Page 1

Instruction Manual

D100255X012

January 2020

Type 92C Steam Regulator

WARNING

!

Fisher™ regulators must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies,

Inc. instructions.

Installation, operation and maintenance

procedures performed by unqualied

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment damage

or personal injury. Use qualied personnel

when installing, operating and maintaining

the Type 92C regulator.

Introduction

Scope of the Manual

This instruction manual provides installation,

maintenance and parts ordering information for the

Type 92C steam self-powered control valve and

the Type 6392 pilot. Both the pilot-operated and the

pressure-loaded constructions are covered. The

Type 92C is also available with a Type 6492HM or

6492HTM safety override pilot. The pressure-loading

device and accessories used with this valve are

covered in other manuals.

regulator or 670 Series panel-mounted regulator may

be used as the loading regulator.

A Type 6492HM (or 6492HTM) safety override pilot is

also available for the Type 92C. The Type 6392 pilot is

used in a series installation with the Type 6492HM (or

6492HTM) safety override pilot installed on the upstream

valve. The Type 6492HM (or 6492HTM) safety override

pilot senses pressure downstream of the second valve,

and prevents pressure from rising above safe operating

pressure in the event the downstream valve fails. This

system is approved by ASME B31.1-1989, 122.14.2.A,

and can replace an ASME safety valve when vent

piping is not practical and upstream pressure does not

exceed 400 psig / 27.6 bar. Local codes and standards

may require approval by an appropriate authority prior

to installation.

Type 92C

W3111_2

Figure 1. Type 92C Pilot-Operated Regulator

WARNING

!

Description

The Type 92C steam regulator is a gray cast iron,

steel or stainless steel pressure-reducing regulator for

steam or hot air service. This regulator is available with

a Type 6392 pilot for use as a pilot-operated regulator

(Figure 1) or without a pilot for use as a pressureloaded regulator. The pilot-operated version uses

inlet pressure as the operating medium; no separate

air supply is required. The pressure-loaded version

is used where remote adjustment of the regulator

pressure setting is required; a 67 or 1301 Series

The Type 92C safety override system

does not provide positive shuto in

dead end service. It is intended for

large distribution systems where steam

leakage will condense before steam

pressure builds up. Downstream piping

and components must be rated for

maximum upstream steam pressure for

dead end service. Failure to do so could

cause personal injury or death.

Page 2

Type 92C

Specications

This section lists the specications for Type 92C regulator. Additional specications for an individual regulator are

found on the regulator body and pilot nameplates.

Body Sizes and End Connection Styles

SIZE

NPS 1/2, 3/4 or 1 /

DN 15, 20 or 25

Gray Cast Iron Steel or CF8M Stainless Steel

NPT

BODY MATERIAL

NPT, CL150 RF, CL300 RF

or PN 16/25/40

Orice Sizes

NPS 1/2 / DN 15 Main Valve:

9/16 in. / 14 mm

NPS 3/4 and 1 / DN 20 and 25 Main Valves:

3/4 in. / 19 mm is standard; 9/16 in. / 14 mm

is optional

Maximum Allowable Inlet and Pilot

Supply Pressures

(1)

Gray Cast Iron Construction: 250 psig / 17.2 bar

Steel and Stainless Steel Construction:

300 psig / 20.7 bar

Regulator Pressure Drops

(1)

Minimum: 15 psi / 1.0 bar

Maximum Operating: 150 psi / 10.3 bar for

outlet pressure settings equal to or below

50 psig / 3.4 bar; 200 psi / 13.8 bar for outlet

pressure settings above 50 psig / 3.5 bar

Maximum Emergency

Gray Cast Iron construction: 250 psi / 17.2 bar

Steel and Stainless Steel construction:

Maximum Material Temperature Capabilities

Gray Cast Iron Construction: 406°F / 208°C

Steel and Stainless Steel Construction:

500°F / 260°C

Optional High-Temperature Steel or

Stainless Steel Body: 650°F / 343°C

Pressure Registration

With Pilot: External

Without Pilot: Internal

Downstream Control Line Connection

1/4 NPT (internal) in pilot body (downstream

control line not required for pressureloaded regulator)

300 psi / 20.7 bar

Loading Pressure Connection

Outlet Control Ranges

See Table 1

Maximum Outlet Pressures

(1)

Maximum Operating Outlet Pressure:

150 psig / 10.3 bar

Maximum Emergency Outlet (Casing) Pressure

Gray Cast Iron construction: 250 psig / 17.2 bar

Steel and Stainless Steel construction:

300 psig / 20.7 bar

Loading Pressure for Pressure-Loaded Regulator

(1)

1/4 NPT (internal) in main valve diaphragm ange

(this connection is factory-piped to the pilot on

pilot-operated regulator)

Pilot Spring Case Vent

3/32 in. / 2.4 mm drilled hole

Approximate Weights

Gray Cast Iron, Steel or Stainless Steel Body

with Pilot: 20 lbs / 9.1 kg

Gray Cast Iron, Steel or Stainless Steel Body

without Pilot: 16 lbs / 7.3 kg

See Figure 2 to determine loading pressure.

Maximum allowable loading pressure is 250 psig /

17.2 bar for gray cast iron construction and

300 psig / 20.7 bar for steel or stainless steel

construction; the maximum allowable diaphragm

dierential pressure of 150 psi / 10.3 bar

for gray cast iron, steel and stainless steel

constructions must not be exceeded.

1. Pressure/temperature limits in this Instruction Manual and any applicable code limitations must not be exceeded.

(1)

2

Page 3

TYPE 92C REGULATOR

PILOT LOADING LINE

Type 92C

26A3808-A

A2508-1

PRESSURE DROP ACROSS VALVE (bar)

2 4 6 8 10 12

20

15

10

5

0

DIAPHRAGM DIFFERENTIAL (psi)

PRESSURE DROP ACROSS VALVE (psi)

3/4 in. / 19 mm

orice size

9/16 in. / 14 mm

orice size

50 100 150 200

Figure 2. Diaphragm Dierential Pressure

for Pressure-Loaded Regulator

TYPE

6492HM

6492HTM

SPRING RANGE

psig bar

10 to 30 0.69 to 2.1 Yellow 5 psig / 0.34 bar over normal distribution pressure

25 to 75 1.7 to 5.2 Green

70 to 150 4.8 to 10.3 Red

80 to 250

15 to 100 1.0 to 6.9

PILOT SUPPLY

TYPE 6392 PILOT

1

0.5

DIAPHRAGM DIFFERENTIAL (bar)

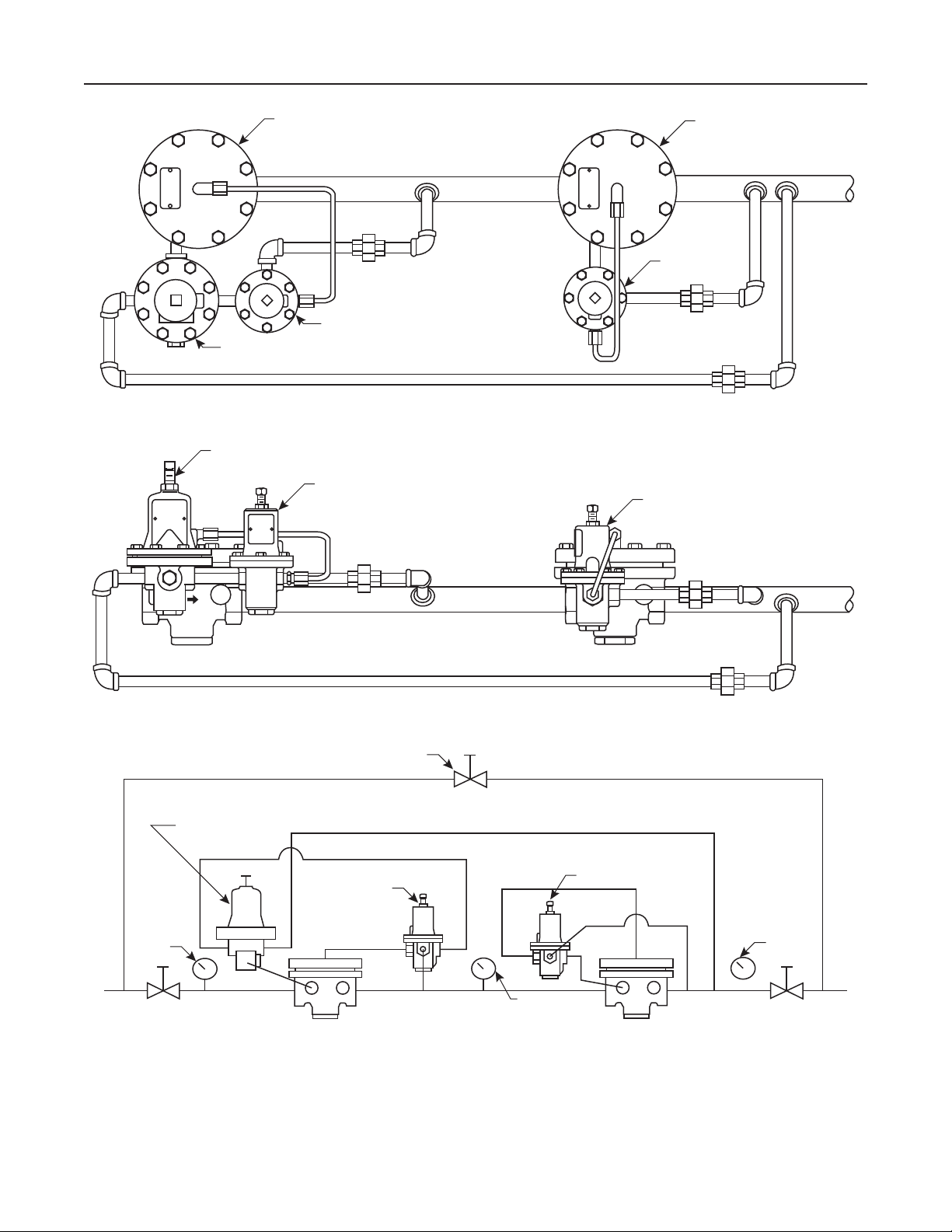

TOP VIEW OF REGULATOR AND

PILOT CONNECTIONS

STRAINER

16A1548-B

A2522-1

Figure 3. Typical Pilot-Operated Type 92C

Regulator Installation

Table 1. Safety Pilot Outlet (Control) Pressure Ranges

MINIMUM PRESSURE AT WHICH MONITORING

10 psig / 0.69 bar over normal distribution pressure

5.4 to 17.2

SPRING COLOR

Unpainted

DOWNSTREAM

CONTROL LINE

BYPASS LINE

PILOT CAN BE SET

TYPE 6392 PILOT

DOWNSTREAM

CONTROL LINE

TYPE 92C REGULATOR

Table 2. Outlet Pressure Ranges

SPRING USAGE

Standard use up to

500°F / 260°C

High-pressure and/or High

temperature over 500°F / 250°C

OUTLET PRESSURE RANGE

psig bar In. mm In. mm

5 to 70 0.34 to 4.8 1E392627012, Green 0.170 4.32 2.00 50.8

20 to 150 1.4 to 10.3 1E392727142, Red 0.207 5.26 1.94 49.0

15 to 100 1.0 to 6.9 14B9941X012, Unpainted 0.192 4.88

80 to 200 5.5 to 17.2 14B9940X012, Unpainted 0.282 7.16

SPRING PART NUMBER

AND COLOR

Table 3. Flow Coecients

ORIFICE SIZE WIDE-OPEN FOR RELIEF SIZING

In. mm C

g

9/16 14 170 8.5 5

3/4 19 240 12 7.1

1. Cv = Cs x 20 ÷ C

1

C

s

C

SPRING WIRE DIAMETER SPRING FREE LENGTH

(1)

C

1

v

34 0.67

Table 4. IEC Sizing Coecients

BODY SIZE

NPS DN X

1/2 15

3/4 or 1 20 or 25 0.44 0.73 0.38 0.82

0.73

9/16 in. / 14 mm 3/4 in. / 19 mm

T

F

D

0.38

ORIFICE SIZE

F

L

0.82

X

T

F

D

- - - - - - - - - - - -

1.96 49.8

K

m

F

L

3

Page 4

Type 92C

TYPE 92C MAIN VALVE

TYPE 6492HM SAFETY

OVERRIDE PILOT

TYPE 6492HM SAFETY

OVERRIDE PILOT

TYPE 92C MAIN VALVE

TYPE 6392 PILOT

TYPE 6392 PILOT

TOP VIEW

TYPE 6392 PILOT

TYPE 6392 PILOT

TYPE 92C MAIN VALVE TYPE 92C MAIN VALVE

E0656

E0657

TYPE 6492HM SAFETY

GAUGE

BLOCK VALVE

BLOCK VALVE

OVERRIDE PILOT

TYPE 6392 PILOT

TYPE 92C MAIN VALVE TYPE 92C MAIN VALVE

SIDE VIEW

GAUGE

TYPICAL TYPE 92C WITH TYPE 6492HM OR 6492HTM SAFETY OVERRIDE PILOT INSTALLATION

TYPE 6392 PILOT

GAUGE

BLOCK VALVE

Figure 3. Typical Pilot-Operated Type 92C Regulator Installations (continued)

4

Page 5

Type 92C

Note

To determine required loading pressure,

add the diaphragm dierential pressure

to the desired outlet pressure setting.

Principle of Operation

Pilot-Operated Regulator

Refer to Figure 5. Pilot supply pressure is piped from the

inlet side of the main valve to the pilot inlet connection.

Downstream pressure registers under the main valve

diaphragm through the pitot tube and under the pilot

diaphragm through the downstream control line.

When downstream pressure decreases to a value

below the setting of the pilot regulator spring, the pilot

spring forces the pilot valve plug open, increasing

the loading pressure on the top of the main valve

diaphragm. The increased loading pressure on top of

the main valve diaphragm and decreased downstream

pressure under the main valve diaphragm force the

main valve diaphragm and stem downward. This

opens the main valve plug, and increases ow to

the downstream system, thus restoring downstream

pressure to the setting of the pilot regulator spring.

When downstream pressure increases it registers

under the pilot diaphragm and overcomes the force

of the pilot spring. This allows the pilot valve spring to

close the pilot valve plug and causes excess loading

pressure to bleed to the downstream system through

the pilot bleed hole. At the same time, increased

downstream pressure registers under the main valve

diaphragm. The decreased loading pressure on top of

the main valve diaphragm and increased downstream

pressure under the main valve diaphragm force

the main valve diaphragm upward. This allows the

main valve plug spring to close the main valve plug,

reducing ow to the downstream system.

Pressure-Loaded Regulator

Refer to Figure 7. With a pressure-loaded regulator, a

remote, adjustable loading regulator provides loading

pressure to the top of the main valve diaphragm.

Downstream pressure registers under the main valve

diaphragm through the pitot tube.

When downstream pressure decreases, it registers

under the diaphragm and allows the stem and plug

to move downward, thereby opening the valve to

increase downstream pressure.

When downstream pressure increases, it registers

under the diaphragm and forces the stem and plug

to move upward. The upward force of the spring

causes the valve to close, which decreases ow to

the downstream system thus decreasing downstream

pressure. In hot air service, supply air above the

diaphragm becomes compressed and is vented to the

atmosphere. If a steam supply is used, the steam is

vented downstream.

Safety Override Pilot Principle

of Operation

Refer to Figure 6. Once placed in operation, the

upstream Type 6392 pilot senses the intermediate

pressure between both valves, and the Type 6492HM

(or 6492HTM) pilot senses downstream pressure

of the second valve. As demand for ow increases,

intermediate pressure will fall causing the Type 6392

pilot to open. As the Type 6392 pilot valve opens,

loading pressure to the main valve increases, opening

the main valve.

The Type 6492HM (or 6492HTM) safety override

pilot remains open because its setpoint is above the

setpoint of the downstream valve. In the unlikely event

that the downstream valve fails open, downstream

pressure will rise above the downstream valve’s

setpoint. This pressure is sensed by the Type 6492HM

(or 6492HTM) safety override pilot. As downstream

pressure increases the safety override pilot closes,

reducing loading pressure to the main valve, which

positions the main valve to maintain downstream

pressure as specied per ASME Boiler and Pressure

Vessel Code, section VIII.

In the event that the upstream valve fails, the

downstream regulator will prevent downstream

pressure from rising above safe operating levels.

It is recommended to install some type of warning

system, such as a sentinel relief valve, to warn the

operator that a valve has failed in the system. This

will prevent prolonged operation with one valve, which

could cause valve trim wear and noise associated with

operation at high dierential pressures.

When operating in most steam systems, valve

setpoints should be in strict accordance to

ASME Boiler and Pressure Vessel Code, section VIII.

The Type 6492HM (or 6492HTM) safety override

pilot should be set at 10 psig / 0.69 bar or 10% above

maximum downstream operating pressure of the

second valve, whichever pressure is greater. For

example, most HVAC systems operate at 15 psig /

1.0 bar, so the safety override pilot should be set no

higher than 25 psig / 1.7 bar.

5

Page 6

Type 92C

LOADING REGULATOR

STRAINER

16A1547-A

A2523-1

Figure 4. Typical Pressure-Loaded Type 92C Regulator Installation

Installation

WARNING

!

Personal injury, equipment damage

or leakage due to escaping steam

or bursting of pressure-containing

parts may result if this regulator is

overpressured or is installed where

service conditions could exceed the

limits given in Specications section on

page 2 and on the appropriate nameplate,

or where conditions exceed any ratings

of the downstream piping or piping

connections. To avoid such injury or

damage, provide pressure-relieving or

pressure-limiting devices to prevent

service conditions from exceeding

those limits. Type 92C regulators and

their installations should be checked

for compliance with all applicable codes

such as the ANSI B31.1-1977 Power

Piping standard and the ASME Boiler and

Pressure Vessel code.

Use a qualied personnel when installing, operating,

and maintaining a Type 92C regulator. Make sure

that there is no damage to or foreign material in the

regulator and that all tubing and piping are clean and

unobstructed. Install the regulator so that ow direction

matches the arrow marked on the regulator body.

Some typical Type 92C regulator installations are

shown in Figures 3 and 4.

The Type 92C regulator may be installed in any

orientation. However, the regulator should not be

BLEED RESTRICTION

OPTIONAL PIPING FOR

STEAM LOADING

TYPE 92C REGULATOR

BYPASS LINE

installed in a tall vertical pipeline where condensate

could collect and create a pressure head aecting

regulator performance.

Apply steam-compatible pipe compound to the

external pipeline threads. Then, using acceptable

piping procedures, install the regulator into

the pipeline.

If continuous operation of the system is required

during inspection and maintenance, install a three-

valve bypass around the regulator. If the owing

medium contains solids, install a proper size strainer

upstream of the regulator.

Pilot-Operated Regulator

The Type 6392 pilot has three 1/4 NPT connections

located in the pilot body. For proper operation of

a pilot-operated regulator, the pilot supply and the

regulator loading connections should be installed

parallel to the ow direction arrow marked on the pilot

body as shown in Figure 10, and the downstream

control line should be installed in the pilot body

connection as shown in Figures 3 and 10. If a pilotoperated regulator is ordered, the pilot supply and

the regulator loading connections will be made at

the factory.

Note

Pilot is shown here above the main valve

body for illustration purposes only. See

Figures 1 and 10 for actual pilot position

and appearance of pilot-supply line and

loading-pressure tubing.

6

Page 7

PILOT REGULATING SPRING

Type 92C Safety Override System

July 2008

Type 92C

Type 92C Safety Override System

July 2008

Type 92C

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

Type 92C Safety Override System

July 2008

Type 92C

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INTERMEDIATE PRESSURE

LOADING PRESSURE

PILOT DIAPHRAGM

DOWNSTREAM BLEED HOLE

Type 92C

36A1546-B

A2520-1

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

PILOT

SUPPLY

PILOT

VALV E

PLUG PILOT

MAIN VALVE SPRING

VALV E

SPRING

MAIN VALVE PLUG

DOWNSTREAM

CONTROL LINE

MAIN VALVE

DIAPHRAGM

PITOT

TUBE

Figure 5. Operational Schematic of Pilot-Operated Type 92C Regulator

TYPE 6492HM SAFETY

OVERRIDE PILOT

TYPE 6392 PILOT

TYPE 92C MAIN VALVE

E0658

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

INTERMEDIATE PRESSURE

Figure 6. Type 92C with Type 6492HM Safety Override Pilot Operational Schematic

TYPE 6392 PILOT

TYPE 92C MAIN VALVE

7

Page 8

Type 92C

Note

Since a clogged vent may cause

improper regulator functioning, install

and maintain the Type 92C regulator so

that the Type 6392 pilot spring case vent

remains clear and unobstructed.

To install a pilot-operated regulator:

1. Connect a downstream control line of at least

1/4 in. / 6.4 mm diameter pipe bushed down to the

1/4 NPT control line connection in the pilot body.

2. For both body-sized and swaged pipelines, locate

the pipeline control line connection in a section of

straight pipe at least 10 pipe diameters away from

the regulator or swage.

3. Do not locate the pipeline control line connection in

an elbow, swage or other area where turbulence or

abnormal velocities may occur.

4. If the pilot is mounted with the control line in a

position other than horizontal, make sure the

control line is sloped away from the pilot so that

condensate can drain into the pipeline.

5. Install a shuto valve (not a needle valve) in

the control line to completely isolate the pilot

during maintenance.

6. Install a pressure gauge in the control line or near

the regulator to aid in setting the outlet pressure.

Each pilot-operated regulator is factory-set for the

pressure setting specied on the order. If no setting

is specied, the unit is factory-set at 30 psig / 2.1

bar. In all cases, check the spring setting to make

sure it is correct for the application.

Pressure-Loaded Regulators

device. In all cases, check the pressure setting to

make sure it is correct for the application.

Startup

The maximum inlet pressure for a specic construction

is stamped on the main valve nameplate. Use

pressure gauges to monitor upstream and downstream

pressures during startup.

To put the regulator into operation:

1. Open the control line shuto valve.

2. For a pilot-operated regulator, open the

downstream block valve.

For a pressure-loaded regulator, open the shuto

valve in the pressure-loading piping or tubing.

3. Slowly open the upstream block valve.

4. If a bypass line is used, slowly close the bypass

line block valve.

5. To adjust the downstream pressure, follow the

appropriate procedure:

a. For a pilot-operated regulator, loosen the

jam nut (key 15, Figure 9). Turn the adjusting

screw (key 16, Figure 9) into the spring case

to increase the downstream pressure. Turn

the adjusting screw out of the spring case to

decrease the downstream pressure. When the

required downstream pressure is maintained for

several minutes, tighten the jam nut to lock the

adjusting screw in position.

b. For a pressure-loaded regulator, refer

to the Instruction Manual of the pressureloading device for downstream pressure

adjustment procedures.

To install a pressure-loaded regulator:

1. Install a shuto valve in the pressure-loading

piping or tubing.

2. Connect the piping or tubing to the 1/4 NPT

connection in the diaphragm ange (key 2, Figure 8).

If the loading regulator used with the pressureloaded regulator does not provide internal relief, an

atmospheric bleed (e.g., no. 60 drill size) is required if

the loading supply is air, or a downstream bleed line is

required if the loading supply is steam. This installation

is shown in Figure 4.

The pressure setting of a pressure-loaded regulator

is adjusted and determined by the pressure-loading

8

Safety Override Pilot Startup

and Adjustment

1. Loosen adjusting screws of the Type 6492HM (or

6492HTM) safety override pilot and Type 6392

intermediate pilot on the upstream valve until there

is no spring load. The screws should turn freely

by hand.

2. Loosen the adjusting screw of the Type 6392

pilot on the downstream valve until there is no

spring load.

3. Tighten the Type 6492HM (or 6492HTM) safety

override pilot of the upstream valve all the way in

to its highest spring setting.

Page 9

Type 92C

LOADING REGULATOR

MAIN VALVE PLUG

36A1546-B

A2947

INLET PRESSURE

LOADING PRESSURE

DOWNSTREAM PRESSURE

Figure 7. Operational Schematic of Pressure-Loaded

Type 92C Regulator

BLEED RESTRICTION

OPTIONAL

PIPING

FOR STEAM

LOADING

MAIN VALVE

DIAPHRAGM

PITOT TUBE

MAIN VALVE SPRING

4. Tighten the Type 6392 pilot of the upstream valve

all the way in to its highest spring setting.

5. Tighten the Type 6392 pilot of the downstream

valve to the desired downstream pressure.

6*. Loosen the Type 6392 intermediate pilot on

the upstream valve to the desired intermediate

pressure (normally 50% of inlet pressure).

7. Loosen the Type 6492HM (or 6492HTM) safety

override pilot of the upstream valve until there is no

spring load.

8. Tighten the Type 6392 pilot of the downstream

valve all the way in to its highest spring setting.

9. Tighten the Type 6492HM (or 6492HTM) safety

override pilot of the upstream valve to desired

pressure as specied per ASME Boiler and

Pressure Vessel Code, section VIII.

10.* Loosen the Type 6392 pilot of the

downstream valve to the desired downstream

pressure setpoint.

*Fisher™ recommends establishing setpoint by tightening the adjusting screw.

Shutdown

To take the regulator out of operation:

1. If a bypass line is used, slowly open the

bypass line block valve while monitoring the

downstream pressure.

2. Close the upstream block valve.

3. For a pilot-operated regulator, close the

downstream block valve.

For a pressure-loaded regulator, close the

shuto valve in the pressure-loading piping

or tubing.

4. Close the control line shuto valve.

5. Vent the regulator, the control line and the pilot

supply line to release any trapped pressure.

Maintenance

Regulator parts are subject to normal wear and must be

inspected periodically and replaced as necessary. The

frequency of inspection and replacement depends upon

the severity of service conditions and upon applicable

Federal, state and local codes and regulations.

WARNING

!

Avoid personal injury or property damage

from sudden release of pressure or

uncontrolled steam or other process

uid. Before starting disassembly:

• Isolate the regulator from the process,

• Release process pressure, and

• Vent the pilot supply and main valve

loading pressures.

This section contains separate procedures for regulator

and pilot maintenance.

Type 92C Regulator

Perform these procedures when replacing diaphragm,

the stem assembly, the valve plug or the orifice. Refer

to the correct section for the required instructions. Key

numbers refer to Figure 8 unless otherwise indicated.

The regulator may remain in the pipeline during

maintenance procedures unless the valve body is to

be replaced or removed for repairs. For pilot-operated

regulators, the pilot may remain on the pipe nipple

(key 23, Figure 10) unless the pilot body (key 1,

Figure 9) is to be removed or the entire pilot replaced

as a unit.

9

Page 10

Type 92C

Replacing Diaphragm and Stem Assembly

1. For the pilot-operated regulator, unscrew the

elbow and connector (keys 25 and 24, Figure 10)

so that the loading tubing (key 22, Figure 10) can

be removed.

For the pressure-loaded regulator, unscrew

the loading tubing (customer supplied) from the

1/4 NPT connection in the regulator diaphragm

ange (key 2).

2. Remove the cap screws (key 12) and the diaphragm

ange (key 2).

Lift out the upper diaphragm gasket (key 9), the

diaphragms (key 8), the lower diaphragm gasket

and for Steel/Stainless Steel constructions, the

diaphragm ring (key 15) and another diaphragm

gasket (key 9).

3. Lift out the stem assembly (key 11) consisting of

the pusher plate and the stem. Check that the pitot

tube (key 10) is clear and free of obstructions.

Clean the parts. Check for wear, scratches, nicks

and other damage, and replace parts as necessary.

4. Install the stem assembly (key 11) in the stem

guide bushing (key 6). Place one diaphragm

gasket (key 9) in the regulator body (key 1).

For Steel/Stainless Steel constructions, place the

diaphragm ring (key 15) and another diaphragm

gasket (key 9) on top of the rst gasket.

For all constructions, place the two molded

diaphragms (key 8) with the raised circle up,

another diaphragm gasket and the diaphragm

ange (key 2) on the body. Insert and tighten the

cap screws (key 12).

5. For the pilot-operated regulator, reconnect

the elbow, the loading tubing and the connector

(keys 25, 22 and 24, Figure 10).

For the pressure-loaded regulator, reconnect

the pressure-loading tubing.

6. When maintenance is completed, refer to the

Startup section to put the regulator back in

operation and to adjust the pressure setting.

Replacing Valve Plug and Orice

1. Remove the valve plug guide (key 5).

2. Remove the valve plug (key 4) and the valve

plug spring (key 7). Inspect the valve plug

seating surface for nicks or scratches. Replace

as necessary.

3. Unscrew the orice (key 3), and inspect the

seating surface for nicks and scratches. Replace

if necessary.

4. Clean the valve plug guide, the valve plug, the

valve plug spring and the orice (keys 5, 4, 7

and 3, respectively).

5. Coat the orice threads with Never-Seez

®

or

equivalent lubricant. Then, being careful not to

damage the seating surface, thread the orice

(key 3) into the regulator body (key 1).

6. Place the valve plug spring (key 7) into the

valve plug guide (key 5). Then slide the valve

plug (key 4) over the spring and into the valve

plug guide.

7. Apply Lok-Cease® 20/20 sealant or equivalent

to the valve plug guide threads, and screw the

valve plug guide (key 5) with attached parts

into the regulator body (key 1), applying 130 to

160 ft-lbs / 176 to 217 N•m of torque.

8. When maintenance is completed, refer to the

Startup section to put the regulator back in

operation and to adjust the pressure setting.

Type 6392 Pilot

Perform this procedure if inspecting, cleaning or

replacing any pilot parts. Key numbers refer to Figure 9

unless otherwise specied.

All pilot maintenance may be performed with the pilot

body (key 1) attached to the pipe nipple and connector

(keys 23 and 24, Figure 10) unless the pilot body must

be removed or the pilot is to be replaced as a unit.

1. Loosen the jam nut (key 15), and turn the

adjusting screw (key 16) counterclockwise until all

compression is removed from the control spring

(key 13). Remove the loading tubing from the

pilot outlet connection. Remove the cap screws

(key 17), spring case (key 2), control spring

(key 13) and upper spring seat (key 14) from

the body.

2. Remove the lower spring seat (key 9), the diaphragm

(key 7) and the diaphragm gasket (key 8) from the

body. Lift out the stem assembly (key 6) consisting

of the stem and the pusher plate. Clean the

1/16 in. / 1.6 mm diameter pilot bleed hole. Clean

and replace parts as necessary, and assemble the

stem assembly, the gasket, the diaphragm and the

spring seat in the order shown in Figure 9.

Never-Seez® is a mark owned by Never-Seez Corp.

Lok-Cease® is mark owned by Certied Laboratories.

10

Page 11

Type 92C

3. Install the control spring (key 13), the lubricated

upper spring seat (key 14) and the spring case

(key 2). Insert and tighten the cap screws (key 17).

Lubricate the adjusting screw (key 16) with

Never-Seez® or equivalent lubricant, and thread it

into the spring case.

4. Unscrew the valve plug guide (key 5). Remove

the strainer screen (key 12), the valve plug

(key 4), the valve plug cap (key 26) and the valve

plug spring (key 11). Unscrew the orice (key 3).

Clean and replace parts as necessary. Apply

Never-Seez® or equivalent lubricant to the orice

threads, and screw the orice into place.

5. Place the valve plug spring (key 11) into the valve

plug guide (key 5). Insert the valve plug cap (key 26)

into the valve plug (key 4), and then slide both

parts over the spring and into the valve plug guide.

Place the strainer screen (key 12) onto the valve

plug guide. Apply Lok-Cease® 20/20 sealant or

equivalent (key 21) to the valve plug guide threads,

and screw the valve plug guide with the attached

parts into the pilot body (key 1).

6. When maintenance is completed, refer to the

Startup section to put the regulator back into

operation, and adjust the pressure setting.

Types 6492HM and 6492HTM

Safety Override Pilots

These procedures are to be performed if inspecting,

cleaning or replacing any pilot parts or of cycling,

erratic control or too high or too low an outlet (control)

pressure is noted. Perform only those procedures

in this section required to correct the problem. Key

numbers refer to Figure 11.

Note

Before performing any maintenance,

loosen the hex nut (key 16), if used,

and turn the adjusting screw (key 15) or

handwheel (key 31) counterclockwise

until all compression is removed from

the control spring (key 12). Remove the

pilot spring from the pipe nipple and

connectors (keys 82 and 83, Figure 12).

2. Clean and replace parts as necessary. Apply

sealant to the orice threads. Thread the orice

into place and tighten using 19 to 25 ft-lbs / 26 to

34 N•m of torque.

3. Handle parts carefully, and place the plug spring

(key 3) in the plug guide (key 2). Slide the inner

valve (key 4) over the spring and into the plug

guide. Place the screen (key 77) onto the plug

guide. Place the stem (key 7) in the center hole

of the plug guide. Apply sealant to the plug guide

threads, and screw the guide plus attached parts

into the body (key 1).

4. Remove the pipe plug (key 74). Then remove the

pipe plug (key 94). Clean and replace the pipe

plugs as necessary.

5. Apply sealant to the threads of the pipe plug

(key 94) and install.

6. Apply sealant to the threads of the pipe plug

(key 74). Thread the pipe plug into place and

tighten using 5 to 15 ft-lbs / 6.8 to 20 N•m

of torque.

7. Remove the cap screws (key 17), spring case

(key 14), control spring (key 12) and upper spring

seat (key 13) from the body (key 1).

8. Remove the lower spring seat (key 11),

diaphragms (key 10) and diaphragm gasket

(key 18) from the body. Inspect and clean the

diaphragm gasket, and replace if necessary.

9. Unscrew the bellows retainer (key 8) and remove

the bellows (key 9). Replace worn parts as

necessary, and install the bellows and bellows

retainer. Tighten the bellows retainer using 19 to

25 ft-lbs / 26 to 34 N•m of torque.

10. Install the diaphragm gasket. Install both

diaphragms with their raised performed centers

facing toward the spring case.

11. Lubricate the upper spring seat and the exposed

threads of the adjusting screw. Install the lower

spring seat (key 11), control spring (key 12), upper

spring seat (key 13) and spring case (key 14).

Insert and tighten the cap screws (key 17) in a

crisscross bolting pattern using 12 to 18 ft-lbs /

16 to 24 N•m of torque.

1. Unscrew the plug guide (key 2). Remove the

screen (key 77), inner valve (key 4), plug spring

(key 3) and stem (key 7). Unscrew the orice

(key 5). Examine the orice and plug seating

surfaces for damage.

Never-Seez® is a mark owned by Never-Seez Corp.

Lok-Cease® is mark owned by Certied Laboratories.

Parts Ordering

When corresponding with your local Sales Oce about

this equipment, always specify the equipment serial

number as found on the regulator nameplate.

When ordering replacement parts, specify the

complete 11-character part number of each needed

part as found in the following parts list.

11

Page 12

Type 92C

Parts List

Regulator

Key Description Part Number

Parts Kit (included are keys 3, 4, 7, 8 and 9)

For 1/2 and 3/4 NPT body

9/16 in. / 14 mm orice R92CX000042

For 1 NPT body

3/4 in. / 19 mm orice R92CX000032

1 Regulator Body Assembly with Bushing

(See key 6 for bushing)

Gray Cast Iron

NPS 1/2 / DN 15 36A1539X012

NPS 3/4 / DN 20 36A1540X012

NPS 1 / DN 25 36A1541X012

Steel

1/2 NPT 36A1542X012

3/4 NPT 36A1543X012

1 NPT 36A1544X012

CL150 RF

NPS 1/2 / DN 15 14B3428X012

NPS 3/4 / DN 20 14B3428X022

NPS 1 / DN 25 19A5459X012

CL300 RF

NPS 1/2 / DN 15 14B3428X032

NPS 3/4 / DN 20 14B3428X042

NPS 1 / DN 25 14B0037X012

PN 16/25/40 RF

NPS 1/2 / DN 15 14B3428X052

NPS 3/4 / DN 20 14B3428X062

NPS 1 / DN 25 14B3428X072

Stainless Steel

1/2 NPT 36A1542X022

3/4 NPT 36A1543X032

1 NPT 36A1544X022

CL150 RF

NPS 1/2 / DN 15 14B3428X082

NPS 3/4 / DN 20 14B3428X092

NPS 1 / DN 25 19A5459X022

CL300 RF

NPS 1/2 / DN 15 14B3428X102

NPS 3/4 / DN 20 14B3428X112

NPS 1 / DN 25 14B0037X022

PN 16/25/40 RF

NPS 1/2 / DN 15 14B3428X122

NPS 3/4 / DN 20 14B3428X132

NPS 1 / DN 25 14B3428X142

2 Diaphragm Flange

Gray Cast Iron 26A1533X012

Steel 26A1534X012

Stainless Steel 26A1534X022

3 Orice

For 1/2 and 3/4 NPT body,

9/16 in. / 14 mm, 416 Stainless Steel 16A1529X012

For 1 NPT body

3/4 NPT / 19 mm, 416 Stainless Steel 16A1528X012

For 3/4 and 1 NPT body,

9/16 in. / 14 mm, Ethylenepropylene (EPDM),

410/416 Stainless Steel 1E399535132

4 Valve Plug, heat-treated, 416 Stainless Steel 1E398146172

5 Valve Plug Guide

Brass (for Gray Cast Iron body) 1E398214012

416 Stainless Steel (for Steel/Stainless Steel body) 1E398235132

6 Stem Guide Bushing, heat-treated

416 Stainless Steel (included in key 1)

For Gray Cast Iron body 1E398535132

For Steel/Stainless Steel body 16A1530X012

7 Valve Plug Spring, Stainless Steel 1E398837022

8* Diaphragm, Stainless Steel (2 required) 1E399236012

Regulator (continued)

Key Description Part Number

9* Diaphragm Gasket

(2 required for Gray Cast Iron body;

3 required for Steel/Stainless Steel body with

Ethylenepropylene (EPDM) seat) 16A1526X012

Steel/Stainless Steel body with metal seat,

3 required 1E3993X0012

Steel/Stainless Steel body with metal seat

(High temperature), 3 required 16A1526X022

10 Pitot Tube

For Gray Cast Iron body, Copper

NPT 16A1525X012

For Steel body, Copper

NPT 1E399417012

CL150 RF 16A1525X012

CL300 RF and PN 16/25/40 1E399417012

For Stainless Steel body, 304 Stainless Steel

NPT 1E399438072

CL150 RF 16A1525X022

CL300 RF and PN 16/25/40 1E399438072

11 Stem Assembly, 416 Stainless Steel 16A1524X012

12 Cap Screw, Zinc-plated steel (8 required)

For Gray Cast Iron body 1A914524052

For Steel/Stainless Steel body 1A782024052

14 Drive Screw, Stainless Steel (2 required) 1A368228982

15 Diaphragm Ring

For Steel body, Steel 16A1531X012

For Stainless Steel body, Stainless Steel 16A1531X022

Type 6392 Pilot (See Figure 10)

Key Description Part Number

Parts Kit (included are keys 3, 4, 8, 7, 11, 12 and 26)

Standard Trim R6392X00012

1 Pilot Body

Gray Cast Iron 26A1518X012

Steel 26A1517X012

Stainless Steel 26A1517X022

2 Spring Case

Gray Cast Iron 2E391219012

Steel 2J127522012

Stainless Steel 2J1275X0012

3 Orice, heat-treated

416 Stainless Steel 16A1511X012

4 Valve Plug, heat-treated

416 Stainless Steel 16A1516X012

5 Valve Plug Guide

Brass (for Gray Cast Iron pilot) 1E391814012

Heat-treated, 416 Stainless Steel

(For Steel pilot) 1E391835132

For Gray Cast Iron and Steel pilot,

Heat-treated, 416 Stainless Steel 1E391835132

For Stainless Steel pilot 1E391835072

6 Stem Assembly, 416 Stainless Steel

For Stainless Steel seat 16A1515X012

For Ethylenepropylene (EPDM) seat 16A1515X022

7 Diaphragm, Stainless Steel (2 required) 1E392836012

8* Diaphragm Gasket

Elastomer seat 1E393104022

Stainless Steel seat, Graphite 1E3931X0012

9 Lower Spring Seat, Aluminum 1E392309012

10 Stem Guide Bushing, 416 Stainless Steel 1E392235132

11 Valve Plug Spring, Stainless Steel 1E392437022

12 Strainer Screen, Stainless Steel 16A1512X012

*Recommended spare part

12

Page 13

Type 92C

Type 6392 Pilot (See Figure 10) (continued)

Key Description Part Number

13 Control Spring,

Standard springs, 416 Stainless Steel

5 to 70 psig / 0.34 to 4.8 bar, Green 1E392627012

20 to 150 psig / 1.4 to 10.3 bar, Red 1E392727142

Spring for use over 500°F / 260°C,

17-7 PH Stainless Steel

15 to 100 psig / 1.0 to 6.9 bar 14B9941X012

20 to 25 psig / 1.4 to 1.7 bar 14B9940X012

14 Upper Spring Seat, Zinc-plated steel 1B798525062

15 Jam Nut, Plate steel 1A352224122

16 Adjusting Screw, Plated steel 1E639928992

17 Cap Screw, Zinc-plated steel (6 required)

For Gray Cast Iron body 1A407824052

For Steel/Stainless Steel body 1A391724052

26 Valve Plug Cap, heat-treated

416 Stainless Steel 16A1549X012

Type 6392 Pilot Mounting Parts

Key Description Part Number

22 Loading Tubing

Copper 16A1527X012

Stainless Steel 16A1527X022

23 Pipe Nipple, Steel 1N584226232

24 Connector

Brass 15A6002X212

Stainless Steel 15A6002X642

25 Elbow

Brass 15A6002X172

Stainless Steel 15A6002X632

Types 6492HM and 6492HTM

Safety Override Pilots (See Figure 12)

Key Description Part Number

1 Pilot Valve Body

WCC Steel 22A0403X052

CF8M Stainless Steel 22A0403X072

2 Valve Guide, Stainless Steel

Steel body, 416 Stainless Steel 1E391835132

Stainless Steel body, 316 Stainless Steel 1E391835072

3 Valve Spring, 302 Stainless Steel 1E392437022

4 Inner Valve

Steel body, 416 Stainless Steel 1F967446172

Stainless Steel body, 316 Stainless Steel 1F9674X0012

5 Orice

Steel body, 416 Stainless Steel 1H564446172

Stainless steel body, 316 Stainless Steel 1H5644X0012

7 Valve Stem

Steel body, 410/416 Stainless Steel 1F967835132

Stainless Steel body, 316 Stainless Steel 1F9678X0012

8 Bellows Retainer

Steel body, Brass 1F971214012

Stainless Steel body, 316 Stainless Steel 1F9712X0012

9 Bellows

Steel body, Brass 1F971318992

Stainless Steel body, 321 Stainless Steel 1F9713X0012

10 Diaphragm, 302 Stainless Steel (2 required) 1E395836012

11 Lower Spring seat

Type 6492HM, Aluminum 1E395408012

Type 6492HTM

Steel 1E3954X0052

Stainless Steel 14B9948X012

Types 6492HM and 6492HTM

Safety Override Pilots

(See Figure 12) (continued)

Key Description Part Number

12 Spring

Type 6492HM, Steel

10 to 30 psig / 0.69 to 2.2 bar 1E395627022

25 to 75 psig / 1.7 to 5.2 bar 1D7455T0012

70 to 150 psig / 4.8 to 10.3 bar 1E395727192

Type 6492HTM, Stainless Steel

15 to 100 psig / 1.0 to 6.9 bar 14B9943X012

80 to 250 psig / 5.5 to 17.2 bar 14B9942X012

13 Upper Spring seat, Steel

Type 6492HM 1D667125072

Type 6492HTM 14B9951X012

14 Spring Case

Steel

With standard adjusting screw 2L416322012

With sealed adjusting screw 2L442022012

Stainless Steel

With standard adjusting screw 2L416333092

With sealed adjusting screw 2L4420X0012

15 Adjusting Screw, Steel

Standard 1D995448702

Handwheel 1J496428982

16 Hex Nut, Zinc-plated steel 1A353724122

17 Cap Screw (8 required)

Type 6492HM

Steel 1A381624052

Stainless Steel 1A3816X0152

Type 6492HTM

Steel 1A3816X0132

Stainless Steel 1A3816X0152

18 Diaphragm Gasket

Type 6492HM, Composition 1E396104022

Type 6492HTM, Graphite 1E3961X0012

34 Machine Screw for use with handwheel, Steel 16A5763X012

38 Handwheel, Zinc 1J496144012

39 Lock Washer for use with handwheel, Steel 1A352332992

74 Pipe Plug

Steel 0Z020128992

Stainless Steel 0Z020135072

77 Screen, 304 Stainless Steel 16A1512X012

78 Reducing Bushing

Steel 1C379026232

Stainless Steel 1C3790X0012

87 Sealed Adjusting Screw Sealing Washer 1V205699012

94 Pipe Plug, Stainless Steel 1E823135042

95 Warning Label 19B0429X0A2

Type 6492HM Pilot Mounting Parts

Key Description Part Number

81 Tubing 0500103809W

82 Pipe Nipple (2 required)

Steel 1C559926232

Stainless Steel 1C5599X0012

83 Connector

Steel 15A6002XY72

Stainless Steel 15A6002X642

84 Elbow

Steel 15A6002XY52

Stainless Steel 15A6002X632

*Recommended spare part

13

Page 14

Type 92C

26A1536-A

APPLY SEALANT:

S = ANTI-SEIZE COMPOUND

9

15

STEEL/STAINLESS STEEL CONSTRUCTION

14

13

9

2

9

6

11

S

3

GREY CAST IRON CONSTRUCTION

Figure 8. Type 92C Steam Regulator Assembly

8

2

9

12

8

1

10

4

S

7

5

16

2

14

13

17

7

1

10

6

3

15

L

18

19

9

8

L

26

4

S

11

5

16A1520-B

APPLY LUBRICANT/SEALANT:

L = ANTI-SEIZE LUBRICANT

S = ANTI-SEIZE COMPOUND

14

12

Figure 9. Type 6392 Pilot Assembly

Page 15

Type 92C

36A1545-A

A2521-1

25

23

1/4 NPT PILOT

SUPPLY CONNECTION

22

24

1/4 NPT REGULATOR

SUPPLY CONNECTION

1/4 NPT DOWNSTREAM

CONTROL LINE CONNECTION

Figure 10. Type 6392 Pilot Mounting Parts

15

11

10

18

5

77

3

E0660

16

13

12

9

8

7

4

2

14

20

19

17

94

74

Figure 11. Type 6492HM or 6492HTM Safety Override Pilot Assembly

95

1

78

15

Page 16

Type 92C

TYPE 6492HM

E0659

TYPE 6392

84

82

83

81

Figure 12. Type 92C with Safety Override Pilot Assembly

91 82

Webadmin.Regulators@emerson.com

Fisher.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D100255X012 © 1979, 2020 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 01/20.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for informational purposes

only, and while every eort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specications of such products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...