Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

Type 657 Diaphragm Actuators

Size 80 and 100

Contents

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 2. . . . . . . . . . . . . . . . . . . . . . . . .

Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Mounting 3. . . . . . . . . . . . . . . . . . . . . . . .

Loading Connection 3. . . . . . . . . . . . . . . . . . . . .

Adjustments 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Travel 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spring 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size 80 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size 100 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuator 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size 80 Disassembly 6. . . . . . . . . . . . . . . . . . . . .

Size 80 Assembly 7. . . . . . . . . . . . . . . . . . . . . . .

Size 100 Disassembly 8. . . . . . . . . . . . . . . . . . . .

Size 100 Assembly 9. . . . . . . . . . . . . . . . . . . . . .

Size 80 Side-Mounted Handwheel 10. . . . . . . . .

Disassembly 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size 80 Hydraulic Snubber 11. . . . . . . . . . . . . . . .

Size 80 Top-Mounted Handwheel

(Adjustable Up Travel Stop) 11. . . . . . . . . . . .

Disassembly 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size 100 Top-Mounted Handwheel

(Adjustable Up Travel Stop) 12. . . . . . . . . . . .

Disassembly 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note

Neither Emersonr, Emerson Process

Managementt, Fisherr, nor any of

their affiliated entities assumes

responsibility for the selection, use

and maintenance of any product.

Responsibility for the selection, use,

and maintenance of any product

remains with the purchaser and

end-user.

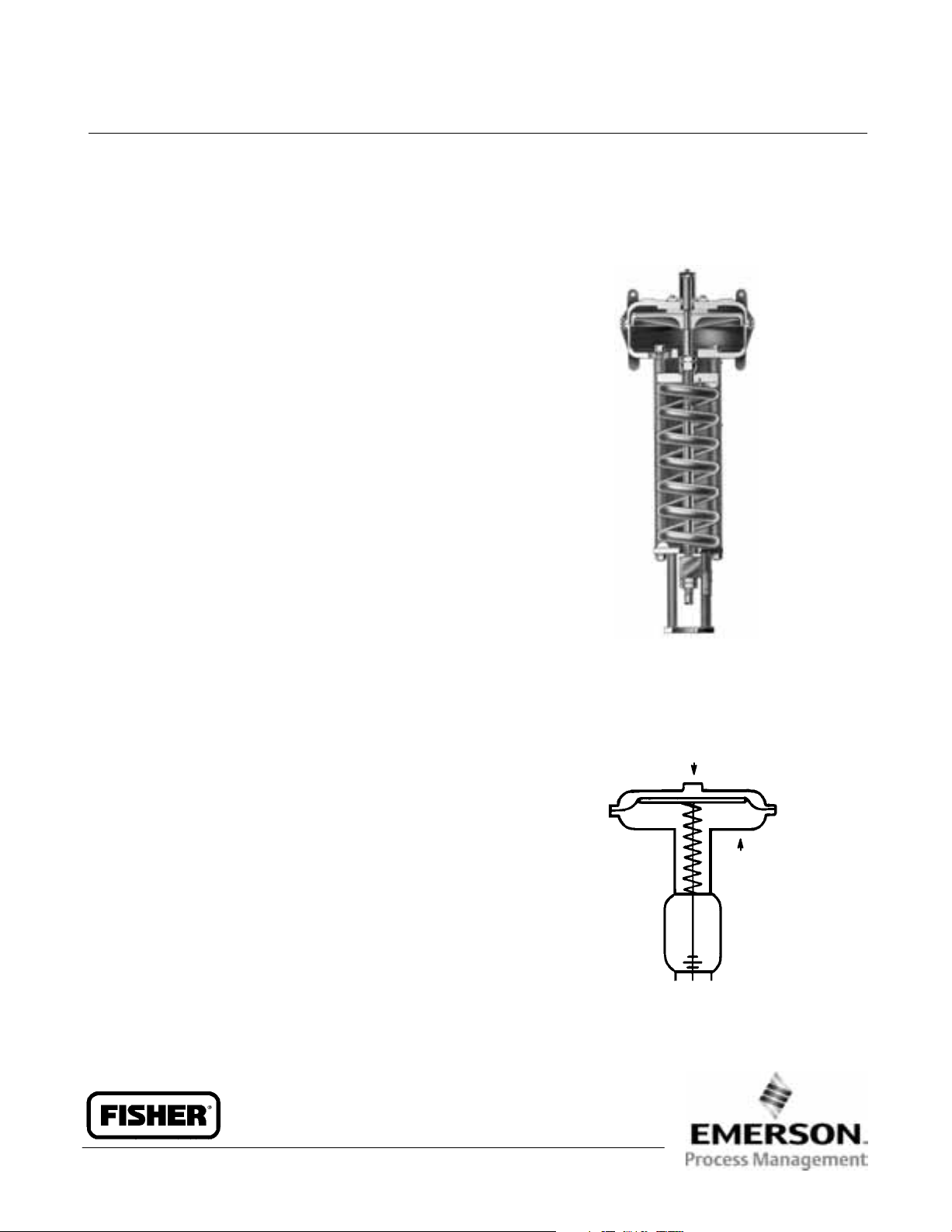

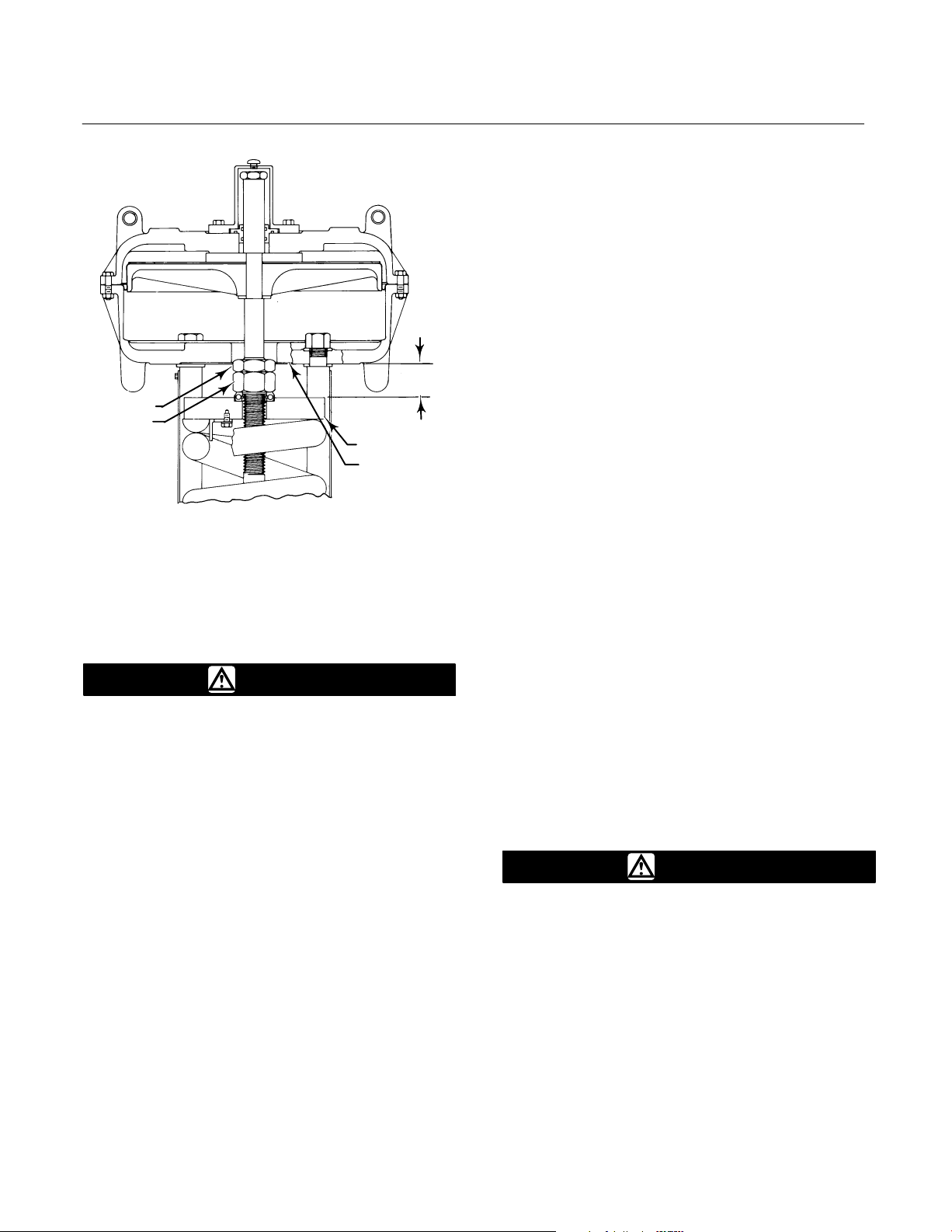

Figure 1. Sectional view of Type 657 Size 100 Actuator

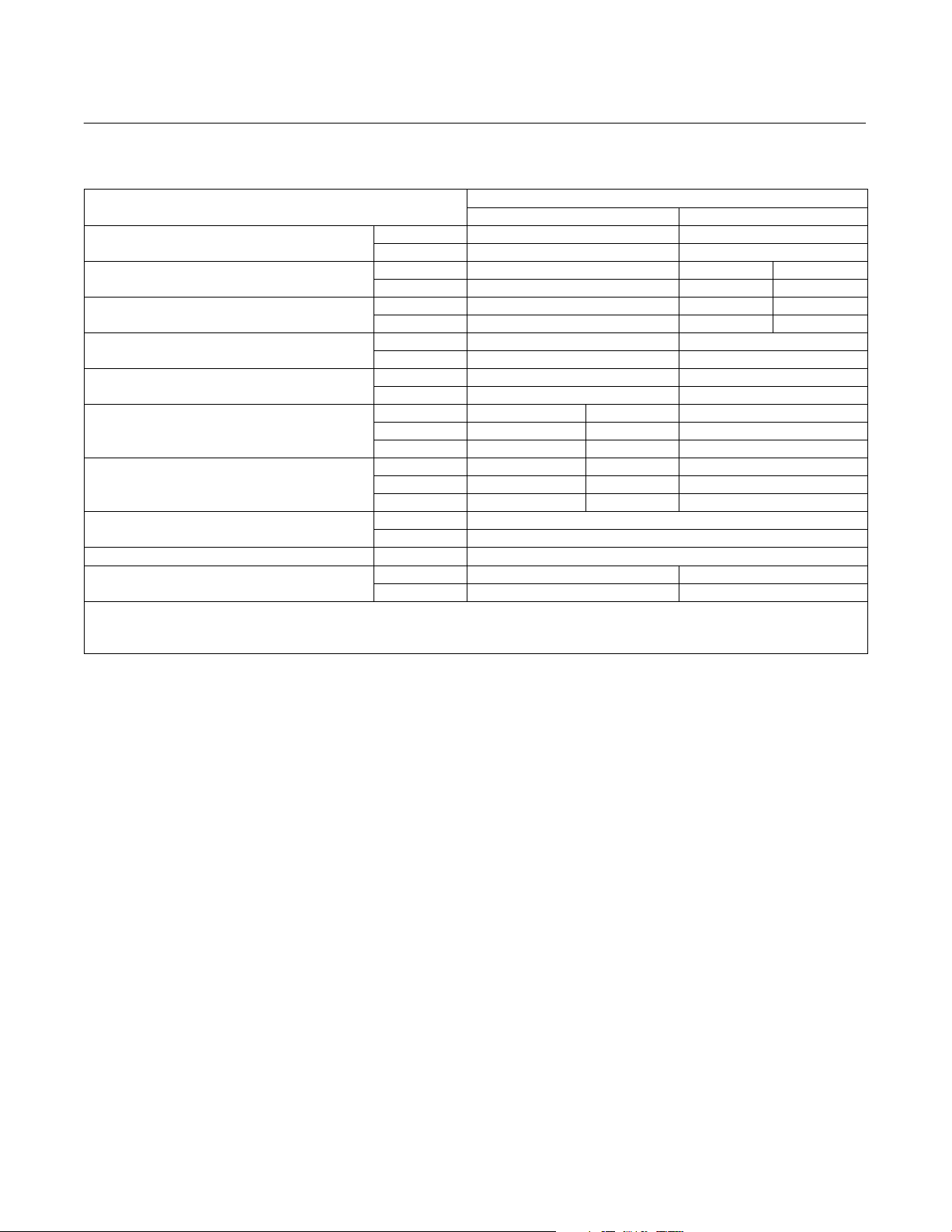

Figure 2. Schematic Representation of Type 657 Actuator

W0366-1 / IL

AF3833-A

A0792-2/IL

AIR PUSHES

STEM DOWN

SPRING

LIFTS

www.Fisher.com

D100307X012

Instruction Manual

Form 1909

657 Size 80 and 100 Actuators

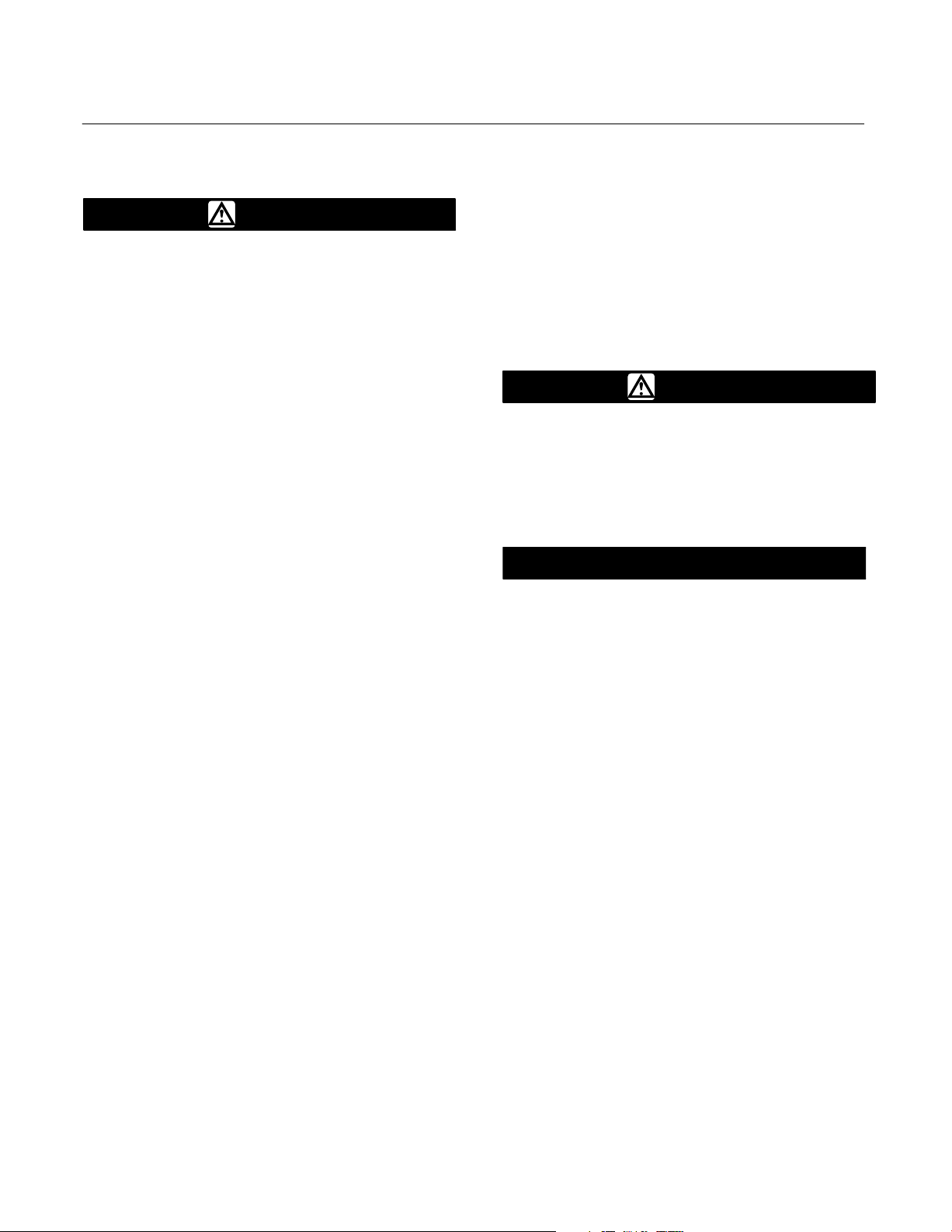

Table 1. Specifications

SPECIFICATIONS

2

Nominal Effective Diaphragm Area

Yoke Boss Diameters

Acceptable Valve Stem Diameters

Maximum Allowable Output Thrust

Maximum Travel

Maximum Casing Pressure for Actuator

(3)

Sizing

Maximum Diaphragm Casing Pressure

Material Temperature Capabilities

Pressure Connections 1/4 inch NPT female

Approximate Weights Without Handwheel

1. Heavy actuator-to-bonnet bolting.

2. 88,075 N (19,800 lb) for steel construction.

3. Maximum diaphragm casing pressure must not be exceeded and must not produce a force on the actuator stem greater than the maximum allowable actuator output thrust or the

maximum allowable valve stem force. (If you have any questions on allowable valve stem force, contact your Emerson Process Management sales office.)

4. This maximum casing pressure is not to be used for normal operating pressure. Its purpose is to allow for typical regulator supply settings and/or relief valve tolerances.

(3)(4)

cm

2

inch

mm 127 127 178

inch 5 5H

mm 25.4 or 31.8 31.8 50.8

inch 1 or 1-1/4 1-1/4 2

N 62,942 200,170

lb 14,150

mm 76 102

inch 3 4

Cast Iron Steel

bar 3.4 4.9 6.9

psig 50 70 100

Cast Iron Steel

bar 4.1 5.5 7.9

psig 60 80 11 5

_C

_F

kg 234 346

lb 515 762

80 100

1761 2902

273 450

ACTUATOR SIZE

(1)

(2)

−40 to 82

−40 to 180

August 2006

45,000

7

Introduction

Scope of Manual

This instruction manual provides information on

installation, adjustment, maintenance, and parts

ordering for the Type 657 actuator in sizes 80 and

100. Refer to separate instruction manuals for

information about other equipment and accessories

used with these actuators.

No person may install, operate, or maintain Type

657 actuators without first D being fully trained and

qualified in valve, actuator, and accessory

installation, operation, and maintenance, and D

carefully reading and understanding the contents of

this manual. If you have any questions about these

instructions, contact your Emerson Process

Management sales office before proceeding.

2

Description

The Type 657 actuator (figure 1) is a direct-acting,

spring-opposed diaphragm actuator used for

automatic operation of control valves. The actuator

positions the valve plug in response to varying

pneumatic loading pressure on the diaphragm.

Figure 2 shows the operation of these actuators.

A Type 657 actuator can be furnished with either a

top-mounted or side-mounted (size 80 only)

handwheel assembly. A top-mounted handwheel

assembly is normally used as an adjustable-up

travel stop. The size 100 top-mounted handwheel

may be used as an auxiliary manual actuator. A

side-mounted handwheel assembly is normally used

as an auxiliary manual actuator.

Specifications

Refer to table 1 for specifications of the Type 657

actuator. See the actuator nameplate for information

about a specific actuator.

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

Installation

WARNING

To avoid personal injury or parts

damage, do not exceed the Maximum

Diaphragm Casing Pressure listed in

table 1. The Maximum Diaphragm

Casing Pressure must not produce a

force on the actuator stem greater than

the maximum allowable actuator

output thrust or the maximum

allowable stem load.

Always wear protective gloves,

clothing, and eyewear when

performing any installation operations

to avoid personal injury.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

When an actuator and valve body are shipped

together, the actuator is normally mounted on the

valve. Follow the valve body instructions when

installing the control valve in the pipeline. If the

actuator is shipped separately or if it is necessary to

mount the actuator on the valve, perform the

Actuator Mounting procedures as described below.

For information on mounting valve positioners, refer

to the appropriate valve positioner instruction

manual.

Actuator Mounting

1. To permit adjustment of the actuator spring, the

size 100 actuator must be installed in a vertical

position above the valve body. Mount the actuator

on the valve bonnet. Insert the cap screws, and

tighten the hex nuts, securing the actuator to the

bonnet.

2. Screw valve stem locknuts (key 16, figure 4) all

the way onto valve stem thread.

3. Connect an air supply to the diaphragm casing.

4. For push-down-to-close valves, be sure the valve

plug is on its seat. Apply pressure to ensure that the

actuator stem is fully extended. Reduce actuator

loading pressure to retract the stem approximately

3.2 mm (1/8-inch).

5. For push-down-to-open valves, move valve plug

to closed position. On large body sizes, this may

require the use of a pry bar inserted through the

body line opening. If the body is installed in a

pipeline, the bottom flange (if one is used) can be

removed and the valve plug pushed to the seat from

the bottom opening. Pressure the actuator to move

the stem out 3.2 mm (1/8-inch).

WARNING

To avoid personal injury due to the

sudden uncontrolled movement of

parts, do not loosen the stem

connector cap screws when the stem

connector has spring or loading

pressure force applied to it.

CAUTION

Incomplete engagement of both valve

stem and actuator stem in the stem

connector can result in stripped

threads or improper operation. Be sure

that the length of each stem clamped

in the stem connector is equal to or

greater than the diameter of that stem.

6. Clamp the actuator and valve plug stems

between the two stem connector halves (key 26,

figure 4). Insert and tighten the stem connector cap

screws.

7. Thread the stem locknuts against the stem

connector.

8. Align the travel indicator scale (key 18, figures 4

and 5) to show valve position.

Loading Connection

1. Connect the loading pressure piping to the

connection in the top of the diaphragm casing.

2. Remove the 1/4-inch bushing (key 33, figure 4

and key 120, figure 5) to increase connection size, if

necessary. The connection can be made with either

piping or tubing.

3. Keep the length of tubing or piping as short as

possible to avoid transmission lag in the control

signal. If an accessory (such as a volume booster or

valve positioner) is used, be sure that the accessory

3

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

is properly connected to the actuator. Refer to the

positioner instruction manual as necessary.

4. Cycle the actuator several times to check that the

valve stem travel is correct and that the travel occurs

when the correct pressure range is applied to the

diaphragm.

5. If valve stem travel is incorrect, refer to the Travel

procedure in the Adjustments section.

6. If the pressure range is incorrect, refer to the

Spring procedure in the Adjustments section.

Adjustments

Travel

Make travel adjustments when the motion observed

during actuator travel is different from the travel

stamped on the actuator nameplate. If the Actuator

Mounting procedure was followed correctly, this

adjustment should not be necessary.

When adjusting travel of a reverse-acting

(push-down-to-open) valve, apply a slight pressure

on the actuator diaphragm. This moves the valve

plug off the seat, reducing the chance of damaging

the valve plug or seat during adjustments.

1. Back the stem locknuts away from the stem

connector, and slightly loosen the stem connector

cap screws.

Spring

Make spring adjustments when the loading pressure

range applied to achieve specified travel is not equal

to the pressure range stamped on the actuator

nameplate. Refer to the Bench Set pressure range

on the nameplate when the valve contains no

pressure and the packing is loosely inserted in the

bonnet. Refer to the Max. Allow. Supply on the

nameplate when the valve is controlling the specified

pressure drop and the packing is tightened to stop

leaks around the stem.

Monitor loading pressure carefully when making

adjustments. Do not exceed the pressure

specifications of either the loading regulator or the

actuator casings.

Each actuator spring has a fixed pressure span.

Changing the spring compression shifts the span up

or down to make valve travel coincide with the

loading pressure range.

Size 80

Remove cover band (key 60, figure 4), insert a rod of

approximately 12.7 mm (1/2-inch) diameter into a

hole in the adjusting screw (key 12, figure 4), and

rotate the adjusting screw with the rod. Rotating the

screw from left to right will increase the loading

pressure required to start actuator stem travel;

opposite rotation will decrease the pressure required

to start travel.

Size 100

CAUTION

Do not use wrenches or other tools

directly on the valve stem. Damage to

the stem surface and subsequent

damage to the valve packing may

result.

2. Tighten the locknuts together, using a wrench,

then screw the valve stem either into the stem

connector to lengthen travel or out of the stem

connector to shorten travel.

3. Cycle the actuator to check the travel. If actual

travel is not equal to the specified travel, adjust and

check travel until correct. Tighten the stem

connector cap screws when correct travel is

obtained.

4. Raise the travel indicator disk by threading the

stem locknuts against the stem connector.

4

CAUTION

The actuator must be in the vertical

position when adjusting spring to

avoid damage to thrust bearing (key

35, figure 5) and to properly position

spacers required for adjustment.

Remove the shroud plate (key 107, figure 5), and

loosen the jam nut (key 115, figure 5).

For small spring forces, adjustments can be made

by rotating the adjusting nut (key 114, figure 5).

Clockwise rotation (when viewed from diaphragm

casings) of the adjusting nut will increase the loading

pressure required to start actuator stem travel, and

counterclockwise rotation will decrease the pressure

required to start travel. Tighten the jam nut when

adjustment is complete.

Instruction Manual

Form 1909

August 2006

B

JAM NUT

ADJUSTING

NUT

A0950-1 / IL

Figure 3. Dimension B for Spring Adjustment

SPRING SEAT

LOWER

DIAPHRAGM

CASING

For high spring forces, it is necessary to use spacers

between the lower diaphragm casing and the spring

seat to isolate spring force from the adjusting nut.

WARNING

To avoid personal injury from the

compressed actuator spring snapping

back to its original length, make and

use the spacers by following the

instructions in the steps below.

657 Size 80 and 100 Actuators

b. If it is desired to increase spring compression,

make the spacers approximately 4.8 mm

(3/16-inch) shorter than either dimension B plus

the amount of adjustment required or dimension

B plus valve travel, whichever is less.

3. Whenever the total amount of adjustment

required is greater than valve travel, the adjustment

must be made in two or more steps, and the amount

of adjustment taken in each step must be less than

valve travel.

4. Pressure the actuator to attain full travel.

Cautiously insert the spacers at equal intervals

around the spring seat (key 11, figure 5). The

spacers must be seated squarely when in use or

they may slip out of position. Keeping hands and

tools away from the spring and spring seat, slowly

decrease loading pressure until the spring force

holds the spacers firmly between the spring seat and

lower diaphragm casing (key 5, figure 5).

5. Loosen the jam nut. The adjusting nut can now

be rotated clockwise (when viewed from the

diaphragm casings) to increase the loading pressure

required to start actuator stem travel or

counterclockwise to decrease the pressure required

to start travel.

6. Pressure the actuator to move the spring seat

away from the spacers, and carefully remove the

spacers.

7. If the total adjustment required was greater than

valve travel, repeat the procedure. It will be

necessary to make new spacers using the new

dimension B and the remaining adjustment required

or valve travel, whichever is less. Tighten the jam

nut when adjustment is complete.

To avoid personal injury, keep hands

and tools away from the spring and

spring seat as instructed in the

following procedure.

1. It is recommended that three spacers be made

of 3-inch schedule 80 pipe cut to the appropriate

length specified in step 2. If other than the

recommended material is to be used, be certain that

the spacers are capable of withstanding the spring

force involved. The spacers must be of equal length

with ends cut squarely.

2. Measure dimension B as shown in figure 3. Cut

length of spacers as follows:

a. If it is desired to decrease spring compression,

make the spacers approximately 4.8 mm

(3/16-inch) longer than dimension B.

Maintenance

WARNING

Avoid personal injury or property

damage from sudden release of

process pressure or bursting of parts.

Before performing any maintenance

operations:

D Always wear protective gloves,

clothing, and eyewear when

performing any maintenance

operations to avoid personal injury.

D Disconnect any operating lines

providing air pressure, electric power,

or a control signal to the actuator. Be

5

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

sure the actuator cannot suddenly

open or close the valve.

D Use bypass valves or completely

shut off the process to isolate the

valve from process pressure. Relieve

process pressure from both sides of

the valve. Drain the process media

from both sides of the valve.

D Vent the power actuator loading

pressure and relieve any actuator

spring precompression.

D Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D The valve packing box may

contain process fluids that are

pressurized, even when the valve has

been removed from the pipeline.

Process fluids may spray out under

pressure when removing the packing

hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

The maintenance instructions are divided into four

sections: actuator (sizes 80 and 100); side-mounted

handwheel assembly (manual operator); hydraulic

snubber; and top-mounted handwheel assembly

(adjustable-up travel stop).

Size 80 Disassembly

1. Bypass the control valve. Reduce the loading

pressure to atmospheric, and remove the tubing or

piping from the top of the diaphragm casing (key 1).

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 2, below), and

carefully remove casing cap screws

(key 22) (step 4, below).

2. Remove cover band (key 60). Insert a rod of

approximately 12.7 mm (1/2-inch) diameter into a

hole in the adjusting screw (key 12), and rotate the

adjusting screw from right to left until spring

compression is relieved. If the actuator has a

handwheel, rotate it counterclockwise, relieving all

spring compression.

3. If necessary, the entire actuator may be removed

from the valve body by unscrewing two cap screws

from stem connector (key 26) and removing

actuator-to-bonnet bolting.

4. Unscrew diaphragm casing cap screws and nuts

(keys 22 and 23), and lift off upper diaphragm casing

(key 1).

5. Remove the molded diaphragm (key 2).

6. For actuators without snubber, remove

diaphragm plate and stem (keys 4 and 10) as an

assembly. This assembly can be broken down

further, if necessary, by removing the cap screw

(key 3).

7. For actuators with snubber (see figure 7),

unscrew cap screw (key 3), and remove diaphragm

plate (key 4). Remove stem connector (key 26).

Unscrew cap screws (key 85), and remove cylinder

assembly (key 74) and attached stem and upper

seat (keys 10 and 90) from actuator.

Actuator

This procedure describes how the actuator can be

completely disassembled and assembled. When

inspection or repairs are required, disassemble only

those parts necessary to accomplish the job; then,

start the assembly at the appropriate step.

Key numbers refer to figure 4 for size 80 actuators

and figure 5 for size 100 actuators.

6

To disassemble snubber:

a. Unscrew stem from piston/piston rod

assembly (key 27).

b. Remove retaining rings, cylinder heads, and

piston/piston rod assembly (keys 76, 75, and 27).

Replace packing and O-rings (keys 103, 104, 77

and 105) as required.

8. Remove actuator spring, upper sleeve, and

spring seat (keys 6, 34 and 11).

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

9. Unscrew cap screws and nuts (keys 62 and 63),

and remove spring case (key 29). Cap screws

(key 62) on units with side-mounted handwheel do

not use hex nuts (key 63).

10. For actuators without side-mounted handwheel,

remove adjusting flange (key 36) and attached thrust

bearing and adjusting screw (keys 35 and 12).

11. For actuators with side-mounted handwheel

(see figure 7), unscrew cap screws (key 64), and

remove adjusting flange (key 36) and attached thrust

bearing and adjusting screw (keys 35 and 12). Do

not lose the key (key 47).

Size 80 Assembly

1. Coat the threads of the adjusting flange (key 36)

with anti-seize lubricant (key 244). Replace the

adjusting flange, adjusting screw, and thrust bearing

(keys 36, 12, and 35). Pack bearing with lithium

grease lubricant (key 241).

For actuators with side-mounted handwheel, install

the key (key 47) on the adjusting flange (key 36).

Coat the adjusting flange threads with anti-seize

lubricant. Install the adjusting flange so that the key

engages the slot in the lower sleeve. Secure

adjusting flange with cap screws (key 64). Adjust set

screws (key 40, figure 7) to eliminate free play in

handwheel bearings.

the upper sleeve, spring case adaptor, and spring

case (keys 34, 72, and 29). Secure with cap screws

(key 85).

5. Place the diaphragm (key 2) with pattern side

facing away from the diaphragm plate (key 4). Align

the holes in the diaphragm and the lower diaphragm

casing (key 5).

6. Position the upper diaphragm casing (key 1) on

the diaphragm (key 2), and align the holes.

Note

When you replace actuator

diaphragms in the field, take care to

ensure the diaphragm casing bolts are

tightened to the proper load to prevent

leakage, but not crush the material.

Perform the following tightening

sequence with a manual torque

wrench for size 80 and 100 actuators.

Note

Over-tightening the set screws will

make handwheel operation difficult.

2. Mount the spring case (key 29) to the yoke (key

9) using cap screws and hex nuts (keys 62 and 63).

3. Position the lower spring seat (key 11), and slide

the actuator spring (key 6) squarely onto the spring

seat.

4. If the diaphragm plate and actuator stem (keys 4

and 10) were separated, fasten them together using

the cap screw (key 3) and tighten to a torque of 544

NSm (400 lbfSft).

For actuators without a hydraulic snubber, slide

upper sleeve (key 34) onto the actuator stem, and

then slide upper sleeve, actuator stem and

diaphragm plate into the spring case (key 29) so that

the spring (key 6) fits squarely between the

diaphragm plate and the spring seat (key 11).

For actuators with a snubber, thread the actuator

stem and upper spring seat (keys 10 and 90) into the

piston/piston rod assembly (key 27). Install the

snubber assembly and attached actuator stem into

CAUTION

Over-tightening the diaphragm casing

cap screws and nuts can damage the

diaphragm. Do not exceed the

following maximum torque values for

the appropriate diaphragm material:

EPDM/Meta-Aramid: 95 NSm (70 lbfSft)

Nitrile, Silicone, FKM

(fluorocarbon)/Meta-Aramid: 68 NSm

(50 lbfSft)

Note

Do not use lubricant on these bolts

and nuts. Fasteners must be clean and

dry.

7

Instruction Manual

657 Size 80 and 100 Actuators

Table 2. Maximum Torque Values

DIAPHRAGM MATERIAL

EPDM/Meta-Aramid 41 (30) 82, +/−13 (60, +/−10)

Nitrile, Silicone, FKM/Meta-Aramid 34 (25) 68 (50)

INITIAL TORQUE

NSm (lbfSft)

FINAL TORQUE

NSm (lbfSft)

Form 1909

August 2006

7. Insert the cap screws (key 22) into the diaphragm

casing, and tighten the hex nuts (key 23) in the

following manner. The first four hex nuts tightened

should be diametrically opposed and 90 degrees

apart. Tighten these four hex nuts to the initial torque

value found in table 2 for the diaphragm material

being used.

8. Tighten the remaining hex nuts in a clockwise,

criss-cross pattern to the initial torque value found in

table 2 for the diaphragm material being used.

9. Repeat this procedure by tightening four hex

nuts, diametrically opposed and 90 degrees apart, to

the final torque value that is specified in table 2 for

the diaphragm material being used.

10. Tighten the remaining hex nuts in a clockwise,

criss-cross pattern to the final torque value that is

specified in table 2 for the diaphragm material being

used.

11. After the last hex nut is tightened complete

another tightening sequence, this time in a circular

pattern around the bolt circle to the final torque value

that is specified in table 2 for the diaphragm material

being used.

12. Once completed, no more tightening is

recommended.

13. Mount the actuator on the valve in accordance

with the procedures in the Installation section.

Size 100 Disassembly

Key numbers used in the following procedure are

shown in figure 5 except when indicated.

Note

Two construction variations of the size

100 are based on spring length. Group

1 springs have a free length of 845 mm

(33-1/4 inches), and group 2 springs

have a free length of 419 mm (16-1/2

inches).

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 1, below), and

carefully remove casing cap screws (key

22) (step 7, below).

1. Remove shroud plate (key 107), loosen jam nut

(key 115), and rotate adjusting nut (key 114) until

spring compression is relieved.

Note

To relieve spring compression when

high spring forces exist, refer to the

Adjusting Actuator Spring section, and

follow the instructions given for size

100 actuators with high spring forces.

2. Remove the pressure tubing or piping from the

top of the diaphragm casing.

3. For actuators with top-mounted handwheel,

rotate handwheel (key 51, figure 8) counterclockwise

as far as it will go, unscrew cap screws (key 109,

figure 5), and remove handwheel and gear case

assembly (key 65, figure 8).

4. For actuators without top-mounted handwheel,

unscrew cap screws (key 109), and remove

diaphragm casing cover (key 123).

5. If necessary, remove the actuator from the valve

body by separating the stem connector (key 26) and

removing the actuator-to-bonnet bolting. Separate

the stem connector by loosening the stem locknuts

(key 16) and unscrewing the four cap screws.

6. Unscrew and remove actuator stem extension

(key 116).

7. Unscrew cap screws (key 22), and remove upper

diaphragm casing (key 1).

8. Remove backup plate, diaphragm retainer,

diaphragm, diaphragm plate, and washer (keys 13,

110, 2, 4, and 117).

9. Unscrew the nuts that attach lower diaphragm

casing (key 5) to actuator tie rods (key 21).

10. Remove lower diaphragm casing from tie rods

and remove hex jam nut, adjusting nut thrust bearing

8

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

(used with group 1 springs only), and spring seat

(keys 115, 114, 35, and 11).

11. Remove seal bushing (key 111) and diaphragm

casing cover O-rings (keys 112 and 113) from upper

diaphragm casing (key 123). Replace with new parts

if necessary. Apply lithium grease lubricant to the

O-rings.

12. Remove actuator spring (key 6).

Size 100 Assembly

Note

Units using a group 2 spring require

one spring seat (key 11) on each end

of the spring (key 6); units using a

group 1 spring require only one spring

seat on the diaphragm end of the

spring as shown in figure 5.

1. Place the spring and spring seats (keys 6 and 11)

inside the spring case.

2. For actuators using a group 1 spring, pack the

thrust bearing (key 35) with lithium grease lubricant

(key 241). Place bearing on the spring seat.

5. Install washer, diaphragm plate, diaphragm,

diaphragm retainer, and backup plate

(keys 117, 4, 2, 110 and 13).

6. Apply lithium grease lubricant (key 241) to the

thread on the diaphragm end of the actuator stem

(key 10).

7. Position the upper diaphragm casing (key 1) on

the diaphragm (key 2), and align the holes.

Note

If backup plate (key 13) interferes with

installation of upper casing, rotate

adjusting nut (key 114) to move the

plate.

Note

When you replace actuator

diaphragms in the field, take care to

ensure the diaphragm casing bolts are

tightened to the proper load to prevent

leakage, but not crush the material.

Perform the following tightening

sequence with a manual torque

wrench for size 80 and 100 actuators.

3. Screw the hex jam nut and adjusting nut (keys

115 and 114) onto the actuator stem.

4. Install the lower diaphragm casing (key 5) on the

actuator tie rods (key 21). Secure with hex nuts.

Note

Before installing diaphragm plate (key

4), rotate adjusting nut (key 114) until

the top of the actuator stem is 264 mm

(10-3/8 inches) above the inside

surface of the lower casing (key 5).

When installing diaphragm (key 2), be

certain that the rubber side of the

diaphragm faces away from the spring.

CAUTION

To avoid product damage, smooth the

edge of the diaphragm to avoid

wrinkling, and be careful that the

diaphragm fold does not get pinched

when the upper casing (key 1) is

installed.

CAUTION

Over-tightening the diaphragm casing

cap screws and nuts can damage the

diaphragm. Do not exceed 68 NSm (50

lbfSft) torque.

Note

Do not use lubricant on these bolts

and nuts. Fasteners must be clean and

dry.

8. Insert the cap screws (key 22), and tighten the

hex nuts (key 23) in the following manner. The first

four hex nuts tightened should be diametrically

opposed and 90 degrees apart. Tighten these four

hex nuts to 34 NSm (25 lbfSft).

9. Tighten the remaining hex nuts in a clockwise,

criss-cross pattern to 34 NSm (25 lbfSft).

10. Repeat this procedure by tightening four hex

nuts, diametrically opposed and 90 degrees apart, to

a torque of 68 NSm (50 lbfSft).

11. Tighten the remaining hex nuts in a clockwise,

criss-cross pattern to 68 NSm (50 lbfSft).

9

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

12. After the last hex nut is tightened to 68 NSm (50

lbfSft), all of the hex nuts should be tightened again

to 68 NSm (50 lbfSft) in a circular pattern around the

bolt circle.

13. Once completed, no more tightening is

recommended.

14. Install the actuator stem extension (key 116),

diaphragm casing cover O-rings (keys 112 and 113),

and seal bushing (key 111). Install the gear case

cover (key 123) or the handwheel assembly (see

figure 8).

15. Mount the actuator on the valve, and secure

with the actuator-to-bonnet bolting. Refer to the

Installation section to connect actuator stem to valve

plug stem.

Size 80 Side-Mounted Handwheel

The side-mounted handwheel assembly (figure 7) is

normally used as a manual operator. The handwheel

can be mounted in either of two positions so that,

regardless of valve plug action, counterclockwise

rotation always opens the valve. The assembly is a

continuously connected type with an indicator to

show neutral position. By rotating handwheel away

from neutral, the handwheel can be used to limit

travel in either direction but not both directions at the

same time.

A grease fitting is provided on the gear box for

periodic gear lubrication with a general-purpose

grease.

Instructions are given below for complete

disassembly and assembly. Perform the

disassembly only as far as necessary to accomplish

the required maintenance; then, begin the assembly

at the appropriate step.

Key numbers refer to figure 7.

Disassembly

1. Complete steps 1 through 9 of the disassembly

portion of the size 80 actuator section.

2. Unscrew cap screws (key 64), and remove

adjusting flange (key 36). Do not lose the key

(key 47).

3. Unscrew the two screws (key 28), and remove

travel stop indicator (key 58) from lower sleeve

(key 46).

4. Turn handwheel (key 51) to raise lower sleeve.

Continue turning handwheel until lower sleeve is free

of worm gear (key 44). Lift out lower sleeve, bearing

and gear retainer, thrust bearings, and worm gear

(keys 46, 66, 67, and 44).

5. The worm shaft (key 45) and associated parts

can be removed in order to replace or lubricate

them. First, remove the handwheel cap (key 54) and

the handwheel (key 51). Do not lose the small ball or

spring (keys 55 and 56).

6. Loosen the two set screws (key 41), and unscrew

the two worm retainers (keys 48 and 49). The ball

bearings (key 50) will come out with the retainers.

Remove the worm shaft (key 45).

Assembly

1. Pack the ball bearings (key 50) with lithium

grease lubricant, and insert one ball bearing in the

back worm retainer (key 49) as shown in figure 7

(section C-C).

2. Thread the back worm retainer and ball bearing

(keys 49 and 50) into the gear case. Align the slot in

the worm retainer with the set screw hole in the gear

case, insert the set screw (key 41), and tighten it.

3. Coat the worm shaft (key 45) threads with

anti-seize lubricant (key 244), and slide the shaft into

the gear case so that the end of the shaft fits snugly

in the back worm retainer.

4. Insert the bearing in the front worm retainer

(key 48), and thread the retainer and ball bearing

into the gear case. Align the slot in the retainer with

the set screw hole in the gear case, insert the set

screw (key 41), and tighten it.

5. Put the spring and ball (keys 56 and 55) in the

handwheel (key 51). Slide the handwheel onto the

worm shaft (key 45). Thread the handwheel cap

(key 54) onto the worm shaft.

6. Pack the two thrust bearings (key 67) with lithium

grease lubricant. Install one thrust bearing; then,

install the worm gear (key 44) followed by the

second thrust bearing and the bearing and gear

retainer (key 66).

7. The lower sleeve (key 46) has two screw holes in

one end. Coat the sleeve threads with lithium grease

lubricant, slide the end of the lower sleeve with the

holes into the thrust bearing (key 67), turn the

handwheel, and feed the sleeve through the worm

gear. Continue turning the handwheel until the lower

sleeve protrudes from the gear case. Fasten the

travel stop indicator (key 58) to the sleeve with the

two machine screws (key 28).

8. Install the key (key 47) on the adjusting flange

(key 36). Coat the adjusting flange threads with

anti-seize lubricant (key 244). Install the adjusting

10

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

flange so that the key engages the slot in the lower

sleeve. Secure adjusting flange with cap screws

(key 64).

9. Adjust set screws (key 40) to eliminate free play

in the bearings.

Note

Over-tightening the set screws will

make handwheel operation difficult.

10. Install the adjusting screw and thrust bearings

(keys 12 and 35). Pack bearings with lithium grease

lubricant (key 241), and install as shown in figure 7.

11. Slide the spring case (key 29) into position, and

secure with cap screws (key 62).

12. Complete steps 3 through 8 of the size 80

actuator assembly section.

Size 80 Hydraulic Snubber

The size 80 Type 657 is available with a hydraulic

snubber, as shown in figure 7, to dampen vertical

instability of actuator stem movement. The snubber

is adjusted by rotating the adjusting screws (key 83,

figure 7) counterclockwise out of the reservoir (key

79, figure 7) to increase damping action and

clockwise to decrease damping action. The adjusting

screw on the right (the lower of the two adjusting

screws in section B-B of figure 7) regulates

downward damping action, and the screw on the left

regulates upward damping action.

Size 80 Top-Mounted Handwheel

(Adjustable Up Travel Stop)

CAUTION

If repeated or daily manual operation is

expected, and the actuator is equipped

with a casing-mounted travel stop or

top-mounted handwheel, the

diaphragm could be subject to

excessive wear.

The actuator should be equipped with

a side-mounted handwheel, which is

designed for more frequent use as a

manual operator.

A top-mounted handwheel assembly is normally

used as an adjustable-up travel stop to limit full

retraction of the actuator stem. Turning the

handwheel clockwise turns the handwheel stem

(key 133, figure 6) into the diaphragm casing and

forces the pressure block assembly (key 179,

figure 6) against the diaphragm and diaphragm

plate. Instructions are given below for complete

disassembly and assembly. Perform the

disassembly only as far as necessary to accomplish

the required maintenance; then, begin the assembly

at the appropriate step.

Key numbers refer to figure 4 for actuator parts and

figure 6 for handwheel parts.

Disassembly

1. Bypass the control valve. Reduce the loading

pressure to atmospheric, and remove the tubing or

piping from the diaphragm casing (key 1).

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 2, below), and

carefully remove casing cap screws

(key 141) (step 3, below).

2. Remove cover band (key 60). Insert a rod of

approximately 12.7 mm (1/2-inch) diameter into a

hole in the adjusting screw (key 12), and rotate the

adjusting screw from right to left until spring

compression is relieved. Rotate handwheel to be

sure it is not compressing actuator spring.

3. Unscrew cap screws (key 141), and remove

handwheel assembly.

4. Remove hex nut (key 54), and lift off the

handwheel.

5. Unscrew support screws (key 182), and remove

pressure block, stem, stem collar, and thrust bearing

(keys 179, 133, 183, and 175).

6. Unscrew body nut (key 186), and remove gland

(key 180). If necessary, remove and replace packing

rings (key 181).

Assembly

1. Install new packing rings and gland (keys 181

and 180), and thread the body nut (key 186) onto the

body.

2. Lubricate the thrust bearing and stem (keys 175

and 133), with lithium grease lubricant (key 241).

Slide stem, stem collar, thrust bearing, and pressure

11

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

block (keys 133, 183, 175, and 179) into the body as

shown in figure 6 and install support screws

(key 182).

3. Install handwheel and hex nut (keys 51 and 54).

4. Install a new handwheel gasket (key 185).

5. Mount the handwheel assembly on the

diaphragm casing, and secure with cap screws

(key 141).

6. Reconnect pressure tubing or piping to actuator

casing.

Size 100 Top-Mounted Handwheel

(Adjustable Up Travel Stop)

A top-mounted handwheel assembly is normally

used as an adjustable-up travel stop to limit full

retraction of the actuator stem. Clockwise rotation of

the handwheel (key 51) moves the actuator stem

(key 10) downward, compressing the spring (key 6).

Spring action returns the stem as the handwheel is

turned counterclockwise. Instructions are given

below for complete disassembly and assembly.

Perform the disassembly only as far as necessary to

accomplish the required maintenance; then, begin

the assembly at the appropriate step.

Key numbers refer to figure 5 for actuator parts and

figure 8 for handwheel parts.

Disassembly

1. Bypass the control valve. Reduce the loading

pressure to atmospheric (refer to the Maintenance

section), and remove the tubing or piping from the

diaphragm casing.

WARNING

To avoid personal injury from the

precompressed spring force thrusting

the upper diaphragm casing (key 1)

away from the actuator, relieve spring

compression (step 2, below), and

carefully remove casing cap screws

(key 124) (step 3, below).

4. Loosen the set screws (key 41) in the front and

back worm retainers (keys 48 and 49) and

handwheel (key 51).

5. Remove retaining ring (key 118), and remove

handwheel.

6. Remove front and back worm retainers (keys 48

and 49).

7. Remove worm shaft (key 45).

8. Pull the power screw assembly (key 122). The

bearing and gear retainer, thrust bearing, and worm

gear (keys 66, 67 and 44) will come out with the

power screw.

Assembly

1. Pack the ball bearings (key 50) with lithium

grease lubricant (key 241), and insert one ball

bearing into the back worm retainer (key 49).

2. Thread the back worm retainer and ball bearing

into the gear case. Align the slot in the worm retainer

with the set screw hole in the gear case, insert set

screw (key 41), and tighten.

3. Coat the worm shaft (key 45) threads with lithium

grease lubricant, and slide the shaft into the gear

case so that the end of the shaft fits snugly in the

back worm retainer.

4. Insert the bearing into the front worm retainer

(key 48), and thread the retainer and ball bearing

into the gear case. Align the slot in the retainer with

the hole in the gear case, insert the set screw

(key 41), and tighten.

5. Slide the handwheel onto the worm shaft

(key 45), and install retaining ring (key 118).

6. Pack the two thrust bearings (key 67) with lithium

grease lubricant. Install one thrust bearing, then the

worm gear (key 44), followed by the second thrust

bearing and the bearing and gear retainer (key 66).

7. Coat the power screw threads (key 122) with

lithium grease lubricant. Slide the power screw into

the thrust bearing (key 67), turn the handwheel, and

feed the sleeve through the worm gear.

8. Adjust set screws (key 40) to eliminate free play

in the bearings.

Note

2. Rotate handwheel counterclockwise, relieving all

spring compression.

3. Unscrew cap screws (key 124), and remove gear

case cover (key 123).

12

Over-tightening the set screws will

make handwheel operation difficult.

9. Install gear case cover (key 123), and tighten cap

screws (key 124).

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

Parts Ordering

Each actuator has a serial number stamped on the

nameplate. Always refer to this number when

corresponding with your Emerson Process

Management sales office regarding replacement

parts or technical information. Also, always refer to

the 11-character part number of each needed part

as found in the following parts list.

WARNING

Use only genuine Fisher replacement

parts. Components that are not

supplied by Emerson Process

Management should not, under any

circumstances, be used in any Fisher

valve, because they will void your

warranty, might adversely affect the

performance of the valve, and might

jeopardize worker and workplace

safety.

Note

Neither Emerson, Emerson Process

Management, Fisher, nor any of their

affiliated entities assumes

responsibility for the selection, use

and maintenance of any product.

Responsibility for the selection, use,

and maintenance of any product

remains with the purchaser and

end-user.

Parts List

Note

Part numbers are shown for recommended spares

only. For part numbers not shown, contact your

Emerson Process Management sales office.

Type 657 Sizes 80 & 100

Key Description Part Number

1 Upper Diaphragm Casing

2* Diaphragm

Size 80

Nitrile 1R6375X0072

Silicone 18B2713X132

Size 100, nitrile & TPES (thermoplastic polyester)

20A2551X012

3 Cap Screw

Key Description Part Number

4 Diaphragm Plate

5 Lower Diaphragm Casing

5 Lower Diaphragm Casing, Yoke, &

Tie Rod Ass’y

6 Spring See tables

8 Cap Screw

9 Yoke

10 Actuator Stem

11 Spring Seat

12 Adjusting Screw

13 Backup Plate

14 Travel Indicator

16 Hex Jam Nut

17 Machine Screw

18 Travel Indicator Scale

19 Nameplate

20 Drive Screw

21 Actuator Tie Rod

22 Cap Screw

23 Hex Nut

26 Stem Connector Ass’y

28 Cap Screw

29 Spring Case

33 Pipe Bushing

34 Upper Sleeve

35 Thrust Bearing

36 Adjusting Flange

60 Cover Band Ass’y

62 Cap Screw

63 Hex Nut

88 Tie Rod Washer

89 Hex Nut

91 Spring Guide

92 Cap Screw

106 Washer

107 Shroud Plate

108 Self-tapping screw

109 Cap Screw

110 Diaphragm Retainer

111* Seal Bushing, brass

Size 100 20A2582X012

112* O-Ring, nitrile (2 req’d) Size 100 1H8627X0042

113* O-Ring, nitrile Size 100 1R834206992

114 Hex Nut

115 Hex Jam Nut

116 Actuator Stem Extension

117 Washer

118 Retaining Ring

120 Hex Bushing

121 Lifting Pin

123 Diaphragm Casing Cover

128 Vent Ass’y

241 Lithium grease (not furnished with actuator) --244 Anti-seize lubricant (not furnished with actuator) --245* O-Ring, nitrile Size 100 only 1C339006992

*Recommended spare parts

13

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

14

APPLY LUB

40A8771-B / DOC

Figure 4. Size 80 Type 657 Actuator

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

APPLY LUB

50A2621-F / DOC

Figure 5. Size 100 Type 657 Actuator

15

657 Size 80 and 100 Actuators

Key 6 Size 80 Actuator Spring, steel

COMPRESSION

335

1000

1650

2100

2600

3100

RATE

58.7

175.1

288.9

367.7

455.3

542.8

COMPRESSION

RATE

Lb/in N/mm Lb N

1775

2950

4500

6000

335

1000

1650

2100

2600

3100

310.8

516.5

787.9

1050.6

58.6

175.1

288.9

367.7

455.2

542.8

2480

5630

7900

10,600

10,600

13,800

SIZE

Lb/in N/mm Lb N

80

Key 6 Size 100 Actuator Spring

GROUP

1

33-1/4 Inch (844 mm)

Free Length

2

16-1/2 Inch (419 mm)

Free Length

MAXIMUM

LOAD

MAX LOAD

17,500

25,000

36,000

45,000

2480

5630

7900

10,600

10,600

13,800

11,031

25,042

35,139

47,148

47,148

61,382

77,840

111,200

160,128

200,160

11,031

25,042

35,139

47,148

47,148

61,382

Instruction Manual

PART

NUMBER

1J518227082

1H747727082

1H747527082

1H747327082

1H747627082

1H747027082

PART

NUMBER

10A2561X012

10A2562X012

10A2563X012

10A2564X012

1J518227082

1H747727082

1H747527082

1H747327082

1H747627082

1H747027082

Form 1909

August 2006

COLOR

CODE

White

Red

Lt. Blue

Yellow

Lt. Green

White

COLOR

CODE

None

None

None

None

Brown

Red

Blue

Yellow

Green

White

16

APPLY LUB

CV8009-E / DOC

Figure 6. Top-Mounted Handwheel for Size 80 Actuator

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

Key Description Part Number

Size 80 Side-Mtd Handwheel

7 Travel Stop

17 Machine Screw

28 Machine Screw

40 Set Screw

41 Set Screw

44 Worm Gear

45 Worm Shaft

46 Lower Sleeve

47 Key

48 Front Worm Retainer

49 Back Worm Retainer

50 Ball Bearing

51 Handwheel

52 Handgrip

53 Handgrip Bolt

54 Handwheel Cap

55 Ball

56 Spring

58 Travel Indicator

61 Grease Fitting

64 Cap Screw

65 Gear Case

66 Bearing & Gear Retainer

67 Thrust Bearing

68 Cap Screw

69 Indicator Scale

70 Stop Indicator Bracket

71 Machine Screw

243 Pliable sealant (not furnished with actuator) ---

Size 80 Top-Mtd Handwheel

(Adjustable Up Travel Stop)

51 Handwheel

54 Nut

133 Stem

141 Cap Screw

142 Handwheel Body

175 Thrust Bearing

179 Pressure Block

180 Gland

181* Packing Ring, TFE-graphite (2 req’d) 1D7496X0012

182 Support Screw

183 Stem Collar

184 Retaining Ring

185* Gasket, composition 1J789504022

186 Body Nut

241 Lithium grease (not furnished with actuator)

246 Spacer

247 Cotter Pin

Key Description Part Number

Size 100 Top-Mtd Handwheel

(Adjustable Up Travel Stop)

17 Machine Screw

40 Set Screw

41 Set Screw

44 Worm Gear

45 Worm Shaft

48 Front Worm Retainer

49 Back Worm Retainer

50 Ball Bearing

51 Handwheel

61 Grease Fitting

65 Gear Case

66 Bearing & Gear Retainer

67 Thrust Bearing

118 Retaining Ring

122 Power Screw Ass’y

123 Gear Case Cover

124 Cap Screw

125 Hex Jam Nut

126 Woodruff Key

127 Slot Cover

Size 80 Hydraulic Snubber

27 Piston/Piston Rod Ass’y

63 Hex Nut

72 Spring Case Adaptor

73 Cap Screw

74 Cylinder

75 Cylinder Head

76 Retaining Ring

77* O-Ring, nitrile (2 req’d) 1F449206992

78* Piston Ring, iron (2 req’d) 1C710321992

79 Reservoir

80* O-Ring, nitrile 1H624706992

81 Cap Screw

82* O-Ring, nitrile (2 req’d) 1D687506992

83 Valve Adj Screw

84 Jam Nut

85 Cap Screw

86 Pipe Plug

87 Pipe Plug

90 Upper Spring Seat

93 Hydraulic Fluid

94* O-Ring, nitrile (2 req’d) 1E591406992

95 Orifice

96 Bypass & Check Valve Plug

97 Spring

98 E-Ring

99 Bushing

100 Flange

101 Packing Sleeve

102 Machine Screw

103* Packing, nitrile (8 req’d) 1P540806992

104* Packing, CR (chloroprene) & cotton (4 req’d) 1P540906992

105* Packing Sleeve O-Ring, nitrile (2 req’d) 1P541206992

*Recommended spare parts

17

657 Size 80 and 100 Actuators

SECTION B-B

Instruction Manual

Form 1909

August 2006

B

C

B

VIEW A

VIEW A

C

APPLY LUB

50A8774-C / DOC

18

SECTION C-C

Figure 7. Size 80 Type 657 Actuator with Side-Mounted Handwheel and Hydraulic Snubber

Instruction Manual

Form 1909

August 2006

657 Size 80 and 100 Actuators

SECTION A-A

APPLY LUB

50A2622-F / DOC

A

A

Figure 8. Top-Mounted Handwheel for Size 100 Actuator

19

657 Size 80 and 100 Actuators

Instruction Manual

Form 1909

August 2006

Fisher is a mark owned by Fisher Controls International LLC, a member of the Emerson Process Management business division of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co.

All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Neither Emerson, Emerson Process Management, Fisher, nor any of their affiliated entities assumes responsibility for the selection, use and

maintenance of any product. Responsibility for the selection, use and maintenance of any product remains with the purchaser and end-user.

Emerson Process Management

Fisher

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

www.Fisher.com

20

EFisher Controls International LLC 1973, 2006; All Rights Reserved Printed in USA

Loading...

Loading...