Fisher DVC6200 Digital Valve Controller on 585C and 471-16, Size 60-130 with 4 to 8 Inch Travel (Linear Roller Cam) Mounting Instructions

Page 1

Mounting Instructions

D103462X012

June 2010

DVC6200 Digital Valve Controller on

585C and 471-16, Size 60-130 with

4 to 8 Inch Travel (Linear Roller Cam)

Use these instructions to mount a Fisher® FIELDVUETM

DVC6200 digital valve controller on Fisher 585C and

471-16 Size 60-130 actuators, with 4 to 8 inch travel.

Avoid personal injury or property damage

from sudden release of process pressure

or bursting of parts. Before performing any

installation o

x Always wear protective clothing, gloves,

and eyewear.

x Do not remove the actuator from the

valve while the valve is still pressurized.

x Disconnect any operating lines

providing air pressure, electric power, or a

control signal to the actuator. Be sure the

actuator cannot suddenly open or close the

control valve.

x Use bypass valves or completely shut

off the process to isolate the control valve

from process pressure. Relieve process

pressure from both sides of the control

valve.

x Vent the pneumatic actuator loading

pressure and relieve any actuator spring

precompression.

x Use lock-out procedures to be sure that

the above measures stay in effect while you

work on the equipment.

x Check with your process or safety

engineer for any additional measures that

must be taken to protect against process

media.

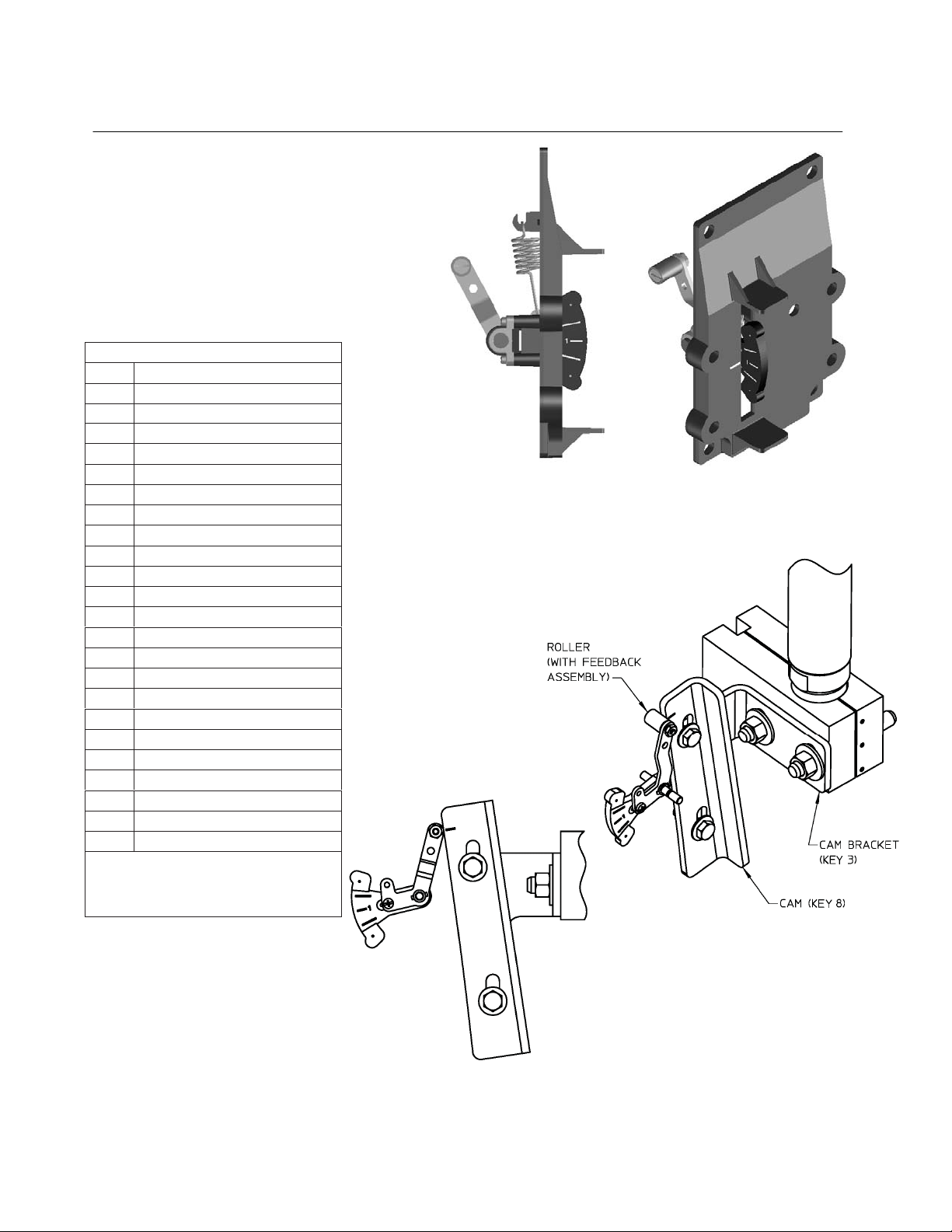

Refer to figure 3 and the parts list for mounting parts

identification. Refer to the DVC6200 digital valve

controller instruction manual for digital valve controller

parts identification. Refer to the appropriate actuator

instruction manual for actuator installation, operation,

maintenance, and parts identification. Figure 1 shows

the arced feedback assembly.

1. Isolate the control valve from the process line

pressure and release pressure from both sides of the

valve body. Shut off all pressure lines to the actuator,

releasing all pressure from actuator.

Use lock-out procedures to be sure that the above

measures stay in effect while you work on the equipment.

2. During the attachment of cam bracket (key 3) to the

valve stem connector it will be necessary to remove the

stem connector cap screws. Consult the appropriate

______________________________________________________________________________________________________

www.Fisher.com

perations:

actuator instruction manual for proper actuator

disassembly and reassembly.

3. Attach the cam bracket (key 3) to the stem connector

using two stud bolts (key 1), two plain washers (key 4)

and four hex nuts (key 6). If provided, use spacers (key

2) and/or two lock washers (key 5) to attach the cam

bracket to stem connector, as shown in figure 4.

4. Attach the cam (key 8) to the cam bracket using plain

washers (key 9), hex head screws (key 10), lock

washers (key 11) and hex nuts (key 12). If provided, use

spacers (key 7) in between cam and cam bracket, as

shown in figure 4. Ensure that the cam is oriented as per

the mounting assembly drawing.

5. Attach mounting plate(bracket) (key 13) to actuator

yoke top mounting face using two lock washers (key 14)

and hex head screws (key 15). If provided, use the

spacer (key 16) in between mounting plate and yoke

mounting face, as shown in figure 4. Similarly, attach the

mounting plate to bottom yoke mounting by using a

spacer (key 17), stud (key 18), plain washer (key 19),

lock washer (key 14) and hex nut (key 20).

6. Attach the digital valve controller to the arced

feedback assembly (key 21) using the four metric hex

socket cap screws (key 22).

7. Attach the arced feedback assembly along with the

digital valve controller to the mounting plate (bracket)

using the four imperial hex socket cap screws (key 23)

as shown in figure 3. Ensure that the roller of arced

feedback assembly is centered and resting on the cam

surface as shown in figure 2.

8. Ensure that the cam is positioned so that when the

actuator stem is fully extended the roller lines up with the

mark on the cam.

9. Make pneumatic and electrical connections to the

digital valve controller as described in the digital valve

controller instruction manual.

10. It may be necessary to fine tune the placement of the

cam so that the digital valve controllers receives the

proper feedback by lining up as shown in figure 2.

11. Setup and calibrate the digital valve controller as

described in instruction manual or quick start guide.

For additional information concerning mounting, setup,

calibration, and maintenance of the DVC6200 digital

valve controller, refer to the appropriate instruction

manual.

Page 2

DVC6200 Digital Valve Controller on

585C and 471-16, Size 60-130 with

4 to 8 Inch Travel (Linear Roller Cam)

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use or maintenance of any product.

Responsibility for the selection, use and

maintenance of any product remains with the

purchaser and end user.

PARTS LIST

KEY DESCRIPTION

1 STUD BOLTS

2 SPACER

3 CAM BRACKET

4 PLAIN WASHER

5 LOCK WASHER

6 HEX NUT

7 SPACER

8 CAM

9 PLAIN WASHER

10 HEX HD SCREWS

11 LOCK WASHER

12 HEX NUT

13 MOUNTING PLATE (BRACKET)

14 LOCK WASHER

15 HEX HD SCREWS

16 SPACER

17 SPACER

18 STUD, CONT THD

19 PLAIN WASHER

HEX NUT

20

21 ARCED FEEDBACK ASSEMBLY

22 SOCKET SCREWS (METRIC)1

23 SOCKET SCREWS (IMPERIAL)2

1. METRIC SOCKET SCREWS HAVE A SLIGHTLY

LARGER HEAD THAN THE IMPERIAL SOCKET SCREWS.

2. THE IMPERIAL SOCKET SCREWS CAN BE IDENTIFIED

BY THE COARSER THREADS.

GE42132

Figure 2. Installing Cam and Roller Feedback Assembly

Mounting Instructions

D103462X012

June 2010

Figure 1. Linear Roller Feedback

Page 3

DVC6200 Digital Valve Controller on

Mounting Instructions

D103462X012

June 2010

NOTE: REFER TO MOUNTING ASSEMBLY DRAWING FOR THE SIZE OF PARTS AND QUANTITY USED

Figure 3. Mounting Parts Identification(refer to the Parts List on page 2)

585C and 471-16, Size 60-130 with

4 to 8 Inch Travel (Linear Roller Cam)

Page 4

DVC6200 Digital Valve Controller on

)

(

_

585C and 471-16, Size 60-130 with

4 to 8 Inch Travel (Linear Roller Cam)

Mounting Instructions

D103462X012

June 2010

Figure 4. Mounting Parts Identification(with Spacer

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co.

Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the

property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All

sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or

specifications of such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated entities assume

responsibility for the selection, Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the

selection, use, or maintenance of any product, Responsibility for the selection, use, and maintenance of any product remains solely with the purchaser

and end user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

___________________________________________________________________________________________________

© Fisher Controls International LLC 2010; All Right Reserved

refer to the Parts List on page 2)

Loading...

Loading...