Page 1

Instruction Manual

Form 5667

T ype A CE95 and T ype A CE95Sr

T ank Blanketing V alves

ACE95 Series

W8156

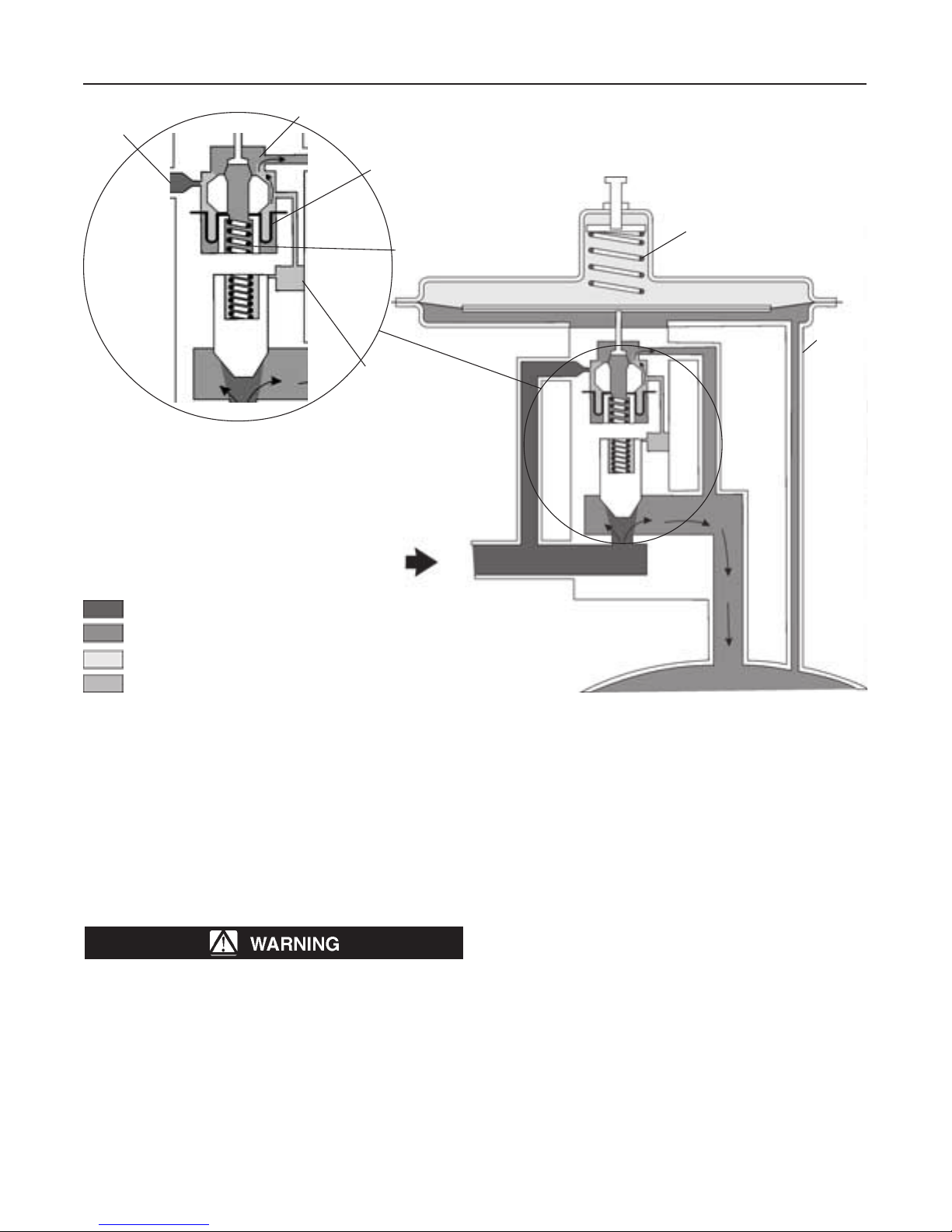

Figure 1. Type ACE95 T ank Blank eting V alve

Introduction

Scope of Manual

This instruction manual provides installation, startup,

and maintenance procedures for the ACE95 Series

(T ype A CE95 and Type ACE95Sr) tank b lanketing

valves. See figures 1 and 2.

Product Description

ACE95 Series tank blanketing valves are self-contained, balanced, pilot operated, and used for accurate

pressure control on gas blanketing systems. These

valves help control emissions and provide protection

against atmospheric contamination. ACE95 Series

Patent Numbers 5,884,655 and 5,836,348

W8155

Figure 2. T ype ACE95Sr T ank Blanketing Valv e

valves maintain a positive pressure and thereby reduce

the possibility of tank wall collapse during pump out

operations, in addition to preventing liquid from vaporizing into the atmosphere.

Specifications

The following page lists specifications and ratings for

ACE95 Series tank blanketing valv es . Factory specifications are stamped on a nameplate fastened to the

upper actuator case of the valve.

D102775X012

04/01

www.FISHERregulators.com

Page 2

ACE95 Series

Specifications

Size and End Connection Style

1-inch: NPT

1-inch: ANSI CL150 RF

1-inch: ANSI CL 150 RF, Weldneck

1-inch: NPT x 2-inch ANSI CL 150 RF

2-inch: NPT

2-inch: ANSI CL 150 RF

2-inch: ANSI CL 300 RF

2-inch: NPT x 3-inch Tank Flange

Maximum Operating Inlet Pressure

200 psig (13,8 bar)

Maximum Outlet (casing) Pressure

20 psig (1,4 bar)

Maximum Operating Outlet Pressure

1.5 psig (103 mbar)

Outlet Pressure Ranges

-5.0-inch w.c. to 1.5 psig

(-12 mbar to 103 mbar)

see table 1

Pressure Registration

External

Flow Coefficients for Relief Valve Sizing

(110% of rated Cv)

Type A CE95: Type A CE95Sr:

Cv 1 use Cv 1.1 Cv 20 use Cv 22

Cv 2 use Cv 2.2 Cv 45 use Cv 50

Cv 4 use Cv 4.4 Cv 60 use Cv 66

Cv 7.5 use Cv 8.25

Cv 10 use Cv 11

Temperature Capabilities

Nitrile (NBR):

–20° to 180°F (–7° to 82°C)

Flourelastomer:

0° to 212°F (–0° to 100°C)

EPDM (FDA):

–20° to 212°F (–7° to 100°C)

FFKM:

–20° to 212°F (–7° to 100°C)

Approximate W eight

With all accessories:

Type ACE95 - 40 lbs (18 kg)

Type ACE95Sr - 60 lbs (27 kg)

Main Valve Flow Characteristic

Linear

T able 1. Outlet (Control) Pressure Ranges

EGNAR

ERUSSERP)LORTNOC(TELTUO

)rabm2,1-ot21-(cwni-5.0-ot5-leetSsselniatS

)rabm2ot2-(cwni-1ot1-leetSsselniatS

)rabm21ot2,1(cwni-5ot5.0

)rabm52ot01(cwni-01ot4

)rabm63ot02(cwni-51ot8

)rabm301ot43(gisp5.1ot5.0

.ylbmessamgarhpaidehtrednudetacolsignirpsdnocesehT.1

LAIRETAMGNIRPS

leetSsselniatS

leetSsselniatS

leetSsselniatS

leetSsselniatS

Principle of Operation

ACE95 Series tank blanketing valves are pilot operated, activated by the diaphragm, and control the vapor

space pressure over a stored liquid. The unit is controlled by a ve ry large diaphragm actuator. The oversized actuator offers high sensitivity to changes in tank

,HTGNELEERFGNIRPS

)mm(SEHCNI

)58,96(57.2

)1(

)253,22(88.0

)58,96(57.2

)1(

))46,04(06.1

)58,96(57.2

)8,05(00.2

)8,05(00.2

)58,96(57.2

,RETEMAIDERIWGNIRPS

)mm(SEHCNI

)230,2(080.0

)1(

)951,2(580.0

)230,2(080.0

)1(

)156,1(560.0

)230,2(080.0

)548,2(211.0

)571,3(521.0

)517,5(522.0

pressure. When a stor age tank cools and tank vapors

condense, ACE95 Series valves replace the condensing vapors with an inert gas to prevent internal tank

pressure from decreasing. P ositive tank pressure

prevents outside air from contaminating the product and

reduces the possibility of atmospheric pressure collapsing the tank. As demand is satisfied, the valve closes.

2

Page 3

ORIFICE

E0623

PILOT V AL VE (OPEN)

ROLLING DIAPHRAGM

DIAGNOSTIC PORT

PILOT SPRING

ACE95 Series

RANGE SPRING

SENSING

LINE

INLET PRESSURE

TANK PRESSURE

INLET BLEED PRESSURE

ATMOSPHERIC PRESSURE

E0622

Figure 3. ACE95 Series Operational Schematic (valve open)

ACE95 Series valves respond to slight decreases in

internal tank pressure by opening and increasing the

flow rate of inert gas into the tank. When the tank’s

liquid level has been lowered to the desired point and

the vapor pressure set point is re-established, the valve

closes.

Installation and Startup

Personal injury , equipment damage, or

leakage due to escaping accumulated gas

or bursting of pressure-containing parts

may result if this gas blanketing system

is over pressured or installed where

service conditions could exceed the

limits given in the Specifications section

and on the appropriate nameplate, or

where conditions exceed any ratings of

the adjacent piping or piping connections.

T o av oid such injury or damage, pro vide

pressure-relieving or pressure-limiting

devices (as required by Title 49, Part 192,

of the U.S. Code of Federal Regulations,

by the National Fuel Gas Code Title 54 of

the National Fire Codes of the National

Fire Protection Agency , or by other

applicable codes) to prevent service

conditions from exceeding those limits.

Additionally , physical damage to the tank

blanketing system could result in personal injury and property damage due to

escaping accumulated gas. T o avoid such

injury and damage, install the tank

blanketing valve in a safe location.

3

Page 4

ACE95 Series

BLANKETING GAS

SUPPL Y LINE

LINE STRAINER

SHUT-OFF V AL VE

SENSING LINE

TANK VENT

BLANKETING

GAS TO T ANK

GAS

LIQUID

E0623

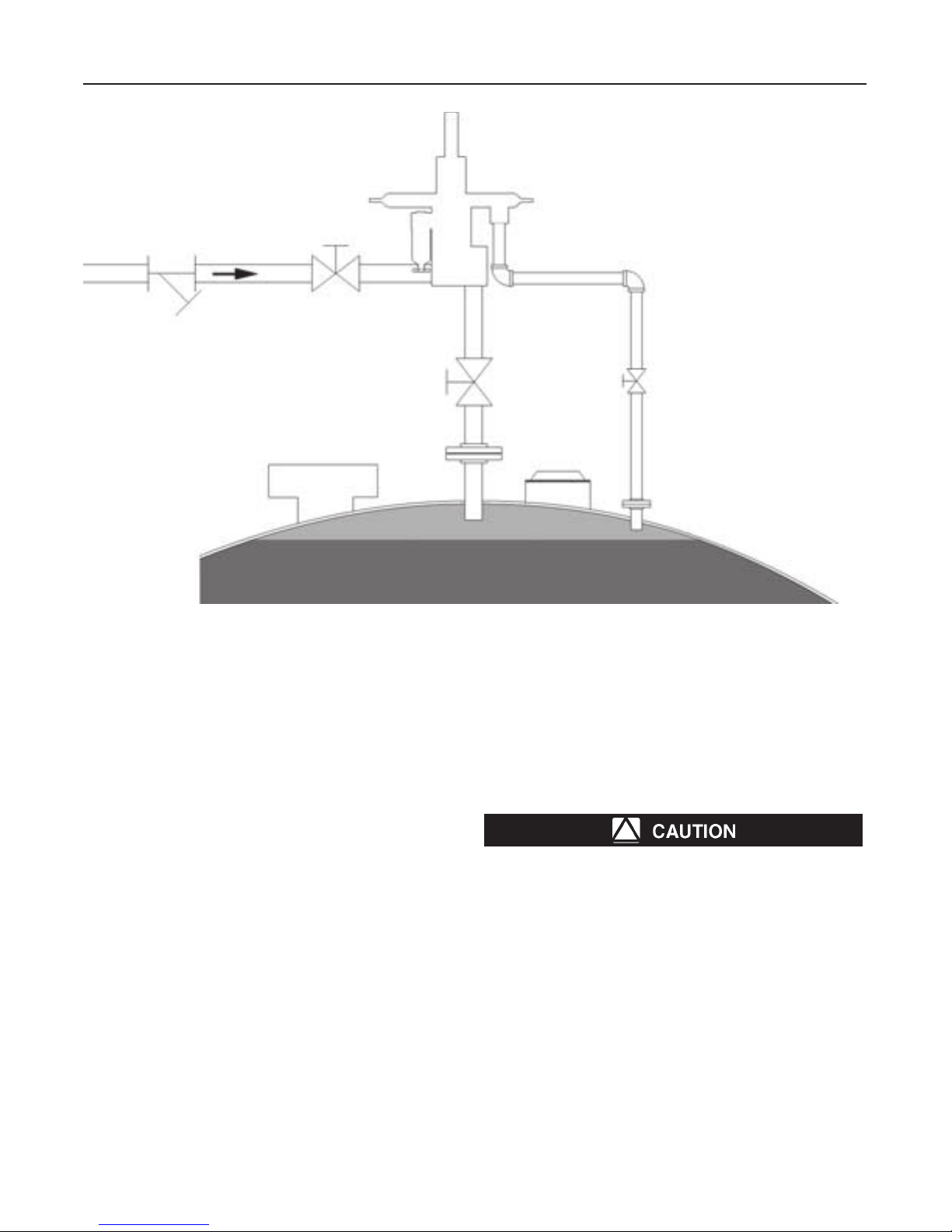

Figure 4. A CE95 Series Tank Blanketing V alve Installation

This ACE95 Series valve was assembled and preset to

the customer specified pressure and set point. The

outlet pressure range of the valve is stamped on the

nameplate fastened to the upper actuator case. The gas

blanketing set point is the only adjustable feature on

this unit.

1. Use qualified personnel when installing, operating,

and maintaining valves. Before installing, inspect the

valve and tubing for any shipment damage or foreign

material that may have collected. Make certain the

body interior is clean and the pipelines are free of

foreign material. Apply pipe compound only to the male

pipe threads with a screwed body, or use suitable line

gaskets and good bolting practices with a flanged body.

2. Inspect the nameplate on the upper actuator case.

It displays the model number , serial number , a b lanketing gas supply pressure range, and the maximum inlet

pressure and set pressure. These m ust agree with the

system that you are blank eting. The serial number will

be needed in any communication with your Fisher Sales

Representative or the Fisher Sales Office.

3. Clean the gas blanketing supply lines of all dirt and

foreign material before connecting them to the ACE95

Series tank blanketing valve.

SHUT-OFF V AL VE

EMERGENCY

TANK VENT

SHUT-OFF VA L VE

TANK

4. The valve must be mounted so the actuator case

is horizontal. The v alve should be mounted abo ve the

tank. Three connections are required: a) blanketing gas

supply to valve, b) valve outlet to tank, and c) sensing

line to tank.

Piping Considerations

Undersized piping may inadequately

deliver blanketing gas at the specified

inlet pressure under full flow conditions.

This may result in unacceptable performance under high demand conditions.

Unnecessarily long or restricted outlet

piping may result in poor set point

control.

Inlet Piping

The blanketing gas supply line should be equipped with

a Number 100 mesh strainer to remove dirt and pipe

scale. Inlet piping must be sized to adequately deliver

4

Page 5

ACE95 Series

blanketing gas at the specified inlet pressure under full

flow conditions.

Outlet Piping

Type ACE95 or Type ACE95Sr valve outlet is piped into

the tank vapor space. Outlet piping must be full size

and self-draining to the tank. The valve should be

situated above and as close as possible to the tank

vapor space for best performance.

Sensing Line

The sensing line should be 1/2-inch tubing or pipe,

must slope toward the tank, and should not contain low

points (or traps) that could catch liquid. The sensing line

must enter the tank above the liquid level at a point that

senses the vapor space pressure and is free from

turbulence associated with tank nozzles or vents.

Note

Best control is obtained when both

connections to the tank are separate. If

the tank has only one available nozzle,

contact Fisher Controls for alternate

methods of installation. A single array

manifold is available for such situations.

order could result in inlet pressure being

applied to the actuator casing, potentially damaging it.

Startup

1. Open shut-off valves between the blanketing valve

and the tank (both sensing and outlet). See figure 4.

2. Slowly open the supply line shut-off valve (to the

blanketing valve) and leave it fully open.

3. Monitor the tank vapor space pressure.

ADJUSTING SCREW

(KEY 2)

ACTUATOR CAP

(KEY 1)

VENT

(KEY 6)

LOCK NUT

(KEY 3)

Gauges and Shut-Off Valves

Inlet gas shut-off valves are desirable for servicing. If

this ACE95 Series tank blanketing valve was not

ordered with an inlet pressure gauge, it is advisable to

install a gauge between the inlet shut-off valve and the

blanketing valve.

Note

Safety considerations may dictate full

port shut-off valves between the tank and

blanketing valve, and at the valve inlet.

Startup, Adjustment, and Shutdown

Note

T ank vents and safety relief valves m ust

be in place and operating.

SPRING CASE

(KEY 7)

W8160

Figure 5. Spring Case, Adjusting Scre w, and Actuator Cap

Adjustment

The set point of this unit is factory set. If an adjustment

is to be made, it should be done so in small increments

while the unit is supplying gas to the tank. T o change

the set point:

1. Unscrew and remove the actuator cap (key 1) from

the top of the spring case (key 7). See figure 5.

2. Loosen the lock nut (key 3) and turn the adjusting

screw (ke y 2) clockwise to r aise the set point. (T urning

the screw counter-clockwise lowers the set point.)

3. Observe the effects of the change.

4. When the adjustment is complete, tighten the lock

nut (key 3) and replace the actuator cap (key 1).

Always open the outlet valve before the

inlet valve. Operation in the reverse

5

Page 6

ACE95 Series

Shutdown

Installation arrangements vary, but in any installation it

is important to open and close valves slowly and to

close the upstream shut-off valve first when shutting

down the system.

Diagnostics

Note

If a diagnostics pressure gauge was not

ordered with the unit, a pressure gauge

must be installed in the diagnostic port to

perform diagnostic analysis.

Diagnostics are an optional feature of the ACE95

Series Tank Blanketing v alves that aid in e v aluating

valve operation. The diagnostic analysis relies on the

relationship of pilot pressure and pressure in the main

valve chambers (see figure 3). The basic relationships

are as follows:

T able 2. Diagnostic Analysis Pressure Ranges

ERUSSERP(CITSONGAID

)REBMAHC

SUTATS

4. Determine the diagnostic pressure for the start to

open pressure of the main valve in the third column.

5. The fourth column displays the diagnostic pressure

for the full open pressure of the main valve.

There are four pressures involved in evaluating a valve:

actual inlet pressure, pressure to start opening pilot

valve , pressure to start opening main valv e, and

pressure to fully open main valve.

Actual Inlet Pressure: The gas pressure supplied to

the inlet of the valve. This is the maximum diagnostic

pressure.

Pressure to Start Opening Pilot V alve: The diagnostic

pressure drops to this value as the valve senses

decreasing tank pressure. The main v alve remains

closed at this pressure.

Pressure to Start Opening Main V alve: The diagnostic

pressure drops to this level as the tank pressure

decreases and reaches the valve set point. The pilot is

fully open at this pressure.

Pressure to Fully Open Main Valve: At this point, both

the main valve and pilot valve are fully open and

supplying gas to the tank.

erusserpylppustelniotlauqE

ylppustelniwolebylthgilS

erusserp

ylppustelniwoleblleW

erusserp

.erusserp

.desolcerasevlavniamdnatoliP

.erusserptesevobarotaknaT

.knatotsagseilppusevlavtoliP

teswolebtsujsierusserpknaT

htoberasevlavniamdnatoliP

knaT.knatehtotsaggniylppus

.tniopteswolebsierusserp

In order to evaluate a valve, examine the valve nameplate to determine the Cv and inlet pressure range main

valve spring. The inlet pressure gauge indicates actual

pressure supplied to the valve.

Follow these steps and refer to the diagnostics tables

on the following pages to evaluate a valve under actual

operating conditions:

1. Select the table (tables 3 through 8) that corresponds to the Cv and inlet pressure range of your

valve.

2. Determine the actual valve operating inlet pressure

in the first column of the diagnostics table.

3. In the second column of the table, determine the

pressure of the pilot as it opens.

Maintenance

V alve parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency of

inspection and replacement of parts depends on the

severity of service conditions and the requirements of

local, state, and federal regulations. Due to the care

Fisher Controls takes in meeting all manufacturing

requirements, use only replacement parts manufactured

or furnished by Fisher Controls.

All O-rings, gaskets, and seals should be lubricated

with a good grade of general purpose lubricant and

installed gently rather than forced into position. Approved lubricant, sealant, and adhesive are as follows:

#222

111

T ape

Lubricant: Dow Corning

Sealant: Loctite

PST #592, Teflon

Adhesive: Loctite

Be certain that nameplates are updated to accurately

indicate any field changes in equipment, materials,

service conditions, or pressure settings.

6

Page 7

ACE95 Series

T able 3. Type ACE95 Diagnostics Table: Cv 1 through 4, Inlet Pressure Range Spring 25 to 50 psig (1,7 to 3,5 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab7,1(52)rab6,1(42)rab6,0(9)rab1,0(2

)rab1,2(03)rab0,2(92)rab9,0(31)rab4,0(6

)rab4,2(53)rab3,2(43)rab1,1(61)rab6,0(9

)rab8,2(04)rab7,2(93)rab4,1(02)rab9,0(31

)rab1,3(54)rab0,3(44)rab7,1(42)rab2,1(71

)rab5,3(05)rab4,3(94)rab9,1(82)rab5,1(12

T able 4. Type ACE95 Diagnostics Table: Cv 1 through 4, Inlet Pressure Range Spring 51 to 120 psig (3,5 to 8,3 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab6,3(15)rab5,3(05)rab0,2(92)rab3,0(5

)rab1,4(06)rab0,4(95)rab5,2(63)rab8,0(21

)rab8,4(07)rab7,4(96)rab0,3(34)rab3,1(91

)rab5,5(08)rab4,5(97)rab6,3(15)rab9,1(72

)rab2,6(09)rab1,6(98)rab0,4(95)rab3,2(43

)rab9,6(001)rab8,6(99)rab6,4(66)rab9,2(24

)rab6,7(011)rab5,7(901)rab1,5(47)rab5,3(05

)rab3,8(021)rab2,8(911)rab6,5(18)rab9,3(75

Monthly Maintenance

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

supply pressure and that all pressure has

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

been released from the valve. (The drain

1. Visually inspect the unit to ensure tight connections, tight seals, and safe operation.

2. Observe the blanketing pressure.

3. Inspect the inlet pressure for the proper pressure

range (stamped on the valve nameplate).

on the inlet filter is convenient to bleed

off gas.) All tank connections must be

closed or sealed in accordance with your

plant’s operating and saf ety procedures. If

installed, electrical connections to the

explosion proof switch must be deactivated before opening the enclosure or

Annual Maintenance

disconnecting the wiring (in accordance

with codes and safety practices).

1. Visually inspect the unit to ensure tight connections, tight seals, and safe operation.

It is recommended that all seals and diaphragms be

replaced as a matter of good practice whenever a valve

2. Observe the blanketing pressure.

3. Inspect the inlet pressure for the proper pressure

range (stamped on the valve nameplate).

4. Visually inspect valve for any external wear.

is disassembled and re-assembled. Parts kits are

available through either your Fisher Sales Representative or the Fisher Sales Office.

If you are performing disassembly or assembly operations on a Type ACE95Sr valve, refer to the Parts List

5. If there is evidence of leakage or unstable internal

motion, a rebuild with seal replacement and

and see figure 8. If you are working on a T ype A CE95

valve , refer to the Parts List and see figure 9.

relubrication may be in order.

NEPOYLLUF

SIEVLAVNIAMNEHW)rab(GISP

SIEVLAVNIAMNEHW)rab(GISP

NEPOYLLUF

Disassembly and Assembly

Before removing the valve from the line,

ensure that it is isolated from the gas

Note

Have your model number , serial number ,

inlet pressure and set pressure range, Cv

value, and tank vent/relief setting available when ordering parts. V alve information is on the nameplate (on the upper

actuator case).

7

Page 8

ACE95 Series

T able 5. T ype A CE95 Diagnostics Table: Cv 1 through 4, Inlet Pressure Range Spring 121 to 200 psig (8,3 to 13,8 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab3,8(121)rab2,8(021)rab1,5(47)rab1,2(03

)rab0,9(031)rab9,8(921)rab6,5(18)rab6,2(73

)rab7,9(041)rab6,9(931)rab1,6(88)rab1,3(54

)rab3,01(051)rab2,01(941)rab6,6(69)rab7,3(35

)rab0,11(061)rab9,01(951)rab2,7(401)rab1,4(06

)rab7,11(071)rab6,11(961)rab7,7(111)rab7,4(86

)rab4,21(081)rab3,21(971)rab2,8(911)rab2,5(57

)rab1,31(091)rab0,31(981)rab8,8(721)rab7,5(38

)rab8,31(002)rab7,31(991)rab2,9(431)rab3,6(19

T able 6. Type ACE95 Diagnostics Table: Cv 5 through 10, Inlet Pressure Range Spring 25 to 50 psig (1,7 to 3,5 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab7,1(52)rab6,1(42)rab8,0(11)rab0,0(0

)rab1,2(03)rab0,2(92)rab0,1(41)rab2,0(3

)rab4,2(53)rab3,2(43)rab2,1(71)rab4,0(6

)rab8,2(04)rab7,2(93)rab5,1(12)rab6,0(9

)rab1,3(54)rab0,3(44)rab7,1(42)rab9,0(31

)rab5,3(05)rab4,3(94)rab9,1(72)rab1,1(61

Disassembly

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

2. Remove the upper and lower diaphragm plates

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

(keys 10 and 48) and the diaphragm (key 11). (The

actuator gasket (key 12) sits on top of the diaphragm.)

In cases where the pressure range is positive, the

T o av oid personal injury resulting from

sudden release of pressure, isolate the

valve from all pressure and cautiously

release trapped pressure from the pilot or

valve before attempting disassembl y .

upper diaphagm plate is larger than the lower diaphragm

plate.

3. Remove the internal bonnet screws (key 28) that

attach the lower actuator case (key 30) to the bonnet.

Remove the lower actuator case and the actuator

gasket (key 27).

Spring Case Disassembly

4. If you are performing disassembly operations on a

1. Remove the actuator cap (key 1) and the spring

load by unthreading the adjusting screw (key 2). See

figure 5.

2. Unthread the hex-head screws, lock washers, and

nuts (keys 32, 28, and 31) from the upper and lower

actuator cases (keys 33 and 30). Lift the upper actuator

case from the lower actuator case.

3. Remove the spring seat and range spring (keys 5

and 8).

Type ACE95Sr, remov e the cap scre ws (k ey 50) that

attach the bonnet (key 17) to the body (key 18).

5. Lift the bonnet (key 17) from the body (key 18).

Note

Slightly rotating the bonnet may help

loosen the O-ring (key 19).

Main Valve Disassembly

NEPOYLLUF

SIEVLAVNIAMNEHW)rab(GISP

SIEVLAVNIAMNEHW)rab(GISP

NEPOYLLUF

Actuator/Diaphragm Disassembly

1. Disassemble the diaphragm by unthreading the

diaphragm retaining nut (key 13) from the diaphragm

bolt (key 15).

8

1. Remove the main valve (key 25) along with the

main valve spring (key 26), spring shim (key 34, 25 to

50 psig, Type ACE95 only), and spring guide (key 49,

Type ACE95Sr only) from the bonnet (key 17).

2. Unthread the screw (key 20) from the main valve.

Page 9

ACE95 Series

T able 7. Type ACE95 Diagnostics Table: Cv 5 through 10, Inlet Pressure Range Spring 51 to 120 psig (3,5 to 8,3 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab5,3(15)rab5,3(05)rab7,1(42)rab2,0(3

)rab1,4(06)rab0,4(95)rab1,2(03)rab6,0(9

)rab8,4(07)rab7,4(96)rab5,2(63)rab0,1(51

)rab5,5(08)rab4,5(97)rab9,2(24)rab5,1(22

)rab2,6(09)rab1,6(98)rab4,3(94)rab9,1(82

)rab9,6(001)rab8,6(99)rab8,3(55)rab3,2(43

)rab6,7(011)rab5,7(901)rab2,4(16)rab8,2(14

)rab3,8(021)rab2,8(911)rab7,4(86)rab2,3(74

T able 8. T ype A CE95 Diagnostics T ab le: Cv 5 through 10, Inlet Pressure Range Spring 121 to 200 psig (8,3 to 13,8 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab3,8(121)rab2,8(021)rab3,4(36)rab2,2(13

)rab0,9(031)rab9,8(921)rab8,4(96)rab6,2(73

)rab7,9(041)rab6,9(931)rab2,5(57)rab0,3(34

)rab3,01(051)rab2,01(941)rab7,5(28)rab4,3(94

)rab0,11(061)rab9,01(951)rab1,6(88)rab9,3(65

)rab7,11(071)rab6,11(961)rab5,6(49)rab3,4(26

)rab4,21(081)rab3,21(971)rab0,7(101)rab7,4(86

)rab1,31(091)rab0,31(981)rab4,7(701)rab2,5(57

)rab8,31(002)rab7,31(991)rab8,7(311)rab6,5(18

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

NEPOYLLUF

SIEVLAVNIAMNEHW)rab(GISP

SIEVLAVNIAMNEHW)rab(GISP

NEPOYLLUF

3. Remove the plug (key 22) from the main valve (key

25). See figure 7.

4. Insert wooden dowel rod (or similar b lunt tool)

through the bottom of the bonnet bore to remove the

cage (keys 35 and 40) sub-assemb ly.

Pilot/Cage Disassembly

Do not wrench or bend the stem of the

poppet (key 42). Use soft-jawed pliers to

hold the piston without damaging it.

1. The upper cage (key 40) will readily separate from

the lower cage (key 35). See figure 6.

2. Gently press the poppet stem (key 42) to remove

the pilot from the upper cage (key 40).

3. Insert a small drill bit into the cross-drilled hole on

the poppet (key 42) to turn and loosen. Unthread the

poppet from the piston (key 37). Remove the rolling

diaphragm (key 38).

unusual wear, and lightly lubricate all O-rings and the

groove that locates the rolling diaphragm bead. See

figures 8 and 9.

Bonnet Sub-Assembly

Prepare the bonnet (key 17) by installing two (2) internal

O-rings (key 16).

Pilot/Cage Sub-Assembly

Refer to figures 6, 8, and 9 when performing pilot/cage

sub-assembly operations.

1. Apply Loctite

the rolling diaphragm (key 38) ov er the threaded portion

of the piston (key 37). Position the bead as shown in

figure 6.

2. Thread the poppet (key 42) onto the piston (key

37). Use soft-jawed pliers to restrain the piston so it is

not damaged. Do not hold the poppet by the poppet

stem. Insert a small drill bit into the cross-drilled hole

on the poppet stem (key 42) to turn and tighten.

3. Slide the O-ring (key 39) onto the poppet (key 42).

#222 to the piston threads. Place

Assembly

When assembling the Type ACE95 or T ype A CE95Sr

tank blanketing valve, clean all parts, inspect for

4. Place the pilot sub-assembly into the upper cage

(key 40).

9

Page 10

ACE95 Series

T ab le 9. Type ACE95Sr Diagnostics T able: Cv 20 through 60, Inlet Pressure Range Spring 25 to 50 psig (1,7 to 3,5 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab7,1(52)rab6,1(42)rab1,1(61)rab3,0(5

)rab1,2(03)rab0,2(92)rab4,1(02)rab6,0(9

)rab4,2(53)rab3,2(43)rab7,1(42)rab0,1(41

)rab8,2(04)rab7,2(93)rab0,2(92)rab2,1(81

)rab1,3(54)rab0,3(44)rab3,2(33)rab6,1(32

)rab5,3(05)rab4,3(94)rab6,2(83)rab9,1(72

T able 10. Type ACE95Sr Diagnostics Table: Cv 20 through 60, Inlet Pressure Range Spring 51 to 120 psig (3,5 to 8,3 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab5,3(15)rab4,3(05)rab7,2(93)rab8,0(11

)rab1,4(06)rab0,4(95)rab3,3(84)rab3,1(91

)rab8,4(07)rab7,4(96)rab9,3(75)rab9,1(82

)rab5,5(08)rab4,5(97)rab6,4(66)rab6,2(73

)rab2,6(09)rab1,6(98)rab2,5(57)rab2,3(64

)rab9,6(001)rab8,6(99)rab8,5(48)rab8,3(55

)rab6,7(011)rab5,7(901)rab4,6(39)rab4,4(46

)rab3,8(021)rab2,8(911)rab0,7(201)rab0,5(37

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

5. Press the lower cage (key 35) and upper cage (key

40) together to ensure the groove in the lower cage

engages the bead on the rolling diaphragm (key 38).

Use soft-jawed pliers to restrain the main

valve (key 25) while applying Loctite

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

Note

#222 to the threads of the screw (key 20).

Note

Ensure that the rolling diaphragm bead is

positioned so that it sits in the groove of

the lower cage (see figures 8 and 9). If it

does not, the rolling diaphragm was

installed upside-down in Cage Sub-

Main Valve Sub-Assembly

1. Prepare the main piston (key 25) by installing the

plug and O-ring (keys 22 and 23) with the screw (key

20) and lock washer (key 21). Apply Loctite

the screw threads.

Assembly step 2.

2. Install the main valve spring (key 26), spring shim

6. Remove the lower cage (key 35).

7. Lubricate the piston (key 37) and lower cage (key

35) groove.

8. Install the pilot spring (key 36) into the piston (key

37) and re-install the lower cage (key 35).

9. Hold the pilot sub-assembly together and insert it

into the bonnet (key 17). Press firmly (the bonnet Orings will offer resistance).

10. Press the poppet stem. It should freely move up

and down. If it does not, repeat the procedure to this

point to determine the cause.

(key 34, 25-50 psig, Type ACE95 only), and spring

guide valve (k ey 49, 25-50/51-120 psig, Type ACE95Sr

only) into the piston (key 25).

3. Place the main valve sub-assembly (piston, spring,

and plug (keys 25, 26, and 22)) into the body (key 18).

4. Place an O-ring (key 19) into the body (key 18).

Body Sub-Assembly

1. Place the bonnet (key 17) onto the body (key 18)

and main valve (key 25).

2. Press firmly to seat the bonnet O-ring joint. If you

are performing assembly operations for the ACE95Sr ,

attach the bonnet (key 17) to the body (key 18) with

four cap screws and lock washers (keys 50 and 51).

NEPOYLLUF

NEPOYLLUF

#222 to

SIEVLAVNIAMNEHW)rab(GISP

SIEVLAVNIAMNEHW)rab(GISP

10

Page 11

ACE95 Series

T able 11. Type ACE95Sr Diagnostics Table: Cv 20 through 60, Inlet Pressure Range Spring 121 to 200 psig (8,3 to 13,8 bar)

YLPPUSTELNILAUTCA

,EVLAVOTERUSSERP

)rab(GISP

)rab3,8(121)rab3,8(021)rab1,7(301)rab1,4(06

)rab0,9(031)rab9,8(921)rab7,7(111)rab7,4(86

)rab7,9(041)rab6,9(931)rab3,8(021)rab3,5(77

)rab3,01(051)rab3,01(941)rab9,8(921)rab0,6(68

)rab0,11(061)rab0,11(951)rab5,9(831)rab6,6(59

)rab7,11(071)rab7,11(961)rab1,01(741)rab2,7(401

)rab4,21(081)rab3,21(971)rab8,01(651)rab8,7(311

)rab0,31(091)rab0,31(981)rab4,11(561)rab4,8(221

)rab8,31(002)rab7,31(991)rab0,21(471)rab2,9(431

TOLIPNEHW)rab(GISP

NEPOOTSTRATS

3. Place the actuator gasket (key 27) and the lower

actuator case (key 30) onto the bonnet (key 17).

4. Install lock washers (key 28), sealing bushings

(key 46, Type ACE95 only), and hex-head screws (ke y

29).

5. Tighten all hex-head screws (key 29) uniformly.

Diaphragm Sub-Assembly

1. Place an O-ring (key 14) into the groove of the

diaphragm bolt (key 15).

2. Build the diaphragm sub-assembly with the lower

diaphragm plate (key 48), diaphragm (key 11), and

upper diaphragm plate (key 10). F asten the plates

together with the diaphragm bolt (key 15) and the

diaphragm retaining nut (key 13). The diaphragm

retaining nut sits on the upper diaphragm plate. Apply

Loctite

#222 to the diaphragm bolt.

Note

POPPET (STEM)

W8162

UPPER CAGE

(KEY 40)

ERUSSERPTROPCITSONGAID

EVLAVNIAMNEHW)rab(GISP

NEPOOTSTRATS

ROLLING DIAPHRAGM

(KEY 38)

(KEY 42)

CROSS-DRILLED HOLE

O-RING

(KEY 39)

W8161

Figure 6. Cage Sub-Assembly

PISTON

(KEY 37)

NEPOYLLUF

LOWER CAGE

(KEY 35)

SIEVLAVNIAMNEHW)rab(GISP

Tw o different diaphragm plates are used

when the pressure range is positive. In

cases where the pressure range is positive, the upper diaphagm plate (key 10) is

larger than the lower diaphragm plate

(key 48).

3. If you are using a negative spring range, install the

lower range spring (key 162) into the lower actuator

case (key 30).

4. Place the diaphragm sub-assembly into the lower

actuator case (key 30) with the diaphragm retaining nut

(key 13) on top. Place the actuator gasket (key 12) on

top of the diaphragm (key 11) and align the holes with

those on the lower actuator case (key 30).

5. If it was removed, place the spring case gasket

(key 9) between the spring case (key 7) and upper

actuator case (key 33) before attaching the spring case

to the upper actuator case. Attach the spring case to

the upper actuator case with hex-head screws (key 29).

6. Place the range spring (key 8) and spring seat (key

5) onto the diaphragm sub-assembly over the diaphragm retaining nut (key 13).

7. Place the upper actuator case (key 33) over the

range spring (key 8), spring seat (key 5), and the lower

actuator case (key 30).

8. Build the actuator case by installing hex-head

screws, lock washers, and nuts (keys 32, 28, and 31)

into the upper and lower acutator cases (keys 33 and

30). Use a washer (key 47) on steel cases.

9. Thread the range spring adjusting screw (key 2) in

about halfway.

11

Page 12

ACE95 Series

SCREW

(KEY 20)

SPRING (MAIN V ALVE)

(KEY 26)

W8160

LOCK WASHER

(KEY 21)

PLUG

(KEY 22)

O-RING

(KEY 23)

PISTON (MAIN)

(KEY 25)

O-RING

(KEY 24)

Key Description Part Number

3 Lock Nut

0.5 to 5 in wc / (1,2 to 12 mbar) GC060314X02

4 to 10 in wc / (10 to 25 mbar) GC060313X02

8 to 15 in wc / (20 to 36 mbar) GC060313X02

0.5 to 1.5 psi/ (34 to 103 mbar) GC060313X02

-1.0 to 1.0 in wc / (-2 to 2 mbar) GC060314X02

-5 to -0.5 in wc (vac) / (-12 to 1,2 mbar) GC060314X02

4* O-Ring

Nitrile 1F463606992

EPDM/FDA 1F 4636X0082

FKM 1N571406382

FFKM 1F4636X0052

5 Spring Seat

0.5 to 5 in wc / (1,2 to 12 mbar) GC050501X02

4 to 10 in wc / (10 to 25 mbar) GC050501X02

8 to 15 in wc / (20 to 36 mbar) GC050501X02

0.5 to 1.5 psig / (34 to 103 mbar) GC050502X02

-1.0 to 1.0 in wc / (-2 to 2 mbar) GC050501X02

-5 to -0.5 in wc (VAC) / (-12 to -1,2 mbar) GC050501X02

Figure 7. Typical Main V alve and Spring (Type ACE95Sr shown)

10. Tighten all nuts (key 31) uniformly.

11. Reinstall the valve according to the instructions in

the Installation section of this manual.

11. Adjust the setpoint according to the instructions

in the Adjustment section.

12. Replace the actuator cap (key 1).

Parts Ordering

Each ACE95 Series valve is assigned a serial number

printed on the nameplate on the main valve actuator .

Refer to this number when contacting your Fisher Sales

Office or Fisher Sales Representative for assistance, or

when ordering replacement parts. When ordering a

replacement part, be sure to reference the key number

for each needed part and include the complete 11character part number from the following parts list.

Key Description Part Number

1Cap

Stainless Steel GC053301X02

Steel GC053301X32

2 Adjusting Screw

0.5 to 5 in wc / (1,2 to 12 mbar) GC060216X12

4 to 10 in wc / (10 to 25 mbar) GC060216X12

8 to 15 in wc / (20 to 36 mbar) GC060216X12

0.5 to 1.5 psi / (34 to 103 mbar) GC060221X12

-1.0 to 1.0 in wc / (-2 to 2 mbar) GC060216X12

-5 to -0.5 in wc (vac) / (-12 to 1,2 mbar) GC060216X12

6 Vent (Y602-A12) 27A 5516A012

7 Spring Case

Stainless Steel GC053101X02

Steel GC053101X32

8 Range Spring

0.5 to 5 in wc / (1,2 to 12 mbar) GC220701X22

4 to 10 in wc / (10 to 25 mbar) GC220702X22

8 to 15 in wc / (20 to 36 mbar) GC220703X22

0.5 to 1.5 PSI / (34 to 103 mbar) GC220708X22

-1.0 to 1.0 in wc / (-2 to 2 mbar) GC220701X22

-5 to -0.5 in wc (VAC) / (-12 to -1,2 mbar) GC220701X22

9* Gasket (spring tower) GC070428X02

10 Diaphragm Plate (upper) GC260104X02

11 Diaphragm (main) - FEP GC070234X72

12 * Gasket (actuator) GC070427X02

13 Diaphragm Retaining Nut

0.5 to 5 in wc / (1,2 to 12 mbar) GC053208X02

4 to 10 in wc / (10 to 25 mbar) GC053208X02

8 to 15 in wc / (20 to 36 mbar) GC053208X02

0.5 to 1.5 PSI / (34 to 103 mbar) GC053215X02

-1.0 to 1.0 in wc / (-2 to 2 mbar) GC053208X02

-5 to -0.5 in wc (VAC) / (-12 to -1,2 mbar) GC053208X02

14* O-Ring

Nitrile GC070173X02

EPDM/FDA GC070173X52

FKM GC070173X12

FFKM GC070173X62

15 Diaphragm Bolt GC053210X02

16 * O-Ring (2 required)

Nitrile 1F115306992

EPDM/FDA 1F 1153X0062

FKM 1F1153X0022

FFKM 1F1153X0032

* Recommended Spare Part

12

Page 13

ACE95 Series

Key Description Part Number

17 Bonnet

Cv 1 through 4 GC052901X02

Cv 5 through 10 GC052901X12

Cv 20 through 60 GC050919X62

18 Body

Cv 1 through 4 GC052902X02

Cv 5 through 10 GC052902X12

Cv 20 through 60 GC050927X62

19* O-Ring

Type ACE95

Nitrile 1C415706992

EPDM/FDA 1C4157X0092

FKM 1C4157X0032

FFKM 1C4157X0082

Type ACE95Sr

Nitrile 1F3581X0082

EPDM/FDA 1F 3581X0102

FKM 1F3581X0022

FFKM 1F3581X0092

20 Round-Head Machine Screw

Type ACE95 GC060218X02

Type ACE95Sr GC060225X02

21 Lock Washer

Type ACE95 GC060903X02

Type ACE95Sr GC060906X02

22 Plug

Type ACE95

Cv 1 GC050206X02

Cv 2 GC053205X02

Cv 4 GC053204X02

Cv 7.5 GC053213X02

Cv 10 GC053212X02

Type ACE95Sr

Cv 20 GC053220X02

Cv 45 GC053221X02

Cv 60 GC053218X02

23* O-Ring

Type ACE95, Cv 1 through 4

Nitrile 1D2888X0032

EPDM/FDA 1D2888X0042

FKM 1D2888X0052

FFKM 1D2888X0022

Type ACE95, Cv 5 through 10

Nitrile 18A1088X022

EPDM/FDA 18 A 1088X042

FKM 18A1088X052

FFKM 18 A 1088X032

Type ACE95Sr Cv 20 through 60

Nitrile 1C782206992

EPDM/FDA 1C7822X0122

FKM 1C7822X0132

FFKM 1C7822X0112

Key Description Part Number

24* O-Ring

Type ACE95 Cv 1 through 4

Nitrile 1C782206992

EPDM/FDA 1C7822X0122

FKM 1C7822X0132

FFKM 1C7822X0112

Type ACE95 Cv 5 through 10

Nitrile 1D2375X0062

EPDM/FDA 1D2375X0082

FKM 1D237506382

FFKM 1D237506372

Type ACE95Sr Cv 20 through 60

Nitrile 1D785306992

EPDM/FDA 1D7853X0032

FKM 1D7853X0042

FFKM 1D7853X0012

25 Piston (main valve)

Type ACE95: Cv 1 through 4 GC053203X02

Type ACE95: Cv 7.5 through 10 GC053219X02

Type ACE95Sr: Cv 20 through 60 GC053211X02

26 Spring (main valve)

Type ACE95

Cv 1 through 4, 25 to 50 psig GC220704X22

Cv 1 through 4, 51 to 120 psig GC220705X22

Cv 1 through 4, 121 to 200 psig GC 220706X22

Cv 5 through 10, 25 to 50 psig GC220705X22

Cv 5 through 10, 51 to 120 psig GC 220706X22

Cv 5 through 10, 121 to 200 psig GC220709X22

Type ACE95Sr

Cv 20 through 60, 25 to 50 psig GC 220714X22

Cv 20 through 60, 51 to 120 psig GC220712X22

Cv 20 through 60, 121 to 200 psig GC220713X22

27 * Gasket (bonnet/actuator) GC070429X32

28 Lock Washer (24 required) GC 060906X02

29 Hex-Head Machine Screw

Type ACE95 (24 required) GC060220X02

Type ACE95Sr (28 required) GC060220X02

30 Actuator Case (lower)

Stainless Steel GC260105X02

Steel GC260105X32

31 Hex Nut (20 required) GC060316X02

32 Hex-Head Machine Screw (24 required) GC060220X02

33 Actuator Case (upper)

Stainless Steel GC260102X02

Steel GC260102X12

34 Spring Shim (Type ACE95 only)

25 to 50 psig (1,7 to 3,5 mbar) GC053209X02

35 Lower Cage GC053002X02

* Recommended Spare Part

36 Spring (cage) GC220707X22

37 Piston (pilot) GC053202X02

13

Page 14

ACE95 Series

Key Description Part Number

38 * Rolling Diaphragm

Nitrile GC071101X02

EPDM/FDA GC071101X22

FKM GC071101X12

FFKM GC071101X32

39* O-ring

Nitrile 1D2888X0032

EPDM/FDA 1D 2888X0042

FKM 1D2888X0052

FFKM 1D 2888X0022

40 Cage (upper) G C053001X02

41* O-Ring

Nitrile 10A0042X052

EPDM/FDA 10 A 0042X072

FKM 10A0042X012

FFKM 10 A0042X062

42 Pilot (poppet) GC053201X02

43 Pilot Filter (optional, not shown)

Aluminum GC040701X02

Stainless Steel GC040708X02

46 Seal Bushing (4 required, Type ACE95 only)

Nitrile GC071202X32

EPDM/FDA GC071202X32

FKM GC071202X32

FFKM GC071202X32

47 Flat Washer

(20 required, steel actuator only) GC060804X22

48 Diaphragm Plate (lower)

Positive Spring Range

(3 inch / 76 mm - diameter) GC260113X02

Negative Spring Range

(9 inch / 229 mm - diameter) GC260104X02

49 Spring Guide (Type ACE95Sr only)

25 to 50 psig / 51 to 120 psig GC050505X22

50 Hex Head Cap Screw (4 required) GC 060224X02

51 Lock Washer (4 required) G C060905X02

16 2 Lower Range Spring

(neg. pressure range only, used with upper spring (key 8))

-1.0 to 1.0 in wc / (-2 to 2 mbar) GC220717X22

-5 to -0.5 in wc (vac) / (-12 to -1,2 mbar) GC220710X22

* Recommended Spare Part

14

Page 15

ACE95 Series

1

LOCATE

GROOVE IN

LOWER CAGE

FOR ROLLING

DIAPHRAGM

BEAD

E0626

42

32

47

28

31

LOCATE GROOVE IN LOWER

CAGE FOR ROLLING

DIAPHRAGM BEAD

41

30

35

28

36

40

39

38

48

29

27

26

37

33

32

162

50

51

19

2

3

4

5

6

7

10 11 12

8

9

13

14

15

16

17

18

49

25

24

23

22

2120

E0625

Figure 8. T ype ACE95Sr T ank Blanketing Valv e

15

Page 16

ACE95 Series

42

LOCATE

GROOVE IN

LOWER CAGE

FOR ROLLING

DIAPHRAGM

BEAD

E0628

47

3332

41

35

40

39

38

37

36

28 32

162

1

2

3

4

5

6

7

8

10 11 12

9

13

30

28

LOCATE GROOVE IN LOWER

CAGE FOR ROLLING

DIAPHRAGM BEAD

46

29

2831

15

27

16

17

26

34

48

25

24

18

19

23

22

E0627

201421

Figure 9. Type ACE95 T ank Blank eting Valve

Fisher and Fisher-Rosemount are marks owned by Fisher Controls International, Inc. or Fisher-Rosemount Systems, Inc.

All other marks are the property of their respective owners.

©Fisher Controls International, Inc., 2001; All Rights Reserved

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

For information, contact Fisher Controls:

Marshalltown, Iowa 50158 USA

28320 Gallardon, France

Sao Paulo 05424 Brazil

Singapore 128461

Printed in U.S.A.

Loading...

Loading...