Page 1

Instruction Manual

D103164X012

November 2010

V150S Slurry VeeBall Valve

Fisherr V150S Slurry Vee-Ballt Control Valve

NPS 3 through 12

Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Specification table 2. . . . . . . . . . . . . . . . . . . . . . . .

Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3

Maintenance 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packing Maintenance 5. . . . . . . . . . . . . . . . . . . . . .

Disassembly 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Mounting 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Mounting Position

for Spline Shaft/Lever Type 8. . . . . . . . . . . . . . .

Determining Closed Position 8. . . . . . . . . . . . . . . .

Parts Ordering 9

Parts List 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W8511

Figure 1. Fisher V150S Slurry Vee-Ball Control Valve

questions about these instructions, contact your

Emerson Process Management sales office before

proceeding.

Scope of Manual

This instruction manual provides installation,

operation, maintenance, and parts information for

Fisher Vee-Ball V150S (NPS 3 through 12) rotary

control valves (see figure 1).

Refer to separate manuals for information

concerning the actuator, positioner and accessories.

Do not install, operate, or maintain V150S valves

without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and

maintenance. To avoid personal injury or property

damage, it is important to carefully read, understand,

and follow all the contents of this manual, including

all safety cautions and warnings. If you have any

Description

The V150S Slurry Vee-Ball valve shown in figure 1

mates with CL150 raised face flanges. Rugged

construction, highly wear-resistant trim materials,

and an unrestricted straight through flow path make

the design ideal for controlling the most abrasive of

slurries.

A shaft with a choice of drive connections will allow a

variety of power operated actuators and valve

positioners or controllers to be used.

The design is particularly effective in minimizing

erosive damage to the adjoining pipework, thereby

providing greater operational safety and service life

when compared with other valve types.

www.Fisher.com

Page 2

Instruction Manual

V150S Slurry VeeBall Valve

Table 1. Specifications

Valve Sizes and End Connection Styles

NPS J 3, J 4, J 6, J 8, J 10, and J 12 with

CL150 raised-face flanges

Shutoff Classification

Construction does not provide tight shutoff.

Nominal gap between ball and flow ring seat is

0.035 inch for high chrome iron construction and

0.015 inch for ceramic insert construction.

Construction Materials

Standard Construction: See table 2

Flow Direction

Reverse flow recommended (into concave face of

ball, out through the flow ring)

Table 2. Standard Construction Materials

Part Material

Valve Body Carbon Steel ASTM A216 WCC

Body Liner

V-notch Ball

Flow Ring

Flow Ring Insert type (optional)

Flow Ring Retainer Carbon Steel ASTM A105

Bearing Shroud

Bearing 440C 58Rc

Drive Shaft 17-4PH Cond. H1025

Follower Shaft 17-4PH Cond. H1025

Shaft Pins Carbon Steel, zinc plated

Spring Carbon Steel

Gaskets Graphite SST Laminate.

Packing Set PTFE, Carbon Filled

Packing Set (optional) Graphite

Packing Box Ring and Follower 316 SST

Studs SA-193-B7

Nuts SA-194-2H

Retainer Screws and Clips 316 SST

Flow Ring Insert (optional) PSZ Ceramic

V-notch Ball (optional) PSZ ceramic

High Chrome Iron ASTM A532

Class III Type A

High Chrome Iron ASTM A532

Class III Type A

High Chrome Iron ASTM A532

Class III Type A

High Chrome Iron ASTM A532

Class III Type A

High Chrome Iron ASTM A532

Class III Type A

November 2010

Valve Installation

Shaft axis shall be horizontal

Actuator Mounting

Right-hand or left-hand, as viewed from upstream

end of valve

Maximum Ball Rotation

90 degrees

Valve/Actuator Action

With diaphragm or piston rotary actuator and

splined shaft, the valve is field-reversible between

PDTC or PDTO: J push-down-to-close

(extending actuator rod closes valve) and

J push-down-to-open (extending actuator rod

opens valve)

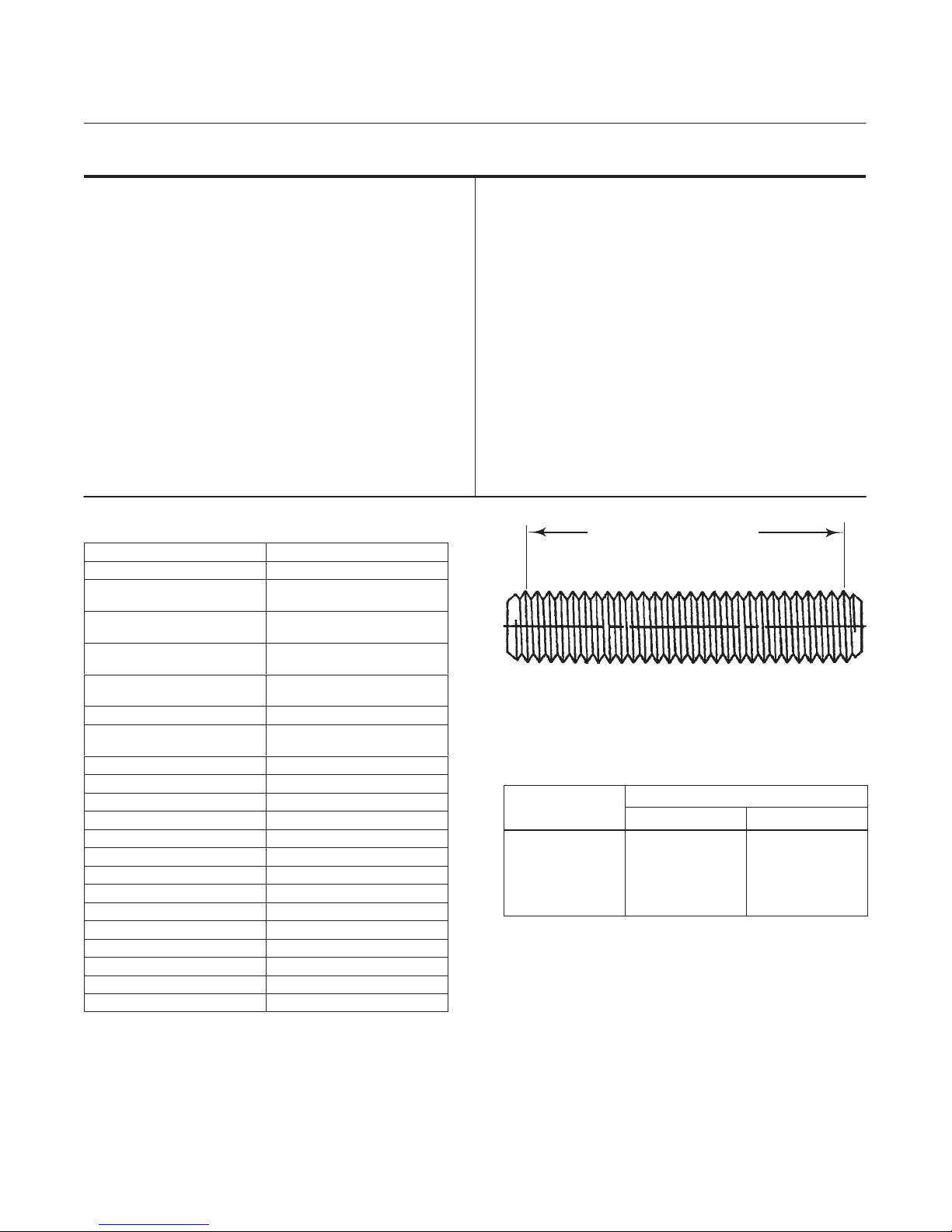

DIMENSION SHOWN IN TABLE 3

FIRST FULL THREAD TO

FIRST FULL THREAD

1A4520

Figure 2. Flange Stud Length for Seal Protector End

Table 3. Flange Stud Lengths Required for Flow Ring End

of Fisher V150S Valves

VALVE

SIZE,

NPS

3

4

6

8

10

12

mm Inches

95

108

114

183

222

256

V150S

3.75

4.25

4.50

7.19

8.72

10.10

Specifications

Specifications for these valves are shown in table 1

and in bulletin 51.3:V150S.

2

Page 3

Instruction Manual

November 2010

Installation

WARNING

Safe work practices should be

followed when handling the valve and

actuator.

Some types of ceramic trim, including

PSZ, can create a spark under certain

conditions when an edge of one

ceramic part is struck against a

second ceramic part with enough

force. Do not use ceramic trim where

the process fluid has volatile or

combustible properties.

The valve drive shaft is not necessarily

grounded to the pipeline when

installed. Personal injury or property

damage could result from an explosion

caused by a discharge of static

electricity from valve components if

the process fluid or the atmosphere

around the valve is flammable. If the

valve is installed in a hazardous area,

electrically bond the drive shaft to the

valve.

WARNING

Always wear protective gloves,

clothing, and eyewear when

performing any installation operations

to avoid personal injury.

Personal injury or equipment damage

caused by sudden release of pressure

may result if the valve assembly is

installed where service conditions

could exceed either the valve body

rating or the mating pipe flange joint

rating. To avoid such injury or

damage, provide a relief valve for

overpressure protection as required by

government or accepted industry

codes and good engineering practices.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

V150S Slurry VeeBall Valve

VALVE BODY

E0880

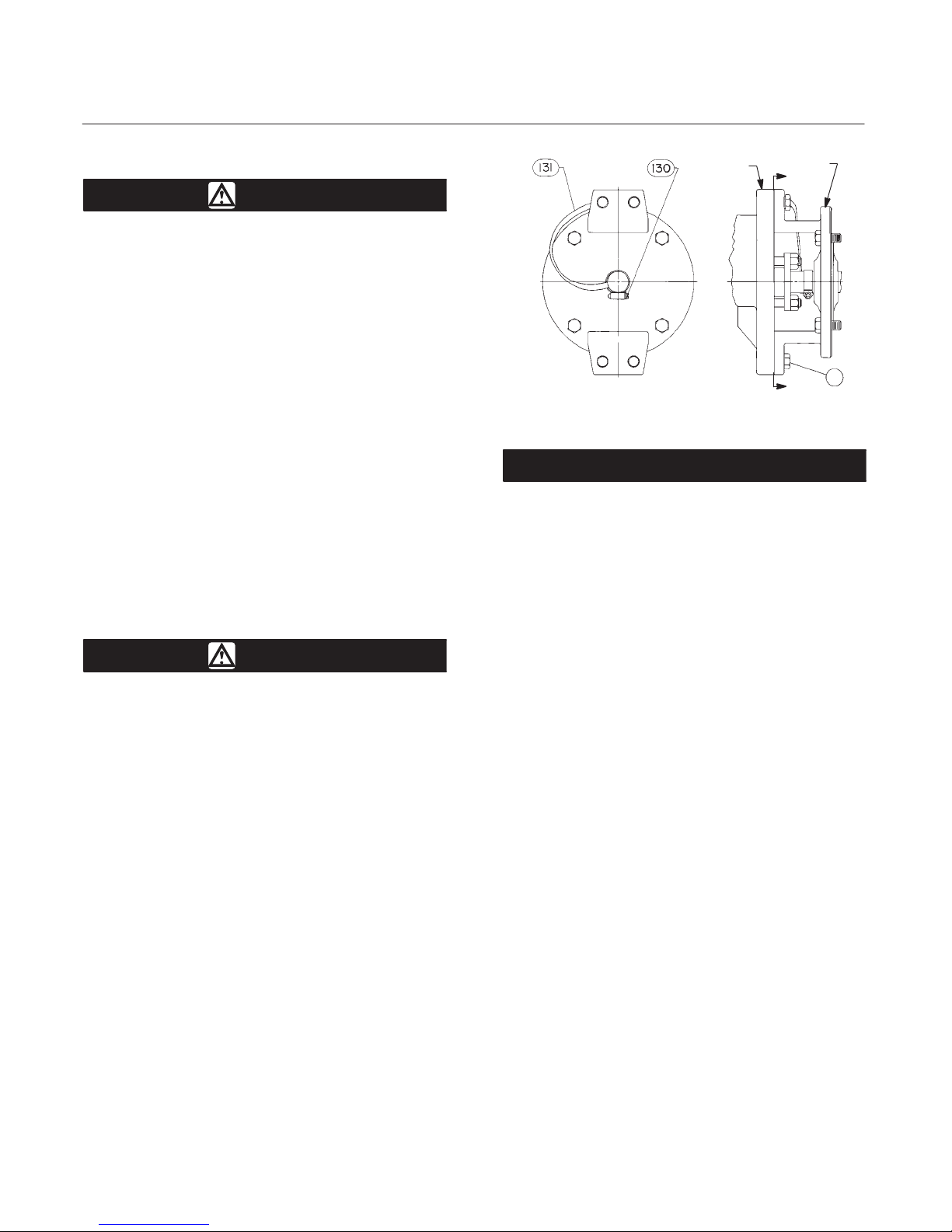

Figure 3. Optional Shaft-to-Body Bonding Strap Assembly

VIEW A-A

CAUTION

When ordered, the valve configuration

and construction materials were

selected to meet particular pressure,

temperature, pressure drop, and

controlled fluid conditions.

Responsibility for the safety of

process media and compatibility of

valve materials with process media

rests solely with the purchaser and

end-user. Because some valve/trim

material combinations are limited in

their pressure drop and temperature

ranges, do not apply any other

conditions to the valve without first

contacting your Emerson Process

Management sales office.

1. Install the valve in the direction of the flow arrow

fitted to the valve body.

2. Install the valve with the shaft axis in the

horizontal position.

3. If required, fit a bonding strap assembly (key 131)

to the drive shaft (key 8) with the clamp, (key 130,

figure 3) and connect the other end of the bonding

strap assembly to the valve body with actuator

mounting cap screw.

4. If the valve and actuator have been purchased

separately or if the actuator has been removed,

mount the actuator according to the Actuator

Mounting section and the appropriate actuator

instruction manual.

5. The actuator can be right- or left-hand mounted

with the shaft in a horizontal orientation as shown in

figure 1. If necessary, refer to the appropriate

actuator instruction manual for actuator installation

and adjustment procedures.

ACTUATOR

A

A

24

3

Page 4

Instruction Manual

V150S Slurry VeeBall Valve

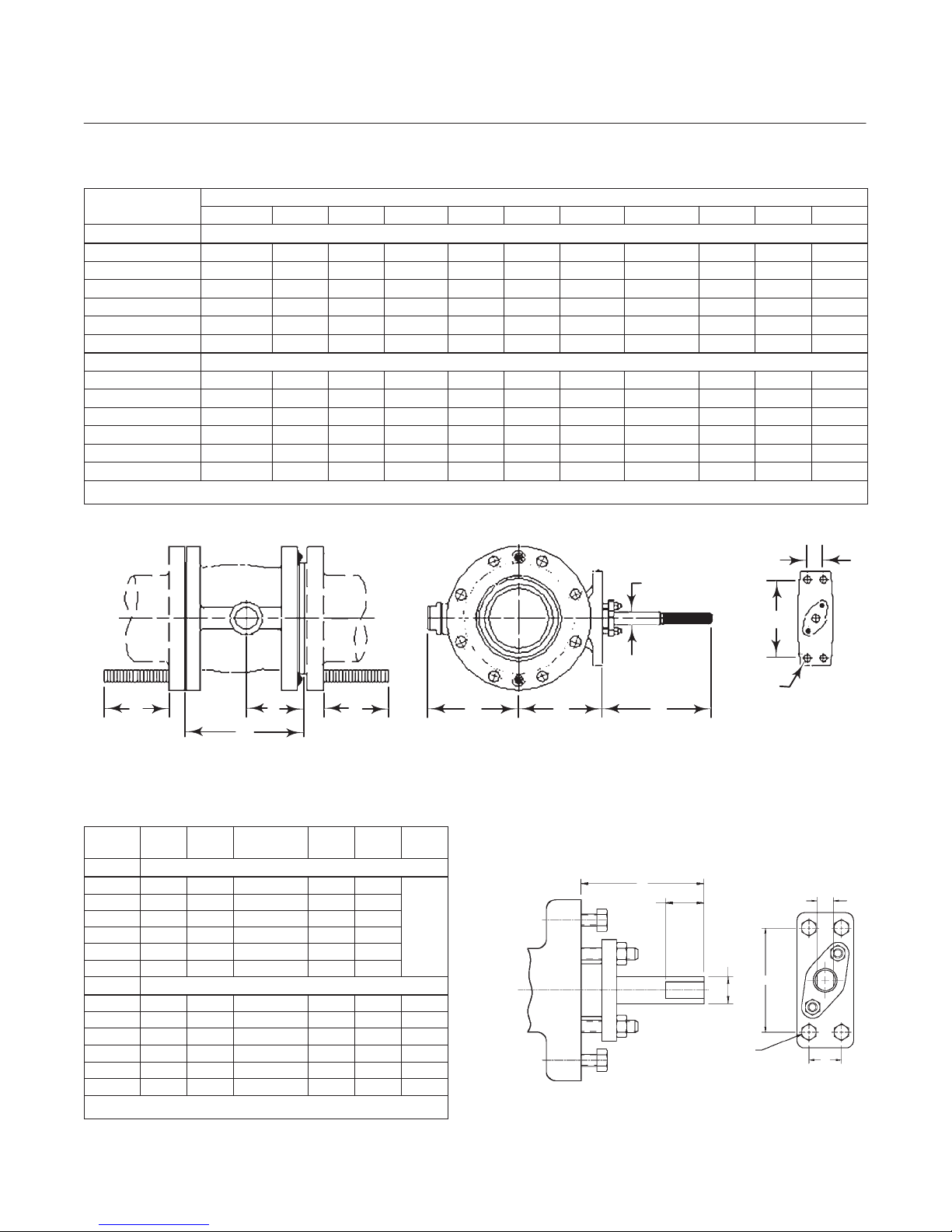

Table 4. Fisher V150S Dimensions

VALVE SIZE

A B D G K M

DN mm

80 165 80.0 235 140 130 104 98.0 19.1 152 31.8 14.2

100 194 102 214 152 140 11 7 98.0 19.1 152 31.8 14.2

150 230 111 214 175 164 124 112 25.4 152 31.8 14.2

200 304 184 208 220 231 195 124 31.8 235 46.0 17.5

250 385 235 208 250 261 235 132 31.8 235 46.0 17.5

300 455 291 208 300 304 270 132 38.1 235 46.0 17.5

NPS Inch

3 6.49 3.15 9.26 5.51 5.12 4.11 3.86 0.75 6.00 1.25 0.56

4 7.62 4.02 8.44 5.98 5.53 4.61 3.86 0.75 6.00 1.25 0.56

6 9.06 4.38 8.44 6.89 6.45 4.90 4.40 1.00 6.00 1.25 0.56

8 11.96 7.25 8.19 8.66 9.11 7.68 4.90 1.25 9.25 1.81 0.69

10 15.16 9.26 8.18 9.84 10.26 9.25 5.19 1.25 9.25 1.81 0.69

12 17.91 11.47 8.18 11.81 11.97 10.63 5.19 1.50 9.25 1.81 0.69

1. Stud length associated with clearance dimension “M” is longer than standard length specified in ANSI B16.5.

2. Clearance necessary to remove flange bolts.

V150S DIMENSIONS

(2)

(1)

(2)

N

S Diameter T U W

November 2010

MN

E0875

B

A

Figure 4. Fisher V150S Dimensions (see table 4)

Table 5. Fisher V150S Dimensions for Double D Shaft Drive

VALV E

SIZE

E S

(1)

FLAT

LENGTH

T U W

DN mm

80 83 19.0 25.4 95 25

100 83 19.0 25.4 95 25

150 83 25.4 25.4 95 25

200 83 31.8 25.4 133 38

250 89 31.8 25.4 133 38

300 89 38.1 38.1 133 38

NPS Inch

3 3.25 3/4 1.0 3.75 1.0 1/2-13

4 3.25 3/4 1.0 3.75 1.0 1/2-13

6 3.25 1 1.0 3.75 1.0 1/2-13

8 3.25 1-1/4 1.0 5.25 1.5 5/8-11

10 3.5 1-1/4 1.0 5.25 1.5 5/8-11

12 3.5 1-1/2 1.5 5.25 1.5 5/8-11

1. This nominal valve shaft diameter is the shaft diameter through the packing box.

Use this diameter when selecting Fisher actuators.

see

below

S DIAMETER

T

W

G K D

E

FLAT SIZE

S

T

W

38B2695-A

FLAT

LENGTH

Figure 5. Fisher V150S Dimensions for Double D Shaft Drive

(see table 5)

U

NPS

3 THROUGH 12

U

4

Page 5

Instruction Manual

November 2010

Maintenance

WARNING

The V-notch ball closes with a

shearing, cutting motion, which could

result in personal injury. To avoid

injury, keep hands, tools, and other

objects away from the V-notch ball

while stroking the valve.

Avoid personal injury from sudden

release of process pressure. Before

performing any maintenance

operations:

D Do not remove the actuator from

the valve while the valve is still

pressurized.

D Disconnect any operating lines

providing air pressure, electric power,

or a control signal to the actuator. Be

sure the actuator cannot suddenly

open or close the valve.

D Use bypass valves or completely

shut off the process to isolate the

valve from process pressure. Relieve

process pressure from both sides of

the valve. Drain the process media

from both sides of the valve.

D Vent the power actuator loading

pressure and relieve any actuator

spring precompression.

D Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D Always wear protective gloves,

clothing, and eyewear when

performing any maintenance

operations to avoid personal injury.

D The valve packing area may

contain process fluids that are

pressurized, even when the valve has

been removed from the pipeline.

Process fluids may spray out under

pressure when removing the packing

hardware or packing rings.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

V150S Slurry VeeBall Valve

Packing Maintenance

1. It is recommended that the valve be removed

from the line when replacing packing to allow correct

set up of the actuator after actuator removal.

2. Remove the packing follower nuts and packing

follower (keys 18 and 16).

3. Remove the packing parts (see figure 4 and

keys 15 and 14) using a purposed designed packing

extraction tool to avoid damaging the packing box

bore and shaft surfaces.

4. Install the new packing parts using the sequence

shown in figure 4. Fit the packing follower (key 16).

Fit nuts (key 18).

5. Tighten the packing nuts to compress the packing

to seal for operating conditions. At the same time

push the ball and shroud on the drive end against

the valve body inside location face to center the ball.

This can be done by using a lever (wood) against

the inside ball lug face and the valve body liner inlet.

Disassembly

WARNING

Observe the steps in the WARNING at

the beginning of the Maintenance

section.

Reference figures 9 and 10.

CAUTION

Trim parts are made from brittle

material, handle with care to avoid

chipping or breakage.

1. Remove the actuator cover (where applicable).

Take note of the orientation of the actuator with

respect to the valve body and the lever orientation

with respect to the valve drive shaft.

2. Remove the actuator.

3. Remove the flow ring retainer screws, clips and

flow ring retainer (keys 22, 23, and 5).

4. Knock or press out the flow ring (key 4).

5. Position the ball to allow access to the shaft pins.

Use a modified parallel pin punch (figure 7) to to

knock out the shaft pins, (key 10) through the shaft

and ball lugs.

Note

The punch dimensions should be as

per table 6 to avoid damaging the ball

5

Page 6

Instruction Manual

V150S Slurry VeeBall Valve

PACKING FOLLOWER (KEY 16)

PACKING SET

(KEY 15)

PACKING

BOX RING (KEY 14)

PTFE V‐RING PACKING

NOTE:

1

INCLUDES ZINC WASHERS FOR

GRAPHITE RIBBON PACKING ONLY.

28B5170

FOR V150S

STANDARD PACKING

Figure 6. Packing Arrangements

PACKING FOLLOWER (KEY 16)

1

GRAPHITE RIBBON PACKING

FOR V150S

November 2010

PACKING SET

(KEY 15)

PACKING

BOX RING (KEY 14)

and shaft. The hole diameter in the ball

is larger than the hole in the shaft and

the punch needs to be centrally

located with the pin.

6. Remove packing follower (key 16). Remove plug

(key 20) and spring, (key 19).

7. Knock or press each shaft (key 9) out through the

ball and the bearings (key 7).

8. Remove ball (key 3) and shrouds (key 6).

9. Knock, press or pull out bearings (key 7).

10. Knock or press out body liner (key 2).

11. Remove packing (key 15).

For service applications involving scale formation

that sets up and “freezes” mating parts,

supplementary recommendations for disassembly

can be provided by your Emerson Process

Management sales office.

Assembly

WARNING

Observe the steps in the WARNING at

the beginning of the Maintenance

section.

Reference figures 9 and 10.

CAUTION

Trim parts are made from brittle

material, handle with care to avoid

chipping or breakage.

1. Clean all surfaces of the parts to be used. Ensure

all mating surfaces are in good condition and free

from scratches and dents. Replace worn parts. Fit

new gaskets (key 13 and 21) and packing (key 15).

2. Position the valve body with flow arrow

uppermost.

3. Fit the valve body liner (key 2) into the valve

body, aligning cross-holes with shaft bore axis.

4. Fit the bearings (key 7) through the valve body

liner into the valve body.

5. Place bearing shrouds (key 6) over the bearings

and through the valve body liner to contact faces in

the valve body bore.

6. Orientate the ball (key 3) so that the lug with the

location slot will be on the non-drive side of the valve

body, that is opposite from the actuator. Place the

ball on a wad of rag to rest in the bottom of the valve

body with the lugs uppermost. Fit the drive shaft

(key 8) through the bearing on the drive side and

into the hexagon hole of the ball, aligning the holes

for the shaft pins. With a splined shaft, the indicator

line on the splined shaft end should be on the ball

side to indicate the ball “seat location”. Fit the

follower shaft (key 9).

6

Page 7

Instruction Manual

November 2010

7. Fit the shaft pins (key 10) through the ball and

into the shaft using a pin punch (figure 7). Position

the pins approximately centrally about the shaft axis.

8. Next install the packing. Fit the studs (key 17 ),

packing box ring (key 14), packing set (key 15),

packing follower (key 16), and nuts (key 18). Adjust

the packing tightness for use.

9. Before fitting the flow ring, tap the end of the

bearing on the drive end to ensure that the

ball/shroud assembly is hard against the valve body

inner recess location on the drive end.

10. Next fit the flow ring.

a. For one piece High Chrome Iron flow ring

(key 4), fit into the valve body and valve body

liner. Fit the gasket, (key 13) and flow ring

retainer (key 5). Secure with retainer screws

(key 22) and clips (key 23). Check that the ball

rotates freely.

b. For flow ring with ceramic insert, position

the valve body on the valve body liner flange face

with the ball secured and facing upwards. Make

sure the flow ring insert type (key 28) and flow

ring insert (key 29) are clean and free of grease

and oil. Apply a bead of Loctitet 620 around the

smaller outside diameter of the ceramic insert

and push the insert into the flow ring. Place shims

on the upper ball face (recommended thickness

.015 inch) and lower the flow ring assembly into

place. Secure with retainer, screws and clips.

Push the insert down onto the shims and allow

the adhesive to set.

11. Fit the spring (key 19), gasket (key 21), and plug

(key 20).

V150S Slurry VeeBall Valve

D

0.010

OA

E0878

Figure 7. Pin Punch

Table 6. Pin Punch Dimensions

Ball

Valve Size,

NPS

3 and 4 0.19 0.16 0.25 0.15 0.085 1.45

6 0.22 0.19 0.25 0.18 0.105 1.85

8 and 10 0.28 0.25 0.38 0.24 0.135 2.2

12 0.28 0.25 0.38 0.24 0.135 2.6

Hole O

Pin

Shaft

Pin

Hole O

OB

A

MinBMaxCMaxDMin

2. Clean the valve shaft and actuator lever splines

to be sure the actuator lever will slide on easily. Only

drive the lever in if absolutely necessary.

3. Carefully wedge the ball solidly against the

actuator-side bearing to center the ball.

4. Keep the wedge in place while installing the

lever, if necessary. Remove the wedge after you

have clamped the actuator lever on the valve shaft

and have connected the lever to the actuator piston

rod or diaphragm rod.

OC

R 0.010

MAX

For service applications involving scale formation

that sets up and “freezes” mating parts,

supplementary recommendations for assembly can

be provided by your Emerson Process Management

sales office.

Actuator Mounting

Use the appropriate actuator instruction manual, this

section of this manual, and figure 8 of this manual

when mounting the actuator or changing actuator

styles and positions.

1. To help ensure correct centering of the V-notch

ball (key 3) on the flow ring (key 4 or 28/29), be sure

the ball is closed when mounting the actuator (for

applications other than Spring Return Fail-Open).

Determining Mounting Position for

Spline Shaft/Lever Type

The actuator can be either right or left-hand

mounted, with the actuator on the right or left side

when viewed from upstream (see figure 8).

For right-hand mounting (standard), the ball will

be in the top of the valve body when the valve is

open and the shaft is horizontal. In this position the

ball rotates CW to Close.

For left-hand mounting, the ball will be in the top of

the valve body when the valve is open and the shaft

is horizontal. In this position the ball rotates CCW to

Close.

7

Page 8

Instruction Manual

V150S Slurry VeeBall Valve

November 2010

Figure 8. Index Marks for Actuator Lever Orientation for NPS 3 through 12 Valves

Determining Closed Position

1. The valve must be removed from the line to

check the position of the ball.

WARNING

The V-notch ball closes with a

shearing, cutting motion. To avoid

personal injury, keep hands, tools, and

other objects away from the ball while

stroking the valve.

2. Rotate the ball to the closed position.

3. Position the ball in the proper location.

4. The ball is in its closed position when the Vee

plane of the ball, (opposite the convex side) is

parallel to the liner end flange face of the valve body.

Measure to check. Adjust the actuator linkage or

travel stops to position.

CAUTION

To extend operating life of the V-notch

ball, always ensure the V-notch ball

rotates into the top of the valve body

to open.

8

Page 9

Instruction Manual

November 2010

V150S Slurry VeeBall Valve

29

28

W8513

Figure 9. Exploded View, Fisher V150S NPS 3 through 12

(Including Alternative Ceramic Insert Construction, Keys 28 and 29)

Parts Ordering

A serial number is assigned to each valve and

stamped on the nameplate. Always refer to the valve

serial number when corresponding with your

Emerson Process Management sales office

regarding spare parts or technical information. When

ordering replacement parts, also specify the

complete 11-character part number from the parts

kits or parts list information.

WARNING

Use only genuine Fisher replacement

parts. Components that are not

supplied by Emerson Process

Management should not, under any

circumstances, be used in any Fisher

valve, because they may void your

warranty, might adversely affect the

performance of the valve, and could

cause personal injury and property

damage.

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use, or maintenance of any

product. Responsibility for the

selection, use, and maintenance of any

product remains with the purchaser

and end user.

9

Page 10

Instruction Manual

V150S Slurry VeeBall Valve

November 2010

E0879

10

Figure 10. Fisher V150S Assembly

Page 11

Instruction Manual

November 2010

Parts List

Note

Part numbers are shown for recommended spares

only. For other part numbers, contact your Emerson

Process Management sales office.

Common Parts (figures 9 and 10)

Key Description Part Number

1 If you need a valve body as a replacement part,

order by valve size, serial number, and desired

valve body material. Contact your Emerson Process

Management sales office for assistance.

2* Valve Body Liner, High Chrome Iron

Schedule 40

NPS 3 1B12124U012

NPS 4 1B12125U012

NPS 6 2B12083U012

NPS 8 2B12193U012

NPS 10 2B12194U012

NPS 12 3B12220U012

Schedule 80

NPS 3 2B12127U012

NPS 4 2B12156U012

NPS 6 2B12021U012

NPS 8 2B12196U012

NPS 10 2B12197U012

NPS 12 3B12219U012

3* V-notch Ball

Standard, High Chrome Iron

NPS 3 3B12121U012

NPS 4 3B12077U012

NPS 6 3B12017U012

NPS 8 3B12079U012

NPS 10 3B12192U012

NPS 12 3B12222U012

PSZ Ceramic

NPS 3 3B12276U012

NPS 4 3B12277U012

NPS 6 3B12278U012

NPS 8 3B12279U012

NPS 10 3B12280U012

NPS 12 3B12281U012

4* Flow Ring, High Chrome Iron

Schedule 40

NPS 3 1B12086U012

NPS 4 1B12110U012

NPS 6 2B12082U012

NPS 8 2B12183U012

NPS 10 2B12185U012

NPS 12 3B12213U012

Schedule 80

NPS 3 1B12085U012

NPS 4 1B12111U012

NPS 6 2B12019U012

NPS 8 2B12184U012

NPS 10 2B12186U012

NPS 12 3B12215U012

V150S Slurry VeeBall Valve

Key Description Part Number

5 Flow Ring Retainer

6* Bearing Shroud, High Chrome Iron (2 req’d)

NPS 3 1B12100U012

NPS 4 1B12100U012

NPS 6 1B12062U012

NPS 8 1B12170U012

NPS 10 1B12170U012

NPS 12 1B12201U012

7* Bearing, 440C (2 req’d)

NPS 3 1B12119U012

NPS 4 1B12119U012

NPS 6 1B12031U012

NPS 8 1B12191U012

NPS 10 1B12191U012

NPS 12 1B12217U012

8 Drive Shaft Spline

8 Drive Shaft, DD

9 Follower Shaft

10* Shaft Pin, carbon steel, zinc plated (2 req’d)

NPS 3 1B12096U012

NPS 4 1B12096U012

NPS 6 1B12034U012

NPS 8 1B12166U012

NPS 10 1B12166U012

NPS 12 1B12206U012

13* Gasket, graphite/laminate

NPS 3 1B12133U012

NPS 4 1B12108U012

NPS 6 1B12036U012

NPS 8 1B12162U012

NPS 10 1B12177U012

NPS 12 1B12203U012

14* Packing Box Ring, 316 SST

NPS 3 and 4 16A6084X012

NPS 6 16A6085X012

NPS 8 16A6086X012

NPS 10 16A6086X012

NPS 12 16A6087X012

15* Packing Set

PTFE

NPS 3 and 4 12A8995X022

NPS 6 12A8832X022

NPS 8 12A8951X022

NPS 10 12A8951X022

NPS 12 12A8935X022

Graphite/laminate

NPS 3 and 4 12A9136X012

NPS 6 12A9137X012

NPS 8 12A9138X012

NPS 10 12A9138X012

NPS 12 12A9139X012

16 Packing Follower

17 Stud, 2 req’d

18 Nut, 2 req’d

19 Spring

20 Plug

*Recommended spare parts

11

Page 12

Instruction Manual

V150S Slurry VeeBall Valve

Key Description Part Number

21* Gasket, graphite/laminate

NPS 3 and 4 1B12098U012

NPS 6 1B12044U012

NPS 8 1B12168U012

NPS 10 1B12168U012

NPS 12 1B12204U012

22 Retainer Screw, 2 req’d

23 Retainer Clip, 2 req’d

24 Actuator Mounting Screw, 4 req’d

25 Nameplate

26 Drive Screw, 4 req’d

27 Flow Arrow

November 2010

Key Description Part Number

28 Flow Ring Insert type, High Chrome Iron

Schedule 40

NPS 3 1B12088U012

NPS 4 1B12112U012

NPS 6 2B12084U012

NPS 8 2B12181U012

NPS 10 2B12187U012

NPS 12 3B12214U012

Schedule 80

NPS 3 1B12087U012

NPS 4 1B12113U012

NPS 6 2B12050U012

NPS 8 2B12182U012

NPS 10 2B12188U012

NPS 12 3B12216U012

29 Flow Ring Insert PSZ Ceramic

NPS 3 1B12134U012

NPS 4 1B12109U012

NPS 6 2B12046U012

NPS 8 2B12157U012

NPS 10 2B12172U012

NPS 12 2B12210U012

130 Clamp

131 Bearing Clamp Assembly

*Recommended spare parts

Fisher, and VeeBall are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are

the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated

entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of

any product remains solely with the purchaser and end user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

EFisher Controls International LLC 2003, 2010; All Rights Reserved

Loading...

Loading...