Fisher TopWorx 4310 Wireless Position Monitor with On/Off Control Option-Supported Manuals & Guides

Page 1

Instruction Manual

D103622X012

TopWorx 4310

October 2016

TopWorx™ 4310 Wireless Position Monitor with

On/Off Control Option (Supported Status)

Contents

Introduction 1.................................

Safety Instructions 1............................

Specifications 2................................

Inspection and Maintenance Schedules 2...........

Parts Ordering 2................................

Installation 3..................................

Operation 4...................................

Maintenance 4.................................

Non‐Fisher (OEM) Instruments, Switches, and

Accessories 6..................................

Latest Published Instruction Manual 7..............

Introduction

The product covered in this document is no longer in production. This document, which includes the latest published

version of the instruction manual, is made available to provide updates of newer safety procedures. Be sure to follow

the safety procedures in this supplement as well as the specific instructions in the included instruction manual.

Part numbers in the included instruction manual should not be relied on to order replacement

parts. For replacement parts, contact your Emerson Process Management sales office

For more than 20 years, Fisher products have been manufactured with asbestos‐free components. The included

manual might mention asbestos containing parts. Since 1988, any gasket or packing which may have contained some

asbestos, has been replaced by a suitable non‐asbestos material. Replacement parts in other materials are available

from your sales office.

.

Safety Instructions

Please read these safety warnings, cautions, and instructions carefully before using the product.

These instructions cannot cover every installation and situation. Do not install, operate, or maintain this product

without being fully trained and qualified in valve, actuator and accessory installation, operation and maintenance. To

avoid personal injury or property damage it is important to carefully read, understand, and follow all of the contents of

www.Fisher.com

Page 2

TopWorx 4310

October 2016

this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact

your Emerson Process Management sales office before proceeding.

Instruction Manual

D103622X012

Specifications

This product was intended for a specific range of service conditions‐‐pressure, pressure drop, process and ambient

temperature, temperature variations, process fluid, and possibly other specifications. Do not expose the product to

service conditions or variables other than those for which the product was intended. If you are not sure what these

conditions or variables are, contact your Emerson Process Management sales office

serial number and all other pertinent information that you have available.

for assistance. Provide the product

Inspection and Maintenance Schedules

All products must be inspected periodically and maintained as needed. The schedule for inspection can only be

determined based on the severity of your service conditions. Your installation might also be subject to inspection

schedules set by applicable governmental codes and regulations, industry standards, company standards, or plant

standards.

In order to avoid increasing dust explosion risk, periodically clean dust deposits from all equipment.

When equipment is installed in a hazardous area location (potentially explosive atmosphere), prevent sparks by proper

tool selection and avoiding other types of impact energy. Control Valve surface temperature is dependent upon

process operating conditions.

WARNING

Control valve surface temperature is dependent upon process operating conditions. Personal injury or property damage,

caused by fire or explosion, can result if the valve body surface temperature exceeds the acceptable temperature for the

hazardous area classification. To avoid an increase of instrumentation and/or accessory surface temperature due to process

operating conditions, ensure adequate ventilation, shielding, or insulation of control valve components installed in a

potentially hazardous or explosive atmosphere.

Parts Ordering

Whenever ordering parts for older products, always specify the serial number of the product and provide all other

pertinent information that you can, such as product size, part material, age of the product, and general service

conditions. If you have modified the product since it was originally purchased, include that information with your

request.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher product. Use of components not supplied by Emerson Process

Management may void your warranty, might adversely affect the performance of the product and could result in personal

injury and property damage.

2

Page 3

Instruction Manual

D103622X012

TopWorx 4310

October 2016

Installation

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before mounting

the product:

D Do not install any system component where service conditions could exceed the limits given in this manual or the limits

on the appropriate nameplates. Use pressure‐relieving devices as required by government or accepted industry codes

and good engineering practices.

D Always wear protective gloves, clothing, and eyewear when performing any installation operations.

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression so the actuator is not

applying force to the valve stem; this will allow for the safe removal of the stem connector.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box might contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids might spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug. Cautiously remove parts so that fluid escapes slowly and safely.

D The instrument is capable of supplying full supply pressure to connected equipment. To avoid personal injury and

equipment damage, caused by sudden release of process pressure or bursting of parts, make sure the supply pressure

never exceeds the maximum safe working pressure of any connected equipment.

D Severe personal injury or property damage may occur from an uncontrolled process if the instrument air supply is not

clean, dry and oil‐free, or noncorrosive gas. While use and regular maintenance of a filter that removes particles larger

than 40 microns will suffice in most applications, check with an Emerson Process Management field office and Industry

Instrument air quality standards for use with corrosive gas or if you are unsure about the proper amount or method of

air filtration or filter maintenance.

D For corrosive media, make sure the tubing and instrument components that contact the corrosive media are of suitable

corrosiion-resistant material. The use of unsuitable materials might result in personal injury or property damage due to

the uncontrolled release of the corrosive media.

D If natural gas or other flammable or hazardous gas is to be used as the supply pressure medium and preventive

measures are not taken, personal injury and property damage could result from fire or explosion of accumulated gas or

from contact with hazardous gas. Preventive measures may include, but are not limited to: Remote venting of the unit,

re‐evaluating the hazardous area classification, ensuring adequate ventilation, and the removal of any ignition sources.

D To avoid personal injury or property damage resulting from the sudden release of process pressure, use a high‐pressure

regulator system when operating the controller or transmitter from a high‐pressure source.

The instrument or instrument/actuator assembly does not form a gas‐tight seal, and when the assembly is in an

enclosed area, a remote vent line, adequate ventilation, and necessary safety measures should be used. Vent line piping

should comply with local and regional codes and should be as short as possible with adequate inside diameter and few

bends to reduce case pressure buildup. However, a remote vent pipe alone cannot be relied upon to remove all

hazardous gas, and leaks may still occur.

D Personal injury or property damage can result from the discharge of static electricity when flammable or hazardous

gases are present. Connect a 14 AWG (2.08 mm

flammable or hazardous gases are present. Refer to national and local codes and standards for grounding

requirements.

D Personal injury or property damage caused by fire or explosion may occur if electrical connections are attempted in an

area that contains a potentially explosive atmosphere or has been classified as hazardous. Confirm that area

classification and atmosphere conditions permit the safe removal of covers before proceeding.

2

) ground strap between the instrument and earth ground when

3

Page 4

TopWorx 4310

October 2016

D For instruments with a hollow liquid level displacer, the displacer might retain process fluid or pressure. Personal injury

or property damage due to sudden release of pressure, contact with hazardous fluid, fire, or explosion can be caused by

puncturing, heating, or repairing a displacer that is retaining process pressure or fluid. This danger may not be readily

apparent when disassembling the sensor or removing the displacer. Before disassembling the sensor or removing the

displacer, observe the appropriate warnings provided in the sensor instruction manual.

D Personal injury or property damage, caused by fire or explosion from the leakage of flammable or hazardous gas, can

result if a suitable conduit seal is not installed. For explosion‐proof applications, install the seal no more than 457 mm

(18 inches) from the instrument when required by the nameplate. For ATEX applications use the proper cable gland

certified to the required category. Equipement must be installed per local and national electric codes.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D If installing into an existing application, also refer to the WARNING in the Maintenance section.

Instruction Manual

D103622X012

Special Instructions for Safe Use and Installations in Hazardous Locations

Certain nameplates may carry more than one approval, and each approval may have unique installation requirements

and/or conditions of safe use. Special instructions are listed by agency/approval. To get these instructions, contact

Emerson Process Management sales office

. Read and understand these special conditions of use before installing.

WARNING

Failure to follow conditions of safe use could result in personal injury or property damage from fire or explosion, or area

re‐classification.

Operation

With instruments, switches, and other accessories that are controlling valves or other final control elements, it is

possible to lose control of the final control element when you adjust or calibrate the instrument. If it is necessary to

take the instrument out of service for calibration or other adjustments, observe the following warning before

proceeding.

WARNING

Avoid personal injury or equipment damage from uncontrolled process. Provide some temporary means of control for the

process before taking the instrument out of service.

Maintenance

WARNING

Before performing any maintenance operations on an actuator‐mounted instrument or accessory:

4

Page 5

Instruction Manual

D103622X012

D To avoid personal injury, always wear protective gloves, clothing, and eyewear.

D Provide some temporary measure of control to the process before taking the instrument out of service.

D Provide a means of containing the process fluid before removing any measurement devices from the process.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression so the actuator is not

applying force to the valve stem; this will allow for the safe removal of the stem connector.

D Personal injury or property damage may result from fire or explosion if natural gas or other flammable or hazardous gas

is used as the supply medium and preventive measures are not taken. Preventive measures may include, but are not

limited to: Remote venting of the unit, re‐evaluating the hazardous area classification, ensuring adequate ventilation,

and the removal of any ignition sources. For information on remote venting of this instrument, refer to the Installation

section.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box might contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids might spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug. Cautiously remove parts so that fluid escapes slowly and safely.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D On an explosion‐proof instrument, remove the electrical power before removing the instrument covers in a hazardous

area. Personal injury or property damage may result from fire and explosion if power is applied to the instrument with

the covers removed.

TopWorx 4310

October 2016

Instruments Mounted on Tank or Cage

WARNING

For instruments mounted on a tank or displacer cage, release trapped pressure from the tank and lower the liquid level to a

point below the connection. This precaution is necessary to avoid personal injury from contact with the process fluid.

Instruments With a Hollow Displacer or Float

WARNING

For instruments with a hollow liquid level displacer, the displacer might retain process fluid or pressure. Personal injury

and property might result from sudden release of this pressure or fluid. Contact with hazardous fluid, fire, or explosion can

be caused by puncturing, heating, or repairing a displacer that is retaining process pressure or fluid. This danger may not

be readily apparent when disassembling the sensor or removing the displacer. A displacer that has been penetrated by

process pressure or fluid might contain:

D pressure as a result of being in a pressurized vessel

D liquid that becomes pressurized due to a change in temperature

D liquid that is flammable, hazardous or corrosive.

Handle the displacer with care. Consider the characteristics of the specific process liquid in use. Before removing the

displacer, observe the appropriate warnings provided in the sensor instruction manual.

5

Page 6

TopWorx 4310

October 2016

Instruction Manual

D103622X012

Non‐Fisher (OEM) Instruments, Switches, and Accessories

Installation, Operation, and Maintenance

Refer to the original manufacturer's documentation for Installation, Operation and Maintenance safety information.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

6

E 2016 Fisher Controls International LLC. All rights reserved.

Page 7

Instruction Manual

D103622X012

4310

February 2016

TopWorx™ 4310 Wireless Position Monitor with

On/Off Control Option

This manual applies to

Device Type E0CE (Hex) 57550 (decimal)

Device Revision 4

Firmware Revision 5

DD Revision 1

Contents

Introduction 2.................................

Scope of Manual 2.............................

Description 2.................................

Terminology 4................................

Specifications 4...............................

FCC Compliance 4.........................

Educational Services 4.........................

Installation 9..................................

Installing Standard and Extended Life

Power Module 10...........................

Installing Unit Supplied with External

Power Option 10............................

Network Setup 12.............................

Using the Field Communicator 12............

Using AMS Wireless Configurator

or AMS Device Manager 13...............

Hazardous Area Classifications and

Special Instructions for “Safe Use” and

Installations in Hazardous Locations 15.........

Valve / Actuator Mounting 19...................

Sliding‐Stem (Linear) Actuators

(e.g. Fisher

Guidelines for Mounting on Quarter‐Turn

(Rotary‐Shaft) Actuators 22...............

Pneumatic Hookup Procedure for

On/Off Control Option 24......................

Vent 26.......................................

Communication Connections 26..................

Wireless Communications 26.....................

Basic Setup 28.................................

Using the Local User Interface 28................

Identifying Device Revision 29...............

Language Selection 29.....................

Quick Position 29..........................

Status 30.................................

Power 30...............................

™

667) 21.....................

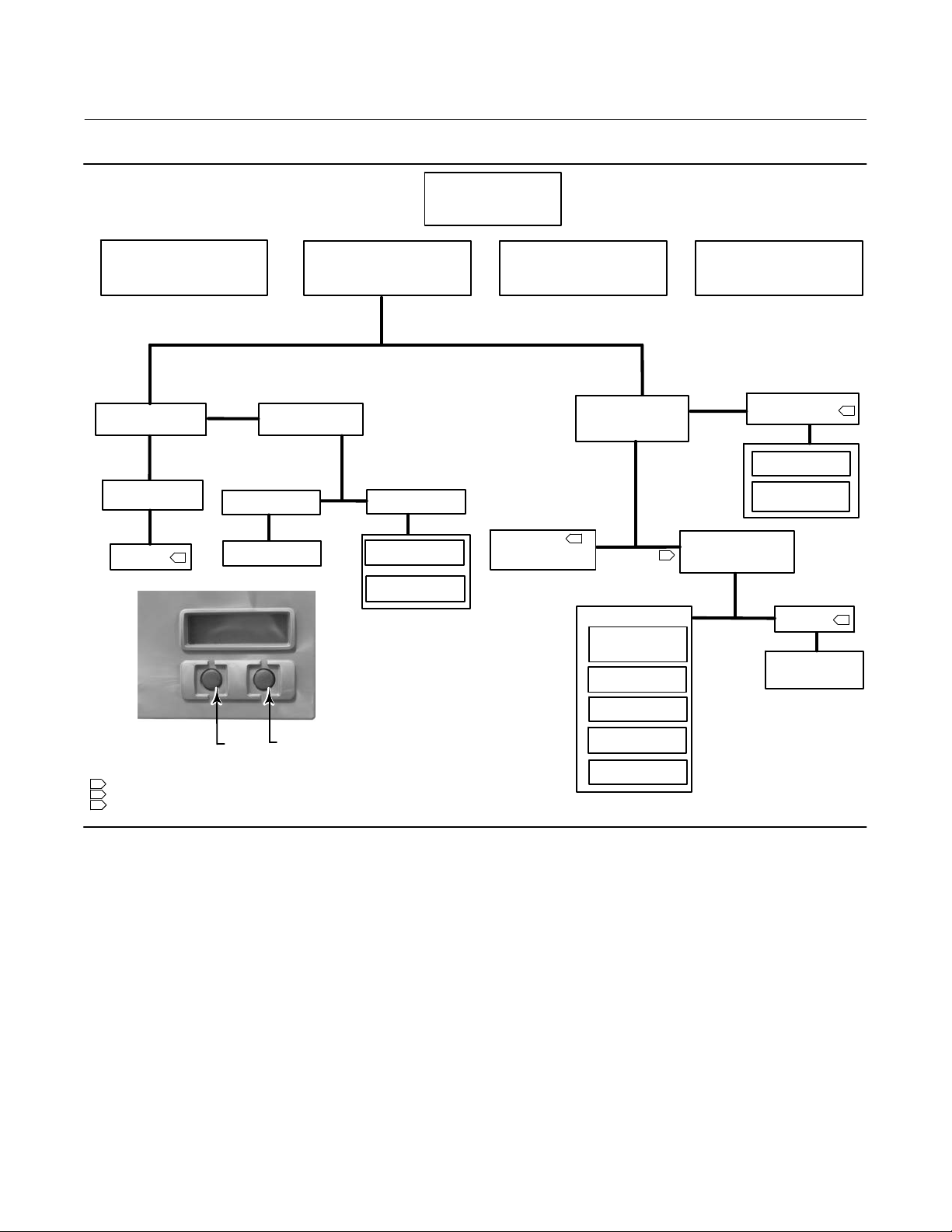

Figure 1. TopWorx 4310 Wireless Position Monitor,

with On/Off Control Option

X0895

Network 30.............................

Calibrate 31............................

Using the Field Communicator 33................

Overview 33..............................

Configure 35.............................

Service Tools 46...........................

Accessing Features 53...........................

Trip Points and Deadband 53....................

Diagnostic Features 53.........................

Locate 57....................................

Maintenance 58................................

Instrument Troubleshooting 59.................

Replacing the Instrument 60....................

Instrument Removal 60.....................

Replacing the Magnetic

Feedback Assembly 61.......................

Replacing the Power Module 61.................

Removal 61...............................

Installation 61.............................

Resetting Power Module Variables 62.........

Component Maintenance—On/Off Control Option 63

Spool Valve and Pneumatic Gasket Removal 63.

Spool Valve and Pneumatic Gasket Installation 64

Pneumatic Interface and Gasket Removal 64...

Pneumatic Interface and Gasket Installation 65.

Filter Replacement 65......................

ON/OFF CONTROL OPTION

www.topworx.com

Page 8

4310

February 2016

Instruction Manual

D103622X012

Contents (continued)

Parts 66.......................................

Repair Kits 66.................................

Replaceable Parts 66...........................

Introduction

Scope of Manual

This instruction manual includes specifications, installation, basic setup and configuration, and maintenance and

troubleshooting information for the TopWorx 4310.

This manual describes using the local interface or a Field Communicator to setup and calibrate the instrument.

Do not install, operate, or maintain a TopWorx 4310 without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all of the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson Process Management sales office

proceeding.

before

Description

Valve position is sensed through the noncontact, linkageless feedback sensor. There are no moving linkages and the

4310 is physically separated from the valve stem through the use of a magnetic Hall effect sensor. A magnetic array is

mounted to the valve stem and the sensor is embedded in the 4310 housing. The sensor is electrically connected to

the printed wiring board to provide a travel feedback signal used in the control algorithm.

On/Off Control Option

The 4310 on/off controller relays a digital set point generated by a control host to deliver a discrete (open/closed)

control action to a valve actuator. Valve position feedback provides confirmation of the control action, as shown in

figure 2. The valve command is converted to a pneumatic output signal. The pneumatic output is connected to the

supply pressure, and depending on set point, will either open or close the valve. The output can be used with either

airtoopen or airtoclose and supports both single and doubleacting actuators. When a single-acting actuator is

used it is necessary to plug one of the output ports on the spool valve.

The on/off control device can also be configured as a snapacting controller. In this configuration, there is no feedback

signal for the controlled equipment. The state of the monitored process triggers a command to the controlled valve.

The control system is alerted to changes in the process and the valve command, but the control action remains in the

field instrument. The 4310 uses the position signal, switch thresholds, and snap-control mode setting to decide when

to open or close the valve. For example, in figure 3, when a high level in the storage tank is reached, the 4310 closes

the inlet valve. In directacting snap, high or open trip on the input causes the controlled valve to open, and low/closed

trip on the input causes the controlled valve to close. In reverseacting snap, high/open trip causes the controlled valve

to close, and low/closed trip causes the controlled valve to open.

2

Page 9

Instruction Manual

D103622X012

Figure 2. Control Operation—Wireless Automated Valve

CHANGE COMMAND

4310

February 2016

2

4

CONTROL SYSTEM HOST

1

5

WIRELESS NETWORK

GATEWAY

VALVE POSITION

FEEDBACK

COMMAND TO MAKE A VALVE CHANGE STARTS AT THE CONTROL SYSTEM HOST AND IS SENT TO THE GATEWAY.

THE GATEWAY ROUTES THE VALVE CHANGE COMMAND TO THE 4310.

THE 4310 ACTS ON THE VALVE COMMAND AND MAKES VALVE CHANGE.

THE 4310 MONITORS VALVE POSITION AND SENDS UPDATES TO THE GATEWAY.

THE GATEWAY PROVIDES CURRENT VALVE POSITION DATA TO CONTROL SYSTEM HOST. THE VALVE POSITION

FEEDBACK IS USED TO CONFIRM THAT THE REQUESTED ACTION “COMMAND” WAS PERFORMED.

Figure 3. Control Operation—Snap-Acting Control

PNEUMATIC

SUPPLY

4

3

3

CHANGE

COMMAND

RESULTS IN

VALVE CHANGE

CONTROL SYSTEM HOST

WIRELESS NETWORK

GATEWAY

FILL VALVE

THE 4310 MONITORS THE PROCESS POSITION (EXAMPLE: LIQUID LEVEL).

THE 4310 ACTS ON PROCESS POSITION CHANGES (EXAMPLE: HIGH LEVEL DETECTED)

AND CAUSES VALVE TO OPEN OR CLOSE. ACTION IS DETERMINED BY THE LOGIC IN THE 4310.

THE 4310 SENDS POSITION AND OUTPUT STATE UPDATES TO GATEWAY.

THE GATEWAY PROVIDES THE CURRENT PROCESS POSITION DATA AND VALVE OUTPUT

COMMAND TO THE CONTROL SYSTEM HOST.

1

INTEGRATED

LEVEL

SENSOR

2

TANK

3

Page 10

4310

February 2016

Instruction Manual

D103622X012

Terminology

Local Interface—All 4310's come standard with a Liquid Crystal Display (LCD) and two (2) pushbuttons. The local

interface provides the capability to setup and calibrate the monitor.

Magnet Assembly—This is the feedback component that is mounted directly to the valve stem. It supplies a magnetic

field that is sensed by the 4310. This component is typically part of most mounting kit assemblies.

Specifications

Specifications for the 4310 are shown in table 1.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

This product is an FCC approved device. Changes or modifications to the 4310 that are not expressly approved by the

party responsible for compliance may void your authority to operate the device.

WARNING

This product is intended for a specific temperature range and other application specifications. Failure to adhere to these

specifications could result in the malfunction of the product, property damage, or personal injury.

Educational Services

For information on available courses for the 4310, as well as a variety of other products, contact:

Emerson Process Management

Educational Services, Registration

Phone: +1-641-754-3771 or +1-800-338-8158

e‐mail: education@emerson.com

http://www.emersonprocess.com/education

4

Page 11

Instruction Manual

D103622X012

Table 1. Specifications

4310

February 2016

Available Mountings

J Quarter‐turn rotary‐shaft

J sliding‐stem or

J linear applications

Can also be mounted on other actuators that comply

with IEC 60534‐6‐1, IEC 60534‐6‐2, VDI/VDE 3845

and NAMUR mounting standards

Input Measurement (Valve or Process)

Stem Travel (linear movement)

Minimum: 2.5 mm (0.10 inch)

Maximum: 210 mm (8.25 inches)

Shaft Rotation (rotary movement)

Minimum: 45_

Maximum: 90_

Shaft Rotation (rotary movement, arced array)

Minimum: 13_

Maximum: 30_

Measurement Output

Discrete: on/off switches (2)

On/Off Control

Output Signal

Pneumatic signal as required by the actuator, up to

95% of supply pressure

Minimum Span: 3.1 bar (45 psig)

Maximum Span: 7 bar (101 psig)

Action: Single or Double Acting

Supply Pressure

Minimum: 3.1 bar (45 psig)

Maximum: 7 bar (101 psig)

Supply Medium

Air or Natural Gas

Supply medium must be clean, dry, and

non-corrosive. The supply air at the device should

have a dew point less than -20_C (-4_F).

Refer to ATEX and IECEx Special Conditions of Safe

Use on page 15 for additional information on use of

natural gas as supply medium.

Per ISA Standard 7.0.01

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended.

Lubricant content is not to exceed 1 ppm weight

(w/w) or volume (v/v) basis. Condensation in the air

supply should be minimized.

‐continued‐

Per ISO 8573-1

Maximum particle density size: Class 7

Oil content: Class 3

Pressure Dew Point: Class 3 or at least 10_C less than

the lowest ambient temperature expected

Air Consumption

(1)

4310

At 5.5 bar (80 psig) supply pressure:

0.036 m

3

/hr (1.27 scfh)

Pilot Valve Leakage

Maximum at 20_C: 8 ml/min (0.0003 scfm/min)

Maximum at -20_C: 800 ml/min (0.028 scfm/min)

Air Capacity / Flow Rate

Supply Pressure: 1.2 Cv

Connections (Optional)

Supply, Output Pressure, and Vent: 1/4 NPT

Wireless Set Point Command

IEC 62591 (WirelessHART) 2.4 GHz DSSS

Local User Interface

Liquid Crystal Display (LCD)

Two pushbuttons for navigation, setup, and

calibration

Communication Protocol

HART 7, IEC 62591 (WirelessHART)

Maintenance Port Communication Signal

Bell 202 Voltage Signaling: 1200 bps binary

phase-continuous Frequency-Shift-Keying (1220 Hz

mark, 2400 Hz space) superimposed on voltage level

Initial Dynamic Variable Assignments (Default)

Dynamic

Variable

Assignment

Primary (PV) Switch States Switch States Switch States

Secondary (SV) Set Point Set Point Switch States

Tertiary (TV) Cycle Counter Cycle Counter Cycle Counter

Quaternary (QV) Supply Voltage Supply Voltage Supply Voltage

Control Snap Control Monitor

DEVICE STRUCTURE

Refer to table 4 for a complete list of Device Variables

Wireless Communication Signal

2.4 GHz, DSSS, IEC 62591 (WirelessHART)

Maximum 10 dBm (10 mW) EIRP at 2.46 GHz

5

Page 12

4310

February 2016

Table 1. Specifications (continued)

Instruction Manual

D103622X012

Wireless Classifications

Class A digital device, complies with part 15 of the

FCC Rules

Contains FCC ID: LW2RM2510

Contains IC: 2731A‐RM2510

Electromagnetic Compatibility

Meets EN 61326‐1:2013

Immunity—Industrial locations per Table 2 of

the EN 61326‐1 standard. Performance is

shown in table 2 below.

Emissions—Class A & B. Performance is shown in

table 3 below.

ISM equipment rating: Group 1, Class A & B

Vibration Testing

Meets or exceeds vibration levels specified in

ANSI/ISA 75.13.01 1996 (2007):

4 mm peak to peak at 5 Hz,

2 g from 15150 Hz, and

1 g from 150 2000 Hz

European Directive Information

This product complies with the following directives:

ATEX Directive (94/9/EC)

Electro Magnetic Compatibility (EMC) (2004/108/EC)

Radio and Telecommunications Terminal Equipment

Directive (R&TTE) (1999/5/EC)

Refer to Safety Instructions (D103022X012)

for the

Declaration of Conformity

Operating Temperature Limits

(2)(3)

Monitoring

Battery Power: -40 to 85_C (-40 to 185_F)

External Power: -40 to 80_C (-40 to 176_F)

LCD may not be readable below -20_C (-4_F)

With Pneumatic Output (On/Off Control):

-20 to 50_C (-4 to 122_F)

Storage Temperature Limits

(2)(3)

-40 to 70_C (-40 to 158_F)

Humidity Limits

10-95% Non‐Condensing Relative Humidity

Electrical Classification

CSA (C/US)— Intrinsically Safe

ATEX— Intrinsically Safe

IECEx— Intrinsically Safe

Refer to Hazardous Area Classifications and Special

Instruction for “Safe Use” and Installations in

Hazardous locations, starting on page 15, for

additional information

Other Classifications/Certifications

CUTR—Customs Union Technical Regulations

(Russia, Kazakhstan, Belarus, and Armenia)

INMETRO—National Institute of Metrology,

Quality and Technology (Brazil)

NEPSI—National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

PESO CCOE—Petroleum and Explosives Safety

Organization - Chief Controller of Explosives (India)

TIIS—Technology Institution of Industrial Safety

(Japan)

Contact your Emerson Process Management sales

office for classification/certification specific

information

Electrical Housing

Type 4X, IP66 & IP67

IEC 61010 Compliance

Meets Pollution Degree 4

Adjustments

Zero and Maximum Span through local interface

Altitude Rating

Up to 2000 meters (6562 feet)

Temperature Sensitivity

0.06% change per degree C

6

Weight

Monitoring— 0.57 kg (1.25 lb)

On/Off Control— 1.6 kg (3.4 lb)

‐continued‐

Page 13

Instruction Manual

D103622X012

Table 1. Specifications (continued)

4310

February 2016

Power Module

(3)

Update Rates

Standard —Lithium, non‐rechargeable

Power Module Limits

(4)

Standard— 5 years at update rate of 16 seconds or

For position feedback, temperature, and power

module voltage—selectable from 1 second to 1 hour;

1s, 2s, 4s, 8s, 16s, 32s, 1 to 60 minutes

longer with 3 additional devices communicating

through it

Extended‐Life— 10 years at update rate of 8 seconds

or longer with 3 additional devices communicating

through it.

Note: Sample rate for position feedback is normally

the same as the update rate. When using Report by

Exception reporting refer to Advanced Wireless

Reporting, on page 39, for additional information.

Shelf life— 10 years (radio off)

External Power (Optional)

12 - 28 volts DC

Construction Material

100 mA maximum operating current

Polarity Insensitive

Wire Size—14-20 gauge

1. Normal m3/hour - Normal cubic meters per hour at 0_C and 1.01325 bar, absolute. Scfh - Standard cubic feet per hour at 60_F and 14.7 psia.

2. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

3. Due to the combustible nature of the lithium content, the power module has special installation, operation, storage, and/or shipping requirements. Observe all warnings included with the power

module before installing, operating, storing, or shipping. Contact your Emerson Process Management sales office

4. When operating in temperatures between -10_C (14_F) and -20_C (-4_F) it is recommended that you use the extended power module, as power module life is impacted. The life expectancy of

an extended life power module used continually in the -10_C (14_F) and -20_C (-4_F) range is 3 years.

Housing: A03600 low copper aluminum alloy

Elastomers: nitrile, fluorosilicone

if additional information is needed.

Table 2. EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level Performance Criteria

Electrostatic discharge (ESD) IEC 61000‐4‐2

Enclosure

DC Power

Performance criteria: +/- 2% of effect

1. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering.

2. Applicable to External Power option only.

Radiated EM field IEC 61000‐4‐3

Rated power frequency

magnetic field

Burst IEC 61000‐4‐4 2 kV (5/50 ns, 5 kHz) B

(2)

Conducted RF IEC 61000‐4‐6 10 Vrms (150 kHz to 80 MHz) A

IEC 61000‐4‐8 100 A/m @ 50 Hz & 60 Hz A

6 kV contact

8 kV air

80 to 1000 MHz @ 10 V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 10 V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 3 V/m with 1 kHz AM at 80%

B

A

(1)

Table 3. EMC Summary Results—Emissions

Port

Enclosure 30 to 230 EN 55011

Enclosure

NOTES:

The 4310 is considered as a Group 1 device.

Industrial, Scientific, and Medial (ISM) radio frequency (RF) equipment is rated according to its Group and Class as follows;

Group I - Equipment in which there is intentionally generated and/or used conductively coupled radio-frequency energy which is necessary for the internal functioning of the equipment itself.

Group II - Equipment in which radio-frequency energy is intentionally generated and/or used in the form of electromagnetic radiation for the treatment of material, and EDM and arc welding

equipment.

Class A - Equipment suitable for use in industrial and commercial environments

Class B - Equipment suitable for use in domestic environments

Frequency

Range (MHz)

230 to 1000 EN 55011

1000 to 3000

3000 to 6000

Basic Standard Emissions Level Given Rating

EN 55022

Group 1 Class A: 40 dB (μV/m) measured at 10 m distance

Group 1 Class B: 30 dB (μV/m) measured at 10 m distance

Group 1 Class A: 47 dB (μV/m) measured at 10 m distance

Group 1 Class B: 37 dB (

Group 1 Class B

50 dB (μV/m) measured at 3 m distance, peak limit not to exceed 70 dB (μV/m)

Group 1 Class B

54 dB (μV/m) measured at 3 m distance, peak limit not to exceed 74 db (μV/m)

μV/m) measured at 10 m distance

Class A & B

Class A & B

Class A & B

Class A & B

7

Page 14

4310

February 2016

Instruction Manual

D103622X012

Table 4. Device Variables

INDEX

1 Closed/Low Limit Switch CLOSED_TRIGGER Reports Closed/Low condition (1 = Tripped, 0 = Not Tripped)

2 Opened/High Limit Switch OPEN_TRIGGER Reports Opened/High condition (1 = Tripped, 0 = Not Tripped)

3 Temperature DEVICE_TEMPERATURE Electronics Module Temperature (Degrees C)

4 Supply Voltage BATTERY_VOLTAGE Power Supply Output (Volts DC)

5 Set Point (on/off control only) SET_POINT Set Point (1 = Closed, 2 = Open)

6 Switch States SWITCH_STATE

7 Last Close Stroke Time CLOSE_STROKE_TIME Time the on/off controller took to previously close the valve

8 Last Open Stroke Time OPEN_STROKE_TIME Time the on/off controller took to previously open the valve

9 Timestamp 0 MESSAGE_0_TIMESTAMP Timestamp of burst message 0

10 Timestamp 1 MESSAGE_1_TIMESTAMP Timestamp of burst message 1

11 Timestamp 2 MESSAGE_2_TIMESTAMP Timestamp of burst message 2

12 Opened/High Dwell OPEN_DWELL_TIME The time the state has been/previously was in the open state.

13 Closed/Low Dwell CLOSED_DWELL_TIME The time the state has been/previously was in the closed state.

14 Transition Dwell PARTIALLY_OPEN_DWELL_TIME The time the state has been/previously was in the partially open state.

15 Cycle Counter CYCLE_COUNTS Cycle counted by the device

243 Battery Life Remaining BATTERY_LIFE Estimated battery life remaining

244 PV % Range PERCENT_RANGE 0 (%)

245 Loop Current CURRENT Always Indeterminate (not a number) (mA)

INDEX

0 Discrete Switch State DISCRETE_SWITCH_STATE Current state of the switch variable

Discrete Set Point

1

(On/Off Control only)

1. 1410 gateway version 4.4.28 or later or 1420 gateway version 4.4.15 or later is required.

DD Published To Gateway

DD Published To Gateway

DEVICE VARIABLE

DISCRETE VARIABLES

DISCRETE_SET_POINT Target value for the controlled variable

(1)

Combines information in variables 1

and 2

DESCRIPTION

(0 = Part Open, 1 = Closed,

2 = Opened, 3 = Unknown,

4 = Mid, 5 = High, 6 = Low)

(days) - meaningless with

External Power option

DESCRIPTION

(6 = Closed, 17 = Opening,

18 = Closing, 46 = Opened

48 = Unknown, 52 = Part-Open,

53 = Mid, 54 = High, 55 = Low)

(4 = Close, 5 = Open,

6 = Closed, 46 = Opened)

8

Page 15

Instruction Manual

D103622X012

4310

February 2016

Installation

WARNING

Before mounting the 4310:

D Always wear protective clothing, gloves, and eyewear when performing any installation procedures to avoid personal

injury or property damage.

D If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

WARNING

The 4310 power module contains two primary lithiumthionyl chloride batteries. Under normal conditions of use, the

battery materials are selfcontained and are not reactive as long as the batteries and power module integrity are

maintained. Care should be taken to prevent mechanical, electrical, or thermal damage. DO NOT recharge, short-circuit,

disassemble, heat, or expose the power module to water. The batteries contain flammable materials and performing any of

the above actions could cause them to become damaged, ignite, or explode, resulting in personal injury or property

damage. Observe all warnings included with the power module before installing, operating, storing, or shipping the 4310.

Personal injury and property damage can result from fire or explosion if the power module is subjected to heat above

100_C (212_F). Power modules should be stored in a cool, dry and ventilated area; for maximum life, storage should not

exceed 30_C (86_F).

CAUTION

When installing components, proper means of electrostatic discharge protection is required. Failure to use a grounding

strap, or other means of electrostatic discharge protection can result in damage to the electronics.

WARNING

To avoid static discharge do not rub or clean the antenna with solvents.

The 4310 has two available power sources; a battery-sourced power module, or an external power source.

Note

A 4310 powered by a battery-sourced power module cannot be converted to a 4310 powered by an external power source. The

housing and electronics are not the same for a 4310 powered by a battery-sourced power module and a 4310 powered by an

external power source.

9

Page 16

4310

February 2016

Instruction Manual

D103622X012

Installing Standard and Extended Life Power Modules

There are two battery-sourced power options, standard life and extended life power modules. Refer to the power

module warning labels, shown in figure 4, to determine which power module you have. Refer to figure 5 when

installing.

Figure 4. Warning Labels from Power Module

GE57654X012

STANDARD LIFE POWER MODULE

Note

Default configuration is for a standard power module. If installing the extended life power module you must change the

configuration. Incorrect power module configuration will affect remaining days of life calculations. If using the Field

Communicator go to Configure, Manual Setup, Power Module, Reset Module Data. In AMS Device Manager go to Configure, Manual

Setup and select Reset Power Module Variables from the Power tab.

To install the power module:

1. Loosen the two instrument screws and open the cover.

2. Align the power module over the four banana plug connectors and insert on the main board.

3. Insert the four self-tapping screws into the corresponding female receptors on the cover/main board assembly and

tighten to a torque of 0.282 N•m (2.5 lbf•in) to ensure that the power module is secured properly.

4. If you are replacing the power module see the additional steps to reset the power module remaining life counter, in

the Resetting Power Module Variables procedure found on page 62.

5. Close the cover and tighten the instrument cover screws to a torque of 5.6 to 6.7 N•m (50 to 60 lbf•in).

GE57655X012

EXTENDED LIFE POWER MODULE

Installing Unit Supplied with External Power Option

Refer to figure 6 when installing the wiring.

1. Loosen the two instrument screws and open the cover.

WARNING

Select a cable gland that is rated for the environment of use (such as hazardous area, ingress protection and temperature).

Failure to use properly rated cable glands can result in personal injury or property damage from fire or explosion.

When installing the cable gland or conduit fitting minimize the amount of wires remaining in the housing cavity so they do

not get compressed or damaged when closing the cover in step 7.

10

Page 17

Instruction Manual

D103622X012

Figure 5. TopWorx 4310 with Battery Sourced Power Modules

4310

February 2016

PWR TERMINAL

COVER SCREWS

X0552-1

HART

TERMINALS

GND

TERMINAL

POWER

MODULE

BANANA PLUG CONNECTORS (4)

SELF TAPPING SCREWS (4)

2. Insert a user-supplied cable gland or conduit fitting into the housing.

3. Insert the wires through the cable gland/conduit fitting.

FILTER (2)

WARNING

Wiring connected to the External Power terminals should be rated for +100_C (212_F) max.

Failure to use properly rated wiring can result in personal injury or property damage from fire or explosion.

4. Connect the wires to the connections as shown in figure 6. The terminal and electronical connections are

polarity-insensitive; i.e., you can connect the positive or negative wire to either terminal screw.

5. As shown in figure 6, a ground terminal is available for connecting a safety ground. Make connections to this

terminal following national and local codes and plant standards.

6. Tighten the wiring terminal screws.

7. Close the cover and tighten the instrument cover screws to a torque of 5.6 to 6.7 N•m (50 to 60 lbf•in).

11

Page 18

4310

February 2016

Figure 6. Installing Unit Supplied with External Power Option

HART

TERMINALS

COVER

SCREWS

X1028-2

ELECTRICAL

WIRING

CONNECTIONS

POWER

WIRES

CABLE GLAND

(USER-SUPPLIED)

Instruction Manual

D103622X012

GROUND TERMINAL

Network Setup

The 4310 should have wireless network parameters configured prior to becoming part of a wireless network. All

WirelessHART devices within a network have two network parameters that are the same; the Network ID and the Join

Key.

The 4310 is shipped with a pre‐configured Network ID of 1229 and a Join Key which is set to all zeros. Prior to being

installed these should be set to match the other devices on the network. These configuration changes can be made

using a 475 or 375 Field Communicator, AMS Wireless Configurator, or AMS Device Manager 10.5 and above.

Note

When the Smart Wireless Gateway is configured in an advanced security mode each device is required to have an individual join

key.

Using the Field Communicator

1. Verify the Field Communicator has a device description (DD) loaded for the 4310 Device Revision 4 (DD Revision 1

or later).

12

Page 19

Instruction Manual

D103622X012

Note

4310 DD's for the Field Communicator are available for download at:

http://www2.emersonprocess.com/en-US/brands/fieldcommunicator/475FC/Pages/SysSoftDDs.aspx

Note that there may be a delay in posting new DD's to this site.

The above link is for the English website. Go to http://www2.emersonprocess.com/Pages/worldwide.aspx to access a specific

country or regional website.

4310

February 2016

2. Obtain the Network ID and Join Key from the gateway via web interface. Go to Setup and select Network. The

Network ID will be shown. Select Yes to see the Join Key.

3. Open the cover of the 4310 and attach the Field Communicator leads to the 4310 HART terminals (see figure 5

or 6).

4. Select Online, Overview, and Join Device to Network to enter the network parameter settings (see figure 24 for the

Overview menu tree).

5. Remove the leads from the 4310 and close the cover. Tighten the instrument cover screws to a torque of 5.6

to 6.7 N•m (50 to 60 lbf•in).

6. Install the 4310 on monitored equipment and/or verify the gateway.

Note

1410 gateway version 4.4.28 or later or 1420 gateway version 4.4.15 or later is required.

Using AMS Wireless Configurator or AMS Device Manager (Using a HART Modem)

1. Verify that AMS has a device description (DD) loaded for the 4310 Device Revision 4 (DD Revision 1 or later).

Note

4310 DD's for AMS are available for download at:

http://www2.emersonprocess.com/en-US/documentation/deviceinstallkits/Pages/deviceinstallkitsearch.aspx

Note that there may be a delay in posting new DD's to this site.

The above link is for the English website. Go to http://www2.emersonprocess.com/Pages/worldwide.aspx to access a specific

country or regional website.

2. Obtain the Network ID and Join Key from the gateway via web interface.

3. Open the cover of the 4310 and attach the HART modem leads to the HART terminals (see figure 5 or 6).

4. In AMS select the device that is connected to the HART modem.

5. Go to Configure, Guided Setup, Wireless to configure network membership (see figure 7). Select Join Device to

Network and enter the network parameter settings.

13

Page 20

4310

February 2016

Figure 7. Wireless Setup

GUIDED SETUP

CONFIGURE

Instruction Manual

D103622X012

JOIN DEVICE TO NETWORK

CONFIGURE

PUBLISHING

There are three burst messages that can be configured. Each can have its own content, one of 5 trigger modes, and a

range of update rates. Burst messages may be set to default values or tailored to your application in Configure

Publishing. Refer to Broadcast Information on page 37 for additional information on burst configuration.

6. Remove the leads from the 4310 and close the cover. Tighten the instrument cover screws to a torque of 5.6

to 6.7 N•m (50 to 60 lbf•in).

7. Install the 4310 on monitored equipment and/or verify the gateway.

Note

1410 gateway version 4.4.28 or later or 1420 gateway version 4.4.15 or later is required.

14

Page 21

Instruction Manual

D103622X012

4310

February 2016

Hazardous Area Classifications and Special Instructions for “Safe Use” and

Installations in Hazardous Locations

Certain nameplates may carry more than one approval, and each approval may have unique installation/wiring

requirements and/or conditions of “safe use”. These special instructions for “safe use” are in addition to, and may

override, the standard installation procedures. Special instructions are listed by approval.

Note

This information supplements the nameplate markings affixed to the product.

Always refer to the nameplate itself to identify the appropriate certification. Contact your Emerson Process Management sales

office for approval/certification information not listed here.

WARNING

Failure to follow these conditions of “safe use” could result in personal injury or property damage from fire or explosion,

and area re‐classification.

CSA (C/US)

Intrinsically Safe

Monitor Version

Battery Sourced Power Module w/out Pneumatic Output External Power w/out Pneumatic Output

Ex ia Intrinsically Safe Ex ia Intrinsically Safe

Class I, Division 1 GP ABCD T3/T4/T5 Class I, Division 1 GP ABCD T5(Tamb ≤ 80_C)

Ex ia IIC T3/T4/T5 Ex ia IIC T5 (Tamb ≤ 80_C)

Class I Zone 0 AEx ia IIC T3/T4/T5 Ga Class I Zone 0 AEx ia IIC T5(Tamb ≤ 80_C) Ga

Install per control drawing GE59530 as shown Install per control drawing GE59530 as shown

in figure 8 and 9 in figure 8 and 10

Enclosure: Type 4X, IP66 & IP67 Enclosure: Type 4X, IP66 & IP67

T3(Tamb ≤ 85_C), T4(Tamb ≤ 75_C), T5(Tamb ≤ 40_C) Temperature Range: -40_C to 80_C

Temperature Range: -40_C to 85_C

Control Version

Battery Sourced Power Module with Pneumatic Output External Power with Pneumatic Output

Ex ia Intrinsically Safe Ex ia Intrinsically Safe

Class I, Division 1 GP ABCD T4/T5/T6 Class I, Division 1 GP ABCD T5

Ex ia IIC T4/T5/T6 Ex ia IIC T5

Class I Zone 0 AEx ia IIC T4/T5/T6 Ga Class I Zone 0 AEx ia IIC T5 Ga

Install per control drawing GE59530 as shown Install per control drawing GE59530 as shown

in figure 8 and 9 in figure 8 and 10

Enclosure: Type 4X, IP66 & IP67 Enclosure: Type 4X, IP66 & IP67

T4(Tamb ≤ 50_C), T5(Tamb ≤ 46_C), T6(Tamb ≤ 31_C) T5(Tamb ≤ 50_C)

Temperature Range: -20_C to 50_C Temperature Range: -20_C to 50_C

15

Page 22

4310

February 2016

Instruction Manual

D103622X012

ATEX II 1 G

IECEx

Intrinsically Safe

Monitor Version

Battery Sourced Power Module w/out Pneumatic Output External Power w/out Pneumatic Output

Ex ia IIC T3/T4/T5 Ga Ex ia IIC T5 Ga

Install per control drawing GE59530 Install per control drawing GE59530

as shown in figure 8 and 9 as shown in figure 8 and 10

Enclosure: Type 4X, IP66 & IP67 Enclosure: Type 4X, IP66 & IP67

T3(Tamb ≤ 85_C), T4(Tamb ≤ 75_C), T5(Tamb ≤ 40_C) T5(Tamb ≤ 80_C)

Temperature Range: -40_C to 85_C Temperature Range: -40_C to 80_C

Control Version

Battery Sourced Power Module with Pneumatic Output External Power with Pneumatic Output

Ex ia IIC T4/T5/T6 Ga Ex ia IIC T5 Ga

Install per control drawing GE59530 Install per control drawing GE59530

as shown in figure 8 and 9 as shown in figure 8 and 10

Enclosure: Type 4X, IP66 & IP67 Enclosure: Type 4X, IP66 & IP67

T4(Tamb ≤ 50_C), T5(Tamb ≤ 46_C), T6(Tamb ≤ 31_C) T5(Tamb ≤ 50_C)

Temperature Range: -20_C to 50_C Temperature Range: -20_C to 50_C

ATEX Special Conditions of Use

The apparatus shall not be subjected to mechanical impacts or friction.

The piezo valve can be used with natural gas as control fluid provided that no gas-air mixtures are present in the

pressure system.

HART communication terminals (WP1-WP2) must be only connected to certified intrinsic safety equipment and this

combination must be compatible regarding intrinsic safety rules.

Battery Sourced Power Module:

The apparatus can only be powered with a module type GE57654X012 or GE57655X012

External Power:

The apparatus may be powered externally via external power module GE61615X012

IECEx Special Conditions of Use

The apparatus shall not be subjected to mechanical impacts or friction.

The piezo valve can be used with natural gas as control fluid provided that no gas-air mixtures are present in the

pressure system.

Apparatus connection:

D The HART COMM terminals (WP1-WP2) can be only connected to intrinsically safe certified equipment.

D The external power module (J5) can be only connected to associated intrinsically safe certified equipment.

These combinations must be compatible regarding intrinsic safety rules.

Battery Sourced Power Module:

The apparatus can only be powered with a module type GE57654X012 or GE57655X012

External Power:

The apparatus may be powered externally via external power module GE61615X012

16

Page 23

Instruction Manual

D103622X012

4310

February 2016

Figure 8. Installation Drawing Notes; See Figure 9 for Battery Module Assembly & Figure 10 for External Power Option

INSTALLATION MUST BE IN ACCORDANCE WITH THE NATIONAL WIRING PRACTICES OF THE COUNTRY IN USE.

BARRIERS MUST BE CONNECTED PER MANUFACTURE'S INSTALLATION INSTRUCTIONS.

INTRINSICALLY SAFE APPARATUS MAY BE CONNECTED TO ASSOCIATED APPARATUS NOT SPECIFICALLY

EXAMINED IN SUCH COMBINATION. THE CRITERIA FOR INTERCONNECTION IS THAT THE VOLTAGE (Ui) AND

THE CURRENT (Ii) OF THE INTRINSICALLY SAFE APPARATUS MUST BE EQUAL TO OR GREATER THAN THE

VOLTAGE (Uo) AND CURRENT (Io) DEFINED BY THE ASSOCATED APPARATUS. IN ADDITION, THE SUM OF

THE MAXIMUM UNPROTECTED CAPACITANCE (Ci) AND INDUCTANCE (Li) OF EACH INTRINSICALLY SAFE

APPARATUS, AND THE INTERCONNECTING WIRING, MUST BE LESS THAN THE ALLOWABLE CAPACITANCE (Co)

AND INDUCTANCE (Lo) DEFINED BY THE ASSOCIATED APPARATUS. IF THESE CRITERIA ARE MET, THEN THE

COMBINATION MAY BE CONNECTED.

FORMULAS Ui > Uo

Ii > Io

Ci + Ccable < Co

Li + Lcable < Lo

Pi > Po

RESISTANCE BETWEEN BARRIER GROUND AND EARTH GROUND MUST BE LESS THAN ONE OHM.

IF HAND-HELD COMMUNICATOR OR MULTIPLEXER IS USED, IT MUST BE APPROVED WITH ENTITY

PARAMETERS AND INSTALLED PER THE MANUFACTURER'S CONTROL DRAWING.

WARNING

THE APPARATUS ENCLOSURE CONTAINS ALUMINUM AND IS CONSIDERED TO CONSTITUTE

A POTENTIAL RISK OF IGNITION BY IMPACT OR FRICTION. AVOID IMPACT AND FRICTION

DURING INSTALLATION AND USE TO PREVENT RISK OF IGNITION.

GE59530-B, sheet 1

Figure 9. Installation Drawing for Battery Module Assembly; See Notes in Figure 8

HAZARDOUS LOCATION NON-HAZARDOUS LOCATION

INTRINSICALLY SAFE

CLASS I DIV 1 GP ABCD

CLASS I, ZONE 0 GP IIC

HART COMM TERMINALS

WP1/WP2

BATTERY

MODULE

ASSEMBLY

MAIN BOARD

ASSEMBLY

4310 POSITION MONITOR

HART COMM TERMINALS

(BATTERY MODULE - WP1 / WP2)

Ui = 6.0 V

Ii = 5 mA

Pi = 30 mW

Ci = 2.5 nF

Li = 0 mH

Uo = 6.0 V

Io = 14 mA

Po = 84 mW

Co = 39 mf

Lo = 150 mH

HAND HELD

GE59530-B, sheet 1

17

Page 24

4310

February 2016

Figure 10. Installation Drawing for External Power Option; See Notes in Figure 8

HAZARDOUS LOCATION NON-HAZARDOUS LOCATION

INTRINSICALLY SAFE

CLASS I, DIV 1 GP ABCD

CLASS I, ZONE 0 GP IIC

HART COMM TERMINALS

WP1/WP2

POWER TERMINAL

(J5)

4310 POSITION

MONITOR

POWER TERMINAL

Ui = 28 VDC

Ii = 100 mA

Pi = 1 W

Ci = 78 nF

Li = 2.63 mH

HART COMM TERMINALS

(WP1 / WP2)

Ui = 6.0 V

Ii = 5 mA

Pi = 30 mW

Ci = 2.5 nF

Li = 0 mH

POWER

Uo = 6.0 V

Io = 14 mA

Po = 84 mW

Co = 39 μf

Lo = 150 mH

(J5)

Instruction Manual

D103622X012

I.S APPROVED

BARRIER

GE59530-B, sheet 2

HAND HELD

18

Page 25

Instruction Manual

D103622X012

4310

February 2016

Valve / Actuator Mounting

The following procedures are general guidelines you should consider when mounting the 4310. See the instructions

that come with the mounting kit for detailed information on mounting the 4310 to a specific actuator model.

Note

All mounting materials should be non-ferrous. Ferrous materials are magnetic and may affect feedback.

The feedback system for the 4310 utilizes a magnetic field for true linkage‐less, non‐contacting position

measurement. In order to prevent inadvertent stem movement while the instrument is in operation, magnetic tools

(such as a magnetic‐tipped screwdriver) should not be used.

CAUTION

The magnet material has been specifically chosen to provide a long‐term stable magnetic field. However, as with any

magnet, care must be taken when handling the magnet assembly. Another high powered magnet placed in close proximity

(less than 25 mm) can cause permanent damage. Potential sources of damaging equipment include, but are not limited to:

transformers, DC motors, stacking magnet assemblies.

CAUTION

General Guidelines for use of High Power Magnets

Use of high power magnets in close proximity to this instrument should be avoided.

Use of Magnetic Tools

D Magnetic Tip Screw Drivers – Magnetic tip screw drivers can be used to work on the 4310.

However, they should not be brought in close proximity to the magnet assembly (located

at the back of the instrument) during process operations.

Note

As a general rule, do not use less than 50% of the magnet assembly for full travel measurement. Performance will decrease as the

assembly is increasingly subranged.

The linear magnet assemblies have a valid travel range indicated by arrows molded into the piece. This means that the Hall sensor

(on the back of the 4310 housing) has to remain within this range throughout the entire valve travel. See figure 11.

The linear magnet assemblies are symmetrical. Either end may be up.

19

Page 26

4310

February 2016

Instruction Manual

D103622X012

Figure 11. Travel Range

VALID TRAVEL

RANGE

25 mm (1 INCH)

SHOWN

MAGNET

ASSEMBLY

(ATTACHED TO

X0543

VALVE STEM)

There are a variety of mounting brackets and kits that are used to mount the 4310 to different actuators. However,

despite subtle differences in fasteners, brackets, and connecting linkages, the procedures for mounting can be

categorized as follows:

D Linear or sliding‐stem actuators with up to 210 mm (8.25 inch) travel

D Rotary actuators with travel up to 90 degrees

D Device-specific applications for rotary actuators requiring 13 to 30 degree rotation

See figure 12 for the different travel feedback magnet assemblies.

Figure 12. Magnet Assemblies

Y

B

ROTARY

LINEAR

7, 19, OR 25 mm

(1/4, 3/4, OR 1 INCH) ASSEMBLY

38, 50, 100, OR 210 mm

(1-1/2, 2, 4, OR 8-1/4 INCH) ASSEMBLY

NOTE: VALID TRAVEL RANGE INDICATED BY WHITE ARROWS

TRAVEL UP TO 90 DEGREES

LINEAR

13 TO 30 DEGREE ROTATION

ARCED

20

Page 27

Instruction Manual

D103622X012

4310

February 2016

Sliding‐Stem (Linear) Actuators (e.g. Fisher 667)

Before mounting, verify that linear travel is greater than one‐half and not more than the maximum recommended

travel of the feedback kit.

1. Attach the mounting bracket to the actuator.

2. Loosely attach the feedback pieces and magnet assembly to the valve stem connector. Do not tighten the fasteners

because fine adjustment is required.

CAUTION

Do not install a magnet assembly that is shorter than the physical travel of the actuator. Loss of control will result from the

magnet assembly moving outside the range of the index mark in the feedback slot of the 4310 housing.

3. Center the magnet assembly inside the retaining slot 5.7 mm (0.22 inch) away from the bottom base of the

housing as measured from the center of the assembly bolt holes to the base of the housing (see figure 13).

4. Align the magnet assembly as shown in figure 13.

5. Tighten the fasteners.

6. Mount the 4310 to the mounting bracket, using the mounting bolts. Any of the mounting holes may be used for

linear actuators. See figure 14.

7. Once the instrument is mounted perform the local interface calibration procedure, as described on page 31. Verify

the magnet assembly position through the entire travel range before putting into service.

Figure 13. Mounting—Sliding‐Stem Magnet Assembly

MOUNTING FACES

MAGNET

MOUNTING

FACES

5.7 $ 2.0

(0.22 $ 0.08)

BASE OF

HOUSING

ASSEMBLY

BOLT

ON/OFF

CONTROL OPTION

GE59830

mm

(INCH)

21

Page 28

4310

February 2016

Instruction Manual

D103622X012

Figure 14. Housing and Mounting for Linear and

Quarter‐Turn Actuators

OPTIONAL

MOUNTING

HOLES

ON/OFF CONTROL OPTION

NOTE: ANY OF THE MOUNTING HOLES

MAY BE USED FOR LINEAR ACTUATORS

X0545

MOUNTING HOLES FOR

ROTARY NAMUR, M6

Figure 15. For Rotary‐Shaft Actuators (Typical

Mounting Bracket)

ROTARY

MOUNTING

BRACKET

X0572

ON/OFF

CONTROL

OPTION

Guidelines for Mounting on Quarter‐Turn (Rotary‐Shaft) Actuators

The 4310 can be mounted to any quarter‐turn (rotary‐shaft) actuator, as well as those that comply with the NAMUR

guidelines. A mounting bracket and associated hardware are required. Refer to figure 15.

Before mounting, verify the rotary motion is 45 to 90 degrees of rotation.

1. Stroke the actuator to one end of its travel.

2. Attach the magnet assembly to the actuator shaft, as shown in figure 16. Position the magnet assembly 19.5 mm

(0.77 inch) away from the bottom base of the housing as measured from the base of the assembly to the base of the

housing. If the actuator is stroked all the way to the left or counterclockwise, attach the magnet assembly so it

points to the antenna (upper left corner of the instrument). If the actuator is stroked all the way to the right or

clockwise, attach the magnet assembly so it points to the upper right corner of the instrument. See figure 17.

Note

When the actuator is at its travel limits the magnetic array must always be at a 45 degree angle, regardless of the orientation of the

4310.

3. Install the mounting bracket on the actuator.

4. Attach the 4310 to the mounting bracket using the 4 mounting bolts, as shown in figure 15.

5. Check for clearance between the magnet assembly and the positioner feedback slot.

6. Stroke the actuator and make sure that the magnet assembly is centered in the slot throughout the entire range of

rotation.

7. Once the instrument is mounted perform the local interface calibration procedure, as described on page 31. Verify

that the magnet assembly remains centered throughout the entire rotating range.

22

Page 29

Instruction Manual

D103622X012

Figure 16. Mounting—Rotary Magnet Assembly

MOUNTING FACES

MOUNTING FACES

19.5 $ 0.8

(0.77 $ 0.03)

BASE OF

HOUSING

GE59831

MAGNET

ASSEMBLY

mm

(INCH)

4310

February 2016

ON/OFF

CONTROL OPTION

Figure 17. Magnet Assembly Orientation

ORIENTATION

AT ONE TRAVEL

EXTREME

ORIENTATION

AT MID‐TRAVEL

(FLATS PARALLEL

TO 4310 HOUSING

CHANNEL)

ORIENTATION

AT THE OTHER

TRAVEL EXTREME

W8836‐1A

W8836‐1B

NOTES:

1 IF THE ACTUATOR IS STROKED ALL THE WAY TO THE RIGHT OR CLOCKWISE, ATTACH THE

MAGNET ASSEMBLY SO IT POINTS TO THE UPPER RIGHT CORNER OF THE INSTRUMENT,

2 IF THE ACTUATOR IS STROKED ALL THE WAY TO THE LEFT OR COUNTERCLOCKWISE, ATTACH

THE MAGNET ASSEMBLY SO IT POINTS TO THE ANTENNA (UPPER LEFT CORNER OF THE INSTRUMENT).

1

2

MOUNTING BRACKET

23

Page 30

4310

February 2016

Instruction Manual

D103622X012

Pneumatic Hookup Procedures for On/Off Control Option

WARNING

To avoid personal injury or property damage resulting from bursting of parts, do not exceed maximum supply pressure.

Personal injury or property damage may result from fire or explosion if natural gas is used as the supply medium and

appropriate preventive measures are not taken. Preventive measures may include, but are not limited to, one or more of

the following: Remote venting of the unit, re‐evaluating the hazardous area classification, ensuring adequate ventilation,

and the removal of any ignition sources. For information on remote venting of this controller, refer to page 26.

Severe personal injury or property damage may occur from an uncontrolled process if the instrument supply medium is not

clean, dry, oil‐free, and noncorrosive. While use and regular maintenance of a filter that removes particles larger than 40

micrometers in diameter will suffice in most applications, check with an Emerson Process Management field office and

industry instrument air quality standards for use with corrosive air or if you are unsure about the amount of air filtration or

filter maintenance.

WARNING

When using natural gas as the supply medium the following also applies:

D When disconnecting any of the pneumatic connections or any pressure retaining part, natural gas will seep from the

unit and any connected equipment into the surrounding atmosphere. Personal injury or property damage may result if

natural gas is used as the supply medium and appropriate preventive measures are not taken. Preventive measures

may include, but are not limited to, one or more of the following: ensuring adequate ventilation and the removal of any

ignition sources.

D The 4310 does not incorporate explosive fluid and/or process seals. Follow appropriate local, regional, and national

codes for installation of these types of products when using natural gas as the supply medium.

Supply pressure medium must be clean, dry, and noncorrosive and meet the requirements of ISA Standard 7.0.01 or

ISO 8573-1. A maximum 40 micrometer particle size in the air system is acceptable. Further filtration down to 5

micrometer particle size is recommended. Lubricant content is not to exceed 1 ppm weight (w/w) or volume (v/v)

basis. Condensation in the supply medium should be minimized.

Use of a 67CFR filter regulator with standard 5 micrometer filter, or equivalent, to filter and regulate supply air should

suffice in most applications. Supply connections are 1/4 NPT.

Prior to connecting the supply air to the spool valve, flush the system to remove any debris or contaminates.

4-Way Spool Valves

The spool valve is a 5 port, 4-way valve driven by an internally mounted pilot. Refer to figure 18 for spool valve supply

and work port locations and installation options.

CAUTION

Failure to install the supplied vents in the exhaust ports (ports 3 and 5) can result in damage to the seals.

Never plug, block or restrict port 5 as any blockage or restriction may cause an internal pressure buildup inside the

enclosure, resulting in damage to the housing gasket.

24

Page 31

Instruction Manual

D103622X012

4310

February 2016

Install the supplied vents in the exhaust ports (ports 3 and 5) to prevent debris from falling into the spool valve. Apply a

general purpose instant sealant to pipe threads and fittings. A flow control, such as a needle valve, may be used in Port

3, but should never be used in Port 5. To achieve IP67 protection remote venting of ports 3 and 5 is required.

Figure 18. 4-Way Spool Valve Installation

EXHAUST OF PORT 4

(WHEN ACTUATOR OPENS)

SUPPLY

1

ALWAYS INSTALL

VENTS (SUPPLIED)

EXHAUST OF PORT 2

(WHEN ACTUATOR CLOSED)

5 1 3

4 2

PORT TO

ACTUATOR CLOSE

5 1 3

4 2

FAIL LAST POSITION

PORT TO

ACTUATOR OPEN

ALWAYS INSTALL

VENTS (SUPPLIED)

SUPPLY

PORT TO CLOSE PORT TO OPEN

DOUBLE-ACTING ACTUATORS SPRING RETURN ACTUATORS

NOTE:

1 THE DD POINTS TO THE PILOT VALVE PORTS AND NOT SPECIFICALLY TO THE

SPOOL VALVE PORTS.

PLUG

SUPPLY

PORT TO OPEN/CLOSE

25

Page 32

4310

February 2016

Instruction Manual

D103622X012

Vent

WARNING

Personal injury or property damage can occur from cover failure due to overpressure. Ensure that the housing vent

opening is open and free of debris to prevent pressure buildup under the cover.

WARNING

This unit vents the supply medium into the surrounding atmosphere. When installing this unit in a non‐hazardous

(non‐classified) location in a confined area, with natural gas as the supply medium, you must remotely vent this unit to a

safe location. Failure to do so could result in personal injury or property damage from fire or explosion, and area

re‐classification.

When installing this unit in a hazardous (classified) location remote venting of the unit may be required, depending upon

the area classification, and as specified by the requirements of local, regional, and federal codes, rules and regulations.

Failure to do so when necessary could result in personal injury or property damage from fire or explosion, and area

re‐classification.

Vent line piping should comply with local and regional codes and should be as short as possible with a minimum inside

diameter of 12.7 mm (1/2‐inch) and few bends to reduce case pressure buildup.

To remotely vent the exhaust or to achieve IP67 protection, connect tubing and 1/4 NPT fittings to spool valve ports 3

and 5. Connect tubing and 1/2NPT fitting to case vent port.

Communication Connections

Convenient termination points are located inside the front cover, as shown in figure 5. The polarity-insensitive

connection pins provide access to the Maintenance Port defined in the WirelessHART specifications.

Wireless Communications

Devices in a WirelessHART network are time synchronized and send their data to the gateway at selectable update

rates. The update rates of the device have an effect on the number of devices that the gateway can service. For

example, if each device sent an update once per minute the gateway could support 100 devices.

Battery powered devices conserve energy by only sensing and transmitting data at the selectable update rate.

The faster the update rate the shorter the life span of a power module. Figures 19, 20, 21, and 22 show the correlation

between power module life and update/sample rate, the number of sub-devices, temperature, and actuations,

respectively.

26

Page 33

Instruction Manual

D103622X012

4310

February 2016

Figure 19. Update Rate Impact on Power Module

Life; On/Off Control and Monitoring

12

10

8

6

4

2

POWER MODULE LIFE (YEARS)

0

110

UPDATE RATE (SECONDS)

NOTE: THREE SUB-DEVICES ARE ASSUMED,

CONSTANT TEMPERATURE OF 22_C (72_F).

100 1000

STANDARD

EXTENDED

10000

Figure 21. Temperature Effects on Power Module

Life; On/Off Control and Monitoring

12

10

8

6

4

2

POWER MODULE LIFE (YEARS)

0

-40 -15 10 35 60

TEMPERATURE (_C)

NOTE: THREE SUB-DEVICES ARE

ASSUMED WITH 60 SECOND UPDATE RATE.

ON/OFF CONTROL; 100 ACTUATIONS PER DAY.

ON/OFF CONTROL

STANDARD

EXTENDED

MONITORING

STANDARD

EXTENDED

85

Figure 20. Number of Sub-Devices Impact on Power

Module Life; Monitoring

12

10

8

6

4

2

POWER MODULE LIFE (YEARS)

0

0

5

NUMBER OF SUB-DEVICES

10 15

16

Figure 22. Effect of Actuations on Power Module Life;

On/Off Control

12

10

8

6

4

2

POWER MODULE LIFE (YEARS)

0

1 10 100 1000

10000

NUMBER OF ACTUATIONS PER DAY

NOTE: 60 SECOND UPDATE RATE, CONSTANT

TEMPERATURE OF 22_C (72_F).

STANDARD

EXTENDED

NOTE: THREE SUB-DEVICES ARE ASSUMED,

60 SECOND UPDATE RATE, CONSTANT

TEMPERATURE OF 22_C (72_F).

STANDARD

EXTENDED

Continuous updates is the default communication method for the selected device variable; the device sends the data

to the gateway at every update period, whether the data has changed or not. However, the 4310 can also be

configured to allow position feedback sampling at faster than the default update rate and to send data only when the

measured variable has changed. This is useful in certain applications; for example, when used with relief valve

27

Page 34

4310

February 2016