Page 1

d e v e l oping s o l u t i o n s

*09005086* DB_BA_EN_ME01_R Rev.A 12/16

*09005086*

Data Sheet and Operating Manual

ME01

Digital manometer

ME01 ## # 87 # HL R####

Gas explosion protection zone 2

Table of Contents

1 Safety guidelines

2 Application purpose

3 Product and function description

4 Installation and assembly

5 Commissioning

6 Maintenance

7 Transportation

8 Service

9 Accessories

10 Waste disposal

11 Technical Data

12 Dimensional drawings

13 Order Codes

14 Attachments

1 Safety guidelines

1.1 General Information

This operating manual contains instructions fundamental to the installation, operation and maintenance of the device

that must be observed unconditionally. It

must be read by the assembler, operator and the

specialized personnel in charge of the instrument

before it is installed and put into operation. This operating manual must always be accessible at the

place of installation.

The subsequent sections on general safety instructions 1.2 - 1.7 as well as the following special instructions ranging from intended use to disposal 210 contain important safety instructions the nonobservance of which can cause danger to persons,

animal and physical objects.

1.2 Personnel Qualification

The instrument may only be installed and commissioned by specialized personnel familiar with the installation, commissioning and operation of this

product.

Specialized personnel are persons who can assess

the work they have been assigned and recognize

potential dangers by virtue of their specialized train-

ing, their skills and experience and their knowledge

of the pertinent standards.

For explosion-proof models the specialized personnel must have received special training or instruction or be authorized to work with explosion-proof

instruments in explosion hazard areas.

1.3 Risks due to Non-Observance of Safety Instructions

Non-observance of these safety instructions, the intended use of the device or the limit values given in

the technical specifications can be hazardous or

cause harm to persons, the environment or the

plant itself. The supplier of the equipment will not be

liable for damage claims if this should happen.

1.4 Safety Instructions for the Operating Company and the Operator

The safety instructions governing correct operation

of the instrument must be observed. The operating

company must make them available to the installation, maintenance, inspection and operating personnel. Dangers arising from electrical components,

energy discharged by the medium, escaping medium and incorrect installation of the instrument must

be eliminated. The particulars can be

found in the respective regulations

such as DIN, EN, explosion hazard,

Page 2

WARNING!

… indicates a potentially dangerous

situation, non-observance of which

could endanger persons, animals, the

environment or objects.

INFORMATION!

… highlights important information efficient and smooth operation.

TIP!

… indicates recommendations that are

not specifically necessary in certain

situations but which could be useful.

accident prevention regulations and also in the industry guidelines issued by the DVWG, GL, etc.

and the VDE as well as the local EVUs.

The instrument must be decommissioned and secured against inadvertent re-operation if a situation

arises in which it must be assumed that safe operation is no longer possible. Reasons for this assumption could be:

• evident damage to the instrument

• failure of the electrical circuits

• long storage in temperatures over 85°C

• considerable strain due to transport

Repairs may be carried out by the manufacturer only.

A professional single conformity inspection as per

DIN EN 61010, section 1, must be carried out before the instrument can be re-commissioned. This

inspection must be performed at the manufacturer's

location. Correct transport and storage of the instrument are required.

1.5 Unauthorised Modification

Modifications of or other technical alterations to the

instrument by the customer are not permitted. This

also applies to replacement parts. Any modifications/alterations required will be carried out by

Fischer Mess- und Regeltechnik GmbH only.

1.6 Impermissible modes of operation

The operational safety of this instrument can only

be guaranteed if it is used as intended. The instrument model must be suitable for the medium used

in the system. The limit values given in the technical

data may not be exceeded.

1.7 Safe working practices for maintenance and installation work

The safety instructions given in this operating manual, any nationally applicable regulations on accident prevention and any of the operating company's

internal work, operating and safety guidelines must

be observed.

The operating company is responsible for ensuring

that all required maintenance, inspection and installation work is carried out by qualified specialized

personnel.

1.8 Explanation of symbols

2 Application purpose

Electronic manometer for measuring over-pressure

and under-pressure of fluid and gas-like measuring

substances. The device is to be exclusively used for

the applications agreed between the manufacturer

and the user.

Explosion hazard area classification

The digital manometers ME01 are suitable for use

as 'Electrical equipment for use in areas with combustible gases', zone 2.

Designation as per guideline 2014/34/EU

II 3G Ex nA IIC T4

3 Product and function description

3.1 Design and mode of operation

A ceramic measuring cell acts as the pressure

transducer. The high resistance of the ceramic materials that are used allow use even for aggressive

media. There is a resistance measuring bridge attached to the side of the measuring diaphragm that

faces away from the medium. When pressure is exerted, the membrane distorts in the elastic range. t

the same time, the resistance values of the bridge

change proportionally to the measuring pressure.

These values are implemented and displayed by

the installed electronics. There are electrical uniform signals 0/4…20 mA and 0…10 V in a 3-wire

system available for remote transmission.

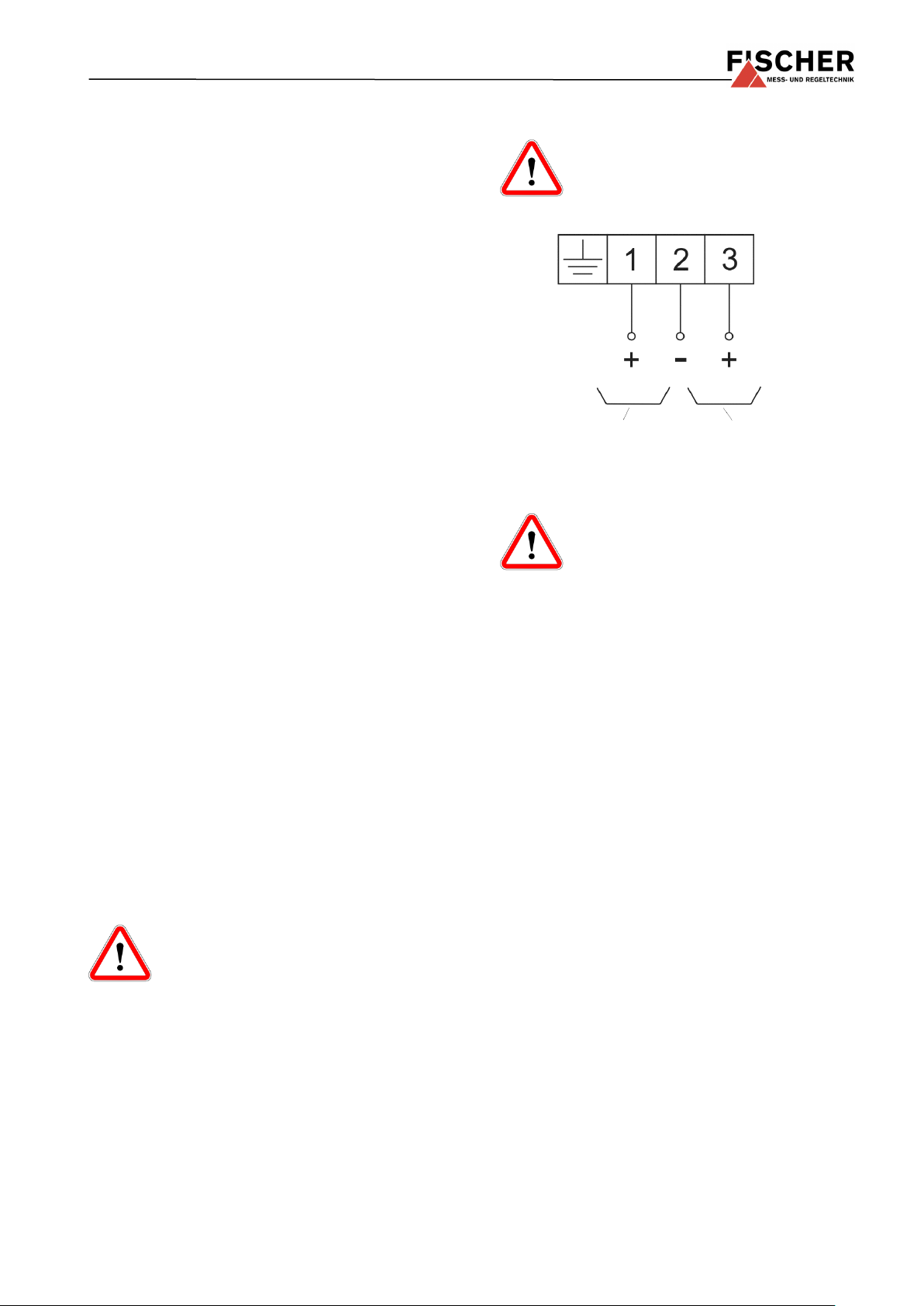

Page 3

Three-conductor circuit

output

Signal

Operating

voltage

4 Installation and assembly

As standard, the device with the connecting port for

connection to pipes and other connection parts,

such as the welding sleeve, union nut with soldering

and welding nipples, is equipped with soldering and

welding nipples (see data sheet MZ...). It can be

mounted to a wall using the wall bracket (see data

sheet MZ...). Manometer screw connections for 10,

8, 6 mm dia. pipes can be supplied for connection

to pipes.The enclosure protection type IP 65 is only

guaranteed, if a suitable power supply cable is

used.

4.1 Process connection

• By authorized and qualified specialized person-

nel only.

• Only for the designated mechanical process

connection - for the model, see the order code

on the device type plate.

• The pipes need to be depressurized when the

device is being connected.

• Do not mount the device against existing water

columns, and secure suitably against pressure

surges.

• Use only with media suitable for operation.

• Observe the maximum pressure.

• Check that the pressure connections do not

leak before commissioning.

4.2 Electrical connection

• By authorized and qualified specialized person-

nel only.

• Disconnect the system from the mains before

connecting the device.

• Do not take out the connecting plug while ener-

gized

Explosion protection instructions

To guarantee safe operation of the instrument, the supply circuit must satisfy

the requirements for zone 2, category 3,

and the locally applicable regulations

and guidelines for the installation and operation of

electrical systems in explosion hazard areas (e.g.

EN 60079-0).

4.3 Wiring diagram

Do not take out the connecting plug

while energized

Static electricity

The case must be equipped with an

earth connection to reduce the surface

resistance.

5 Commissioning

• All electrical supply, operating and measuring

lines, and the pressure connections must have

been correctly installed before commissioning.

All supply lines are arranged so that there are

no mechanical forces acting on the device.

• If liquid measuring media are used the pressure

connection line must be vented, as liquid columns of different heights in the pipes can cause

measuring errors. The instrument must be protected against frost if water is used as a medium.

• The pressure sensing lines must be installed on

an incline so that no condensation pools can

form.

• The pressure sensing lines need to be kept as

short as possible and installed without sharp

bends to avoid interfering delay times.

• Appropriate shutoff valves must be provided to

ensure safety during installation, maintenance

and inspection

The supply voltage may not exceed 30 V DC. The

supply circuit must be protected by a slow 200 mA

fuse. Only a CE-compliant power supply unit may

be used as a power supply.

Page 4

6 Maintenance

The instrument is maintenance-free.

We recommend checking the instrument at regular

intervals to ensure reliable operation and a long

service life.

• Inspecting the output signal.

• Check the leak-tightness of the pressure con-

nection lines.

• Check the electrical connection (cable clamp

connections).

The precise test cycles and operating and ambient

conditions need to be adjusted. If various instrument components interact, the operating instructions of all the other instruments also need to be

observed.

7 Transportation

The measuring device must be protected against

impacts. It may only be transported in packaging

specifically intended for transport.

8 Service

All defective or faulty devices should be sent directly to our repair department. We would ask you to

please coordinate all return shipments with our

sales department so that we can ensure careful

processing of all faulty devices for our customers.

Measuring residues in and on dismantled devices can be a hazard to people,

animals and the environment. Take adequate preventive measures. If required,

the devices must be cleaned thoroughly.

9 Accessories

• Manometer accessories acc. to data sheet

MZ...

10 Waste disposal

For the sake of the environment ....

Please help to protect our environment and dispose of or recycle used

instruments as stipulated by the applicable regulations.

Page 5

Measuring range in bar

0-1.6

0-2.5

0-4

0-6

0-10

0-16

0-25

0-40

0-60

Overpressure-proof in bar

3.2 5 8

12

20

32

50

80

120

Permissible ambient temperature

-10°C 60°C

Admissible medium temperature

Max. 60°C

Pressure connection

Connection ports with external thread

G½ B stainless steel, rustproof

Electrical connection

Standardised plug DIN EN 175 301-803-A

Protection class:

IP 65 acc. to DIN EN 60529

Parts in contact with the medium

AISI 316L (1.4404), Seal: Viton®

Material: Casing

AISI 304 (1.4305)

Electrical data

Power supply

Only CE-compliant power supply units with a slow 200 mA

fuse may be used.

Rated voltage

24V DC

Allowed operating voltage Ub

15....30 V DC

inner effective capacity Ci

max. 270nF

effective inner inductivity Li

max. 980H

Electrical connection type

Three-conductor

Output signal

0..20 mA / 4..20 mA / 0..10 V

Load at rated voltage

450

Current/voltage limit

for output 0..10V: ca. 10.5 V

for output 0/4..20 mA: ca. 24 mA

Zero-point, temperature drift

0.4 % FS/10 K

Measuring range, temperature drift

0.05 % FS/10 K

Linearity

< 1 % of the measuring range

Hysteresis

< 0.5 % of the measuring range

Identification acc. to

ATEX guideline 2014/34/EU

II 3G Ex nA IIC T4

Measuring range in bar

- 1..0

-1..0.6

-1..1.5

-1..3

-1..5

-1..9

-1..15

0...-1

Overpressure-proof in bar

2 3 3 8 12

20

32

2

11 Technical Data

Page 6

M16 x 1.5

Manometer connection port G1/2

nach DIN EN 837

SW22

12 Dimensional drawings

(all dimensions in mm unless otherwise specified)

Page 7

Digital manometer

Type ME01

8 7 H L R####

Measuring range

0 ... 1 bar ............................................... >

0 2

0 ...1.6 bar ............................................... >

0 3

0 ...2.5 bar ............................................... >

0 4

0 ... 4 bar ............................................... >

0 5

0 ... 6 bar ............................................... >

0 6

0 ... 10 bar ............................................... >

0 7

0 ... 16 bar ............................................... >

0 8

0 ... 25 bar ............................................... >

0 9

0 ... 40 bar ............................................... >

1 0

0 ... 60 bar ............................................... >

1 1

-1 ... 0 bar ............................................... >

3 1

-1 ...0.6 bar ............................................... >

3 2

-1 ...1.5 bar ............................................... >

3 3

-1 ... 3 bar ............................................... >

3 4

-1 ... 5 bar ............................................... >

3 5

-1 ... 9 bar ............................................... >

3 6

-1 ... 15 bar ............................................... >

3 7

Measurement accuracy

Characteristic curve dev. Relative pressure 1.0 ............>

M

Characteristic curve dev. Absolute pressure 1.0 ............>

S

Discharge port

Connection ports with external thread G½ B bottom,

Stainless steel ............................................................. >

8

7

Electrical output signal

0 – 20 mA 3-wire (STANDARD) .................................................... >

A

0 – 10 V DC 3-wire (STANDARD) ................................................. >

C

4 – 20 mA 3-wire (STANDARD) .................................................... >

P

Electrical connection

Plug 4-pin, standardised plug DIN EN 175 301-803-A .............. >

H

Operating voltage

24 V DC / AC ............................................................................................. >

L

Customer-specific no.

Code for use in Zone 2 -

Risk from vapours: II 3G Ex nA IIC T4 ........................................................ >

R####

13 Order Codes

Page 8

14 Attachments

Technische Änderungen vorbehalten • Subject to change without notice • Changements techniques sous réserve

Fischer Mess- und Regeltechnik GmbH • Bielefelder Str. 37a • D-32107 Bad Salzuflen • Tel. +49 5222 9740 • Fax +49 5222 7170 •

eMail: info@fischermesstechnik.de • www.fischermesstechnik.de

Loading...

Loading...