Page 1

Operating manual

MS13

Digital pressure transmitter / switch

with colour change display

09005885 • BA_EN_MS13 • Rev. ST4-A • 10/16

*09005885*

Page 2

| Masthead FISCHER Mess- und Regltechnik GmbH

2 / 32 BA_EN_MS13

Masthead

Manufacturer:

FISCHER Mess- und Regeltechnik GmbH

Bielefelderstr. 37a

D-32107 Bad Salzuflen

Telefon: +49 5222 974 0

Telefax: +49 5222 7170

eMail: info@fischermesstechnik.de

web: www.fischermesstechnik.de

Technical editorial team:

Documentation representative: S. Richter

Technical editor: R.Kleemann

All rights, also those to the translation, reserved. No part of these instructions

may be reproduced or processed, duplicated or distributed using electronic systems or any other form (print, photocopy, microfilm or another process) without

the written consent of the company Fischer Mess- und Regeltechnik GmbH,

Bad Salzuflen.

Reproduction for internal use is expressly allowed.

Brand names and procedures are used for information purposes only and do

not take the respective patent situation into account. Great care was taken

when compiling the texts and illustrations; nevertheless, errors cannot be ruled

out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any

legal responsibility or liability for this.

Subject to technical amendments.

© FISCHER Mess- und Regeltechnik 2016

Version history

Rev. ST4-A 04/16 Version 1 (first edition)

Page 3

FISCHER Mess- und Regltechnik GmbH Table of Contents

BA_EN_MS13 3 / 32

Table of Contents

1 Product and functional description ..............................................................................................................4

1.1 Delivery scope ..........................................................................................................................................4

1.2 Performance features ...............................................................................................................................4

1.3 Intended use .............................................................................................................................................4

1.4 Product Overview .....................................................................................................................................5

1.5 Function diagram ......................................................................................................................................6

1.6 Design and mode of operation..................................................................................................................7

2 Installation and assembly..............................................................................................................................8

2.1 Generalities...............................................................................................................................................8

2.2 Process connection ..................................................................................................................................8

2.2.1 Measuring lines that need to be connected ..................................................................................9

2.2.2 Pressure surge absorption............................................................................................................9

2.3 Electrical connections .............................................................................................................................11

3 Commissioning.............................................................................................................................................12

3.1 General ...................................................................................................................................................12

3.2 Control elements.....................................................................................................................................12

3.2.1 LC display ...................................................................................................................................12

3.2.2 Keyboard..................................................................................................................................... 13

3.3 Menu levels.............................................................................................................................................14

3.3.1 Menu Level Switch points ...........................................................................................................14

3.3.2 Menu Level Input ........................................................................................................................15

3.3.3 Menu Level Measuring................................................................................................................ 16

3.3.4 Menu Level Output...................................................................................................................... 17

3.3.5 Menu Level Function................................................................................................................... 18

3.3.6 Menu Level Display..................................................................................................................... 20

3.3.7 Menu Level System .................................................................................................................... 22

4 Technical Data .............................................................................................................................................. 24

4.1 General Information ................................................................................................................................24

4.2 Input variables ........................................................................................................................................24

4.3 Output parameters..................................................................................................................................24

4.4 Measurement accuracy ..........................................................................................................................25

4.5 Auxiliary energy .....................................................................................................................................25

4.6 Application conditions .............................................................................................................................25

4.7 Display and operating interface ..............................................................................................................26

4.8 Construction design ................................................................................................................................26

4.8.1 Dimensional picture .................................................................................................................... 26

4.8.2 Process connection..................................................................................................................... 27

5 Order Codes..................................................................................................................................................28

5.1 Accessories ............................................................................................................................................29

6 Attachments..................................................................................................................................................30

Page 4

1 | Product and functional description FISCHER Mess- und Regltechnik GmbH

4 / 32 BA_EN_MS13

1 Product and functional description

1.1 Delivery scope

• MS13 Digital pressure transmitter / switch

• Operating instructions

The unit is supplied ex-works with standard parameters.

For accessories, please see the list in section Order code [}29].

1.2 Performance features

Important features

• LCD colour change display

• Switchable pressure units

• 2 independent switching points with lots of configuration options

• Analogue signal output with possibility of characteristic curve spread, characteristic curve reversal and offset setting

• Characteristic curve implementation via table with max. 30 measuring points

• Complete adjustment of all parameters and measuring point protocol possible through optional transmitter PC interface.

Typical applications

• Simple pump control systems

• Monitoring of pumps and compressors

• Filling level measuring

Application areas

• Technical facility equipment (TGA)

• Process engineering

• Process technology

• Environmental technology

1.3 Intended use

The MS13 is a pressure transmitter/ switch for measuring relative pressure. The

unit is suitable for measuring pressure and under-pressure in non-agressive

gas-like and fluid media.

The MS13 complies with the state-of-the-art and is safe; it also takes into account the relevant regulations and EC directives. The manufacturer will not be

liable for damage arising from incorrect or improper use.

The unit was designed bearing in mind all relevant factors that could impact on

its safety. Also, the unit was produced, inspected and supplied with a user

manual so that if it is used in unforeseeable reasonable conditions, its safety is

guaranteed for its entire service life.

NOTICE

Soiled or aggressive media

Please contact the manufacturer before using this unit with dirty or aggressive

media because the unit needs to be adapted for the specific customer in terms

of the parts that come into contact with the media.

The device may only be used for the purpose stipulated by the manufacturer.

Page 5

FISCHER Mess- und Regltechnik GmbH Product and functional description | 1

BA_EN_MS13 5 / 32

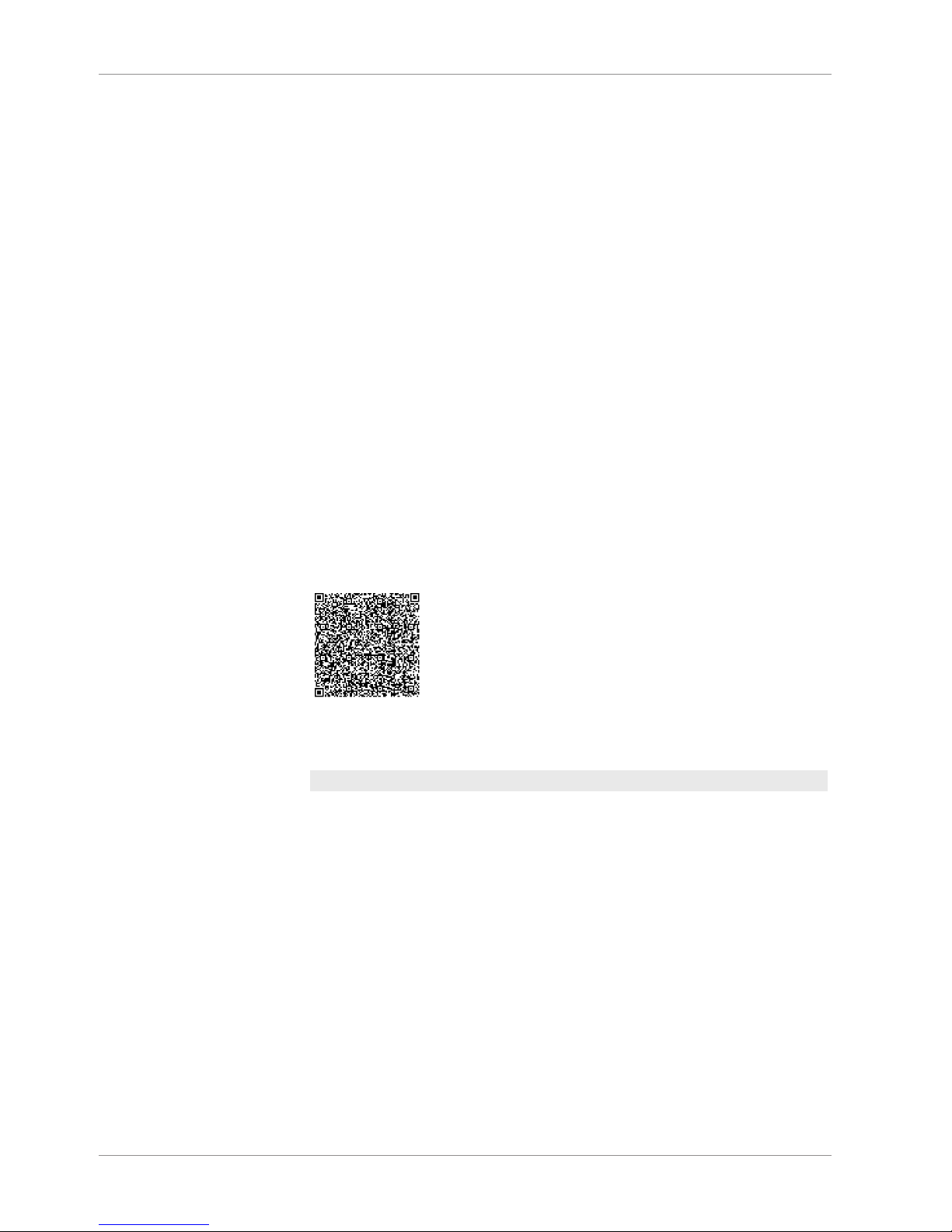

1.4 Product Overview

All units of the series MS13 are supplied in an NG100 bayonet ring housing

made of stainless steel.

1 2

3

4

5

6

7

Code U

Process connection

Illustration1: Product Overview

1 Colour change display 2 Bayonet ring housing

3 Keyboard 4 Process connection

5 Blowout plug 6 M12 plug 1

7 M12 plug 2

Process connection

The following options are available for the process connection.

Code L

Process connection

0 R

Illustration2: Process connection direction

Code 85 87 88 S1

G½ B ¼ -18 NPT EXTG¼ B Schrader ®

Illustration3: Process connections

Page 6

1 | Product and functional description FISCHER Mess- und Regltechnik GmbH

6 / 32 BA_EN_MS13

Code Process connection

85 Connection shanks with external thread G¼ B

87 Connection shanks with external thread G½ B

88 Connecting port with outer thread ¼ -18 NPT EXT

S1 Schrader® screw connection inner thread 7/16 UNF

Electrical connections

The power is connected using two M12 connectors.

M12 flanged connector DIN EN 61076-2-101 coding A

Connector 1 5-pin Ms-nickel-plated

Connector 2 4-pin Ms-nickel-plated

Nameplate

This type plate serves as an example of the information that is stated. The data

shown is purely fictive, but does correspond to the actual conditions. For more

information, please see the order code at the end of these instructions.

MESS- UND

REGELTECHNIK

GmbH

D-32107 Bad Salzuflen

Article no MS1303M87PKC0MV0

Measuring range 0-1.6 bar

electrical output 4 - 20 mA / 3-wire

Oper. voltage 24V AC/DC

P max. 3.2 Bar (45 PSI)

Prod. No. 1600624.01.001

Made in Germany

142

3

142

3

*

ge/gnswbr

wsblsw

br

ws

bl

+ Signal

+ supply

- Signal

- supply

( GND)

Plug guide

Switch

contact 1

Switch

contact 2

* bridged

internally

Order Codes

Serial number

Wiring diagrams

Technical data

Illustration4: Nameplate

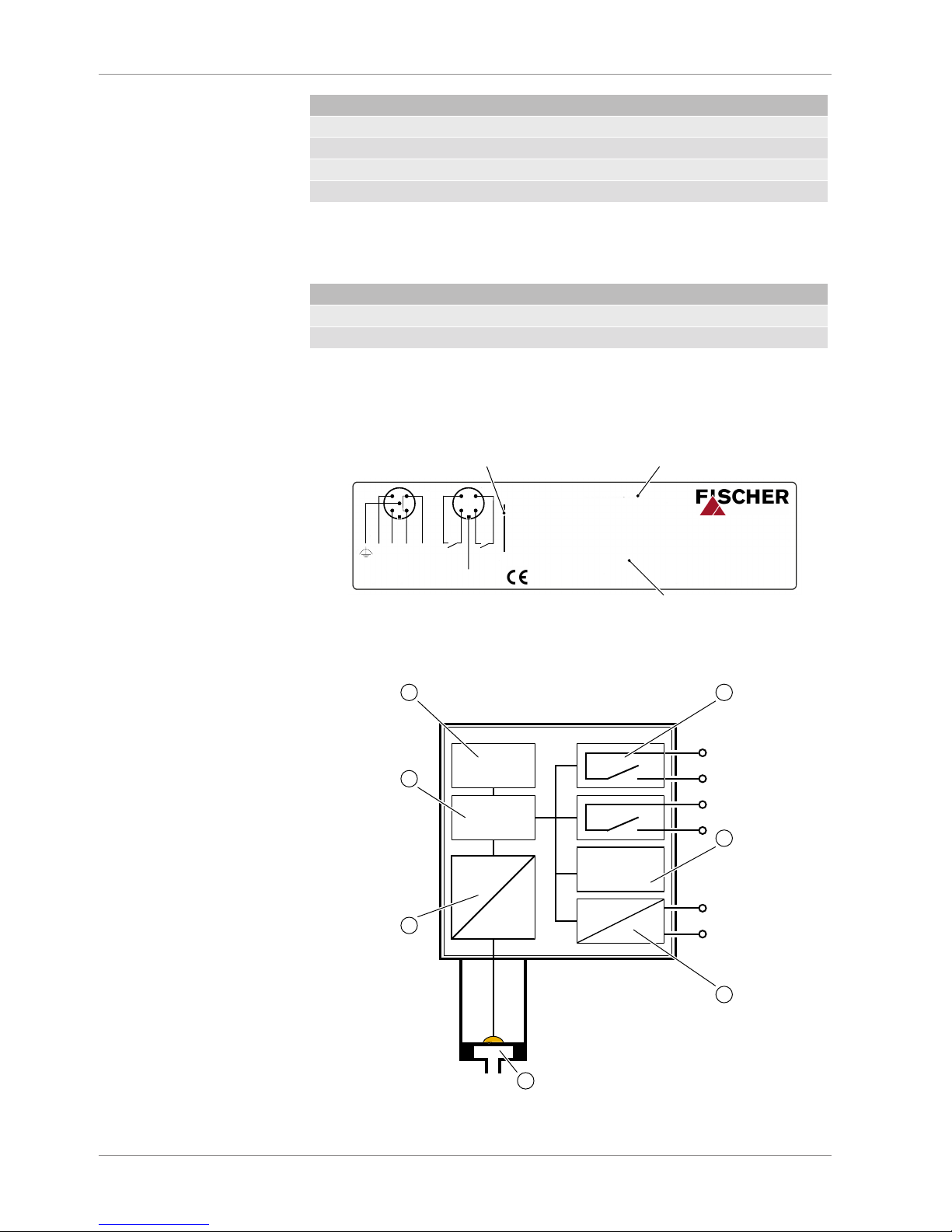

1.5 Function diagram

SP2

1.275 bar

U/I

SP1

D

A

A

D

µC

IJK

3

4 5

6

7

2

1

Illustration5: Function diagram

Page 7

FISCHER Mess- und Regltechnik GmbH Product and functional description | 1

BA_EN_MS13 7 / 32

1 Measuring cell 2 A/D converter

3 Micro-controller 4 Keyboard

5 Switching outputs 6 LCD colour change display

7 D/A converter

1.6 Design and mode of operation

The device is based on a ceramic sensor element that is suitable for measuring

over-pressure and under-pressure. The pressure deforms the measuring membrane causing a change in resistance on the attached measuring bridge. This

change is evaluated by the device's electronics and transformed into the display, switch contacts or an standardised analogue output signal.

The optional output signal can be dampened, spread, inverted and transformed

via a table function even if it is non-linear. Overstepped limits can be visualised

with the LCD colour change display.

The unit is configured with a keyboard or by means of remote configuration from

a PC.

Page 8

2 | Installation and assembly FISCHER Mess- und Regltechnik GmbH

8 / 32 BA_EN_MS13

2 Installation and assembly

2.1 Generalities

The instrument may only be installed and commissioned by specialized personnel familiar with the installation, commissioning and operation of this product.

Specialized personnel are persons who can assess the work they have been

assigned and recognize potential dangers by virtue of their specialized training,

their skills and experience and their knowledge of the pertinent standards.

WARNING

Mounting pressure transmitters

During assembly, observe the respective national and international guidelines

and safety regulations.

Only mount the pressure transmitter to systems that are depressurized. Only

ever operate the unit within the permitted measuring range or below the maximum overload.

Illustration6: Shutoff valve.

The device is set ex-works for vertical installation, however any installation position is possible.

To guarantee safe working conditions during installation and maintenance, suitable stop valves must be fitted in the system (see accessories). By means of

the manometer shutoff, the unit

• Can be depressurized or taken out of operation.

• Be disconnected from the power supply within the applicable system for repairs or inspections.

2.2 Process connection

• By authorized and qualified specialized personnel only.

• The pipes need to be depressurized when the instrument is being connected.

• Appropriate steps must be taken to protect the device from pressure surges.

• Check that the device is suitable for the medium being measured.

• Maximum pressures must be observed (cf. Tech. data)

WARNING

Earth connection via the system earth

During assembly, ensure that the earth connection between the pressure transmitter and the system earth is ensured. The connection to the system earth is

realised via the process connection. Therefore, never use an insulated Teflon

tape or similar. Design the process connection acc. to EN 837 and use a suitable flat seal.

Page 9

FISCHER Mess- und Regltechnik GmbH Installation and assembly | 2

BA_EN_MS13 9 / 32

2.2.1 Measuring lines that need to be connected

The following points need to be observed when connecting the pressure line:

• To ensure there is no influence on the measured values, severe bends and

coils in the wire should be avoided.

• To prevent deposits, there should be a continuous incline or drop of at least

8%.

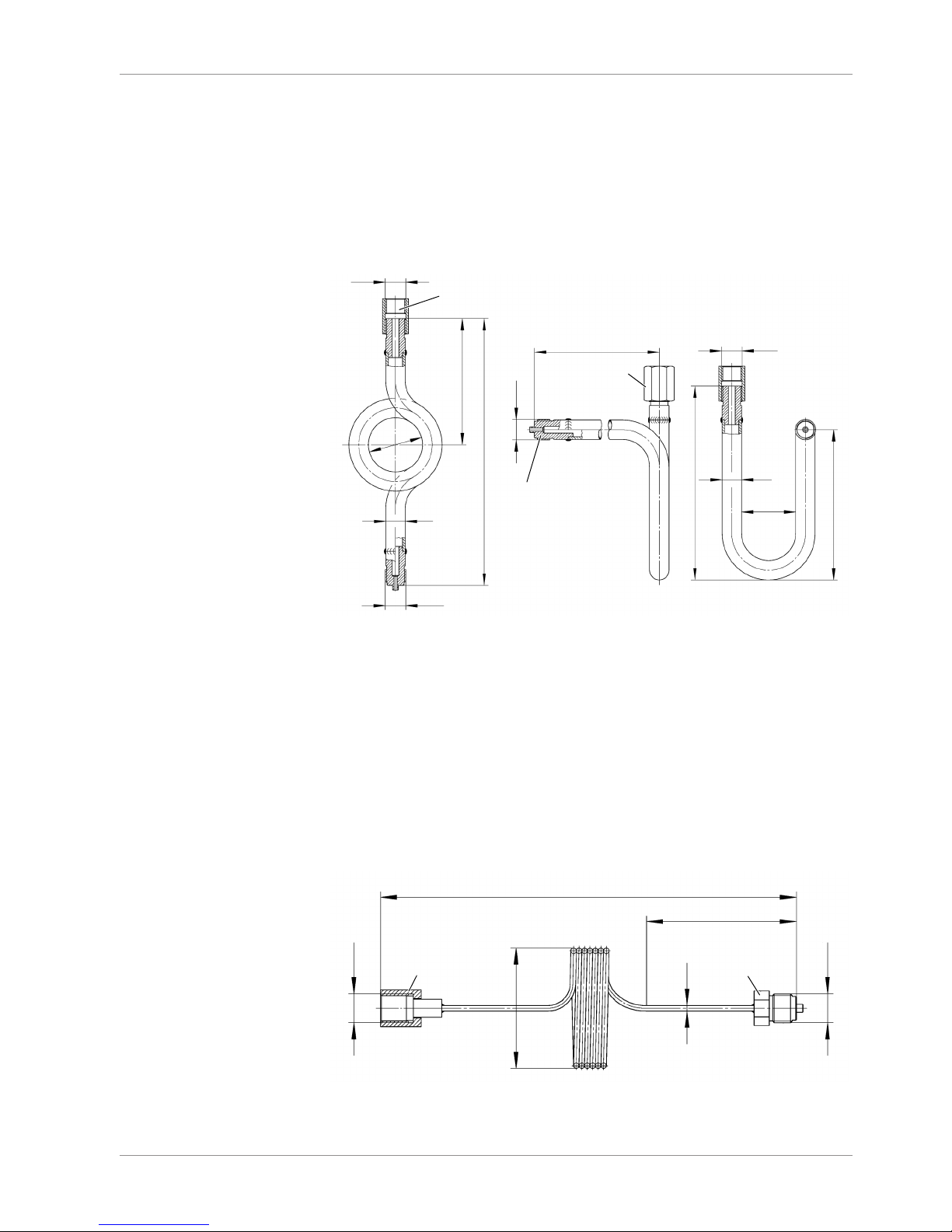

• When measuring steam pressure, a water bag-forming loop must be

provided due to the temperature (see accessories).

Round shape U-shape

G½

ca. 180

Ø20

56

155

ca. 200

G½

G½

ca. 275

ca. 130

Ø20

Ø56

G½

SW27

Manometer connection

Connection spigot

according to DIN EN 837-1

Illustration7: Siphon MZ1###

• The transmitter must be positioned below the measuring point for liquid

measurements. Vent the pressure line before commissioning.

• The transmitter must be positioned above the measuring point for gas

measurements.

2.2.2 Pressure surge absorption

Pulsating pressure on the system side can lead to functional problems. We recommend installing a damping element in the pressure connection lines as a

protective measure.

a) Capillary throttle

Manometer connection

SW27 SW27

Connection spigot

according to DIN EN 837-1

305

110

G½

G½

Ø88

Ø4

Illustration8: Capillary throttle MZ400#

Page 10

2 | Installation and assembly FISCHER Mess- und Regltechnik GmbH

10 / 32 BA_EN_MS13

b) Settable damping reactor

In operating mode, the damping throttle must be set so that the output signal

follows the pressure changes with a delay.

G½

G½

20

66

19

SW27

Setting screw

Connection spigot

according to DIN EN 837-1

Manometer connection

Illustration9: Damping reactor MZ410#

Page 11

FISCHER Mess- und Regltechnik GmbH Installation and assembly | 2

BA_EN_MS13 11 / 32

2.3 Electrical connections

• By authorized and qualified specialized personnel only.

• When connecting the unit, the national and international electro-technical

regulations must be observed.

• Disconnect the system from the mains, before electrically connecting the

device.

• Install the consumer-adapted fuses.

• Do not connect the connector if strained.

3-Leiterschaltung

Input

Output

AC

DC

Sensor

Signal

+U

b

- U

b

- Sig

+Sig

+U

b

- U

b

p

1

3

2

4

Connector 1: Supply and output signal

Illustration10: M12 connector 5pin

Item Description Cable colour

A Coding A

B Internal bridge

1 +U

b

Supply brown

2 -Sig Signal white

3 -U

b

Supply blue

4 +Sig Signal black

5 FE Functional earth Green/yellow

Connector 2: Switching outputs

Illustration11: M12 Plug 4-pin

Pos Description Cable colour

A Coding A

1 SP1 Switch point 1 (no) brown

2 SP2 Switch point 2 (no) white

3 SP2 Switch point 2 (com) blue

4 SP1 Switch point 1 (com) black

Page 12

3 | Commissioning FISCHER Mess- und Regltechnik GmbH

12 / 32 BA_EN_MS13

3 Commissioning

3.1 General

All electrical supply, operating and measuring lines, and the pressure connections must have been correctly installed before commissioning. All supply lines

are arranged so that there are no mechanical forces acting on the device.

Check that the pressure connections do not leak before commissioning.

3.2 Control elements

3.2.1 LC display

1

3

4

2

Illustration12: LC display

1 Measurement display 4…6 digits 2 Bar chart display

3 Status display of the switch

points

4 Unit

Illustration13: LC display 2SP

The unit is shown to the right of the measured value. If the device is equipped

with contacts, a closed contact is always symbolised by an inverted text "SP1"

or "SP2". One exception is the 1-channel bar chart diagram. Here, the switching

points are symbolised with simple numbers "12".

Page 13

FISCHER Mess- und Regltechnik GmbH Commissioning | 3

BA_EN_MS13 13 / 32

3.2.2 Keyboard

1

2

3

Illustration14: Keyboard

1 Page down menu Decrease value

2 Call up menu Save value OK

3 Page up menu Increase value

The individual menu items and parameters can be displayed using the buttons

and

. The respective menu item is selected or the parameters for making

changes are called up via the button

.

If a parameter can be changed, the display flashes. The change is made via the

buttons

and

. The value is saved with the button

.

To leave a menu level or the entire menu, select the parameter "Quit" and

press

.

Example: Switch-on point set switchpoint 1

In normal mode, press the button

to enter the menu. The menu level Switch

points appears. Press the enter key

again to call up the display parameter.

The first parameter Switch point 1 on is displayed. To change this parameter,

press the button

again.

The device jumps to the input:

• The parameter is stated in the 1st line.

• The value that is to be changed is shown in the 2nd line, the display flashes.

• The input limits are displayed in the 3rd line (if there is one).

The required value is set with the buttons

and

and then confirmed with

.

Page 14

3 | Commissioning FISCHER Mess- und Regltechnik GmbH

14 / 32 BA_EN_MS13

3.3 Menu levels

The menu levels are structured as follows:

End

menu level

Menu Level

Switch points

Menu Level

Input

Menu Level

Measuring

Menu Level

Output

Menu Level

Function

Menu Level

Display

Menu Level

System

End

menu level

Reception

Output

Output

Illustration15: Menu levels

The following tables provide an overview of the parameters of the individual

menu levels. In the Menu Level Systemyou can change to the respective national language using the language parameter. You can see which languages

are supported there.

3.3.1 Menu Level Switch points

Parameter name Description Value range

SP1 On Switch point 1 On MBA-50% … MBE+50%

SP1 Off Switching point 1 off MBA-50% … MBE+50%

SP1 delay Switching point 1 delay 0…1800 s

SP1 Function Switching point 1 function NO, NC

SP2 On Switch point 2 On MBA-50% … MBE+50%

SP2 Off Switching point 2 off MBA-50% … MBE+50%

SP2 delay Switching point 2 delay 0…1800 s

SP2 Function Switching point 2 function NO, NC

The two switching outputs are configured by four parameters respectively.

For the switch point 1 these are

Page 15

FISCHER Mess- und Regltechnik GmbH Commissioning | 3

BA_EN_MS13 15 / 32

• SP1 On

• SP1 Off

• SP1 delay

• SP1 Function

Accordingly for switch point 2:

• SP2 On

• SP2 Off

• SP2 delay

• SP2 Function

The function of the individual parameters is explained for both switch points using Switch point 1 as an example.

SP1 On defines the activation point, SP1 Off the deactivation point of switching

output 1. The values are shown in the valid unit and set accordingly. The values

are shown in the valid unit and set accordingly. Both parameters can be set independently over the entire value range.

The value range ranges from MBA – 50% to MBE + 50%. MBA stands for start

of measuring range and MBE for the end of the measuring range.

Example: Measuring range = 0 … 160 kPa

The value range for this measuring range is -80 kPa … +240 kPa.

Together, the two parameters SP1 On and SP1 Off determine the switch function of switching output 1:

• If SP1 On > SP1 Off, the output switches on, if the measured value exceeds SP1 On. It is only switched off again if the measured value SP1 Off is

undercut (hysteresis function).

• If SP1 On = SP1 Off, the output switches on if the measured value exceeds

SP1 On and off if the measured value undercuts the same value (SP1 Off).

• If SP1 On < SP1 Off, the output switches on, if the measured value lies

within these switch points: i.e:

SP1 On < Measured value < SP1 Off (window function).

SP1 Delay allows the reaction of the switch output to be delayed by between 0

and 1800 s. This parameter applies equally for switching on and off.

SP1 Function changes the function of the switching output 1. It is possible here

to define whether the contact should work as a open contact (NO) or a break

contact (NC).

3.3.2 Menu Level Input

Parameter name Description Value range

Absorption Attenuation, damping 0…100 s

Offset corr. Offset correction ⅓ basic measuring

range

Zero-pt. wind. Zero-point window ⅓ basic measuring

range

If there are unsteady pressure readings during operation, you can use the parameters Absorption and Zero-pt. wind. to stabilise the reading and the output

signal.

The parameter Absorption functions like a capillary throttle. However, it only

acts on the display, output signal and switch points (if these exist) but not on the

measuring cell itself.

You can set the response time to pressure jumps in the range 0.0 to 100 s.

Page 16

3 | Commissioning FISCHER Mess- und Regltechnik GmbH

16 / 32 BA_EN_MS13

NOTICE

Response time

At maximum damping it can take over 2 minutes until the pressure jump from

the nominal pressure 100% to 0% is also shown as zero in the display.

In many cases, unsteady readings are not a problem during normal operating

mode, but this is not true for the idle state, i.e. if a measured value of zero is expected. The parameter Zero-pt. wind. is designed to solve this. Its value

defines a range around zero at which the measured value is set to zero (see

fig.).

The display only stops showing zero when the pressure leaves the set window.

When twice the window value is reached, the measuring pressure and the display correspond again. This avoids jumps in the display.

Differential pressure

Display value

-x-2x x 2x

Zero-point window

Illustration16: Zero-point window

It makes sense to set the Offset (zero-point displacement) if, without differential

pressure (remove measuring line), the display shows a value that is not zero.

Before the offset correction, the zero-point window must be set to zero.

Select the Offset corr. parameter and correct the reading using the buttons

or

until zero is shown in the display.

When setting the offset, the current measured value is displayed. The zeropoint window is not active during the offset setting.

3.3.3 Menu Level Measuring

Parameter name Description Value range

MB start Measuring range start Basic measuring

range

MB end Measuring range end Basic measuring

range

Unit Measuring range unit bar, mbar, Pa, kPa,

MPa, psi, InWc,

mmWs, mmHg

Limit Measuring range limit yes, no

The transmitter output signal primarily depends on the sensed pressure. However, you have the option of adjusting the output signal to a large extent to suit

your requirements.

Page 17

FISCHER Mess- und Regltechnik GmbH Commissioning | 3

BA_EN_MS13 17 / 32

NOTICE

Adjustment of the output signal

The basic measuring range (indicated on the type label) and the type of output

signal (voltage / current) are not variable.

The parameters MB start and MB end initially define the two pressures

between which the output signal will change at all. Both values are adjustable

across the entire basic measuring range. The set values also refer to the pressure in the respective unit. However, the signal values (current / voltage) for

‘Start of measuring range’ and ‘End of measuring range’ are fixed.

If MB start is smaller than MB end, this is called an increasing characteristic

curve; the output signal increases as the pressure increases.

If MB end is smaller than MB start, this is a decreasing characteristic curve and

the output signal decreases as the pressure increases.

The difference between the values MB start and MB end must be at least 25 %

of the basic measuring range.

You can select a unit other than the unit of the basic measuring range with the

parameter Unit. The user should remember however that not every unit is suitable. The conversion is automatic.

The parameter Limit allows the display, output and switching points to be limited to the range between Start of measuring range and End of measuring

range. This makes sense when content is measured to avoid "negative contents". If Limit is set to "no", those measured values that are greater or smaller

than the end values are shown.

3.3.4 Menu Level Output

Parameter name Description Value range

min. output min. output

0.0 … 21.0 mA or

0.0 … 11.0 V

max. output max. output

Error signal Measuring range unit

The parameters min. output, max. output and error signal define the limits of

the output signal that may not be undercut or exceeded regardless of the pressure. The limit values take priority over the range defined by the MB start and

MB end parameters! These parameters primarily serve to prevent error mes-

sages in downstream systems caused by brief overstepping of measuring

ranges.

The parameter min. output is usually only used for devices with an output signal 4…20 mA because frequently values of below 3.8 mA are evaluated as error signals.

The max. output value can be used for the voltage and current to limit the maximum value.

The value defined via the parameter Error signal is issued if the device detects

an internal error and can no longer work correctly. It should be noted here that

not all potential errors and faults can be detected by the device itself.

Page 18

3 | Commissioning FISCHER Mess- und Regltechnik GmbH

18 / 32 BA_EN_MS13

3.3.5 Menu Level Function

The Function menu level is a variable menu whose appearance depends on the

value of the Function parameter. There are linear, square rooted and table functions

Linear function

The input signal is linear before being sent to the display and the output. The

range defined in the menu "Measuring" serves as the measuring range. If the

function LINEAR is active, the other menu items are cancelled.

Parameter name Description Value range

Function Function Value = linear

Square rooted function

Here, the input signal is square rooted before being sent to the display and the

output. This is necessary e.g. for flow measurements with differential pressure.

A free unit can be defined for the display. To do this, the start and end of the

display range and the number of decimal points are defined. It is also possible

to define the unit with 4 characters.

Parameter name Description Value range

Function Function Value = square

rooted

MB decimal pl. Measuring range

decimal places

1234, 123.4, 12.34,

1,234, 12345, 123456

MB start Measuring range start -9999 … +9999

MB end Measuring range end -9999 … +9999

MB unit Measuring range unit 4 characters

The following section contains descriptions of the parameters MB decimal pl.,

MB start, MB end and MB unit to describe the table function.

Tables function

This function allows free adjustment of the input variable to the display and output via a table with up to 30 support points. A value pair comprising a measured

value and display value is issued for every support point.

NOTICE

Change of parameter

When switching from TABLE to another function, the table is initialised again

and the existing values are lost.

Parameter name Description Value range

Function Function Value = Table

MB decimal pl. Measuring range

decimal places

1234, 123.4, 12.34,

1,234, 12345, 123456

MB start Measuring range start -9999 … +9999

MB end Measuring range end -9999 … +9999

MB unit Measuring range unit 4 characters

No. of pairs Number of pairs n = 3…30

Value pair1 Value pair 1

MB-start … MB-end

Value pair2 Value pair 2

Value pair3 Value pair 3

Page 19

FISCHER Mess- und Regltechnik GmbH Commissioning | 3

BA_EN_MS13 19 / 32

Parameter name Description Value range

∙∙∙

Value pair30 Value pair 30

The display range is defined with the parameters MB decimal pl., MB start and

MB end. The user can select the configuration freely.

Using the parameter MB decimal pl., it is possible to select between a 5 or 6digit presentation. The resolution is not increased. Only an extra zero or two

zeros are added. This serves the correct display of larger values. The measuring range must be positive for the 6 digit presentation.

The MB unit gives the user the option of defining a completely independent

unit. Letters, numbers or special characters can be used. The unit can be max.

4 characters long.

If the function TABLE is selected, then it is also necessary to state the No. of

pairs. It is defined here how many pairs of values (support points) are used in

the table. A table is made up of at least 3, max. 30 support points.

NOTICE

Number of value pairs

If the number of value pairs is changed, the table is initialised again and the existing values are deleted.

Value pair

2

+14,6 mbar +8,6 %

+0,0 ... +100,0 mbar

1

2

1 input mark (value flashes)

2 allowed range of values

Illustration17: Value pair

Start End

Measuring range

Output / display [%]

100

0

0.0 100.0

Value pair 2

Illustration18: Table function (example)

The individual value pairs can be seen and changed with the Value pair1 to

Value pair30 parameters. A value pair comprises a measured value (left side)

and a display value (right side). The measured value must lie within the measuring range and the display value must lie within the defined "free unit". The respective limits are shown during input. The table must contain either increasing

or decreasing values. the table must contain either continuously increasing or

continuously failing values. A change from an increasing to a decreasing characteristic curve within a support point table is not allowed.

Page 20

3 | Commissioning FISCHER Mess- und Regltechnik GmbH

20 / 32 BA_EN_MS13

3.3.6 Menu Level Display

The Display menu level is a variable menu whose appearance depends on the

value of the colour parameter. In addition to the various colours for the background lighting, there are also two auto-functions with colour switching available.

Parameter name Description Value range

Colour Colour Off, red, green, yellow,

blue, pink, turquoise,

white,

Auto1: Red-green

Auto2: Red-yellowgreen

Lighting Lighting time 0 s, 10 … 600 s

Contrast Contrast 15 … 45

Bar chart Barchart display yes, no

The mots important parameter is Colour. A fixed colour can be defined for the

background colour here. There are also two auto-functions with colour switching

available. Alternatively, the background illumination can be permanently deactivated.

If permanent lighting is not required, the parameter Lighting time can be used

to define when the lighting should be switched off after the last time a button is

pressed. In addition to permanent lighting (0 s), automatic shut-down after 10…

600 s is also possible. The set time is only valid if the parameter Colour is not

set to "off".

Amongst other things, the legibility of the display depends on the temperature

and the reading angle. To ensure optimised legibility, the display can be adjusted using the parameter Contrast. When the contrast is changed, it is possible

that the display appears empty or almost completely black. In this case, the

contrast must be turned up or down.

Via the parameter Bar chart, the display can be switched between a display

where the measured value is either shown in large digits or the display shows

small digits and an additional barchart.

Auto1: Colour-change red to green

In the mode with the automatic colour switchover, it is possible to enter the required switch thresholds "red-green switchover", "green-red switchover".

The switching thresholds can be moved within the measuring range. The series

of switch points cannot be altered.

Parameter name Description Value range

Red-Gr. switch. Red-green switching MRS - 50% …

MRE + 50%

Gr-Red switch. Green-red switching

Hysteresis Hysteresis 0.1 … 10.0 %

Delay Delay 0 … 1800 s

Colour Colour Off, red, green, yel-

low, blue, pink, turquoise, white,

Auto1: Red-green

Auto2: Red-yellowgreen

Lighting Lighting time 0 s, 10 … 600 s

Contrast Contrast 15 … 45

Bar chart Barchart display yes, no

Page 21

FISCHER Mess- und Regltechnik GmbH Commissioning | 3

BA_EN_MS13 21 / 32

Basic measuring range

ME

F1 F2

MA

Illustration19: Function Auto1

MA MB-start Measuring range start

F1 Red-Gr. switch. Red-green switching

F2 Gr-Red switch. Green-red switching

ME MB-end Measuring range end

The parameter Hysteresis can be used to prevent fast and unwanted colour

changes. The hysteresis is set in the range 0.1... 10%.

NOTICE

Overlapping colour areas

Note: In the case of large hysteresis values, steps must be taken to ensure that

the ranges of the individual colours do not overlap. Otherwise it is possible that

the colour change may not function in the desired way.

The parameter Delay offers a further option to prevent unwanted colour

changes. The colour change here can be delayed between 0…1800 s.

The parameter Lighting can be used to define when the lighting should be

switched off after the last time a button is pressed. In addition to permanent

lighting, automatic shut-down after 10…600 s is also possible. The set time is

only valid if the parameter Colour is not set to "off". The lighting can be

switched on permanently with the value 0s.

The legibility of the display can be adjusted using the parameter Contrast.

When the contrast is changed, it is possible that the display appears empty or

almost completely black. In this case, the contrast must be turned up or down

again.

Via the parameter Bar chart, the display can be switched between a display

where the measured value is either shown in large digits or the display shows

small digits and an additional barchart.

Auto2: Colour-change red-yellow-green

In the Auto 2 mode with the automatic colour switchover, it is possible to enter

the required switch thresholds "red-yellow switchover", "yellow-green

switchover", green-yellow switchover, "yellow-red switchover".

The switching thresholds can be moved within the measuring range. The series

of switch points cannot be altered.

Parameter name Description Value range

Red-Yell.switch. Red-yellow switchover

MRS - 50% …

MRE + 50%

Yell.-Gr.switch. Yellow-green switchover

Gr.-Yell. switch Green-yellow switchover

Yell.-Red switch Yellow-red switchover

Hysteresis Hysteresis 0.1 … 10.0 %

Delay Delay 0 … 1800 s

Colour Colour Off, red, green, yel-

low, blue, pink, turquoise, white,

Page 22

3 | Commissioning FISCHER Mess- und Regltechnik GmbH

22 / 32 BA_EN_MS13

Parameter name Description Value range

Auto1: Red-green

Auto2: Red-yellowgreen

Lighting Lighting time 0 s, 10 … 600 s

Contrast Contrast 15 … 45

Bar chart Barchart display yes, no

Basic measuring range

MA ME

F1 F2 F3 F4

Illustration20: Function Auto2

MA MB-start Measuring range start

F1 Red-Yell.switch. Colour-change red to yellow

F2 Yell.-Gr.switch. Colour-change yellow to green

F3 Gr.-Yell. switch Colour-change green to yellow

F4 Yell.-Red switch Colour-change yellow to red

ME MB-end Measuring range end

In this menu the same parameters are used as those described in the previous

sections.

NOTICE

Unused range

If a range is not to be used, the associated switch thresholds (F1…F4) can be

set to the same value.

Example

The parameter Colour is set to Auto2. Only the green, yellow and red ranges

are required here. To fade out the lower ranges red and yellow, the switch

thresholds "red-yellow switching" and "yellow-green switching" are set to the

start of the measuring range.

Basic measuring range

MA ME

F1

F2

F3 F4

Illustration21: Example Auto2

3.3.7 Menu Level System

Parameter name Description Value range

Language Language change DE, EN, FR, ES,

IT,PT,HU

Page 23

FISCHER Mess- und Regltechnik GmbH Commissioning | 3

BA_EN_MS13 23 / 32

Parameter name Description Value range

Software Info Information about the software Device type, serial

number, firmware

version

Config Info Information about the configur-

ation

Basic measuring

range, output signal,

contacts

Key numbers Key numbers Operating time,

switch cycles of the

contacts

Password Password 0/1…999

Load config. Load configuration

Save config Save configuration

The user menu can be switched to German, English, French, Spanish, Italian,

Portuguese or Hungarian using the parameter Language.

The menu items Software - Info and Config - Info provide information about

the device. This information helps to answer questions about the device quickly.

• The device type, controller ID and the firmware version is shown in the soft-

ware info.

• The basic measuring range, the defined output signal and existing contacts

are stated in the Config Info.

The Statistics provide information about the operating time and the relay

switching cycles from the time of delivery. The operating time is shown in days

(d) and hours (h)

A Password can be used to protect the menu against unauthorised access.

The password is a figure from 1 to 999. The input 0 means that no password is

active.

The password needs to be set if the user presses the button in normal mode to

enter the menu. If a wrong password is entered, the system automatically jumps

back to normal mode again. If no password is active, the display immediately

jumps to the menu.

NOTICE

Forgotten password

The user cannot restore a forgotten password. Please contact the manufacturer

in this case.

The user can load a saved configuration via the menu item Load config. This

means that a functional set of parameters can be loaded after trying out various

settings.

The menu item Save config. serves to save the existing parameters in a protected memory area. This is helpful if the settings of a functional device needs

to be optimised. Save config. and Load config. can be used to quickly restore

the initial status again.

NOTICE

Delivery condition

If the user has not yet saved a configuration, the default values (status on delivery) are loaded. In this case, any measuring range spreads or switch points are

reset and the device needs to be newly configured.

Page 24

4 | Technical Data FISCHER Mess- und Regltechnik GmbH

24 / 32 BA_EN_MS13

4 Technical Data

4.1 General Information

Reference conditions (acc. to IEC 61298-1)

Temperature error +15 … +25 °C

Relative humidity 45 … 75 %

Air pressure 86 … 106 kPa 860 … 1060 mbar

Installation position User-defined

4.2 Input variables

Relative pressure

Measuring

range

Pressure safety Characteristic curve devi-

ation

Overpressure Bursting pres-

sure

Option Default

0…+1.6 bar 4 bar (56 PSI) 7 bar 0.5%FS 1.0 % FS

0…+2.5 bar 10 bar 15 bar 0.5%FS 1.0 % FS

0…+4 bar 10 bar 15 bar 0.5%FS 1.0 % FS

0…+6 bar 20 bar 35 bar 0.5%FS 1.0 % FS

0…+10 bar 40 bar 70 bar 0.5%FS 1.0 % FS

0…+16 bar 40 bar 70 bar 0.5%FS 1.0 % FS

0…+25 bar 100 bar 150 bar --- 1.0 % FS

0…+40 bar 100 bar 150 bar --- 1.0 % FS

0…+60 bar 200 bar 250 bar --- 1.0 % FS

Vacuum and

± measuring ranges

Measuring

range

Pressure safety Characteristic curve devi-

ation

Overpressure Bursting pres-

sure

Option Default

0…-1 bar 4 bar (56 PSI) 7 bar --- 1.0 % FS

-1…0 bar 4 bar (56 PSI) 7 bar --- 1.0 % FS

-1…+0.6 bar 4 bar (56 PSI) 7 bar --- 1.0 % FS

-1…+1.5 bar 4 bar (56 PSI) 7 bar --- 1.0 % FS

-1…+3 bar 10 bar 15 bar --- 1.0 % FS

-1…+5 bar 20 bar 35 bar --- 1.0 % FS

-1…+9 bar 40 bar 70 bar --- 1.0 % FS

-1…+15 bar 40 bar 70 bar --- 1.0 % FS

-1…+24 bar 100 bar 150 bar --- 1.0 % FS

4.3 Output parameters

Analogue output

Output signal Signal range Apparent ohmic resistance

0…20 mA 0.0…21.0 mA RL ≤ 600 Ω

4…20 mA

0…10 V 0.0…11.0 V RL ≥ 2 kΩ

Page 25

FISCHER Mess- und Regltechnik GmbH Technical Data | 4

BA_EN_MS13 25 / 32

Switching outputs

2 potential-free relay contacts or

2 potential-free semiconductor switches (MOSFET)

Relay MOSFET

Progr. switching function Open contact (NO)

Break contact (NC)

One-pin activator (NO)

One-pin deactivator (NC)

Max. switching voltage 32 V AC/DC 3…32 V AC/DC

Max. switching current 2 A 0.25 A

Max. switching output 60 W (VA) 8 W / 8 VA

RON ≤ 1 Ω

4.4 Measurement accuracy

Non-linearity Default < 1.0 % FS

Option

1)

< 0.5 % FS

Hysteresis < 0.5 % FS

Characteristic curve deviation

2)

Default 1.0 %

Option

1)

0.5 %

Temperature drift Zero point 0.07 % FS/K

Measuring range 0.05 % FS/K

1)

only possible for certain measuring ranges

2)

incl. non-linearity and hysteresis

4.5 Auxiliary energy

Rated Voltage 24 V AC/DC

Admissible operating voltage Ub = 12…32 V DC

Ub = 16.5…32 V AC

Electrical connection 5-pin M12 circular plug connector

4.6 Application conditions

Ambient conditions

Increase ambient temperature

-10 … +70 °C

Media temperature -10 … +70 °C

Storage temperature -20 … +70 °C

Enclosure protection class IP 65 acc. to EN 60529

EMC EN 61326-1:2013

EN 61326-2-3:2013

RoHS EN 50581:2012

Materials of the parts that come into contact with the surroundings

Housing Stainless steel 1.4301

Bayonet ring Stainless steel 1.4301

Front plate Aluminium

Front film PET Polyethylene terephthalate

Bayonet ring seal NBR Nitrile rubber

Blowout plug FKM Fluorocarbon rubber

Materials of the parts that come into contact with the measuring medium

Process connection Stainless steel 1.4404

Measuring diaphragm ceramic

Seal FKM Fluorocarbon rubber

Page 26

4 | Technical Data FISCHER Mess- und Regltechnik GmbH

26 / 32 BA_EN_MS13

4.7 Display and operating interface

Advertisement

4...6-digit LCD, full graphic, colour backlighting

Programming

Attenuation 0.0…100.0s (jump response 10/90%)

Switch output Switch-off point, switch-on point, delay (0...1800s),

function (NC / NO contact)

Measuring range unit bar, PSI, kPa, "free unit"È, starting value, end

value and decimal point for "free unit"

Output signal User-definable within the basic measuring range

(1)

Zero-point stabilising 0…⅓ of the basic measuring range

(2)

Zero point correction (offset)

±⅓ of the basic measuring range

(3)

Implementation of characteristic curve

linear, square rooted, table with 3...30 support

points

Password 001 ... 999 (000 = no password protection)

(1) Max. effective spread 4:1

(2) measured values around zero are set to zero.

(3) To compensate different installation positions.

4.8 Construction design

4.8.1 Dimensional picture

M12 plug 1 M12 plug 2

Blowout plug

4

68

203

Process connection

Ø100

51.6

40

G½

Ø6

Illustration22: Dimensional drawing

Page 27

FISCHER Mess- und Regltechnik GmbH Technical Data | 4

BA_EN_MS13 27 / 32

4.8.2 Process connection

G½B G¼B ¼-18 NPT EXT Schrader

®

20

Code 87 85 88 S1

13

20

7.5

3

2

Ø6

Ø5

Ø2

Ø17.5

Ø9.5 ¼-18 NPT

7/16 UNF

G½

G¼

G½

Illustration23: Process connection

Port Material

G½ B Connection shanks with external thread 1.4404

G¼ B Connection shanks with external thread 1.4404

¼-18 NPT EXT Connection shanks with external thread 1.4404

7/16 UNF Connection with inner thread for the

Schrader®- screw connection >

1.4404

Page 28

5 | Order Codes FISCHER Mess- und Regltechnik GmbH

28 / 32 BA_EN_MS13

5 Order Codes

Process connection

Output signal

operating voltage

Electrical connection

Measuring System / Design

M S 1 3

Type

Measuring range

0

1 2 5 6 7 8 9 10 11 123 4Code no.

Measurement accuracy

L V

Process connection direction

[1.2] Measuring range converted ranges

[bar] [kPa] [PSI]

03 0…1.6 bar 0 … 160 kPa 0 … 23.21 PSI

04 0…2.5 bar 0 … 250 kPa 0 … 36.26 PSI

05 0…4 bar 0 … 400 kPa 0 … 58.01 PSI

06 0…6 bar 0 … 600 kPa 0 … 87.02 PSI

07 0…10 bar 0 … 1000 kPa 0 … 145.0 PSI

08 0…16 bar 0 … 1600 kPa 0 … 232.1 PSI

09 0…25 bar 0 … 2500 kPa 0 … 362.6 PSI

10 0…40 bar 0 … 4000 kPa 0 … 580.1 PSI

11 0…60 bar 0 … 6000 kPa 0 … 870.2 PSI

31 -1…0 bar -100 … 0 kPa -14.50 … 0 PSI

32 -1…0.6 bar -100 … 60 kPa -14.50 … 8.702 PSI

33 -1…1.5 bar -100 … 150 kPa -14.50 … 21.75 PSI

34 -1…3 bar -100 … 300 kPa -14.50 … 43.51 PSI

35 -1…5 bar -100 … 500 kPa -14.50 … 72.52 PSI

36 -1…9 bar -100 … 900 kPa -14.50 … 130.5 PSI

37 -1…15 bar -100 … 15000 kPa -14.50 … 217.5 PSI

38 -1…24 bar -100 … 2400 kPa -14.50 … 348.1 PSI

39 0…-1 bar 0 … -100 kPa 0 … -14.50 PSI

[3] Measurement accuracy

M 1.0 % characteristic curve deviation

0 0.5 % characteristic curve deviation

[4.5] Process connection Material

85 Connection shanks with external thread G¼ B

1.4404

87 Connection shanks with external thread G½ B

88 Connecting port with outer thread ¼ -18 NPT EXT

S1 Schrader® screw connection inner thread 7/16 UNF

Page 29

FISCHER Mess- und Regltechnik GmbH Order Codes | 5

BA_EN_MS13 29 / 32

[6.7] Output signal Operating voltage

EL 0 … 20 mA 24 V AC/DC 3-wire version

PL 4 … 20 mA 24 V AC/DC 3-wire version

CL 0 … 10 V 24 V AC/DC 3-wire version

[8] Measuring value display/switching elements

C 4...6-digit colour change LCD 2 relay contacts

D 4...6-digit colour change LCD 2 semiconductor switches

[9] Process connection direction

L Port left

R Port right

0 Port on top

U Port below

[10] Electrical connection

L M12 connector socket Ms-nickel-plated

[11] Measuring System / Design

V FKM Fluororubber, Viton®

5.1 Accessories

Order no. Designation No. of

Poles

Length

06401993 Connection cable for switching outputs

with M12 connector

4-pin 2 m

06401994 Connection cable for switching outputs

with M12 connector

4-pin 5m

06401995 Connection cable for supply/signal

with M12 connector

5-pin 2 m

06401996 Connection cable for supply/signal

with M12 connector

5-pin 5 m

Accessories acc. to data sheet MZ

*)

MZ310# Wall mount acc. to DIN 16281

MZ1### Siphons

MZ400# Capillary throttle coil

MZ5### Manometer shutoff valve acc. to DIN 16270/16271

MZ6### Manometer shutoff valve acc. to DIN 16272

Parameter setting adapter

*)

EU05 Transmitter PC Interface incl. PC software

*)

A data sheet is available on our website or on request..

Page 30

6 | Attachments FISCHER Mess- und Regltechnik GmbH

30 / 32 BA_EN_MS13

6 Attachments

Illustration24: CE_DE_MS13

Page 31

FISCHER Mess- und Regltechnik GmbH Attachments | 6

BA_EN_MS13 31 / 32

Page 32

6 | Attachments FISCHER Mess- und Regltechnik GmbH

32 / 32 BA_EN_MS13

Loading...

Loading...