Page 1

Product Bulletin

V270 Valve

D104178X012

Fisher™ V270 Full-Bore Ball Control Valve

The Fisher V270 is a three piece, trunnion mounted,

full-bore control valve designed from the ground up

with features for optimized pressure, flow and process

control.

The V270 full-bore ball valve is designed for

automated control in bypass, batch, monitor, and

emergency shutoff service applications, and it

presents little or no restriction to flow.

The V270 full-bore ball valve is available with

composition seals, and process type live-loaded shaft

packing for improved service life and lower emissions.

Unless otherwise noted, all NACE references are to

NACE MR0175/ ISO 15156.

51.3:V270

March 2021

Features

n Excellent Flow Control—Shaft and trunnion guiding

provides improved dynamic control.

n Sour Service and Sour Crude Oil Capability—

Standard construction materials comply with NACE

Standard MR0175 / ISO 15156.

n Tight Shutoff—Self-adjusting seals that are pressure

assisted provide Class VI shutoff for long reliable

service. The design incorporates a heavy duty

S31600 stainless steel carrier that retains the

composition seal.

n Free Standing Design—Comes standard with a base

bracket allowing the valve to sit upright.

X1454

FISHER V270 VALVE

n Heavy Duty Trunnions—The ball trunnions are

designed for demanding applications requiring long

service life, with a reduction in maintenance time

and costs.

n Double Block and Bleed—Design comes standard

with a dual seal arrangement.

n Optional Fire-Tested Construction—Certified for API

607 and 6FA.

www.Fisher.com

Page 2

Product Bulletin

51.3:V270

March 2021

Specifications

V270 Valve

D104178X012

Valve Body Sizes and End Connection Styles

NPS J 6, J 8, J 10, J 12, J 14, J 16, J 20, and

J 24 flanged valves with CL150, CL300, or CL600

raised-face flanges compatible with ASME

B16.5-2013

Designed in accordance with API 6D

Maximum Inlet Pressures and Temperatures

(1)

Consistent with CL150, CL300, or CL600

pressure-temperature ratings per ASME B16.34-2013

Allowable Temperature Range: -40 to 82_C

(-40 to 180_F)

Flow Characteristic

Modified equal percentage

Flow and Shutoff Direction

Dual Seal Construction: The V270 may be used for

unidirectional or bidirectional flow

Flow Coefficients

See Fisher Catalog 12

Shutoff Classification

ANSI/FCI 70-2 Class VI

Seal Material

Standard: POM (Polyoxymethylene)

Maximum Ball Rotation

90_

Packing Arrangements

Standard: Live-Loaded Packing

This packing system provides improved sealing,

guiding, and transmission of loading force to control

liquid and gas emissions

Dimensions

See figure 2 through 7

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation for this valve should not be exceeded.

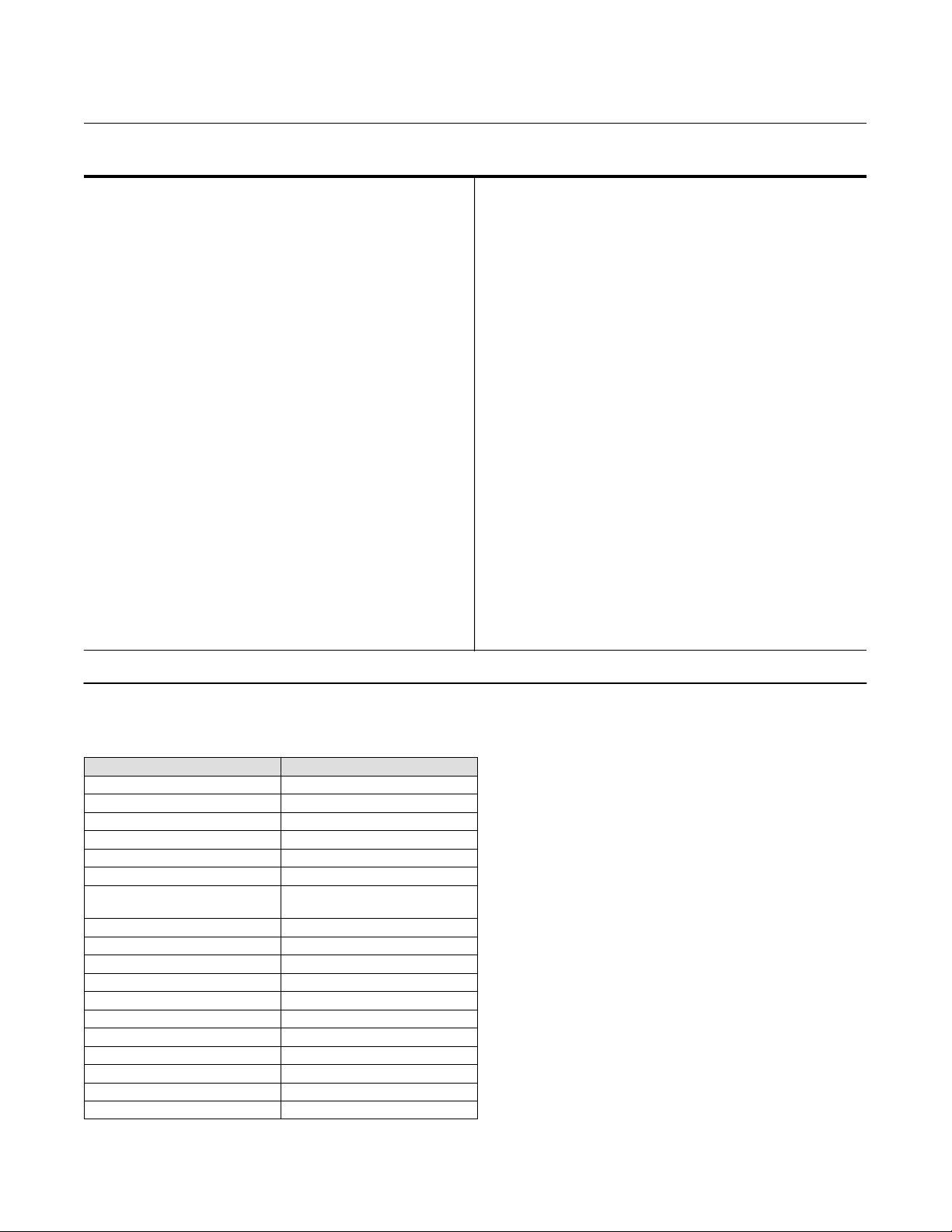

Table 1. Standard Materials of Construction

Part Material

Valve Body LF2 Carbon Steel

Ball LF2 Carbon Steel / ENP

Seal POM with S31600 SST Seal Carrier

Drive Shaft S17400 H1150D

Spring N07750

Tailpiece LF2 Carbon Steel

Tailpiece Mounting and

Packing Box Bolting

Bearing Plate LF2 Carbon Steel

Trunnion Bushings

Thrust Washer Glass filled PTFE

Shaft Bushing N04400 / Comp

Packing Box Housing Carbon Steel

Packing Live-Loaded PTFE

Packing Bolting B7M Steel

Packing Follower, Packing Box Ring S31600 SST

Straight Pins S17400 H1150D

O-Rings, Backup Rings Nitrile

Actuator Mounting Bolting Steel Grade 5

L7M Steel

Carbon Steel, Bronze, PTFE

2

Page 3

V270 Valve

D104178X012

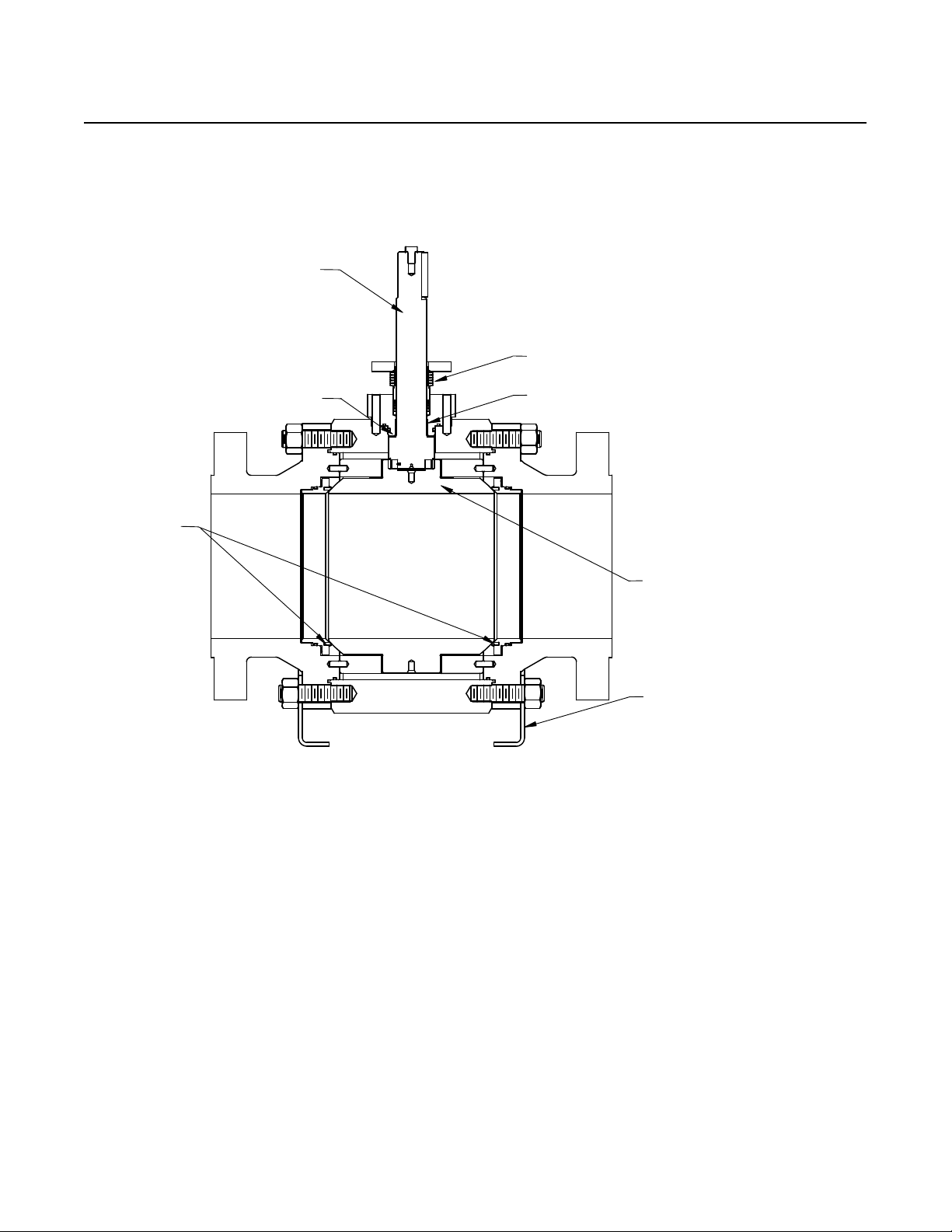

Figure 1. Sectional View of V270 Valve

SHAFT

Product Bulletin

51.3:V270

March 2021

LIVE LOADED PTFE PACKING

DUAL SEAL

ARRANGEMENT

THRUST BEARING

E1652

SHAFT BEARING

BALL

BASE BRACKET

3

Page 4

Product Bulletin

51.3:V270

March 2021

V270 Valve

D104178X012

Figure 2. Envelope Dimensions (see table 2)

A

U

W

E1653

Figure 4. NPS 24 CL600 Packing Box Housing

Mounting Pad Dimensions (see table 2)

U1

U2

T

R

E1656

W

T

Figure 3. Envelope Dimensions (see table 2 and 3)

G

N

Z

D

J

E1654

N

S

K

Figure 5. Shaft Detail (see table 3)

C

B

H

E1655

SECTION N-N

4

Page 5

V270 Valve

D104178X012

Product Bulletin

51.3:V270

March 2021

Figure 6. NPS 6 CL600 thru NPS 14 CL300 Base

Bracket Dimensions (see table 3)

E1

E1657

L

F1

Figure 7. NPS 14 CL600 thru NPS 24 CL600 Base

Bracket Dimensions (see table 3)

E1

E2

E1658

L

F2

F1

Figure 8. Live-Loaded Packing Arrangement Details

E1659

5

Page 6

Product Bulletin

51.3:V270

March 2021

Table 2. Envelope Dimensions

VALVE SIZE,

NPS

6

8

10

12

14

16

20

24

6

8

10

12

14

16

20

24

PRESSURE

CLASS

150 394 210.2 388.2 330

300 403 216.4 387.9 343 190

600 559 220.4 470.5 351 280

150 457 259.4 521.1 424 305

300 502 259.4 526.1 426 350

600 660 265.7 565.6 440 465

150 533 295.3 616.3 482

300 568 301.3 622.3 492 495

600 787 313.8 645.4 525 745

150 610 338.8 704.5 569 645

300 648 345.8 716.6 587 770

600 838 359.5 736.0 615 1050

150 686 369.0 821.0 628

300 762 401.8 827.2 630 1065

600 889 419.0 866.8 673 1365

150 762 435.2 936.9 701 1275

300 838 440.7 878.9 713 1455

600 991 464.5 923.1 762 1925

150 914 522.9 1074.9 875

300 991 530.0 1110.2 895

600 1194 555.5 1129.2 947 3450

150 1067 600.0 1287.9 1029

300 1143 615.0 1312.2 1066 88.8 4280

600 1397 649.0 1280.4 1140 101.6 609.6

150 15.50 8.27 15.28 12.99

300 15.88 8.52 15.27 13.50 415

600 22.00 8.68 18.52 13.82 620

150 18.00 10.21 20.52 16.70 670

300 19.75 10.21 20.71 16.77 775

600 26.00 10.46 22.27 17.32 1020

150 21.00 11.62 24.26 18.98

300 22.38 11.86 24.50 19.37 1095

600 31.00 12.35 25.41 20.67 1640

150 24.00 13.34 27.74 22.40 1425

300 25.50 13.61 28.21 23.11 1695

600 33.00 14.15 28.97 24.21 2320

150 27.00 15.59 32.32 24.70

300 30.00 15.82 32.57 24.80 2350

600 35.00 16.50 34.13 26.50 3015

150 30.00 17.13 36.89 27.61 2810

300 33.00 17.35 34.60 28.05 3210

600 39.00 18.29 36.34 29.98 4250

150 36.00 20.59 42.32 34.45

300 39.00 20.87 43.71 35.24

600 47.00 21.87 44.46 37.28 7610

150 42.00 23.62 50.71 40.51

300 45.00 24.21 51.66 41.97 3 1/2 9435

600 55.00 25.55 50.41 44.88 4 24.00

A K H R∅

V270 Valve

D104178X012

S∅ G∅

Shaft

Dia.

Keyway

Dia.

T U

mm kg

44.4 41.3 237.1 50.8

63.5 57.1 336.6 76.2

76.2

88.9

101.6

69.8

533.4 127.0

82.5

69.8 3380

475.2 (U1)

254.0 (U2)

Inches Pounds

1 3/4 1 5/8 10.75 2.00 3/4-10

2 1/2 2 1/4 13.25 3.00 7/8-9

3

3 1/2

4

2 3/4

21.00 5.00

3 1/4

2 3/4 7450

18.00 (U1)

10.00 (U2)

W

(THREADED)

See Below

1-1/4-8

APPROXIMATE

WEIGHT

170

430

1045

2245

2580

5775

370

950

2305

4945

5685

12740

6

Page 7

V270 Valve

D104178X012

Table 3. Additional Envelope Dimensions

VALVE SIZE,

NPS

6

8

10

12

14

16

20

24

6

8

10

12

14

16

20

24

PRESSURE

CLASS

150

300

600 242.4 200.1

150 250.4 273.1

300 269.4 231.4

600 302.4 292.1

150

300 282.4 251.8

600 328.9 307.6

150 318.0 279.9

300 328.2 330.2

600 389.4 330.2

150

300 428.5 396.8

600 644.0 415.4 453.3 224.7

150 706.1 439.4 489.3 222.6

300 678.0 487.5 502.5 312.0

600 677.1 486.6 568.2 352.3

150 823.2 556.5 598.7 338.3

300

600 871.2 604.5 708.4 441.7

150 394.0 408.3 282.7 82.8 15.9 944.6 627.1 634.6 317.1

300 381.0 409.0 260.6 98.3 22.2 1001.3 658.4 657.3 314.4

600 363.0 379.0 N/A 112.5 25.4 1009.5 704.7 853.4 548.6

150

300

600 9.54 7.88

150 9.86 10.75

300 10.61 9.11

600 11.91 11.50

150

300 11.12 9.92

600 12.95 12.11

150 12.52 11.02

300 12.92 13.00

600 15.33 13.00

150

300 16.87 15.62

600 25.35 16.35 17.85 8.85

150 27.80 17.30 19.26 8.76

300 26.69 19.19 19.78 12.28

600 26.66 19.16 22.37 13.87

150 32.41 21.91 23.57 13.32

300

600 34.30 23.80 27.89 17.39

150 15.51 16.07 11.13 3.26 0.63 37.19 24.69 24.99 12.49

300 15.00 16.10 10.26 3.87 0.88 39.42 25.92 25.88 12.38

600 14.29 14.92 N/A 4.43 1.00 39.74 27.74 33.60 21.60

D Z J

228.6 239.8 149.1 45.3 9.5

297.0 309.4 201.7 62.6 12.7

394.0 408.3 279.7 76.7 15.9

381.0 409.0 260.6 90.7 19.1

9.00 9.44 5.87 1.78 0.38

11.69 12.18 7.94 2.46 0.50

15.51 16.07 11.01 3.02 0.63

15.00 16.10 10.26 3.57 0.75

C B

Shaft &

Key

Height

mm

Inches

Key

Width

Product Bulletin

51.3:V270

March 2021

E1 E2 F1 F2 L

N/A

278.1 297.0

422.5 482.5

813.5 559.5 618.9 364.9

N/A

10.95 11.69

16.63 19.00

32.03 22.03 24.37 14.37

N/A

N/A

N/A

N/A

N/A

N/A

N/A

15.9

19.1

N/A

0.63

0.75

7

Page 8

Product Bulletin

51.3:V270

March 2021

Figure 9. Dead Angle (also see table 4)

V270 Valve

D104178X012

VIEW A

VIEW A

SCALE 1:2

THE AMOUNT THE BALL ROTATES FROM CLOSED,

AT WHICH, CONTROLLABLE FLOW BEGINS

GH08473

Table 4. Dead Angle Degrees

VALVE SIZE, NPS DEAD ANGLE, DEGREES

6 12

8 11

10 8

12 9

14 8

16 7

20 7

24 7

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2017, 2021 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...