Page 1

Instruction Manual

D103678X012

Types BLE and BLX

July 2018

Types BLE and BLX Throttle Valves

SUMMARY

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or re

causing property damage and personal

injury or death.

Fisher™ throttle valve device must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations and

Emerson Process Management Regulator

Technologies, Inc. (Emerson) instructions.

If the throttle valve vents gas or a leak

develops in the system, service to the unit

may be required. Failure to correct trouble

could result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualied person must install or

service the device.

INTRODUCTION

Scope of the Manual

This manual provides installation, startup, maintenance and

parts ordering information for the Types BLE and BLX

throttle valves.

Figure 1. Type BLE-BLX Throttle Valve

The Type BLX is equipped with an integral slam-shut valve

Type OS2 used to cut off pressure ow in the case of

outlet overpressure.

The Type BLE version consists of:

• A body (Type E body) with removable orice, closed with

a cap also serving as a valve guide.

• A balanced valve plug, opened by uid ow,

linear characteristic.

• A valve plug/orice nitrile disc plug, removable and

tight shutoff.

• A valve plug guide with plastic rings and manual handwheel.

• The button serves as an opening indicator.

The Type BLX version, equipped with slam-shut Type OSE

with release relay Type OS2:

• A body (Type X body) including an inferior opening for

lodging the slam-shut.

The slam-shut includes:

• A valve plug/orice assembly with connecting part.

• A release relay Type OS2 including a mechanism box

(BM and a safety manometric box (BMS).

Product Description

The Type BLE throttle valve functions as a bypass on

transmission pressure reducing stations up to 100 bar.

The Types BLE and BLX are in conformity with the

Pressure Equipment Directive PED 2014/68/UE

and are classied in Category IV.

Page 2

PS

18.65 100 16 25 40

Security Class

Types BLE and BLX

CHARACTERISTICS

Table 1. Types BLE and BLX Trottle Valve Characteristics

OPERATING PRESSURE

Body PS 100 bar max

Associated BMS* according to size PSD 10 to 100 bar

Maximum inlet pressure Pumax 100 bar

Type DS Differential strength**

OPERATING TEMPERATURE TS -30 / +71 °C

Body Size DN 25, 50, 80, 100

THROTTLE VALVE

Inlet Pressure Pu 100 bar max

Maximum Differential ∆P max 100 bar

FLUID

Groups 1 and 2 according to PED 2014/68/EU, gas 1 sts and 2nd family according to EN437or other gases (compressed air, nitrogen).

The gas must be non corrosive, clean (ltration on inlet size necessary) and dry.

* BMS: Safety Manometric Box

** Differential strength (according to BMS choice)

SLAM SHUT (TYPE BLX ONLY)

European EN Standard EN 14382

Operation Class A or B (see Figure 2)

Response Time ta < 1 s

Diaphragm

Accuracy

Set Pressure Range Wdu - Wdo 0.010 / 100 bar

Rearming Manual after rectication of fault

Travel Indicator On mechanism box

Bellows

Piston 5

AG

Table 2. Flow Coefcients

DN 25 50 80 100

Qf 230 970 2150 3367

Cg 450 1880 4170 6500

C1 35

Materials

Body Steel

Bonnet Steel

Screw holder Bronze

Orice Stainless steel

Valve plug Steel

Disc plug Nitrile

Connections

Inlet / Outlet Class 600B (ANSI 600 RF)

Class 300B (ANSI 300 RF)

Class 150B (ANSI 150 RF)

Other connections available

(contact factory)

PN 16 B, 25 B, 40 B

2.5

B69a

B69b

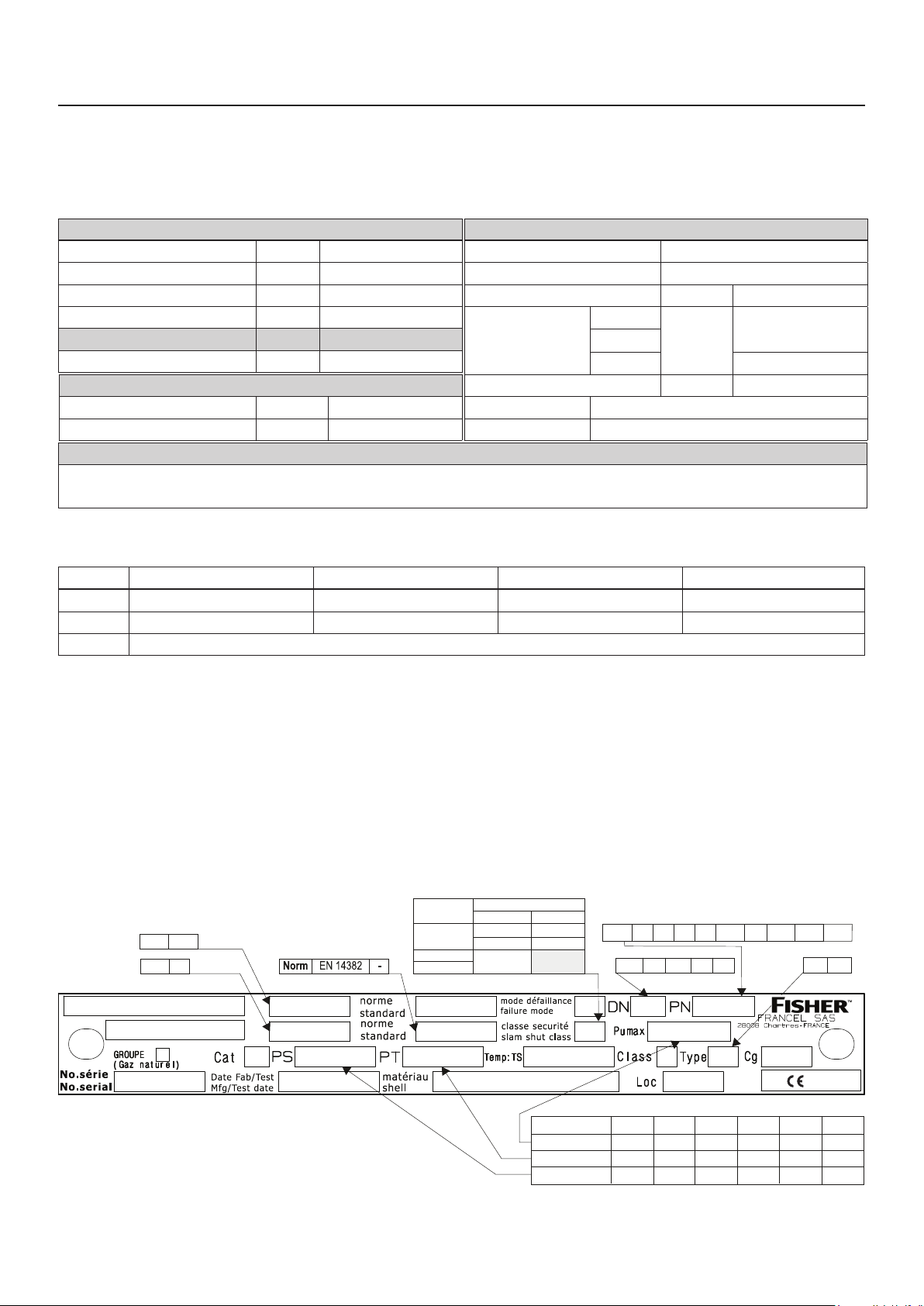

LABELLING

BLE

OS2

VANNE/VALVE

SECURITE/SLAM-SHUT

2

BMS setting

BLX

-

1

IV

DD MM YEAR

bar

Max only

Min only

Max-Min

- -

AB

BMS 027/017 BMS 162

BMS 236/315 BMS 071

All BMS

types

-30/+71 °C

A352LCC+A350LF2

Rating

16B

25B 40B

DN 25 50 80

150 150B 300 300B 600B

100

bar

-

600J

IS

0062

DS

150 300 600 16 25 40Rating

Pumax 18.650 100 16 25 40

PT

32 79 158 26 40 63

Figure 2. Label for Types BLE and BLX Trottle Valve

Page 3

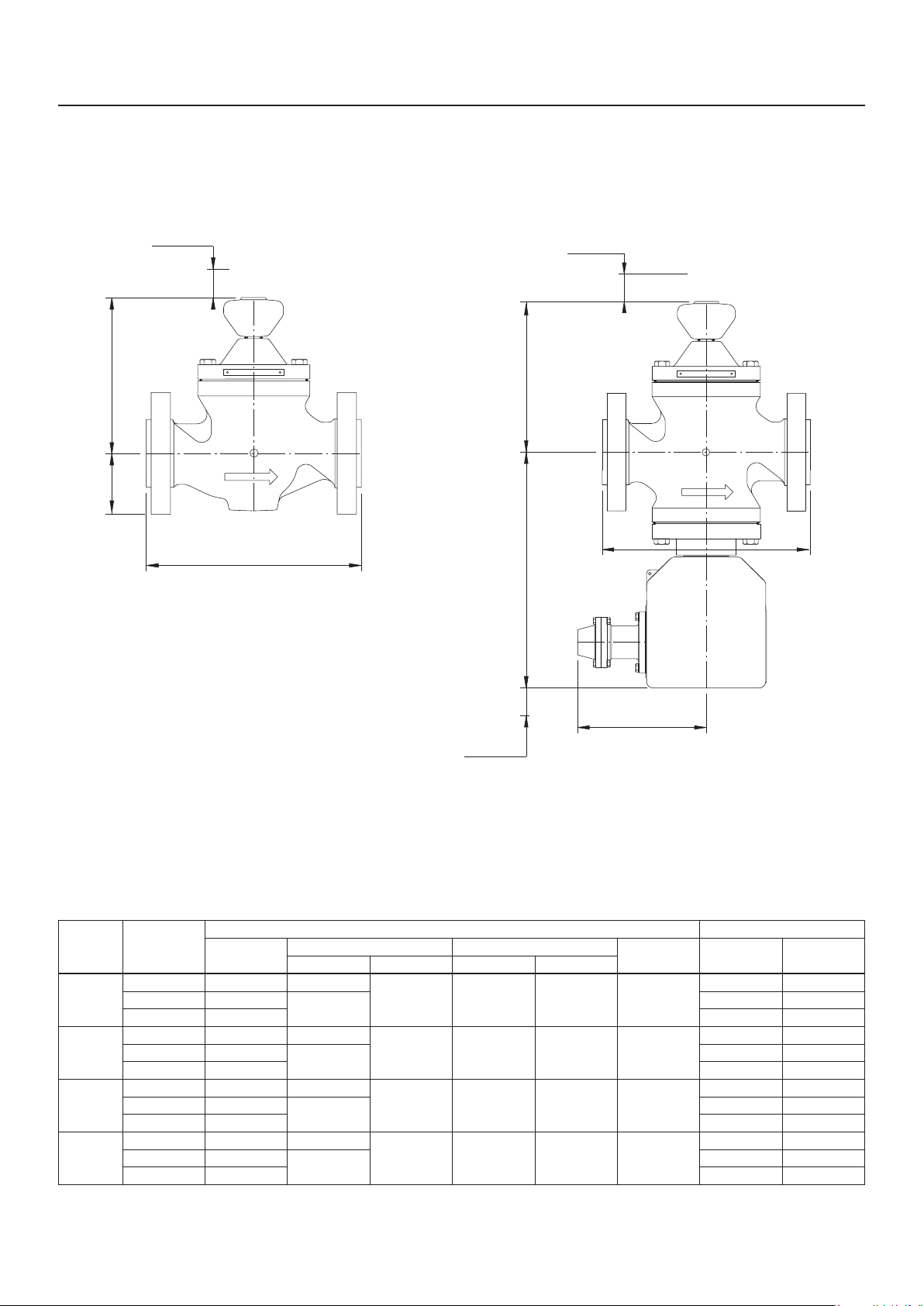

DIMENSIONS AND WEIGHTS

B

A

C

Removal

Types BLE and BLX

B73a

Removal

C

B

A

C

B

Removal

A

DN CLASS

150 185 54

25

50

80

100

300 197

600 210 14 22

150 254 76

300 267

600 287 26.5 40

150 298 95

300 318

600 337 51 65

150 352

300 368

600 394 96 131

220

Removal

Figure 3. Types BLE and BLX Trottle Valve Dimensions

Table 3. Types BLE and BLX Trottle Valve Dimensions and Weights

DIMENSIONS TYPES BLE (WITHOUT SLAM-SHUT) AND BLX (WITH SLAM-SHUT) WEIGHT (kg)

A

(nish B)

BLE BLX BLE BLX

B C

62

83

105

137

315 183 196 55

330 196 213 75

361 223 241 95

410 267 289 120

Removal BLE BLX

12 20

13 21

22.5 36

24.5 38

43 57

49 63

80 115

92 127

B73b

B74

3

Page 4

Types BLE and BLX

OPERATION

Type BLE or BLX

The Type BLE throttle valve is a balanced plug type, opened

by pressure ow.

The opening control is manually performed by a torque

handwheel (approx. 4 N

(see Table 4).

Tight shutoff is achieved by a nitrile disc plug situated on the

valve plug. The disc plug and orice are easily replaced.

The opening control is progressive to start and then linear.

In closed position, an O-ring situated below the handwheel

protects the control screw for exterior corrosion.

A rotation of 1/8 turn after contact with the valve plug / orice

is sufcient to assure tight shutoff.

Slam-Shut (Type BLX)

The pressure of the zone to be protected (in general the

pipeline, outlet side of the regulator and after the slam-shut)

reacts on the safety manometric box (BMS).

•m). 1 handwheel turn = 2 mm travel

If the pressure rises above the set range, the release relay

releases the valve plug.

Due to the action of the closing spring and the uid (trying to

close), the valve plug closes on the orice.

The gas ow is obstructed until the fault has been corrected

and the mechanism box manually rearmed.

Equal pressure balance on inlet and outlet sides are

necessary to reopen the valve plug.

The mechanism box is rearmed after opening the

internal bypass.

Rearming and balancing are achieved at the same time.

Table 4. Opening Control Measurements

DN NO. OF TURNS TRAVEL

25 4 8

50 7.5 15

80 11.5 23

100 15 30

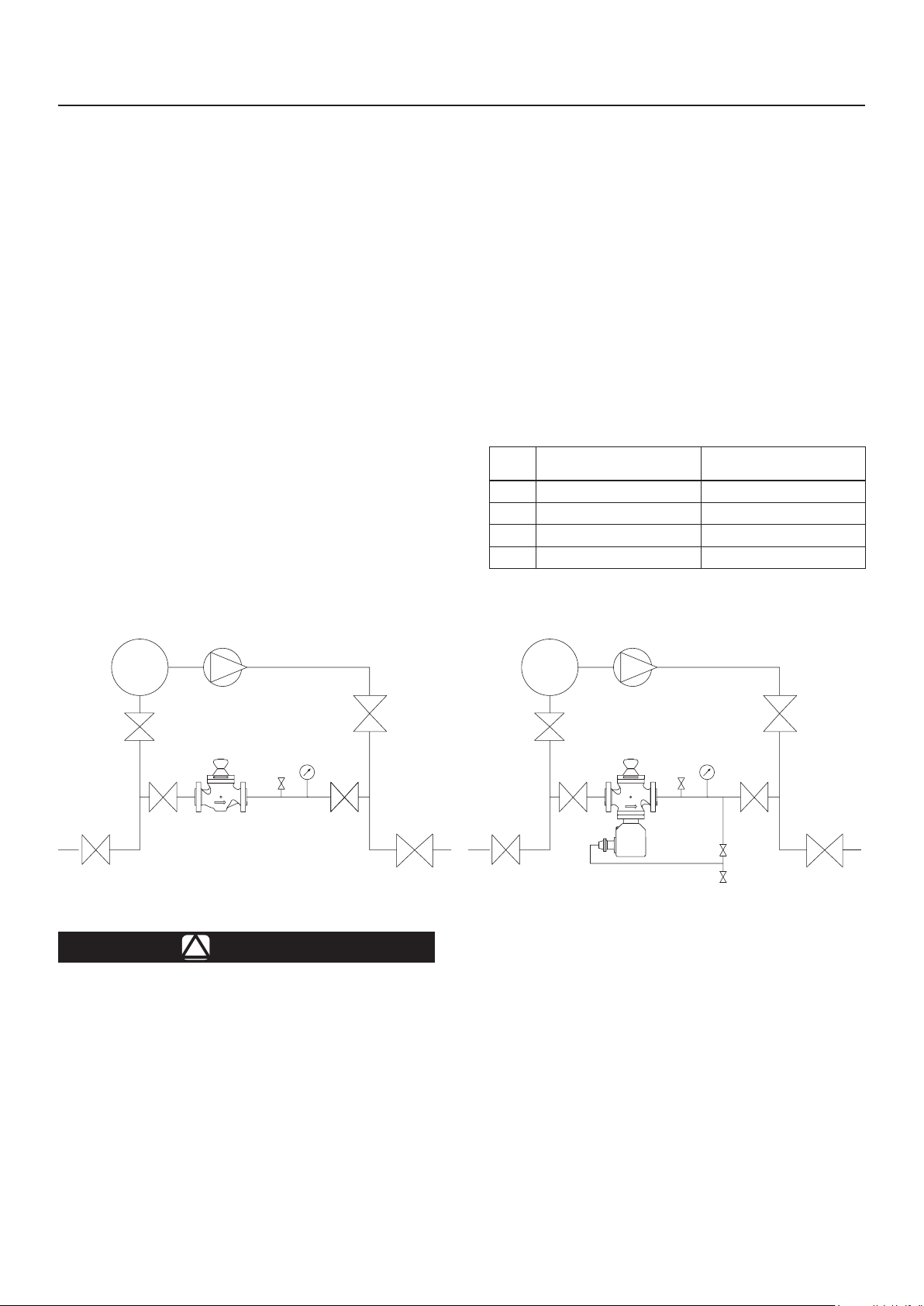

INSTALLATION

WARNING

!

Personal injury or equipment damage, due

to bursting of pressure-containing parts

may result if this device is overpressured or

is installed where service conditions could

exceed the limits given in the Specication

section and on the appropriate nameplate

or where conditions exceed any rating of

the adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions

from exceeding those limits. Also, be sure

the installation is in compliance with all

applicable codes and regulations.

Figure 4. Types BLE and BLX Installation

Additionally, physical damage to the device

can cause personal injury and property

damage due to bursting of pressurecontaining parts. To avoid such injury and

damage, a possible approach could be e.g.

install the device in a safe location.

Respect the direction of the uid ow and the

position of the valve (uid opening the throttle

valve plug).

All interventions on the equipment should

only be performed by qualied and

trained personnel.

Type BLE version, the valve is to be installed on

horizontal or vertical pipeline with the control

handwheel in a top, bottom or lateral position.

B75

4

Page 5

Types BLE and BLX

Type BLX version, the valve is to be installed

on a horizontal pipeline with the control

handwheel in a top or bottom position.

Install according to direction of uid ow

(arrow). Opened by uid ow.

When assembling with adjacent elements

care must be taken not to create pressure

force on the body and the assembling

elements (bolts, O-rings, anges) should be

compatible with the geometry and working

conditions of the equipment.

If the case arises a support must be used to

avoid pressure force on the body (a support

can be installed under the anges).

No modication should be made to the

structure of the equipment (drilling,

grinding, soldering...).

Verify that the inlet side is protected by an

appropriate device(s) to avoid exceeding the

limits of utilization (PS, TS).

Verify that the limits of utilization correspond

to the appropriate operating conditions.

Type BLX version, verify that the safety

manometric box (BMS) and spring correspond

to the appropriate operating conditions on the

outlet side of the throttle valve.

The equipment should not receive any type

of shock, especially the handwheel and

release relay.

Preliminary Verications

Start-up positions

• Inlet and outlet station valves

Open

• Expansion line(s)

Operating

Type BLE (without slam-shut)

• Type BLE inlet valve

Closed

• Type BLE throttle valve

Closed

Positions before commissioning

• Expansion line(s)

Isolated

• Type BLE inlet valve

Open

The equipment is ready for commissioning.

Commissioning

• Type BLE throttle valve

Open slowly observing the manometer outlet

side of the station.

Fire, seismic and lightning are not taken

into consideration in standard regulators.

If required, a special product selection and/

or specic calculations may be supplied

according to specic requirements.

The user should verify or carry out a

protection adapted to the environment.

COMMISSIONING

WARNING

!

All interventions on the equipment should

only be performed by qualied and

trained personnel.

Be sure to slowly introduce pressure into the

system to prevent downstream overpressure

due to potential rapid pressure increase.

Pressure gauges should always be used to

monitor downstream pressure during startup.

The equipment is commissioned.

Type BLX (with slam-shut)

• Type BLX inlet valve

Closed

• Type BLX throttle valve

Closed

• Type BLX slam-shut

Closed

• Impulse line isolation valve

Closed

• Impulse line atmospheric valve

Opened

5

Page 6

Types BLE and BLX

Slam-shut Setpoint Verication

1

3

TRAVEL

STOP

TRIGGERED

POSITION

Figure 5. Slam-Shut Positions

TRAVEL

STOP

STAGE 1 STAGES 2 AND 3

2

TRAVEL

STOP

Using the atmospheric valve, inject a pressure equal to the

pressure required for the regulator.

• 1st release relay stage (BM)

Set (Stage 1)

• Slam-shut valve plug

Open (Stages 2 and 3)

Progressively increase the pressure to reach tripping

Adjust the setting if necessary

(see D103683X012-OS2-IM manual)

Note the setpoint value on the equipment

or mark it on a commissioning document.

Positions Before Commissioning

• Expansion line(s)

Isolated

• Impulse line isolation valve

Open

• Impulse line atmospheric valve

Closed

• Valve plug

Closed

The equipment is ready for commissioning.

Commissioning

• Type BLX inlet valves

Open slowly

• 1st release relay stage

Set (Stage 1)

• Slam-shut internal bypass

Open slowly (Stage 2)

• Slam-shut valve plug

Open (Stage 3)

B76

• Outlet valve

Open slowly

• Type BLX throttle valve

Open slowly observing the manometer outlet side of

the station.

The equipment is commissioned.

It is recommended to seal the release relay.

MAINTENANCE

WARNING

!

To avoid personal injury or property damage

from sudden release of pressure, isolate the

throttle valve from the pressure system and

release all pressure from the main valve before

performing maintenance operations.

Servicing Check

Recommended frequency:

• Types BLE and BLX Once every 2 years for the throttle valve

• Type BLX Twice yearly minimum for the slam-shut

Verication:

• Types BLE and BLX Verication manual opening of the valve

Tight shutoff of the throttle valve plug

• Type BLX Triggering and setpoint verication

Valve plug tight shutoff

Departure positions

• Inlet valve

• Outlet valve

• Servicing valve

• Throttle valve (Types BLE, BLX)

• Slam-shut (Type BLX)

Tight shutoff verication of the throttle valve (Types BLE - BLX)

• Inlet valve

• Servicing valve

• Servicing valve

• Throttle valve

• Throttle valve Observe the evolution of outlet

pressure

Verication of tight shutoff and slam-shut triggering (Type BLX)

• Throttle valve

Open very slowly to slam-shut set

point without exceeding permitted limits

Closed

Closed

Closed

Closed

Open

Open

Open

Closed

Open very slowly and close

when outlet regulator pressure

is achieved

6

Page 7

Types BLE and BLX

Table 5. Troubleshooting for Type BLE Throttle Valve

SYMPTOMS CAUSE ACTIONS

If outlet pressure increases Leak in the throttle valve plug

If outlet pressure is constant Throttle valve plus is tight shutoff

Table 6. Troubleshooting for Type BLX Throttle Valve

SYMPTOMS CAUSE ACTIONS

If the slam-shut valve plug will not close Operation faulty

If the slam shut valve plug closes Operation correct

If the slam-shut valve plug outlet

pressure decreases

If the slam-shut valve plug outlet

pressure is constant

External leak

Purge the outlet side of the

throttle valve

Control the throttle valve plug

Control the throttle orice

or contact after-sales

Control the release relay

Control the slam-shut valve plug

or contact after-sales

Observe the evolution of the outlet pressure

(control tightness)

Locate and seal the leak

or contact after-sales

Observe the evolution of the outlet pressure

(control tightness)

Control the slam-shut valve plug

If the outlet pressure increases Internal leak

Control the orice

Control the internal bypass

or contact after-sales

If the outlet pressure is constant Valve plug is tight shutoff

Table 7. Torque Specications for Screw (key 1) Table 8. Torque Specications for Screws (keys 4 & 15)

(BONNET (KEY 2) CONNECTING PART (KEY 18))

TIGHTENING SCREW KEY 1

DN DIMENSIONS SPANNER (INCHES) TORQUE (N•m)

25 9/16 - 12 x 1 3/4 13/16” 11 0

50 1/2 - 13 x 1 1/2 3/4” 110

80 5/8 - 11 x 1 3/4 15/16” 175

100 3/4 - 10 x 3 1”1/8 200

KEY

4

15 M8 15

DIMENSIONS TORQUE (N•m)

M4 and M5 4

TIGHTENING

M6 6

Table 9. Torque Specications for Bypass (key 19)

TIGHTENING BYPASS (KEY 19)

DN TORQUE (N•m)

25

50

80 20

100 24

14

B78

7

Page 8

Types BLE and BLX

MAINTENANCE

Disassembly of the Throttle Valve

Recommended frequency:

Every 4 to 6 years (or less depending on operating conditions)

CAUTION

In the case of BMS 162 or 071, it is strongly

recommended to check the condition of the

diaphragm once a year.

Verication:

• Condition of O-rings, valve disc plug, lubrication

Replacement:

• O-rings, valve disc plug

Tools:

• 2 at spanners according to DN (see Table 7)

• Six-sided spanners numbers 3, 4, 5, 6, 13, 24

• Box spanner numbers 13, 19

• Remove valve plug (key 6)

• Remove the valve plug support (key 7) (wrench DN 25

and six-sided spanner for DN 50 and 80)

• Unscrew safety nut (key 8) while holding knob (key 9)

• Recover the lower stop part (key 10) (thick washer, cage,

thin washer) and fully unscrew the knob (key 9) to remove

the knob (key 9)/control stem (key 11) assembly

• Remove the valve plug plate (key 13)

• Recover the upper stop part (key 12) (thin washer, cage,

thick washer)

Type BLX (with slam-shut)

As well as above operations

• Unscrew impulse connector IS

• Remove cover (key 14) from BM

• Unscrew xing screws (key 15)

• Remove holding pin

• Remove BM

• Unscrew screw (key 1) from connecting part (key 16)

Precautions Before Disassembly

• Close inlet and outlets valves.

• Valve plug open

Open fully the valve plug by turning the

knob (key 9) until metal/metal contact is made

with the valve plug (key 13) on the bonnet (key 2)

• Bleed off outlet pressure

• Bleed off inlet pressure

Type BLE (without slam-shut)

• Unscrew screws (key 1) from bonnet (key 2)

• Remove bonnet/valve plug assembly

• Remove orice (key 3)

WARNING

!

With knob (key 9) in bottom position

(equipment turned upside down) the orice

(key 3) descends with the bonnet/valve

plug assembly and is just centered by the

columns on the edge of the orice (key 3).

• Remove connecting part (key 16)

• Remove spring (key 17) and valve plug (key 18)

• Unscrew bypass (key 19)

Removing the orice (not recommended) requires a special

extraction tool.

Reassembly

Type BLE (without slam-shut)

• Perform above operations in reverse order (respect

tightening torques)

• Replace O-rings at every disassembly

• Lubricate screws before tightening

• Lightly lubricate O-rings (silicone grease)

• Lubricate the stem (key 11) in the rim (key 20)

(molybdenum graphite grease)

• Precaution must be taken concerning the passage of the

valve plug over the segments

• Unscrew screws (key 4) from pad retainer (key 5)

(only one for DN 25)

8

Page 9

Types BLE and BLX

Type BLX (with slam-shut)

As well as above operations

• Lightly lubricate the O-rings (silicone grease) except for

the valve plug O-ring

• Precaution must be taken concerning the passage of the

valve plug over the segments

11

12

10

6

3

20 9 2

• Lightly lubricate the stem (silicone grease)

• Lubricate the release relay mechanism (yoke and bolt

(molybdenum graphite grease)

• Lubricate the BMS spring (molybdenum graphite grease)

A special tool is required for reassembling a new orice.

1

13

8

7

4

5

19

17

1

14

IS

Figure 6. Types BLE and BLX Maintenance Schematic

18

16

15

B77

9

Page 10

Types BLE and BLX

SPARE PARTS

Release relay Type OS2: see D103683X012-OS2-IM manual

Table 10. Types BLE and BLX Spare Parts

KEY DESCRIPTION QUANTITY

1 O-ring 1

2 O-ring 1 FA400298X12 FA400295X12 FA400297X12 M6020169X12

3 Guide ring 2 M0274090X12 M0272760X12 M0272810X12 ERAA20327A0

4 Anti-extrusion washer 2 M0194530X12 M0194690X12 M0192170X12 ERAA20324A0

5 O-ring 1 FA400524X12 FA400535X12 FA400543X12 ERAA20323A0

6 O-ring 1 FA400104X12 FA400098X12 FA400107X12 M6020171X22

7 O-ring 1 FA400105X12 FA400101X12 FA400108X12 -

8 O-ring 1 FA400106X12 FA400005X12 FA400109X12 ERAA10213A0

9 Valve plug 1 M0280900X12 M0280910X12 M0280920X12 M02990090X12

10 Bypass 1

11 Valve plug O-ring 1 FA400257T12 FA400263T12 FA400258T12 FA400260T12

12 Segment 2 FA401950T12 FA401951T12 FA401952T12 FA401953T12

Packing gland kit

Spare parts kit* FA197801X12 FA197802X12 FA197803X12 FA197987X12

* Including all commissioning spares and O-rings

-

DN 25 DN 50 DN 80 DN 100

BLE BLX BLE BLX BLE BLX BLE BLX

FA400513X12

FA180977T12

-

FA197395X12 FA197395X12 FA197395X12 FA197395X12

-

FA180977T12

-

FA180977T12

FA180977T12

-

B72

10

Page 11

Types BLE and BLX

1

2

3

4

5

6

7

8

9

10

11

12

2

BMS

BM

Type BLXType BLE

Figure 7. Types BLE and BLX Spare Parts

B71

11

Page 12

Types BLE and BLX

Webadmin.Regulators@emerson.com

Fisher.com

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

Asia Pacic

Singapore 128461, Singapore

T +65 6770 8337

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Francel SAS, 3 Avenue Victor Hugo,CS 80125, Chartres 28008, France

SIRET 552 068 637 00057 APE 2651B, N° TVA : FR84552068637, RCS Chartres B 552 068 637,

SAS capital 534 400 Euro

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D103678X012 © 2017, 2018 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 07/18.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for information purposes

only, and while effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available on request. We reserve the right to modify or improve the

designs or specications of our products at any time without notice.

Emerson Process Management Regulator Technologies, Inc does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...