Page 1

DELTASCOPE® FMP10

ISOSCOPE® FMP10

DUALSCOPE® FMP20

Guidelines

Coating Thickness Material TestingMicrohardnessMaterial Analysis

Page 2

Page 3

Please study the safety information in the operator’s

manual as well.

Observe the warnings and hints in th e opera tor’s manual

in order to avoid injury and damage to the instrument!

Table of Contents

1 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Areas of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Description of the Instrument . . . . . . . . . . . . . . . . . . . 3

3.1 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Control Panel Key Functions . . . . . . . . . . . . . . . . . . . . 5

4 Probe handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 The Path to the First Measurement . . . . . . . . . . . . . 6

6 System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1 Install the batteries/rechargeable batteries . . . . . . . . . . 7

6.2 Probe connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.3 Instrument On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Adjusting Instrument and Probe . . . . . . . . . . . . . . . 11

7.1 Assigning a New Probe . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2 Normalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3 Corrective Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.4 Reference Measurements . . . . . . . . . . . . . . . . . . . . . . 16

8 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Service Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Order number: Version 1.0

901-095 08/08

Page 4

1Notes

This brief guide offers a first, brief overview of your instrument's operation and

provides quick steps towards your first measurement results. An extensive operator's manual can be found on the CD-ROM that is supplied with the instrument.

The following symbols are used in this brief guide.

Indicates safety information referring to danger for persons and warnings regarding damage to the measuring

instrument or to accessories.

Indicates particularly important information and hints.

Indicates a reference to a page or chapter in this guide.

Notes

Brief Guide FMP10 / FMP20 Page 1

Page 5

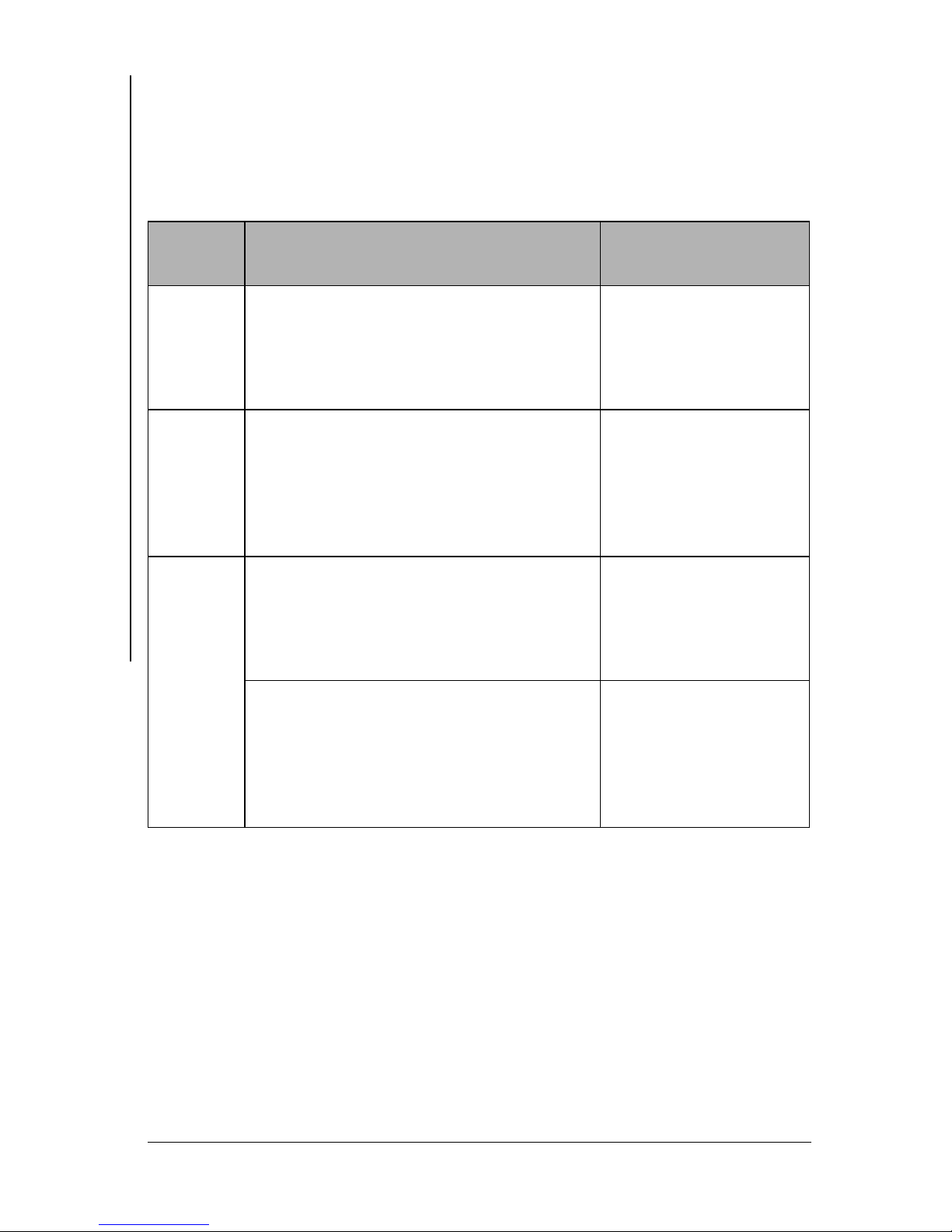

2 Areas of Application

The instrument is used for coating thickness measurements.

The following table lists the measurement methods that are used in the various

FMP instruments.

Instrument Area of application

Areas of Application

DELTASCOPE

ISO-

SCOPE

Determination of the thickness of non-magnetic

coatings on steel or iron. E.g, chrome, copper, zinc

as well as paint, lacquer, enamel or plastic coatings on steel or iron.

Determination of the thickness of electrically nonconducting, non-magnetic coatings on non-ferromagnetic electrically conducting base materials.

Paint, lacquer or plastic coatings on, for example,

aluminum, copper, zinc, etc. as well as anodized

coatings on aluminum.

Determination of the thickness of non-magnetic

coatings on steel or iron. E.g, chrome, copper, zinc

as well as paint, lacquer, enamel or plastic coatings.

Measurement method /

Probe type

Magnetic Induction Method

According to DIN EN ISO

2178.

Probe: e.g., FGAB1.3

Amplitude-Sensitive Eddy

Current Method According to

DIN EN ISO 2360.

Probe: e.g., FTA3.3

Magnetic Induction Method

According to DIN EN ISO

2178.

Probe: e.g., FD10

DUALSCOPE

Determination of the thickness of electrically nonconducting, non-magnetic coatings on non-ferromagnetic electrically conducting base materials.

Paint, lacquer or plastic coatings on, for example,

aluminum, copper, zinc, etc. as well as anodized

coatings on aluminum.

Amplitude-Sensitive Eddy

Current Method According to

DIN EN ISO 2360.

Probe: e.g., FD10

The instrument has the capability of setting up up to 1000 readings to save.

Page 2 Brief Guide FMP10 / FMP20

Page 6

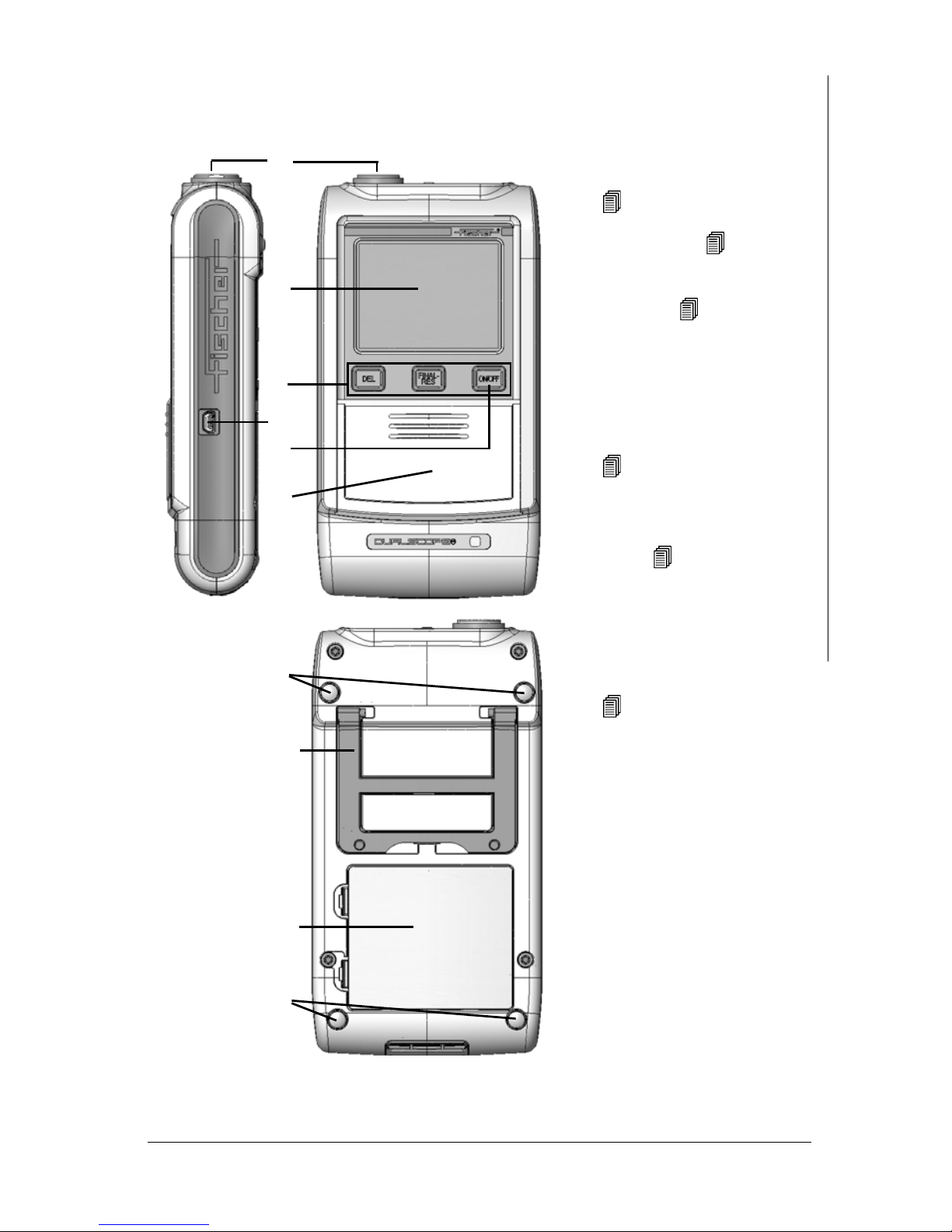

3 Description of the Instrument

1 Probe connector socket,

Page 8

2 LCD Display, Page 4

3 Keys for directly retrieving

functions, Page 5

4 USB port for connecting a

PC

5 ON/OFF key to turn the in-

strument on or off,

Page 9

6 Cover; additional function

keys can be found under the

cover, Page 5

7 Non-slip rubber supports

8 Foldable instrument stand

9 Battery compartment,

Page 7

1

2

3

4

5

6

7

8

9

7

Description of the Instrument

Fig. 3-1 Front and rear view of the instrument, connections

Brief Guide FMP10 / FMP20 Page 3

Page 7

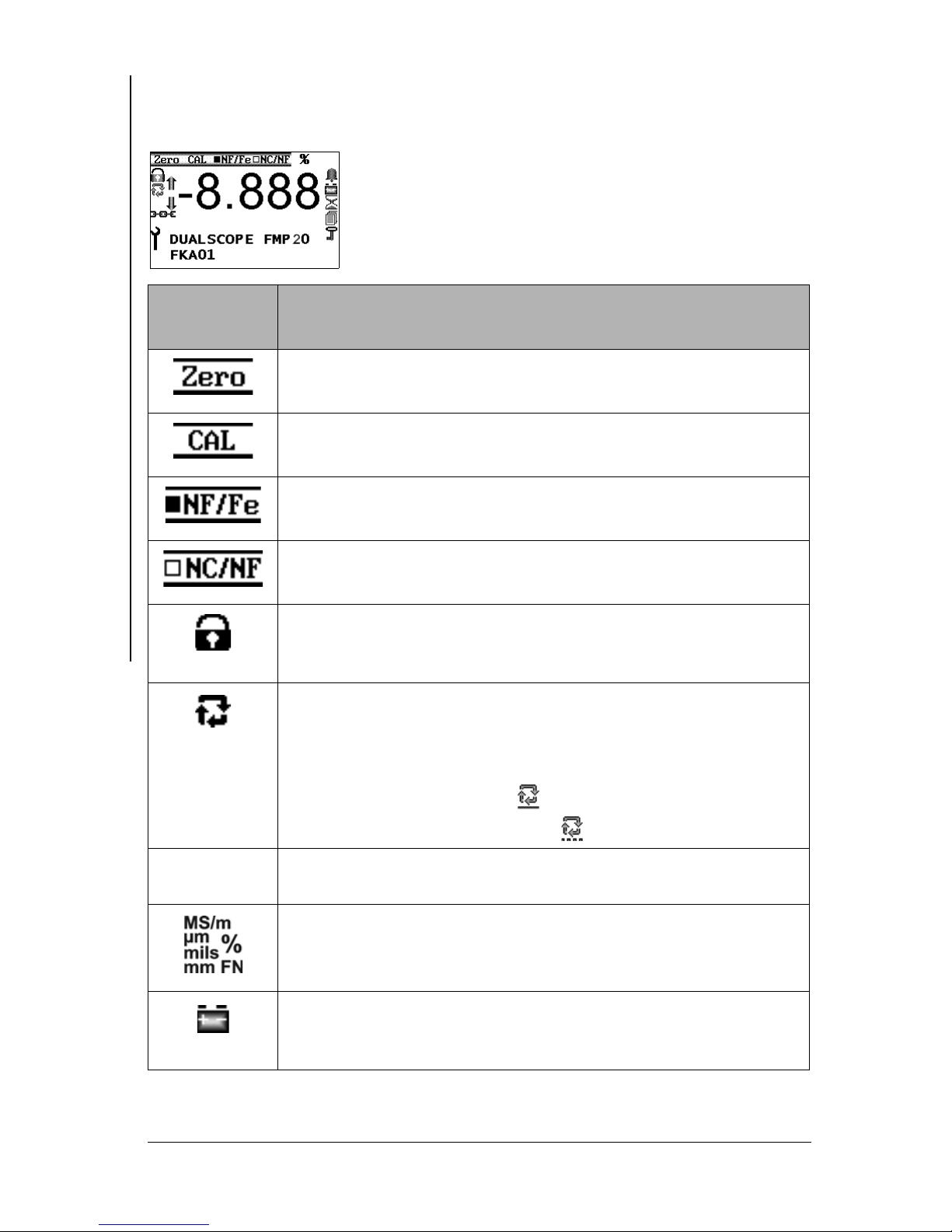

3.1 LCD Display

The LCD display consists of several display elements.

When powering up the instrument using ON/OFF, all

display elements will appear briefly at the same time.

Display

element

Description of the Instrument

Explanation

A normalization is performed (on the uncoated specimen =

base material).

A calibration is carried out.

The measurement uses the magnetic induction method.

The measurement uses the e dd y curre n t me th od .

Padlock:

Restricted operating mode is enabled, i.e., the keys ZERO and

CAL are not active, the service functions cannot be retrieved.

Arrow circle: “Free-running” display is enabled, measurements

are displayed continuously when the probe is placed on the

specimen

Alternatively:

Area measurement display

Automatic measurement display

-8.8.8.8

Page 4 Brief Guide FMP10 / FMP20

Numeric elements for presenting readings, errors and warning

messages.

Unit of measurement for the displayed reading.

Battery: The battery must be replaced or the rechargeable battery must be charged because the voltage has dropped below a

minimum value.

Page 8

Display

element

Explanation

Hourglass: Measurements are currently not possible because

an instrument-internal routine is running.

...SCOPE ...

FKA...

Information lines:

Instrument type

Instrument-internal software version

3.2 Control Panel Key Functions

Key Function

DEL z Deletes the last measured reading

z Returns to the previous menu or

z Cancels the procedure

FINAL-RES Retrieves the final result

ON/OFF Turns the instrument on and off

ZERO Retrieves the normalization

CAL Retrieves the corrective calibration

∧

z Changes the information shown on the LCD display.

Description of the Instrument

z The display will change faster if

3 seconds.

∨

SEND Transfers the values to a connected computer.

ENTER Confirms entries

z Changes the information shown on the LCD display.

z Turns the “free-running” display mode on/off.

z The display will change faster if

3 seconds.

5 x ENTER: Calls the service functions

The instrument settings in the

password-protected. “157” will be displayed after pressing EN-

TER 5 times. Press ∧ 2 times to increase this value to the factory-default

ENTER.

password “159” and confirm the entry with

∧ is pressed for longer than

∨ is pressed for longer than

Service Functions menu are

Brief Guide FMP10 / FMP20 Page 5

Page 9

4 Probe handling

z Always hold the probe at its grip sleeve (right figure).

z Always place the probe gently and at a right angle on

Probe handling

the specimen surface.

z Slide the grip sleeve to the specimen surface such that

the sleeve rests on the specimen (center and bottom

Figure, right).

z With the default setting, a beep will signal the mea-

surement capture.

z Lift the probe off the specimen before making the

next measurement.

Avoid hard impacts.

Do not allow the probe to hover directly above

the surface. Doing so will lead to erroneous

readings.

Do not bend the probe connector cable! Doing

so can lead to broken wires.

5 The Path to the First Measurement

z Instrument Start Up ( 6 ‘System Setup’, beginning on Page 7)

insert the batteries, connect the probe and turn on the instrument

z Adjust the instrument and probe to the base material to be measured

( 7 ‘Adjusting Instrument and Probe’, beginning on Page 11) Normalization and Calibration

z Make measurements on the specimen ( 8 ‘Measuring’, beginning on

Page 16)

Page 6 Brief Guide FMP10 / FMP20

Page 10

6 System Setup

1.

-

+

-

-

-

+

+

+

LR6 1.5V

LR6 1.5V

LR6 1.5V

LR6 1.5V

Observe the cor-

rect polarity when

installing the bat-

teries.

2.

3.

6.1 Install the batteries/rechargeable batteries

Use only type MIGNON, 1.5 V, LR6 - AA - AM3 - MN1500 batteries or 4

individual rechargeable batteries 1.2 V 2400 mAh Type AA.

Using other batteries may lead to instrument damage.

Use only non-damaged batteries/rechargeable batteries.

System Setup

Fig. 6-1 Installing batteries

If the battery voltage is too low, the instrument will turn off

automatically!

Brief Guide FMP10 / FMP20 Page 7

Page 11

6.2 Probe connection

1.

Probe connector plug

Connector socket

Instrument

2.

A measurement probe must be connected to the instrument to make coat ing thickness measurements. This must be an appropriate probe suitable for the base material.

Connect probes only when the instrument is off!

System Setup

To turn the instrument off: Press the ON/OFF key on the right side of the

control panel. The LCD display is not backlit and no characters are visible.

Protect the instrument and accessories from electrostatic

charges!

Electrical discharges may damage internal components or

delete internal memories.

Such discharges may occur, for example, when connecting the probe to

the instrument. Thus, please ensure that the person connecting a probe

is properly grounded.

It is recommended to store the instrument with the connected probe.

Fig. 6-2 Connecting a probe

Page 8 Brief Guide FMP10 / FMP20

Page 12

6.3 Instrument On/Off

Turning the instrument on

Detail of the LCD

Explanation

display

Press the ON/OFF key to turn on the instrument.

An audible signal will sound.

A monitoring routine will run automatically. All display ele-

ments of the LCD display will appear briefly at the same

time ( Page 4).

At the end of the monitoring routine, the instrument is

ready to make measurements. The icon of the measurement method of the connected probe is displayed

( Page 10).

[μm] or [mm] or [mils]:

Unit of measurement for the displayed reading

[Thickn.]: Measurement program “Coating thickness”

(alternative display options can be set from the service

functions in menu option Measurement/Display)

System Setup

[n=]: Number of the stored measurements

Brief Guide FMP10 / FMP20 Page 9

Page 13

Measurement Method of the Connected Probe

Display Explanation

[NF/Fe] Magnetic induction probe connected.

[NC/NF] Eddy current probe connected

System Setup

[NF/Fe NC/NF] Dual probe connected and dual method [both] set (i.e., in

the open application, both measurement methods can be

used to make measurements).

[NF/Fe NC/NF] Dual probe connected and dual method [NF/Fe] set (i.e.,

in the open Application, only the magnetic induction method can be used to make measurements). Or: The probe

was last placed on an Fe base material.

[NF/Fe NC/NF] Dual probe connected and dual method [NC/NF] set (i.e.,

in the open Application, only the eddy current method can

be used to make measurements).

Or: The probe was last placed on an NF base material.

Turning Off the Instrument

Press the ON/OFF key to turn the instrument off manually.

The instrument shuts down automatically if for about 5 minutes no measurements

are made or no key is pressed.

Page 10 Brief Guide FMP10 / FMP20

Page 14

7 Adjusting Instrument and Probe

The following options exist after the instrument is turned on:

1.

The instrument recognizes the connected probe. The measurement screen

appears on the LCD display. The display of the measurement method does

not flash. In this case, you can start immediately making measurements.

2.

If the instrument is turned on and a probe other than the one used last is

connected, the following display will appear: “W006 Probe changed”. The

probe must be assigned ( Chapter 7.1).

7.1 Assigning a New Probe

Key sequ. /

Action

Detail of the LCD

display

Explanation

This warning appears briefly after powerup if a probe other than the last one used

is connected to the instrument.

Adjusting Instrument and Probe

After a brief time, the display to the left will

appear.

Example: FD10 = Name of the connected

probe

DEL: Probe assignment starts

ENTER: Probe will not be assigned, mea-

surement method display flashes

DEL DEL: All stored readings will be deleted.

ENTER: The probe will not be assigned,

measurement method display continues to

flash

ZERO and CAL appear on the display. A

normalization and a corrective calibration

must be performed

Page 12).

( beginning on

Brief Guide FMP10 / FMP20 Page 11

Page 15

7.2 Normalization

With the normalization, a new zero point is established for the calibration curve

and stored in the instrument.

Required materials

Reference part: Uncoated part from the production.

Procedure

Key sequ. /

Action

ZERO Use ZERO to start the normalization.

Adjusting Instrument and Probe

Detail of the LCD

display

Explanation

ZERO appears and remains on the LCD

display while the normalization is performed.

[s]: Standard deviation

[n]: Number of measurements

[Base material (Fe/NF)]: Measurements

should be performed on an uncoated specimen (Fe or NF display for the type of base

material).

When using dual probes, the type of base

material will be displayed only after the 1st

measurement is completed.

Perform measurements on the uncoated

specimen (base material).

Make measurements at various points of

the reference area.

The mean value of all readings obtained

for the normalization will be displayed.

ENTER A confirmation indicating that the normal-

Page 12 Brief Guide FMP10 / FMP20

ization has been carried out successfully

appears.

Pressing ENTER confirms the message.

Page 16

Key sequ. /

Action

ENTER The new characteristic will be computed

Detail of the LCD

display

Explanation

automatically and stored. The instrument

is again ready to make measurements.

7.3 Corrective Calibration

Options

One-point calibration with one calibration standard: A new zero point and

one additional point are established for the calibration curve and stored in the instrument.

Two-point calibration with two calibration standards: A new zero point and

two additional points are established for the calibration curve and st ored in the

instrument.

Adjusting Instrument and Probe

Required materials

z Reference part (uncoated part from the production)

z Calibration Standards

Selecting the Calibration Standards for the Corrective Calibration

A corrective calibration using the calibration standards included with the probe

shipment provides the best measuring precision for the entire measurement range

of the probe.

Brief Guide FMP10 / FMP20 Page 13

Page 17

Procedure

Key sequ. /

Action

CAL Use CAL to start the corrective calibration.

Adjusting Instrument and Probe

Detail of the LCD

display

Explanation

CAL appears and remains on the LCD dis-

play while the corrective calibration is performed.

[s]: Standard deviation

[n]: Number of measurements

[base material (Fe/NF)]: Measurements

should be performed on an uncoated specimen (Fe or NF display for the type of base

material), i.e., a Normalization is carried

out.

When using dual probes, the type of base

material will be displayed only after the 1st

measurement is completed.

Perform measurements on the uncoated

specimen (base material) (normalization).

Make measurements at various points of

the reference area.

The mean value of all readings obtained

for the normalization will be displayed.

ENTER

Page 14 Brief Guide FMP10 / FMP20

[Entry:

nominal thickness value of the calibration

standard. The rated value is printed onto

the calibration standard.

The rated value can be set faster if a measurement is performed on the calibration

standard and then the rated value is corrected using the arrow keys.

[CAL Nom. v . 1: 23.70]: Display of the set

rated value for the thickness of the calibration standard (Example: 23.7 µm)

∧∨]: Use the arrow keys to set the

Page 18

Key sequ. /

Action

Detail of the LCD

display

Explanation

Place the calibration standard 1 (in the example with a thickness of 23.7 µm) on the

uncoated specimen and perform measurements.

Make individual measurements at various

points of the reference area. Displayed is

the mean value of all measurements performed for this step.

∧ or ∨ [Entry: ∧∨]: Use the arrow keys to set the

nominal thickness value of the calibration

standard. The rated value is printed onto

the calibration standard. The rated value

can be set faster if a measurement is performed on the calibration standard and

then the rated value is corrected using the

arrow keys.

This step is not required if - as shown in

the example - the rated value for the thickness of the calibration standard coincides

with the stored thickness.

Adjusting Instrument and Probe

ENTER If a corrective calibration is desired with 2

standards, proceed in the same manner

with calibration standard #2.

Otherwise: Use ENTER to end the corrective calibration.

The new characteristic will be computed

automatically and stored.

The instrument is again ready to make

measurements.

ENTER A confirmation indicating that the correc-

tive calibration has been carried out successfully appears.

Pressing ENTER confirms the message.

Brief Guide FMP10 / FMP20 Page 15

Page 19

7.4 Reference Measurements

z Perform several reference measurements by measuring the thickness of a

calibration standard placed on the uncoated reference area in order to verify

a correct normalization or corrective calibration. The thickness of the stan-

Measuring

dard should be close to the nominal thickness value of the coating to be measured.

z If the obtained mean value is within the guaranteed error limits stated on the

foil, delete the readings of the reference measurement before starting with

the measurements on your specimens.

z If the mean value is not within the guaranteed error limits, perform a correc-

tive calibration, or repeat the corrective calibration, respectively.

8 Measuring

The information stated in the operators's manual must be

observed when making measurements!

To make a measurement, place the probe at a right angle on the specimen surface.

The probe can be lifted off after the measurement acquisition, i.e., after the reading appears on the LCD display. The instrument is again ready to make measurements.

Observe the following during the measurement:

z Measurements should be made within the reference area.

z To avoid erroneous readings, do not allow the probe to hover above the spec-

imen.

z How high the probe should be lifted off depends on the measurement range

of the probe. To obtain a correct air value, the distance to the specimen

should be at least 3 to 4 times the max. measurable coating thickness.

z To allow sufficient time for a measurement acquisition, the time between

individual measurements must be greater than 0.5 seconds.

Page 16 Brief Guide FMP10 / FMP20

Page 20

9 Service Functions

How to access the “Service function” menu

Key sequ. /

Action

ON/OFF

5 x ENTER

2 x ∧

ENTER The Service settings menu will be dis-

Detail of the LCD

display

Explanation

Use ON/OFF to turn the instrument on

After pressing ENTER 5 times, the identification number 157 appears on the LCD

display.

Enter the identification number 159 by

pressing the arrow key ∧ 2 times.

Use ENTER to confirm the setting.

played.

Press the arrow keys

desired service function.

∧ or ∨ to select the

How to exit the “Service functions” menu

Service Functions

Key sequ. /

Action

DEL Press the DEL key to exit the Service func-

Explanation

tions menu.

The instrument is ready to make measurements.

Brief Guide FMP10 / FMP20 Page 17

Page 21

Service Functions Overview

Service menu Functions

System Language

Contrast

Lighting

Autom. off

Initialization

Service Functions

USB Send free-running mode

Instrument mode Restr. Mode

Analog display

Measurement Audible signal

Measurement effect

External start

Measuring mode - Standard/

Area measurement/Autom atic measurement

Display

dual method

Units metric/imperial

Storage mode save/don't save/delete on off

Master calibration Performing a master calibration

About ... Information about the instrument configuration

Page 18 Brief Guide FMP10 / FMP20

Page 22

Sales and Service Departments

DKD-D-33101

Accredited acc. to

DIN EN ISO/IEC 17025

Valid for Helmut Fischer AG and

Branch Offices

- all around the world -

GERMANY

HELMUT FISCHER GMBH

Industriestraße 21

D-71069 Sindelfingen

: +49 (0) 70 31 / 30 3-0

Fax: +49 (0) 70 31 / 30 3-79

mail@helmut-fischer.de

www.helmut-fischer.com

GREAT BRITAIN

FISCHER INSTRUMENTATION

(G.B.) LTD.

Gordleton Industrial Park

Hannah Way · Pennington

GB-Lymington/Hants SO41 8JD

: (+44) 15 90 68 41 00

Fax: (+44) 15 90 68 41 10

mail@fischergb.co.uk

www.fischergb.co.uk

SWITZERLAND

HELMUT FISCHER AG

Moosmattstrasse 1 · Postfach · CH-6331 Hünenberg

: (+41) 41 785 08 00 · Fax: (+41) 41 785 08 01

switzerland@helmutfischer.com

www.helmutfischer.com

Branch Offices of Helmut Fischer AG, Switzerland:

SPAIN

FISCHER INSTRUMENTS, S.A.

C/Almogàvers 157 · 3a Planta

E-08018 Barcelona

: (+34) 93 309 79 16

Fax: (+34) 93 485 05 94

spain@helmutfischer.com

www.helmutfischer.com

ITALY

HELMUT FISCHER S.R.L.

Tecnica di Misura

Via Columella 40 · I-20128 Milano

: (+39) 0 22 55 26 26

Fax: (+39) 0 22 57 00 39

italy@helmutfischer.com

www.helmutfischer.com

USA

FISCHER TECHNOLOGY, INC.

750 Marshall Phelps Road

Windsor, CT 06095 USA

: (+1) 86 06 83 07 81

Fax: (+1) 86 06 88 84 96

Watts 800 243 84 17

info@fischer-technology.com

www.fischer-technology.com

JAPAN

FISCHER INSTRUMENTS K.K.

Shinmei 1-9-16· Souka-shi

Saitama-ken 340-0012 · Japan

: (+81) 489 29 34 55

Fax: (+81) 489 29 34 51

japan@helmutfischer.com

www.helmutfischer.com

FRANCE

FISCHER INSTRUMENTATION

ELECTRONIQUE

Parc d'Activités Nord du Pas

du Lac · 5, rue Michaël Faraday

F-78180 Montigny le Bretonneux

BP 289 · F-78053 St Quentin en

Yvelines Cedex

: (+33) (0) 1 30 58 00 58

Fax: (+33) (0) 1 30 58 89 50

france@helmutfischer.com

www.helmutfischer.com

CHINA

NANTONG FISCHER

INSTRUMENTATION LTD.

7F, No. 2 Building

2601 Songhuajiang Road

Shanghai 200437 · P.R.C.

: (+86) 21 65 55 74 55

Fax: (+86) 21 65 55 24 41

china@helmutfischer.com

www.helmutfischer.com

HONG KONG

FISCHER INSTRUMENTATION

(FAR EAST) LTD.

Unit 2901 · Level 29

Metroplaza Tower 2

223 Hing Fong Road

Kwai Chung, N.T.

Hong Kong

: (+852) 24 20 11 00

Fax: (+852) 24 87 02 18

hongkong@helmutfischer.com

www.helmutfischer.com

SINGAPORE

FISCHER INSTRUMENTATION (S)

PTE LTD.

102 E Pasir Panjang Road #04-04

Citilink Warehouse Complex

Singapore 118529

: (+65) 62 76 67 76

Fax: (+65) 62 76 76 67

singapore@helmutfischer.com

www.helmutfischer.com

THE NETHERLANDS

HELMUT FISCHER

MEETTECHNIEK B.V.

Tarasconweg 10

NL-5627 GB Eindhoven

Postbus 1828

NL-5602 CA Eindhoven

: (+31) 40 248 22 55

Fax: (+31) 40 242 88 85

netherlands@helmutfischer.com

www.helmutfischer.com

INDIA

FISCHER MEASUREMENT

TECHNOLOGIES (INDIA) PVT. LTD.

Florida Amenity

S. No. 41, Keshav Nagar

Mundhwa

IN-Pune 411036

: (+91) 20 26 82 20 65

Fax: (+91) 20 26 82 20 75

india@helmutfischer.com

www.helmutfischer.com

Page 23

Loading...

Loading...