Page 1

Instruction Manual

D101296X012

Fisher™ 1077 Manual Handwheel Actuator

1077 Actuator

June 2017

Contents

Introduction 1...................................

Scope of Manual 1.............................

Description 1.................................

Specifications 1...............................

Installation 3

Adjustment 8................................

Operation 9..................................

Maintenance 10

Lubrication 10................................

Disassembly 11...............................

Assembly 11..................................

Parts Ordering 13

Parts Reference 13...............................

....................................

.................................

................................

Figure 1. Fisher 1077 Handwheel Actuator

Mounted on a V150 Valve

W8176‐1

Introduction

Scope of Manual

This instruction manual includes installation, adjustment, operation, and maintenance information for the Fisher 1077

manual handwheel actuator. Instructions for the control valve is included in a separate manual.

Do not install, operate, or maintain a 1077 actuator without being fully trained and qualified in valve, actuator,

and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all the contents of this manual, including all safety

cautions and warnings. If you have any questions about these instructions, contact your Emerson sales office

Business Partner before proceeding.

or Local

Description

The 1077 manual‐only handwheel actuator (figure 1) is used with rotary‐shaft valves such as the Fisher 9500 butterfly

valve, 8532, 8560, and 8580 High Performance Butterfly valves, V150, V200 and V300 Vee‐Ball™ valves, V250 valves,

and CV500 and V500 valves.

In the 1077 actuator, torque is transmitted from the handwheel through the handwheel input shaft to a worm and

drive sleeve gear (sector) with splined bore. The worm and drive sleeve gear multiply the torque and transmit it to a

splined valve shaft or splined stub shaft. The size 10‐KE:6 actuator additionally has a spur gear reduction drive for

increased torque capability.

Specifications

1077 actuator specifications are given in table 1. Some specifications for a given actuator as it comes from the factory

are stamped on a metal nameplate attached to the actuator mounting yoke (key 7, figure 6).

www.Fisher.com

Page 2

1077 Actuator

June 2017

Table 1. Specifications

Instruction Manual

D101296X012

Actuator Sizes

See table 2

Acceptable Valve Shaft Diameters

See table 2

Output Torque

See table 2

Wheel‐Rim Force

See table 2

Handwheel Turns Required for Full Rotation

See table 2

Handwheel Rotation

Direct Acting Construction: Clockwise handwheel

rotation closes the valve (produces clockwise rotation

of valve shaft) as shown in figure 2

Educational Services

Reverse Acting Construction: Clockwise handwheel

rotation closes the valve (produces counterclockwise

rotation of valve shaft) as shown in figure 2

Maximum Output Rotation

0 to 90 degrees

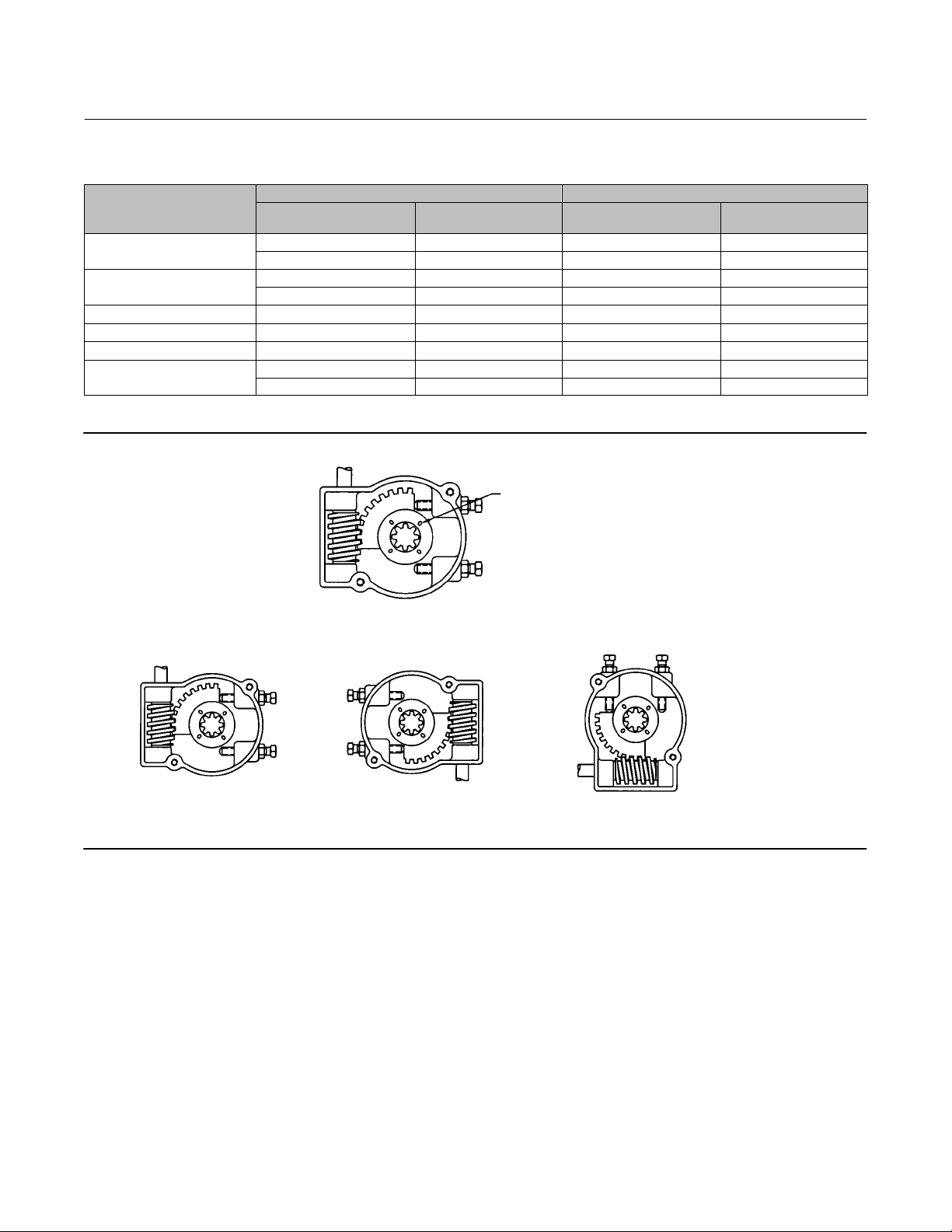

Mounting Positions

J Right‐hand (actuator on right side of valve body

when viewed from the body inlet) or

J Left‐hand (actuator on left side of valve body when

viewed from the body inlet). Position 1 as shown in

figure 3 is standard; however, the actuator may be

mounted in any of the positions shown in figure 3.

Refer to figure 2 to determine the correct actuator

construction

Approximate Weights

See table 3

For information on available courses for the Fisher 1077 Manual Handwheel Actuator, as well as a variety of other

products, contact:

Emerson Automation Solutions

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

emerson.com/fishervalvetraining

2

Page 3

Instruction Manual

D101296X012

1077 Actuator

June 2017

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

The 1077 actuator is normally shipped mounted on a control valve body. Follow the procedures in the control valve

body instruction manual for valve installation. Then proceed to the Operation section of this manual.

If the actuator has been shipped separately for installation on a valve body, or if the actuator was removed for

maintenance, mount the actuator by following the instructions presented in this section before installing the valve

body in the pipeline.

Individual part key numbers and part descriptions referenced in this procedure are shown in figure 6 except where

otherwise indicated.

CAUTION

Rotating the valve disk or ball in the wrong direction will damage seals and other internal parts in some valve bodies. If the

drive sleeve gear (key 1A) is not properly positioned, improper disk or ball rotation could result. If there is any doubt as to

whether or not the drive sleeve gear is properly positioned, remove the gearbox cover plate. Use the appropriate view in

figures 3, 4, and 5 to determine that the drive sleeve gear is at the proper end of its rotation.

1. Rotate the valve disk or ball to the closed position. Refer to the separate valve body instruction manual to

determine the closed position. Consult the appropriate valve instruction manual Installation section for valve shaft

orientation marks.

2. Rotate the handwheel (key 5) to move the drive sleeve gear to the position that is to correspond to the closed

position of the valve disk or ball as follows:

For direct acting turn the handwheel so the drive sleeve gear and travel indicator are rotated fully clockwise.

For reverse acting turn the handwheel so the drive sleeve gear and travel indicator are rotated fully counterclockwise.

3. Remove the travel indicator pointer by removing the machine screws. For a size 0‐KE actuator only, remove the

O‐ring seal from the hub of the drive sleeve gear. Locate the four index marks on the drive sleeve gear hub. Also

locate the index mark on the end of the valve shaft.

4. Refer to figures 3, 4, and 5 and locate the correct view for the valve body and mounting position being used. When

the actuator is installed, the valve shaft index mark must be aligned with the proper gear hub index mark.

3

Page 4

1077 Actuator

June 2017

Instruction Manual

D101296X012

Table 2. Actuator Size Selection

WHEEL‐RIM FORCE

To Produce Torque Lower

Than Maximum Allowable

Shaft Torque

ACTUATOR SIZE

ACCEPTABLE

VALVE

SHAFT DIAMETER

MAXIMUM

ALLOWABLE

(1)

TORQUE

HAND‐

WHEEL

DIAMETER

To Produce

Maximum

Allowable Torque

Metric Units

mm NSm mm N N

0‐KE

2‐KE

6‐KE

7‐KE

9‐KE

10‐KE:6

12.7

15.9

19.1

22.2 & 25.4

22.2 & 25.4 468 203 485

31.8

38.1

31.8

38.1

44.5

50.8

44.5

50.8

44.5

50.8

63.5 3390

63.5 6305 431 431

76.2 6780

88.9 6780

138

240

271

678

678

1110

1360

1360

1360

2260

2260

2260

2260

58

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

152

152

203

203

305

305

610

610

610

610

762

762

762

762

445

467

467

445

445

440

440

914 463

610 310

610 310

129

307

396

365

445

436

436

Torque Req'd

(NSm) 0.4572

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

Torque Req'd

(NSm) 0.6096

Torque Req'd

(NSm) 0.9652

Torque Req'd

(NSm) 1.4478

Torque Req'd

(NSm) 3.0480

Torque Req'd

(NSm) 5.1435

Torque Req'd

(NSm) 6.096

Torque Req'd

(NSm) 7.3152

Torque Req'd

(NSm) 15.476

Torque Req'd

(NSm) 21.848

Torque Req'd

(NSm) 21.848

U.S. Units

Inches Inch‐Pounds Inches Pounds Pounds

1/2

0‐KE

5/8

3/4

7/8 & 1

7/8 & 1 4140 8 109

2‐KE

6‐KE

7‐KE

9‐KE

1‐1/4

1‐1/2

1‐1/4

1‐1/2

1‐3/4

2

1‐3/4

2

1‐3/4

2

2‐1/2 30,000

2‐1/2 55,762 16 97

10‐KE:6

3 60,000

3‐1/2 60,000

1. Values shown are the maximum allowable torque of a splined valve shaft except where indicated. Without regard to the shaft, maximum allowable torque output is 271 NSm (2400 inch‐

pounds) for the size 0‐KE actuator, 678 N

size 7‐KE actuator, 3390 N

2. Limited to this value by the maximum allowable output torque of the actuator.

3. Wheel‐rim force required to produce maximum actuator output torque.

Sm (30,000 inch‐pounds) for the size 9‐KE actuator, and 6780 NSm (60,000 inch‐pounds) for the size 10‐KE:6 actuator.

Sm (6000 inch‐pounds) for the size 2‐KE actuator, 1360 NSm (12,000 inch‐pounds) for the size 6‐KE actuator, 2260 NSm (20,000 inch‐pounds) for the

515

1225

2120

2400

6000

6000

9820

12,000

12,000

12,000

20,000

20,000

23,524

23,524

6

6

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

8

8

12

12

24

24

24

24

30

30

30

30

36 104

24 69

24 69

100

105

105

100

100

99

99

29

69

89

82

100

98

98

Torque Req'd

(In.‐Lb.) 18.00

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

Torque Req'd

(In.‐Lb.) 24.00

Torque Req'd

(In.‐Lb.) 38.00

Torque Req'd

(In.‐Lb.) 57.00

Torque Req'd

(In.‐Lb.) 120.00

Torque Req'd

(In.‐Lb.) 202.50

Torque Req'd

(In.‐Lb.) 240.00

Torque Req'd

(In.‐Lb.) 288.00

Torque Req'd

(In.‐Lb.) 612.00

Torque Req'd

(In.‐Lb.) 864

Torque Req'd

(In.‐Lb.) 864

HANDWHEEL TURNS REQUIRED

FOR FULL VALVE DISK OR BALL

ROTATION

60‐Degree

Rotation

90‐Degree

Rotation

4 6

4 6

6‐1/2 9‐1/2

6‐1/2 9‐1/2

6‐1/2 10

9 13‐1/2

10‐1/2 16

10‐1/2 16

48 72

48 72

48 72

4 6

4 6

6‐1/2 9‐1/2

6‐1/2 9‐1/2

6‐1/2 10

9 13‐1/2

10‐1/2 16

10‐1/2 16

48 72

48 72

48 72

4

Page 5

Instruction Manual

D101296X012

VALVE SERIES OR DESIGN VALVE SERIES OR DESIGN

MOUNTING

Right‐Hand

Left‐Hand

Left‐Hand

(Optional)

1. A left hand ball will be required for the NPS 3 through 12 Series B and the NPS 14 to 20, with or without attenuator.

2. Counterclockwise

3. Clockwise

(1)

Figure 2. Direct and Reverse Acting Actuator Constructions

Ball/Plug

Rotation To

Close

(2)

CCW

CCW

CCW

CCW

(3)

CW

CW

V250 V150, V200 & V300

CV500

V500

REVERSE REVERSE REVERSE

NA

NA

NA

NA

REVERSE REVERSE

DIRECT

NA

NA

Disk/Ball

Rotation To

Close

CW

CW

CW

CW

NA

NA

1077 Actuator

June 2017

V250

NA

NA

DIRECT DIRECT

NA

NA

8532, 8560

8580, & 9500

DIRECT

NA

NA

40B1561-A

DIRECT ACTING CONSTRUCTION REVERSE ACTING CONSTRUCTION

5

Page 6

1077 Actuator

June 2017

Instruction Manual

D101296X012

Figure 3. Available Mounting Positions

POSITION 1

FLOW

DIRECTION FOR

RIGHT‐HAND

MOUNTING

POSITION 4

FLOW

DIRECTION FOR

RIGHT‐HAND

MOUNTING

POSITION 4

VALVE BODY

FLOW DIRECTION

FOR LEFT‐HAND

MOUNTING

POSITION 1

VALVE BODY

FLOW DIRECTION

FOR

LEFT‐HAND

MOUNTING

POSITION 3

DIRECT ACTING ACTUATOR CONSTRUCTION

30B0668‐A

B2002‐3

POSITION 3

REVERSE ACTING ACTUATOR CONSTRUCTION

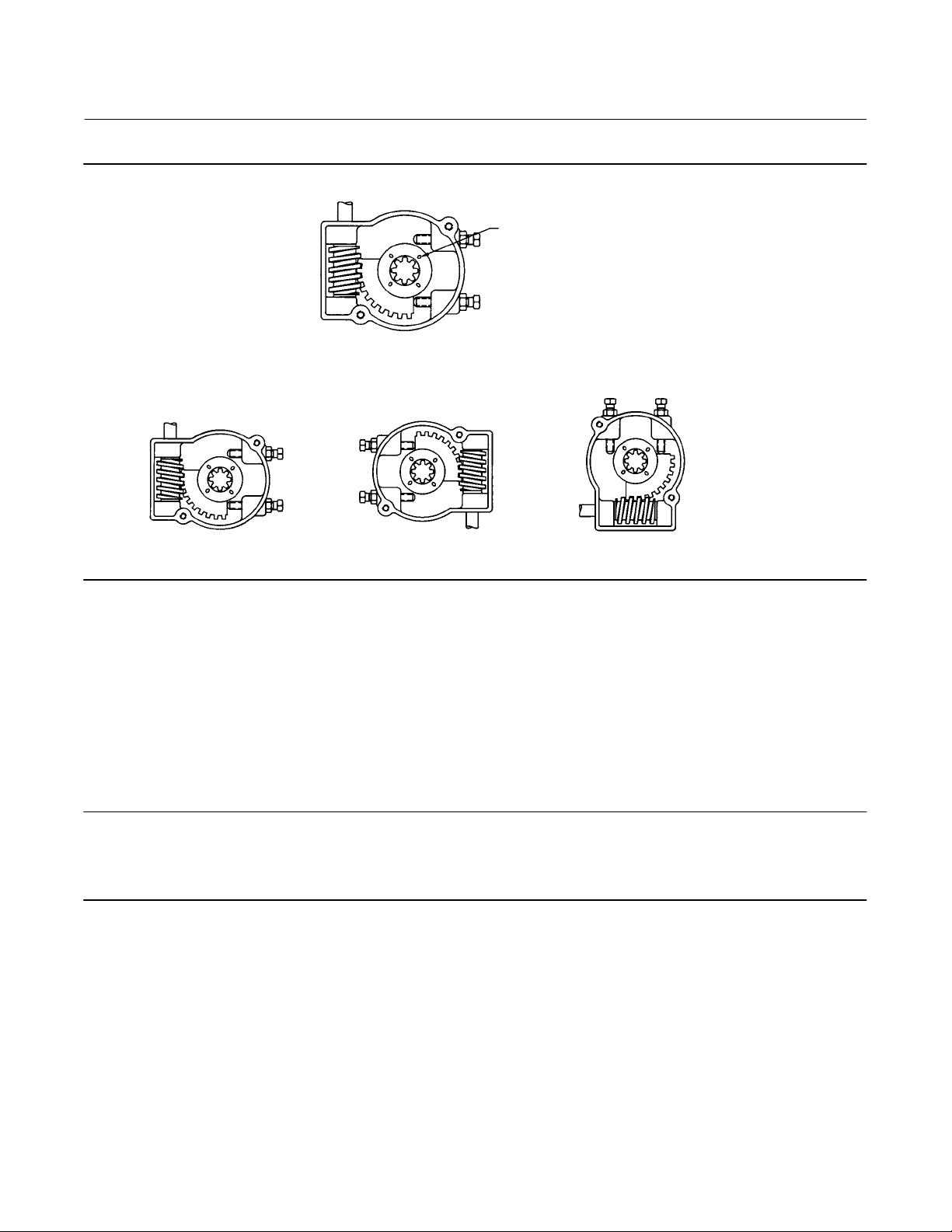

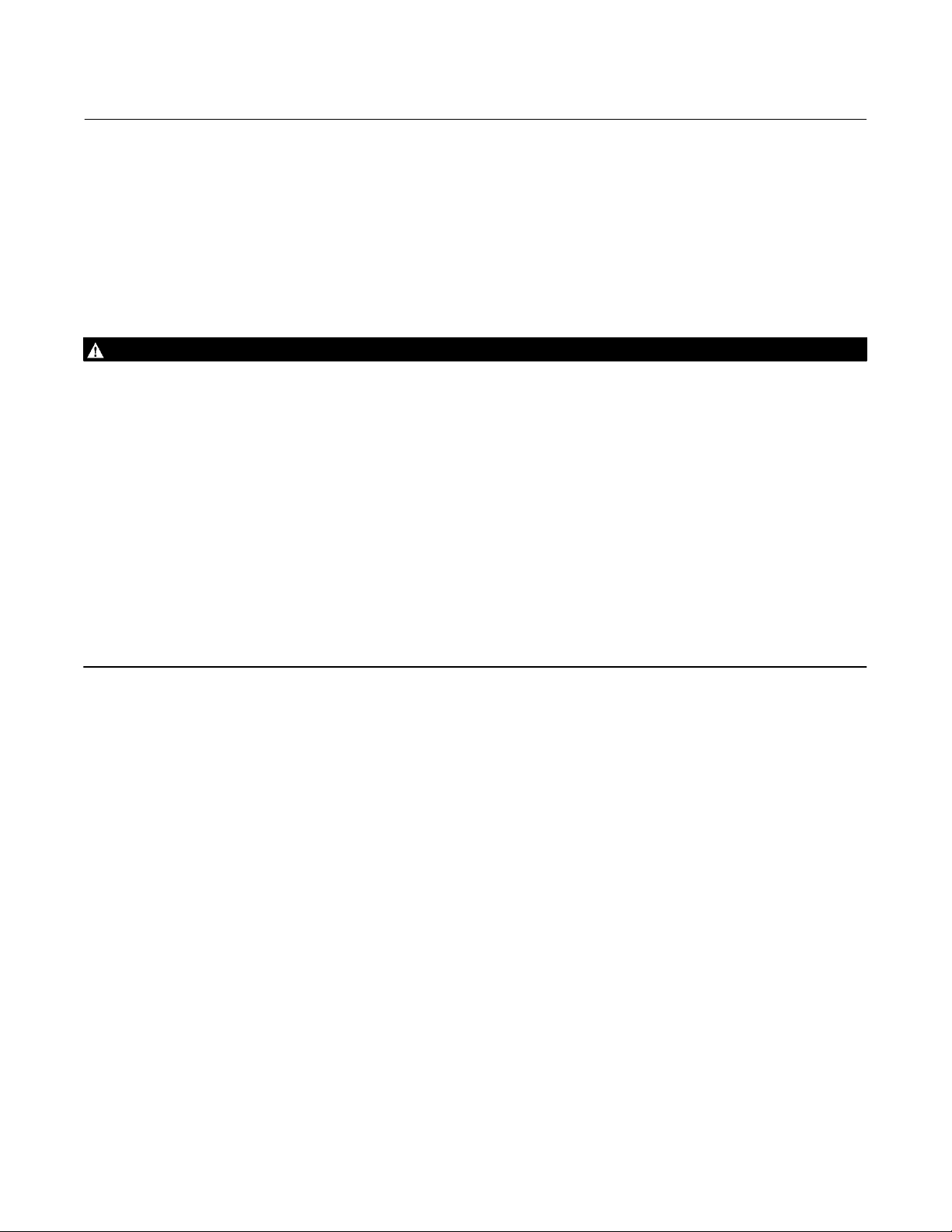

5. Making certain that index mark alignment is correct, slide the actuator onto the valve shaft in the desired mounting

position (figure 4 or 5). Check to be sure the valve shaft index mark is still aligned with the proper gear hub index

mark.

6. Check the alignment of the mounting holes in the mounting yoke (key 2) with those in the valve body. If the holes

are not aligned, rotate the handwheel to allow repositioning of the yoke. It may be necessary to loosen the hex nuts

and back out the travel stop set screws (key 10) to allow this repositioning.

7. When hole alignment is correct, secure the mounting yoke to the valve body with washers (key 4) and the valve

body cap screws (key 9).

8. If removed for inspection, install the gearbox cover plate. For a size 0‐KE actuator only, also install the O‐ring onto

the hub of the drive sleeve gear.

9. Making certain that the travel indicator pointer is aligned as it was prior to disassembly, install the travel indicator.

10. Before installing the valve body and actuator in the pipeline, perform the procedures presented in the Adjustment

section of this manual.

6

Page 7

Instruction Manual

D101296X012

Table 3. Approximate Weights

METRIC UNITS U.S. UNITS

ACTUATOR SIZE

0‐KE

2‐KE

6‐KE 610 20.2 24 43

7‐KE 762 28.2 30 60

9‐KE 914 40.9 36 87

10‐KE:6

Figure 4. Direct Acting Mounting Positions (Shown in the Closed Position)

Handwheel Diameter,

mm

152 3.7 6 8

203 4.7 8 10

203 10.3 8 22

305 11.3 12 24

432 62.6 16 133

610 62.6 24 133

Weight of Actuator

Assembly, Kg

DRIVE SLEEVE

GEAR INDEX

MARKS (4)

Handwheel Diameter,

Inches

1077 Actuator

June 2017

Weight of Actuator

Assembly, Pounds

E0718

MOUNTING

POSITION 1

PLATE AND TRAVEL POINTER REMOVED

GEARBOX WITH COVER

MOUNTING

POSITION 3

MOUNTING

POSITION 4

7

Page 8

1077 Actuator

June 2017

Figure 5. Reverse Acting Mounting Positions (shown in the closed position)

DRIVE SLEEVE

GEAR INDEX

MARKS (4)

Instruction Manual

D101296X012

GEARBOX WITH COVER

MOUNTING

POSITION 3

MOUNTING

POSITION 4

E0719

PLATE AND TRAVEL POINTER REMOVED

MOUNTING

POSITION 1

Adjustment

Perform the following steps to adjust the travel stops and the travel indicator pointer. Individual part key numbers and

part descriptions referenced in this procedure are shown in figure 6 except where otherwise indicated.

Travel stops (key 10) consist of two set screws and two hex nuts. For 90‐degree valve disk or ball rotation, both set

screws are of equal length. For 60‐degree disk or ball rotation, one set screw is longer than the other. To change from

90‐degree to 60‐degree disk or ball rotation, one set screw must be replaced with a longer one as explained below.

Note

Sizes 2‐KE, 7‐KE, 9‐KE & 10‐KE:6 use the same actuator for both 0‐60 degrees and 0‐90 degrees, with the replacement of the

appropriate set screw. Sizes 0‐KE & 6‐KE require a different actuator when changing from 90‐degree to 60‐degree disk or ball

rotation.

For Direct acting (except for 0‐KE & 6‐KE), replace the set screw that limits counterclockwise drive sleeve gear and

travel indicator rotation.

8

Page 9

Instruction Manual

D101296X012

1077 Actuator

June 2017

For Reverse acting (except for 0‐KE & 6‐KE), replace the set screw that limits clockwise drive sleeve gear and travel

indicator rotation.

Note

A 60‐degree set screw used as an opening stop can limit valve ball or disk opening to any angle between 60 and 90 degrees.

Alternately, it may be used as a closing stop to limit valve closing to any angle between 0 and 30 degrees. One or two 60‐degree

set screws may be used to extend the range of the valve opening stop, the valve closing stop, or both

1. If the valve body is in the line, remove it by following the instructions in the separate valve body instruction manual.

2. Loosen the hex nuts and back out both set screws.

3. Rotate the handwheel (key 5) to move the valve disk or ball to the fully closed position. Refer to the separate valve

body instruction manual for instructions to determine the fully closed position of the disk or ball.

4. With the valve disk or ball closed, rotate the set screw that is to limit valve closing until this set screw just hits the

drive sleeve gear. Lock the set screw with the hex nut.

5. Rotate the handwheel until the disk is at the desired maximum rotation as indicated by the pointer tip on the travel

indicator dial. Rotate the remaining travel stop set screw until it just hits the drive sleeve gear. Lock the set screw

with the hex nut.

6. Install the valve body and actuator in the pipeline by following the instructions in the separate valve body

instruction manual; then proceed to the Operation section.

Operation

Individual part key numbers and part descriptions referenced in this procedure are shown in figure 6 except where

otherwise indicated.

After the travel stops (key 10) and travel indicator pointer have been adjusted and the control valve assembly installed,

the actuator is ready for operation. The handwheel rotation direction required to open the valve is indicated on the

face of the handwheel (key 5).

CAUTION

To avoid damage to the actuator, the valve shaft splines, and internal valve parts, do not exceed the maximum allowable

torques listed in table 2 or any other torque limitation of internal valve parts. Also, do not use wrenches or other devices on

the handwheel or handwheel shaft to increase operating force.

If the force required to rotate the handwheel will exceed the wheel‐rim force listed in table 2, check for the following

conditions:

D Insufficient lubrication,

D Seized actuator parts,

D Excessive pressure drop across the valve body, or

D Obstruction to the valve body disk or ball rotation.

9

Page 10

1077 Actuator

June 2017

Instruction Manual

D101296X012

Instructions are given in the Maintenance section for lubrication of actuator parts. Refer to the separate valve body

instruction manual if valve body maintenance is required.

If the actuator does not seem to control the process fluid, worm or drive sleeve gear teeth may be broken, the pin

(key 6) may be sheared, or internal valve body parts may be broken. Refer to the separate valve body instruction

manual if valve body maintenance is required.

Maintenance

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Be sure the actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lockout procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Individual part key numbers and part descriptions referenced in the following procedures are shown in figure 6 except

where otherwise indicated.

Lubrication

The interior parts of a 1077 actuator should be lubricated on a regular schedule with a quality gear lubricant. The

interior parts should also be lubricated whenever difficulty in handwheel rotation indicates a need for lubrication.

To lubricate the 1077 actuator, perform the following steps:

1. Note the location of the travel indicator pointer in relation to the indicator dial. When reassembling the actuator,

the travel indicator pointer must be returned to its original position. Remove the machine screws and the travel

indicator pointer.

2. For a size 0‐KE actuator only, remove the O‐ring grease seal from the hub of the drive sleeve gear.

3. Remove the cap screws which secure the gearbox cover plate and remove the gearbox cover plate.

4. Coat the worm, the drive sleeve gear teeth, and the bearing surfaces of the gearbox housing and worm with a

quality gear lubricant.

5. Install the cover on the gearbox (key 1) and secure it with the cap screws.

6. For a size O‐KE only, install the the O‐ring grease seal onto the hub of the drive sleeve gear.

7. Attach the travel indicator pointer so that it indicates the same point of rotation as was noted before the pointer

was removed. Secure the pointer with the machine screws.

10

Page 11

Instruction Manual

D101296X012

1077 Actuator

June 2017

Disassembly

Parts are subject to normal wear and must be inspected periodically. The following procedure describes actuator

disassembly for general inspection and replacement of the drive sleeve gear.

Note

In order to remove the drive sleeve gear, it is necessary to first remove the actuator input shaft and worm.

1. Remove the pin (key 6) and the handwheel (key 5).

2. For a size 10‐KE:6 actuator only, remove the cap screws which secure the reduction drive (item not shown) and slide

the reduction drive off the input shaft.

3. Perform steps 1, 2, and 3 of the lubrication procedure above.

4. Remove the pin which secures the worm to the input shaft by following the appropriate procedure for the actuator

size:

For a size 0‐KE or 2‐KE actuator, drive the pin into the shaft (the pin length is less than the shaft diameter). Remove the

input shaft from the actuator housing and drive the pin out of the shaft.

For a size 6‐KE actuator, rotate the input shaft so that the pin may be driven through the soft plug (item not shown) on

the back side of the gearbox housing.

For a size 7‐KE, 9‐KE, or 10‐KE:6 actuator, there is sufficient clearance in the gearbox housing to drive the pin through

the shaft. Rotate the input shaft so that the pin will emerge on the drive sleeve gear side of the shaft and carefully drive

the pin out of the shaft.

5. Remove the input shaft and push the worm away from the drive sleeve gear.

6. Carefully noting the position of the index marks on the drive sleeve gear hub, remove the drive sleeve gear.

7. Remove the worm gear along with any shims or thrust bearings where used.

8. Inspect all parts for excessive wear.

Assembly

Note

Before or during assembly, coat the following surfaces with a quality gear lubricant: The teeth of the worm and the drive sleeve

gear; and the bearing surfaces of the gearbox housing, worm and input shaft

1. Install the worm and any shims and thrust bearings into the gearbox casing. Keep the worm at the maximum

possible distance from the installed position of the drive sleeve gear.

2. Install the drive sleeve gear onto the splined valve shaft. Be sure that the index marks are aligned as they were prior

to disassembly.

3. Noting the position of the pin holes and the original position of all shims and thrust bearings, install the actuator

input shaft into the bore of the worm.

4. Make sure that the pin holes are aligned and install the worm pin. Be certain that the pin does not protrude from

either side of the worm and interfere with the teeth on the drive sleeve gear.

11

Page 12

1077 Actuator

June 2017

Instruction Manual

D101296X012

For a size 6‐KE actuator only, install the soft plug on the back side of the gearbox (key 1) housing.

5. Install the gearbox cover plate.

6. For a size 0‐KE actuator only, install the O‐ring grease seal onto the hub of the drive sleeve gear.

7. Install the travel indicator making certain that the pointer indicates the same degree of rotation as was noted prior

to disassembly.

8. For a 10‐KE:6 actuator only, install the reduction drive onto the input shaft and secure with capscrews.

9. Install the handwheel (key 5) and pin (key 6).

10. If necessary, adjust the actuator by following the instructions given in the Adjustment procedure.

12

Page 13

Instruction Manual

D101296X012

1077 Actuator

June 2017

Parts Ordering

A serial number is assigned to each actuator and stamped on the nameplate (key 7, figure 6). Always refer to the

actuator serial number when corresponding with your Emerson sales office. When ordering replacement parts, also

specify the part name and desired material. If parts other than those listed in the parts list require replacement,

contact your Emerson sales office

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

or Local Business Partner for assistance.

Parts List

Note

Contact your Emerson sales office or Local Business Partner for Part

Ordering information.

Actuator Assembly

Key Description

1 Gearbox, cast iron

1A Drive Sleeve Gear

2 Mounting Yoke

3 Cap Screw, plated steel

4 Washer, plated steel

5 Handwheel

6 Pin, steel

7 Nameplate, stainless steel

8 Drive Screw, stainless steel (4 req'd)

9 Cap Screw (for use with 7600 or 9500 valve body)

10 Travel Stop Set Screw, steel

11 Connector, stainless steel

12 Pin, alloy steel

13 Stub shaft, S17400

13

Page 14

1077 Actuator

June 2017

Figure 6. Fisher 1077 Actuator Assembly for Splined Shaft

TRAVEL

INDICATOR

POINTER

Instruction Manual

D101296X012

O‐RING

WORM

39A8956‐B

B2001

WORM

PIN

COVER PLATE

14

Page 15

Instruction Manual

D101296X012

1077 Actuator

June 2017

15

Page 16

1077 Actuator

June 2017

Instruction Manual

D101296X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and Vee-Ball are marks owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson

Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

16

E 1986, 2017 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...