Page 1

Instruction Manual

D104413X012

Yarway Series 4300 TempLow

January 2019

Service Instructions for Yarway™ Series 43000

™

TempLow

Steam Desuperheater

This instruction manual was prepared by Emerson.

Do not install, operate or maintain this product

without being fully trained and qualified in valve,

actuator and accessory installation, operation and

maintenance.

To avoid personal injury or property damage it is

important to carefully read, understand, and follow all

of the contents of this manual, including all safety

cautions and warnings.

If you have any questions about these instructions,

contact your Emerson sales office

before proceeding.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations. Check with your

process or safety engineer for any other hazards that may be present from exposure to process media.

Personal injury or equipment damage caused by sudden release of pressure may result if the desuperheater is installed

where service conditions could exceed the limits given on the product nameplate. To avoid such injury or damage, provide

a relief valve for over‐pressure protection as required by government or accepted industry codes and good engineering

practices.

CAUTION

When ordered, the desuperheater configuration and construction materials were specified to meet particular pressure,

temperature, pressure drop, and fluid conditions. Do not apply any other conditions to the desuperheater without first

contacting your Emerson sales office.

www.Fisher.com

Page 2

Yarway Series 4300 TempLow

January 2019

Instruction Manual

D104413X012

Maintenance

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Safely vent the power actuator loading pressure.

D Use lock-out procedures to be sure the above measures stay in effect with you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even with the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

CAUTION

When adjusting the travel stop for the closed position of the valve ball or disk, refer to the appropriate valve instruction

manual for detailed procedures. Undertravel or overtravel at the closed position may result in poor valve performance

and/or damage to the equipment .

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Yarway and Templow are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson

Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

2

E 2019 Fisher Controls International LLC. All rights reserved.

Page 3

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

Before installation these instructions must be fully read and understood

PRINCIPLES OF OPERATION

The Yarway TempLow Desuperheater (also

model 91 and 93) responds to pneumatic or

electric signals generated by a temperature

instrumentation control loop to provide

automatic introduction and metering of

cooling water for steam temperature control.

This desuperheating process effectively

and efficiently cools steam in accordance

to a thermodynamic heat balance at

constantpressure.

Desuperheating water, at a pressure at least

50 psi above steam pressure, enters the

valve at a flanged inlet. Water flows down

through the jacket to the seating area above

the disc where tight shutoff is achieved.

Whenthetemperaturecontrol unit signals for a

reduction in steam temperature, the pneumatic

actuator moves the stem/disc downward,

progressively uncovering a series ofvortex

feedholes. The water enters the vortex,

acquires a rotational sense and exits the spray

nozzle as a thin spinning conical fan which

immediately breaks up into a finely atomized

mist of water droplets. These mix with the

superheated steam for rapid evaporation.

There are seven stages of water control for

each vortex nozzle. Multiple nozzles are fitted

to the spray cylinder, thus giving a fine control

capability and fast response to a change

in the temperature control signal. Use of

multiple swirl chamber, orifice fan type spray

nozzles provide the sequential application

of an efficiently generated spray cone. The

combination provides a precise method of

control with a high order of rangeability. In the

normally closed position, the desuperheater

maintains a tight shutoff by virtue of the

actuator top works.

Valve selection is based on flow requirement

at maximum conditions of water need and

nominal water pressure. The valve exhibits

a linear or modified linear characteristic.

Nominal flow should be in the range

of50% to 80% of maximum valve capacity.

Follow the Yarway certified engineering

drawing for specific details which supersede

these general instructions. If the conditions

differ from those specified, consult the Yarway

Customer Services Department.

STANDARD SPECIFICATIONS

• Steam pressure and temperature ratings Standard Class Valve ASME B16.34 - limits

as specified for ASTM-A217-WC6 in Pressure

Classes 150, 300, 600, 900 and 1500.

• Steam line installation diameters

(minimum)- nozzle sizes A6 and B6 - 6inch

diameter minimum, C6, D6, and E6 - 8inch

diameter minimum. Consult certified

drawing.

• Cooling water supply pressure - water

pressure 50 psi greater than steam

pressureas measured at the valve inlet.

• Steam line nozzle and valve outlet flange3inch ASME B16.5 (DN 80) raised face pressure class as specified.

Extension pipe 3 inch schedule 160 maximum

(2.6 inch diameter clearance).

• Valve water inlet flange - 1 inch (DN 25)

ASMEB16.5 raised face flange; pressure

class or DIN flange as specified.

• Valve actuator/positioner - standard

actuator; Yarway Model 20, air failure to

close diaphragm type. Positioner upon

clientrequest.

• Instrument air failure mode - loss of

instrument air, valve fails closed.

• Instrument electric signal: 4-20 mA.

• Instrument air signal - standard - 3 to 15 psig

(.21 to 1.03 bar).

• Connections - ¼ inch - NPT instrument air

supply (IA) and PG 20 instrument signal (IS).

Check certified order drawing for

specificdetails.

Emerson.com/FinalControl

© 2017 Emerson. All rights reserved.

Engineering Doc. #961245 Rev. H

VCIOM-03325-US 15/04

Page 4

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

UNPACKING, PREPARATION AND STORAGE

Upon receipt of the valve, inspect valve and

shipping container for transit damage such as

a broken crate, broken yoke, bent valve stem or

broken accessories. Check the documentation,

identification plate, valve tag data, instruction

manual, etc. Locate and identify spare parts

included in the shipment.

Use the shipping container for temporary

valve protection. Leave protective covers in

place until ready to proceed with inspection

and installation. Store the valve in a clean, dry

location. If outdoor storage is unavoidable,

support the valve off the ground or pavement

and provide a waterproof covering. Lift the valve

by means of straps around valve body and inlet

flange. Do not use the actuator yoke to attach

lifting straps.

LONG TERM STORAGE

Use a dry, heated, inside storage area. Remove

the valve stem packing. Make sure valve is dry

and free from moisture. Apply Cosmoline-type

protective grease to the flange face, packing

stuffing box and valve stem.

PREPARATION FOR INSTALLATION

Remove all paper, tape and packing materials,

and all foreign materials. Transport carefully

to the installation site. Remove valve protective

covers and install the valve in the system.

INSTALLATION

See Yarway Engineering Approval Drawings

forcertified dimensions, installation details

andmarking for each TempLow Desuperheater

by serial no./tag no.

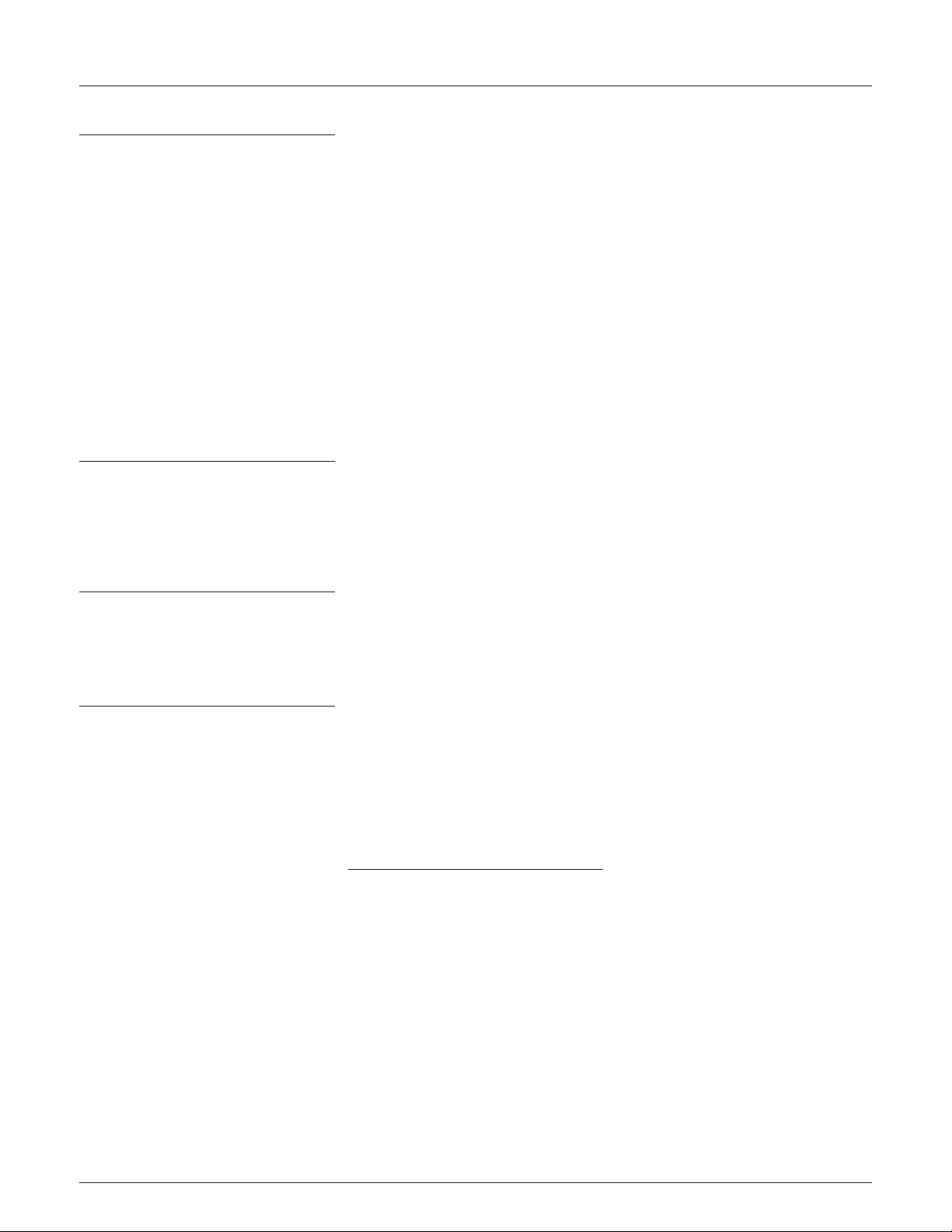

Main steam system piping (Figures 1 and 2)

1. The desuperheater requires a minimum

of 15 feet (4.6 meters) of straight pipe

from the valve installation to the first

bend downstream and six straight pipe

diametersupstream.

2. Branching of the main steam pipe should

not be allowed between the desuperheater

and the temperature sensor.

3. Pipe bends should be long radius type to aid

keeping the steam/water vapor mixture in

suspension until evaporated.

4. Avoid using “T” fittings between the

desuperheater and the temperature sensor.

5. The distance from the desuperheater

to the temperature sensor is nominally

40feet (12.2 meters). The certified drawing

specifies a minimum based on system

requirements. Greater distance assures

full mixing and total evaporation at low

steamvelocities.

Care must be exercised to accommodate

low steam flow conditions near saturation

temperature. A water film can form on the

pipe wall and reach the temperature sensor.

6. The temperature sensor should be mounted

in accordance with manufacturer’s

recommendation. Yarway recommends

mounting in the top of the line ± 45°.

The sensor should not be mounted at the

outside of an elbow.

7. The steam velocity can be increased by

reducing the steam pipe size by one or

two sizes for the distance between the

desuperheater and the sensor.

8. Desuperheater applications requiring

control over large turn down load ranges

can utilize split range control from a

single sensor for multiple desuperheaters

installed in the steam pipe.

9. Steam dump systems may require multiple

units to control maximum temperature.

Pipe mounting orientation

1. The desuperheater may be mounted at90°

to the steam line for all orientations of

steam flow.

2. The “vertical-up” position is preferred for

the valve stem and actuator. If the TempLow

is installed in other than vertical position,

consideration must be given to supporting

the actuator.

3. The cooling water supply should be clean,

filtered condensate or boiler feed water.

The source selection must consider water

temperature.

4. Yarway recommends that the cooling water

line include a locked open shut-off valve

and a strainer with 0.004 inch (0.1mm)

perforated mesh sized for the flow

requirements. The cooling water line must

be thoroughly flushed prior to connection

for use.

5. The water line pressure at the inlet to

the valve is to be per certified drawing

datasheet.

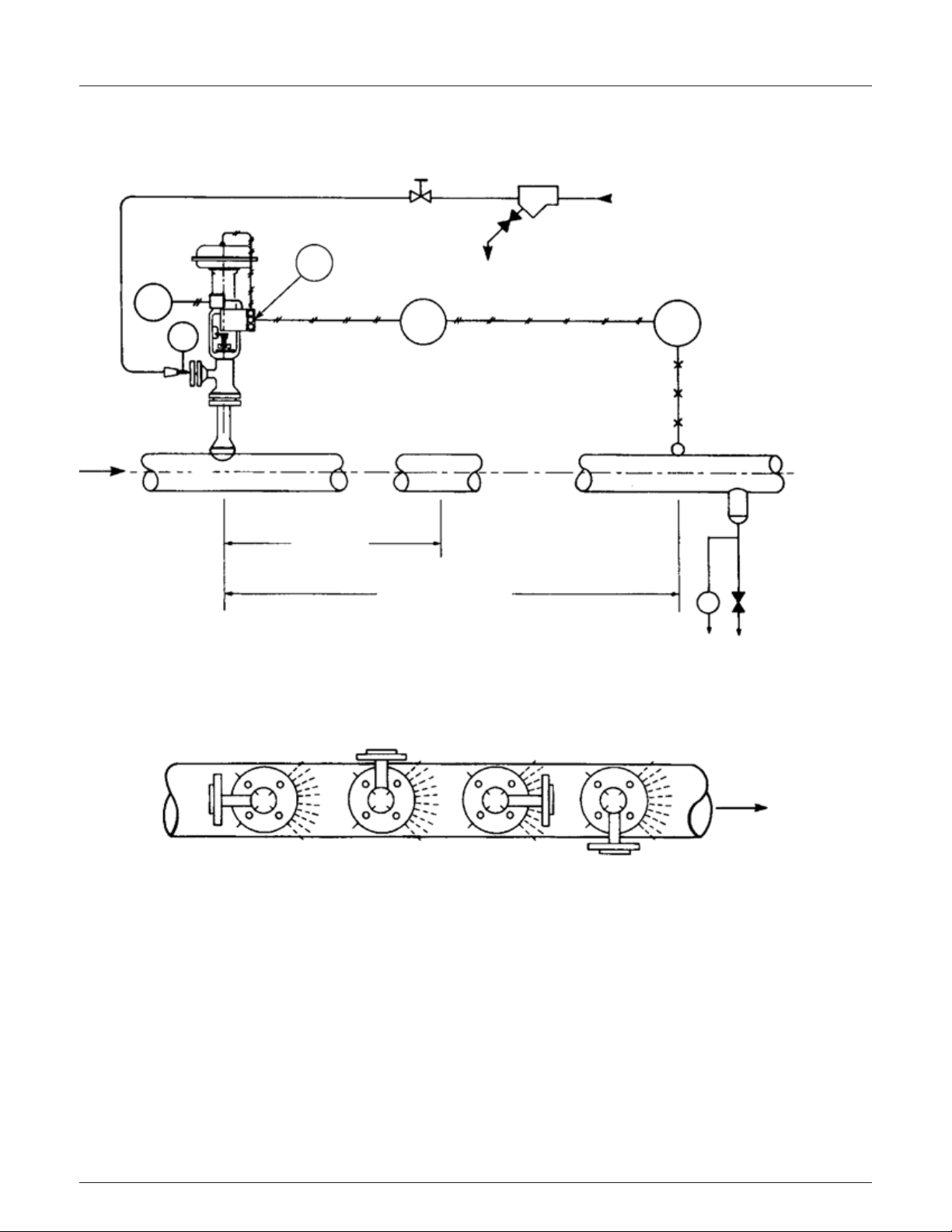

STEAM LINE

Mounting flange and pipe (Figure 3)

1. The spray cylinder should be located at

the center line of the pipe which is most

important in small lines.

2. The primary dimension variable is the

length “X” of the 3-inch (DN 80) nozzle that

supports the mounting flange. The 3-inch

(DN 80) connecting pipe must provide

a 2.60-inch (65 mm) diameter internal

clearance. A 3-inch schedule 160 pipe

provides the maximum wall thickness

pipeallowed.

3. The variable “X” is nominally calculated by

subtracting ½ the pipe OD dimension from

15½ inches (394 mm). This dimension varies

in order that the spray cylinder portion of the

valve is centered within the pipe OD(“Y”).

For pipe sizes greater than 24inches

(600 mm) the “X” dimension is 3½inches

(88.9mm). (See certified drawing.)

2

Page 5

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

RECOMMENDED STANDARD INSTALLATION

DESUPERHEATING STATION

FIGURE 1

Lock open

Strainer

Water

Steam flow

IS

Blow down

IA

TTTIC

PI

Boot locate

at low point

15 ft. minimum

straight pipe

downstream

40 ft. minimum

distance to sensor

Spray nozzles must be oriented to direct spray with thedirection of flowing steam. No deviation allowed.

Important

T

Blow down

Dirt leg

FIGURE 2

Configuration position

Water inlet orientation

Steam flow

1 2 3 4

3

Page 6

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

FIGURE 3

Y = O.D. pipe diameter - inches

When Y is greater than 24” O.D. X is 3.5 inches

Consult Yarway certified drawing for “X” dimension

90°

Reinforcement

2.60 dia. clear

X

Pipe O.D.

3⅛

6⅛

Gasket

1” (DN 25) flange water inlet

1½”(DN 40) for class 2500/pn400

90°

Spray

cylinder

3” (DN 80) flange

By Yarway

By customer

Thickness max. wall

sched. 160 pipe

Pipe dia. O.D.

Steam flow

CONFIGURATION 1 POSITION

4

Page 7

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

MOUNTING INSTRUCTIONS

1. Use gasket and bolting material, installed

and meeting recommendations of

ASMEB31.1 “Power Piping” Code or

another recognized standard.

2. Put the gasket on the mounting flange.

3. Carefully insert the desuperheater into

the3-inch (DN 80) nozzle.

4. Mount the desuperheater to aim water

sprayoutlet points with the direction of

steam flow.

5. Assemble the bolting and tighten.

6. Clean and flush the cooling water line.

7. Connect the water line.

OPERATING CONTROLS

The desuperheating station instrument control

loop should include an indicating temperature

controller, a temperature transmitter, and a

thermo well (Figure 1).

If the steam pressure varies widely, a

self-compensating cascade pressure loop can

be added to vary the temperature set point to

assure control close to saturation conditions.

START UP

1. Verify the proper system installation,

thesensor location and the distance.

2. Connect the instrument air supply (IA) and

the instrument signal (IS) tubing.

3. Adjust the instrument air regulator for

correct output pressure.

4. Switch the temperature controller

tomanual.

5. Assuming an instrument air signal (IS)

of3-15 psi, the valve has three important

instrument signal response points.

Inst. signal, psi (IS) Valve position

3 Closed

3.5 Valve stem starting to move

15 Full valve stem stroke

The zero positioner output pressure

(diaphragm pressure) at 3 psig (IS)

instrument signal provides full actuator

spring force to close the desuperheater

andassure tight shutoff.

6. Set (IS) at 3.5 psi. Adjust the positioner

sothe valve is barely closed.

7. Set (IS) at 15 psi. Check the valve stem

for full stroke. Adjust the positioner to the

correct range and re-zero if needed by

checking the 3.5 psi point.

8. Set (IS) at 3 psi - the valve should close and

the output of the positioner should drop

to0psi.

9. Calibrate the temperature transmitter (TT).

Adjust for increasing temperature to give

anincreasing signal.

10. With the temperature controller (TIC)

in automatic position, ascertain that an

increase in temperature will cause an

increase in the instrument signal (IS)

(controller output).

11. Manual start up

a. Warm the main steam line.

b. Instrument signal (IS) 3 psi

(desuperheater closed).

c. Open the water valve to the

desuperheater.

d. Verify the water pressure at the valve.

e. Establish the main steam flow

(atleastthe design minimum).

12. Slowly increase the instrument signal (IS)

to4 or 5 psi. The indicated temperature

starts to fall. The temperature transmitter

(TT) signal decreases. The controller (TIC)

output pressure also decreases.

13. Slowly decrease the instrument signal (IS)

to 3.5 psi. The temperature will increase,

the temperature transmitter (TT) output will

increase, and the controller (TIC) output will

increase.

14. When satisfactory coordination between

the instrument air signal (IS) and the

steam temperature is reached, adjust

the controller setpoint to the desired

temperature using the directions of the

manufacturer.

15. Transfer from manual to automatic

controlwill put the desuperheater station

inoperation.

16. Log records of steam pressure, water

pressure, inlet steam temperature,

controlled steam temperature and

steam flow should be maintained to

verifyoperation.

IMPORTANT

Verify tightness of the valve stuffing box regularly

after start-up.

Re-tighten if necessary. Do not overtighten the

stuffing box.

5

Page 8

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

INSPECTION PROCEDURE

Spray nozzle assemblies (3) and (6), fastener

ring (4), stem assembly (2) and piston rings (5)

shall be considered wear parts. The materials

selected are such that they do cope with

the conditions as found on applications in

steam/water environments. Thermal cycling

does occur and users should realize that the

temperature differentials at Desuperheaters

are usually the highest found in the Plant. It

is recommended to check the spray nozzle

assembly, with the integrally vacuum brazed

injection nozzles, fastener ring and tack-welds

after the first year of service.

At the inspection, by use of dye check or fluor

penetrant investigation, these parts shall be

checked for cracks. Parts with hair crack

indications shall not be re-used. ‘Defect free’

heads in such installations shall be inspected

once per 2 year of operation.

It is advised to replace the above mentioned

components at least once per 5 years of

service. Taking these precautions has

historically proven to give reliable service.

Note: spray nozzle assemblies may have been

made specifically for the specification. Delivery

time of such components will be 8 weeks.

INSPECTION

1. Review the current operating conditions

of temperature, steam flow, pressure

of steam and pressure of cooling water

and compare with those specified on

theinstallationdrawing.

2. Estimate the valve position from the

operating conditions and the heat balance.

3. Check the valve stem position.

4. Check the valve stem packing leakage. The

packing gland should appear slightly wet.

5. Check to assure that the packing gland is

equally centered on the valve stem.

6. Check to assure that the valve stem is

smooth and not scored due to rubbing

orbinding.

7. Check the instrument air supply pressure

and check the filter.

8. Check the air signal from the controller.

9. Inspect the positioner linkage to assure

proper non-binding action.

10. Check the steam pressure and temperature.

11. Compare the temperature, temperature

setpoint of the controller and the steam

pressure to provide a minimum margin

above saturation.

12. Blow down the strainer-changes in water

inlet pressures indicate a contaminated

supply.

13. Evaluate.

14. If operation conditions permit:

manually cause small changes to

thesystem

1. To stroke valve.

2. To change temperature.

3. Note changes.

15. If the findings for the above checkpoints are

satisfactory, return the valve to service.

ASSEMBLY, INSPECTION AND OVERHAUL

1. Isolate (valve out) the desuperheater valve

from the system.

2.

CAUTION: secure the steam line by shutting

off the block valves. Cool the line and

vent, assure the steam line is cold and

depressurized. Shut off the water supply.

3. Stroke the valve full open to fully closed.

Check the stroke and adjustments. Note the

smoothness of operation. Repeat several

times noting the positioner gage readings.

Observe the motion and inspect for freeness

and proper action.

4. Disconnect and remove the valve.

CAUTION: use care in lifting by using the

proper sling rigging. Assure proper removal

without bending the positioner linkages, etc.

5. Check leakage.

6. Connect the temporary supply of water to

the inlet port.

7. Increase the water pressure to approximate

the difference between the installed

water pressure and the steam pressure

(differential pressure).

8. Factory test: leakage allowed 7 drops per

minute at 550 psig.

6

Page 9

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

FIGURE 4FIGURE 5

16

14

17

18

13

12

11

7

2

A

15

2

10

8

1

9

Witness mark

PARTS LIST

Item Part

1 Body assembly

2 Stem assembly

3 Spray cylinder assembly

4 Fastener ring

5 Set Piston ring

6 Vortex nozzle

20

7* Set Packing

8 Packing gland

9 Gland bushing

10 Cap screw

11 Lock nut

12 Data plate

13 Drive screw

14 Split nut stem connector

15 Actuator

16 Jam nut

17 Scale plate

18 Coupling bolt (2x)

19 Welded Stellite 6 seat**

20 Positioner

NOTES

* Recommended spare part. Specify spare part

byitem no., figure no., serial no.

** Integral part of the body, no spare part

FIGURE 6

4

19

5

6

3

Tangential water port

Water valve

feed holes in

spray cylinder

Rotating water

to cone shape

spray fan

Vortex ring

Vortex

spray

nozzle

Outlet

orifice

SPRAY CYLINDER DETAIL

VORTEX SPRAY NOZZLE NOT

AVAILABLE AS A SPARE PART

7

Page 10

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

DISASSEMBLE WITH VALVE IN BENCH VISE

(FIGURES 4, 5 AND 6)

1. Mark the body assembly (1) and the spray

cylinder assembly (3) (Figure 4) with witness

marks to ensure proper alignment at

reassembly. Fastener ring (4) has right and

left hand threads to allow properly oriented

tightening at reassembly. RH and LH for

right hand and left hand respectively are

stamped on fastener ring (4).

2. Grind out the tack weld (A) (Figure 5) at

two places. To release the fastener ring (4)

from the body assembly (1) and the spray

assembly (3):

a. Hold cylinder (3); loosen the ring (4)

byturning the ring clockwise.

b. Inspect the piston rings (5) for wear

orerosion.

c. Inspect the cylinder bore (3) for gouges

or ridges.

d. Clean the spray cylinder assembly (3)

using boiler acid wash to remove scale.

Thoroughly rinse in clean water.

e. Inspect the spray nozzles (6) for erosion

of outlet orifices.

f. Replace worn or eroded parts.

g. Connect the filtered air supply (IA)

and, using the regulator, supply

approximately 9 psi to the instrument

signal (IS) ports of the positioner.

h. The actuator will cause the stem

assembly (2) to extend.

i. Inspect the seat (19) and the disc (2)

seating surface. The seating surface

should be clean and free from cuts,

gouges or wiredrawing. A proper seat

shows a narrow concentric lapped

seating band.

j. Slowly decrease the instrument signal

(IS) allowing the actuator to retract,

closing the valve. Shut off the air

andvent.

DECISION POINT

If the seat band and leakage are correct,

proceed to Reassembly procedure. If the stem

and disc are to be replaced or refinished,

proceed to “Removal of stem/disc assembly.”

Removal of stem/disc assembly

Place valve in vise. The instrument

air (IAandIS) should be connected to

thepositioner.

1. Carefully observe and make sketch notes of

the orientation of the:

a. Positioner link attachment to valve stem

and the orientation of the split nut stem

connector (14). Count the stem threads

above and below the connector to aid in

proper reassembly.

b. Carefully disconnect the positioner links.

c. Loosen the jam nut (16) and leave on the

actuator stem.

d. With (IA) at 40 to 50 psi and (IS) at 7

psi, slowly move the positioner arm to

cause the actuator stem to extend to

mid-travel.

e. With the valve stem at mid-position,

loosen the split nut stem connector

bolts(18) and stem connector (14).

f. Slowly retract the actuator stem.

Remove the instrument signal (IS).

g. Loosen and remove the cap screws (10),

packing gland (8) and gland bushing (9).

h. With a packing hook, remove packing (7).

i. Remove the valve stem and disc (2).

j. Clean the packing box of packing and

foreign material.

k. The stem disc (2) and seat (19) may

be lapped to repair the seat using

Carborundum Compound, Grade 360

(fine) or equivalent. A proper seat

shows a narrow concentric lapped

seatingband.

l. Clean the seat and disc thoroughly

afterlapping.

8

Page 11

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

REASSEMBLY OF VALVE

1. Insert the stem/disc assembly (2) into the

valve body (1).

2. Install the packing rings (7) alternating

the ring gaps. Bottom each ring. Refer to

packing installation instructions supplied

with replacement packing.

3. Install the gland bushing (9).

4. Install the packing gland (8).

5. Install the cap screws (10).

6. Pull down the packing evenly taking up

slack, making sure not to bind the stem,

bushing or gland.

7. Leave the final packing adjustment until

later in this instruction.

8. Place the scale plate (17) on actuator stem

(Figure 8).

9. Actuator/stem coupling (Figure 7).

a. Make a temporary witness mark at the

actuator stem and spring adjustor actuator fully retracted.

b. Connect 7 to 9 psi regulated instrument

air to actuator port to cause actuator to

extend ¾” (19 mm).

c. Couple valve stem and actuator stem

with two-piece stem connector (14).

Stems to touch or gap slightly to match

fit the thread form. Valve stem to have

a full thread engagement with stem

connector.

d. Attach mating stem connector

half, assemble positioner bracket if

applicable. Tighten assembly using

connector bolts (18). Tighten to 20 ft/lb

(27 Nm) torque.

e. Slowly remove regulated instrument

air to allow actuator stem to retract at

final position (“0” air pressure) and valve

disc on seat. The actuator stem witness

1

mark shall be extended

/

16” (1.5 mm)

minimum. Full actuator spring force is

on valve to close, assuring tight shutoff.

10. Tighten the jam nut (16) to 50 ft/lb (68 Nm)

on the scale plate (17) and the split nut (14).

Adjust indicator scale.

11. Remove the air pressure to the actuator.

12. Connect the positioner link in the same

position as found at disassembly.

13. Reconnect actuator line to the positioner.

Cause valve to open and close by raising

andlowering pressure (IS) (3 to 15 psi).

14. Turn off the air pressure to the positioner.

REASSEMBLE SPRAY CYLINDER ASSEMBLY

1. Inspect the piston ring (5) position and

make proper orientation with respect to

witness marks established at disassembly

(Figure4).

2. Orient piston rings as shown in Figure 8.

3. Engage ring (4) 1-2 threads on body (1) to

hold in place. Align the witness marks on

cylinder (3) and valve body (1). Assemble

cylinder (3) by inserting disc (2) with properly

oriented piston rings (5). Water can be used

as a lubricant.

4. Engage the threads in ring (4)

simultaneously with thread in body (1) and

cylinder (3).

5. Rotate the ring (4) counterclockwise to pull

body (1) and the cylinder (3) into face to face

contact. Do not rotate cylinder (3).

6. Tighten the ring (4) to 40 to 50 ft/lb

(54-68Nm).

7. The fastener ring (4) must have a gap on

1

both sides -

/

64” (0.4 mm) minimum.

8. Inspect location of witness marks for

alignment of spray cylinder (3) and body (1).

9. Turn on the instrument air supply pressure

port (IA). Apply 3 to 15 psi at port (IS). Slowly

extend and retract the valve stem (2). Valve

action should be smooth.

10. Shut off the air pressure and vent. Remove

connections.

11. Tack weld ring (4) to the body (1) and to the

cylinder (3) - 2 places, 180° apart.

12. Use welding filler material, Specification

SFA 5.14, AWS ER NiCrMo-3. Preheat not

required. Post weld heat treat not required.

13. Apply 500 psi water at water inlet flange.

Check leakage.

14. Tighten packing cap screws (10) equally

until gland leakage is a drop per minute.

Donot bind stem.

15. Remove pressure.

9

Page 12

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

FIGURE 7 VALVE AND ACTUATOR REASSEMBLY

ANDADJUSTMENT

Actuator shaft reference mark

assembled

Valve disc on seat

1

/

16” minimum gap.

Bolt 18

Stem connector to have

full thread engagement

with valve stem

FIGURE 8

Actuator

shaft

Valve

stem

120°

1 2 3

Ring 1Ring 2Ring 3

120°

Nozzle side

Jam nut 16

14

2

9

1. Actuator and positioner adjustment are

covered in manufacturer’s manuals.

2.

CAUTION: the actuator has springs installed

with a preload in place. Do not disassemble

without proper preparation.

3. Pin the positioner arm linkage to the split

nut stem connector (14) in the same manner

as noted at disassembly. Take care to

ensure freedom of motion to linkage.

4. The valve trim has a linear or modified

linear stroke/flow characteristic.

5. Valve to remain on valve seat at 3 psi

instrument signal (IS), “0” diaphragm

pressure, and to start open at 3.5 psi (IS).

This ensures positive seating force at

minimum signal. Full stroke at 15 psi (IS).

6. Install the valve using new gaskets

as described in mounting and startup

instructions above.

6

5

FIGURE NUMBERS

Weight*

ANSI class rating ISO rating Figure number

150 20 4322 141 (64)

300 50 4324 150 (68)

600 110 4326 155 (70)

900 150 4328 171 (77)

1500 260 4330 187 (85)

2500 420 4332 231 (105)

* Including pneumatic actuator

Spray cylinder nozzle assemblies are furnished in 7 standard capacities depending on application requirements.

Special nozzle configuration may be supplied. Consult certified order drawing.

Size C

AS 6 0.09 0.07 1⅛ (28)

AO 6 0.19 0.16 1⅝ (41)

A 6 0.30 0.26 1⅝ (41)

B 6 0.80 0.68 2⅛ (54)

C 6 2.10 1.80 2⅞ (73)

D 6 3.20 2.60 3⅛ (80)

E 6 5.50 4.70 3

v

K

v

lb (kg)

Valve stroke

inch (mm)

5

/

16 (84)

10

Page 13

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

RECOMMENDED SPARES

Packing set - Item (7).

Special note:

1. All parts are available. Identify by name,

HOW TO ORDER SPARE PARTS

When ordering spare parts, always give the:

Figure no.

Serial no.

item number, and desuperheater valve

serial number.

The seat is a part of the body assembly

Describe parts by name and item number.

See Figure 5.

andnot available separately.

2. Spray cylinder assembly (3) includes

Data plate is attached to actuator yoke.

vortex nozzles (6) which are not available

separately.

3. When ordering a spray cylinder (3),

matching piston rings (5) must be ordered

toassure proper sealing.

4. When ordering stem assembly (2), piston

ring set (5) will be supplied.

TROUBLESHOOTING CHART FOR SYSTEM

Steam

flow

Very low Low Low Low Closed Startup

Very high Low Low OK Normal Water on sensor

Normal Normal Low OK Normal Wet sensor Sensor too close to valve Move sensor

Very low High Low OK Normal to flood Setpoint at press. sat. temp. Poor heat transfer Raise setpoint or lower

Normal Normal OK OK

Normal Low OK OK Normal High superheat Poor heat transfer Raise system pressure

Normal High OK OK Poor control Sat. steam Setpoint at saturation Lower system pressure

Low High High High Fails open Temp. above Over temperature Lower system pressure

Low Normal High OK Closes Water on sensor Sensor too close to valve Move sensor

Very low Normal High High Opens Water fallout Steam velocity low Lower system pressure

Normal Normal High High Opens Operating saturated Wet steam Lower system pressure

Normal Normal High High Open Needs water Water supply Clean the strainer

Very high Low High High Open Needs water Check water supply Raise water pressure

Steam

pressure

Actual effective

steamtemp.

Temp.

control Valve action Cause What is wrong To correct

Evap. beyond sensor

pressureDue to syst. heat losses Sat. steam

Wet steam

Floods Sat. temp. Wet steam

Floods

Floods Raise setpoint

11

Page 14

YARWAY TEMPLOW® STEAM DESUPERHEATER

InstallatIon and MaIntenance InstructIons

VALVE TROUBLESHOOTING CHART

Malfunction Reason Corrective action

Low temperature Valve cycling, low system flow, valve throttling too close to seat 1. Reduce water pressure

Must be steam saturated pressure plus 50 psi

Low temperature Controller action reversed 1. Check system signal sense

Low temperature Water pressure too high 1. Reduce inlet water pressure

Low temperature Valve does not shut off 1. Check valve stroke

2. Check 3.5 psi Instrument Signal (IS) shutoff point

Low temperature Valve seat leakage indicated 1. Secure system and evaluate seat leakage

High temperature, no control Water pressure at valve inlet less than specified 1. Open water valve

2. Blow down strainer

3. Check supply pressure

High temperature, no control Air pressure to actuator/positioner 1. Air pressure too low. Adjust to 40-50 psi

2. Clean air set filter

3. Blow down air supply line

4. Check for moisture in instrument air

High temperature, no control Water pressure at valve as specified 1. Check valve stroke

2. Check water temperature

3. Check for valve plugging

4. Check water quality

Hunting or limit cycling Temperature setpoint too close to saturation pressure temperature 1. Increase temperature (steam superheat)

2. Evaluate and readjust controller action

Hunting or limit cycling Temperature controller tuning not correct 1. Positioner arm link bent, loose or binding

Hunting or limit cycling Valve binding or friction 1. Check packing adjustment (some leakage expected)

2. Check packing gland/stem clearance

3. Use correct original type packing

4. Review positioner calibration

5. Check instrument air supply pressure

GRAFOIL

®

is a registered trademark of UCAR Carbon.

© 2017 Emerson. All rights reserved.

12

Loading...

Loading...