Page 1

Instruction Manual

Fisher Scientific Isotempâ

Chromatography and General Purpose Laboratory

Refrigerators

Chromatography Refrigerator Models

13-986-127G/GR/GA 13-986-127GHK

13-986-133G/GR/GA 13-986-133GHK

13-986-138G/GR/GA 13-986-138GHK

13-986-145G/GR/GA 13-986-145GHK

13-986-149G/GR/GA 13-986-149GHK

13-986-172G/GR/GA 13-986-172GHK

General Purpose

Laboratory Refrigerator Models

13-986-227R/G/RR/RA/GR/GA 13-986-227GHK

13-986-238G/GR/GA 13-986-238GHK

13-986-245G/GR/GA 13-986-245GHK

13-986-249R/G/RR/RA/GR/GA 13-986-249GHK

13-986-272G/GR/GA 13-986-272GHK

Page 2

Service Division (Repairs): 1-800-395-5442

Technical Support: 1-800-926-0505

Customer Service: 1-800-766-7000

Prior to calling for service, have the following information readily available:

Catalog Number:

Serial Number:

Date of Purchase:

The catalog number and serial number can be found on the data plate located on the left interior

wall of the unit.

Part Number: 104416

Page 3

Table of Contents Isotemp Chromatography/ Laboratory Refrigerators

Introduction.................................................................................................................................... 1

Unpacking ...................................................................................................................................... 1

Visible Loss or Damage............................................................................................................. 1

Concealed Loss or Damage ..................................................................................................... 1

Packing List ................................................................................................................................. 1

Installation...................................................................................................................................... 2

Selecting a Location................................................................................................................... 2

Leveling the Unit......................................................................................................................... 2

Door Handles .............................................................................................................................. 2

Door Removal and Adjustment ................................................................................................ 2

Shelves......................................................................................................................................... 3

Electrical Connection ................................................................................................................. 4

Operation........................................................................................................................................ 5

Control Layout............................................................................................................................. 5

Temperature Controller.............................................................................................................. 6

Setting the Temperature....................................................................................................................................6

Units Select............................................................................................................................................................6

Calibration Offset................................................................................................................................................6

Hold-Off Time......................................................................................................................................................7

Error Codes ................................................................................................................................. 7

Fluorescent Lamps..................................................................................................................... 8

Convenience Outlet.................................................................................................................... 8

Manual/Automatic Condenser Fan .......................................................................................... 8

Trouble Shooting Table .............................................................................................................. 9

Maintenance................................................................................................................................. 10

Cabinet Cleaning ...................................................................................................................... 10

Cleaning the Condenser.......................................................................................................... 10

Condensate Evaporator Pan .................................................................................................. 10

Replacement Parts..................................................................................................................... 11

Performance Characteristics .................................................................................................. 11

Power Requirements ................................................................................................................. 11

Wiring Diagram ........................................................................................................................... 12

Part Number: 104416

Page 4

Page 1 of 12

Introduction

Unpacking

Visible Loss or

Damage

Concealed Loss or

Damage

Packing List

Isotempâ Laboratory and Chromatography Refrigerators

Your satisfaction and safety are important to Fisher Scientific, a

complete understanding of this unit is necessary to attain these

objectives.

As the ultimate user of this apparatus, it is your responsibility to

understand its proper function and operational characteristics. This

instruction manual should be thoroughly read and all operators given

adequate training before

Awareness of the stated cautions and warnings, and compliance with

recommended operating parameters – together with maintenance

requirements – are important for safe and satisfactory operation. The

unit should be used for its intended application; alterations or

modifications will void the Warranty.

WARNING: As a routine laboratory precaution, always

wear safety glasses when working with this apparatus.

This product is not intended, nor can it be used, as a sterile or

patient connected device. In addition, this apparatus is not

designed for use in Class I, II or III locations as defined by the

National Electrical Code, unless otherwise noted.

Save all packing material if apparatus is received damaged. This

merchandise was carefully packed and thoroughly inspected before

leaving our factory.

Responsibility for its safe delivery was assumed by the carrier

upon acceptance of the shipment; therefore, claims for loss or

damage sustained in transit must be made upon the carrier by

the recipient as follows:

Note any external evidence of loss or damage on the freight bill, or

express receipt, and have it signed by the carrier’s agent. Failure to

adequately describe such external evidence of loss or damage may

result in the carrier’s refusing to honor your damage claim. The form

required to file such a claim will be supplied by the carrier.

Concealed loss or damage refers to loss or damage, which does not

become apparent until the merchandise has been unpacked and

inspected. Should either occur, make a written request to the

carrier’s agent within

with the carrier since the damage is the carrier’s responsibility.

If you follow the above instructions carefully, we will guarantee our full

support of your claim to be compensated for loss from concealed

damage.

DO NOT – FOR ANY REASON – RETURN THIS UNIT WITHOUT

FIRST OBTAINING AUTHORIZATION

The following items are packed in the envelope located inside the

refrigerator chamber. If any of the following items are not present,

report the missing item to your local Fisher representative.

1. Warranty Card 5. Chart Recorder Instructions

2. This Instruction Manual

3. Door Lock Key

4. Power Switch Key

attempting to place this unit in service.

15 days of the delivery date; then file a claim

Part Number: 104416

Page 5

Isotempâ Laboratory and Chromatography Refrigerators

Installation

Selecting a Location

Leveling the Unit

Door Handles

Door Removal and

Adjustment

Choose a location for the refrigerator that will provide at least three

inches of clearance

surface at the sides and rear. Appropriate electrical power must be

available. Locate the refrigerator within 6 feet of the power outlet so

that no extension cord is required.

The refrigerator must be level in order to provide adequate

condensation drainage as well as proper door alignment and

operation. The refrigerator should be in its final operating location and

set so that it is firmly positioned on the floor. There are four leveling

screws, one on each corner. . Level the cabinet front to rear and sideto-side using the corner leveling screws. The leveling screws are

accessed by removing the base grille, as described below:

1. Remove the lower grille attaching screws.

2. Grasp the grille with both hands.

3. Tilt the lower end of the base grille toward you.

4. Pull grille away from the refrigerator

(Swinging Door Models Only)

Door handles are packed inside each refrigerator. To mount the

handle, lift the door gasket behind the two screws on the front of the

door. Attach handle with offset away from the cabinet corner and

tighten the screws.

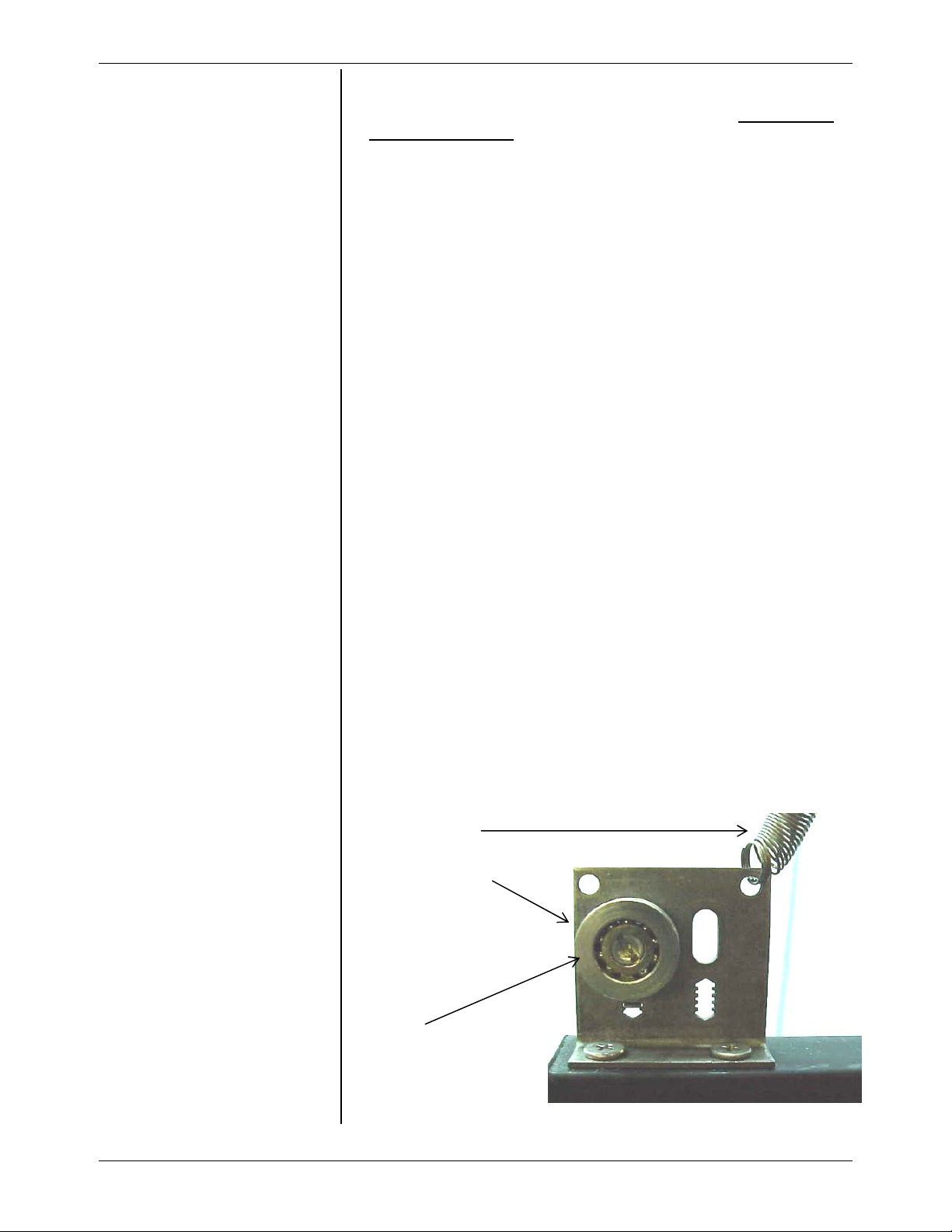

(Sliding Door Models Only)

Each door has its own closing spring located at the top of the door

track. Each spring is set for proper tension. If adjustment is required:

1. Check for cabinet level (see above).

2. Remove the door(s) by lifting it and sliding about half way

open. The roller will fall into a gap in the upper track. While

maintaining upward pressure on the door, pull the bottom

outward until it clears the bottom track.

3. Adjust the location of the door rollers in the roller brackets

(above door) as shown by loosening the lock nut on the back

of the roller bracket and moving the roller up or down.

Closing spring

Lock nut on back

Roller

between the cabinet and any adjacent vertical

Page 2 of 12

Fig. 1

Part Number: 104416

Page 6

Page 3 of 12

Isotempâ Laboratory and Chromatography Refrigerators

Shelves

4. The spring tension can be adjusted by moving the spring to

the outside hole of the bracket or by snipping a portion of it off

and then refastening it to the bracket.

CAUTION: Where safety glasses before snipping spring.

Shipped inside each cabinet are shelves packed in plastic and a bag

of shelf supports. Two different types of shelf supports are used.

The shelf supports have tab lengths of ¼ inch and ½ inch. The ¼

inch versions are used in the front of the shelf (See below) and the ½”

shelf supports are used in the rear.

Shelf spacing is adjustable to suit user requirements. Insert four shelf

supports for each shelf into the pilasters as shown. Note the

numbers on the pilasters. Place supports on the same numbers on

each pilaster to ensure the shelf will be level. Place the shelf on the

pilasters as shown in Fig’s 2 and 3.

Replacement shelves are available individually. See page 11 for

shelf part numbers. Proper shelf orientation is illustrated in Figure 2.

NOTE: Chromatography units include additional ½ shelves, which

can be used in place of the full shelves.

Tab Length

Shelf Support

Part Number: 104416

Fig. 2 Use ¼” tab length supports on sides and ½’ in back.

Page 7

Isotempâ Laboratory and Chromatography Refrigerators

Electrical

Connection

Fig. 3 Place shelves at desired height on four shelf supports.

NOTICE: Insufficient line voltage is often the

cause of compressor start-up failure. It is

strongly recommended that a dedicated

circuit, conforming to the National Electrical Code,

Article 440, be used for powering the refrigerator.

CAUTION: Be sure that the power supply is the same voltage that is

specified on the refrigerator’s data plate.

The frequency and nominal voltage requirements for the unit are

specified on the data plate, which is located on the interiors upper left

side. Only plug the unit into a power source that meets these

requirements. Low line voltage is often the cause of service

complaints. With the unit running, check that the line voltage is

within ±10% of that specified on the data plate.

WARNING: For personal safety this unit must be

properly grounded.

The power cord of this instrument is equipped with a three prong

(grounding) plug (NEMA 5-15P). This plug mates with a standard

three prong (grounding) wall receptacle (NEMA 5-15R) to minimize

the potential of an electrical shock hazard. Chromatography models

are equipped with a (NEMA 5-20P). This plug must mate with a

(NEMA 5-20R).

Page 4 of 12

Part Number: 104416

Page 8

Page 5 of 12

Isotempâ Laboratory and Chromatography Refrigerators

Operation

Control Layout

The customer should have the wall receptacle and circuit checked by

a qualified electrician to verify the receptacle is properly grounded

and meets power requirements specified on the data plate.

WARNING: DO NOT

remove the third (ground) prong from the power cord. DO

NOT use a two-prong adapter plug.

Where a two prong wall receptacle is encountered, it is the personal

responsibility and obligation of the user to have it replaced with a

properly grounded three prong receptacle.

under any circumstances cut or

CAUTION: Do not use an extension cord. Use of an

ungrounded cord or an overloaded circuit VOIDS the

compressor warranty.

WARNING: If the unit is tilted in excess of 30 degrees, level

the unit then wait at least 12 hours before applying power to

it.

WARNING: This product is not approved for storage

of flammable or explosive materials. Also, it is not

approved for use in hazardous locations containing

explosive atmospheres.

Before operation, become familiar with the refrigerator controls

located on the refrigerator header panel. A layout of the control is

given below.

Part Number: 104416

Page 9

Isotempâ Laboratory and Chromatography Refrigerators

Page 6 of 12

Temperature

Controller

Setting the Temperature

Units Select

Calibration Offset

Begin operation by inserting the key into the key switch located on the

header panel. The key switch is packed inside the envelope, which is

shipped in the refrigerator chamber. Turning the key switch to the ON

( | ) position will energize the evaporator fans and the digital

controller.

The digital temperature controller is located on the left side of the

header panel (See Figure 4). When the unit is initially turned on, the

display will indicate current chamber temperature. The temperature

units will be indicated by the °C or °F LED located just to the right of

the temperature display. The refrigerator is factory set at 4°C. When

the unit is first energized the evaporator fans will operate however it

will not immediately cool. A 3-minute compressor delay is

programmed into the controller to provide sufficient time for the

evaporator to defrost and to allow the system pressure time to

equalize. When the delay time is over, the Cool LED will illuminate,

the compressor will run and the chamber will cool.

NOTE: The compressor requires a 3-minute delay time

between activations. The unit will not cool during this

delay. The delay is also activated when the controller

is first energized.

To change the set temperature, press and release the Menu keypad

once. The display will flash SP and the Mode LED will be illuminated.

The last set temperature will then be shown in the display.

To change the temperature, press the UP or DOWN arrow key. The

adjustable temperature range is 1 to 12°C (34 to 54°F). When the

desired set temperature is displayed, press the Menu keypad to enter

the set temperature and activate the Units Select menu.

The second menu selects the units. The refrigerator control displays

temperature in °C or °F. The factory setting is °C. Starting from the

temperature display mode (Mode LED off), press the Menu key twice.

The current temperature units are displayed. To switch between

units, press the UP or DOWN arrow key then press the Menu key to

select. The unit LED will be displayed on the right of the temperature

display.

In the event the refrigerator needs to be calibrated, a simple routine is

available to adjust the display and control point to a referenced

standard. To set a temperature offset, press and hold the Menu

keypad for 5 seconds. The display will flash oS followed by the last

temperature offset value. The factory setting is 0. To change the

offset value, press the UP or DOWN arrow key, then press the Menu

key. The value shown in the display will be added to the previous

temperature reading. The display will then flash Ho.

Part Number: 104416

Page 10

Page 7 of 12

Isotempâ Laboratory and Chromatography Refrigerators

Hold-Off Time

Error Codes

For Example:

The display indicates 4°C but a reference thermometer in the

refrigerator chamber indicates 6°C. The operator presses and holds

the Menu keypad for 5 seconds, then changes the display value from

0 to +2 by using the UP arrow key. Press the Menu key again. Now

the display indicates a chamber temperature of °6 C and the

controller begins to cool (as long as 3-min. delay period has expired)

to the desired temperature of 4°C as shown on the reference

thermometer.

Allow an additional 30 to 40 minutes for the refrigerator to again

stabilize. If the display is still inaccurate, repeat the calibration offset

procedure.

CAUTION: INCREASING the offset value DECREASES

the temperature at which the system controls. If the

offset is inadvertently set too high, the chamber’s

control temperature can fall below zero and cause

evaporator freeze-up. This is caused by the

evaporator temperature not rising above 0°C and not

defrosting during the compressor “off cycle”.

NOTE: While in any of the controller mode setups (temp set,

calibration offset or units), the controller will wait 15 seconds for

a new value to be entered. If there is no keypad operation within

the 15-second time window, control will automatically revert to

the temperature display mode and the Mode LED will turn off.

Following the offset menu is the hold-off (Ho) menu. The display will

momentarily flash “Ho”, followed by a number. The number shown is

the delay time in minutes between compressor activations. Use the

UP/DOWN keypads to change the value.

Increasing the hold-off time will allow additional time for the

evaporator to defrost during the off-cycle. This can reduce the

chance of evaporator freeze-up during times of high humidity.

Pressing the Menu keypad while in the Ho mode, enters the hold-off

time displayed, and returns controller operation to the temperature

display mode.

Error codes indicate when the controller is sensing a problem. A

description of each is given below. See the Troubleshooting Table

for additional information on error codes.

E1 Open sensor.

E2 Under temperature. Temperature at sensor is less than

–36°C.

E3 Over temperature. Temperature at sensor is greater than

37°C.

Part Number: 104416

Page 11

Isotempâ Laboratory and Chromatography Refrigerators

Page 8 of 12

Fluorescent Lamps

Convenience Outlet

(Chromatography

Refrigerators Only)

Manual/Automatic

Condenser Fan

The interior lamp is controlled by a rocker switch on the header panel.

This light may be operated any time the cabinet power is turned on at

the keyed power switch. If the interior lamp fails, replace with the

same size and wattage lamp. DO NOT USE REDUCED WATTAGE

LAMPS. The reduced wattage lamps generally fail to light below 60

°F (15 °C).

Chromatography Refrigerators come equipped with a convenience

outlet located in the center of the back wall. Model 172G’s (three

doors) have two convenience outlets. The total power that can be

supplied by the outlet (or outlets

(4A @ 120VAC for the 3-door models). The outlet(s) is protected by

a circuit breaker located just below and to the right of the outlet(s).

Pressing the breaker button resets the breaker after a fault.

WARNING: The convenience outlet is LIVE at any time the

unit is connected to an electrical power source, regardless

of the position of the key switch.

A rocker switch located on the left side of the top of the inside of the

chamber is used to operate the condenser fan automatically or

manually. With the switch in the automatic position, the condenser

fan operates with the compressor. In the manual position, the

condenser fan operates continuously.

During times of high ambient relative humidity conditions, more water

is condensed on the evaporator and directed to the condensate pan.

The condenser fan will run continuously in the manual setting to

better dispose of this water. At times of low relative humidity, the

switch can be set to automatic.

in 3-door models) is 5A @ 120VAC

Part Number: 104416

Page 12

Page 9 of 12

Isotempâ Laboratory and Chromatography Refrigerators

Trouble Shooting

Table

This table is intended to assist in resolving user-correctable

Refrigerator problems by relating symptoms to their likely causes. If

service beyond the scope of this table is required, contact Fisher

Scientific Service Division @ 1-800-395-5442.

Symptom Probable Cause Action

Does Not Run Unit Unplugged

Blown fuse or tripped circuit

breaker.

Runs

Continuously

Clicking

Sound

Insufficient

Cooling

Display shows

E1 (error

code)

Display shows

E2 (error

code)

Display shows

E3 (error

code)

Frost buildup on refrigeration

coils

The compressor is equipped

with a thermal protector. This

device shuts off the

compressor when it becomes

to hot. A clicking sound

occurring about every 30

seconds indicates this

protector is working

Set temp is to high

Condenser coil dirty

Unit frosted

Open sensor Check sensor

Under Temp Temperature at sensor

Over Temp Temperature at sensor

Plug in Unit

Check fuse or circuit

breaker at breaker

box.

Defrost unit. Increase

Ho time.

Disconnect power and

call for service.

Reduce temperature

setting, verify Cool

LED is on.

Clean condenser coil

with a vacuum cleaner

Defrost unit

connection

is less than –36°C or

sensor is

malfunctioning.

is greater than 37°C or

sensor is

malfunctioning

Part Number: 104416

Page 13

Isotempâ Laboratory and Chromatography Refrigerators

Page 10 of 12

Maintenance

Cabinet Cleaning

Cleaning the

Condenser

Condensate

Evaporator Pan

CAUTION: When servicing the unit, disconnect from

the electrical power source

The cabinet interior should be cleaned frequently. Any spilled liquid

should be wiped off immediately. Stains resulting from some spills

can be permanent if not quickly removed. The most convenient time

to clean the interior is after defrosting. The cabinet exterior should be

cleaned occasionally. A mild detergent and lukewarm water or a

solution of bicarbonate of soda (1 tablespoon per gallon of water) is

recommended for cleaning the interior and exterior of the cabinet. All

surfaces should be rinsed and thoroughly dried.

CAUTION: Do not use any type of abrasive such as steel

wool, or fluids such as gasoline, Naphtha, or thinner. These

materials could be harmful to plastic materials, door gasket,

and painted surfaces.

For efficient operation, it is recommended that the condenser coil and

fan be cleaned every 4 to 6 months.. The condenser coil is located

behind the base grille, at the bottom of the unit.. See Leveling the

Unit for instructions on removing the base grille.

Vacuum clean the front surface of the coil thoroughly, or direct forced

air through the condenser from the rear. If necessary, use a stiff

bristled brush to loosen any dirt. Failure to keep the condenser clean

will void the warranty.

Caution: Accessing and cleaning the condenser coil or

evaporator pan should be done by qualified personnel.

The condensate evaporator pan is located behind the base grill

between the condenser fan and compressor. This pan should be

cleaned at least once a year to prevent foul odors and operate

efficiently. Vacuum clean if dry, or sponge clean with soapy water.

Part Number: 104416

Page 14

Page 11 of 12

Isotempâ Laboratory and Chromatography Refrigerators

Replacement

Parts

Performance

Characteristics

Power

Requirements

Replacements for Laboratory Refrigerator parts serviceable by the

user may be ordered, by part number, from Fisher Scientific Co. @

1-800-766-7000.

Item Part Number

Shelves

Model 127/227 13-986-210A

Model 133/233 13-986-210B

Model 138/238 13-986-210U

Model 145/245 13-986-210C

Model 149/249 & 172/272 13-986-210D

½ Shelves

Model 127/227 13-986-210F

Model 133/233 13-986-210G

Model 138/238 13-986-210T

Model 145/245 13-986-210H

Model 149/249 & 172/272 13-986-210J

Solid State Relay (K1) SPN88616

Temperature Controller SPN103508

International Version Controller (220V) SPN105402

Condenser Pan Wick SPN104433

Front Shelf Support SPN103264

Rear Shelf Support SPN103265

Temperature Range: 1° to 12°C (34° to 54°F)

Temperature Stability: +/- 3°C

Catalog Number Volts(+/-10%) Amps Hz

13-986-127G/GR/GA 115 13.5 60

13-986-133G/GR/GA 115 16.0 60

13-986-138G/GR/GA 115 16.0 60

13-986-145G/GR/GA 115 16.0 60

13-986-149G/GR/GA 115 16.0 60

13-986-172G/GR/GA 115 16.0 60

13-986-227G/GR/GA 115 8.5 60

13-986-227R/RR/RA 115 8.5 60

13-986-233G/GR/GA 115 10.5 60

13-986-238G/GR/GA 115 10.5 60

13-986-245G/GR/GA 115 10.5 60

13-986-249G/GR/GA 115 10.5 60

13-986-249R/RR/RA 115 10.5 60

13-986-272R/RR/RA 115 12.0 60

Part Number: 104416

Page 15

Part Number: 104416

Wiring Diagram

Page 12 of 12

Convenience Outlet, Chromatography Refrigerators Only

Isotempâ Laboratory and Chromatography Refrigerators

Page 16

Part No. 104416 Rev G Fisher Scientific Co.

Isotemp Laboratory Refrigerators 2000 Park Lane

Published 10 – 2003 Pittsburgh, PA 15275

Loading...

Loading...