Fisher FM Hazardous Area Approvals for Fisher i2P-100 Electro-Pneumatic Transducer Manuals & Guides

Instruction Manual Supplement

D104193X012

i2P-100 Transducer - FM

July 2018

FM Hazardous Area Approvals

™

Fisher

Hazardous Area Classifications and Special Instructions for “Safe Use” and

Installation in Hazardous Locations

Certain nameplates may carry more than one approval, and each approval may have unique installation/wiring

requirements and/or conditions of “safe use”. These special instructions for “safe use” are in addition to, and may

override, the standard installation procedures. Special instructions are listed by approval.

Note

This information supplements the nameplate markings affixed to the product and the i2P-100 instruction manual

(D103198X012

Always refer to the nameplate itself to identify the appropriate certification.

i2P-100 Electro‐Pneumatic Transducer

), available from your Emerson sales office or Local Business Partner, or at www.Fisher.com.

WARNING

Failure to follow these conditions of “safe use” could result in personal injury or property damage from fire or explosion,

and area re‐classification.

Special Conditions of Use

Intrinsically Safe, Explosion-proof, Type n, Non‐incendive, Dust‐Ignition proof

1. When product is used with natural gas as the pneumatic medium, the maximum working pressure of the natural

gas supply is limited to 50 psi.

2. When product is used with natural gas as the pneumatic medium the product shall be provided with the proper

remote venting, as described in the i2P-100 instruction manual (D103198X012).

3. The apparatus enclosure contains aluminum and is considered to constitute a potential risk of ignition by impact or

friction. Care must be taken into account during installation and use to prevent impact or friction.

Refer to table 1 for additional information.

www.Fisher.com

i2P-100 Transducer - FM

July 2018

Instruction Manual Supplement

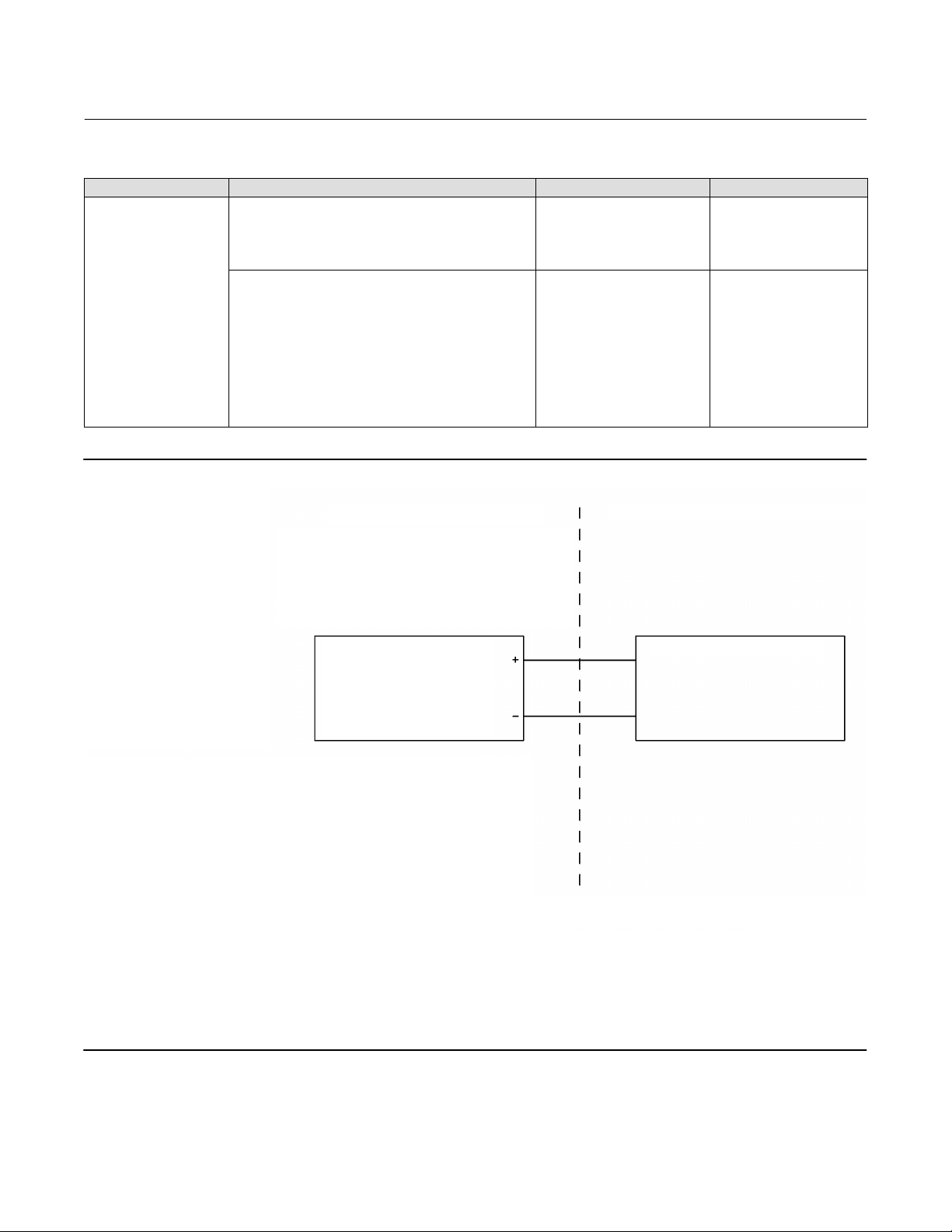

Table 1. Additional Approval Information

Certification Body Certification Obtained Entity Rating Temperature Code

FM

IS Intrinsically Safe

Class I, II, III Division 1 GP A, B,C,D,E,F,G

per drawing GE07470 (see figure 1)

Class I Zone 0 AEx ia IIC T3/T4/T5

per drawing GE07470 (see figure 1)

XP Explosion Proof

Class I, Division 1, GP A,B,C,D T5/T6

Class I Zone 1 AEx d IIC T5/T6

NI Non-incendive

Class I, Division 2, GP A,B,C,D T5/T6

Type n

Class I, Zone 2 AExnC IIC T5/T6

DIP Dust-ignition proof

Class II, III Division 1, GP E,F,G T5/T6

S Suitable for Use

Class II, III Division 2, GP F,G T5/T6

Vmax = 30 VDC

Imax = 100 mA

Pi = 1.0 W

Ci = 0 uF

Li = 0 uH

- - -

T3 (Tamb ≤ 85°C)

T4 (Tamb ≤ 81°C)

T5 (Tamb ≤ 46°C)

T5 (Tamb ≤ 85°C)

T6 (Tamb ≤ 75°C)

Figure 1. FM Loop Schematic (Drawing GE07470)

D104193X012

HAZARDOUS LOCATION

INTRINSIC SAFETY

CLASS I, II, III, DIV 1, GROUPS A,B,C,D,E,F,G

CLASS I, ZONE 0 AEx ia IIC

NON-INCENDIVE

CLASS I, DIV 2, GROUPS A,B,C,D

FISHER TYPE: i2P-100

Vmax = 30 Vdc

Imax = 100 mA

Ci = 0 nF

Li = 0 mH

Pi = 1.0 W

NOTES:

1. THE INSTALLATION MUST BE IN ACCORDANCE WITH

THE NATIONAL ELECTRIC CODE (NEC), NFPA 70, ARTICLE

504 AND ANSI/ISA RP12.6 OR ARTICLE 505.

2. CLASS 1, DIV 2 APPLICATIONS MUST BE INSTALLED AS SPECIFIED

IN NEC ARTICLE 501-4(B). EQUIPMENT AND FIELD WIRING IS

NON-INCENDIVE WHEN CONNECTED TO APPROVED BARRIERS WITH

ENTITY PARAMETERS.

3. LOOPS MUST BE CONNECTED ACCORDING TO THE BARRIER

MANUFACTURER'S INSTRUCTIONS.

4. MAXIMUM SAFE AREA VOLTAGE SHOULD NOT EXCEED 250 Vrms.

5. RESISTANCE BETWEEN BARRIER GROUND AND EARTH GROUND

MUST BE LESS THAN ONE OHM.

6. NORMAL OPERATINGI CONDITIONS 30 Vdc 20 mADC.

7. FOR ENTITY INSTALLATION (I.S. AND N.I.):

Vmax > Voc, or Vt Ci + Ccable < Ca

Imax > Isc, or It Li + Lcable < La

Pi > Po, or Pt

GE07470_B

NON-HAZARDOUS LOCATION

FM APPROVED BARRIER

WARNING:

THE APPARATUS ENCLOSURE CONTAINS ALUMINUM AND

IS CONSIDERED TO CONSTITUTE A POTENTIAL RISK OF

IGNTION BY IMPACT OR FRICTION. AVOID IMPACT AND

FRICTION DURING INSTALLATION AND USE TO PREVENT

RISK OF IGNITION.

2

Instruction Manual Supplement

D104193X012

i2P-100 Transducer - FM

July 2018

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2016, 2018 Fisher Controls International LLC. All rights reserved.

3

Loading...

Loading...