Page 1

Connector : WSO 1031

with sealed or unsealed cable clamp

Fischer Connectors SA

Saint-Prex, Switzerland

Phone +41 21 800 95 95

Fax +41 21 800 39 24

www.fischerconnectors.com

mail@fischerconnectors.ch

Assembly Instruction

Instruction de Montage

Montageanleitung

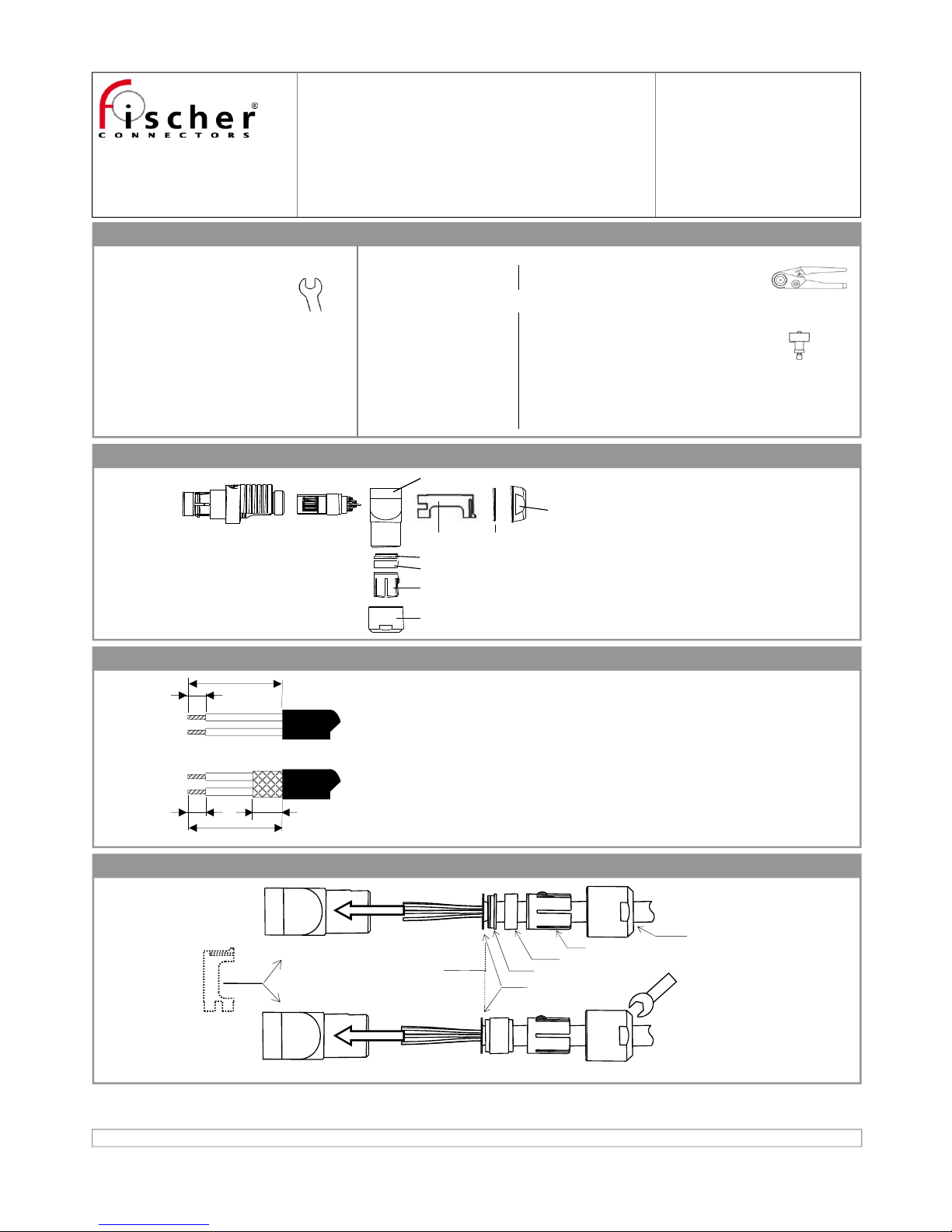

Tool Required

For all versions:

• Flat Spanners:

• 12 mm

• Wire Cutter

• Stripping Tool

• Soldering Iron

Fischer Part Number

TX00.012

Additional tools for Crimp Contact versions:

• Crimping Tool for:

• Positioner for:

Fischer Part Number

TX00.240

TX00.301

TX00.303

TX00.304

TX00.305

2 - Strip Cable

1 - Disassemble Connector

3 - Assemble Clamp Set

Document No. 600.00.439 Rev : 1.2 Date : 18-May-2015 Established by : ARZ/VGI Approved by : SKE

© Fischer Connectors SA / All rights reserved

This document is the property of Fischer Connectors SA.

All communications to third parties or the reproduction in any form, even partial, are prohibited without our written consent.

Connector

Body (a)

Contact

Block (b)

Right Angle Body (c)

Spacer (d) O-ring (e)

Back Nut (f)

Ring (g)

Cap Nut (j)

Cable Clamp (i)

Seal (h)

A

C

A

A ≈ 20-22 mm

(1)

B ≈ 2 mm

(1)

C ≈ (6 – 1/2 cable Ø) mm

(1) (2)

Or trim shield after step 3

if possible

B

(2)(1)

These values are given for reference and must

be adjusted to each specific cable

construction.

It is recommended to strip “B” after step 3.

Sealed Clamp Version

Unsealed Clamp Version

Jacket position for

non-shielded cables

Cable Shield

Ring (g)

Seal (h)

Cable Clamp (i)

Right Angle Body (c)

Recommended torque value: 1.5 Nm

(depending on cable)

Threadlocking adhesive recommended

(*) See note (2) in step 2

12

(*)

(*)

Cap Nut (j)

• 0.5 to 1.3mm contacts

• 0.5mm male contacts

• 0.5mm female contacts

• 0.7mm male contacts

• 0.7mm female contacts

See step 4:

with large

cables, insert

spacer before

Page 1/2

Page 2

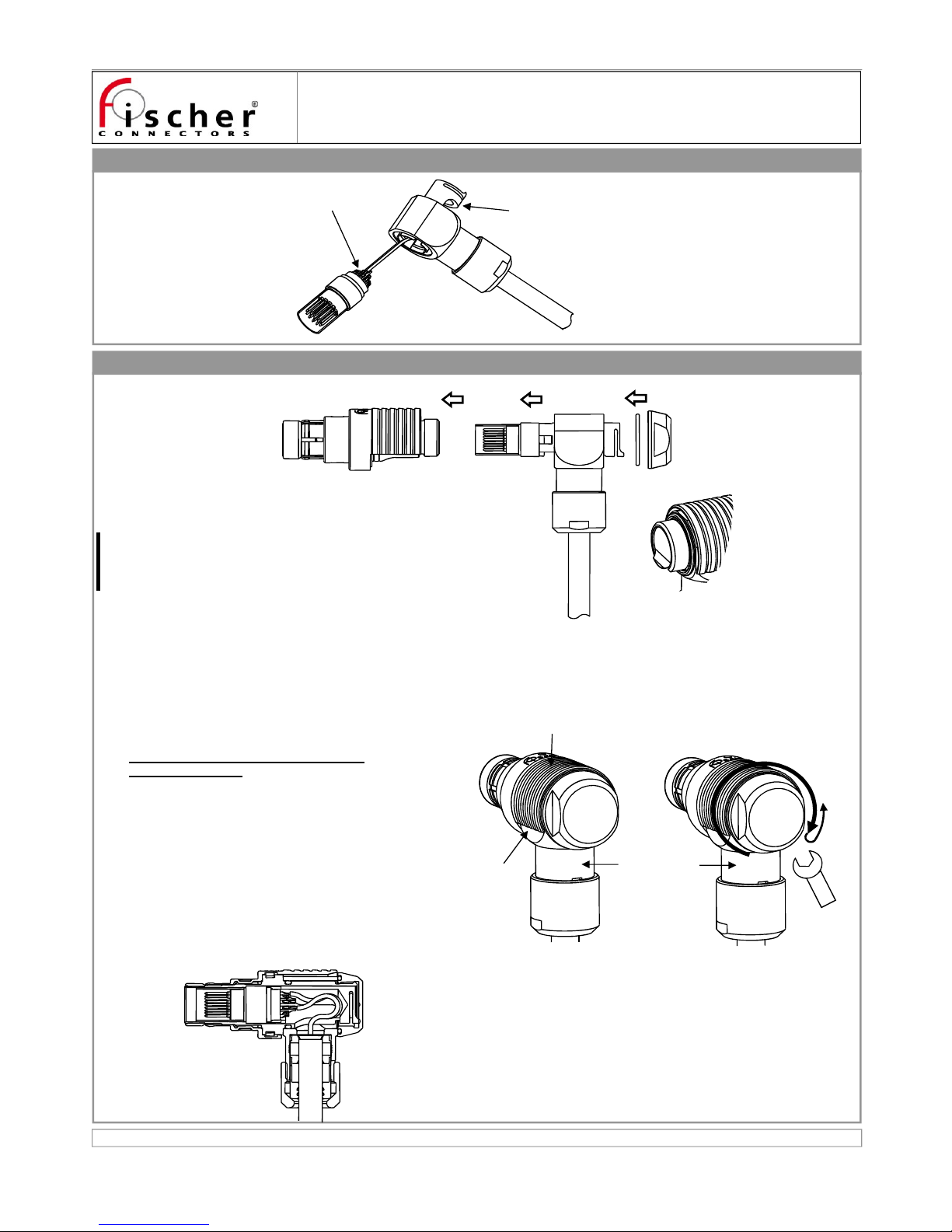

4 - Terminate Contacts

5 - Assemble Connector

Connector : WSO 1031

with sealed or unsealed cable clamp

Document No. 600.00.439 Rev : 1.2

Solder or crimp

Pull Spacer (d) over Cable and

through Right Angle Body (c)

Tighten Back Nut (f). Torque ≈ 2.0 Nm

Do not squeeze Connector Body in a vice

to tighten Back Nut!

Confirm that Outer Sleeve of Connector Body (a) can move

freely. If not, it can be released by holding Right Angle Body (c)

and turning slightly Back Nut (f) counter-clockwise.

After the threadlocking adhesive has cured, check locking

mechanism by mating connector with counterpart and

pulling on Right Angle Body (c) in unmating direction. The

connector should stay mated.

Pull on Outer Sleeve of connector. It should unlock and

disconnect.

5B

Correct fit of

Spacer (d)

Fit Spacer (d) onto Contact Block (b), bending wires smoothly and being careful

not to damage wires.

Caution with crimp contacts:

Crimp contacts need extra space in the insulator, therefore they can move.

Never twist the cable and wires during the cable assembly; this can apply

too much force on the contacts.

Insert Block (b) into Connector Body (a).

Apply threadlocking adhesive on inner thread of Back Nut (f).

Fit O-ring (e) into Back Nut (f) and close connector.

5A5B

5C

Outer Sleeve of

Connector Body

Gap on

both sides

Ensure that Right Angle Body (c) is centred in Outer Sleeve of

Connector Body (a) (gap on both sides) before tightening Back

Nut (f).

5D

Right Angle

Body (c)

5E

5F

12

5A

5B

5C

5D

5E

5F

5G

Page 2/2

Loading...

Loading...