Page 1

Instruction Manual

MS10 Contact Pressure Vacuum Gauge

Table of Contents

1. Safety Instructions

2. Intended Applications

3. Product Description and Functions

4. Installation

5. Commissioning

6. Maintenance

7. Transport

8. Service

9. Accessories

10. Disposal

11. Specifications

12. Dimensions

13. Ordering Code

14. Declaration of Conformity

15.7.10 BA_GB_MS10.fm

1. Safety Instructions

1.1. General

This manual contains detailed

information about the product

and instructions for its installation, operation and maintenance.

Operators and other technical

personnel responsible for the equipment must read

this thoroughly before attempting to install or operate this equipment. A copy of this manual must

always be kept accessible at the place of work for

reference by concerned personnel.

Chapter 1 (sections 1.2 through 1.7) contains general as well as specific safety instructions. Chapters

2 through 10, covering topics ranging from intended

purpose of the equipment to its final disposal, also

include important points relating to safety. Overlooking or ignoring any of these safety points can

endanger humans and animals, and possibly cause

damage to other equipment.

1.2. Personnel Qualification

Personnel responsible for installation, operation,

maintenance and inspection of this product must

have the qualifications, training and experience

necessary to carry out such work on this type of

equipment.

1.3. Risks of Disregarding Safety Instructions

Disregarding safety instructions, use of this product

for purposes for which it is not intended, and/or operation of this product outside the limits specified for

any of its technical parameters, can result in harm to

persons, the environment, or the plant on which it is

installed. Fischer Mess- und Regeltechnik GmbH

will not be responsible for consequences in such

circumstances.

Page 2

1.4. Safety Instructions for Operators

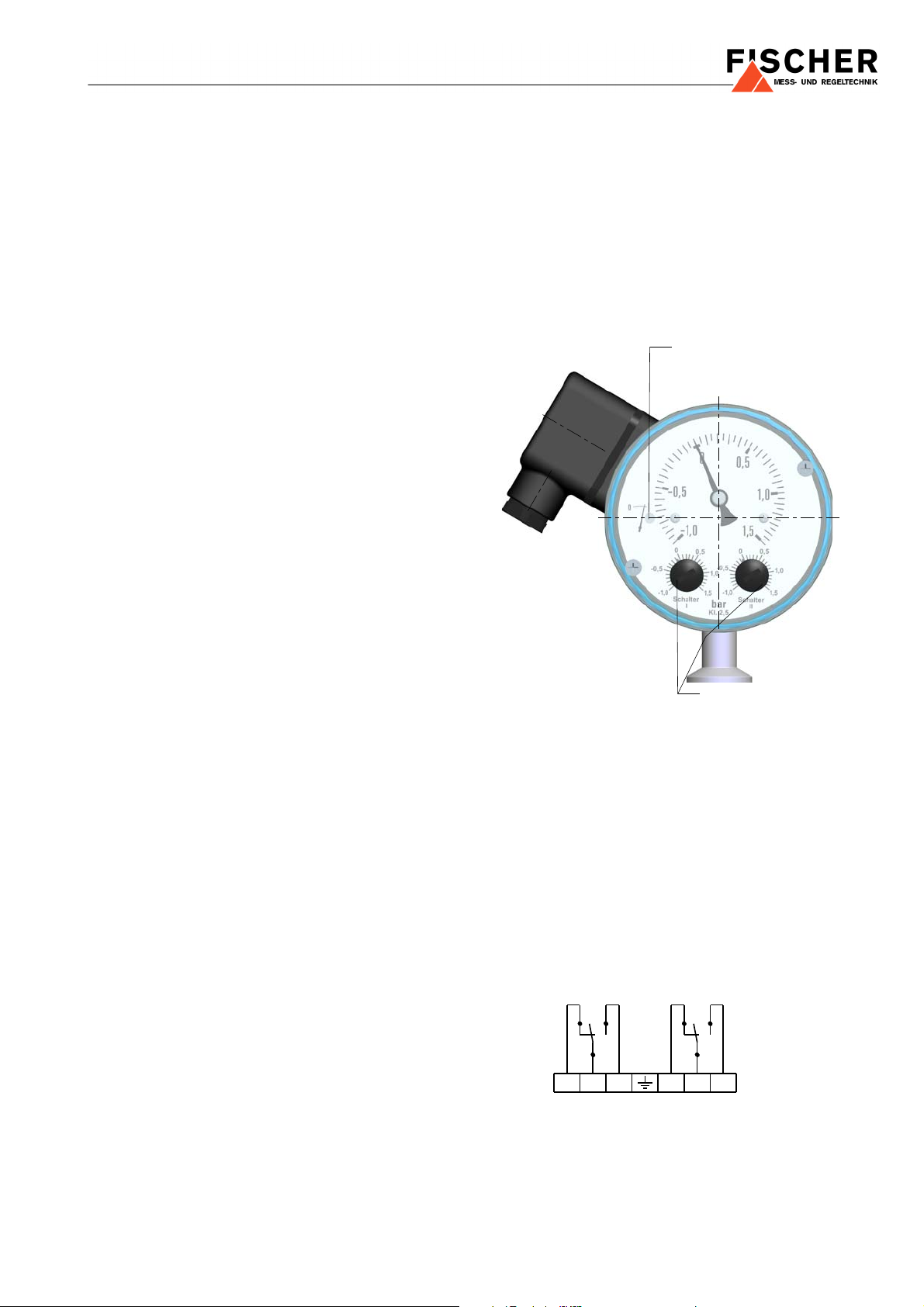

1. Measuring diaphragm

2. Motion work

3. Tappet

4. Micro switches,

Operating elements

5. Pressure chamber

Safety instructions for the proper use of this product must

be followed. This information must be available at all times

to personnel responsible for installation, operation, maintenance and inspection of this product. Adequate steps

must be taken to prevent the occurrence of hazardous

conditions that can be caused by electric energy and the

convertible energy of the process media. Such conditions

can, for example, be the result of improper electrical or

process connections. Detailed information is available in

relevant published norms (DIN EN, UVW in Germany;

and equivalents in other countries), industrial standards

such as DVWG, GL-, VDE guidelines, as well as regulations of the local authorities (e.g., EVUs in Germany).

1.5. Modifications Forbidden

Modification or other technical alteration of the product is

not permissible. This also applies to the use of unauthorized spare parts for repair / maintenance of the product.

Any modifications to this product, if and as necessary,

should be done only by Fischer Mess- und Regeltechnik

GmbH.

1.6. Operational Restrictions

The operational reliability of the product is guaranteed

only when used for intended purposes. The product must

be selected and configured for use specifically with

defined process media. The limiting values of operating

parameters, as given in the product specification sheet,

must never be crossed.

1.7. Safety Considerations during Installation and Maintenance

The safety instructions given in this manual, existing national regulations relating to accident prevention and the

internal safety rules and procedures of the user organization regarding safety during installation, operation and

servicing must all be followed meticulously.

It is the responsibility of the users to ensure that only suitably qualified and experienced technical personnel are

used for installation, operation and servicing of this equipment.

3. Product Description and Functions

3.1. Schematic Diagram

3.2. Principles of Operation

The measuring system consists of two encapsulated and

hydraulically coupled metal diaphragm. When subjected

to pressure it causes a deflection proportional to the

strength of pressure. Opposite of the medium-touched

diaphragm a tappet returns the deflection to a motion work

and the operating elements of the micro switches.

When subjected to excessive pressure each metal diaphragm based oneself on the chassis of the capsule.

Therefore the device is prevented from damage.

4. Installation

The instrument is intended for pipe mounting by KF10

small flange pipe connection per DIN 28403 / ISO 2861.

The instrument is factory calibrated while mounted upright, pressure port downward and must be mounted that

way.

2. Intended Applications

Overpressure and vacuum proof contact pressure gauge

for control and supervising purposes in vacuum processes.

The product must be used only for applications and under

conditions specified by Fischer Mess- und Regeltechnik

GmbH.

Please confer with Fischer Mess- und Regeltechnik

GmbH prior to using this instrument along with polluted or

aggressive media. For use with this media it needs to be

adapted in every part with direct contact to the media.

To ensure safety during installation and maintenance integrate adequate shut-off valves. By recommended

accessories the instrument can be

• depressurized or shut down,

• cut off a plant to enable controlling or repairing,

• operational checked on site.

2

Page 3

4.1. Process Connection

setting of switching points

zero point adjustment screw

Gerät druck- und spannungslos

6

413

2

S1 S2

5

Instrument pressureless and dead

• Only qualified technicians authorized for this type of

work should undertake installation.

• Only for intended mechanical process connection.

• Ensure that process equipment and pressure lines

are at atmospheric pressure before making pressure

connections.

• The instrument should be provided with suitable pro-

tection against pressure surges (e.g., snubber or

pulsation damper).

• Ensure that the mechanical configuration and mate-

rials of construction of the instrument are compatible

with the process media.

• Ensure that process pressure is always less than the

specified safe pressure rating.

4.2. Electrical Connection

• Only qualified technicians authorized for this type of

work should undertake installation.

• Switch off electrical power to the plant before attempt-

ing electrical installation work of any kind.

• Electrical connections must comply with relevant in-

ternational, national and local regulations and norms

relating to electrical and instrumentation installations.

5.2. Adjustment of Zero Point

• Vent pressure lines to atmosphere.

• Remove cover.

• Set measuring indicator to zero by zero point adjustment screw (see 5.3.).

• Mount cover.

5.3. Location of Zero Point Adjustment Screw and

Setting of Switching Points

• Make electrical connections to the instrument through

a suitable fuse.

5. Commissioning

• Power supply and signal cabling as well as process

connections to the instrument must be correctly selected to meet operational requirements, and installed

in a way that does not cause physical stress to the

instrument.

• The pressure line must have a downward gradient

throughout, from the pressure instrument to the process vessel / pipe. This is to prevent formation of air /

gas pockets (for liquid applications) and liquid plugs

(for air / gas applications). If this continuous downward gradient cannot be provided for any reason,

then suitable water and / or air separation devices

must be inserted in the pressure line.

• The instrument and lines must be protected against

frost when used with water.

• The pressure line must be kept as short as possible

and must not have short bends to avoid measurement

errors induced by pressure line delays.

• Carefully check the pressure-tightness of pressure

connection before start-up.

5.1. Pressure Connection

Pressure connection must be installed in a way that does

not cause physical stress to the instrument.

5.4. Setting of Switching Points

• Unscrew plugs from cover.

• Set desired switching points according to marks on

reference value scale by screwdriver. Achievable

accuracy: 5% FS. More exact settings can be achieved by using accessories like testing manometer,

ohmmeter on site or ex factory.

• Screw plugs in.

5.5. Connection Diagram

3

Page 4

6. Maintenance

The instrument is inherently maintenance-free.

However, to ensure reliable operation and maximize the

operating life of the instrument, it is recommended that the

instrument, its external electrical and process connections

and external connected devices be regularly inspected,

e.g.:

• Check the display.

• Check the switching output connections and external

devices that are connected to these.

• Check all pressure connections for leak-tightness.

• Check the integrity of all electrical connections of the

instruments.

Inspection and test schedules depend on operating and

site conditions. The operating manuals of other equipment

to which the instrument is connected must be read thoroughly to ensure that all of them work correctly when connected together.

7. Transport

The product must be protected against shock and vibration during transport. It must therefore be properly packed,

preferably in the original factory packaging, whenever it is

to be transported.

8. Service

Any defective devices or devices with missing parts

should be returned to Fischer Mess- und Regeltechnik

GmbH. For quick service contact our service department.

Remaining medium in and on dismantled

measuring instruments may cause danger

to persons, environment and equipment.

Take reasonable precautions! Clean the

instrument thoroughly if necessary.

9. Accessories

N.A.

10. Disposal

Protect your environment!

Use the product in accordance with relevant regulations. Please be aware of environmental consequences of disposal

at the end of the product's life, and take

care accordingly.

4

Page 5

11. Specifications

General

Measuring range (s. Ordering Code)

Nominal pressure 25 bar

Max. pressure overpressure proof to nominal pressure (all measuring ranges),

vacuum proof up to fine vacuum 10

Leakage rate

Perm. ambient temperature -10 ... +70°C

Perm. media temperature 70°C

Degree of protection IP54 per DIN EN 60529

Mounting position vertical, pressure port downward

Accuracy ± 2.5% FS

Adjustment of zero point located in the dial

Switching Points

10

10

-7

Pa m³/s

-6

mbar l/s

-2

mbar

Output contacts 1 or 2 micro switches, 1-pole changing contacts

Setting of switching points

adjustable by reference value scale

smallest adjustable value: approx. 5% FS

Switching hysteresis approx. 2.5% FS

Load / contact U ~ max. = 250 V AC, I max. = 5 A, P max. = 250 VA

U = max. = 30 V DC, I max. = 0,4 A, P max. = 10 W

Connections

Electrical Connection cable terminal box

Pressure Connection

KF10 small flange pipe connection DIN 28403 and ISO 2861

Measuring System metal diaphragm measuring system, welded

Materials

Pressure

Measuring

chamber stainless steel 1.4404

diaphragm 1.4571, Duratherm®

Materials, wetted inner parts stainless steel 1.4404, 1.4571

Materials, housing aluminium, eloxadized in black

Materials, front cover macrolon

Weight 2,6 kg

Mounting pipe mounting by KF10 small flange pipe connection per DIN 28403 / ISO 2861

5

Page 6

12. Dimensions (all units in mm unless otherwise stated)

KF10 small flange

pipe connection

cable terminal box

M16 x 1.5 plastic

connection

6

Page 7

13. Ordering Code

0

0

EA 0 00K

K

Contact Pressure

Vacuum Gauge MS10

Measuring range

-200 . . . 200 mbar.................................................. > B 5

0 . . . 400 mbar.................................................. > 8 3

-1 . . . . . 0,6 bar.................................................. > 3 2

-1 . . . . . 1,5 bar.................................................. > 3 3

-1 . . . . . 3 bar.................................................. > 3 4

-1 . . . . . 5 bar.................................................. > 3 5

-1 . . . . . 9 bar.................................................. > 3 6

-1 . . . . 15 bar.................................................. > 3 7

-1 . . . . 24 bar.................................................. > 3 8

Other ranges upon request ..................................... > 9 9

Wetted Parts

1.4404/1.4571 .......................................................................> E

Pressure Chamber

Aluminium, eloxadized in black.....................................................> A

Type

Bottom connection, KF small flange pipe connection ................................. > K

Switching Elements

1 adjustable microswitch.................................................................................... > A

2 adjustable microswitches ................................................................................ > B

Electrical Connection

cable terminal box..................................................................................................... > K

7

Page 8

14. Declaration of Conformity

Technische Änderungen vorbehalten • Subject to change without notice • Changements techniques sous réserve

Fischer Mess- und Regeltechnik GmbH • Bielefelder Str. 37a • D-32107 Bad Salzuflen • Tel. +49 5222 9740 • Fax +49 5222 7170

eMail: info@fischermesstechnik.de • www.fischermesstechnik.de

8

Loading...

Loading...