Page 1

Instruction Manual

D100381X012

HS Valve

June 2019

Fisher™ HS Control Valve - OBS Valve

Contents

Introduction 1.................................

Safety Instructions 1............................

Specifications 2................................

Inspection and Maintenance Schedules 2...........

Parts Ordering 2................................

Installation 3..................................

Maintenance 4.................................

Latest Published Instruction Manual 5..............

Introduction

The product covered in this document is no longer in production. This document, which includes the latest published

version of the instruction manual, is made available to provide updates of newer safety procedures. Be sure to follow

the safety procedures in this supplement as well as the specific instructions in the included instruction manual.

Part numbers in the included instruction manual should not be relied on to order replacement parts. For replacement

parts, contact your Emerson sales office

For more than 20 years, Fisher products have been manufactured with asbestos‐free components. The included

manual might mention asbestos containing parts. Since 1988, any gasket or packing which may have contained some

asbestos, has been replaced by a suitable non‐asbestos material. Replacement parts in other materials are available

from your sales office.

.

Safety Instructions

Please read these safety warnings, cautions, and instructions carefully before using the product.

These instructions cannot cover every installation and situation. Do not install, operate, or maintain this product

without being fully trained and qualified in valve, actuator and accessory installation, operation and maintenance. To

avoid personal injury or property damage it is important to carefully read, understand, and follow all of the contents of

this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact

your Emerson sales office before proceeding.

www.Fisher.com

Page 2

HS Valve

June 2019

Instruction Manual

D100381X012

Specifications

This product was intended for a specific range of service conditions‐‐pressure, pressure drop, process and ambient

temperature, temperature variations, process fluid, and possibly other specifications. Do not expose the product to

service conditions or variables other than those for which the product was intended. If you are not sure what these

conditions or variables are, contact your Emerson sales office

other pertinent information that you have available.

for assistance. Provide the product serial number and all

Inspection and Maintenance Schedules

All products must be inspected periodically and maintained as needed. The schedule for inspection can only be

determined based on the severity of your service conditions. Your installation might also be subject to inspection

schedules set by applicable governmental codes and regulations, industry standards, company standards, or plant

standards.

In order to avoid increasing dust explosion risk, periodically clean dust deposits from all equipment.

When equipment is installed in a hazardous area location (potentially explosive atmosphere), prevent sparks by proper

tool selection and avoiding other types of impact energy. Control Valve surface temperature is dependent upon

process operating conditions.

WARNING

Control valve surface temperature is dependent upon process operating conditions. Personal injury or property damage,

caused by fire or explosion, can result if the valve body surface temperature exceeds the acceptable temperature for the

hazardous area classification. To avoid an increase of instrumentation and/or accessory surface temperature due to process

operating conditions, ensure adequate ventilation, shielding, or insulation of control valve components installed in a

potentially hazardous or explosive atmosphere.

Parts Ordering

Whenever ordering parts for older products, always specify the serial number of the product and provide all other

pertinent information that you can, such as product size, part material, age of the product, and general service

conditions. If you have modified the product since it was originally purchased, include that information with your

request.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher product, because they may void your warranty, might adversely affect

the performance of the product, and could cause personal injury and property damage.

2

Page 3

Instruction Manual

D100381X012

HS Valve

June 2019

Installation

WARNING

D Personal injury or equipment damage caused by sudden release of pressure or bursting of parts may result if the valve

assembly is installed where service conditions could exceed the limits given in the applicable product literature, the

limits on the appropriate nameplates, or the mating pipe flange rating. Use pressure‐relieving devices as required by

government or relevant industry codes and good engineering practices. If you cannot determine the ratings and limits

for this product, contact your Emerson sales office

D To avoid personal injury, always wear protective gloves, clothing, and eyewear when performing any installation

operations.

D To avoid personal injury or property damage, use proper lifting and rigging practices while lifting, installing or

removing the valve assembly. Be sure to use lifting and rigging equipment properly sized and selected for the weight

and configuration of the valve assembly or component being lifted.

D Personal injury could result from packing leakage. Valve packing was tightened before shipment; however, the packing

might require some readjustment to meet specific service conditions.

D Many rotary shaft valves are not necessarily grounded to the pipeline when installed in a flammable, hazardous, oxygen

service, or explosive atmospheres. An explosion is possible, due to the discharge of static electricity from the valve

components. To avoid personal injury or property damage, make sure that the valve is grounded to the pipeline before

placing the control valve assembly into service. Use and maintain alternate shaft‐to‐body bonding, such as a

shaft‐to‐body bonding strap assembly.

D Rotary shaft valves are designed and intended for installation between flanges. Personal injury or property damage may

result from improper installation. To avoid personal injury or property damage caused by the sudden release of

pressure or bursting of parts, do not use or install rotary shaft valves (including single lug constructions) for dead‐end

service.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

D If installing into an existing application, also refer to the WARNING in the Maintenance section.

D When ordered, the valve configuration and construction materials were selected to meet particular pressure,

temperature, pressure drop, and controlled fluid conditions. Responsibility for the safety of process media and

compatibility of valve materials with process media rests solely with the purchaser and end‐user. To avoid possible

personal injury and because some valve/trim material combinations are limited in their pressure drop and temperature

ranges, do not apply any other conditions to the valve without first contacting your Emerson sales office.

before proceeding.

CAUTION

D Ensure that the valve and adjacent pipelines are free of foreign material that could damage the valve seating surfaces.

3

Page 4

HS Valve

June 2019

Instruction Manual

D100381X012

Maintenance

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Always wear protective gloves, clothing, and eyewear.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure.

D Do not remove the actuator while the valve is pressurized.

D Relieve process pressure from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring pre‐compression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box might contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids might spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug. Cautiously remove parts so that fluid escapes slowly and safely.

D Many valve parts that are moving can injure you by pinching, cutting, or shearing. To help prevent such injury, stay

clear of any moving part.

D Never apply pressure to a partially assembled valve.

D To avoid personal injury or property damage caused by uncontrolled movement of a valve bonnet, loosen the bonnet by

following these instructions: Do not remove a stuck bonnet by pulling on it with equipment that can stretch or store

energy in any other manner. The sudden release of stored energy can cause uncontrolled movement of the bonnet.

Loosen bonnet nuts approximately 3 mm (0.125 inch). Then loosen the body‐to‐bonnet gasketed joint by either rocking

the bonnet or prying between the bonnet and body. Work the prying tool around the bonnet until the bonnet loosens.

If no fluid leaks from the joint, proceed with bonnet removal.

D As you remove parts, such as valve shafts, other parts, such as disks can fall from the valve body or suddenly move to

another position in the valve. To avoid injury from falling or moving parts, be sure to support parts and be sure they are

in a stable position as you disassemble the valve.

D Personal injury could result from packing leakage. Do not scratch the drive shaft or packing box wall while removing

packing parts.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

4

E 2019 Fisher Controls International LLC. All rights reserved.

Page 5

Instruction Manual

D100381X012

Fisher™ HS Control Valve

HS Valve

June 2019

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 2...............................

Installation 2..................................

Maintenance 3.................................

Packing Lubrication 3..........................

Packing Maintenance 4.........................

Adding Packing Rings 6.....................

Replacing Packing 7........................

Trim Maintenance 9...........................

Replacing Valve Plug, Seat Ring(s)

and Guide Bushings 9....................

Lapping Metal Seats 12.....................

Mounting Actuator and Adjusting Travel 13.........

Direct-Acting Valves 13........................

Parts Ordering 14...............................

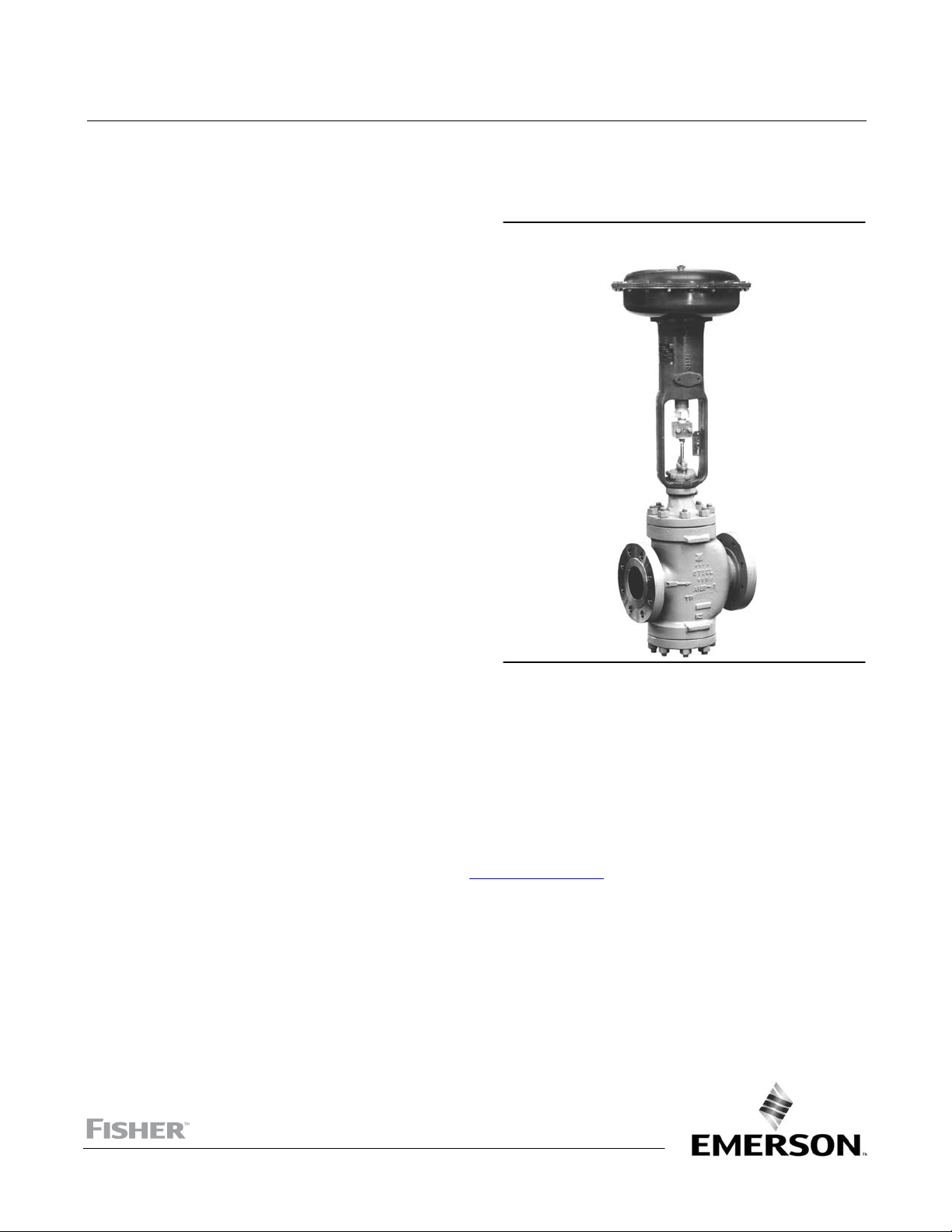

Figure 1. Fisher HS Control Valve with

Diaphragm Actuator

W6003-1

Introduction

Scope of Manual

This instruction manual provides installation, maintenance, and parts information for the NPS 1 through NPS 10 HS

control valves with ANSI CL900 through CL1500 pressure ratings. Refer to separate manuals for instructions on the

actuator and accessories.

Do not install, operate, or maintain a HS control valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office

Description

These valves are either single-port or double-port constructions. Direct-acting valves have push-down-to-close action.

If the valve is installed in a horizontal pipe run and the actuator is vertical above the valve, downward motion of the

valve stem will close the valve.

HS valve plugs are, top-and- bottom guided. With top-and-bottom guiding, a bushing in the bottom flange and in the

bonnet guide the valve plug. Maintenance procedures in this manual are valid for either single or double-port valves.

before proceeding.

www.Fisher.com

Page 6

HS Valve

June 2019

Table 1. Specifications

Instruction Manual

D100381X012

End Connection Styles

Buttwelding: Available in ASME B16.25 schedules that

are compatible with ASME B16.34

pressure/temperature ratings

Flanged: CL900 or CL1500 ring-type joint (RTJ) or

Flow Characteristics

Equal Percentage: V-Pup

Modified Parabolic: Throttle Plug

Quick Opening: Quick Opening Valve Plug

raised-face (RF) flanges per ASME B16.5

Pressure/Temperature Ratings

(1)

Consistent with CL900 or CL1500

pressure-temperature ratings per ASME B16.34

1. The pressure or temperature limits in this manual and any applicable standard or code limitations should not be exceeded.

Flow Direction

Single Port bodies are flow up

Double Port bodies (see figure 2)

Specifications

Typical specifications for HS control valves are shown in table 1.

Figure 2. Double-Port Fisher HS Valve with Top-and Bottom-Guided Throttle Plug Valve Plug

W0474‐1

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure may result if the valve assembly is installed

where service conditions could exceed the limits given in table 1 or on the appropriate nameplates. To avoid such injury or

damage, provide a relief valve for over‐pressure protection as required by government or accepted industry codes and

good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

2

Page 7

Instruction Manual

D100381X012

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

HS Valve

June 2019

Before installing the valve, inspect it for shipping damage and be certain the valve cavity and adjacent pipelines are

free of any foreign material that may damage the seating surfaces. If continuous operation is required during

maintenance, install a three-valve bypass around the valve.

HS valves may be installed in any position, but the standard position is with the valve in a horizontal run of pipe with

the actuator above the valve.

When installing the valve, use accepted piping and welding practices. For flanged valves, use a suitable flange gasket

between the valve and the pipeline flanges. Orient the valve so that flow will be in the direction indicated by the flow

arrow.

If the actuator was not attached to the valve before installation, or if valve plug travel has not been adjusted, refer to

the Mounting Actuator and Adjusting Travel section in this manual and the appropriate actuator instruction manual.

Maintenance

Valve parts, such as the packing, valve plug, seat ring, and guiding bushings, are subject to normal wear and must be

inspected and replaced as necessary. Inspection and maintenance frequency depends on the severity of service

conditions. This section includes instructions for disassembly necessary for inspection or replacement of parts. All

maintenance operations may be performed with the valve in the line.

WARNING

D Avoid personal injury or property damage from sudden release of process pressure. Before performing any

maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Packing Lubrication

If a lubricator or lubricator/isolating valve (figure 3) is provided for PTFE/composition or other packings that require

lubrication, it will be installed in place of the pipe plug. Use a good quality silicon-base lubricant. Packing used in

oxygen service or in processes with temperatures over 500°F (260°C) should not be lubricated. To operate the

3

Page 8

HS Valve

June 2019

Instruction Manual

D100381X012

lubricator, simply turn the cap screw clockwise to force the lubricant into the packing box. The lubricator/isolating

valve operates the same way except the isolating valve must first be opened and then closed after lubrication is

completed.

Figure 3. Lubricator and Lubricator/Isolating Valve

LUBRICATOR

10A9421-A

AJ5428-D

A0832-2/IL

LUBRICATOR/ISOLATING VALVE

Packing Maintenance

Note

If the valve has ENVIRO‐SEAL live‐loaded packing installed see the Fisher instruction manual entitled ENVIRO‐SEAL Packing System

for Sliding‐Stem Valves (D101642X012

If the valve has HIGH‐SEAL heavy‐duty live‐loaded packing installed, see Fisher instruction manual entitled HIGH‐SEAL Live‐Loaded

Packing System (D101453X012

Installation of graphite ribbon packing requires special care to avoid trapping air between the rings. Start with only one

ring at a time without forcing the top of the packing ring below the bottom of the entrance chamfer of the packing

box. Thus, when a ring is added, the stack should not be pushed into the cavity more than the thickness of the added

ring. Key numbers refer to figure 3 for PTFE V-ring packing and to figure 4 for PTFE/composition packing, unless

otherwise indicated.

For spring-loaded single PTFE V-ring packing, the spring maintains a sealing force on the packing. If leakage is noted

around the packing follower, check to be sure the shoulder on the packing follower is touching the bonnet. If the

shoulder is touching the bonnet, tighten the packing flange nuts until the shoulder is provided for PTFE/composition

or other packings that require lubrication, it will be installed in place of the pipe plug until the shoulder is against the

bonnet. If leakage cannot be stopped in this manner, proceed to the replacing packing procedure.

If there is undesirable packing leakage with other than spring-loaded packing, first try to limit the leakage and

establish a stem seal by tightening the packing flange nuts. If the packing is relatively new and tight on the stem, and if

tightening the packing flange nuts does not stop the leakage, it is possible that the valve stem is worn or nicked so that

a seal cannot be made. The surface finish of a new valve stem is critical for making a good packing seal. If the leakage

comes from the outside diameter of the packing, it is possible that the leakage is caused by nicks or scratches around

the packing box wall. If performing any of the following procedures, inspect the valve stem and packing box wall for

nicks and scratches.

) for packing instructions.

) for packing instructions.

4

Page 9

Instruction Manual

D100381X012

Figure 4. PTFE V-Ring Packing Arrangements for Standard and Radiation Bonnets

UPPER WIPER

(KEY 12)

PACKING FOLLOWER

(KEY 13)

WASHER

(KEY 10)

SPRING

(KEY 8)

FEMALE

ADAPATER

PACKING

RING

MALE

ADAPATER

PACKING SET

(KEY 6)

(2 REQ'D FOR

DOUBLE

ARRANGEMENT)

FEMALE

ADAPATER

PACKING

RING

MALE

ADAPATER

HS Valve

June 2019

UPPER WIPER

(KEY 12)

PACKING FOLLOWER

(KEY 13)

SPACER

(KEY 8)

PACKING BOX RING

(KEY 11)

FOR S31600 OR S17400 SST

METAL PACKING BOX PARTS

12A7637-A

B1429-4*/IL

ASSEMBLY 1

(POSITIVE

PRESSURES)

ASSEMBLY 2

(VACUUM)

3/8 INCH (9.5 MM) STEM

ASSEMBLY 3

(POSITIVE

PRESSURES

& VACUUM)

LOWER

WIPER

SINGLE ARRANGEMENTS

ASSEMBLY 1

(POSITIVE

PRESSURES)

ASSEMBLY 2

(VACUUM)

1/2 INCH (12.7 MM) STEM

ASSEMBLY 3

(POSITIVE

PRESSURES

& VACUUM)

ASSEMBLY 1

(POSITIVE

PRESSURES)

LOWER

WIPER

FOR ALL OTHER

METAL PACKING BOX PARTS

ASSEMBLY 2

(VACUUM)

ASSEMBLY 3

(POSITIVE

PRESSURES

& VACUUM)

3/4 OR 1-1/4 INCH

(19.1. 25.4, OR 31.8 MM) STEM

PACKING BOX RING

(KEY 11)

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER

(KEY 13)

MALE

ADAPATER

PACKING

RING

FEMALE

ADAPATER

LATNERN

RING (KEY 8)

PACKING

BOX RING

(KEY 11)

LOWER

WIPER

B1428-4*/IL

DOUBLE ARRANGEMENTS

5

Page 10

HS Valve

June 2019

Instruction Manual

D100381X012

Adding Packing Rings

This section covers adding packing rings to PTFE V-ring, PTFE/composition, and graphite/ribbon packing as used in

standard and radiation bonnets. PTFE V-ring packing is shown in figure 3, PTFE/composition packing is shown if figure

4, and graphite/ribbon packing is shown in figure 5. When using packing with a lantern ring (key 8, figure 3, 4, or 5), it

is possible to add packing rings above the lantern ring as a temporary measure without removing the actuator from

the valve.

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve, and drain the process

media from both sides of the valve. Use lock-out procedures to be sure that the above measures stay in effect while

you work on the equipment.

2. Remove the packing flange nuts and lift the packing flange and follower away from the valve.

3. Avoid scratching the valve stem or packing box wall as the old packing rings are removed from on top of the lantern

ring. Clean all metal parts to remove particles that would prevent the packing from sealing.

4.

Install packing rings.

If split-ring packing is being added, spread the rings over the stem and slide the rings into the packing box.

Alternate the positions of the splits to avoid creating a leak path.

If solid-ring packing is being added, remove the stem connector and slip the rings over the end of the valve stem.

5. Replace the packing flange and packing follower. Tighten the packing flange nuts only far enough to stop leakage

under operating conditions.

6. If the valve-actuator stem connection was taken apart, reconnect according to the appropriate actuator instruction

manual.

7. Check for leakage around the packing follower when the valve is being put into service. Retighten the packing

flange nuts as required.

Figure 5. Detail of PTFE/Composition Packing Arrangements for Standard and Radiation Bonnets

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER (KEY 13)

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX

RING (KEY 11)

3/8 INCH

(9.5 mm)

STEM

TYPICAL (DOUBLE) ARRANGEMENTS

6

1/2 INCH

(12.7 mm)

STEM

3/4, 1, OR

1‐1/4 INCH

(19.1, 25.4, OR

31.8 mm) STEM

Page 11

Instruction Manual

D100381X012

HS Valve

June 2019

Figure 6. Detail of Graphite Ribbon/Filament Packing for Standard and Radiation Bonnets

PACKING FOLLOWER

(KEY 13)

GRAPHITE RIBBON

PACKING RING

(KEY 7)

GRAPHITE FILAMENT

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

3/8 INCH

(9.5 mm) STEM

1/2 INCH

(12.7 mm) STEM

SINGLE ARRANGEMENTS

3/4, 1, OR 1‐1/4 INCH

(19.1, 25.4, OR 31.8 mm) STEM

PACKING FOLLOWER

(KEY 13)

GRAPHITE RIBBON

PACKING RING

(KEY 7)

GRAPHITE FILAMENT

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX RING

(KEY 11)

3/8 INCH

A5864/IL

NOTES:

1

0.004 INCH (0.102 mm) THICK SACRIFICIAL ZINC WASHERS; USE ONLY ONE BELOW EACH GRAPHITE RIBBON RING.

(9.5 mm) STEM

1/2 INCH

(12.7 mm) STEM

DOUBLE ARRANGEMENTS

3/4, 1, OR 1‐1/4 INCH

(19.1, 25.4, OR 31.8 mm) STEM

Replacing Packing

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, also shut-off all pressure lines to the power

actuator, release all pressure from the actuator. Use lock-out procedures to be sure that the above measures stay in

effect while you work on the equipment.

2. Disconnect the valve stem from the actuator by unscrewing the cap screws and removing the stem connector.

3. Unscrew the yoke locknut (valves with 3/8, 1/2, or 3/4-inch stems) or eight cap screws and nuts (valves with 1 or

1-1/2-inch stems). Remove the actuator from the valve.

4. To remove the bonnet (key 29), unscrew the bonnet nuts (steel valves); then proceed as follows:

a. For direct-acting valves, remove the bonnet, valve plug, and stem as a unit. Unscrew the packing flange nuts and

remove the packing flange, upper wiper (if one is used) and packing follower. Slide the valve plug and stem out

of the bonnet.

7

Page 12

HS Valve

June 2019

Instruction Manual

D100381X012

5. Carefully push out all the remaining packing parts from the valve side of the bonnet using a rounded rod or

other tool that will not scratch the packing box wall.

6. Clean the packing box and all metal packing box parts.

7. Install a new bonnet gasket on the valve. With the valve plug and stem in the valve, slide the bonnet over the stem

and onto the valve.

Note

The prelubricated stud bolt nuts referred to in step 8 can be identified by a black film coating on the nut threads. The accepted

bolting procedures in step 8 include—but are not limited to—ensuring that bolting threads are clean, and evenly tightening the cap

screws, or the nuts onto the studs, in a crisscross pattern. Repeat the crisscross tightening pattern several times until each cap

screw or nut is tight and the body-to-bonnet seal is made.

8. Lubricate the bonnet bolting with anti-seize lubricant (not necessary if factory prelubricated stud bolt nuts are

used) and install it, using accepted bolting procedures during tightening so that the body-to-bonnet joint will

withstand test pressures and application service conditions. The bolt torques in table 4 may be used as guidelines.

9. Using care to avoid damaging packing on the valve stem thread, install packing and associated parts in the

appropriate sequence. Replace the packing flange and packing flange nuts.

10. Tighten the packing flange nuts as follows:

a. For spring-loaded PTFE V-ring packing, tighten the packing flange nuts until the shoulder on the packing follower

contacts the bonnet.

b. For graphite packing, tighten the packing flange nuts to the maximum recommended torque shown in table

5. Then, loosen the packing flange nuts, and retighten them to the recommended minimum torque shown in

table 5.

c. For other packing types, tighten the packing flange nuts alternately in small equal increments until one of the

nuts reaches the minimum recommended torque shown in table 5. Then, tighten the remaining flange nuts until

the packing flange is level and at a 90-degree angle to the valve stem.

d. For ENVIRO-SEAL or HIGH-SEAL live-loaded packing, refer to the note at the beginning of the Maintenance

section.

11. Mount the actuator and adjust the stem connector per the Mounting Actuator and Adjusting Travel section and the

appropriate actuator instruction manual.

Table 4. Body‐to‐Bonnet Bolt Torque Guidelines

VALVE SIZE,

NPS

NSm LbfSft NSm LbfSft

1 400 90 400 90

1‐1/2 534 120 534 120

2 845 190 845 190

3 1223 275 1223 275

4 1223 275 1223 275

6 2335 525 2335 525

8 4159 935 4159 935

10 4159 935 4159 935

1. Contact your Emerson sales office for torques required for other bolting materials.

2. For bolting field-lubricated using anti-seize lubricant, contact your Emerson sales office for torques required with other lubricants.

(1)

SA‐193‐B7

SA‐193‐B16

BOLT TORQUES

Steel and Stainless Steel Valves with Studs and Nuts

(2)

Strain Hardened

SA‐193‐B8M

8

Page 13

Instruction Manual

D100381X012

Table 5. Recommended Torque for Packing Flange Nuts (Non Live‐loaded Graphite Packing)

STEM

DIAMETER

mm Inches Min Max Min Max

12.7 1/2 CL900 12 18 9 13

12.7 1/2 CL1500 15 22 11 16

19.1 3/4 CL900 27 41 20 30

19.1 3/4 CL1500 34 50 25 37

25.4 1 CL900 42 62 31 46

25.4 1 CL1500 52 77 38 57

31.8 1‐1/4 CL900 56 83 41 61

31.8 1‐1/4 CL1500 68 102 50 75

50.8 2

1. For intermediate class ratings, use the same torque as the next lower standard class.

VALVE BODY

(1)

RATING

CL1500 98 146 72 108

NSm lbfSft

TORQUE

Trim Maintenance

WARNING

HS Valve

June 2019

D Observe the warnings at the start of the Maintenance section.

Replacing Valve Plug, Seat Ring(s), and Guide Bushings

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, also shut-off all pressure lines to the power

actuator, release all pressure from the actuator. Use lock-out procedures to be sure that the above measures stay in

effect while you work on the equipment.

2. Disconnect the valve stem from the actuator by unscrewing the cap screws and removing the stem connector.

3. To remove the valve plug, use the appropriate procedure below:

For direct-acting valves:

a. Disconnect all pressure lines from the actuator. Unscrew the yoke locknut (valves with 3/8, 1/2, or 3/4-inch

stems) or eight cap screws and nuts (valves with 1 or 1-1/4 inch stems). Remove the actuator from the valve.

b. Unscrew the bonnet bolts bonnet nuts (steel valves). Remove the bonnet, valve plug , and stem as a unit.

c. Loosen the packing flange nuts and carefully slide the valve plug and stem out of the bonnet.

4. To replace the guide bushings, press them out of the bonnet and bottom flange. If the bushings cannot be removed

in this manner, machine out the old bushings. Press the new bushings into place. Spin or crimp the bushing

retaining lip into place per figure 7.

9

Page 14

HS Valve

June 2019

Figure 7. Bushing Placement

BONNET

OR

LOWER FLANGE

Instruction Manual

D100381X012

DETAIL A

BUSHING

GE99834

DETAIL A

5. Before removing the seat ring(s) check to see if the seat rings have been welded in place. If so, cut away the weld

before proceeding. Apply penetrating oil to the seat ring threads before attempting to remove the ring(s).

The following seat ring removal instructions are presented assuming a seat ring puller, as shown in figure 8, is being

used:

a. Place the proper size seat lug bar across the seat ring so that the bar contacts the seat lugs as shown in figure 8.

b. Insert a drive wrench and place enough spacer rings over the wrench so that the hold-down clamp will rest about

1/4 inch above the valve flange.

Figure 8. Seat Ring Puller

TURNING BAR

DRIVE WRENCH

HOLD DOWN CLAMP

SPACER RINGS

SEAT LUG BAR

AD5222-B

A1615/IL

Slip a hold-down clamp onto the drive wrench and secure the clamp to the valve with two cap screws (or two studs and

hex nuts) from the bonnet. Do not tighten the cap screws or nuts.

10

Page 15

Instruction Manual

D100381X012

HS Valve

June 2019

c. Use the turning bar to unscrew the seat ring. Stuck seat rings may require additional force on the turning bar.

Apply a steady force to the turning bar and hit the other end of the bar with a heavy hammer as hard as possible

to break the ring loose. In addition, a 24- or 36-inch pipe wrench can be used on the drive wrench near the hold

down clamp. Applying penetration oil to the seat ring before attempting to remove it will facilitate the

operation.

d. After the seat ring is loose, alternately unscrew the flange bolts (or hex nuts) on the hold-down clamp and

continue to unscrew the seat ring.

e. Before installing new ring(s), thoroughly clean the threads in the valve port(s). Apply pipe compound to the

threads of the new seat ring(s).

Note

On double-port valves, one of the seat rings is smaller than the other. On direct-acting valves (push-down-to-close action), install

the smaller ring in the valve body port farther from the bonnet before installing the larger ring.

Screw the seat ring(s) into the valve. Use the seat ring puller, to tighten the seat rings in the valve to the torque values

specified in table 6 and 7. Remove all excess pipe compound after tightening. The seat ring can be spot welded in

place to ensure that it does not loosen.

6. Reassemble the valve in the reverse order of the procedure used to disassemble. Use new bonnet and bottom

flange gaskets when reassembling.

7. Mount the actuator and adjust the stem connector per the Mounting Actuator and Adjusting Travel section and the

appropriate actuator instruction manual.

Table 6. HS Single Port Seat Ring Torque Values

VALVE SIZE, NPS TORQUE (ftSlbs)

1 145

1.5 230

2 270

3 470

4 745

6 2635

8 3345

Table 7. HS Double Port Seat Ring Torque Values

VALVE SIZE, NPS TOP SEAT RING TORQUE (ftSlbs) BOTTOM SEAT RING TORQUE (ftSlbs)

1.5 235 195

2 425 315

3 320 300

4 550 510

6 1845 1705

8 6190 4920

10 5800 4605

11

Page 16

HS Valve

June 2019

Instruction Manual

D100381X012

Lapping Metal Seats

A certain amount of leakage should be expected with metal-to-metal seating in any valve body. However, if the

leakage becomes excessive, the condition of the seating surfaces of the valve plug and seat ring(s) can be improved by

lapping. (Deep nicks should be machined out rather than ground out.) Use a good quality lapping compound of a

mixture of 280 to 600-grit. Apply the compound to the bottom of the valve plug.

To ensure correct alignment of the valve plug, bolt the bonnet in place during the lapping process. Removal of the

packing facilitates the lapping. A simple handle can be made from a piece of strap iron locked to the valve plug stem

with nuts. Rotate the handle alternately in each direction to lap the seats.

On double-port valves, the top ring normally grinds faster than the bottom ring. Under these conditions, continue to

use lapping compound on the bottom ring, but use only a polishing compound (rottenstone and oil) on the top ring. If

either of the ports continues to leak, use more lapping compound on the seat ring that is not leaking and polishing

compound on the other ring. This procedure grinds down the seat ring that is not leaking until both seats touch at the

same time. Never leave one seat ring dry while grinding the other.

After lapping, remove the bonnet, clean the seating surfaces, reassemble, and test the valve for shutoff. Repeat the

lapping procedure if leakage is still excessive.

Figure 9. Actuator Mounting (Type 657 Actuator Shown)

CAP SCREWS

STEM CONNECTOR

1

YOKE LOCKNUT

TRAVEL INDICATOR DISK

STEM LOCKNUTS

TRAVEL INDICATOR SCALE

NOTES:

1

YOKE LOCKNUT IS REPLACED BY EIGHT CAP SCREWS AND

NUTS ON 5-INCH YOKE BOSS (1 AND 1-1/4 INCH STEMS).

A1507/IL

12

Page 17

Instruction Manual

D100381X012

HS Valve

June 2019

Mounting Actuator and Adjusting Travel

Direct-Acting Valves

(Push-Down-to-Close)

1. If the actuator and valve have been separated, mount the actuator and secure with the yoke locknut (valves with

3/8, 1/2, or 3/4-inch stems) or eight cap screws and nuts (valves with 1 or 1-1/4 inch stems).

2. Move the valve plug to the closed position.

3. Screw two locknuts all the way onto the valve plug stem thread. Set the travel indicator disk on these nuts with the

concave side of the disk facing the valve. On some larger actuator sizes, a pointer attached to the stem connector is

used instead of the travel indicator disk.

WARNING

To avoid personal injury, keep hands and tools away from the actuator stem when pressuring the actuator.

4. If the actuator stem is not fully extended, pressure the actuator to move the stem to the fully extended position.

Retract the actuator stem approximately 1/8 inch by reducing actuator pressure. (This requires pressuring the

actuator for reverse-acting diaphragm actuators and piston actuators).

5. Clamp the actuator stem to the valve stem with the stem connector. Raise the indicator disk to the stem connector

and tighten in position with the stem locknuts.

6. Cycle the actuator to be sure that full travel is being obtained and that the valve plug seats before the travel stop (if

one is present) is contacted.

CAUTION

Do not use wrenches or other tools directly on the valve plug stem, or damage to the stem surface and subsequent damage

to the valve packing may result. Never rotate the valve plug stem while the valve plug is in contact with the valve seat ring,

or damage to the valve seating surfaces may result. Be certain the plug is off the seat before rotating the stem.

Minor travel adjustments can be made by loosening the stem connector slightly, tightening the locknuts together,

and screwing the stem into or out of the stem connector by using a wrench on the locknuts. If an increase in travel is

desired, the increase must be less than the 1/8 inch the actuator stem was retracted in step 4, or the valve will not shut

off.

7.

After adjustments are complete, tighten the stem connector securely, lock the travel indicator disk against the

connector with the locknuts, and adjust the travel indicator scale to show valve plug position.

8. Final adjustments to establish the starting point of valve travel (zero) and to obtain full travel for the given signal

range (span) can be made to the actuator spring or valve positioner. Refer to the appropriate actuator or valve

positioner instruction manual for instructions.

13

Page 18

HS Valve

June 2019

Instruction Manual

D100381X012

Parts Ordering

Each HS control valve is assigned a serial number, which can be found on the nameplate. Refer to the number when

contacting your Emerson sales office

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

for assistance or when ordering replacement parts.

14

Page 19

Instruction Manual

D100381X012

HS Valve

June 2019

15

Page 20

HS Valve

June 2019

Instruction Manual

D100381X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson

Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

16

E 1975, 2019 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...