Fisher & Paykel DishDrawer DD24D Series, DishDrawer DD24S Series, DishDrawer DD60D Series, DishDrawer DD60S Series Service Manual

Service Manual

DishDrawer™

Models:

DD24D

DD24S

DD60D

DD60S

599735A

599735A

2

599735A - APRIL 2009

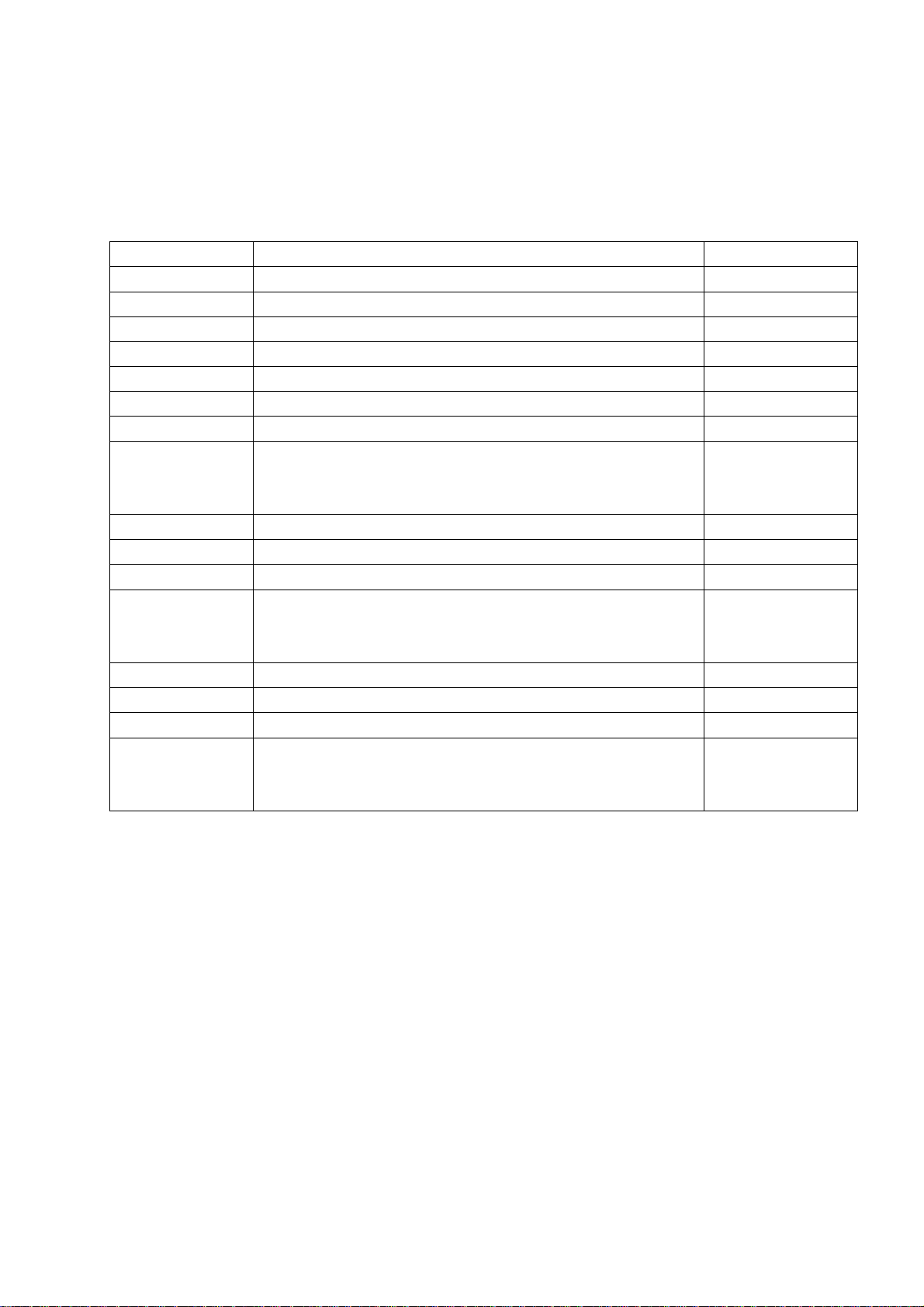

PRODUCTS

Brands Fisher & Paykel

DCS

Standard Product Codes

Double Models Description – Markets

DD24DCB6 Double, Prefinished Black 88531 - US

DD24DCW6 Double, Prefinished White 88526 - US

DD24DCX6 Double, Prefinished Brushed Stainless 88527 - US

DD24DDFX6 Double, Designer, Brushed Stainless 88532 - US

DD24DI6 Double, Integrated 88529 - US

DD60DCB6 Double, Prefinished Black 80576 - NZ/AU

DD60DCHB6 Double, Prefinished Black, Water Softener 89227 - GB

DD60DCHW6 Double, Prefinished White, Water Softener 89240 - DK

DD60DCHX6 Double, Brushed Stainless, water softener 89225 - GB

89241 - DK

89234 - EU

DD60DCM6 Double, Iridium Stainless 80591 - NZ/AU

DD60DCW6 Double, Prefinished White 80588 - NZ/AU

DD60DCX6 Double, Brushed Stainless 80589 - NZ/AU

DD60DDFHX6 Double, Designer, Brushed Stainless, Water Softener 89228 - GB

89236 - EU

89243 - DK

DD60DDFM6 Double, Designer, Iridium 80592 - NZ/AU

DD60DDFX6 Double, Designer, Brushed Stainless 80593 - NZ/AU

DD60DI6 Double, Integrated 80590 - NZ/AU

DD60DIH6 Double, Integrated, Water Softener 89226 - GB

89235 - EU

89242 - DK

3

599735A

Standard Product Codes

Single Models Description – Markets

DD24SCW6 Single, prefinished, white 88519 - US

DD24SCX6 Single, prefinished, Brushed Stainless 88520 - US

DD24SCB6 Single, prefinished, Black 88524 - US

DD24SI6 Single Integrated 88522 - US

DD24SDFX6 Single, designer, Brushed Stainless 88525 - US

DD60SCHW6 Single, Prefinished White, Water Softener 89229 - GB

89244 - DK

DD60SCHX6 Single, Brushed Stainless, Water Softener 89230 - GB

89237 - EU

89245 -DK

DD60SIH6 Single, Integrated, Water Softener 89231 - GB

89238 - EU

89246 - DK

DD60SCHB6 Single, Prefinished Black, Water Softener 89232 - GB

DD60SDFHX6 Single, Designer, Brushed Stainless, Water Softener 89233 - GB

89239 - EU

89247 - DK

DD60SCHLI6 Single, Integrated, Long Door 89248 - DK

DD60SDFM6 Single, Designer, Iridium Stainless 80601 - NZ/AU

DD60SDFX6 Single Designer, Brushed Stainless 80602 - NZ/AU

DD60SI6 Single, Integrated 80596 - NZ/AU

DD60SCB6 Single, Prefinished Black 80583 - NZ/AU

DD60SLX6 Single, Brushed Stainless 80597 - NZ/AU

DD60SCM6 Single, Iridium Stainless 80600 - NZ/AU

DD60SLFX6 Single, Long Door 80603 - NZ/AU

DD60SCHW6 Single, Water Softener, Prefinished White 89173 -TW

DD60SCHX6 Single, Water Softener, Brushed Stainless 89174 - TW

DD60SIH6 Single , Water Softener, Integrated 89175 - TW

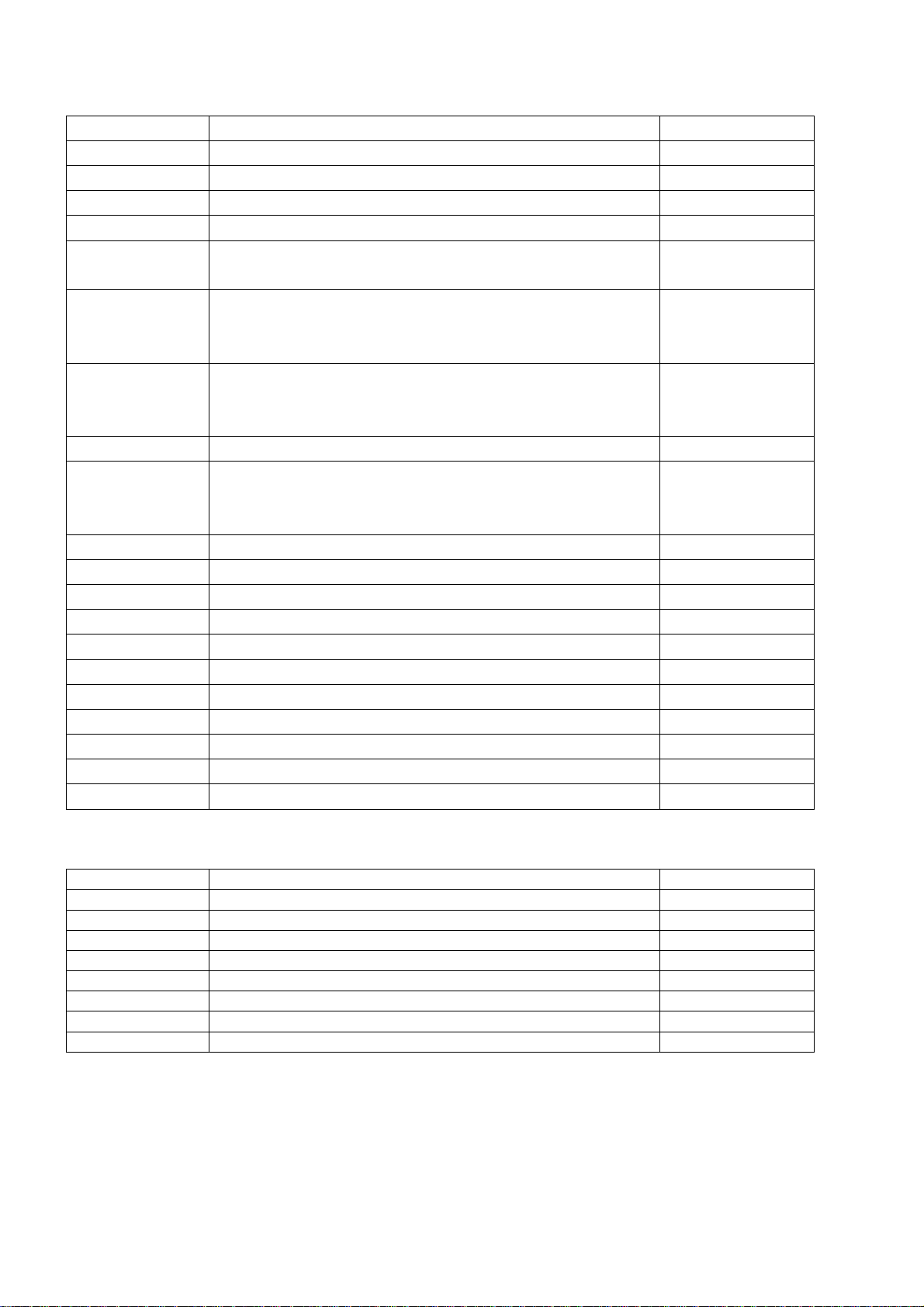

Tall Tub Product Codes

Double Models Description – Markets

DD24DDFTX6 Double Designer, Brushed Stainless Tall Tub 88502 - US

DD24DTI6 Double Integrated, Tall Tub 88504 - US

DD24DCCTX6 Double Curved Door, Curved Handle, Tall Tub 88518 - US

DD24DCTX6 Double, Brushed Stainless, Tall Tub 88511 - US

DD24DCHTX6 Double, Brushed Stainless, Water Softener 88528 - US

DD24DHTI6 Double, Integrated, Water Softener 88530 - US

DD24DCTW6 Double, Tall Tub, Prefinished White 88514 - US

DD24DCTB6 Double, Tall Tub, Prefinished Black 88509 - US

DD24DUT Double, Tall Tub 88542 - DCS US

4

599735A

Tall Tub Product Codes

Single Models Description – Markets

DD24SDFTX6 Single, Designer, Tall Tub, Brushed Stainless 88503 - US

DD24STI6 Single Integrated, Tall Tub 88505 - US

DD24SCTX6 Single, Brushed Stainless Steel 88512 - US

DD24SCCTX6 Single Curved Door, Curved Handle, Tall Tub 88513 - US

DD24SCTW6 Single, Tall Tub, Prefinished White 88515 - US

DD24SCTB6 Single, Tall Tub, Black 88510 - US

DD24SCHTX6 Single, Brushed Stainless, Water Softener, Tall Tub 88521 - US

DD24SHTI6 Single, Integrated, Water Softener, Tall Tub 88523 - US

DD60SHTI6 Single, Integrated, Tall Tub, Water Softener 89271 - GB

89273 - EU

89275 - DK

DD60SDFHTX6 Single, Designer, Brushed Stainless, Tall Tub, Water

Softener.

89272 - EU

89274 – DK

89270 - GB

DD60SDFTX6 Single, Designer, Brushed Stainless, Tall Tub 80644 - NZ/AU

DD60SDFTM6 Single, Designer, Iridium Stainless, Tall Tub 80645 - NZ/AU

DD60STI6 Single Integrated, Tall Tub 80646 - NZ/AU

DD24SUT Single, Tall Tub 88541 - DCS US

The specifications and servicing procedures outlined in this manual are subject to change without

notice.

The latest version is indicated by the reprint date, and replaces any earlier versions.

Fisher & Paykel Appliances Ltd

78 Springs Road,

East Tamaki,

PO Box 58-732, Greenmount,

Auckland,

New Zealand

Phone: 09 273 0600

Fax: 09 273 0656

Email: customer.care@fp.co.nz

Fisher & Paykel Appliances

Unit D2

North Dublin Corporate Park

Swords

Co Dublin

Ireland

Telephone: 1800 625 174

Facsimile: 1800 635 012

E-mail: customer.care@fisherpaykel.ie

Fisher & Paykel Customer Services Pty Ltd

PO Box 798, Cleveland, QLD 4163

A.C.N. 003 3335 171

19 Enterprise Street

Cleveland, QLD 4163

Australia

Telephone: (07) 3826 9100

Facsimile: (07) 3826 9164

E-mail: customer.care@fp.com.au

Fisher & Paykel Appliances Inc

5800 Skylab Rd,

Huntington Beach

California, CA92647

USA

Telephone: 888 936 7872

E-mail: customer.care@fishpaykel.com

5

Fisher & Paykel Appliances Ltd U.K

Maidstone Road

Kingston

Milton Keynes

Buckinghamshire

MK10 0BD

England

Telephone: 0845 066 2200

Facsimile: 0845 331 2360

E-mail:

customer.care@fisherpaykel.co.uk

599735A

CONTENTS

1 SERVICE REQUIREMENTS......................................................................................................9

1.1 Health & Safety....................................................................................................................9

1.1.1 Electrical Safety .............................................................................................................9

1.1.2 Electrostatic Discharge ..................................................................................................9

1.1.3 Good Working Practices ................................................................................................9

1.1.4 Isolate Water Supply......................................................................................................9

1.1.5 Water Leak Check .........................................................................................................9

1.1.6 Insulation Test................................................................................................................9

1.1.7 Solvent and Excessive Heat Damage............................................................................ 9

1.1.8 Sheet Metal Edges......................................................................................................... 9

1.1.9 Diagnostics ..................................................................................................................10

1.2 Specialised Tools ..............................................................................................................10

1.2.1 Static Strap ..................................................................................................................10

1.2.2 Fisher & Paykel Smart Tool .........................................................................................10

2 DIMENSIONS & SPECIFICATIONS........................................................................................11

2.1 Dimensions ........................................................................................................................11

2.2 Specifications ....................................................................................................................11

2.2.1 Electrical ......................................................................................................................11

2.2.2 Components................................................................................................................. 11

2.2.3 Performance ................................................................................................................13

2.2.4 Wash Profiles...............................................................................................................13

3 TECHNICAL OVERVIEW ........................................................................................................15

1.1 Chassis ..............................................................................................................................15

1.2 Drawer Fronts ....................................................................................................................15

3.1 Electronics .........................................................................................................................15

3.1.1 Tub Home Sensor........................................................................................................16

3.1.2 Touch Switches............................................................................................................ 16

3.2 Motor..................................................................................................................................16

3.2.1 Rotor ............................................................................................................................16

3.2.2 Spray Arm .................................................................................................................... 16

3.3 Wiring Cover ......................................................................................................................16

3.4 Lid System .........................................................................................................................16

3.4.1 Lid Operation ...............................................................................................................16

3.4.2 During a Power Failure ................................................................................................17

3.5 Tub.....................................................................................................................................17

3.6 Filling .................................................................................................................................17

3.6.1 Water Inlet.................................................................................................................... 17

3.6.2 Dispensing Detergent and Rinse-aid ...........................................................................17

3.6.3 Amount of Water .......................................................................................................... 18

3.6.4 Flood Protection...........................................................................................................18

3.7 Heating ..............................................................................................................................18

3.7.1 The Heating Element ...................................................................................................18

3.7.2 Heating the Water ........................................................................................................ 18

3.7.3 Maintaining the Temperature ....................................................................................... 18

3.7.4 Overheat Protection ..................................................................................................... 18

3.8 Motor and Heater Plate Locknuts ......................................................................................18

3.9 Drain Cycle ........................................................................................................................19

3.10 Filter Plate..........................................................................................................................19

3.10.1 The Filter System........................................................................................................19

3.10.2 Removing and Cleaning the Drain Filter and Filter Plate............................................ 19

3.11 Drying Cycle ......................................................................................................................19

3.12 Water Softener (Where Fitted)...........................................................................................20

3.12.1 Delivering Softened Water..........................................................................................20

3.12.2 Regeneration ..............................................................................................................20

3.12.3 Salt..............................................................................................................................20

6

599735A

4

OPTION ADJUSTMENT MODE..............................................................................................21

4.1 Rinse Aid Setup (rA)..........................................................................................................21

4.2 Water Supply Hardness Setup (hd)...................................................................................21

4.3 Auto Power Option (AP) .................................................................................................... 22

4.4 End of Cycle Beeps (EC) .................................................................................................. 22

4.5 Closed Drawer Option (Ld)................................................................................................22

4.6 Clean/Dirty Dish Symbol (dS)............................................................................................22

4.6.1 Option Adjustment Quick Reference Charts................................................................ 23

5 DIAGNOSTICS ........................................................................................................................25

5.1 DishDrawer™ Diagnostics ................................................................................................ 25

5.1.1 Optical LED Download / Fault Display......................................................................... 25

5.1.2 Clearing Fault Logs...................................................................................................... 25

5.1.3 Hardware Output Diagnostic Test Mode...................................................................... 26

5.1.4 Fast Test Cycle............................................................................................................ 27

5.1.5 Continuous Cycle Test Mode....................................................................................... 28

5.1.6 Cycle Count Retrieval .................................................................................................. 28

5.1.7 Temperature & Voltage Display Mode......................................................................... 28

5.1.8 Show Off / Showroom Wash Mode.............................................................................. 29

5.2 Diagnostics Quick Reference Charts ................................................................................ 30

5.2.1 Fault Display/Download Mode ..................................................................................... 30

5.2.2 Hardware Output Test Mode ....................................................................................... 30

5.2.3 Fast Test Cycle............................................................................................................ 31

5.2.4 Continuous Cycle......................................................................................................... 31

5.2.5 Temperature & Voltage Display Mode......................................................................... 31

6 FAULT CODES AND POOR PERFORMANCE......................................................................32

6.1 Fault Code Description Chart ............................................................................................ 33

6.2 Fault Code Problem Solving Charts .................................................................................. 35

6.3 Poor Dry Performance.......................................................................................................40

6.4 Poor Wash Performance ................................................................................................... 40

7 WIRING DIAGRAMS ...............................................................................................................43

7.1 Power Distribution Concept ............................................................................................... 43

7.2 Wiring Diagram..................................................................................................................44

8 SERVICE PROCEDURES....................................................................................................... 45

8.1 Component Testing ........................................................................................................... 45

8.2 Drawer Front ..................................................................................................................... 46

8.3 Handle and LCD Display ................................................................................................... 47

8.4 Toe Kick Removal .............................................................................................................47

8.5 Lower Tub Cowling............................................................................................................47

8.6 Tub Removal ..................................................................................................................... 48

8.7 Drying Duct - Top Tub Only...............................................................................................48

8.8 Drying Fan and Flap Valve ................................................................................................ 49

8.9 Water Softener (Where Fitted) ..........................................................................................49

8.10 Strainer (Where Fitted)......................................................................................................50

8.11 Detergent Dispenser .........................................................................................................50

8.12 Electronic Controller .......................................................................................................... 51

8.13 Filter Plate .........................................................................................................................51

8.14 Rotor.................................................................................................................................. 51

8.15 Wiring Cover...................................................................................................................... 52

8.16 Tub Disconnection............................................................................................................. 52

8.17 Hall Sensor........................................................................................................................53

8.18 Heater Plate and Motor Assembly..................................................................................... 53

8.19 Lid...................................................................................................................................... 54

8.20 Yoke ..................................................................................................................................55

8.21 Lid Actuator .......................................................................................................................55

8.22 Slide Rail Replacement ..................................................................................................... 56

8.23 Mains Filter Cover and PCB Mains Filter .......................................................................... 56

8.24 Water Inlet Valve ............................................................................................................... 57

7

599735A

Fill Hose, Drain Hose, Wiring Harness Replacement........................................................57

8.25

8.26 Link Support Wire Position ................................................................................................57

8.27 Front Trim Replacement....................................................................................................58

8

599735A

1 SERVICE REQUIREMENTS

1.1 Health & Safety

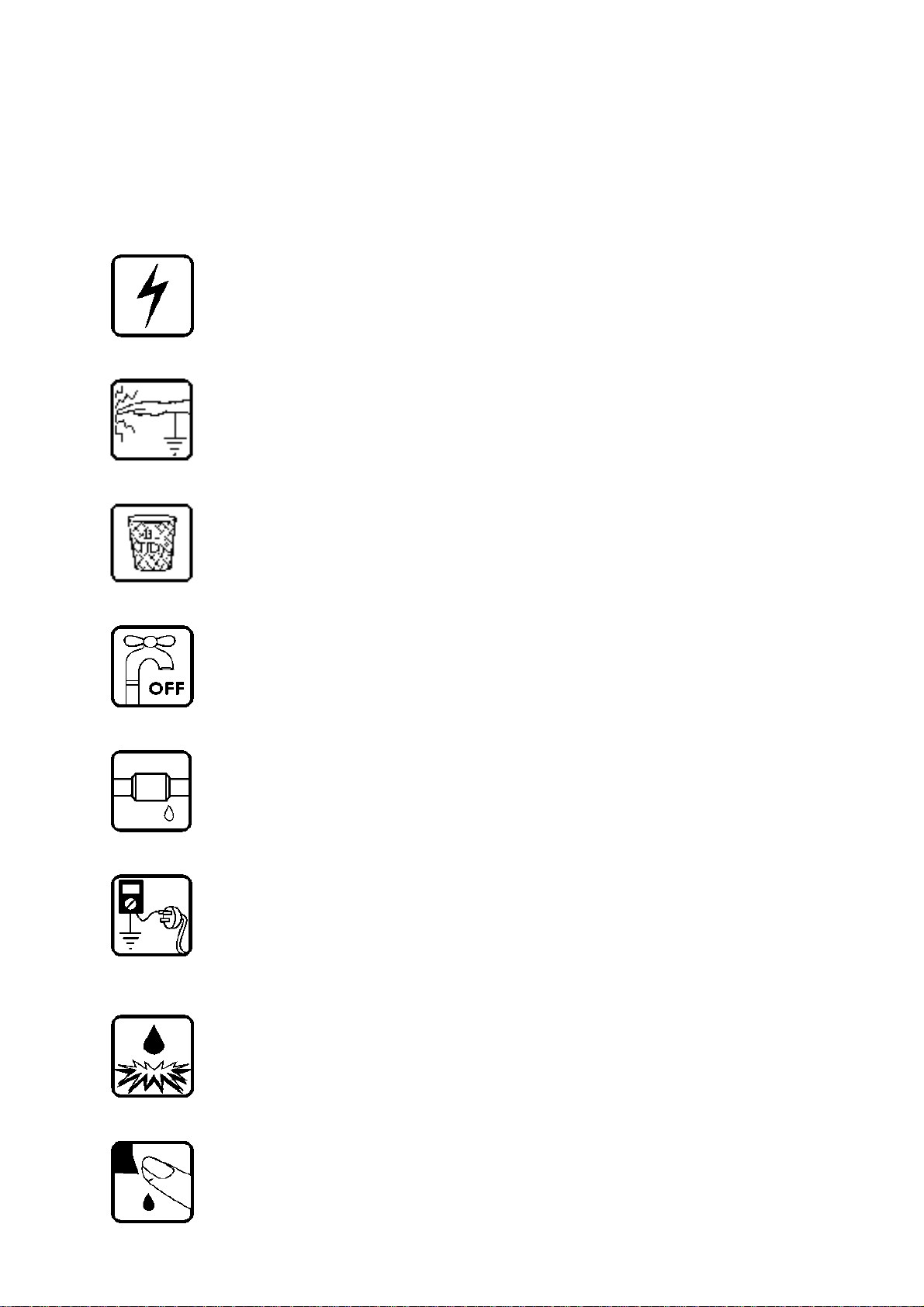

Note: When servicing the DishDrawer™, Health and Safety issues must be considered at all

times. Specific safety issues are listed below with their appropriate icon. These are illustrated

throughout the service information to remind service people of the Health and Safety issues.

1.1.1 Electrical Safety

Ensure the mains power has been disconnected before servicing the DishDrawer™. If

the mains supply is required to be on to service the DishDrawer™, make sure it is

turned off when removing any electrical component or connection to avoid electrical

shock.

1.1.2 Electrostatic Discharge

An anti-static strap is to be used as electrical static discharge (ESD) protection when

servicing electronic components.

1.1.3 Good Working Practices

Ensure the work area is in a tidy and orderly condition at all times so as not to cause a

hazard while service work is being completed. Always clean and tidy the DishDrawer™

and work area after service is completed.

1.1.4 Isolate Water Supply

Turn off the water connection tap before servicing.

1.1.5 Water Leak Check

Check for water leaks as part of the testing after the service has been completed.

1.1.6 Insulation Test

Megger test to check insulation.

Warning: Short together the phase and neutral pins on the plug so as not to damage

any electronic circuitry.

1.1.7 Solvent and Excessive Heat Damage

Solvents and excessive heat can damage plastic surfaces.

1.1.8 Sheet Metal Edges

When working around cut sheet metal edges use appropriate gloves or protection to

eliminate the chance of receiving a laceration.

9

599735A

1.1.9 Diagnostics

While in diagnostics some safety devices are bypassed.

Ensure you do not run components unattended. They may overheat, flood, burnout or

cause water damage.

1.2 Specialised Tools

For servicing this product specialised tools are required.

1.2.1 Static Strap

To be used as ESD (electrostatic discharge) protection when replacing or handling electronic

components.

1.2.2 Fisher & Paykel Smart Tool

Handheld palm computer supplied in a protective case with F&P diagnostics software and service

information loaded:

Part Number 813141 (includes light pen Part Number 425930).

Smart Tool Software is available to download from service website “Cool Blue World” for laptop /

pocket PC’s. Refer to list of compatible devices on the web site.

www.cbw.fp.co.nz

10

2 DIMENSIONS & SPECIFICATIONS

2.1 Dimensions

599735A

Standard Product Product

Size

(mm)

Height (double) 819.5 -

879.5

Height (single) 409mm 161/8 inch 412mm 161/4 inch

Width 595mm 237/16 inch 600mm 235/8 inch

Depth 570mm 227/16 inch 580mm 227/8 inch

Drawer Open (inc

cabinet)

Tall Tub Product Product

Height (Double) 863.5 –

Height ( Single) 453mm 173/16 inch 456mm 1715/16 inch

Width 595mm 237/16 inch 600mm 235/8 inch

Depth 570mm 227/16 inch 580mm 227/8 inch

Drawer Open (inc

cabinet)

1090mm 42

Size

(mm)

923.5

1090mm 42

Product Size

(inches)

32¼ inch – 345/8

inch

7

/8 inch

Product Size

(Inches)

34inch – 363/8

inch

7

/8 inch

Minimum

Cavity Size

(mm)

822.5 -

882.5mm

Minimum

Cavity Size

(mm)

864 -926.5 34 inch – 361/2

Minimum Cavity

Size (inches)

325/16 inch – 343/4

inch

Minimum Cavity

Size (Inches)

inch

2.2 Specifications

2.2.1 Electrical

Market Voltage Frequency Current Double / Single

NZ/AUS/GB/EU/DK 230/240V AC 50/60 Hz 10 A / 5 A max

USA/TW 110/120V AC 60 Hz 10.6 A / 5.3 A max

2.2.2 Components

Component Specifications Comments

Controller – 2 types 120V

230V

Water Inlet Valve 24V DC

65+/- 10 Ohms per coil

2.5litres/min (0.65 US gal/min)

Dispenser coils

Rinse Aid tank

capacity

PCB Mains Filter – 2

types

Motor

Drain speed

Wash speed

Stator 8.0 +/- 5 Ohms (per winding), 16

24V DC per coil

65+/- 10 Ohms per coil

50mls (approximately 25 washes)

3.05 cubic inches

230V AC

110V AC

80V DC 3 Phase Brushless

4200 RPM

2300 - 2850 RPM

ohms phase to phase from the

controller connector

US, TW, 110V NZ/AU

NZ, AU, GB, EU, DK

All markets

NZ, AU, GB, EU, DK

US, TW, 110V NZ/AU

Pump out rate 5 litres / min.

11

599735A

Component Specifications Comments

Heater Plate 230V

Water Heater Track

Power Supply

230V AC

50 Ohms +/- 4 Ohms

98 Ohms +/- 7 Ohms

NZ, AU, GB, EU, DK

Resistor

Heater Plate 110V

Water Heater Track

Power Supply

Resistor

Temperature Sensor 12000 Ohms @ 20OC (68OF)

120V AC

24 Ohms +/- 3 Ohms

24 Ohms +/- 3 Ohms

8300 Ohms @ 30

3000 Ohms @ 60

O

O

C (86OF)

C (140OF)

US, TW 110V NZ/AU

Located on the heater Plate

Fusible Link 268 – 302OC (514 – 576OF) Located on the heater plate

Water Inlet Hose 1000Kpa / 145 P.S.I.

1561 mm from LHS

1344 mm from RHS

Water pressure 1 MPa (145 psi) max, 0.1 MPa (14.5

psi) min

1 MPa (145 psi) max, 0.03 MPa (4.3

Pressure rating

Length from chassis edge

(viewed from the front)

Water softener models

Non water softener models

psi) min

Drain Hose

Power Cord 1776 mm from LHS (69 Inches)

Drying Fan 24V brushless DC motor 0.27A

2011mm from LHS (79 inches)

1794 mm from RHS (71 inches)

1559 mm from RHS (61 Inches)

Approximately 2 to 3 Meg Ohms

Length from chassis edge

(viewed from the front)

Length from chassis exit

(viewed from the front)

Polarity sensitive

Meter +ve to red wire, -ve to

black wire

Diverter Valve

Softener Assy

Brine Pump Assy 24V DC Coil

24V DC Coil

65 +/- 10 Ohms Coil

65 +/- 10 Ohms Coil

Water Softener 500 grams Salt Capacity

Approximately 14 regenerations

290+/- 10ml Resin

Lid Actuator

Hall Sensor 4.13, and 3.43 mOhms

24 V DC

Approximately 30 Ohms

measured +ve in centre, -ve to outside

LCD LCD has back light 5 volt rail between pins 2 & 5

12

2.2.3 Performance

Europe, GB, IE (Per Tub)

Energy Wash Dry

A A A

0.64 kWh/cycle 8 litres/cycle

USA

Based on 4 wash loads per week

Product Energy

Single 160 kWh/year

Double 314 kWh/year

NZ, Australia

Based on 7 wash loads per week, using normal eco programme

Product Energy Water

Single 141 kWh/year – 3 star 7.4 Litres/wash – 3.5 star

Double 282 kWh/year – 3 star 14.7 Litres/wash – 3.5 star

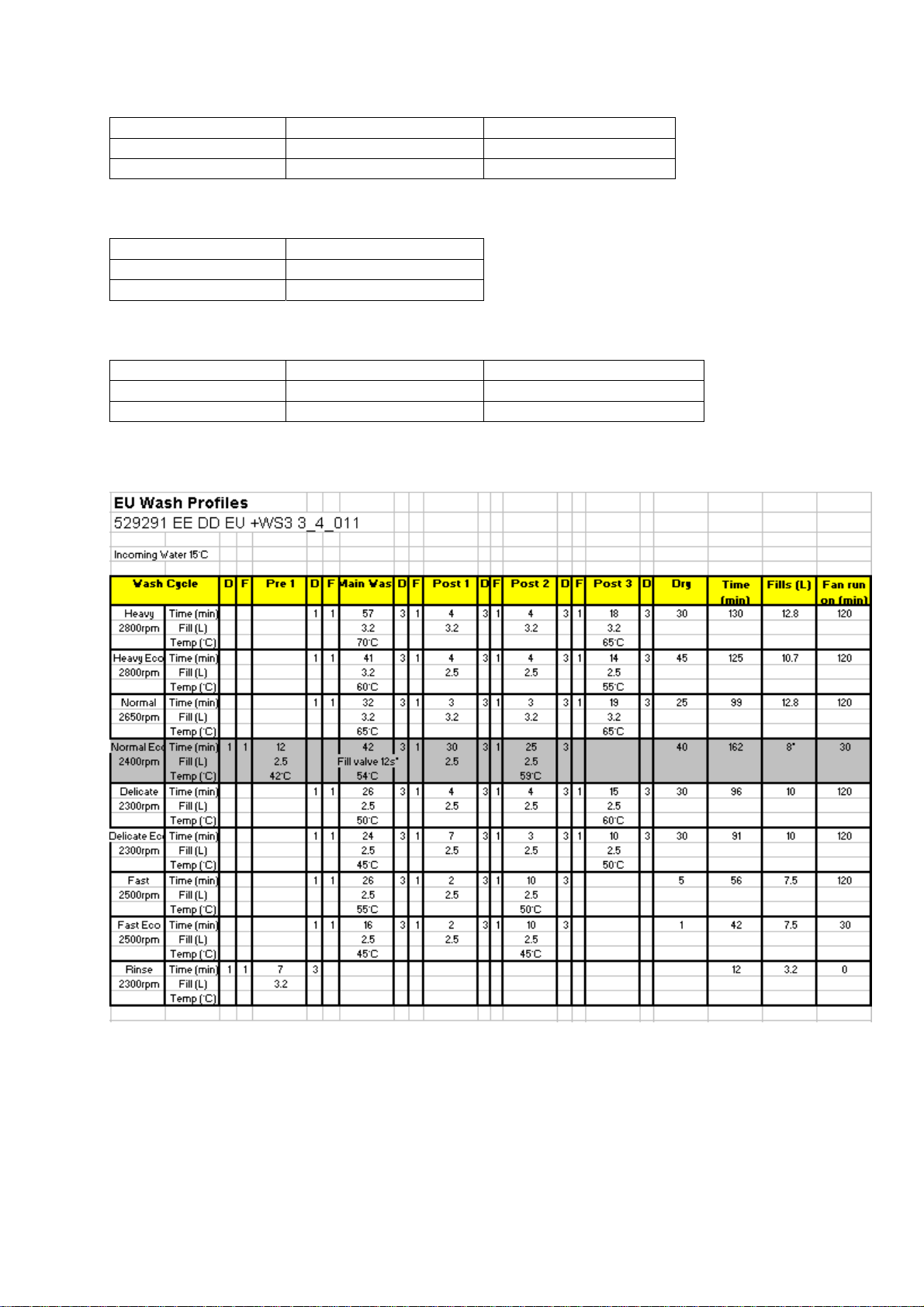

2.2.4 Wash Profiles

2.2.4.1 Europe, Great Britain, Ireland

599735A

13

599735A

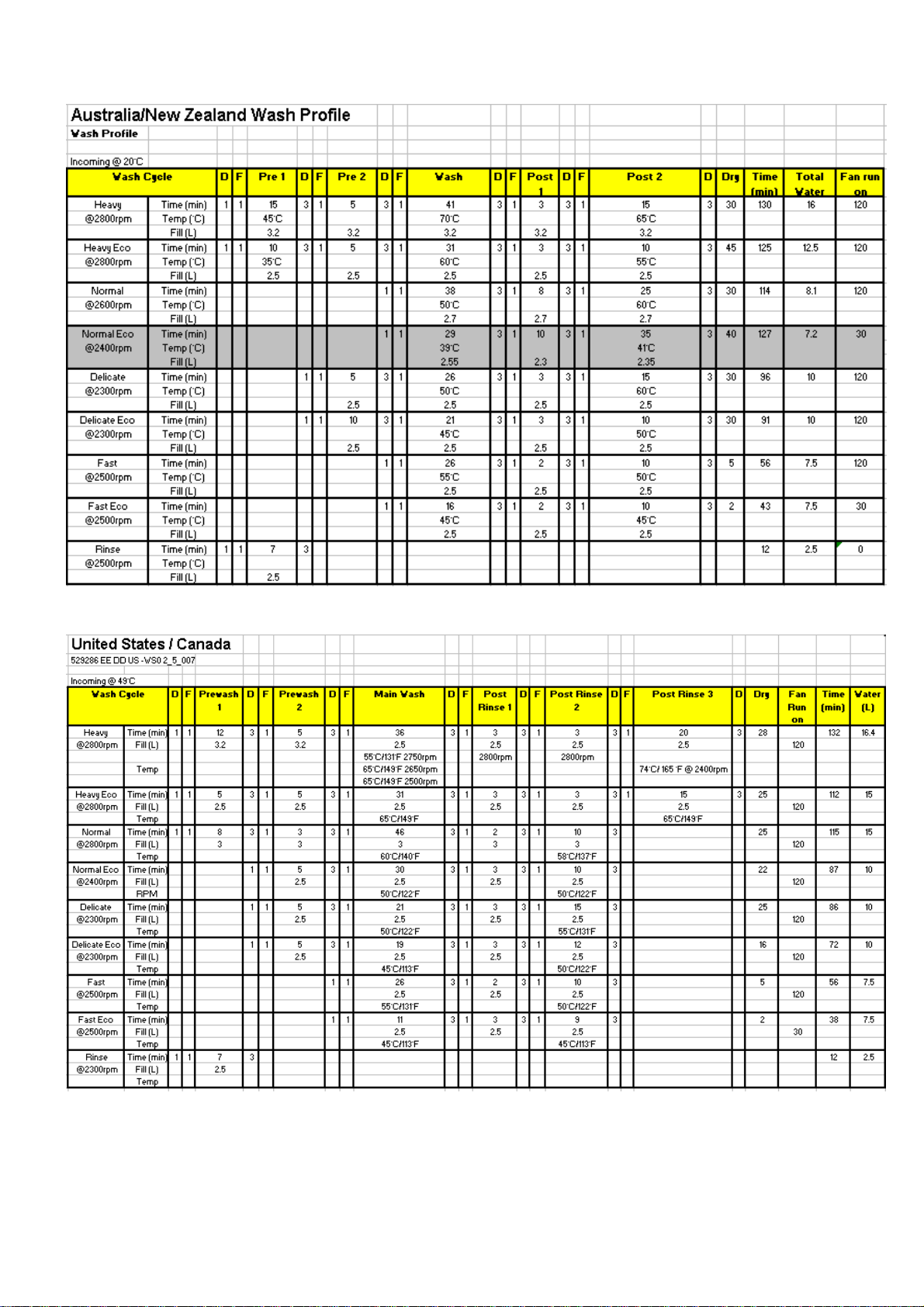

2.2.4.2 Australia, New Zealand

2.2.4.3 Canada, U.S.A.

14

599735A

3 TECHNICAL OVERVIEW

1.1 Chassis

The DishDrawer™ chassis is one complete assembly composed of 5 steel metal components

locked together by a proprietary riveting process. The chassis exterior is made of a lacquered

electro-galvanised material.

Unlike most other dishwashers, the chassis assembly is a load carrying structure designed to

impart stiffness to the product and to ensure deflection is minimised.

The feet of the double cabinet are assembled into the chassis by means of four steel inserts that

are clinched in place to form a permanent threaded connection.

The tub extends 520mm (20

on either side of the tub.

1.2 Drawer Fronts

Prefinished drawer fronts are formed from a painted, brushed or Iridium finish stainless steel blank.

The drawer fronts are attached to the tub by means of formed hooks and two pins that are inserted

through either side of the tub.

On the integrated model, the front panel supplied on each drawer is the mounting panel for the

joinery finished drawer front. The joinery finished drawer front is supplied by the customer.

15

/32”) out of the cabinet by travelling along two rigidly attached slides

3.1 Electronics

In the DD24 / DD60 (Phase 6) electronic controller, the functions of controlling the motor as well as

controlling the user interface console are combined into a single 16-bit micro controller on the main

printed circuit board.

This micro controller also controls a transformerless 85w switch mode power supply. This power

supply utilises a large dropping resistor on the heater plate in conjunction with phase control of the

mains voltage in order to produce a variable voltage supply for the motors, solenoids and drying

fan. From this the controller can supply voltages from 5V to 85V to the various components in the

DishDrawer™.

A separate 24volt dc power supply on the PCB mains filter board (located within the mains filter

housing in the lower left corner of the chassis) supplies power to the microcontroller and LEDs in

the electronic controller.

An isolation relay is mounted on the PCB mains filter and will disconnect power to major

components when signalled to by the controller under certain fault conditions. Once the fault has

been cleared, it will require the power to be disconnected from the product for the isolation relay to

reset.

NOTE: - With power supplies of this nature, all components, regardless of supply voltage,

should be treated as live to earth, i.e. at supply voltage.

The user interface comprises a printed circuit board for front controls and a touch switch panel for

internal controls.

The electronics can connect to a computer service tool via an optical light pen for fault finding and

product information.

The element is switched by one single pole relay. Overheat protection is provided by a thermal

fuse in series with the water heater track on the heater plate. In an over-heat situation, this gravity

fuse drops off and disconnects the water heater element from the supply voltage.

A non-serviceable fuse is mounted within the controller to provide additional safety protection.

15

599735A

3.1.1 Tub Home Sensor

The tub home sensor determines when the tub is closed. The tub home sensor consists of an

infrared sender and receiver mounted on the right side of electronic controller. When the tub is

fully closed, infrared light is transmitted from the sender through a light pipe on the side of the tub,

through a prism mounted in the chassis trim, then back through the other light pipe to the receiver.

If the tub is not fully closed, the circuit is not complete and the appliance will not operate.

3.1.2 Touch Switches

Two touch switches are used on the secondary control panel. The one on the left is used to select

the required wash cycle and the one on the right is used to turn the ECO option on or off. (ECO

times are not necessarily shorter than non-ECO times, but will use less energy.) They are

capacitive touch switches and are supplied with an analogue signal from the controller that will

change in the presence of an earthed mass (i.e. customer’s finger).

3.2 Motor

The motor is a fully electronically controlled 80V, 60w, 3 phase, 6 pole brushless DC motor,

running on wash at between 2300-2850rpm depending on the cycle selected, and at approximately

4200 rpm on drain.

3.2.1 Rotor

The rotor is a four-pole permanent magnet rotor with a graphite bearing at each end of the vertical

shaft. At the lower end of the rotor shaft is the drain impellor and at the upper end is the wash

impellor.

The rotor can only be placed in one position within the motor housing (refer to Section

fitting instructions).

3.2.2 Spray Arm

The spray arm is shaped for most efficient water flow. The holes are positioned for best

penetration into the wash load, with the water jets angled to ensure the spray arm rotates at the

most efficient speed. The pressure of the water being pumped from the spray arm produces

enough downwards pressure to ensure the spray arm does not lift off the rotor. There is a flap

valve moulded into the top of the spray arm. This lets air escape through the spray arm when the

DishDrawer™ is filling with water.

8.14 for

3.3 Wiring Cover

The wiring cover protects the customer from all electrical components in the motor area

underneath the tub. All electrical components, regardless of voltage, should be treated as live with

respect to earth. It also serves to protect the motor assembly, drain and fill hoses from damage

when opening and closing the drawers. The wiring cover acts as a cosmetic part of the product.

The centre of the cover is made from rubber to prevent the transmission of noise from the motor to

other components.

3.4 Lid System

3.4.1 Lid Operation

The lid is a single piece of polymer plastic with a diaphragm/seal co-injection moulded into it. The

centre of the lid can move relative to the seal. Each side of the lid is clipped into a yoke, which is

in turn connected to a worm drive lid actuator assembly containing a small brushed DC 24 volt

motor.

When the product is first plugged in and switched on at the wall, the lid motors are powered up to

ensure that the lid is fully raised. At the beginning of each wash cycle, both lid motors are powered

up to pull the lid down onto the tub in approximately 2 to 3 seconds. The lid remains down for the

duration of the cycle and is only lifted when the DishDrawer™ beeps to signal the end of the cycle,

or if the customer pauses it to gain access to the tub.

16

599735A

3.4.2 During a Power Failure

If power to the DishDrawer™ fails with the lid down, the tub can still be forced open manually if

access is required. It is very difficult however to close the tub again without raising the lid. The lid

actuators can be wound up manually with the tub fully removed. Failure to raise the lid before

closing the drawer can result in the lid seal being damaged.

3.5 Tub

The tub is the main cavity where all the wash activity occurs. The tub is a polymer plastic

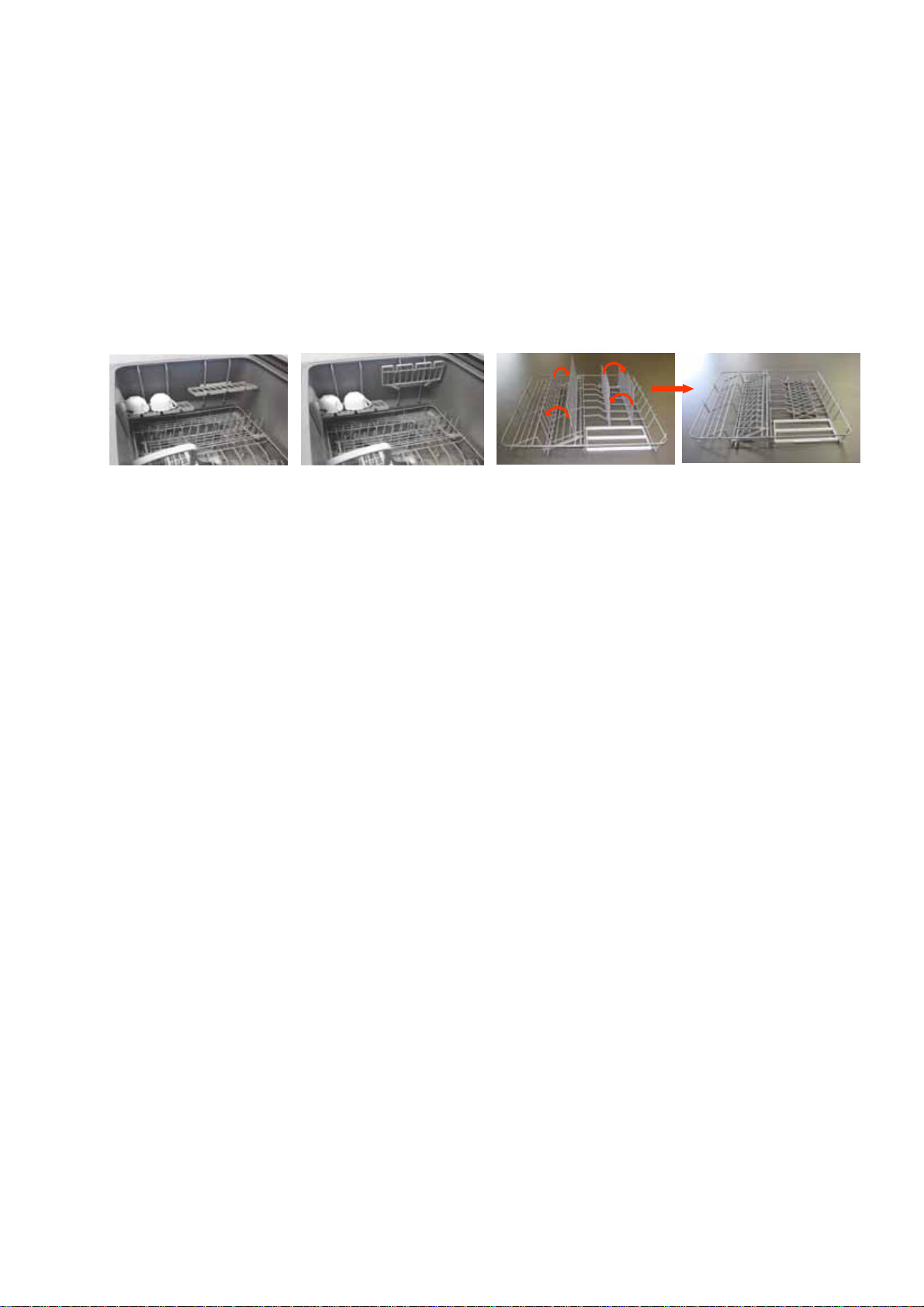

receptacle that houses the basket ware that includes adjustable cup racks and basket with fold

down tines along with a wash pump and spray arm at the base. The tub also has guide vanes

around its walls which direct falling water from the wash cycle in a clockwise direction around the

filter plate. This clears the filter plate of food particles and washes them into the sump where they

are trapped by the drain filter or pumped out during the drain cycle.

3.6 Filling

3.6.1 Water Inlet

The tub of the DishDrawer™ fills by a single water inlet hose. Hot water connection is

recommended for USA and Japanese products, and a cold water connection recommended for the

Australasian, UK and European products. From the connection to the water supply tap in the

kitchen, the inlet hose enters the cabinet of the dishwasher at the base, onto a dual water valve.

On double models, each tub is supplied water independently via one of the dual valve coils and a

fill hose that runs through a customised link assembly at the back of each tub and travels along the

base of the tub under the wiring cover to the front. At the front of the tub, the fill hose connects to

the water softener (if fitted) then to the detergent dispenser, which directs water into the tub.

Depending on the market and cycle chosen, the product fills through the pre-rinse section of the

dispenser for the pre-rinse cycles and secondly through the main wash section for all other cycles.

In a double product, the controller allows only one inlet valve to operate at a time. This has been

done to reduce EMC emissions. The top tub has priority. This restriction does not apply in

diagnostics mode.

3.6.2 Dispensing Detergent and Rinse-aid

The dispenser is mounted in the front wall of the wash tub.

The detergent dispenser consists of two detergent chambers, one for pre wash and the other for

the main wash.

The detergent dispenser door is opened manually for detergent loading and then manually closed

ready for the detergent to be transported to the wash tub by the inlet water. To enable each

detergent chamber to be dispensed separately, an inlet water diverter valve controlled by the

electronics is required.

Additionally, a positive displacement pump unit and storage tank is incorporated within the

dispenser to supply rinse aid. The rinse aid dispensed volume can be adjusted by the customer in

option adjustment mode. A glowing red light on the tank filler cap indicates an empty rinse aid

tank. The pump frequency is 1 Hz, and makes a slight beeping sound.

17

599735A

3.6.3 Amount of Water

The tub fills with approximately 2.5 litres / 0.8 US gallons of water, almost level with the base of the

spray arm. Once this level is reached, the wash pump (which has load-sensed the fill via the

electronics) becomes primed and pumps the water through the spray arm causing it to rotate. The

load on the wash pump is constantly monitored throughout the wash cycle and the water level

adjusted if necessary. If the wash pump loses prime, the electronics will top up the water level by

opening the fill valve for approximately 5 seconds. It will do this up to 3 times before carrying on

regardless.

3.6.4 Flood Protection

A flood sensor mounted on the side of the mains filter housing provides flood protection. If a flood

is detected, the drain pump will run and an F1 fault code will be signalled to the customer

3.7 Heating

3.7.1 The Heating Element

The heater plate is a porcelain enamelled steel plate with a thick film resistive circuit printed onto

the dry side. A gravity thermal fuse is mounted on the heater plate in series with the heating

element. A large dropping resistor is also printed onto the heater plate which forms part of the

controllers power supply. The element is clamped in place by a locknut and supports the motor at

the base of the tub.

3.7.2 Heating the Water

The heater plate is positioned beneath the filter plate. A flow through water heating system is

created during the wash cycle by allowing water to flow through the filter plate, over the surface of

the element and into the wash pump.

3.7.3 Maintaining the Temperature

A printed circuit board with a temperature sensitive thermistor is mounted on the heater plate.

Sensor components are unserviceable and if they fail a new heater plate is required.

3.7.4 Overheat Protection

The heater plate is only activated during the wash cycles. It is not used for drying. The

temperature is monitored by the thermistor. If a failure occurs with the electronic control of the

heater plate, overheat protection is effected by the thermal fuse on the heater plate.

The thermal fuse consists of a gravity fuse in series with the water heater track that will melt at a

relatively low temperature, 268 –

This fuse does not isolate the dropper resistor and so does not remove power from the controller.

302OC (514 – 576OF) and disconnect the power to the element.

3.8 Motor and Heater Plate Locknuts

There are two locknuts holding the heater plate and motor housing assembly into the base of the

tub to form a watertight seal. They do this by compressing two seals, one between the heater

plate and tub, and the other between the heater plate and the motor assembly.

When reassembling the motor, it is important that a motor shim is placed between the inner locknut

and the inner element seal.

The outer locknut has locations that hold the drain hose, fill hose and wiring loom in place.

Another function of the larger outer locknut is to support and clip the wiring cover.

18

Loading...

Loading...