Page 1

INSTALLATION INSTRUCTIONS

Gas Cooktop

CG905DW

models

NZ AU

www.fi sherpaykel.com

590684C 10.16

Page 2

1 SAFETY AND WARNINGS

!

WARNING!

Electrical Shock Hazard

Before carrying out any work on the electrical section of the appliance, it

must be disconnected from the mains electricity supply.

Connection to a good earth wiring system is absolutely essential and

mandatory.

Alterations to the domestic wiring system must only be made by a qualified

electrician.

Failure to follow this advice may result in electrical shock or death.

!

WARNING!

Hot Surface Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

IMPORTANT SAFETY INSTRUCTIONS

●

Particular attention shall be given to the relevant requirements regarding ventilation.

●

Read these instructions carefully before installing this product.

●

Please make this information available to the person installing the appliance as it could

reduce your installation costs.

●

This appliance is to be installed and serviced only by an authorised person.

●

Installation must comply with your local building and local gas authority codes and

electricity regulations.

●

Incorrect installation, for which the manufacturer accepts no responsibility, may cause

personal injury or damage and could invalidate any warranty or liability claims.

●

These appliances are registered in: (New Zealand) at www.energysafety.govt.nz and

(Australia) with AGA at www.aga.asn.au.

●

Appliances are factory set for Natural gas but are convertible to LPG. If in doubt, refer to

the local gas network operator or gas supplier to confirm gas type at installation site.

●

Do not modify this appliance.

●

Do not use or store flammable materials on or near this appliance.

●

Do not spray aerosols in the vicinity of this appliance while it is in operation.

●

Packing elements (eg plastic bags, polystyrene foam, staples, packing straps etc) and

tools should not be left around during and after installation, especially if they are within

easy reach of children, as these may cause serious injuries.

Before you install the appliance, please make sure that

●

the local distribution conditions (nature of gas and pressure) and the adjustment of the

appliance are compatible. For adjustment conditions for this appliance see ‘Gas rate

summary’.

●

a suitable disconnection switch is incorporated in the permanent wiring, mounted and

positioned to comply with the local wiring rules and regulations. A means of disconnection

with at least a 3 mm air gap contact separation in all poles must be incorporated into

the fixed wiring in accordance with the wiring rules, unless the local wiring rules allow for

alternative means.

●

the appliance is connected to a 220V - 240V 50Hz (10 A) power supply only and earthed

via the power supply cable.

●

there is a power outlet within reach of the power supply cable (900 mm from the centre

rear of the product). This must be accessible after installation. The power supply cable

should not touch any metal parts.

●

if the power supply cable is damaged, it is replaced only by the special cable: Part no.

534993 KIT SPARES TRMNL BLK-FLEX 10, obtainable from authorised Fisher & Paykel

Service Agents.

●

the supply connection point (gas shut-off valve) is accessible after installation.

●

the benchtop is made of a heat resistant material.

●

the installation complies with all the requirements of Australian and New Zealand Gas

Installation Standards (AS/NZS 5601.1 current edition), including that the product has to be

installed so that the surface temperature of any nearby combustible surface will not exceed

65 OC above ambient. See ‘Clearance Dimensions’.

When you install the appliance

●

As servicing requires removing of the cooktop from the benchtop we do not recommend

flush mounting. To the fullest extent permissible by law, the owner carries all risk for flush

mounting of the cooktop. The owner must ensure the cooktop has been cut out from the

benchtop before servicing can be carried out. Fisher & Paykel will not be liable for any

costs associated with removing or replacing a flush-mounted and/or sealed-in product, nor

for repairing any damage that may be incurred by doing this. Fisher & Paykel does not

exclude any statutory liability it may have and which by law cannot be excluded, because of

the giving of this notice.

●

If installed with an approved flexible hose, the hose should not come in contact with the

bottom of the appliance or any sharp edges. Flexible hose assemblies should be AS/NZS

1869 Class B or Class D certified with a maximum length of 1.20m.

●

Seal exposed bare edges of the cutout with an oil-based paint or moisture-proof

polyurethane to prevent possible moisture creeping between the cooktop trim and the

benchtop.

●

If, after following the instructions given, correct performance cannot be achieved, please

contact your nearest Fisher & Paykel Authorised Service Centre, Customer Care, or contact

us through our local website listed at the end of this document.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our

website www.fisherpaykel.com or contact your local Fisher & Paykel dealer.

1

Page 3

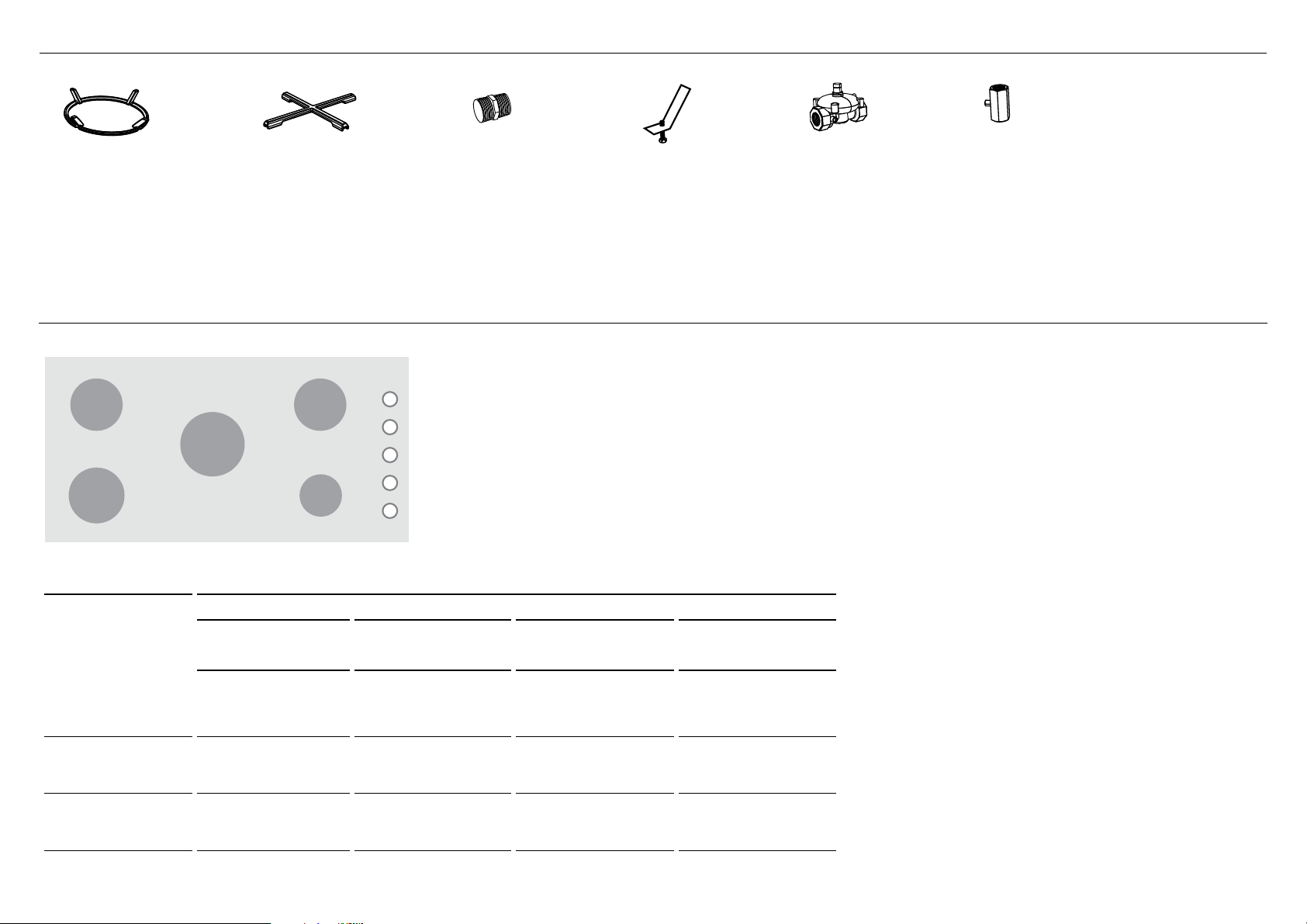

2 PARTS SUPPLIED

Wok stand (1)

Small pan

support (1)

SEMI-RAPID SEMI-RAPID

DUAL WOK

RAPID

CG905DW

AUX

Nipple 1/2 “

BSPT thread (1)

Clamping

brackets (6)

and screws (6)

3 GAS RATE SUMMARY

All appliances are factory set for either Natural Gas or LPG.

Check the ‘Gas type’ sticker on the base of the appliance.

BURNER

Regulator (1)

(NG models)

Test point

adaptor (1)

(LPG models)

GAS TYPE

Jet size

NG (1.00 kPa)* 0.90 4.20 1.35 9.10 1.45 10.05 1.45

LPG (2.75 kPa)* 0.55 4.00 0.80 8.50 0.87 10.80 0.80

*Nominal pressure with the two semi-rapid burners on High.

AUX SEMI-RAPID RAPID DUAL WOK

(mm)

Nominal

rating

(MJ/h)

Jet size

(mm)

Nominal

rating

(MJ/h)

Jet size

(mm)

Nominal

rating

(MJ/h)

Jet size

(mm)

0.70

0.80

0.50

Nominal

rating

(MJ/h)

21.50

1.45

20.50

2

Page 4

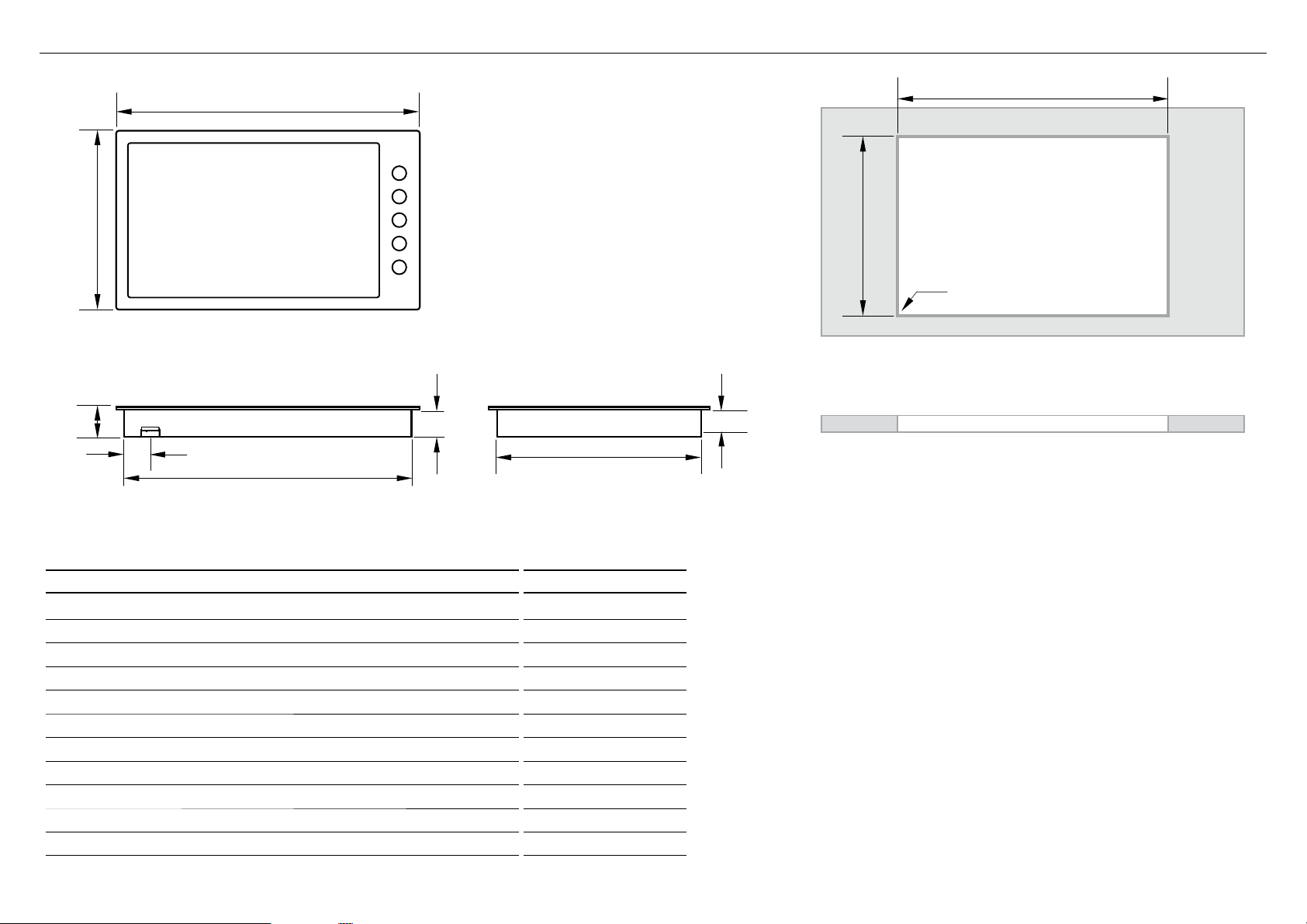

A

K

D

B

E

C

G

F

J

H

I

TOP

Note: Gas inlet connection is located in the

rear right corner.

REAR

4 PRODUCT & CABINETRY DIMENSIONS

SIDE

TOP

FRONT

PRODUCT DIMENSIONS mm

Overall height of product (excluding burners, dials and pan supports) 79

A

Overall width of product 900

B

Overall depth of product 530

C

Height of chassis (below top of counter) 76

D

Width of chassis 860

E

Depth of chassis 487

F

Overall width of cutout 870

G

Overall depth of cutout 494

H

Corner radius of cutout max. 10

I

Distance from top of counter to center of gas inlet on product 76

J

Distance from edge of chassis to gas inlet on product 22

K

3

Page 5

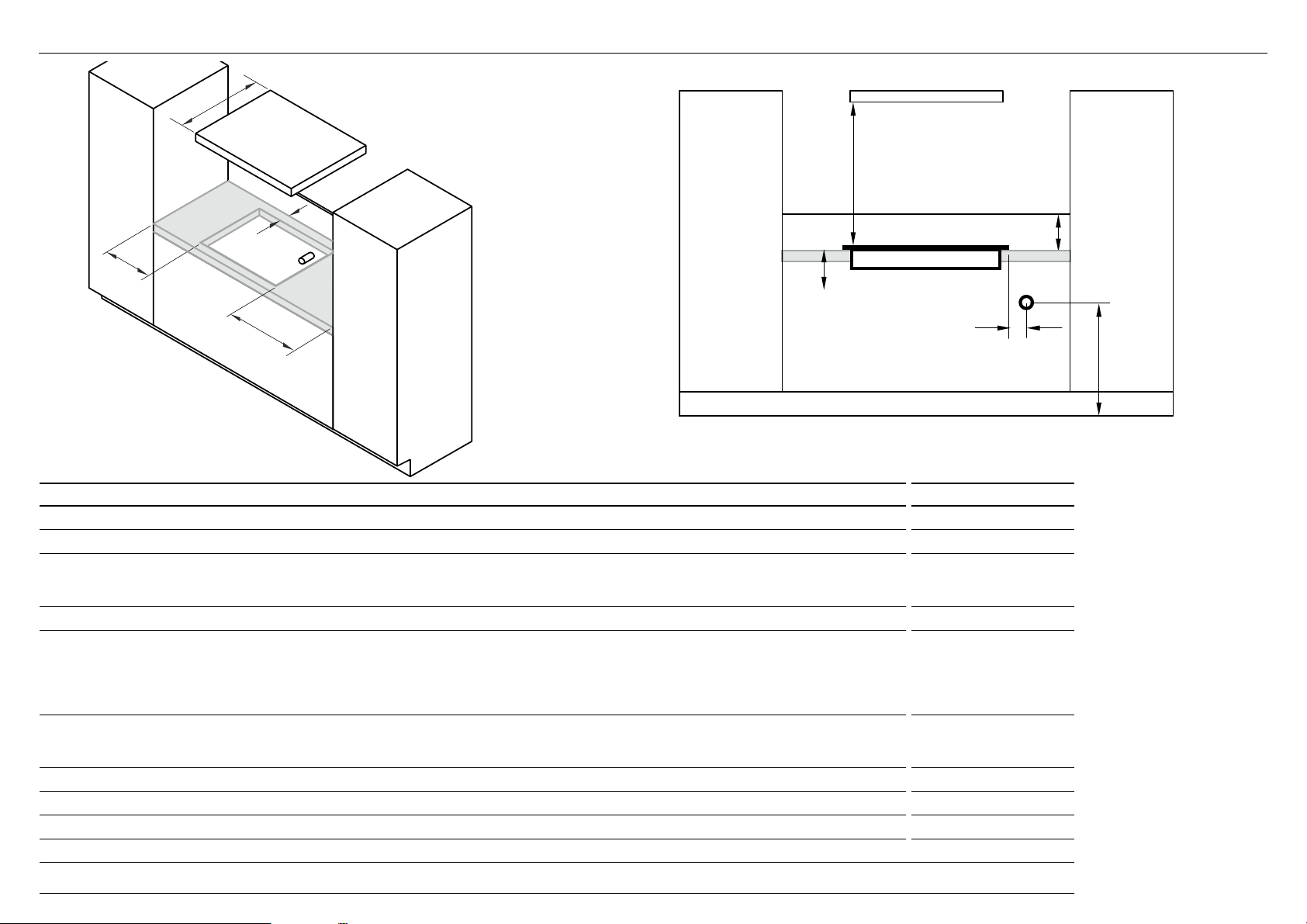

I

5 CLEARANCE DIMENSIONS

E

C

A

B

ISO

CLEARANCE DIMENSIONS mm

Minimum clearance from left edge of cutout to nearest combustible surface 100

A

Minimum clearance from right edge of cutout to nearest combustible surface 100

B

Minimum clearance from rear edge of cutout to:

C

Nearest combustible surface

Nearest non-combustible surface

Minimum height of non-combustible material when used on adjacent walls 150

D

Minimum clearance from cooktop surface to:

E

Rangehood

Any other overhead exhaust fan

Downward facing combustible surface

Downwards-facing tiled or fire resistant surface

Minimum clearance below top of benchtop to:

F

Combustible surface

Fisher & paykel oven or nearest non-combustible surface

Minimum distance from right edge of cooktop to gas connection point on wall (if using a flexible hose) 250

G

Distance from floor to gas connection point on wall (if using a flexible hose) min. 800 - max. 900

H

Maximum overall depth of overhead cabinetry 600

I

F

G

FRONT

D

115

35

650

800

650

500

H

81

81

Note: Ensure there is an earthed power outlet within 900 mm of the centre rear of the product. The gas connector on the wall should be 800-850 mm (H) above the floor and to a distance of at least 250 mm (G) outside

the width of the product, on the right-hand side. It should be accessible with the product installed.

4

Page 6

A

K

D

B

E

C

F

J

6 FLUSH MOUNTING INSTALLATION (OPTIONAL)

IMPORTANT!

Refer to ‘When you you install the appliance’ in the

Safety and Warnings section before you flush mount

this appliance.

HH

G

G

TOP

Note: Electrical

connection is

made at the right rear

M

REAR

PRODUCT AND CABINETRY DIMENSIONS mm

Overall height of product (excluding burners, dials and pan supports)

A

Overall width of product

B

Overall depth of product

C

Height of chassis (below top of counter)

D

Width of chassis

E

Depth of chassis 487

F

Overall width of routered recess

G

I

Width of cutout

G

Overall depth of routered recess

H

I

Depth of cutout

H

Corner radius of cutout

I

Corner radius of routered recess

J

Height of routered recess

K

Distance from top of counter to center of gas inlet on product 76

L

Distance from edge of chassis to gas inlet on product 22

M

Minimum clearance below top of benchtop to:

N

rear top of oven* installed below cooktop or cabinetry

thermal protection barrier

5

SIDE

L

79

900

530

76

860

905

875

535

494

max. 5

IJ

TOP

K

FRONT

N

10

3

81

81

Page 7

7 FLUSH MOUNTING INSTALLATION (OPTIONAL)

A ROUTER THE BENCHTOP TO THE SPECIFIED DEPTH

3 mm

5 mm

D APPLY SILICONE

B FIT THE CLAMPING BRACKETS

3/4” - 2”

(19 mm - 50 mm)

REPEAT ON ALL THE OTHER SIDES

(Total 6 brackets)

E WIPE OFF EXCESS SILICONE

C MASK OFF THE AREA TO BE SILICONED

1

3

F IF REMOVING PRODUCT, CUT

AROUND THE SILICONE

2

min. 150 OC rated

Ensure silicone does not leak underneath the steel edge.

TO REMOVE PRODUCT

2

1

6

Page 8

8 DISCARD PACKAGING 9 FIT THE NIPPLE AND WASHER

Model may vary from illustrations shown

!0 LOWER GENTLY INTO THE CUTOUT

Recycle responsibly

IMPORTANT! - Use gas tape

to seal the connection

Nipple (1/2” BSPT thread)

Nipple (½” NPT thread)

7

Page 9

!1 SECURE TO COUNTERTOP WITH BRACKETS BASED ON THE COUNTERTOP THICKNESS

on

Arrow

Place the cooktop into the cutout and

tighten it with the supplied clamps. These

will cope with the countertop thicknesses

19 - 50 mm when used in the two

orientations shown.

IMPORTANT! - Do not over tighten.

19 mm - 50 mm

!2 GAS CONNECTION

●

Make sure the connection point will be accessible with the cooktop installed.

●

To enable the gas supply to be readily shut off by the customer, make sure the connection is fitted with an isolating valve

close to the cooktop.

●

A manual shut-off valve must be installed in an accessible location in the gas line external to the appliance for the purpose

of turning on or shutting off gas to the appliance.

●

Gas connection to the product must use the nipple supplied with a 1/2” BSP external thread. The supplied gas pressure

regulator must be installed where it will be accessible for adjustment.

REPEAT ON ALL THE OTHER SIDES

(Total 6 brackets)

If connecting the gas with a flexible hose

●

Ensure the hose is long enough to allow for removal of cooktop for servicing.

●

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

●

The hose assembly must be with an Rp 1/2” (ISO 7-1) female thread connection (AS/NZS 1869 Class B or D certified).

●

The hose assembly must be as short as practicable (maximum length of 1.20m) and comply with the relevant

AS/NZS5601.1 requirements.

●

The hose must not be kinked, subjected to abrasion or permanently deformed.

●

The hose must not be near or in contact with any hot surfaces (e.g. base of metal hotlplate, flue, or chassis of

undercounter oven etc.)

NG LPG

Adjust to obtain a test point

pressure of 1 kPa with all the

burners operating at highest

setting.

Make sure the supply pressure

is regulated to 2.75 kPa, with all

the burners operating at highest

setting.

8

Page 10

!3 LEAK TESTING

●

Leak testing of the appliance shall be conducted according to the manufacturer’s instructions.

●

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system in excess of 3.5kPa.

●

Maximum inlet gas supply pressure 5 kPa

After installing the gas supply and making all connections, check thoroughly for possible leaks:

1 Turn all control dials on unit to “OFF” position.

2 Open the valve on the gas supply.

3 Using a leak detection fluid, check each gas connection one at a time by spraying or brushing the solution over

the connection. The presence of bubbles will indicate a leak.

4 If necessary, tighten the fitting and recheck for leaks.

5 Turn on burner valve and light each burner.

6 Check for a clear blue flame without yellow tipping. If burners show any abnormalities, check that they are

located properly and in line with the injector.

ON

ON

GAS

GAS

9

Page 11

!4 AFFIX DUPLICATE DATA LABEL SOMEWHERE

INSTALLATION INSTRUCTIONS

ACCESSIBLE & PLUG COOKTOP IN

Duplicate data label

!6 TEST OPERATION

!5 FIT PAN SUPPORTS

●

To check that the ignition system operates correctly, light each burner by itself, then all burners in combination.

●

Check for a well-defined blue flame without any yellow tipping.

●

If any abnormality is evident, check that the components of the burner assembly are located properly

●

If proper operation cannot be obtained, contact Customer Care or your nearest F&P Authorized Service Center.

●

The cooktop must not be used by the customer until proper operation has been achieved.

Lifting off

Yellow tip

Good flame

10

Page 12

!7 WIRING SCHEMATIC

11

Page 13

!8 FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

Have you installed the clamping brackets?

Have you verified that the type of model (factory-set for NG or LP) matches the type of gas at the site of installation?

Have you sealed all connections with gas tape?

Have you leak-tested all connections?

Is the cooktop set to the correct working pressure?

Have you affixed the supplied duplicate data plate label on an adjacent

surface accessible to the customer?

Is the cooktop grounded?

Check that the power supply cord is NOT touching the cooktop.

OPERATION:

Do all burners ignite both individually and in combination?

Are the flames consistent and appropriately sized?

Have you demonstrated the basic operation to the customer?

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

12

Page 14

Page 15

Page 16

www.fi sherpaykel.com

Copyright © Fisher & Paykel Appliances 2016. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

NZ AU

590684 C 10.16

Loading...

Loading...