Page 1

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

Fisherr Specification Manager

www.Fisher.com

Page 2

Fisher Specification Manager

December 2012

Contents

General Overview 3.............................

Software Installation 4..........................

Installation From Emerson External Website 4......

Launching the Application for the First Time 8.......

More Important Features 20......................

Duplicate 20..................................

Save Projects & Save Projects As 21...............

Compare 21..................................

Cv Plot 22....................................

Next Tag & Previous Tag 22.....................

Save As Template 23...........................

Help & About 23..............................

Drawings 23..................................

Report Generation Process 24....................

Profile Features 25..............................

User Profile 25................................

Project Profile 26..............................

Update your Software 27........................

Quick Start Guide

D103533X012

2

Page 3

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

GENERAL OVERVIEW

Enabling engineers to be more productive at control valve sizing & selection.

Overview

Designed for engineers, Fisher Specification Manager software offers a powerful set of tools for producing an ISA

specification sheet faster, improving noise prediction calculations and exporting dimensional data for Fisher and

Baumann control valves. You’ll find it easy to learn and use. Fisher Specification Manager software helps take the worry

out of control valve specification.

Clear, Sequential Specification Process

Create an ISA specification sheet with ease using Fisher Specification Manager software. Simply navigate through the

tabbed steps to enter your mechanical requirements and service conditions. Fisher Specification Manager software

will guide you through control valve models and construction details to complete your specification sheet.

It’s All About Efficiency

Convenient hot buttons and rightclick options provide quick access to view Cv plots and create new projects, tags,

and revisions. The Windowsr Explorertype view allows for quick navigation between projects and tags. You can set

engineering unit preferences for each new project.

Fisher and Baumann™ control valve bulletins in PDF format are available from the software during control valve

selection.

Powerful Comparison and Editing Tools

You can build a default specification sheet for the project and quickly use notes from a clipboard. The “find and

replace” feature ensures a fast process for changes across the entire project.

Fisher Specification Manager software offers a powerful comparison tool for evaluating differences between tags

and/or revisions.

Quickly Generate Dimensional Drawings

Fisher Specification Manager software can create dimensional drawing reports for your project that are consistent with

the Intergraph DDP (Dimensional Data for Piping) module. The dimensional data can be viewed in a Microsoftr Word

document as a drawing or exported to an Excel spreadsheet for Import into DDP.

Share Information Quickly With Other Programs

Fisher Specification Manager software can reliably export the data on the ISA specification sheet into a text or XML file

format. Mapping features deliver the data ready to use for Intergraph’s Intools and your Emerson sales engineer’s

quotation tool.

The custom mapping tool empowers you to create your own data map so that you can exchange data with other

systems as well.

Electronic Reports

You can easily generate and share the following Microsoft reports with your project team using Fisher Specification

Manager software: ISA specification sheet; Control valve sizing calculation; Actuator sizing calculation; Project

Summary; Cv versus travel plot; Dimensional drawing.

3

Page 4

Fisher Specification Manager

December 2012

SOFTWARE INSTALLATION

Below is a stepbystep guide to help you get Fisher Specification Manager setup on your PC.

Installation From Emerson External Website

1. Open Internet Explorer and navigate to www.FisherSpecificationManager.com.

2. Click the link “Download Fisher Specification Manager”.

Quick Start Guide

D103533X012

3. Click the link “Click here” towards the bottom of the next web page.

4

Page 5

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

4. Once the registration form appears, fill in the required fields (highlighted Yellow below) and click the Register

button.

5. If you see the web page below, your registration is complete. Click the button “Download” to proceed with

downloading Fisher Specification Manager.

5

Page 6

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

6. When you see the below dialog boxes, click “Yes” then “Run“. Download will take approximately 1 minute

depending on your network connection.

7. Once the download has completed, select Run on the below dialog box.

6

Page 7

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

8. The Fisher Specification Manager installation wizard will guide you through the setup process. Below is a

suggested method of installation.

7

Page 8

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

Launching the Application for the First Time

Now that your Fisher Specification Manager installation is complete, you will need to learn how to navigate

throughout the application. To do so, we will perform several mock scenarios and examples to help familiarize you

with the program.

1. Launch Fisher Specification Manager by doubleclicking the icon on your desktop. If you have another way you

would like to launch the app, please do so at your preference.

2. The Splash Screen will appear for a few moments, followed by the main screen (shown below).

3. We will want to size a valve for this project, therefore we need to CREATE a New Project by clicking the “New

Project” button on the far left side of the Toolbar.

4. A project folder will appear within the Tree View on the left hand side of the screen. At this point you can modify

the Project Name (e.g. “Project1”) if you like. For this sample’s purpose, we will leave it as “Project1”, and click the

“New Tag” button just to the right of the “New Project” button. You can also rename the Tag to something more

meaningful.

8

Page 9

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

5. Within each Tag you can size a valve, and you can create multiple Tags within a Project. As you can see, Fisher

Specification Manager operates by using a TAB system. A new tag always begins on the “1Installation Data” tab. A

user steps through each tab in order (“1” through “7”), but is not required to complete them all by any means.

Typically a user will stop at tab “3” for Valve Selection, and that will be all the user will need.

6. Within the Installation Data tab, select/fillin the following fields on the form with these values:

a. Style “Globe”

b. Rating “CL300”

c. Nominal Inlet Pipe Size “2”

d. Nominal Outlet Pipe Size - “2”

e. End Connection “RF Flg”

f. Insulation “None”

g. Allowable Noise “90”

h. Body to Bonnet bolt & nuts material “Manufacturer Standard”

i. Packing Flange Studs & Nuts “Manufacturer Standard”

j. Design Pressure “100”, “psig”

k. Design Temperature “60”, “deg F”

l. ANSI Shutoff - “ANSI CL II”

m. Service Description “Service Description Sample”

You can’t see the values very well in this image, but it should look something like this:

9

Page 10

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

7. Click the “2Valve Sizing” tab to proceed to the next step of sizing your valve. As an alternative, you can also click

the “Next” button in the lower right hand corner of the application.

OR

8. The first thing we will do in our sample is click the “Gas” option button on the right hand side of the Valve Sizing

form.

9. Next, rightclick anywhere within the grid, and make sure that there is NOT a check mark next to the “Display Short

Names” selection. This will ensure that you are looking at the Long Names which are more meaningful if you are

new to sizing valves.

10. You will notice along the top of the grid there are four default headings. “Minimum”, “Normal”, “Maximum”, and

“Others”. These are call Service Conditions (also known as Sizing or Process Conditions). Under the “Units”

column, make sure the values look as follows:

a. Gas

b. Mass Flow Rate Gas “lb/h”

c. Inlet Pressure “psig”

d. Pressure differential “psi”

e. Inlet Temperature “deg F”

f. Molecular Weight / Specific Gravity “SG”

g. Kinematic viscosity “cSt”

h. Ratio of specific heats

i. Inlet Compressibility Factor

j. Pressure Drop ratio factor (xt)

k. Recovery Factor (Fl)

10

Page 11

Quick Start Guide

D103533X012

l. Valve style modifier (Fd)

m. Upstream pipe size “in”

n. Upstream pipe schedule

o. Downstream pipe size “in”

p. Downstream pipe schedule

q. Valve Diameter “in”

r. Valve/Trim for aerodynamic noise

s. Aerodynamic distance Rn “ft”

t. Valve Outlet Area “in2”

u. Outlet temperature “deg F”

v. Outlet Compressibility Factor

11. Under the “Minimum” service condition, make sure to enter data as follows:

a. Gas “AIR”

b. Mass Flow Rate Gas “15000”

c. Inlet Pressure “100”

d. Pressure differential “101”

e. Inlet Pressure “102”

f. Molecular Weight / Specific Gravity “1”

g. Kinematic viscosity

h. Ratio of specific heats “1.4”

i. Inlet Compressibility Factor “0.01”

j. Pressure Drop ratio factor (xt) “0.65”

k. Recovery Factor (Fl) “0.9”

l. Valve style modifier (Fd) “0.35”

m. Upstream pipe size “2”

n. Upstream pipe schedule

o. Downstream pipe size “2”

p. Downstream pipe schedule

q. Valve Diameter “2”

r. Valve/Trim for aerodynamic noise “Globe/Angle”

s. Aerodynamic distance Rn “5”

t. Valve Outlet Area “6”

u. Outlet temperature “7”

v. Outlet Compressibility Factor “8”

Fisher Specification Manager

December 2012

12. Click the “Calculate” button in the lowerright corner of the Valve Sizing form. Output results will be generated

within the yellow cells towards the bottom of the grid.

11

Page 12

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

13. Next, we are going to Copy & Paste the Minimum service condition values to the other service conditions

(“Normal”, “Maximum”, “Others”). To do so, rightclick any cell within the “Minimum” service condition, and

select “Copy Condition”.

14. Rightclick in ANY of the Service Condition columns, and select “Paste Condition To All”. This will paste all your

copied values to the other service conditions to save time and eliminate the need to reenter data. Click the

“Calculate” button again to generate output results for all service conditions.

15. Moving on, click on the tab labeled “3Valve Selection”. A list of Valve products will be listed in the top pane of the

form.

16. Click the plussign to the left of the product “ET”.

17. Click the plussign to the left of “Equal Percent:”.

18. Finally, click on the Attribute labeled “Trim Style/Characteristic Equal Percent”. A grid will be populated with

data within the bottom pane of the form.

19. In the “Valve Size” column, click the GREEN cell labeled “NPS 2”.

12

Page 13

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

20. Continue on to the next step by clicking the “4Valve Construction” tab.

21. The first five text boxes should already be populated with data, so we will skip down to the Body Material and start

from there. Click the “Options” button just to the right of the Body Material dropdown box. Select “Cast Iron” from

the grid, and click OK.

22. Click the “Options” button to the right of the “Type of Bonnet” dropdown box. Select “Plain” from the grid, and

click OK.

23. Click the “Options” button to the right of the “Packing Material” dropdown box. Select “Single Graphite” from the

grid, and click OK. You will notice that Packing Type gets prepopulated based on your Packing Material selection.

13

Page 14

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

24. Click the “Fisher Trim Tables” button to the right of the “Plug/Ball/Disk” dropdown box. Select TrimNumber “1”

from the grid, and click OK. Based on your selection, “Seat Material”, and “Cage/Guide Material” will be

automatically populated.

25. Finally click on the “Options” button to the right of the “Stem Material” dropdown box. Select “N05500 Nickel

Alloy” from the grid, and click OK. Your screen should look something like this:

26. Let’s move on to Actuator Sizing by click the “5Actuator Selection” tab.

27. Fill in the Actuator Selection tab as follows:

a. Type “Spring & Diaphragm”

b. Spring action/fail mode “Open”

c. Hand Wheel “Side Mounted”

d. Note “Actuator Note Sample”

14

Page 15

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

28. This will enable the “Sliding Stem Actuator Sizing” button. Click this button. The Actuator Wizard will appear.

29. Select “Standard” from the Actuator Attribute dropdown list. The Actuator Sizing screen will appear. Make sure

that “Sizing For:”, “Sizing Method”, “Sizing Mode”, “Flow”, and “Bonnet Style” match this screen shot.

15

Page 16

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

30. Within the left “Inputs” sizing grid, make sure these values are present. If they are not, please enter them.

a. Operating Range(std) “033 psi”

b. Pa “0.00” “psig”

c. Pb “33.00” “psig”

d. Valve Body Size “2.0” “in”

e. Port Diameter “1.3125” “in”

f. Unbalanced Area “0.16” “in2

g. Valve Travel “0.75” “in”

h. Valve Stem Size “.5” “in”

i. Valve Friction “230.00” “lbf”

j. Additional Friction “0.00” “lbf”

k. Seat load force “5.000” “lbf/in”

l. P1 Max “100.000” “psig”

m. P2 Min “0.00” “psig”

n. Unbal Frce @ Open “0.00” “lbf”

o. Fluid Neg. Gradient “0.000” “in”

p. dP Flowing “0.00” “psi”

q. With Side MO “Yes”

31. Click the “Calculate” button. The Solutions window appears along with a grid for selection.

32. Click the “Select” button. Your input values will be calculated, and output results will be generated within the

paleyellow grid on the right.

33. Click “OK” to exit the Actuator Sizing screen. This will bring you back to the Actuator Selection tab. Rarely will a

user need to go past this step of the application, but to further your exposure we will continue on to the final two

tabs.

34. Let’s fill in some Positioner data by clicking the “6Positioner” tab.

35. Populate the Positioner frame with the following data:

a. Type “Pneumatic”

b. Manufacturer “Fisher”

c. Model “3582”

d. Positioner Input Signal “Foundation Fieldbus”

e. Positioner Action “Direct”

f. Gauges - “Yes”

g. Hazardous Area “ASME Approved”

h. Note “Positioner Note Sample”

36. Populate the I/P Transducers frame with the following data:

a. Manufacturer “Fisher”

b. Model “i2P100”

c. Output “018 psi”

d. Note “IP Transducers Note Sample”

16

Page 17

Quick Start Guide

D103533X012

37. Populate Air Set Regulator frame with the following data:

a. Manufacturer “Fisher”

b. Model “Mfg. Standard”

c. Air Set Pressure “60”

d. Gauges “Yes”

e. Note “Air Set Regulator Note Sample”

38. Once these values have been entered, your Positioners tab should look like this:

Fisher Specification Manager

December 2012

39. Click the “7Additional Accessories” tab to proceed to the final tab of our Fisher Specification Manager tutorial.

40. Populate the Solenoid Valve frame with the following data:

a. Manufacturer - “ASCO”

b. Model “55102025”

c. Bug Vent Required “Yes”

d. To VentActuator “Energize”

e. Voltage “110 VDC”

f. Material “Brass”

17

Page 18

Fisher Specification Manager

December 2012

41. Populate the Limit Switches frame with the following data:

a. Type “Mechanical”

b. Manufacturer “WestLock”

c. Model “7313524A2”

d. Contacts Form “SPST”

e. Actuation Points “1 Open”

f. Current Rating “1” “A”

g. Voltage Rating “2” “V”

h. Frequency “3” “Hz”

i. Note “Limit Switches Note Sample”

42. Once these values have been entered, your Additional Accessories tab should look like this:

Quick Start Guide

D103533X012

43. Congratulations! You have just walked through a majority of the application.

44. The whole point of filling out all of these tabs is to generate an overall summary of your valve that you sized, and

selected. This summary is called the ISA Sheet. Click the “ISA Sheet” tab.

18

Page 19

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

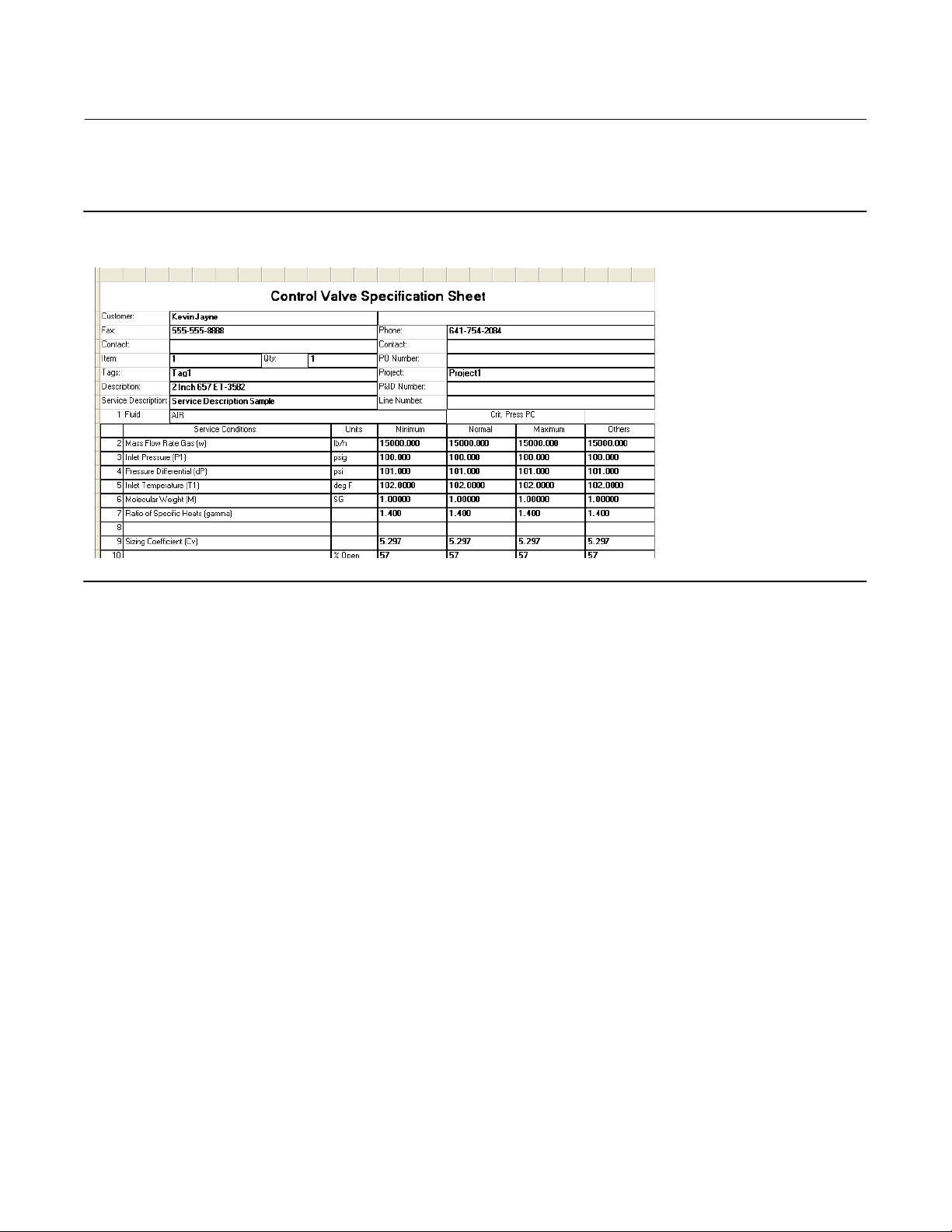

45. Look over the Control Valve Specification Sheet. You will notice that all of the values that we chose/entered within

the tabs has been centralized to this sheet.

Here is a screen shot of what your ISA Sheet should look like:

19

Page 20

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

More Important Features

Duplicate

To save you some time of having to start a new tag over from scratch, you can simply click the duplicate button on the

Toolbar. This will create an exact copy of whichever tag you choose. You can also duplicate by rightclicking a tag, and

selecting “Duplicate” from the submenu while in the TreeView.

20

OR

RESULT

Page 21

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

Save Projects and Save Projects As

Be sure to save your projects frequently. You may do this by clicking the Save Projects button on the Toolbar, or

File > Save Projects from the menubar. If you want to save a separate copy of an existing project without overriding it,

you may do so by clicking File > Save Projects As from the menubar.

Compare

Another great tool that comes equipped with Fisher Specification Manager is the Compare feature. It is a quick and

easy way to look that the difference between two tags. To take advantage of this, select two tags within the TreeView

by clicking their checkboxes, then click the Compare button on the Toolbar. The result is a window pointing out all the

differences between the two tags you selected. In this example, there are only two differences.

RESULT

21

Page 22

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

Cv Plot

Click the Cv Plot button on the Toolbar to generate a graph of the Cv values generated in Valve Sizing, and where they

lie in conjunction with the % Open values for the valve.

RESULT

Next Tag & Previous Tag

If you do not wish to use the TreeView to navigate between tags, you can use the Next Tag or Previous Tag buttons on

the toolbar.

22

Page 23

Quick Start Guide

D103533X012

Fisher Specification Manager

December 2012

Save As Template

By choosing this feature from either “File > Save As Template” or clicking the “Save As Template” button on the

toolbar, you can save every single setting, and field value within the current tag that you’re viewing. This featured is

designed to save time. Fisher Specification Manager will read this saved template file every time you create a new tag

which will prepopulate every field value that you saved. Thus, lessening the hassle of filling in those fields in future

projects.

Help & About

If you are having trouble at any point within the application, please refer to the Help resources that Fisher Specification

Manager has to offer. There are three different ways of finding what you are looking for: 1.) Clicking "Help > Contents" ,

2.) clicking “Help > Help By Screen”, and 3.) clicking “Help > Control Valve Handbook”. The first one is contentsbased,

the second is HTML based, and the third is a link to our online Fisher Control Valve Handbook. Also if you wish to know

what version of Fisher Specification Manager you're using, simply click “Help > About” on the menu bar. You can also

find out the Sizing Engine and Database versions from here. The sizing engine a separate, behind the scenes

application that generates your output results for you in the Valve Sizing step.

Drawings

After you have sized and selected a valve (ED, ET, etc.), you have the option of taking advantage of the Drawings

feature included with Fisher Specification Manager. To do so, select “Drawings” from the “View” menu on the

23

Page 24

Fisher Specification Manager

December 2012

menubar. The Select Drawing dialog window will appear. Select the first row of the grid, and click the “View Drawing”

button in the lower right corner. This result is a document displaying a basic drawing of the valve that you sized and

selected with dimensions.

Quick Start Guide

D103533X012

Report Generation Process

How To Generate Reports

1. Select a project that you would like to generate reports for within the TreeView.

2. Click “File > Reports” from the menubar.

3. The Reports dialog window will appear. Click a check mark in the following checkboxes.

a. DataSheet

b. Valve Sizing Calculation

c. Project Summary

24

Page 25

Quick Start Guide

D103533X012

4. Place a check mark in the checkbox just to the left of Item 1, Tag1 in the right pane.

5. Click the “OK” button. All the reports you placed a check mark next to will now be generated. The progress bar will

tell what report it's working on, and how long you will have to wait for all of the reports to finish. NOTE: Sizing

warnings will print to the Valve Sizing Calculation report by default unless you place a check mark within the “No

Sizing Warning” checkbox.

6. Each report type (DataSheet, Valve Sizing Calculation, etc.) will be on a separate document. At this point you can

either Print, Save, and/or Exit the document.

7. Congratulations! You just learned how to generate reports in Fisher Specification Manager!

Fisher Specification Manager

December 2012

Profile Features

There are two types of Profiles that you can setup for Fisher Specification Manager.

1. PROJECT Can edit before you start any tags. Settings will hold throughout the entire project.

2. USER Can edit before you start any projects or tags. Settings will hold indefinitely until you go in and manually

change them.

User Profile

1. Let’s start fresh. Close Fisher Specification Manager and relaunch it to start with a clean slate. You can also close all

of the projects in the TreeView if you would rather do that.

2. Click “Profile” on the menubar to expand the submenu.

25

Page 26

Fisher Specification Manager

December 2012

3. Select “User” from the submenu. At this point, this should be your only selectable option.

4. The User Profile dialog window will appear.

5. Clicking this button will take you to a dialog window where you can setup the units that you wish to use a majority

of the time when you’re sizing a valve (within the Valve Sizing tab). We will not utilize the “Edit Pull Downs” for this

tutorial.

6. Click the “OK” button to save, and close the dialog window.

Quick Start Guide

D103533X012

Project Profile

1. This feature is project specific. Click “Profile” on the menubar to expand the submenu, and select “Project”.

2. The Project Profile dialog window will appear. Fill in the text boxes as shown below. Notice there is a “Set Units”

button here as there is in the User Profile setup. There are a few other things you can set here as well. For now, we

will just worry about the top 5 text boxes.

3. Click “OK” to save, and close the dialog window. The “Project” row on the ISA Sheet will change according to what

you entered in the Project Profile setup.

4. Also, if you generate a DataSheet, Valve Sizing Calculation, and/or Actuator Sizing Calculation report, the 4

heading lines that you entered will show up there.

26

Page 27

Quick Start Guide

D103533X012

5. As long as you are creating new tags within this same Project, all of your Project Profile settings will stay the same.

Fisher Specification Manager

December 2012

Update Your Software

1. Fisher Specification Manager has the capability of updating itself. To do so, click “Update Now” from the Help

menu. If you have any projects open in your Tree View, you will be prompted to save your work and close them all

to proceed with the update.

2. You will be directed to the following web page. Enter your email address, and click the “Update Software” button

to proceed with the download and installation.

3. Similar to the full installation of Fisher Specification Manager, click “Run” to both messages that appear during the

download process. NOTE: This requires you to have installation privileges. If you do not have installation privileges

please click “Save” to the messages and have a system administrator perform the installation for you.

27

Page 28

Fisher Specification Manager

December 2012

Quick Start Guide

D103533X012

4. In addition to using Update Now from the Help menu, every 90 days Fisher Specification Manager will remind you

to check for an update. If you choose, you can customize the settings of the Update Reminder from either the

dialog box or the Update Settings options in the Help menu.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and Baumann are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

28

E2010, 2012 Fisher Controls International LLC. All rights reserved.

This software is protected by U.S. and International copyright laws.

Loading...

Loading...