabious

i[b'ess a_"d w}_ h a_'e k_ ow_" to the State of Ca_ifo_'_da to ca_,sse cat"eel', bi_'th

defect% o_ othe_' _'ep_'od_sct[ve ha_'mo lb _'ed<s<e t}_e _[sk f_'o_r,substa_'ces i_ f_se}

0_ f_om fl_e[ <e"_b_st o_ , make s ._'e this appIia_"ce is _staI/ed, epe_'ated, a_d

_>_)h_ah_ed ac o_'di_% to the may_.,_fa<%_'e_s b"_st_u<tioy_s

Contents

Dryer Safety

Important Safety Instructions

Warranty

Installation Instructions

Installer Responsibilities, Location Requirements

Dimensions

Exhausting

Maximum Length of Exhaust Duct

Alternative Exhaust Directions

ExhaustVenting

Installation

Grounding Instructions

Electrical Requirements

GasRequirements

Level Machine, Final Installation Check List

Features

Operating Instructions

Reversing the Door

Quick Start / Using Your Dryer

Care Labels

Drying Spedal Items

Other Features

Cleaning

Trouble Shooting

Limited Warranty

6

8

9

10

12

13

15

17

19

2O

21

22

25

28

29

30

32

33

38

39

41

42

44

46

Thankyou for buying a Fisher& Paykeldryer.

We hope you enjoy using the dryer as much aswe haveenjoyed designing it. We'vegone to a lot

of effort to ensure it treats your clothes with the utmost care,drying them gently so they will look

better for longer. We know you'll enjoy the benefits of its easyloading drum.

Pleasetake the time to read this UserGuide carefully. It will help you operate and maintain your

new dryer.

Your safety,and the safety of others isvery important. Located

or] your dryer and throughout this guide are safety messagesand

instructions; it isimportant that you understand and follow them.

Dryer Safety

'Toreduce 'therisk of fire, electric shock, or injury 'to persons, read

the iMPORTANTSAFETYiNSTRUCTiONSbefore operatin 9 this

Failureto follow to do so can result in death or electric shock°

Symbols

Symbols will be used in this Guide to highlight when extra care isrequired. Abide by these at all

times to ensure you and your family are not harmed while operating your dryer.

It isimportant to always act with caution and usecommon sense when operating your dryer. Use

only as perinstructed by the UserGuide.

This isthe safety alert symbol. This symbol alerts you to hazardsthat carl kill

or hurt you and others.

The safety alert symbol and the word DANGERor WARNINGwill precede all

safety messages. These words mean:

Youcan be killed or seriously injured ifyou don't

immediate[ 2 follow instructions.

Youcan be killed or seriously injured ifyou don't follow

[nstructionso

All safety messageswill identify the hazard,tell you how to reduce the chance of injury, and

tell you what carl happen if the instructions are not followed.

Important Safety Instructions

Emectric Shock Hazard

Follow the safety precautk_ns outlined in this User Guide°

Failureto do so can result in death or electric shock,

Safety Precautions

a Readall instructions carefully before using this dryer.

• Usethis dryer only for its intended purpose as described in this UserGuide.

• To minimize the possibility of electric shock, unplug this dryer from the power supply or

disconnect the dryer at the household distribution par]el (by removing the fuse or switching off

the circuit breaker) before attempting any user mair]ter]ance or cleaning.

• [r]stallation must conform with local codes, or in absence of localcodes,with the National FuelGas

Code,ANSIZ223.l/NFPA 54 or the Canadian NaturalGasand Propane [r]stallatior] Code,CSAB149.1.

• [r]stallationsand service must be performed by a qualified or licensed contractor, plumber or

gasfitter qualified or licensedby the state, province, or region where this appliance is being installed.

This dryer must be properly installed and located in accordance with the Ir]stallation Instructions

before it is used.

• This dryer,when installed, must be electrically grounded in accordance with local codes,or in the

absence of local codes,with the National Electrical Code,ANSI/NFPA70, or the Canadian Electrical

Code,CSAC22.1.

Do not install or store the dryer where it will be exposed to water or exposed to the weather.

Connect to aproperly protected, rated and sized power supply circuit to avoid electrical overload.

• Do not repair or replace any part of the appliance or attempt any servicing, unless specifically

recommended in the published user repair instructions that you understand and have the skills to

carryout.

When discor]r]ecting the dryer, pull by the plug rather than the cord or junction of the cord plug,

to avoid damage to the cord or junction of the cord plug.

Makesure the cord is located so that it will not be stepped or],tripped over or otherwise subject

to stress or damage.

Do not tamper with the controls.

Note:Turning the CycleSelector knob to an OFF position does NOTdisconnect the appliance

from the power supply.

Do not operate this dryer if it isdamaged, malfur]ctior]ing, partially disassembled or has missing

or broker] parts, including a damaged cord or plug.

This dryer must be directly connected to an approved fixed electrical outlet. Itcar]not be

plugged into an extension cord or an adaptor plug.

Important Safety Instructions

Only dry fabrics that have been washed with water°

Do not useheat to dry articles containing foam rubber or simi[dy

textured rubber.like materia[so Dry on the Fluff cyc[eo

A clothes dryer produces combustible lint and must be exhausted

outdoors, Takecare to prevent'the accumulation of lint around

the exhaust opening and in the surrounding area,

Failureto follow these instructions can result in death or persona[

injury,

To Reduce the Risk of Fire in a Tumble Dryer the Following Should

be Observed:

a Do not place items in atumble dryer that havepreviously beer] cleaned in, washed in, soaked

in, or spot cleaned with flammable liquids or solids. They are a fire or explosion hazard. Highly

flammable substancescommonly used in domestic environments include acetone, denatured

alcohol, gasoline, kerosene,some brands of spot removers and dry cleaning solvents, turpentine,

waxes,wax removers,vegetable oi1,fish oi1,massageoi1,and cooking oik

Do not leave hot oi1affected items in a pile or stack. This carl prevent heat from escaping and carl

create afire hazard. 0i1 affected items carl ignite spontaneously, especially when exposed to heat

sources such asatumble dryer. The items become warm causing an oxidation reaction in the oik

This oxidation creates heat. If the heat cannot escapethe items carl become hot enough to catch

fire.

Donot useheatto dryitemscontainingrubber,foamrubber,plasticor similarmaterials,(suchas

paddedbras,bathmats,rugs,bibs,babypants,plasticbags,pillowsetc),asthesematerialsmight

meltor burr]. Somerubbermaterialswhenheatedcarlundercertaincircumstancesproducefire

byspontaneouscombustion. Dryonlyor]the FLUFFcycle.

Unlessspecificallyrecommendedbytheirmanufacturer,do not usefabricsoftenersor similar

productsin a tumbledryer.

Donot storeor usegasolineorotherflammablegasesand liquidsnearthisoranyother

appliance.

Keeptheareaaroundthe exhaustopening andadjacentsurroundingareasfreefrom the

accumulationofcombustiblematerialssuchaslint,paper,rags,chemicalsetc.

Donot storeany itemsthat mayburr]or melt (suchaspapermaterials,plasticsor plastic

containers,etc) nextto thedryer.

Clear]the lintfilter eachtimeyou usethedryer,beforeoraftereachload.

Important Safety Instructions

a The dryer must be exhausted to the outside. Carefully follow the venting details in the Ir]stallation

Instructions.

Keepthe floor around your dryer clearsand dry to reduce the possibility of slipping.

Ifyour dryer is rur]r]ing and you want to unload or add clothes, open the dryer door.

Do not reach into the appliance if the drum is moving.

Close supervision is necessary if this dryer is usednear children. Do not allow children to play

inside, around or with this dryer or any other appliance.

Neverclimb ors,climb into, or stand orsthe dryer top or drum.

Undergarments that contain metal reinforcements should not be placed directly in the dryer.

Damage to the dryer carl result if the metal reinforcements come loose during drying. If you wish

to dry these items use a drying rack (available asan optional accessory refer to page 9).

The interior of the appliance and exhaust duct should be cleaned periodically by quali_ed service

personnel.

When discarding or storing old clothes dryer, remove the door.

Warranty

Your dryer hasbeersmade to the highest standards. Yearsof development and rigorous testing

ensure that you have bought a world classproduct, in the unlikely event that a problem should

occur, referto the Limited Warranty section at the back of this Guide (referto page 46).

Ifyou havea problem with your dryer refer to our troubleshooting section. If your problem is not

referenced, pleasealways contact your Fisher& PaykelAuthorized Service Agent or our Customer

CareCenter (Toll Free ] 888 9 FNPUSA(1 888 9 367 872)) rather than attempting to _xit yourselfl

nstallation Instructions

6 o Risk of fire

• Clothes dryer installation must be performed by a qualified installer.

• Install the clothes dryer according to the manufacturer's instructions and local codes.

Do not install a clothes dryer with flexible plastic venting materials. If flexible metal (fOil type)

duct isinstalled, it must be of a specific type identified bythe appliance manufacturer assuitable

for usewith clothes dryers. Flexible venting materials are known to collapse, be easilycrushed,

and trap lint These conditions will obstruct clothes dryer airflow and increase the risk of fire.

To reduce the riskof sever injury or death, follow all installation instructions.

Savethese instructions

Read the Important Safety Instructions on pages 6 - 8 before you start

installing your dryer.

Check to make sure you haveall the tools and parts necessary to correctly install this appliance.

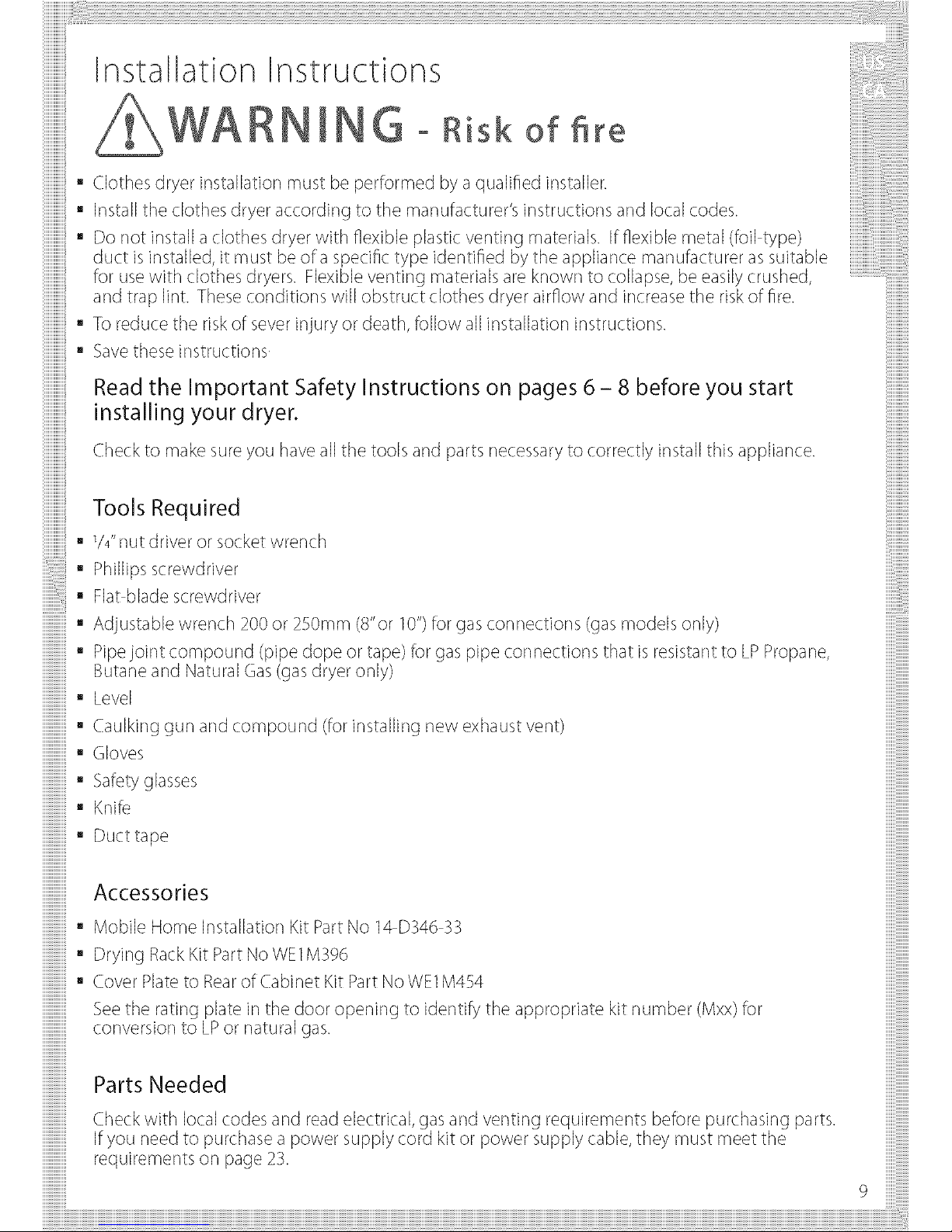

Tools Required

]/4"nut driver or socket wrench

Phillips screwdriver

• Flat blade screwdriver

• Adjustable wrench 200or 250mm (8"or 10")for gas cormections (gasmodels only)

• Pipejoint compound (pipe dope or tape) for gas pipe cormections that is resistant to LPPropane,

Butanea nd Natural Gas(gasdryer only)

Leve

• CauIk_nggunandcompound<for_nstaU_ngnewexhaustvent)

6loves

" Safetyglasses

,, Knife

Duct tape

Accessories

" Mobile Home Installation Kit PartNo 14 D346 33

DryingRackKitPartNoWE1M396

" Cover Plate to Rearof Cabinet Kit Part No WE]M454

Seethe rating plate in the door opening to identify the appropriate kit number (Mxx) for

conversion to LPor natural gas.

Parts Needed

Check with local codes and readelectrical, gas and venting requirements before purchasing parts.

Ifyou need to purchase apower supply cord kit or power supply cable,they must meet the

requirements or] page 23.

ii!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

To the Installer

The correct installation of the dryer isyour responsibility.

Besureyou read the following instructions carefully before you start to install the dryer. These

instructions should be left with the home owner for future reference.

It is Your Responsibility to:

• Observe all governing codes and ordinances.

• Check code requirements. Some codes limit or do not permit installation of clothes dryers in

garages, closets, mobile homes or sleeping quarters. Contact your local building inspector.

• Adhere to these installation instructions.

• Allow for spacing requirements with side by side installations (refer page ]]).

• Makesure you have all items necessaryfor correct installation.

• Properly install the dryer.

• Contact a qualified installer asappropriate to ensure that the electrical and gasinstallation meets

all national and local codes and ordinances. (Seepage 6).

Location Requirements

£xIIosio_ Hazard

KeeDflammable materials and vaDorg such asgasoline_away

from the dryer°

Placedrier at least @aOmm(1t inches) above the floor for a

Failureto do so can result in death, e×plosion, £re,or burns°

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiii

!!!!!!10

The dryer must be installed or stored in an areawhich is not exposed to water or weather.

It isextremely important that the dryer is installed in a well ventilated location. This dryer must

exhaust air outdoors. Do not install the dryer in any room or closet which does not permit the

free flow of replacement air.

Allow sufficient room behind the dryer for the exhaust. The air intake isat the rear of the dryer.

Ensurethat there isa sufficient air passage or] each side of the dryer for intake air.

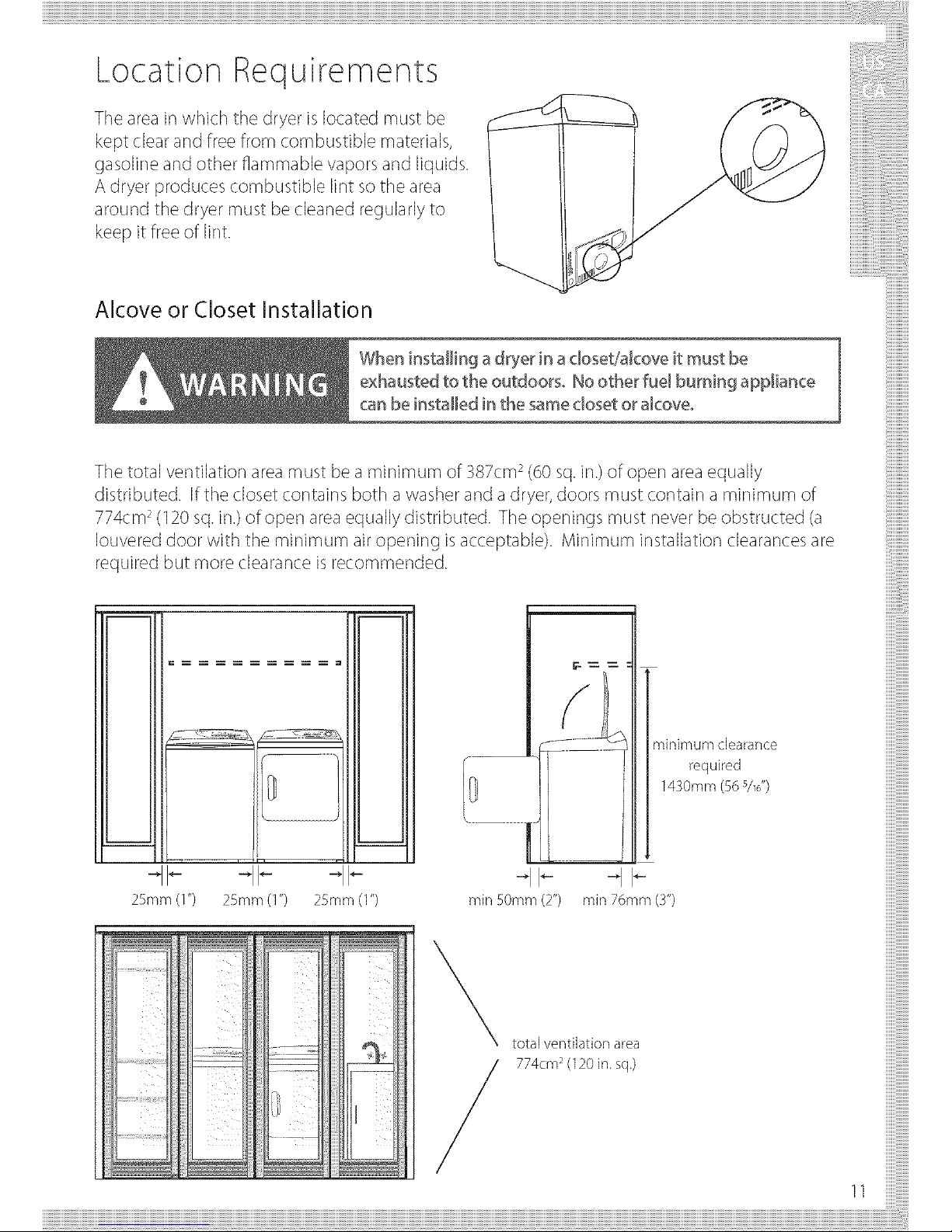

Location Requirements

The area in which the dryer is located must be

kept clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

A dryer produces combustible lint so the area

around the dryer must be cleaned regularly to

keep it free of lint

Alcove or Closet Installation

When installing a dryer in aclose't/alcove it must be

exhausted to the outdoors° No other fuel burning appliance

canbe insta[bd in the same closet or alcoveo

iiiiiiiiiiiiii

iiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiii

The total ventilation area must be a minimum of 387cm2(60 sq. in.)of open area equally

distributed. Ifthe closet contains both a washer and a dryer, doors must contain a minimum of

774cm2(120sq.in.) of open area equally distributed. The openings must never be obstructed (a

Iouvered door with the minimum air oper]ing isacceptable). Minimum installation clearances are

required but more clearance is recommended.

"ll--

25mm (1")25mm (1") 25mm (1") min 50mm (2")

minimum clearance

required

1430mm (56s/_,,)

<-.

min 76ram (Y)

total ventilation area

774cm2(120in.sq.)

11

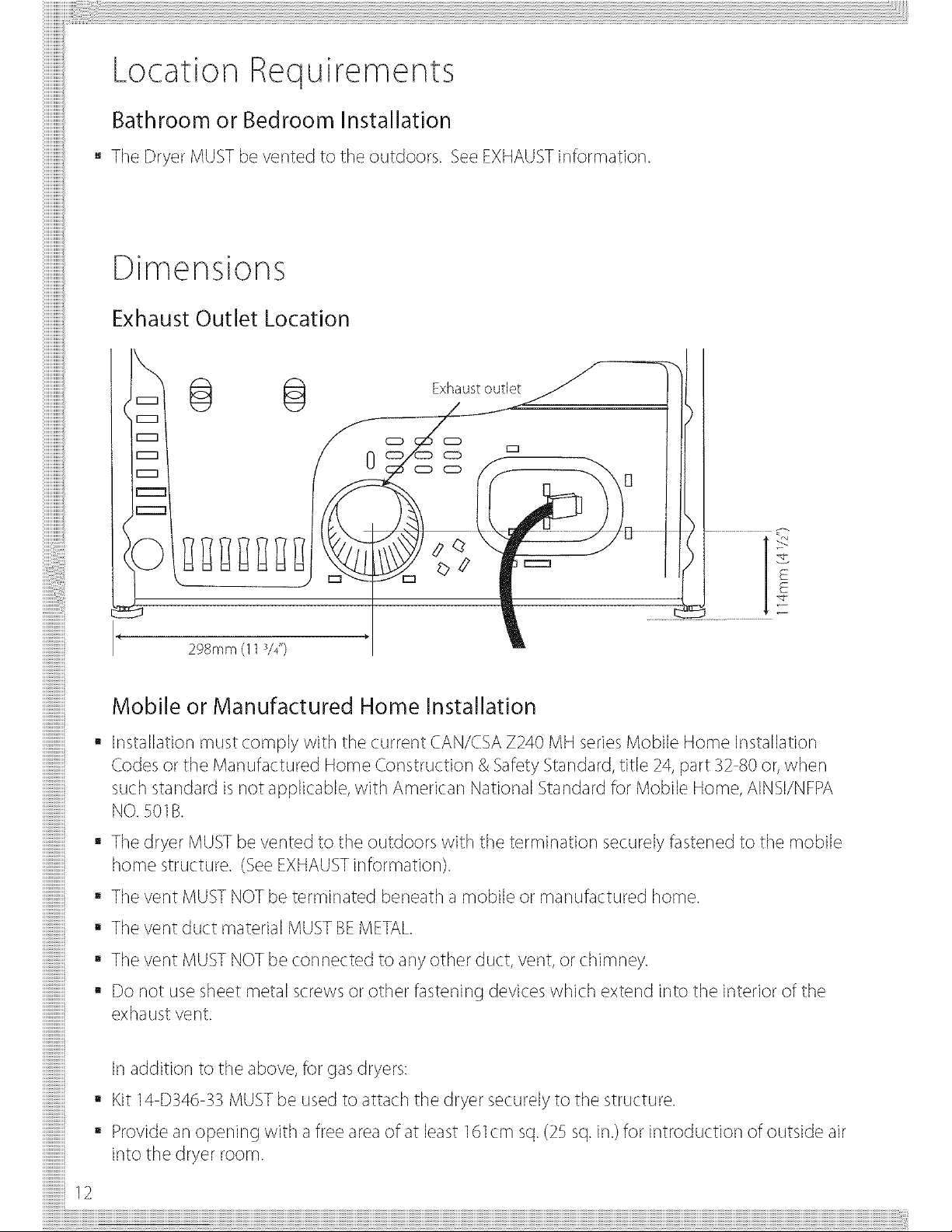

Location Requirements

Bathroom or Bedroom Installation

• The Dryer MUSTbe vented to the outdoors. SeeEXHAUSTinformation.

Dimensions

Exhaust Outlet Location

/

Exhaust outlet . / _']/

_ CD CD -- _,

l;, .............

Mobile or Manufactured Home Installation

• Installation must comply with the current CAN/CSAZ240 MH series Mobile Home Installation

Codes or the Manufactured Home Construction & Safety Standard,title 24, part 32 80 or, when

such standard is not applicable, with American National Standard for Mobile Home, AINSI/NFPA

NO.501B.

The dryer MUSTbevented to the outdoors with the termination securely fastened to the mobile

home structure. (SeeEXHAUSTinformation).

The vent MUSTNOTbe terminated beneath a mobile or manufactured home.

The vent duct material MUSTBEMETAL.

Thevent MUSTNOTbe connectedto anyother duct,vent,or chimney.

Donot usesheetmetalscrewsor otherfasteningdeviceswhichextendinto the interior of the

exhaustvent.

Inaddition to the above, for gasdryers:

Kit 14 D346 33 MUST be used to attach the dryer securely to the structure.

Provide an opening with afree area of at least ] 61cm sq.(;25sq.in.) for introduction of outside air

into the dryer room.

Exhausting

The dryer must be vented to the outdoors°

Userigid or thick wall flexible metal exhaust duct°

Do not usea plastic exhaust duct°

Do not usea me'tal foiJexhaust duct°

Failureto follow these instructions can _esu_tin death o_fire°

The dryer must be exhausted to the outdoors. This will prevent the build up of lint and moisture

in the room in which it is located and reduce the risk of fire.

This appliance must always be vented to the outdoors.

Only rigid or flexible metal duct shall be used for exhausting.

Jr]Canada and in the United States,only those foil type flexible ducts, if any, specifically identified

for usewith the appliance bythe manufacturer and that comply with the Outline for Clothes

DryerTransition Duct, Subject 2158A, shall be used.

Jr]Canada and in the United States,the required exhaust duct diameter is 102mm (4").

Exhaustducting products carl be purchased from your local Appliance storeor Hardware store.

Plasticor metal foil flexible duct carl kink, sag, be punctured, reduce airflow, extend drying times

and affect dryer operation.

A minimum of 100mm (4")thick wall flexible metal or rigid galvanized metal duct must be used.

Usingducts largerthan 100ram (4")diameter may result in more lint accumulating.

Using straight rigid metal ducting will minimize lint accumulation. Thick wall flexible metal

ducting may be used but care must be exercised to avoid sharp bends which may squashthe

duct and cause blockages. Do not use plastic ducting or thin wall flexible metal ducting.

Useduct tape to securejoints. Do not use screws as they collect lint.

Keepducting asshort and straight aspossible. Do not exceed the maximum exhaust duct

lengths stated later in these ir]sta%tion instructions.

Do not exhaust the dryer into a chimney or gas vent, awall, a ceiling, an attic, a crawl space,or

any concealed space in a building. Do not exhaust the dryer under a house or mobile home or a

porch, or into a window well or other area that will accumulate lint.

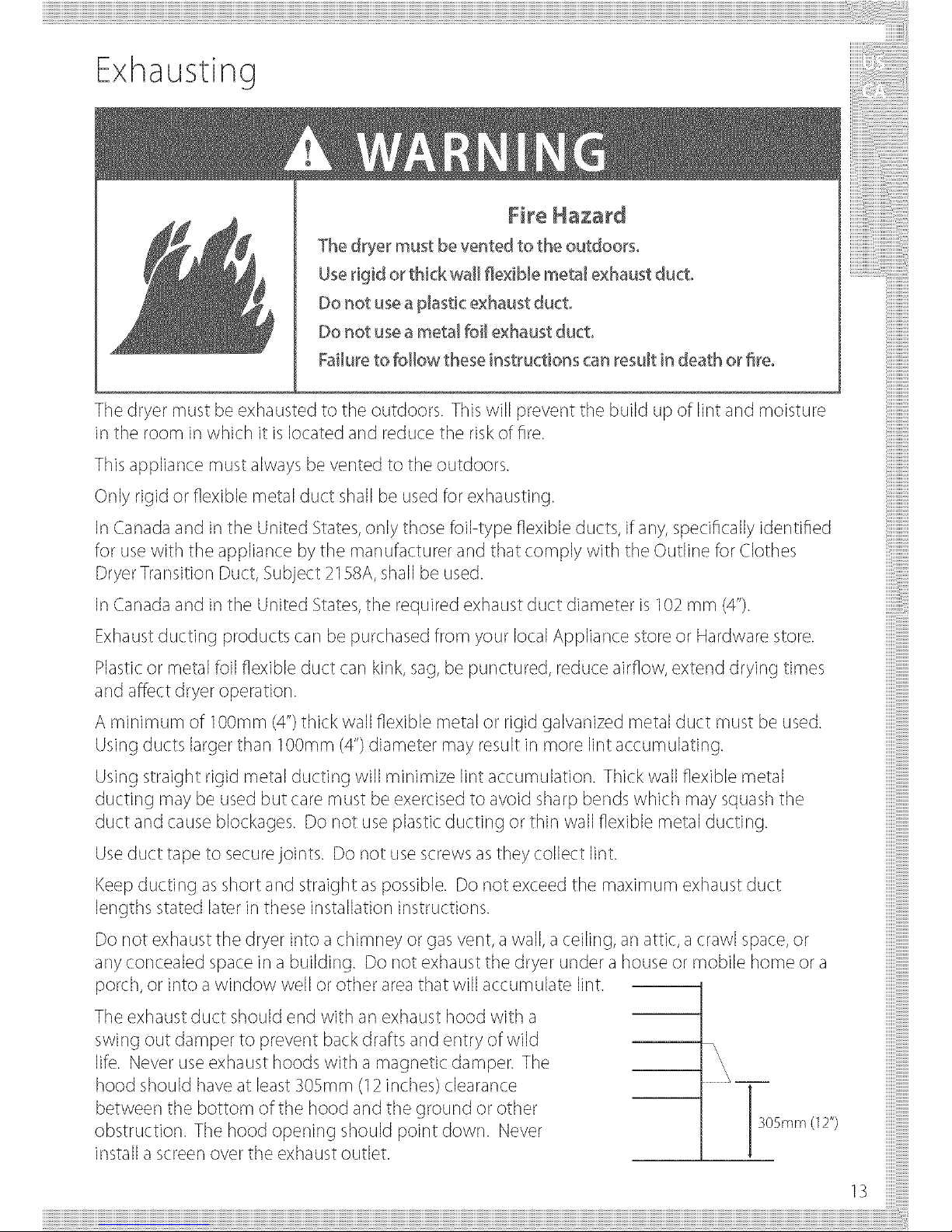

The exhaust duct should end with an exhaust hood with a

swing out damper to prevent back drafts and entry of wild

life. Never useexhaust hoods with a magnetic damper. The

hood should have at least305ram (12inches) clearance

between the bottom of the hood and the ground or other

obstruction. The hood opening should point down. Never

install a screen over the exhaust outlet.

305mm (12")

13

Exhausting

To reduce condensation, insulate any ducting which passesthrough unheated areas.

Slopethe duct gently downwards to the hood, to drain condensation and reduce lint build up.

Avoid sagor loops in the duct asthey may collect and store water and accumulate lint.

Beforeusing an existing exhaust duct system for a dryer ensure that:

No plastic or other potentially combustible duct or flexible metal foil ducting has beer] used.

The duct isnot pierced, kinked or crushed.

The duct does not exceed the maximum recommended length for the new dryer.

The exhaust hood damper opens and closesfreely and with sufficient movement.

Static pressure in the exhaust ducting does not exceed 3SOPa(1 inch of water column), or is not

lessthan 0 inches of water column (i.e.negative pressure),when measured with amanometer in

the first ] FOrum(6")of the duct, with the dryer running or] Fluff (no heat) setting.

The exhaust duct system meets all relevant local, state,province and national codes.

All ducting should be inspected and cleaned at least once a year to remove accumulated lint.

Frequently check that the damper or] the exhaust hood moves sufficiently and opens and shuts

freely.

Mobile Home Installations

AMobile Home Installation Kit isavailable (seeAccessories page _3and notes page 13).

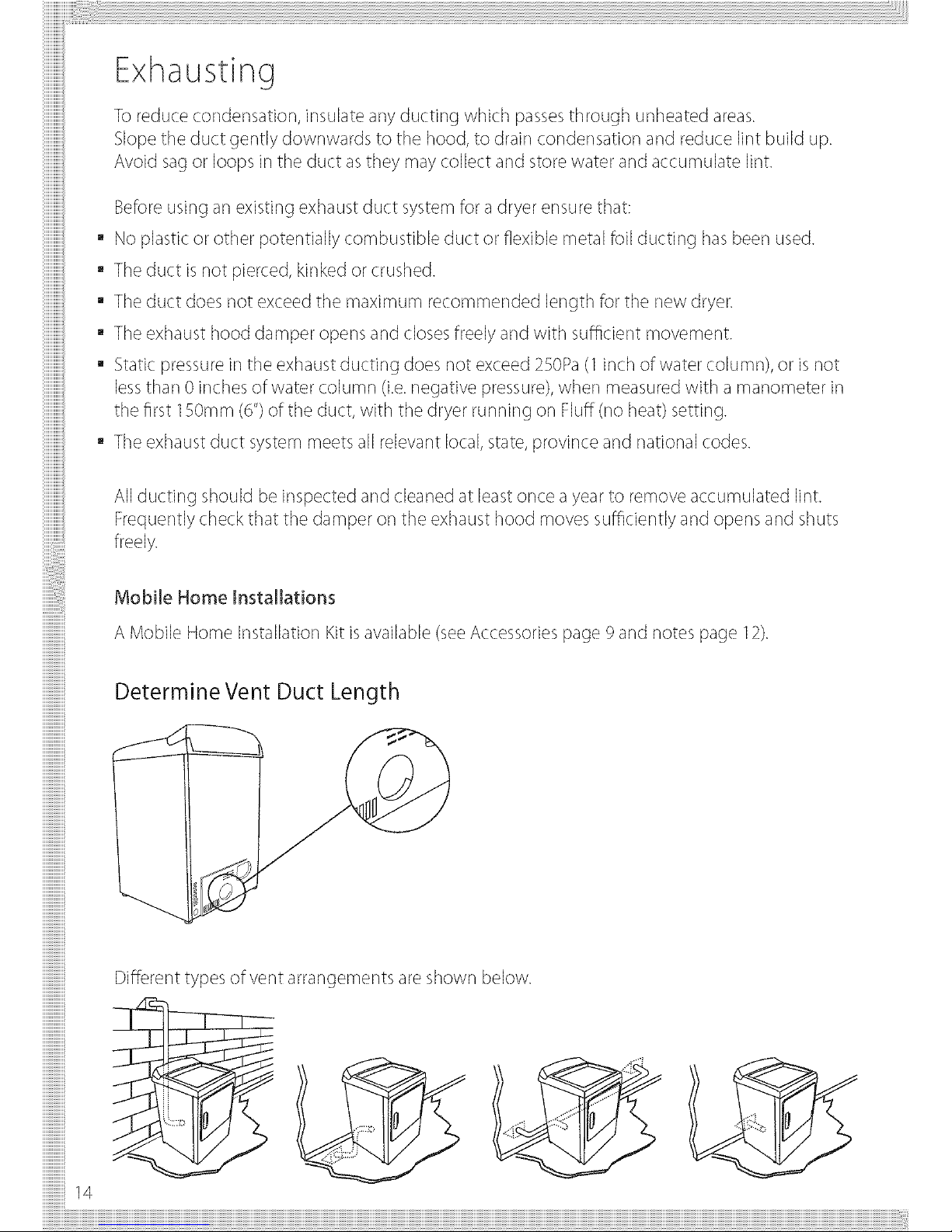

Determine Vent Duct Length

Different types of vent arrangements are shown below.

!!!!!!!!!!!!!!!i

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!14

Exhausting

Choose a route that will provide the straightest and most direct path outdoors. Planthe

installation to use the fewest number of elbows and turns.

When using elbows (rigid duct) or making turns (thick wall flexible metal duct), allow as much

room aspossible. With thick wall flexible metal duct bend duct gradually to avoid kinking and

avoid 90° turns.

recommend_

iiiiiiiiiiiiii

iiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiii

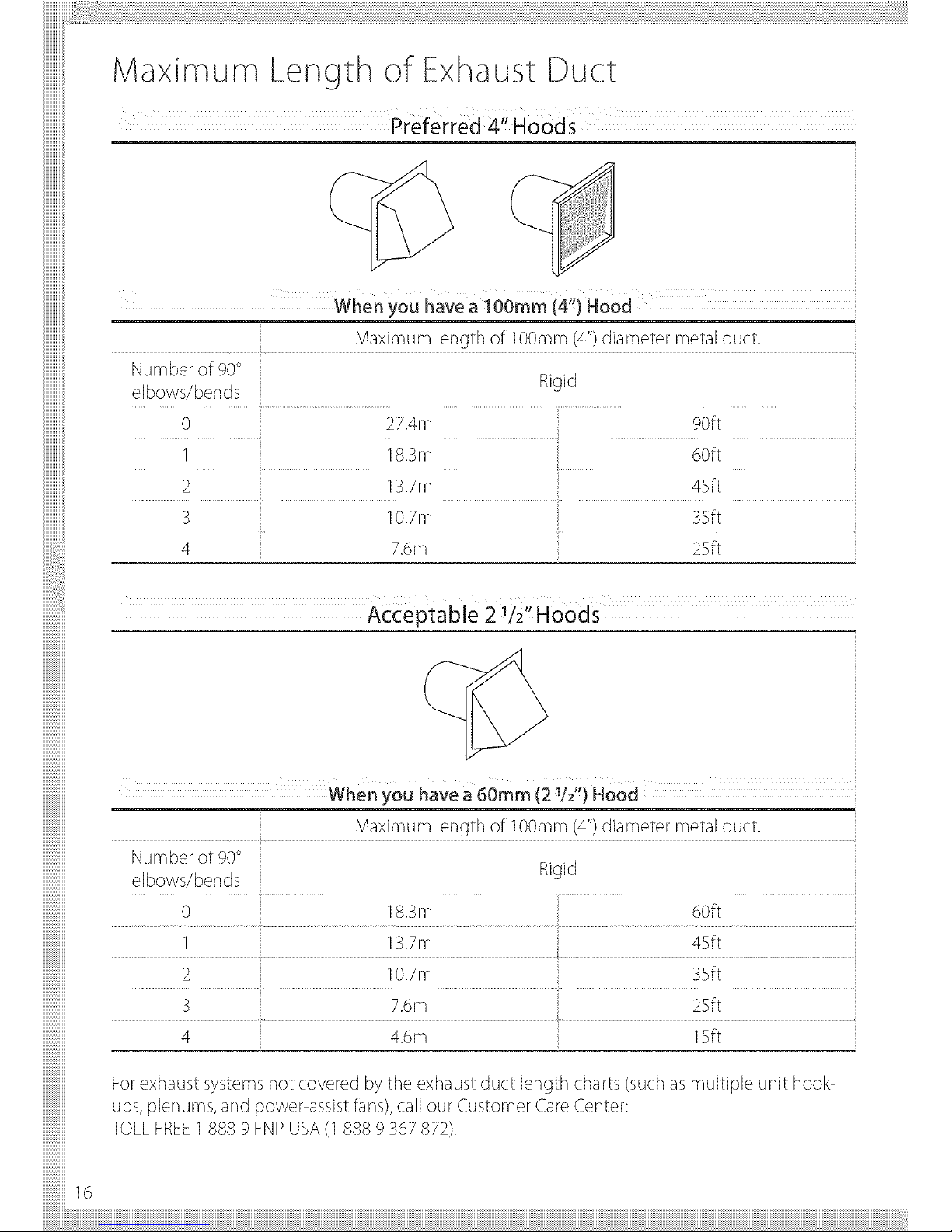

Maximum Length of Exhaust Duct

The maximum length of the exhaust duct system depends upon:

a The type of ducts (rigid or thick walled flexible metal).

The number of elbows or bends used.

1 Refer to the exhaust duct length chart for the maximum duct lengths you carl use. Do not use

duct runs longer than specified in the exhaust duct length charts (refer to next page).

Exhaustduct systemslonger than specified will:

Accumulate lint creating a potential fire hazard.

Shorter] the life of the dryer.

Reduce performance, resulting in longer drying times and an increased energy usage.

;2Determine the number of elbows/bends you will need.

:3In the following table, find the maximum length of rigid metal duct or] the same line as the

number of elbows/bends to be used (refer to next page).

4 The total length of flexible metal duct shall not exceed 2.4m (8 ft).

15

Maximum Length of Exhaust Duct

!!!!!!!!!!!!!!!_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!16

........... When you have a 60rnm (21/2") Hood ....

....... Maximum length of l OOmm(4")diameter metal duct.

Number of 90° Rigid

e!bows/bends..............................................................................................................................................................................

0 18.3m 60ft

......... I ................................. 13.7m ...... .......................45ft .........................................................................................

.................................2..................................................................................................................10.7m..............................................................................................................................................................BSft..................................................................................

3 .... 7.6m .... 25ft

4 4.6m 15ft

Forexhaust systems not covered by the exhaust duct length charts (such asmultiple unit hook

ups, plenums, and power assistfans),call our Customer CareCenter:

TOLLFREEI 888 9 FNPUSA(1888 9 367872).

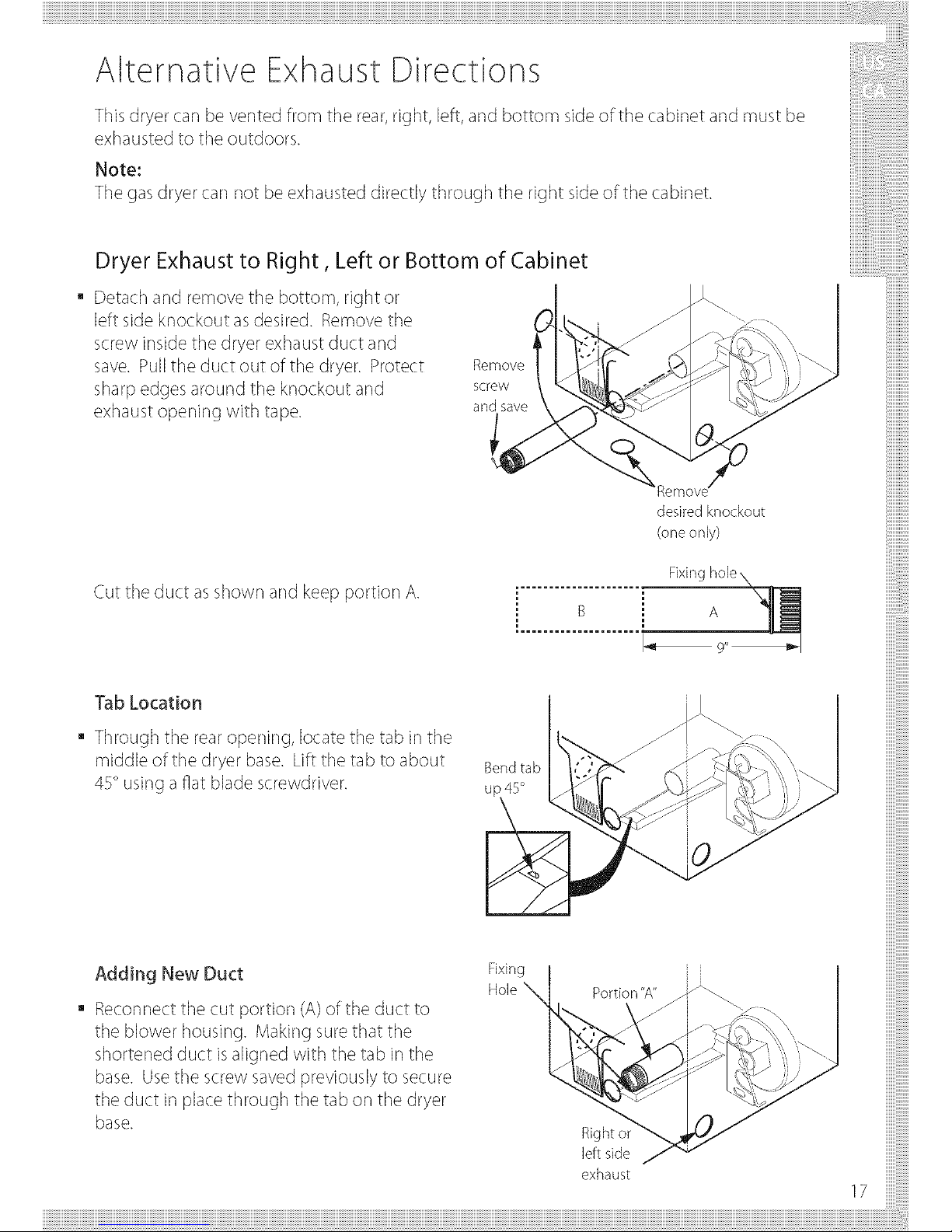

Alternative Exhaust Directions

This dryer car] be vented from the rear, right, left, and bottom sideof the cabinet and must be

exhausted to the outdoors.

Note:

The gas dryer car] not be exhausted directly through the right sideof the cabinet.

Dryer Exhaust to Right, Left or Bottom of Cabinet

a Detach and remove the bottom, right or

left side knockout asdesired. Remove the

screw inside the dryer exhaust duct and

save. Pull the duct out of the dryer. Protect

sharp edges around the knockout and

exhaust opening with tape.

Remove

screw

and save

iiiiiiiiiiiiii

iiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiii

Cut the duct as shown and keep portion A.

desired knockout

(oneonly)

Fixir/g hole

Tab Location

Through the rear opening, locate the tab in the

middle of the dryer base. Lift the tab to about

45° using afiat blade screwdriver.

Bendtab

UF

Adding New Duct

Reconnect the cut portion (A)of the duct to

the blower housing. Making sure that the

shortened duct is aligned with the tab in the

base. Use the screw saved previously to secure

the duct in place through the tab on the dryer

base.

Fixing I

Hole _1 P°rti°n"A"_

exhaust

17

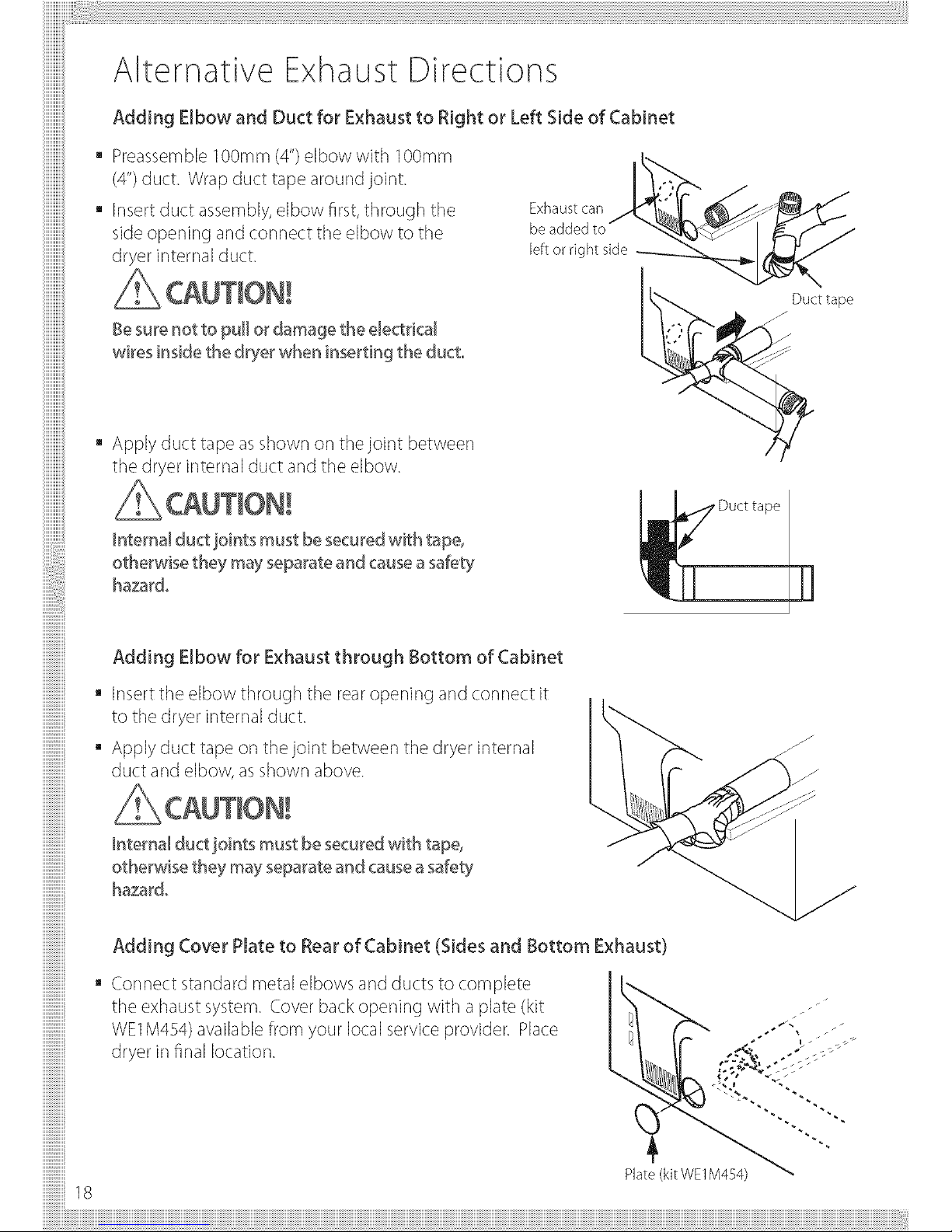

Alternative Exhaust Directions

Adding Elbow and Duct for Exhaust to Right or Left Side of Cabinet

mPreassemble ]OOmm (4")elbow with ]OOmm

(4")duct. Wrap duct tape around joint.

mInsert duct assembly,elbow frst, through the

side opening and connect the elbow to the

dryer internal duct.

Besurenot to pu[[ or damage the electrical

wires inside the dryer when inserting the duct°

• Apply duct tape as shown or] thejoint between

the dryer internal duct and the elbow.

Exhaust can _,__s_i_]4J

beaddedtoj _)_'_" ___--"_j

leftorrightside_______

_"-..,_ .-"Duct tape

.. j"

Internal duct joints must be secured with tape,

otherwise they may separate and cause a safety

hazard.

Duct tape

Adding Elbow for Exhaust through Bottom of Cabinet

• Insert the elbow through the rearopening and connect it

to the dryer internal duct.

• Apply duct tape or] the joint between the dryer internal

duct and elbow, as shown above.

Internal duct joints must be secured with tape,

otherwise they may separate and causeasafety

hazard.

Adding Cover Plate to Rear of Cabinet (Sides and Bottom Exhaust)

• Connect standard metal elbows and ducts to complete

the exhaust system. Cover back opening with a plate (kit

WE1M454) available from your local service provider. Place

dryer in final location.

Plate (kit WE1M454)

Exhaust Venting

Fire Hazard

Use metal exhaust duct°

Do not usea plastic exhaust duct°

Do not usethin metal Dil exhaust ducto

Failuireto do socaniresult in death oirfire°

1 Readthe exhaust section (pages ]3 - 18)before installing the exhaust system to determine the

maximum allowable exhaust duct length.

Do not use sheet metal screwswhen assembling ducting. Always use suitable duct tape. Never

use plastic or thin metal foil flexible exhaust material.

2 The exhaust outlet islocated close to the center of the rear of the dryer. Make sure you join the

exhaust duct to the dryer with duct tape only. This will prevent lint and dust from escaping from

the dryer and exhaust system.

!

@ Exhaust outlet

298mm (11 3/4")

3 The exhaust vent car] be routed up, down, left, right or straight out the back of the dryer. Referto

diagram.

19

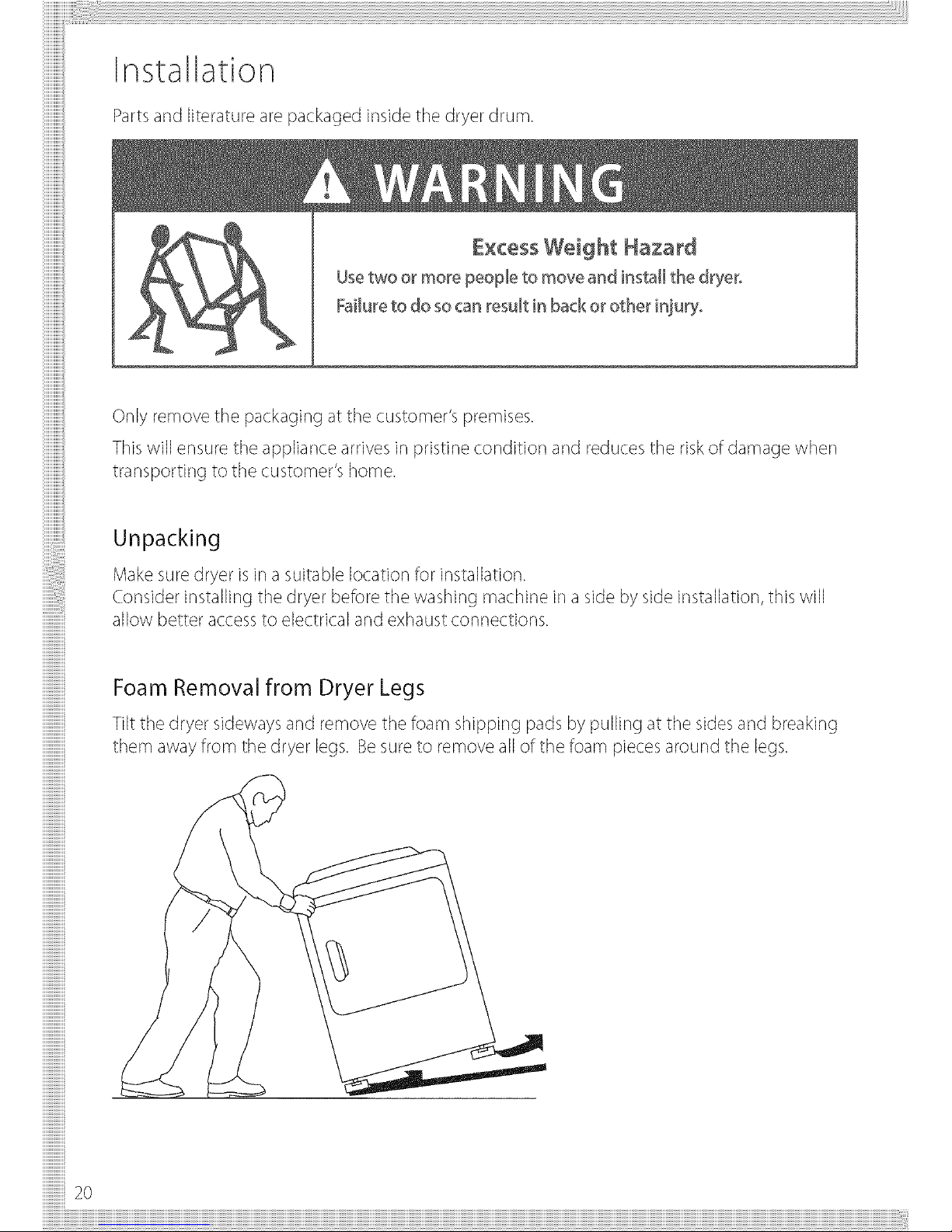

Installation

Partsand literature are packaged inside the dryer drum.

Usetwo or more people to move and install the drye_o

Failureto do socan result [n back or other injury°

Only remove the packaging at the customer's premises.

Thiswill ensure the appliance arrives in pristine condition and reduces the riskof damage when

transporting to the customer's home.

iiiilililililililililililililil

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

!!!!!!!!!!!!!!!_

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!2o

Unpacking

Make sure dryer isin a suitable location for installation.

Consider installing the dryer before the washing machine in aside by side installation, this will

allow better accessto electrical and exhaust connections.

Foam Removal from Dryer Legs

Tilt the dryer sideways and remove the foam shipping pads by pulling at the sidesand breaking

them away from the dryer legs. Besureto remove all of the foam pieces around the legs.

Grounding Instructions for Gasand Electric Dryers

£lect_i¢ Shock Hazard

Make sure appliance iswired or plugged into a grounded out[e'to

Do not usean adaptor°

Do not usean extension cord°

Failureto follow these instructions can result in death, fire,or

electrical shock.

El÷€tHe Shock Hazard

Check with a qualifed electrician or service person if you arein

doubt asto whether the appliance isproperly grounded°

Do not modify the plug if it will not fit the outlet.

Havethe proper outlet installed by aquaJifed e[ectriciano

Failureto follow these instructions can result in death, fire,or

electrical shock°

Grounding for a Cord-Connected Appliance

This appliance must be grounded. Jr]the event of malfunction or breakdown, grounding will

reduce the riskof electric shock by providing a path of least resistancefor electric current.

When this appliance isequipped with a cord having an equipment grounding conductor and a

grounding plug, the plug must be plugged into an appropriate outlet that isproperly installed

and grounded in accordance with all local codes and ordinances, or in their absence,with the

National Electrical Code ANSI/NFPA70,or the Canadian Electrical Code CSAC22.1.

Improper connection of the equipmentogroundin9

conducto_ can result in a risk of electric shock. Check with

aqualified electrician or service representative if you are [n

doubt asto whether the appliance [sproperty grounded°

Referto pages 22 - 24 for wiring details for electric dryers, including the grounding requirements

for a direct wired appliance.

21

Electrical Requirements for Electric Models Only

Usea new UL/_SAapproved 30._ampereDower cord or direct wire

cab[co

Usea ULapproved strain re[[efo

Disconnect Dower before making e[ectrk:a[connect[onso

Connect neutral wire (white or center wire) to center terminal

On a[[four wire installations remove 'thegrounding [ink and

connect the ground wire to the green ground connecting screw°

Connect remaining 2supply wires to remaining 2terminalso

Securely tighten a[[ electrical connections°

Failureto do socan result in death, fire, or electrical shock°

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiilililililililililililililil

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiilililililililililililililil

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!22

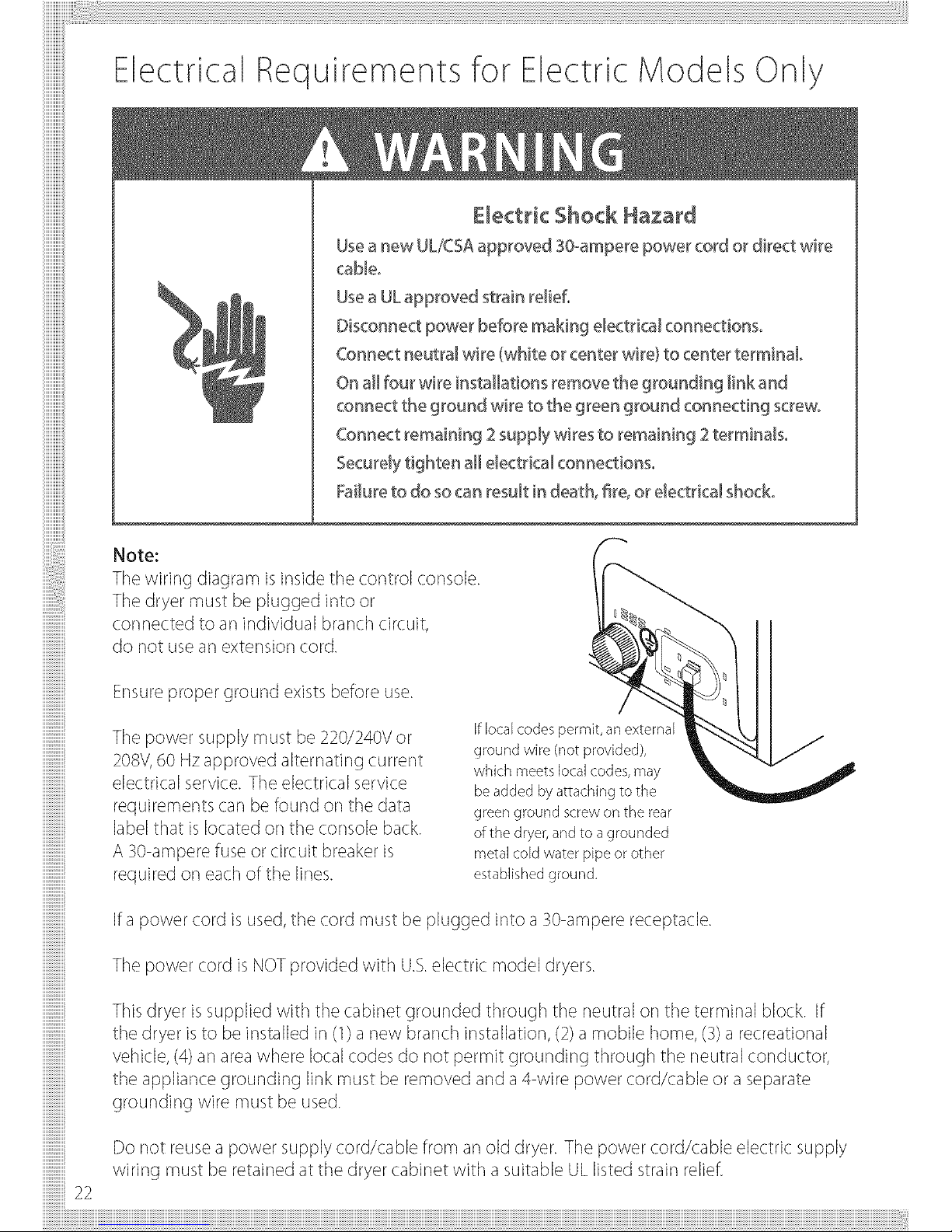

Note:

Thewiring diagram isinside the control console.

The dryer must be plugged into or

connected to an individual branch circuit,

do not usean extension cord.

Ensureproper ground exists before use.

The power supply must be 220/240V or

208V,60 Hzapproved alternating current

electrical service. The electrical service

requirements carl be found on the data

label that islocated or]the console back.

A 30 ampere fuse or circuit breaker is

required or] each of the lines.

if local codes permit, an external

ground wire (not provided),

which meets local codes, may

be added by attaching to the

green ground screw on the rear

of the dryer, and to a grounded

metal cold water pipe or other

established ground.

Ifa power cord is used,the cord must be plugged into a 30 ampere receptacle.

The power cord is NOTprovided with U.S.electric model dryers.

Thisdryer issupplied with the cabinet grounded through the neutral or] the terminal block. If

the dryer isto be installed in(1) a new branch installation, (2)a mobile home, (3)a recreational

vehicle, (4)an area where local codes do not permit grounding through the neutral conductor,

the appliance grounding link must be removed and a4 wire power cord/cable or a separate

grounding wire must be used.

Do not reuse a power supply cord/cable from an old dryer. The power cord/cable electric supply

wiring must be retained at the dryer cabinet with a suitable UL listed strain relief.

Electric Power Supply for Gasand Electric Dryers

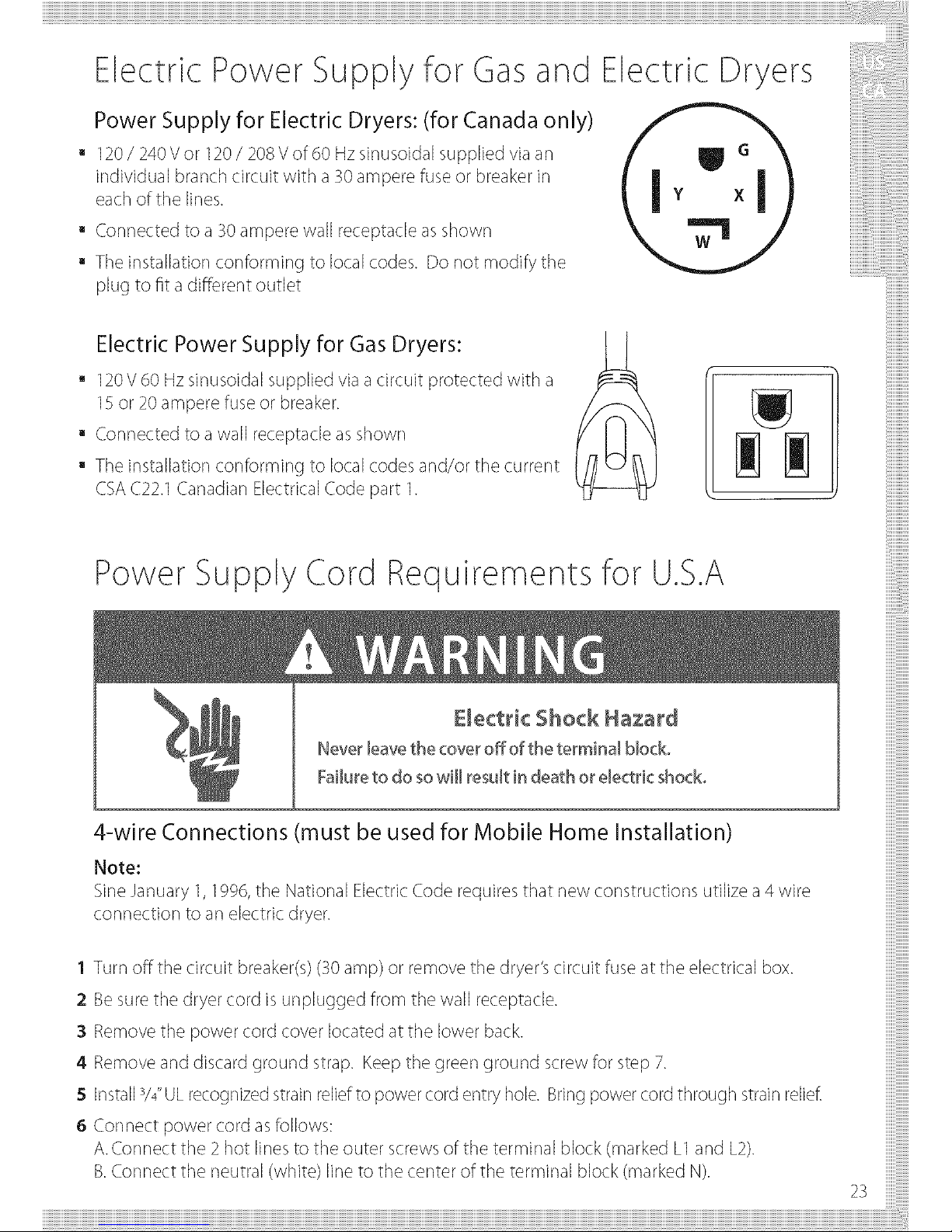

Power Supply for Electric Dryers: (for Canada only)

120/ 240Vor 120/ 208 V of 60 Hzsinusoidal supplied via an

individual branch circuit with a30 ampere fuse or breaker in

eachof the lines.

a Connected to a 30 ampere wall receptacle as shown

a The installation conforming to local codes. Do not modify the

plug to fit a different outlet

iiiiiiiiiiiiii

iiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiii

Electric Power Supply for Gas Dryers:

120V60 Hz sinusoidal supplied via a circuit protected with a

15or 20ampere fuse or breaker.

Connected to a wall receptacle as shown

The installation conforming to local codes and/or the current

CSAC22.1Canadian Electrical Code part 1.

ii

Power Supply Cord Requirements for U.S.A

Emoct_icShockHozo_d

Neve_leave the cove_off of the terminal block°

Failureto do sowill result in death o_dect_'k: shock°

4-wire Connections must be used for Mobile Home Installation)

Note:

SineJanuary 1,1996,the National Electric Code requires that new constructions utilize a 4 ,,ire

connection to an electric dryer.

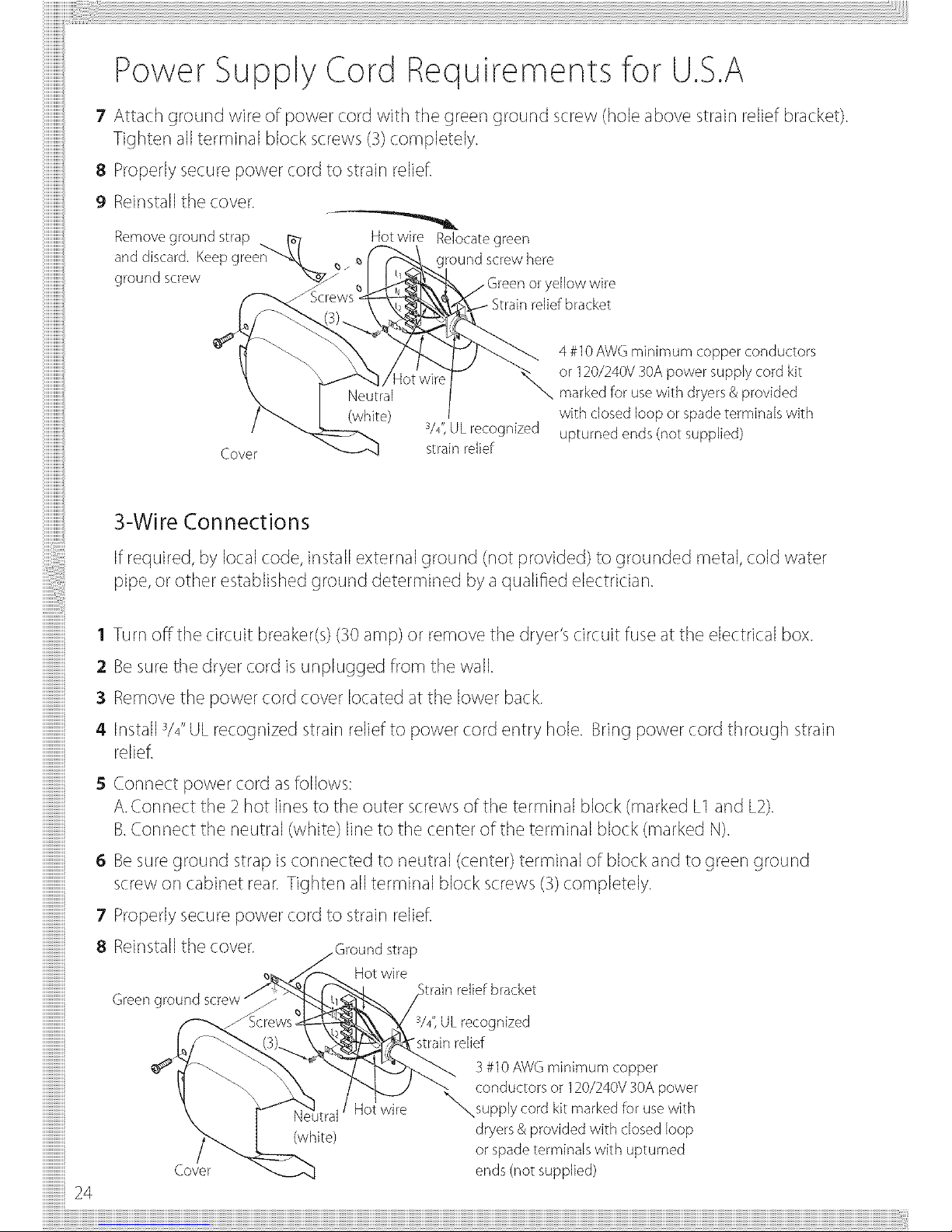

1 Turn off the circuit breaker(s)(30 amp)or remove the dryer's circuit fuse at the electrical box.

2 Besure the dryer cord is unplugged from the wall receptacle.

:3Remove the power cord coverlocatedatthe lower back.

4 Remove and discard ground strap. Keep the green ground screw for step 7.

5 Installs/4"ULrecognizedstrainreliefto power cord entry hole. Bringpower cord through strain relief.

6Connectpowercordasfollows:

A.Connect the 2 hot linesto the outer screwsof the terminal block (marked L1and L2).

B.Connect the neutral (white) line to the center of the terminal block (marked N).

Power Supply Cord Requirements for U.S.A

7 Attach ground wire of power cord with the green ground screw (hole above strain relief bracket).

Tighter] all terminal block screws (3)completely.

8 Properly secure power cord to strain reliefl

9 Reinstallthe cover.

Removeground strap

anddiscard. Kee

ground screw

Hot wire Relocate green

ound screw here

bracket

3/4",UL recognized

Cover strain relief

4 #10 AWG minimum copper conductors

or 120/240V 30A power supply cord kit

marked for use with dryers & provided

with closed loop or spade terminals with

upturned ends (not supplied)

3-Wire Connections

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

B_B_B_B

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

B_B_B_B

iiiilililililililililililililil

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!24

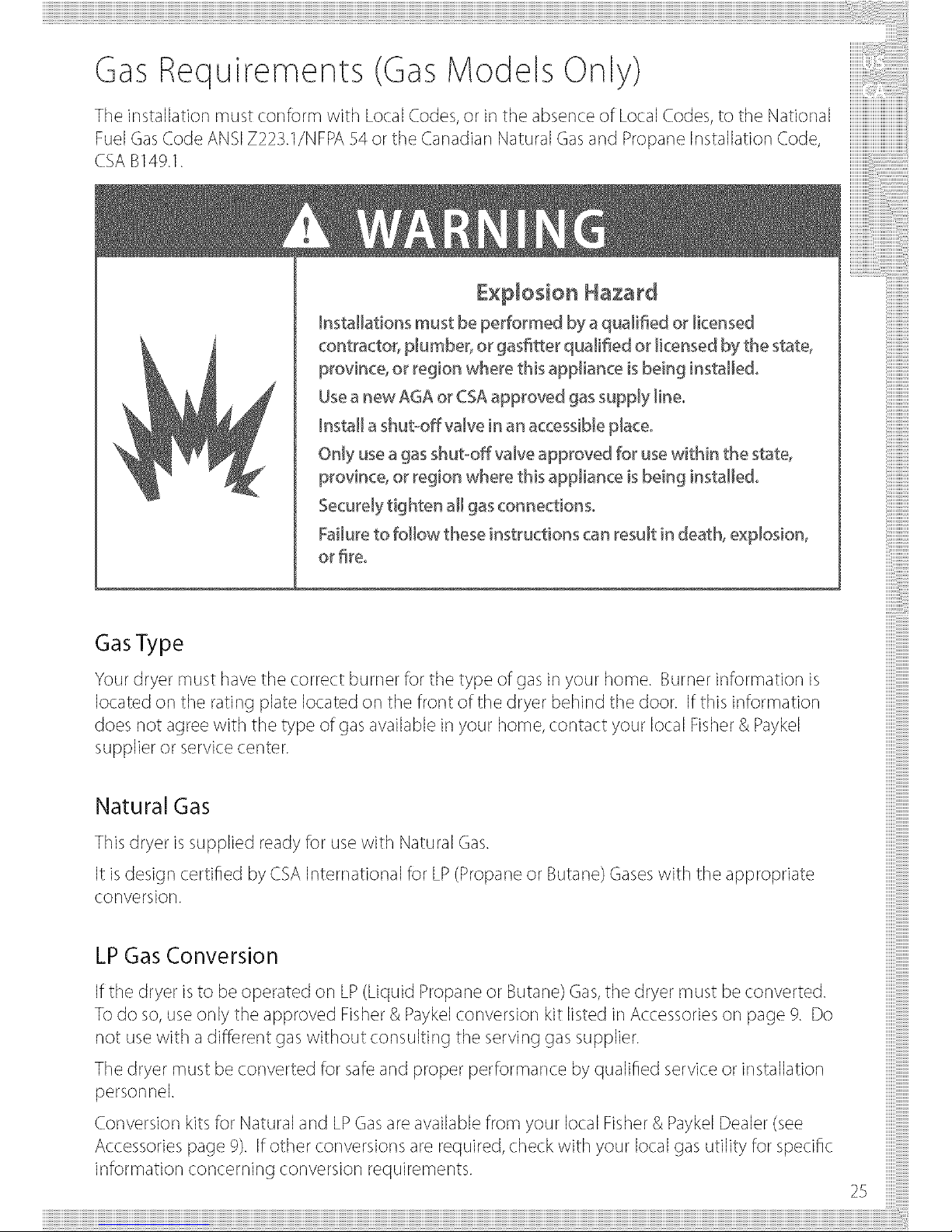

Ifrequired, by local code, install external ground (not provided) to grounded metal, cold water

pipe,or other established ground determined by a qualified electrician.

1 Turn off the circuit breaker(s) (30 amp) or remove the dryer's circuit fuse at the electrical box.

2 Besure the dryer cord isunplugged from the wall.

3 Removethe power cord cover located at the lower back.

4 Jr]stallV4"ULrecognized strain relief to power cord entry hole. Bring power cord through strain

relief.

5 Cor]nect power cord asfollows:

A.Connect the 2 hot linesto the outer screws of the terminal block (marked L1and L2).

B.Connect the neutral (white) line to the center of the terminal block (marked N).

6 Besure ground strap isconnected to neutral (center) terminal of block and to green ground

screw or] cabinet rear.Tighter] all terminal block screws (3)completely.

7 Properly secure power cord to strain relief.

8 Reinstallthe cover, strap

Hot wire

Green ground

Cover

(white)

ot wire

W', ULrecognized

"strainrelief

3#10AWGminimum copper

conductors or 120/240V30A power

supplycord kit markedfor usewith

dryers&provided with closed loop

or spadeterminals with upturned

ends(not supplied)

Theinstallationmustco ]formwithLocalCodes,orit]theabsenceofLocalCodes,totheNatio ]aliiiiiiiii!!!!!!iii

FuelGasCodeANSiZ22S._/NFPAS4ortheCanadianNaturalC_asandPropaneInstaUat_onCode,

CSAB149.1.

£×D[osion Hazard

installations must be performed by aqua[i_ed or licensed

contractor, plumber, or gas_tter qualified or licensed by the stat÷_

province, or region where this appliance isbeing installed°

Useanew AGA or CSAapproved gassupply [ineo

Insta[[a shuboff vaJvein an accessibJep[aceo

OnJyusea gas shut-off vaJveapproved for usewithin the stat÷_

province, or region where this appJianceisbeing instaJJedo

Securely tighten a[[ gasconnections°

Failureto follow these instructions can result in death, e×pJosion_

or _reo

GasType

Your dryer must have the correct burner for the type of gas in your home. Burner information is

located or] the rating plate located or] the front of the dryer behind the door. Ifthis information

does not agree with the type of gasavailable in your home, contact your local Fisher& Payke[

supplier or service center.

Natural Gas

This dryer issupplied ready for usewith Natural Gas.

It isdesign certified by CSA International for LP(Propane or Butane) Gaseswith the appropriate

conversion.

LP Gas Conversion

Ifthe dryer isto be operated or] LP(Liquid Propane or Butane) Gas,the dryer must be converted.

Todo so,use only the approved Fisher& Payke[conversion kit listed in Accessories or] page 9. Do

not usewith a different gas without consulting the serving gas supplier.

The dryer must be converted for safeand proper performance by qualified service or installation

personne[.

Conversion kits for Natural and LPGasareavailable from your local Fisher& PaykelDealer (see

Accessories page 9). If other conversions are required, check with your local gas utility for specific

information concerning conversion requirements.

25

Connecting Gasto Your Dryer (GasModels Only)

Usecompound or thread tape appropriate to the gas type that isto be used (Natural or LPGas),

or] the male threads of all non flared connections.

Never usean open flame to test for gas leaks.

This dryer will operate satisfactorily up to altitudes of 2000m (6SOOft)above sealevel at the

BTUrating indicated on the model/serial plate. Burner input adjustments may be required if

operating above this elevation.

The dryer must be isolated from the gas supply piping system by closing the supply shut off

valve during any pressuretesting of the gas supply piping system.

Gas Ignition

This dryer hasan automatic ignition system to ignite the burner. There is no pilot flame burning

in this dryer.

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiilililililililililililililil

iiiilililililililililililililil

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiiiiiiiiiiiii

iiiiiiiiiiiiiii

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!26

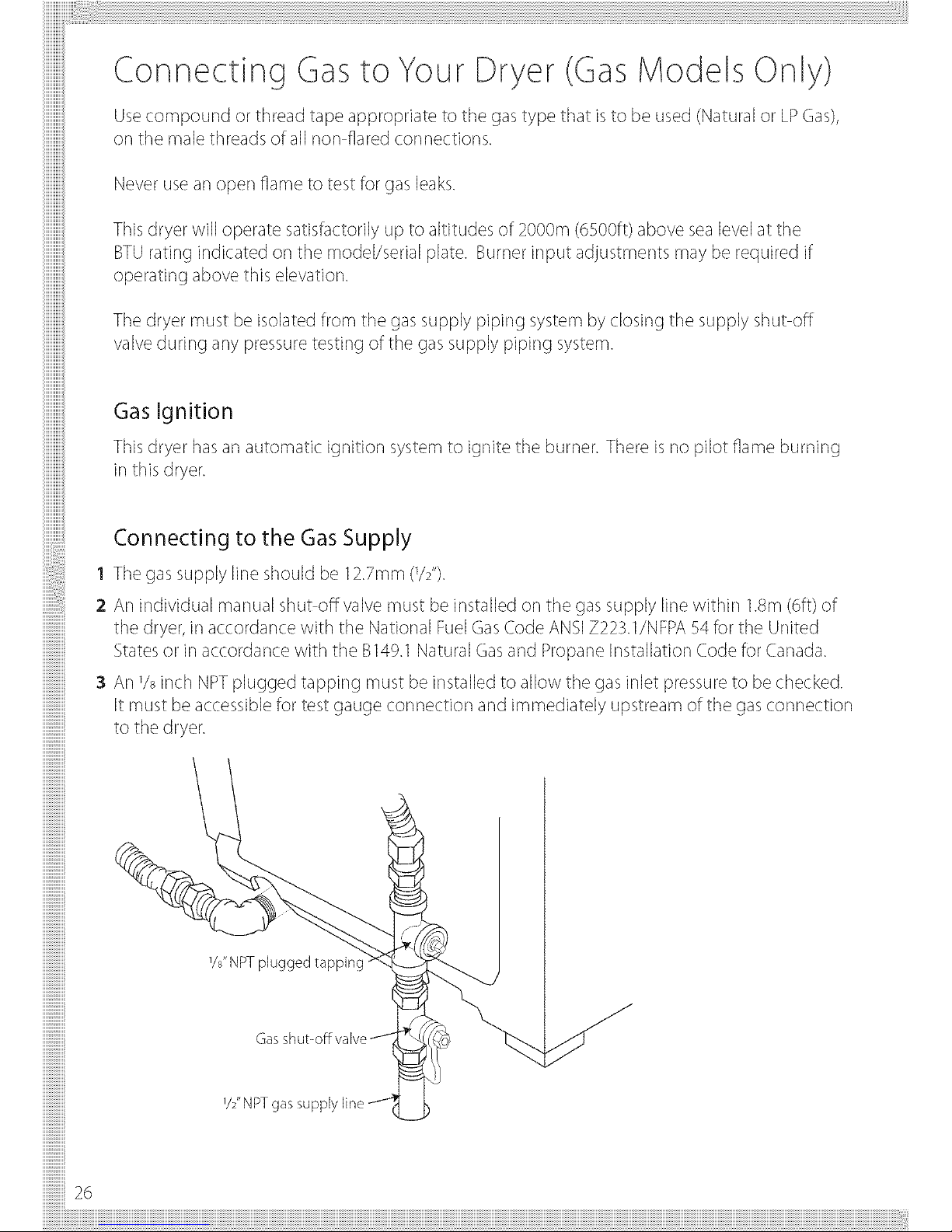

Connecting to the Gas Supply

1 The gas supply line should be 12.7mm (1/2'%

2 An individual manual shut off valve must be installed on the gas supply line within 1.8m(6ft) of

the dryer, in accordance with the National FuelGasCode ANSIZ223.1/NFPA 54 for the United

Statesor in accordance with the B149.1Natural Gasand Propane Installation Code for Canada.

3 An % inch NPTplugged tapping must be installed to allow the gas inlet pressure to be checked.

it must be accessible for test gauge connection and immediately upstream of the gasconnection

to the dryer.

%" NPT plugged tapping

V2"NPT

Connecting Gasto Your Dryer (GasModels Only)

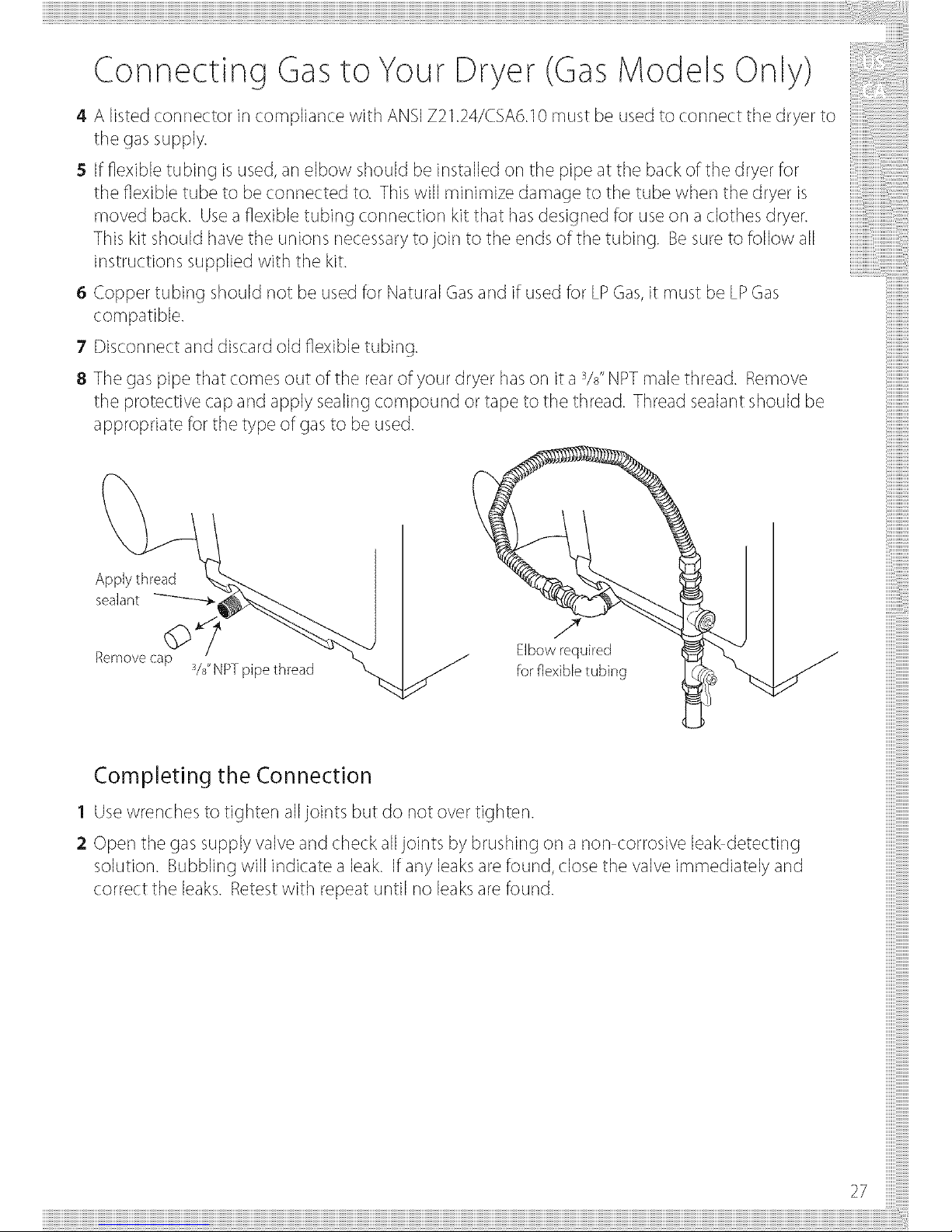

4 A listed connector in compliance with ANSIZ21.24/CSA6.10 must be used to connect the dryer to

the gas supply.

5 If flexible tubing is used,an elbow should be installed on the pipe at the back of the dryer for

the flexible tube to be connected to. This will minimize damage to the tube when the dryer is

moved back. Useaflexible tubing connection kit that hasdesigned for useor] a clothes dryer.

This kit should have the unions necessary to join to the ends of the tubing. Besure to follow all

instructions supplied with the kit.

6 Copper tubing should not be used for Natural Gasand if used for LPGas,it must be LPGas

compatible.

7 Disconnect and discard old flexible tubing.

8 The gas pipe that comes out of the rear of your dryer hasor] it a sA"NPTmale thread. Remove

the protective cap and apply sealing compound or tape to the thread. Thread sealant should be

appropriate for the type of gasto be used.

' %" NPT pipe thread %

S

Elbowrequired

forflexibletubing

ijjjjjjjjjjjjjjjJ_iii_

Completing the Connection

1 Use wrenches to tighter] all joints but do not over tighter].

2 Open the gas supply valve and check alljoints by brushing or] a non corrosive lea_detecting

solution. Bubbling will indicate a leak. If any leaks arefound, close the valve immediately and

correct the leaks. Retest with repeat until no leaksarefound.

27

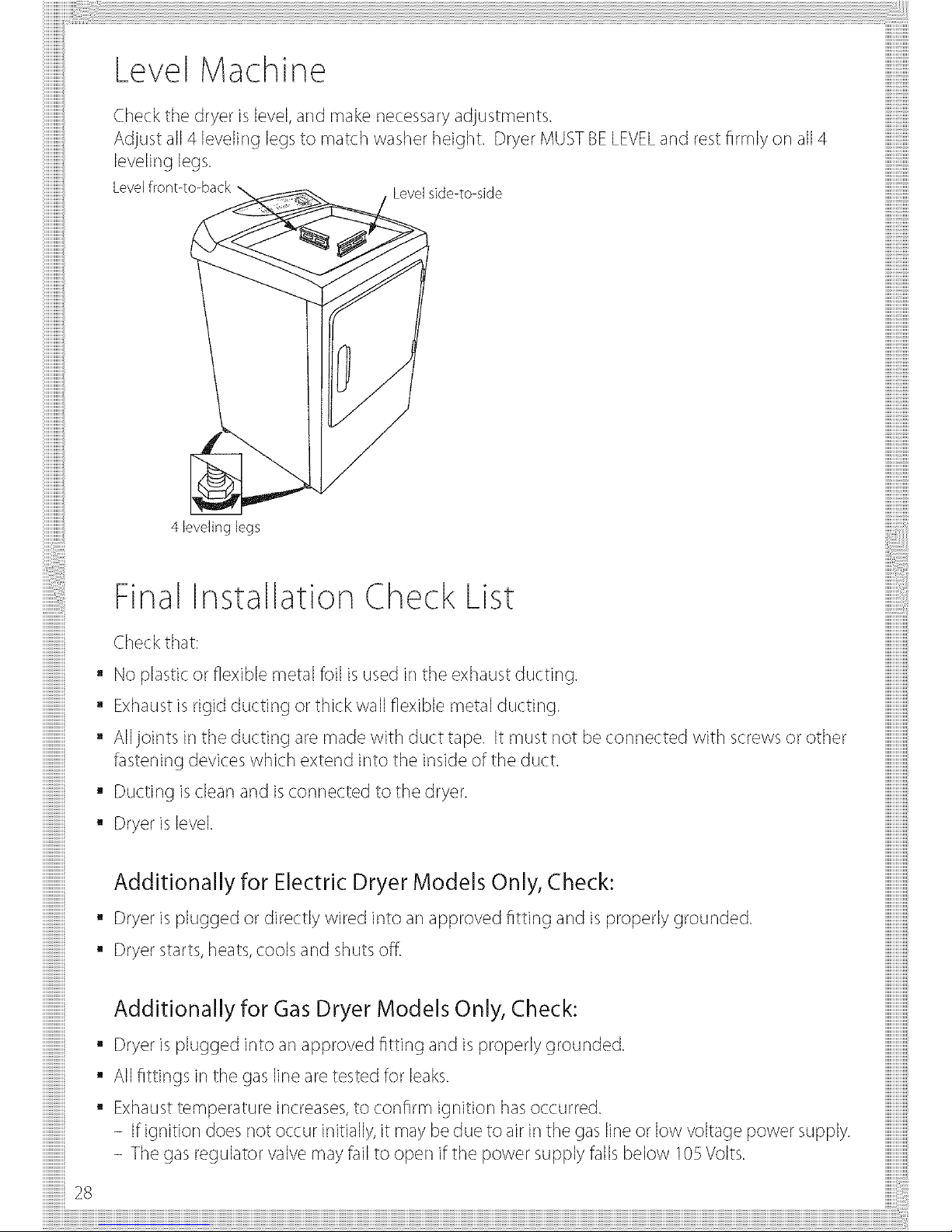

Final Installation Check List

Check that:

• No plastic or flexible metal foil isused in the exhaust ducting.

• Exhaustis rigid ducting or thick wall flexible metal ducting.

• All joints in the ducting are made with duct tape. It must not be connected with screws or other

fastening devices which extend into the inside of the duct.

• Ducting is clear] and isconnected to the dryer.

• Dryer is level.

Additionally for Electric Dryer Models Only, Check:

• Dryer is plugged or directly wired into an approved fitting and is properly grounded.

• Dryer starts,heats,cools and shuts off

Additionally for Gas Dryer Models Only, Check:

• Dryer is plugged into an approved fitting and is properly grounded.

• All fittings in the gas line are tested for leaks.

• Exhausttemperature increases,to confirm ignition hasoccurred.

- If ignition does not occur initially, it may be due to air in the gas line or low voltage power supply.

- The gas regulator valve may fail to open if the power supply falls below 105Volts.

Features

Extra Care

• Use this option to minimize the wrinkles in clothes. This option provides

approximately 15minutes of no heat tumbling after the clothes aredry.

This option car] only be used with the Automatic cycles.

Hint: If the Signal option is selected, the Signal will sound at the end of the drying

time and will sound severaltimes during the ExtraCarecycle. This will remind you

that the cycle iscomplete.

o

Signal

This signal will sound just before the end of the cycle to remind you to remove the

clothes.

Ifyou selected the ExtraCareoption a signal will sound a the end of the drying

time and will sound severaltimes during the ExtraCarecycle.

This will remind you that the dry cycle iscomplete and you should remove your

clothes.

Note:

• Removegarments promptly at the sound of the signak Placeclothes or] hangers

so wrinkles won't set in.

• Usethe Signal especially when drying fabrics like polyester knits and permanent

press.These fabrics should be removed promptly so wrinkles won't set in.

o

Reset Options

Selecting ResetOptions canceB all options that have beer] selected.

Drum Lamp

A handy light inside the dryer to help make unloading easier.

Drying Rack (Optional or] some models)

A handy drying rack may be used for drying articles such as stuffed

toys, pillows or washable sweaters.

Hook the rack over the lint filter so the rackextends into the dryer

drum.

Note:

The drying rack must be used with the Timed cycle. Do not use this

drying rack when there are other clothes in the dryer.

\\

29

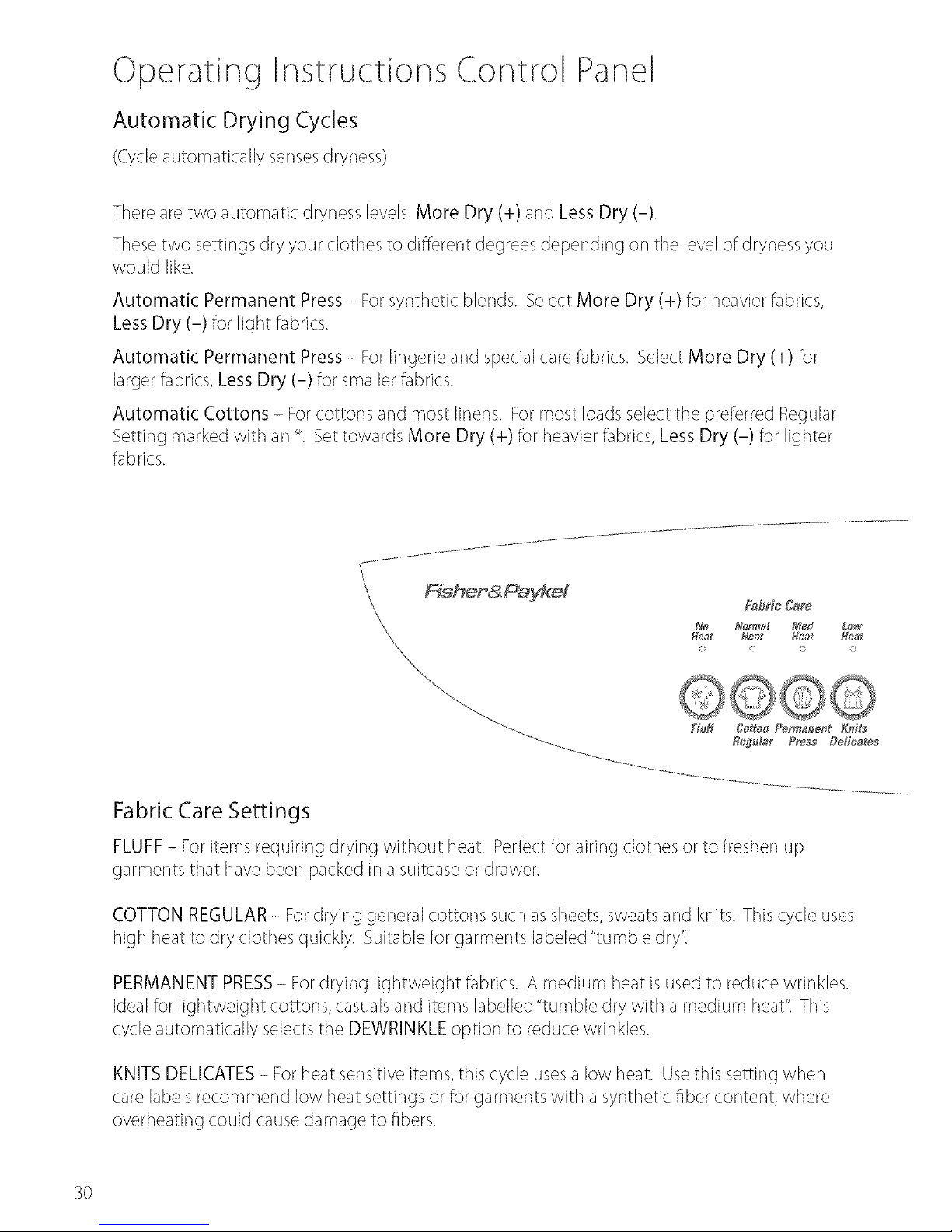

Operating Instructions Control

Automatic Drying Cycles

(Cycleautomatically sensesdryness)

Panel

There aretwo automatic dryness levels:More Dry (+) and Less Dry (-).

Thesetwo settings dry your clothes to different degrees depending or] the level of dryness you

would like.

Automatic Permanent Press - Forsynthetic blends. Select More Dry (+) for heavier fabrics,

Less Dry (-) for light fabrics.

Automatic Permanent Press - Forlingerie and special care fabrics. Select More Dry (+) for

larger fabrics, Less Dry (-) for smaller fabrics.

Automatic Cottons - Forcottons and most linens. For most loads select the preferred Regular

Setting marked with an _. Settowards More Dry (+) for heavier fabrics, Less Dry (-) for lighter

fabrics.

_ii \ F_bdc Cam

Ha Hem'm_ Mad Lew

\ Heat Hea_ Heat Heet

<:) , <:

RuH C#H## Pem_#e#¢ KM_

_eg_ r Press Dd_eaCes

Fabric Care Settings

FLUFF- Foritems requiring drying without heat. Perfect for airing clothes or to fresher] up

garments that have beer] packed in asuitcase or drawer.

COTTON REGULAR- Fordrying general cottons such as sheets, sweatsand knits. This cycle uses

high heat to dry clothes quickly. Suitable for garments labeled "tumble dry't

PERMANENT PRESS- Fordrying lightweight fabrics. A medium heat is used to reduce wrinkles.

Ideal for lightweight cottons, casualsand items labelled "tumble dry with a medium heat't This

cycle automatically selectsthe DEWRINKLE option to reduce wrinkles.

KNITS DELICATES- For heat sensitive items, this cycle usesa low heat. Usethis setting when

care labels recommend low heat settings or for garments with a synthetic fiber content, where

overheating could causedamage to fibers.

3O

Loading...

Loading...