Page 1

Instruction Manual

D102030X012

Fisherr SS-83 Angle Valve

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 1...............................

Installation 2..................................

Maintenance 3.................................

Introduction

SS-83 Valve

March 2013

Packing Lubrication 4..........................

Packing Maintenance 5.........................

Replacing Packing 7........................

Trim Maintenance 9...........................

Parts Ordering 10...............................

Parts List 11...................................

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for the Fisher SS-83 angle valve

(figure 1). Refer to separate manuals for instructions covering the actuator and accessories.

Do not install, operate, or maintain an SS-83 valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

The SS-83 is an integral bonnet angle control valve. It is designed for handling highly corrosive fluids and is usually

mounted on a tank. Body sizes refer to nominal inlet and outlet dimensions (for example, a 4 x 6 body has an NPS 4

nominal inlet and an NPS 6 nominal outlet).

Specifications

Some specifications for this valve can be found on the valve or actuator nameplate. Other specifications and limits

were specified when you ordered this valve. If you are not sure what the specifications and limits for this valve are,

contact your Emerson Process Management sales office. Specify the valve serial number and any other information

about the valve.

www.Fisher.com

Page 2

SS-83 Valve

March 2013

Instruction Manual

D102030X012

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure may result if the valve assembly is installed

where service conditions could exceed the limits specified when the valve was purchased or on the appropriate

nameplates. To avoid such injury or damage, provide a relief valve for over-pressure protection as required by government

or accepted industry codes and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop and controlled fluid conditions. Because some body/trim material combinations are limited in their pressure

drop and temperature ranges, do not apply any other conditions to the valve without first contacting your Emerson

Process Management sales office.

If hoisting the valve, use a nylon sling to protect the surfaces. Carefully position the sling to prevent damage to the actuator

tubing and any accessories. Also, take care to prevent people from being injured in case the hoist or rigging slips

unexpectedly. Be sure to use adequately sized hoists and chains or slings to handle the valve.

1. Before installing the valve, inspect the valve body cavity and associated equipment for any damage and any foreign

material.

2. Make certain the body interior is clean, that pipelines are free of foreign material, and that the valve is oriented so

that pipeline flow is in the same direction as the arrow on the side of the valve.

3. If possible, install the valve with the valve stem vertical. All valves with size 80 or larger actuators mounted between

45_ above and 45_ below horizontal should be supported. Small actuators might also need support if vibrational or

other non-gravitational forces are present. For more information on seismic considerations, consult your Emerson

Process Management sales office.

4. Use accepted piping, flange, or welding practices when installing the valve in the line. For flanged valve bodies, use

a suitable gasket between the body and pipeline flanges.

Note

For valves with a welding-end, depending on valve body materials used, post weld heat treating may be required. If so, damage to

internal elastomeric and plastic parts, as well as internal metal parts is possible. Shrink-fit pieces and threaded connections may

also loosen. In general, if post weld heat treating is to be performed, remove all trim parts. Contact your Emerson Process

Management sales office for additional information.

2

Page 3

Instruction Manual

D102030X012

SS-83 Valve

March 2013

5. With a leak-off bonnet construction, remove the pipe plug from the bonnet to hook up the leak-off piping. If

continuous operation is required during inspection or maintenance, install a three-valve bypass around the control

valve assembly.

6. If the actuator and valve are shipped separately, refer to the actuator mounting procedure in the appropriate

actuator instruction manual.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened before shipment; however, the packing

might require some readjustment to meet specific service conditions.

Valves with ENVIRO-SEALt live-loaded packing or HIGH-SEAL live-loaded packing will not require this initial

re-adjustment. See the Fisher instruction manuals, ENVIRO-SEAL Packing System for Sliding-Stem Valves or HIGH-SEAL

Live-Loaded Packing System (as appropriate), for packing instructions.

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. Inspection and maintenance

frequency depends on the severity of service conditions. This section includes instructions for packing lubrication,

packing maintenance, trim maintenance, and lapping metal seats.

WARNING

Avoid personal injury or damage to property from sudden release of pressure or uncontrolled process fluid. Before starting

disassembly:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Note

Whenever a gasket seal is disturbed by removing or shifting gasketed parts, install a new gasket upon reassembly. This is necessary

to ensure a good gasket seal because the used gasket may not seal properly.

3

Page 4

SS-83 Valve

March 2013

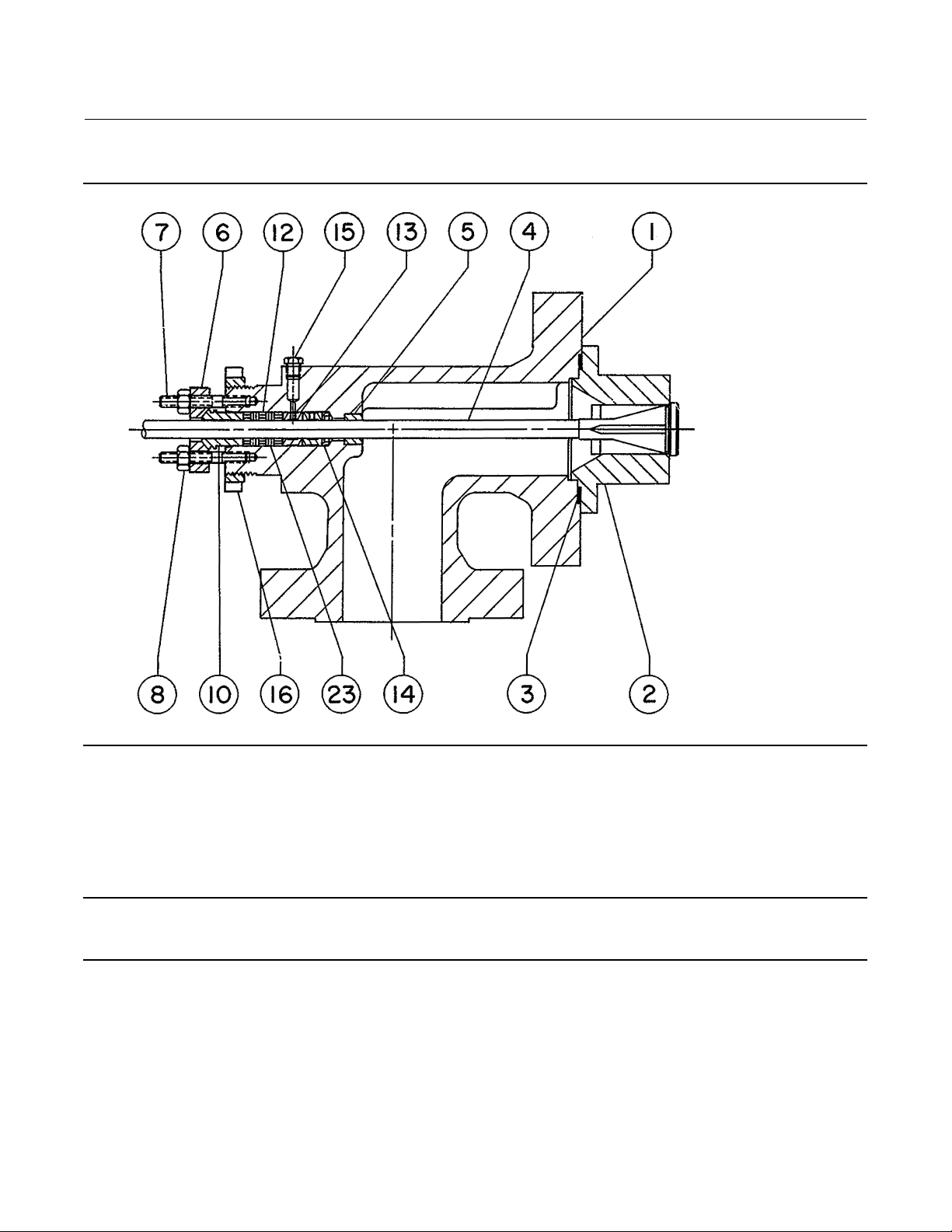

Figure 1. Fisher SS-83 Valve

Instruction Manual

D102030X012

15A1618-A

91 mm (3-9/16 INCH) YOKE BOSS

Packing Lubrication

Note

ENVIRO-SEAL or HIGH-SEAL packing does not require lubrication.

If a lubricator or lubricator/isolating valve is provided for PTFE/composition or other packings that require lubrication,

it will be installed in place of the pipe plug (key 15). Use a good quality silicon-base lubricant. Do not lubricate packing

used in oxygen service or in processes with temperatures over 260_C(500_F). To operate the lubricator, simply turn

the cap screw clockwise to force the lubricant into the packing box. The lubricator/isolating valve operates the same

way,exceptopentheisolatingvalvebeforeturningthecapscrewandthenclosetheisolatingvalveafterlubricationis

completed.

4

Page 5

Instruction Manual

D102030X012

Figure 1. Fisher SS-83 Valve (Continued)

SS-83 Valve

March 2013

15A1619-A

5-INCH (127 mm) YOKE BOSS

Packing Maintenance

Note

For valves with ENVIRO-SEAL live-loaded packing, see the Fisher instruction manual, ENVIRO-SEAL Packing System for Sliding-Stem

Valves, for packing instructions. For valves with HIGH-SEAL live-loaded packing, see the Fisher instruction manual, HIGH-SEAL

Live-Loaded Packing System, for packing instructions.

For spring-loaded single PTFE V-ring packing, the packing spring maintains a sealing force on the packing. If leakage is

noted around the packing follower, check to be sure the shoulder on the packing follower is touching the bonnet. If

the shoulder is not touching the bonnet, tighten the packing flange nuts until the shoulder is against the bonnet. If

leakage cannot be stopped in this manner, proceed to the Replacing Packing procedure.

5

Page 6

SS-83 Valve

March 2013

Figure 1. Fisher SS-83 Valve (Continued)

Instruction Manual

D102030X012

35A8298-A

7-INCH (178 mm) YOKE BOSS

If there is undesirable packing leakage with other than spring-loaded packing, first try to limit the leakage and

establish a stem seal by tightening the packing flange nuts.

If the packing is relatively new and tight on the stem and if tightening the packing flange nuts does not stop the

leakage, the valve stem may be worn or nicked so that a seal cannot be made. The surface finish of a new valve stem is

critical for making a good packing seal. If the leakage comes from the outside diameter of the packing, the leakage

may be caused by nicks or scratches around the packing box wall. If performing any of the following procedures,

inspect the valve stem and packing box wall for nicks and scratches.

6

Page 7

Instruction Manual

D102030X012

SS-83 Valve

March 2013

CAUTION

Use care to avoid damaging gasket sealing surfaces.

The surface finish of the valve stem is critical for making a good packing seal. The seating surfaces of the valve plug and the

seat ring on a metal-seat construction are critical for tight shutoff. Assume all these parts are in good condition and protect

them accordingly, unless inspection reveals otherwise

WARNING

Refer to the warning at the beginning of the maintenance section.

Replacing Packing

Key numbers are shown in figure 1 except where indicated.

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve, and drain the process

media from both sides of the valve. If using a power actuator, also shut off all pressure lines to the power actuator,

releaseallpressurefromtheactuatorandrelievespringcompressionfromtheactuator.Uselock-outproceduresto

be sure that the above measures stay in effect while you work on the equipment.

2. Disconnect the operating lines from the actuator and any leak-off piping from the valve.

3. Being careful to avoid damage to the valve plug (key 4), remove the valve from the line. Disconnect the stem

connector, and then remove the actuator from the valve by unscrewing the yoke locknut (key 16) or the cap screws

(key 17).

4. Remove any stem connector parts or locknuts. Remove packing flange nuts, packing flange, and packing follower

(keys8,6,and10).

5. Remove the seat ring (key 2) and the valve plug and stem assembly (key 4) through the bottom of the valve body.

Set removed parts on a protective surface to prevent damage to gasket or seating surfaces.

6. Being careful to avoid damaging the packing box wall, remove all packing parts with a formed wire hook.

7. Clean the packing box and the metal packing box parts. When installing new packing, refer to figure 2 for the order

of placement of packing box parts.

8. Clean the gasketed surfaces and install a new gasket (key 3). Install the seat ring (key 2) and slide the plug and stem

assembly (key 4) back into the valve body.

9. Slide the packing box parts over the stem and into the packing box. Place a smooth-edged pipe over the valve stem

and gently tap each soft packing part into the packing box, being sure that air is not trapped between adjacent soft

parts. Refer to figure 2 for the order of placement of parts. Contact your Emerson Process Management sales office

if your packing is not shown in figure 2.

Key numbers are shown in figure 1 except where indicated.

10. Install the packing follower, packing box flange, and nuts. Tighten the packing flange nuts snuggly.

11. Before putting the valve in service, cycle the valve until packing friction is reduced to an acceptable level.

12. Install the actuator according to instructions in the appropriate actuator instruction manual. Install the valve back

in the line.

7

Page 8

SS-83 Valve

March 2013

Instruction Manual

D102030X012

Figure 2. Typical Packing for Fisher SS-83 Valves

12A8160-A

PTFE V-RING

SINGLE PACKING

12A7839-A

Sht 1

PTFE V-RING

DOUBLE PACKING

UPPER WIPER (KEY 12)

PACKING FOLLOWER

(KEY 13)

FEMALE ADAPTOR

(KEY 32)

V-RING (KEY 7)

MALE

ADAPTOR (KEY 31)

WASHER (KEY 10)

SPRING (KEY 8)

PACKING BOX RING

(KEY 11)

LOWER WIPER

(KEY 30)

UPPER WIPER (KEY 12)

PACKING FOLLOWER

(KEY 13)

FEMALE ADAPTOR

(KEY 32)

V-RING (KEY 7)

MALE ADAPTOR

(KEY 31)

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

LOWER WIPER

(KEY 30)

KEY 6

1

14A3412-B

GRAPHITE LAMINATE AND FILAMENT

SINGLE PACKING

KEY 6

1

1

14A3414-B

GRAPHITE LAMINATE AND

FILAMENT DOUBLE PACKING

PACKING ARRANGEMENTS FOR 1-1/4 INCH (31.8 mm) VALVE STEMS

PACKING FOLLOWER

(KEY 13)

GRAPHITE LAMINATE

PACKING RING (KEY 7)

2

GRAPHITE FILAMENT

PACKING RING (KEY 9)

3

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

PACKING FOLLOWER

(KEY 13)

GRAPHITE LAMINATE

PACKING RING (KEY 7)

2

GRAPHITE FILAMENT

PACKING RING (KEY 9)

3

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

12A8163-A

13A0112-A

GRAPHITE/COMPOSITION

DOUBLE PACKING

PTFE/COMPOSITION

DOUBLE PACKING

UPPER WIPER (KEY 12)

PACKING FOLLOWER

(KEY 13)

PACKING RING

(KEY 7)

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

UPPER WIPER (KEY 12)

PACKING FOLLOWER

(KEY 13)

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

PACKING

FOLLOWER

(KEY 13)

GRAPHITE

LAMINATE

PACKING RING

1

14A3419-B 14A3418-A

(KEY 7)

GRAPHITE

FILAMENT

PACKING RING

(KEY 9)

LANTERN RING

(KEY 8)

PACKING

BOX RING

(KEY 11)

GRAPHITE LAMINATE AND FILAMENT

SINGLE PACKING

C0634-1

NOTES:

1

0.004 INCH (0.102 mm) THICK SACRIFICIAL ZINC WASHERS. USE ONLY ONE BELOW EACH GRAPHITE LAMINATE RING.

2

HAS THE APPEARANCE OF FLAT WASHERS PRESSED TOGETHER.

3

HAS THE APPEARANCE OF A WOVEN OR BRAIDED RING.

PACKING ARRANGEMENTS FOR 50.8 mm (2-INCH) VALVE STEMS

1

2

3

1

GRAPHITE LAMINATE AND FILAMENT

DOUBLE PACKING

PACKING

FOLLOWER

(KEY 13)

GRAPHITE

LAMINATE

PACKING RING

(KEY 7)

GRAPHITE

FILAMENT

PACKING RING

(KEY 9)

LANTERN RING

(KEY 8)

8

2

3

PACKING

BOX RING

(KEY 11)

13A0029-A

GRAPHITE/COMPOSITION AND

PTFE/COMPOSITION DOUBLE PACKING

UPPER WIPER (KEY 12)

PACKING FOLLOWER

(KEY 13)

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

Page 9

Instruction Manual

D102030X012

SS-83 Valve

March 2013

13. For spring-loaded PTFE V-ring packing, tighten the packing flange nuts until the shoulder on the packing follower

contacts the bonnet.

For graphite packing, tighten the packing flange nuts to the maximum recommended torque shown in table 1.

Then loosen the packing flange nuts, and retighten them to the recommended minimum torque shown in table 1. If

the stem diameter of your valve is not shown in the table, contact your Emerson Process Management sales office.

For ENVIRO-SEAL or HIGH-SEAL live-loaded packing, refer to the note at the beginning of the Maintenance section.

For other types of packing, contact your Emerson Process Management sales office.

14. Mount the actuator on the valve assembly and reconnect the actuator and valve stem according to the procedure

in the appropriate actuator instruction manual.

Table 1. Packing Flange Nut Torque for Graphite Packing

STEM DIAMETER

mm Inches NSm LbfSIn NSm LbfSIn

19.1 3/4

25.4 1

31.8 1-1/4

50.8 2

PRESSURE RATING

CL150

CL300

CL600

CL900

CL150

CL300

CL600

CL900

CL150

CL300

CL600

CL900

CL600

CL900

MINIMUM TORQUE MAXIMUM TORQUE

11.2

15.0

20.6

25.0

19.1

25.5

35.1

42.5

26.9

35.9

49.4

59.8

63.8

77.3

99

133

182

221

169

226

310

376

238

318

437

530

565

684

16.9

22.5

30.9

37.5

28.7

38.3

52.6

63.8

40.4

53.8

74.0

89.7

95.7

116

149

199

274

332

254

339

466

564

357

477

655

794

847

1,026

Trim Maintenance

WARNING

Refer to the warning at the beginning of the maintenance section.

CAUTION

Use care to avoid damaging gasket sealing surfaces.

The surface finish of the valve stem is critical for making a good packing seal. The seating surfaces of the valve plug and the

seat ring on a metal-seat construction are critical for tight shutoff. Assume all these parts are in good condition and protect

them accordingly, unless inspection reveals otherwise.

1. Isolate the valve body and actuator from all pressure. Release all pressure from the valve. Disconnect any operating

lines providing air pressure, electric power, or a control signal to the actuator. Be sure the actuator cannot suddenly

openorclosethevalve.Usebypassvalvesorcompletelyshutofftheprocesstoisolatethevalvefromprocess

pressure. Relieve process pressure from both sides of the valve. Drain the process media from both sides of the

valve.Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.Use lock-out

procedures to be sure that the above measures stay in effect while you work on the equipment.

2. Disconnect the operating lines from the actuator and any leak-off piping from the valve.

3. Being careful to avoid damage to the valve plug (key 4), remove the valve from the line. Disconnect the stem

connector, and then remove the actuator from the valve by unscrewing the yoke locknut (key 16) or the cap screws

(key 17).

9

Page 10

SS-83 Valve

March 2013

4. Remove any stem connector parts or locknuts. Loosen the packing flange nuts (key 8).

5. Remove the seat ring (key 2) and the valve plug and stem assembly (key 4) through the bottom of the valve body.

Set removed parts on a protective surface to prevent damage to gasket or seating surfaces.

6. Inspect the plug and stem assembly for nicks, scratches, scoring, or signs of galling. (If the stem is worn, packing

leakage can result.) Clean the gasketed surfaces and replace the seat ring gasket (key 3), seat ring (key 2), and valve

plug and stem assembly (key 4).

7. Tighten the packing flange nuts snuggly.

8. Before putting the valve in service, cycle the valve until packing friction is reduced to an acceptable level.

9. Install the actuator according to instructions in the appropriate actuator instruction manual. Install the valve back in

the line.

10. For spring-loaded PTFE V-ring packing, tighten the packing flange nuts until the shoulder on the packing follower

contacts the bonnet.

For graphite packing, tighten the packing flange nuts to the maximum recommended torque shown in table 1.

Then loosen the packing flange nuts, and retighten them to the recommended minimum torque shown in table 1. If

the stem diameter of your valve is not shown in the table, contact your Emerson Process Management sales office.

For ENVIRO-SEAL or HIGH-SEAL live-loaded packing, refer to the note at the beginning of the Maintenance section.

For other types of packing, contact your Emerson Process Management sales office.

11. Mount the actuator on the valve assembly and reconnect the actuator and valve stem according to the procedure

in the appropriate actuator instruction manual.

Instruction Manual

D102030X012

Parts Ordering

Eachvalveisassignedaserialnumberwhichcanbefoundonthevalveoronthenameplate.Thenameplatewill

normally be fitted to the actuator. Refer to this serial number when contacting your Emerson Process Management

sales office for technical assistance. When ordering replacement parts refer to this serial number and give the part

description from the following parts list.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

10

Page 11

Instruction Manual

D102030X012

Parts List

Note

For part numbers not shown, contact your Emerson Process

Management sales office.

Valve(Seefigure2forPacking

Parts)

Key Description

1ValveBody

2SeatRing

3* Seat Ring Gasket

4* Valve Plug and Stem Assembly

5 Bushing

6 Packing Box Flange

7 Packing Box Stud

8 Packing Box Nut

10 Packing Follower (also see figure 2)

12* PackingRing(alsoseefigure2)

13 Lantern Ring (also see figure 2)

14 Packing Box Ring (also see figure 2)

15 Pipe Plug

16 Yoke Locknut

17 Cap Screw

23* PackingRing(alsoseefigure2)

SS-83 Valve

March 2013

*Recommended spare parts

11

Page 12

SS-83 Valve

March 2013

Instruction Manual

D102030X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection,use, and maintenance of any product remains solely withthe purchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

E 1995, 2013 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...