Page 1

Instruction Manual

D103163X012

Fisherr HVP Series Control Valves

HVP Valve

April 2012

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 2...............................

Installation 2..................................

Maintenance 4.................................

Parts Ordering 7................................

Parts List 7....................................

Introduction

Figure 1. Fisher HVP-TS Valve

W5494-1

Scope of Manual

This instruction manual provides installation, maintenance, and parts information for the HVP Series control valve.

Do not install, operate, or maintain HVP control valves without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

The HVP (high viscous polymer) Series control valve is used extensively by the polymer industry. These processes

generally require the valves to operate at and maintain high temperatures to assure that the polymer fluid flows freely.

The HVP Series can provide integral valve body passages through which a heat-transfer fluid is pumped to keep the

valve and process fluid heated.

Forged and fabricated valve body styles are engineered to meet your process and piping requirements. Standard valve

body and trim designs can be adapted to exactly match specifications. Models include: HVP-TS (figure 1) for throttling

service; HVP-DS (figure 2) for diverting service (three-way valve); and HVP-SS for stop service (on/off).

www.Fisher.com

Page 2

HVP Valve

April 2012

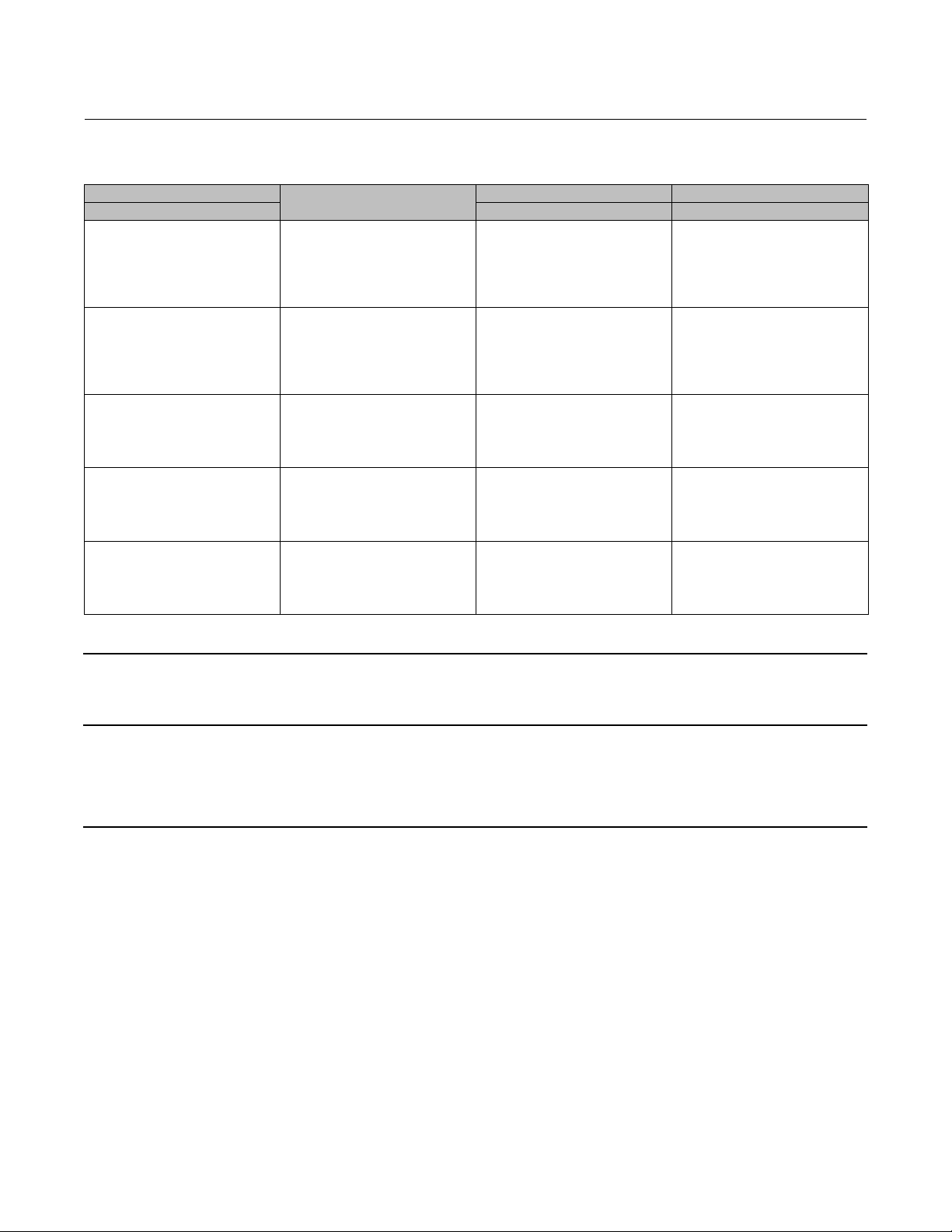

Table 1. Specifications

Instruction Manual

D103163X012

Valve Body Sizes

NPS 1 through 10, larger sizes on request

Flow Coefficient C

v

0.1 to 200

Inlet Pressure

(1)

Consistent with CL150 through 2500 ratings per

ASME B16.34

Temperatures

(1)

ends (SWE) consistent with ASME B16.11

ends consistent with ASME B16.5

Shutoff Classification per ANSI/FCI 70-2

and IEC 60534-4

To Class V as required

Travel

25 through 102 mm (1 through 4-inch)

Yoke Boss and Stem Diameter

As required to mate with specified actuator

-18 to 427_C(0to800_F) as required by specific

application

End Connections

J Buttweld ends (BWE) consistent with ASME B16.25

J Socketweld ends (SWE) consistent with ASME

B16.11

J Flanged ends consistent with ASME B16.5

Transfer Fluid Connections

NPS

J 1/2, J 3/4, or J 1withJ Buttweld ends

(BWE) consistent with ASME B16.25

1. The pressure/temperature limits in this manual, and any applicable standard or code limitation, should not be exceeded.

J Socketweld

Construction Materials

Valve Body, Bonnet, and Flanges: S30400/S31600

stainless steel

Packing: Graphite

Valve Plug and Valve Stem: S30400/S31600 stainless

steel (Alloy 6 overlays applied as required)

Dimensions

Depends on actuator requirements; contact your

Emerson Process Management sales office

J Flanged

Specifications

Table 1 lists specifications for the HVP control valve. Some of the specifications for a given control valve as it originally

comes from the factory are stamped on a nameplate located on the actuator spring barrel.

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or system damage caused by sudden release of pressure may result if the valve assembly is installed where

service conditions could exceed the limits given in table 1 and on the appropriate nameplates. To avoid such injury or

damage, use pressure-relieving devices as required by applicable industry codes to prevent the service conditions from

exceeding these limits.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

2

Page 3

Instruction Manual

D103163X012

Figure 2. Fisher HVP-DS Valve

HVP Valve

April 2012

W5493

CAUTION

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Responsibility for the safety of process media and compatibility of valve

materials with process media rests solely with the purchaser and end-user. Since some body/trim material combinations

are limited in their pressure drop and temperature ranges, do not apply any other conditions to the valve without first

contacting your Emerson Process Management sales office.

1. Use accepted piping and welding practices when installing the valve in the line. For welding end valve bodies,

completely disassemble the valve removing all trim parts before welding the valve body in the line. For flanged

valvebodies,usesuitablegasketsbetweenthevalvebodyflangesandpipelineflanges.

Note

Depending on valve body materials used, post-w eld heat treating might be needed. Post-weld heat treatment can damage

internal elastomeric, plastic, and metal parts. Shrunk-fit pieces and threaded connections might loosen. In general, if post-weld

heat treating is needed, remove all trim parts. Contact your Emerson Process Management sales office for additional information.

2. If the actuator and valve body are shipped separately, refer to the actuator mounting procedure in the appropriate

actuator instruction manual.

3. If the valve was shipped without packing installed in the packing box, install the packing before putting the valve

into service.

3

Page 4

HVP Valve

April 2012

Instruction Manual

D103163X012

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection

and maintenance depends on the severity of the service conditions.

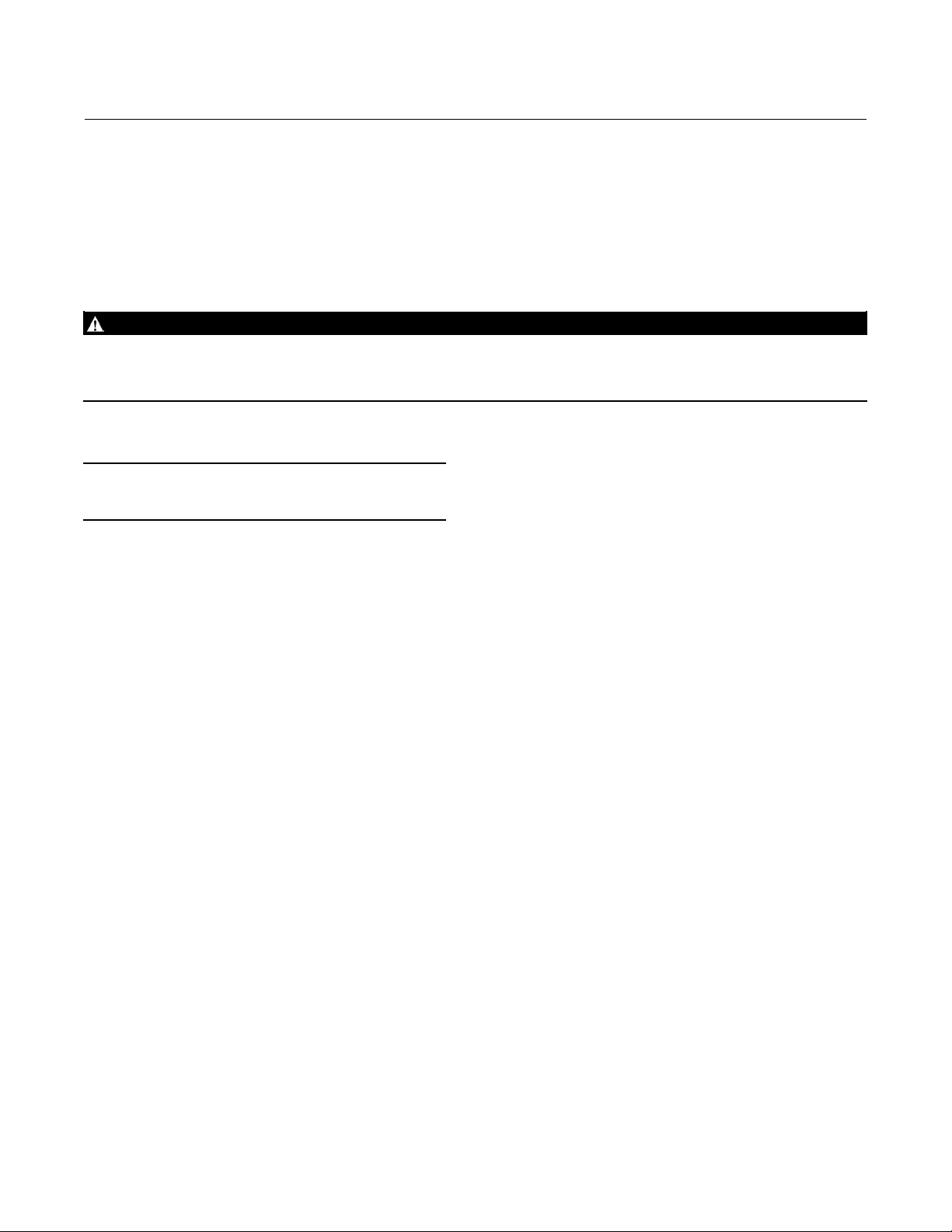

Table 2. Recommended Bonnet Bolt Torque

BOLT SIZE

Inch LbfSft

1/2 13 71

9/16 12 95

5/8 11 125

3/4 10 200

7/8 9 290

1 8 405

1-1/8 8 550

1-1/4 8 730

1-3/8 8 980

1-1/2 8 1290

1-5/8 8 1650

1-3/4 8 2070

1-7/8 8 2560

2 8 3130

2-1/4 8 4490

2-1/2 8 6200

3 8 10800

1. Torques for lubricated studs with heavy hex nuts.

WARNING

THREADS PER INCH

RECOMMENDED BOLT TORQUE

(1)

Avoid personal injury from sudden release of process pressure or bursting of parts. Before performing any maintenance

operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

4

Page 5

Instruction Manual

D103163X012

Table 3. Recommended Packing Nut Torque

STEM DIAMETER

Inch LbfSft LbfSft

1/2

3/4

1

1-1/4

2

PRESSURE CLASS

CL150

CL300

CL600

CL900

CL1500

CL2500

CL150

CL300

CL600

CL900

CL1500

CL2500

CL300

CL600

CL900

CL1500

CL2500

CL300

CL600

CL900

CL1500

CL2500

CL300

CL600

CL900

CL1500

CL2500

HVP Valve

April 2012

MAXIMUM TORQUE MINIMUM TORQUE

6

7

10

13

16

18

12

15

22

30

37

45

27

37

46

57

67

36

49

61

75

90

48

67

88

108

125

4

5

7

9

11

13

8

10

15

20

25

30

18

25

31

38

45

24

33

41

50

60

43

61

80

98

115

Note

Whenever a gasket seal is disturbed by removing or shifting gasketed parts, a new gasket should be installed upon reassembly.

This is necessary to ensure a good gasket seal.

Note

If the valve has HIGH-SEAL heavy-duty live-loaded packing installed, see Fisher instruction manual entitled HIGH-SEAL ULF

Live-Loaded Packing System (D101453X012) for packing instructions.

5

Page 6

HVP Valve

April 2012

Figure 3. Fisher HVP Assembly

Instruction Manual

D103163X012

GA02384-A

6

Page 7

Instruction Manual

D103163X012

HVP Valve

April 2012

Parts Ordering

Each HVP control valve is assigned a serial number, which can be found on the nameplate. Refer to the number when

contacting your Emerson Process Management sales office for assistance or when ordering replacement parts.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Note

For part numbers not shown, contact your Emerson Process

Management sales office.

Parts List

Key Description

1ValveBody

5 Bonnet

6* Plug Guide

7* Seat

10* Packing Ring

11* Packing Follower

12* Packing Flange

13* Plug

Key Description

20* Seat Gasket

21* Bonnet Gasket

24* Packing

25* Bonnet Stud

26* Bonnet StudNut

27* Bonnet StudWasher

28* Packing Stud

29* PackingStudNut

*Recommended spare parts

7

Page 8

HVP Valve

April 2012

Instruction Manual

D103163X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management businessunit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our termsand conditions,which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

8

E 2003, 2012 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...