Page 1

Operators Manual

FERITSCOPE® FMP30

Coating Thickness Material TestingMicrohardnessMaterial Analysis

Page 2

Page 2 Operators Manual FERITSCOPE® FMP30

Page 3

Order number: Version 1.0

902-097 08/08

FERITSCOPE® FMP30

Operators Manual

Determination the ferrite content

of austenitic and DUPLEX stainless steel and

determination of the ratio of

martensite in austenitic stainless steels

© 2008 Copyright by

Helmut Fischer GmbH

Institut für Elektronik und Messtechnik, Sindelfingen (Germany).

All rights reserved. No part of this manual may be reproduced by any

means (print, photocopy, microfilm, or any other method) or processed,

multiplied or distributed by electronic means without the written consent

of Helmut Fischer GmbH Institut für Elektronik und Messtechnik.

Operators Manual FERITSCOPE® FMP30 Page 3

Page 4

Table of Contents

1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Trademarks and Liabilities . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Symbols and Conventions Used in the Manual . . . . . . . 9

1.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Requirements on the Operating Personnel . . . . . . . . . 10

1.6 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . 11

1.8 Probe Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.9 Handling, Storage and Transport of the Base and

the Calibration Standards . . . . . . . . . . . . . . . . . . . . . . 13

1.10 Instrument Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.11 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Description of the Instrument . . . . . . . . . . . . . . . . . . 15

2.1 LCD-Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Control Panel Key Functions . . . . . . . . . . . . . . . . . . . 18

2.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.1 Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.2 Base and Calibration Standards . . . . . . . . . . . . . . . . 24

2.3.3 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.5 Contents of Shipment and Options . . . . . . . . . . . . . . . 27

2.5.1 Standard Contents of Shipment of the Instrument . . . 27

2.5.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3 System Setup, Maintenance and Cleaning . . . . . 29

3.1 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1.1 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1.2 Installing or Replacing Batteries . . . . . . . . . . . . . . . . 31

3.2 Connecting Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Page 4 Operators Manual FERITSCOPE® FMP30

Page 5

3.3 Instrument: On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.3.1 Measurement Method of the Connected Probe . . . . 36

3.3.2 Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3.3 Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3.4 Switching Off the Instrument . . . . . . . . . . . . . . . . . . 41

3.4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Probe Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.1 Handling During Measurements . . . . . . . . . . . . . . . . . 42

4.2 Assigning a New Probe . . . . . . . . . . . . . . . . . . . . . . 43

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.1 Setting Up an Application . . . . . . . . . . . . . . . . . . . . . . 45

5.2 Selecting the Desired Application . . . . . . . . . . . . . . . 48

5.3 Deleting an Application . . . . . . . . . . . . . . . . . . . . . . . . 49

5.4 List of Set Up Applications . . . . . . . . . . . . . . . . . . . . . 50

5.5 Assigning Application Designations . . . . . . . . . . . . . . 52

5.6 Application Specific Settings . . . . . . . . . . . . . . . . . . . . 52

5.6.1 Tolerance Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.6.2 Measurement Display Resolution . . . . . . . . . . . . . . 56

5.6.3 Automatic Block Size and Block Creation . . . . . . . . . 57

5.6.4 Auto-Averaging Mode . . . . . . . . . . . . . . . . . . . . . . . . 58

5.6.5 Outlier rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.6.6 Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7 Linking Applications . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.7.1 Application Linking Procedure . . . . . . . . . . . . . . . . . . 63

5.7.2 Enabling and Disabling the Linking Mode . . . . . . . . . 64

5.7.3 Example for Linked Applications . . . . . . . . . . . . . . . . 64

6 Normalization, Calibration and Master

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1 Information Regarding Normalization, Calibration

and Master Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2 Normalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.1 Normalization Procedure . . . . . . . . . . . . . . . . . . . . . 69

6.2.2 Documenting the Normalization with a Printer . . . . . 70

Operators Manual FERITSCOPE® FMP30 Page 5

Page 6

6.3 Corrective Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.3.1 Selecting the Calibration Standards for the

Corrective Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.3.2 Corrective Calibration Procedure . . . . . . . . . . . . . . . 72

6.3.3 Deleting a Corrective Calibration . . . . . . . . . . . . . . . . 75

6.3.4 Documenting the Corrective Calibration with a

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4 Master Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.1 Selecting the Calibration Standards . . . . . . . . . . . . . 78

6.4.2 Performing a User Master Calibration . . . . . . . . . . . . 78

6.4.3 Master Calibration Procedure . . . . . . . . . . . . . . . . . 79

6.4.4 Displaying Xn Ranges for Calibration Standards

for the Master Calibration . . . . . . . . . . . . . . . . . . . . 83

6.4.5 Documenting the Master Calibration with a Printer . 84

6.5 Determination of the Normalized Countrate Xn of a

Calibration Standard During a Master Calibration . . . 85

7 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.1 Preparing for a Measurement . . . . . . . . . . . . . . . . . . 86

7.2 Parameters That Influence the Ferrite Content

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.3 Making a Measurement . . . . . . . . . . . . . . . . . . . . . . . 87

7.3.1 Measurement Acquisition . . . . . . . . . . . . . . . . . . . . 89

7.3.2 Measurements With External Start Enabled . . . . . . . 90

7.3.3 Automatic Measurement Acquisition . . . . . . . . . . . . 90

7.3.4 Audible Signals After the Measurement Acquisition 93

7.3.5 Measurements With Tolerance Limits Enabled . . . . 94

7.3.6 Measurements With a Fixed Block Size . . . . . . . . . . 94

7.3.7 Measurements in Auto-Averaging Mode . . . . . . . . . 96

7.3.8 Measurements With Outlier Rejection Enabled . . . . 97

7.4 Documenting the Measurement with a Printer . . . . . . . 98

7.5 Erroneous Readings . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.5.1 Deleting Erroneous Readings . . . . . . . . . . . . . . . . 101

7.5.2 Deleting All Readings of a Block That Has

Not Been Closed . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.5.3 Deleting All Readings of an Application . . . . . . . . . 101

7.5.4 Overwriting Individual Erroneous Measurements

at a Later Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.6 Measurements in the Free-Running Display Mode . 104

Page 6 Operators Manual FERITSCOPE® FMP30

Page 7

7.6.1 Turning the Free-Running Display Mode On/Off . . . 105

7.6.2 Procedure For Making Measurements With the

Free-Running Display Mode . . . . . . . . . . . . . . . . . 106

7.6.3 Analog Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.7 Measurements in Standard and

Matrix Measuring Mode . . . . . . . . . . . . . . . . . . . . . . 109

7.7.1 The Standard Measuring Mode . . . . . . . . . . . . . . . . 109

7.7.2 Making Measurements in the

Standard Measuring Mode . . . . . . . . . . . . . . . . . . . 110

7.7.3 The Matrix Measuring Mode . . . . . . . . . . . . . . . . . 111

7.7.4 Making Measurements in the

Matrix Measuring Mode . . . . . . . . . . . . . . . . . . . . . . 112

7.7.5 Assigning Block Designations . . . . . . . . . . . . . . . . 115

7.8 Correction Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.8.1 Influence of the Specimen Curvature . . . . . . . . . . . 116

7.8.2 Influence of the Specimen Thickness . . . . . . . . . . . 119

7.8.3 Influence of the Cladding Thickness . . . . . . . . . . . . 120

7.8.4 Influence of the Edge Distance on the

Measurement Location . . . . . . . . . . . . . . . . . . . . . . 122

8 Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

8.1 Evaluation of the Current Block “Block Result” . . . . 125

8.1.1 Documenting the Block Result With a Printer . . . . . 128

8.1.2 Printout of the List of Single Readings . . . . . . . . . . . 129

8.1.3 Computed parameters - Block result . . . . . . . . . . . . 130

8.2 Evaluation of the Open Application “Final Result” . . 131

8.2.1 Documenting the Final Result with a Printer . . . . . 133

8.2.2 Computed Parameters - Final Result . . . . . . . . . . . 135

8.2.3 Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

9 Data Transfer Using USB . . . . . . . . . . . . . . . . . . . . 138

9.1 USB Connection to a PC . . . . . . . . . . . . . . . . . . . . . 139

9.2 Installing the USB Drivers . . . . . . . . . . . . . . . . . . . . . 139

9.3 Transfer of the Measurement Data to the Computer 140

9.3.1 Online Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

9.3.2 Offline Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

9.3.3 Transferring Data With a Group Separator . . . . . . . 141

9.4 Transmission from the PC to the Instrument . . . . . . . 141

9.4.1 Transfer Formats . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Operators Manual FERITSCOPE® FMP30 Page 7

Page 8

9.4.2 Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . 142

9.5 Connecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . 146

9.5.1 Print Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

10 Instrument Settings - Service Function Menu 147

10.1 Service Menu Overview . . . . . . . . . . . . . . . . . . . . . . . 148

10.2 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10.2.1 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10.2.2 Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10.2.3 Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

10.2.4 Date format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

10.2.5 Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

10.2.6 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

10.2.7 Automatic Switch Off . . . . . . . . . . . . . . . . . . . . . . . 156

10.2.8 Re-Initialization of the Instrument . . . . . . . . . . . . . . 157

10.3 Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

10.3.1 Block Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

10.3.2 Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

10.4 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

10.4.1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

10.4.2 Group Separator . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10.4.3 Send Free-Running Mode . . . . . . . . . . . . . . . . . . . 163

10.5 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

10.5.1 Printer Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 164

10.5.2 Left Margin Setting . . . . . . . . . . . . . . . . . . . . . . . . . . 165

10.5.3 Print Individual Single Readings . . . . . . . . . . . . . . . 166

10.5.4 Block Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

10.5.5 Final Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.5.6 Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

10.5.7 Auto Formfeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

10.6 Instrument Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

10.6.1 Restricted Operating Mode . . . . . . . . . . . . . . . . . . . 171

10.6.2 Analog Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10.6.3 Matrix Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

10.6.4 Linking Applications . . . . . . . . . . . . . . . . . . . . . . . . . 177

10.7 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

10.7.1 Audible Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

10.7.2 Measurement Effect . . . . . . . . . . . . . . . . . . . . . . . . 179

10.7.3 External Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Page 8 Operators Manual FERITSCOPE® FMP30

Page 9

10.7.4 Measuring Mode - Standard/Area Measurement/

Automatic Measurement . . . . . . . . . . . . . . . . . . . . 182

10.7.5 Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

10.7.6 Measured Variable . . . . . . . . . . . . . . . . . . . . . . . . 185

10.8 Storage Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

10.9 Performing a Master Calibration . . . . . . . . . . . . . . . . 187

10.10 About ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

10.11 Documentation of the Instrument Configuration . . . 188

11 Malfunctions and Messages . . . . . . . . . . . . . . . . . . 190

11.1 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

11.2 Messages on the LCD Display . . . . . . . . . . . . . . . . . 194

12 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

12.1 Terms and Formula Symbols . . . . . . . . . . . . . . . . . . . 205

12.2 Additional Literature . . . . . . . . . . . . . . . . . . . . . . . . . . 230

12.2.1 Statistics and ferrite content measurement . . . . . . . 230

12.2.2 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

13 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Operators Manual FERITSCOPE® FMP30 Page 9

Page 10

Page 10 Operators Manual FERITSCOPE® FMP30

Page 11

1 Important Information

1.1 Trademarks and Liabilities

FERITSCOPE® is a registered trademark of the Helmut Fischer GmbH Institute

for Electronics and Metrology.

The fact that the trademark characters ® and ™ may be missing

does not indicate that a name is a free trademark.

Great care has been exercised in creating this operator's manual. The Helmut Fischer GmbH Institute for Electronics and Metrology assumes no liability for potentially remaining erroneous or incomplete statements and their results. We

would, however, appreciate if you can make us aware of potentially existing errors or incomplete information.

1.2 Symbols and Conventions Used in the Manual

The following symbols and conventions are used in this manual:

Indicates safety information referring to danger for persons and warnings regarding damage to the measuring

instrument or to accessories.

Indicates particularly important information and hints.

Indicates a reference to a page or chapter in this manual.

1.

Operation to be carried out by the operator at the instrument.

Important Information

z

ENTER Writing convention for instrument keys and command buttons on the

Operators Manual FERITSCOPE® FMP30 Page 9

Listing.

display.

Page 12

1.3 Intended Use

The FERITSCOPE® FMP30 is to be used to determine the ferrite content of austenitic and DUPLEX steel and to determine the portion of deformation martensite

in austenitic materials.

Only accessories recommended and approved by the Helmut Fischer GmbH Institute for Electronics and Metrology ( beginning on Page 23) may be connected to this instrument.

Important Information

1.4 General Information

The values shown for the measured ferrite contents and the texts of the

information lines of the LCD display serve as examples for possible displays. It is entirely possible that different values appear on the LCD display or in the printout without having made any mistakes.

1.5 Requirements on the Operating Personnel

The instrument should be operated only by staff trained for

this purpose!

In addition, basic knowledge of metrology according to DIN 1319 is essential for

performing correct ferrite content measurements and evaluations.

Basic computer knowledge regarding configuration, operation and programing

as well as knowledge of the software in use, which may be obtained from respective instruction manuals, is required when using the instrument in conjunction

with a computer.

Page 10 Operators Manual FERITSCOPE® FMP30

Page 13

1.6 Power Connection

To avoid damage to the instrument or wrong measurement

results due to a wrong line voltage, the instruments must be

connected to a power outlet only via the AC adapter provided by Helmut Fischer GmbH Institute for Electronics and

Metrology. The line voltage must agree with the line voltage

rating stated on the nameplate of the AC adapter.

1.7 Environmental Conditions

EMC

The instrument complies with the laws concerning electromagnetic compatibility

of instruments (2004/108/EC). The measured values are not influenced by the

highest level of interference mentioned in the EN 61000-6-2 Standard (which references the Standards EN 61000-4-2, EN 61000-4-3 and EN 61000-4-4).

In particular, the instrument is shielded effectively from strong electromagnetic

fields (e.g., motors, power lines, radio transmission towers).

Low Voltage

The instrument adheres to the Low Voltage Directive 2006/95/EC.

Ambient Temperature Range During Operation: +10°C ...+40°C

Important Information

Temperature Range During Storage and Transport: +5°C ... +60°C

Temperature behind glass panes (e.g., in cars) in direct sunlight easily rise above 60°C!

To avoid damage from heat, do not store the instrument or

accessories in such places.

The instrument and accessories (in particular the AC

adapter) must not come in direct contact with water! Risk of

electrical shorts! Instruments or accessories may be operated, kept or stored only in places, where the relative humidity is between 30% and 90% (non-condensing).

Operators Manual FERITSCOPE® FMP30 Page 11

Page 14

Because the instrument and accessories are not acid resistant, avoid direct contact with acid or acidic liquids.

The instrument and accessories are not suited for operation

in explosion-hazard areas!

Protect the instrument and accessories from static charges!

Electrical discharges may damage internal components or

Important Information

delete internal memories.

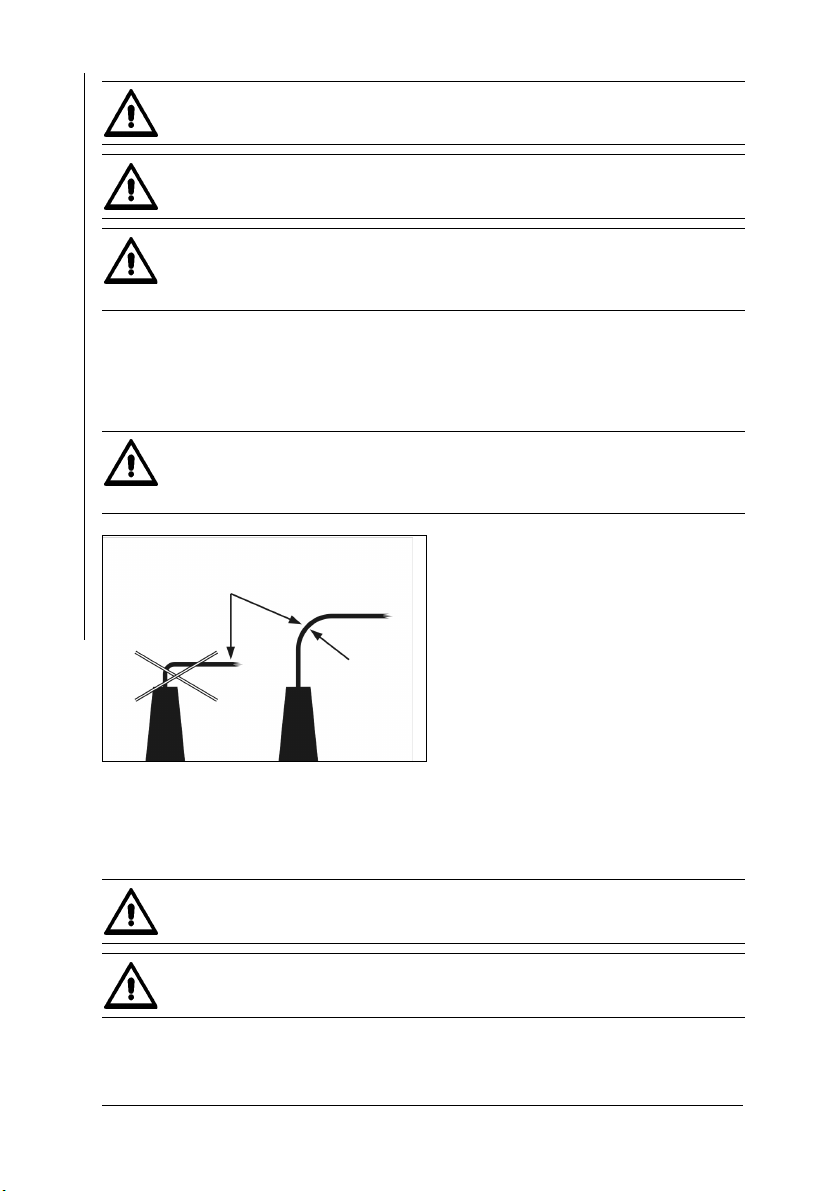

1.8 Probe Handling

To avoid breakage of the wiring, do not bend the probe connector cable! The radius of rolled up probe connector cables

should always be at least 50 mm!

Probeconnector cable

R ≥ 50 mm !

Fig. 1-1 Probe handling

During the measurement, the magnetic poles of the probes are placed directly

onto the specimen. Observe the following to keep wear of the magnetic poles during the contacting measurement to a minimum:

Place the probes speedily yet gently on the specimen surface! Avoid hard impacts!

Do not drag the probe across the specimen surface.

Page 12 Operators Manual FERITSCOPE® FMP30

Page 15

Do not place standard probes on hot or acid-wetted surfaces; do not immerse them in liquids. Special probe models

are available for such applications (ref. the probe data

sheets of the brochure “Measurement Probes and Measurement Aids - Optimized Probes”). You can obtain this brochure from the Helmut Fischer GmbH Institute for

Electronics and Metrology or from your authorized supplier.

1.9 Handling, Storage and Transport of the Base and the Calibration Standards

The instrument is normalized and calibrated using a base and calibration standards (ferrite standards).

Proper condition of the calibration standards is an important prerequisite for a

correct calibration, and thus for a correct measurement.

Observe the following to ensure the proper condition of the calibration standards:

To keep wear of the base and the calibration standards during the contacting measurements to a minimum, use them for the calibration only

and not for test measurements!

Do not soil or scratch calibration standards!

Replace corroded or scratched calibration standards or those with strong

indentations with non-damaged, clean standards.

Important Information

To protect the calibration standards from dirt or damage, keep them in

their supplied case for transporting and storing.

Operators Manual FERITSCOPE® FMP30 Page 13

Page 16

1.10 Instrument Repairs

No repairs should be performed on the instrument.

The instrument may be opened only for replacing rechargeable or regular batteries (

Page 31). Other service opera-

tions on the instrument or the accessories must be

performed only by technical personnel authorized by the

Helmut Fischer GmbH Institute for Electronics and Metrology.

Important Information

1.11 Warranty

The Helmut Fischer GmbH Institute for Electronics and Metrology will assume

no warranties in the following instances:

z Use of instrument or accessories for purposes other than the intended use.

z Connection of accessories not recommended or approved by the Helmut Fis-

cher GmbH Institute for Electronics and Metrology.

z Repairs or structural changes to the instrument or accessories that have not

been carried out by authorized persons.

z Improper handling of instrument or accessories (e.g., use in explosion-haz-

ard or very hot environments).

z Disregard of information in this operator's manual.

Page 14 Operators Manual FERITSCOPE® FMP30

Page 17

2 Description of the Instrument

1

2

3

4

5

6

7

8

9

1 Probe connector socket,

Page 33

2 LCD Display, Page 16

3 Keys for directly retrieving

functions, Page 18

4 USB port for connecting a

printer and a PC

5 ON/OFF key to turn the in-

strument on or off,

Page 36

6 Connector socket for the AC

adapter (included)

7 Cover; additional function

keys can be found under the

cover, Page 18

8 Non-slip rubber supports

9 Foldable instrument stand

10 Battery compartment,

Page 31

Description of the Instrument

10

8

Fig. 2-1 Front and rear view of the instrument, connections

Operators Manual FERITSCOPE® FMP30 Page 15

Page 18

2.1 LCD-Display

The LCD display consists of several display elements. When powering up the instrument using ON/OFF ( Page 36), all display elements will appear briefly at

the same time.

Description of the Instrument

Fig. 2-2 Display elements of the LCD display after power up (example)

Display element Explanation

A normalization is performed (on the base of the calibration standard set) ( beginning on Page 68).

A calibration is carried out ( beginning on Page 71).

Displays the measurement method

Bell:

Tolerance limits are enabled ( beginning on Page 94).

Padlock:

Restricted operating mode is enabled, i.e., the keys

MENU, ZERO and CAL are not active, the service functions cannot be retrieved, applications cannot be deleted

( beginning on Page 171).

Page 16 Operators Manual FERITSCOPE® FMP30

Page 19

Display element Explanation

Arrow circle:

“Free-running display” is enabled, measurements are

displayed continuously when the probe is placed on the

specimen

( beginning on Page 104).

Alternatively:

Area measurement display

Automatic measurement display

-8.8.8.8

Arrow up:

Upper specification limit is exceeded.

Arrow down:

Measurement below lower specification limit.

Both arrows together:

The displayed measurement was recognized as an outlier.

Numeric elements for presenting readings, errors and

warning messages.

Unit of measurement for the displayed reading.

Battery:

The battery must be replaced or the rechargeable battery must be charged because the voltage dropped be-

low a minimum value ( beginning on Page 30).

Hourglass:

Measurements are currently not possible because an instrument-internal routine is running.

Description of the Instrument

Operators Manual FERITSCOPE® FMP30 Page 17

Page 20

Display element Explanation

Chain: Applications that have been set up using the

same probe are linked to each other, i.e., the same normalization and/or corrective calibration is used for determining the measurements for these Applications

( beginning on Page 63).

Sheets: Matrix measuring mode is enabled ( beginning on Page 111).

Key: Measurement block is closed.

Description of the Instrument

Information lines:

...SCOPE ...

FKA...

Instrument type:

Instrument-internal software version

2.2 Control Panel Key Functions

For easier opening of the cover:

1.

Press on the corners of the cover

and then

2.

slide the cover downwards.

Fig. 2-3 Opening the cover of the control panel keys

Page 18 Operators Manual FERITSCOPE® FMP30

Page 21

The following overview provides a brief description of the functions of the individual control panel keys:

Key Function

DEL Deletes the last measured reading

Repeated pressing of DEL: Deletes the readings of the open

block in succession.

2 x DEL: Deletes all readings

.. during normalization:

1x DEL - Deletes the last reading,

2x DEL - Deletes the measurement series of the base material

.. during calibration:

1x DEL - Deletes the last reading,

2x DEL - Deletes the measurement series of the current cali-

bration standard.

Repeated pressing of DEL: Deletes the measurement series

of the previous calibration standard ( beginning on

Page 101).

.. in all menus:

DEL - Returns to the previous menu or cancels the procedure.

FINAL-RES

Retrieving the final result ( beginning on Page 131)

Repeated pressing of FINAL-RES:

Displays the individual components of the final result (mean

value, standard deviation, etc.) in succession.

.. and then ENTER:

Ends the display of the final result (return to the measurement

screen) without deleting the stored values (the current measurement block will not be closed).

.. and then DEL:

Ends the display of the final result (return to the measurement

screen) and deletes the values stored in the open Application.

.. during calibration or normalization:

Enabling and disabling the “free-running” display mode (display of the normalized countrates of the readings; readings will

not be stored and will not be integrated in the calibration or

normalization) or with external start enabled: Triggers a measurement.

Description of the Instrument

Operators Manual FERITSCOPE® FMP30 Page 19

Page 22

Key Function

BLOCK-RES

Description of the Instrument

ON/OFF

Retrieves the block result ( beginning on Page 125

Repeated pressing of BLOCK-RES:

Displays the individual components of the block result (mean

value, standard deviation, etc.) in succession.

.. and then

Ends the display of the block result (return to the measurement

screen) without closing the open measurement block (the cur-

rent measurement series can be continued).

.. and then

Displays the block result of the previous or following measurement block of the open Application.

All block results of the open Application can be retrieved in

succession through repeated pressing of ∨.

.. and then PRINT:

Prints the displayed block result.

.. and then MENU:

Displays the single readings of the evaluated measurement

data block (then all single readings can be displayed by press-

∧ or ∨ ). Pressing MENU again ends the single reading

ing

display.

.. and then DEL:

Deletes the readings of the last measurement data block that

has not been concluded and ends the display of the block result (return to the measurement screen).

.. and then ENTER:

Ends the display of the block results (return to the measurement screen) and closes the current block. The next measurement opens a new block.

Turns the instrument on and off ( beginning on Page 36)

∧:

∨:

ZERO

CAL

Page 20 Operators Manual FERITSCOPE® FMP30

Retrieves the normalization ( beginning on Page 68)

Retrieves the corrective calibration ( beginning on

Page 71)

.. and then CAL:

Cancels the corrective calibration.

.. and then DEL:

Deletes the corrective calibration of the open Application.

Page 23

Key Function

∧

∨

APPL No Selects the desired Application.

With Application selection and tolerance limit input:

Changes the information displayed on the LCD display.

With the calibration: Sets the target value of the used calibration standard that will be displayed after the “CAL Target” notification.

With parameter selection: Selects the desired parameters.

The display will change faster if

seconds.

with external start enabled: Triggers a measurement.

Turns the “free-running” display mode on/off.

With Application selection and tolerance limit input:

Changes the information displayed on the LCD display.

With the calibration: Sets the target value of the used calibration standard that will be displayed after the “CAL Target” notification.

With parameter selection: Selects the desired parameters.

The display will change faster if

seconds.

.. and then DEL:

Deletes the selected Application;

.. and then APPL No:

Displays the probes assigned to the Applications.

.. and then

Selects the desired Application.

.. and then ENTER:

Confirms the selection of the desired Application and returns to

the measurement screen.

∧ or ∨:

∧ is pressed for longer than 3

∨ is pressed for longer than 3

Description of the Instrument

Operators Manual FERITSCOPE® FMP30 Page 21

Page 24

Key Function

MENU Displaying and entering of the application-specific set-

tings:

z Tolerance Limits

z Resolution

z Block size

z i individual values

z Outlier

.. and then

Description of the Instrument

PRINT Output of the values stored in the selected application (includ-

ENTER Confirms entries

Selects the settings to be edited

.. and then PRINT:

Prints or displays a print form of the instrument configuration.

.. and then ENTER:

Confirms the selection of the setting to be edited.

.. and then DEL:

Exits the application-specific settings and returns to the measurement screen.

ing the block results) to a printer or transfer of these values to

a connected computer.

5 x ENTER:

Calls the service functions

The instrument settings in the

password-protected. “157” will be displayed after pressing EN-

TER 5 times. Press ∧, 2 times to increase this value to the fac-

tory-default

ENTER.

∧ or ∨:

Service Functions menu are

password “159” and confirm the entry with

Page 22 Operators Manual FERITSCOPE® FMP30

Page 25

2.3 Accessories

2.3.1 Probes

All probes that can be connected to the instrument are equipped

with a memory chip, a so-called EEPROM, in their connector

plug. Probe-specific information (such as probe type, production number, measurement method or coefficients of the master

characteristic, for example) is stored permanently - even without power supply - in this memory chip, which can be overwritten as many times as desired.

When powering up the instrument, this information is automatically retrieved and processed by the instrument; the instrument “recognizes” the connected probe.

Correct measurements can be performed only if the probe that

is assigned to the open Application is used for the measurement.

( Chapter 4.2 ‘Assigning a New Probe’, beginning on

Page 43).

Fig. 2-4

Probe plug of an

FGAB 1.3-Fe

probe

Various probe models are available for measurements on objects with different

shapes and different surface properties. Special probes with different measurement ranges are available for the following areas of application, for example:

z particularly rough or abrasive surfaces

z Particularly soft surfaces

z damp, acidic contamination on the surface

z particularly thick or thin coatings

z hot surfaces

z Coatings in pipes and bore holes

For available probe models and the probe model best suited for your application,

see the respective probe data sheets of the brochure “Measurement Probes and

Measurement Aids - Optimized Probes”. You can obtain this brochure from

Helmut Fischer GmbH or from your authorized supplier.

Description of the Instrument

Operators Manual FERITSCOPE® FMP30 Page 23

Page 26

2.3.2 Base and Calibration Standards

A so-called base is used for the normalization; for the corrective calibration, one,

two or three calibration standards (ferrite standards) are used in addition to the

base.

Different calibration standard sets (corrective sets) are available for the corrective calibration of the instrument for the different measurement ranges. The calibration standard sets include:

z Base

z 3 calibration standards with ferrite contents according to the desired mea-

surement range

A probe-specific calibration standard set for the master calibration (can be or-

Description of the Instrument

dered as an option) and a probe-specific calibration standard set for the corrective

calibration (included with the probe) are available for each probe model and have

been compiled specifically for this probe model.

You can obtain additional calibration standards on request from Helmut Fischer

GmbH Institute for Electronics and Metrology or from your authorized supplier.

Calibration standards

(Ferrite standards)

Base

Ferrite con-

tent informaSet number of

the calibration

standard set

Fig. 2-5 Calibration standard set (example)

tion

The measurements for the corrective calibration must be performed on

the base and on the calibration standard! Measurements on the plastic

surrounding the base or calibration standard will lead to erroneous measurements.

Page 24 Operators Manual FERITSCOPE® FMP30

Page 27

The measurements for the normalization and for the calibration should

be made within a radius of 10 mm from the center of the base or the calibration standard, respectively.

You can obtain information about available calibration standard sets from the

Helmut Fischer GmbH Institute for Electronics and Metrology or from your authorized supplier.

Certification of the Calibration Standards

The Helmut Fischer GmbH Institute for Electronics and Metrology supplies calibration standard sets complete with a valid certificate.

The certificate includes information about warranties and monitoring of

the test devices.

2.3.3 Printer

For an overview of printers suitable to be connected to the instrument see the

menu Service Functions

/ PRINT ( Chapter 10.5.1 ‘Printer Selection’, be-

ginning on Page 164).

Description of the Instrument

For information about operation, maintenance and care of the printer,

consult the instruction manual of the printer.

Operators Manual FERITSCOPE® FMP30 Page 25

Page 28

2.4 Technical Data

Instrument model

Display Graphical backlit LCD display

Measurable coat-

ings

Measuring modes Magnetic induction measurement method

Dimensions z Instrument: 170 mm x 90 mm x 35 mm (L x W x H)

Description of the Instrument

Weight approx. 340 g (without probe, ready to operate)

Permissible ambi-

ent temperature

during operation

Permissible storage temperature

Permissible relative air humidity

Power

supply

Power consumption

Connectors z Probe:10-pin round plug

Minimum

time between two

measurements

Minimum

lift-off distance

between two measurements

FERITSCOPE

z Ferrite content measurements in weld seams and clad-

dings made of austenitic or duplex steel

z Determination of the portion of deformation martensite

in austenitic materials

z LCD display: 44 mm x 57 mm (L x W)

+10 °C ... +40 °C

+ 5 C°... + 60 °C

30 ... 90% (non-condensing)

z 4 x 1.5 V batteries with about 50 h service life,

(Size AA or Mignon) or

z 4 x 1.5 V NiMH rechargeable batteries with about 45 h

service life at 2100 mAh, (Size AA or Mignon)

z AC adapter 9 V 150 mA, 100V - 230 V

z 0.3 W with the LCD display not illuminated

z 0.5 W with the LCD display illuminated

z AC adapter:2-pin barrel connector

z Mini USB port for connecting a printer and a PC

About 0.2 seconds in the free-running mode

min. 25 mm

®

FMP30

Page 26 Operators Manual FERITSCOPE® FMP30

Page 29

Measurement

range, trueness

and repeatability

precision

Depends on the connected probe

(These and other probe characteristics can be obtained

from the brochure “Measurement Probes and Measurement Aids - Optimized Probes”) of Helmut Fischer GmbH

Institute for Electronics and Metrology or can be requested from your authorized supplier or directly from Helmut

Fischer GmbH Institute for Electronics and Metrology.)

2.5 Contents of Shipment and Options

After receiving the shipment, packaging and content should be checked for potential damage. If the packaging, the content or the accessories show signs of

damage, retain the packaging. It might be needed to assert a claim for damages

versus the shipping company.

It is also advisable to keep the packaging for future transport.

Also verify that all components of the standard content of the shipment and all

ordered options are present. Notify your authorized supplier or he Helmut Fischer

GmbH Institute for Electronics or Metrology if this is not the case.

2.5.1 Standard Contents of Shipment of the Instrument

The standard contents of shipment of the instrument includes:

z Instrument

z Batteries

z Interface cable FMP/PC,

z Carrying and storage case, carrying strap

z CD-ROM with operator's manual and USB drivers

z Brief guide (short form operator's manual)

Description of the Instrument

Operators Manual FERITSCOPE® FMP30 Page 27

Page 30

2.5.2 Options

Available options are:

z AC adapter

z Various measurement probes

z Master and corrective calibration standards sets %Fe/FN

z 1.5 V NiMh rechargeable battery (4 each/unit)

z Charger for NiMh battery

z Support stand V12 for reproducible positioning of measurement

probes on the specimen

z Jig for angle probes for use in the support stand V12 (e.g., for probe

FGABW 1.3)

Description of the Instrument

z Jig for inside probes for use in the support stand V12 (e.g., for probe

FGABI 1.3-150 mm)

z Support stand V12-AM for motor-controlled touch-down and lift-off

of measurement probes

z Guide device V5GW2/TW3 for angle probes for measurements at

recessed or hard to reach areas

z PC-Datex software for transferring measurement data from the instru-

ment to a Microsoft® Excel spreadsheet (add-in module for Microsoft® Excel beginning with Version 95 under Windows® 95 to

Windows

®

Vista)

Page 28 Operators Manual FERITSCOPE® FMP30

Page 31

3 System Setup, Maintenance and Clean-

ing

Connect or disconnect plug-type connectors only when the

instrument is switched off in order to avoid electrical discharge. Connecting the AC adapter or inserting a battery

should be done carried out with the unit turned off as well!

Even a small discharge can delete the instrument memory.

Do not tilt the plug when inserting or unplugging them;

doing so could damage the contact pins of the plugs.

The information in the chapter “1 Important Information” must be

observed!

System setup consists of the following steps:

z Providing the power supply for the instrument

( 3.1 ‘Voltage supply’, beginning on Page 30)

z Connecting a measurement probe to the instrument

( 3.2 ‘Connecting Probes’, beginning on Page 33)

z Connecting a printer (where applicable) to the instrument

( 9.5 ‘Connecting a Printer’, beginning on Page 146)

z Connecting a computer (if desired) to the instrument

( 9 ‘Data Transfer Using USB’, beginning on Page 138)

z Selecting the language for the instrument if your language has not been set

when the instrument was shipped

( 10.2.1 ‘Language’, beginning on Page 149)

System Setup, Maintenance and Cleaning

Operators Manual FERITSCOPE® FMP30 Page 29

Page 32

3.1 Voltage supply

Electrical power can be supplied to the instrument in the following ways:

z with AC adapter (9 V 150 mA, 100 V - 230 V),

z 4 x 1.5 V batteries (AA or mignon) or

z 4 x 1.5 V NiMh rechargeable batteries, 2100 mAh (AA or mignon).

3.1.1 Power Connection

To avoid damage to the instrument or wrong measurement results

due to a wrong line voltage, the instruments must be connected to

a power outlet only via the AC adapter provided by Helmut Fischer

GmbH Institute for Electronics and Metrology. The line voltage

must agree with the line voltage rating stated on the nameplate of

the AC adapter.

To connect the instrument to the line voltage via the AC adapter, the AC adapter

System Setup, Maintenance and Cleaning

must be connected to the instrument and to the line power outlet. The instrument

must be switched off for this purpose!

Page 30 Operators Manual FERITSCOPE® FMP30

Page 33

3.1.2 Installing or Replacing Batteries

Procedure Battery Replacement

1.

2.

Indicator for battery replacement. Batteries or rechargeable batteries should be replaced.

If the battery voltage is too low, the instrument will turn

off automatically.

Use ON/OFF ( Page 36) to switch the instrument off (if not yet done).

Place the instrument with its back pointing up on the table. Open and

remove the battery compartment cover on the rear of the instrument as

depicted below.

System Setup, Maintenance and Cleaning

Fig. 3-1 Opening the battery compartment cover

3.

If old batteries are in the instrument, remove them from the unit. Otherwise, install new batteries directly; observe the correct polarity of the bat-

teries

Disposal: Do not dispose of batteries with regular household waste!

Place damaged or used batteries / rechargeable batteries in designated

collection containers! Please observe the guidelines in your region concerning proper handling of waste electrical and electronic equipment and

accessories.

Operators Manual FERITSCOPE® FMP30 Page 31

Page 34

4.

Close the battery compartment cover.

Observe the cor-

rect polarity when

installing the bat-

teries.

-

-

+

LR6 1.5V

LR6 1.5V

System Setup, Maintenance and Cleaning

Fig. 3-2 Inserting the batteries and closing the battery compartment cover

Use only type MIGNON, 1.5 V, LR6 - AA - AM3 - MN1500 batteries or 4

individual rechargeable batteries 1.2 V 2400 mAh Type AA.

Using other batteries may lead to instrument damage.

LR6 1.5V

LR6 1.5V

+

-

-

+

+

Use only non-damaged batteries/rechargeable batteries.

Page 32 Operators Manual FERITSCOPE® FMP30

Page 35

3.2 Connecting Probes

Connect probes only when the instrument is off!

To turn the instrument off: Press the ON/OFF key on the right side of the

control panel. The LCD display is not backlit and no characters are visible.

Protect the instrument and accessories from electrostatic

charges!

Electrical discharges may damage internal components or

delete internal memories.

Such discharges may occur, for example, when connecting the probe to

the instrument. Thus, please ensure that the person connecting a probe

is properly grounded.

It is recommended to store the instrument with the connected probe.

1.

Use ON/OFF ( Page 36) to switch the instrument off (if not yet done).

2.

If the probe connected to the instrument is to be replaced, unscrew the

knurled nut of the probe plug completely and pull the probe plug carefully

from the connector socket of the instrument.

3.

Plug the probe plug of the new probe into the probe connector socket of

the instrument.

System Setup, Maintenance and Cleaning

Operators Manual FERITSCOPE® FMP30 Page 33

Page 36

When inserting the plug, ensure that the key of the plug fits

into the groove of the socket. Otherwise, an erroneous connection between the instrument and the plug may occur or

the contact pins of the probe plug may be damaged.

Groove (socket)Key (plug)

Fig. 3-3 Probe plug and probe connector socket

4.

Tighten the knurled nut of the probe plug.

System Setup, Maintenance and Cleaning

Hold the plug tight to avoid an unintentional turning of the probe plug.

To avoid damage to the contact pins of the probe plug, only

the knurled nut may be turned! The probe plug must not be

turned in the connector socket.

Page 34 Operators Manual FERITSCOPE® FMP30

Page 37

1.

2.

Probe connector plug

Connector socket

Instrument

Fig. 3-4 Connecting a probe

5.

Use ON/OFF to turn the instrument on again. The instrument automatically recognizes the type of probe connected to it.

Exception: A flashing symbol for the measurement method on the LCD display

indicates that the instrument does not recognize the connected probe. In such a

case:

z A new Application must be set up for the connected probe

( 5.1 ‘Setting Up an Application’, beginning on Page 45) and/or

z The probe must be assigned to the instrument or to the respective Applica-

tion, respectively ( 4.2 ‘Assigning a New Probe’, beginning on Page 43)

or

z The probe that has been linked to the respective Application thus far must be

reconnected.

.

A new corrective calibration must be performed after the probe has been

assigned (

Page 71)!

System Setup, Maintenance and Cleaning

Operators Manual FERITSCOPE® FMP30 Page 35

Page 38

3.3 Instrument: On/Off

To avoid erroneous readings, no metallic objects must be in close

proximity to the probe tip when powering up the instrument.

The minimum distance is 25 mm.

3.3.1 Measurement Method of the Connected Probe

After powering up the instrument, the measurement method [Ferrite] appears on

the LCD display. The unit of measurement for displaying the readings of the current Application is displayed next to it ( 10.7.5 ‘Unit’, beginning on

Page 184).

Unit Explanation

Fe % Ferrite content in ferrite percent

FN Ferrite content in ferrite numbers

System Setup, Maintenance and Cleaning

If [Ferrite] flashes on the display, an Application has not yet been set up

using the connected probe. It is not possible to make measurements

when the display is flashing.

To make measurements, an Application must be set up using the connected probe

5.1 ‘Setting Up an Application’, beginning on Page 45).

(

Page 36 Operators Manual FERITSCOPE® FMP30

Page 39

3.3.2 Power Up

Key sequence

ON/OFF Press the ON/OFF key to power up the in-

Detail of the LCD

display

Explanation

strument.

An audible signal will sound.

A monitoring routine will run. All display elements of the LCD display will appear

briefly at the same time ( Page 16).

At the end of the monitoring routine, the

Application that was used the last time to

make measurements with the connected

probe will open automatically and the instrument is ready to make measurements.

The last reading of the last not closed

block appears.

[%] or [FN]:

Unit of measurement for the displayed

reading (Setting: 10.7.5 ‘Unit’, beginning on Page 184)

[Appl:]: No. of the open Application

System Setup, Maintenance and Cleaning

[Blck:]: Number of the current block

[n=]: Number of single readings stored in

the current block

Alternatively to the LCD displays presented above, the following displays may

appear after power-up:

Operators Manual FERITSCOPE® FMP30 Page 37

Page 40

Detail of the LCD

display

Explanation of the LCD displays after power up

No reading appears after powering up the instrument because the last not closed block does not contain any readings.

If the settings in the Service function Storage mode are

[do not save] or [delete upon off], no reading will appear upon power up as well because the readings have

either not been stored at all or have been deleted when

the instrument was switched off.

( 10.8 ‘Storage Mode’, beginning on Page 187)

A designation (in this case “sheet”) has been assigned to

the open Application.

( 5.5 ‘Assigning Application Designations’, beginning

on Page 52)

System Setup, Maintenance and Cleaning

Once a designation has been assigned to an Application,

it appears in the information lines of the LCD display,

where applicable alternating with the Application number.

The tolerance limits are enabled in the open Applica-

tion:

( 5.6.1 ‘Tolerance Limits’, beginning on Page 54 and

7.3.5 ‘Measurements With Tolerance Limits Enabled’, beginning on Page 94).

The open Application is set to automatic block creation

( 5.6.3 ‘Automatic Block Size and Block Creation’, beginning on Page 57 and 7.3.6 ‘Measurements With a

Fixed Block Size’, beginning on Page 94).

[n=]: Number of the single readings stored in the current /

Block size

Page 38 Operators Manual FERITSCOPE® FMP30

Page 41

Detail of the LCD

display

Explanation of the LCD displays after power up

The open Application is set to auto-averaging mode (

5.6.4 ‘Auto-Averaging Mode’, beginning on Page 58 and

7.3.7 ‘Measurements in Auto-Averaging Mode’, beginning

on Page 96).

[i=]: Number of single readings measured using the autoaveraging / set number of single readings to be combined

The open Application is set to the “free-running” display

mode:

( 7.6 ‘Measurements in the Free-Running Display

Mode’, beginning on Page 104)

The open Application is set to the “free-running” display

mode:

( 7.6 ‘Measurements in the Free-Running Display

Mode’, beginning on Page 104 and 10.6.2 ‘Analog Dis-

play’, beginning on Page 173).

[10.00 11.00]: Limits of the analog display (example)

Matrix measuring mode is enabled:

and analog display is enabled

System Setup, Maintenance and Cleaning

( 7.7 ‘Measurements in Standard and Matrix Measuring Mode’, beginning on Page 109 and 10.6.3 ‘Matrix

Mode’, beginning on Page 174).

Matrix measuring mode is enabled:

( 7.7 ‘Measurements in Standard and Matrix Measuring Mode’, beginning on Page 109 and 10.6.3 ‘Matrix

Mode’, beginning on Page 174).

In addition, a designation each has been assigned to the

open Application (“sheet”) and to the current block (“back

side”) ( 5.5 ‘Assigning Application Designations’, beginning on Page 52 and 7.7.5 ‘Assigning Block Designa-

tions’, beginning on Page 115).

Operators Manual FERITSCOPE® FMP30 Page 39

Page 42

Detail of the LCD

display

System Setup, Maintenance and Cleaning

Explanation of the LCD displays after power up

This error message appear briefly after power-up if no

probe is connected to the instrument, if the probe is not

connected properly or if the connected probe is defective.

It is not possible to make measurements without a connected probe.

( 3.2 ‘Connecting Probes’, beginning on Page 33).

This warning appears briefly after power-up if a probe other than the last one used is connected to the instrument.

( 4.2 ‘Assigning a New Probe’, beginning on Page 43).

The current Application has not yet been set up. To make

ferrite content measurements, an Application must be set

up using the connected probe

( 5.1 ‘Setting Up an Application’, beginning on

Page 45).

3.3.3 Measured Variables

( Chapter 10.7.6 ‘Measured Variable’, beginning on Page 185)

Depending on the measured variable selected for display,

z Fe % or FN (display of the ferrite content in ferrite percent or in ferrite num-

bers),

z normalized countrate X

z Countrate X

z Fe % / FN and Xs

z Xn and Xs

may appear on the display.

Page 40 Operators Manual FERITSCOPE® FMP30

Page 43

3.3.4 Switching Off the Instrument

Press the ON/OFF key switch the instrument off manually.

The instrument shuts down automatically if for about 5 minutes no measurements

are made or no key is pressed.

3.4 Cleaning

To avoid damage to the instrument due to electrical shock, the line

plug of the AC adapter must be pulled before cleaning the instrument or the accessories!

Soiled instruments or accessories should be cleaned using a plastic care product

and a soft cloth.

The following should be observed during cleaning:

Risk of electrical shorts!

Water or other liquids must not enter the instrument or the accessories! Do not immerse or place the instrument or accessories into

liquids to loosen dirt through soaking! Do not pour liquids of the

instrument or accessories!

System Setup, Maintenance and Cleaning

Wipe off dirt immediately to avoid it from drying onto the surface!

Do not use aggressive agents to clean the instrument or the accessories

because they could attack the plastic housing!

To prevent damage, avoid scraping as a means of cleaning off dirt, in

particular in the area of the probe tip.

Do not use aggressive agents to clean the calibration standards because

they could damage the calibration standards! The use of damaged calibration standards (e.g., soiled or scratched standards) will lead to wrong

measurement results! (Additional information: 1.9 ‘Handling, Storage

and Transport of the Base and the Calibration Standards’, beginning on

Page 13)

Operators Manual FERITSCOPE® FMP30 Page 41

Page 44

4 Probe Handling

4.1 Handling During Measurements

Probe Handling

z Always hold the probe at its grip sleeve (right fig-

ure).

z Always place the probe gently and at a right angle

on the specimen surface.

z Slide the grip sleeve to the specimen surface such

that the sleeve rests on the specimen (center and bottom Figure, right).

z With the default setting, a beep will signal the mea-

surement capture.

z Lift the probe off the specimen before making the

next measurement.

Avoid hard impacts.

Do not allow the probe to hover directly above the surface. Doing so

will lead to erroneous readings.

Do not bend the probe connector cable! Doing so can lead to broken

wires.

Example:

Probe

FGAB1.3

Grip sleeve

Specimen

Page 42 Operators Manual FERITSCOPE® FMP30

Page 45

4.2 Assigning a New Probe

The instrument recognizes if the probe connected to the unit is different than the

one expected according to the probe identification in the current Application.

Reason: Each individual probe has a name that is comprised of the identification

number and the model designation (e.g., FGAB 1.3F). The probe must be “registered” in the instrument under this name.

Potential Causes of the Problem:

z The probe received a different identification number after a repair.

z A newly purchased probe has not yet been assigned.

z If a user has more than one probe of the same probe model, a problem occurs

if a not yet assigned probe is connected to the instrument. In such a case, it is

advisable to identify the probes and/or instruments with numbers.

If the measurements of an opened Application have not been made with the connected probe, [Ferrite] will flash on the display.

The corrective calibrations are deleted when the probe is assigned

to one or more Applications; the user will have to perform a new cor-

rective calibration for each of these Applications (

6.3 ‘Corrective Calibration’, beginning on Page 71

).

Probe Handling

How to assign a probe to an Application:

1.

Use ON/OFF ( Page 41) to switch the instrument off.

2.

Connect the new probe ( Page 33).

3.

Use ON/OFF to turn the instrument on ( Page 37).

Key sequ. /

Action

Operators Manual FERITSCOPE® FMP30 Page 43

Detail of the LCD

display

Explanation

This warning appears briefly after powerup if a probe other than the last one used

is connected to the instrument. After that,

the display of the measurement method

flashes.

Page 46

Key sequ. /

Action

Detail of the LCD

display

Explanation

4.

ZERO

Probe Handling

5.

DEL

6.

DEL

7.

Example: FGAB1.3F = Name of the connected probe

DEL: Probe assignment starts

ENTER: Probe will not be assigned, mea-

surement method display flashes

DEL: Probe will be assigned to all Applications

ENTER: The probe will be assigned only to

the current Application

DEL: All stored readings will be deleted;

the probe will be assigned to the current

Application / all Applications

ENTER: The probe will not be assigned,

measurement method display continues to

flash

ZERO appears on the display.

A normalization is required ( beginning

on Page 68).

[Base material (Fe)]: The measurements

for the normalization should be made on

base.

ENTER: Cancels the normalization.

Page 44 Operators Manual FERITSCOPE® FMP30

Page 47

5 Applications

All relevant settings and parameters for a measuring application as well as the

captured measurement data are stored in a file - we refer to this file as an Application.

The instrument has the capability of setting up up to 100 different Applications.

A maximum of 20,000 readings can be stored in these Applications. The measurements can be combined in up to 4,000 blocks.

Due to the magnetic induction measuring method, which captures

all ferromagnetic components in the same manner, the measurements are always stated in ferrite. No distinction is made between

the different material components, such as ferrite and martensite.

An Application consists of:

z Single readings,

z Application-specific settings, and the

z Coefficients that have been determined during the normalization and

corrective calibration (used for adapting the master characteristic

stored in the probe plug to the current measuring application).

5.1 Setting Up an Application

Applications

A probe must be connected and an application must be set up before measurements can be made in an Application.

From the service function Measurement/Unit ( Page 184), specify the unit of measurement for measuring the ferrite contents of an

Application that is to be set up.

Once the linking mode is enabled (indicated by: on the LCD display),

an automatic check will be carried out to see, whether one or more Applications

have already been set up with the connected probe. If this is the case, no normalization is required when setting up the Application. Instead, the normalization

and corrective calibration of the Application(s) that has/have been set up with this

probe will be used.

Operators Manual FERITSCOPE® FMP30 Page 45

Page 48

Applications

Procedure

As long as the restricted operating mode is enabled (indicated by

on the LCD display), only Applications that have already been

set up can be selected, i.e., it is not possible to set up new Applica-

tions ( 10.6.1 ‘Restricted Operating Mode’, beginning on

Page 171).

Key sequ. /

Action

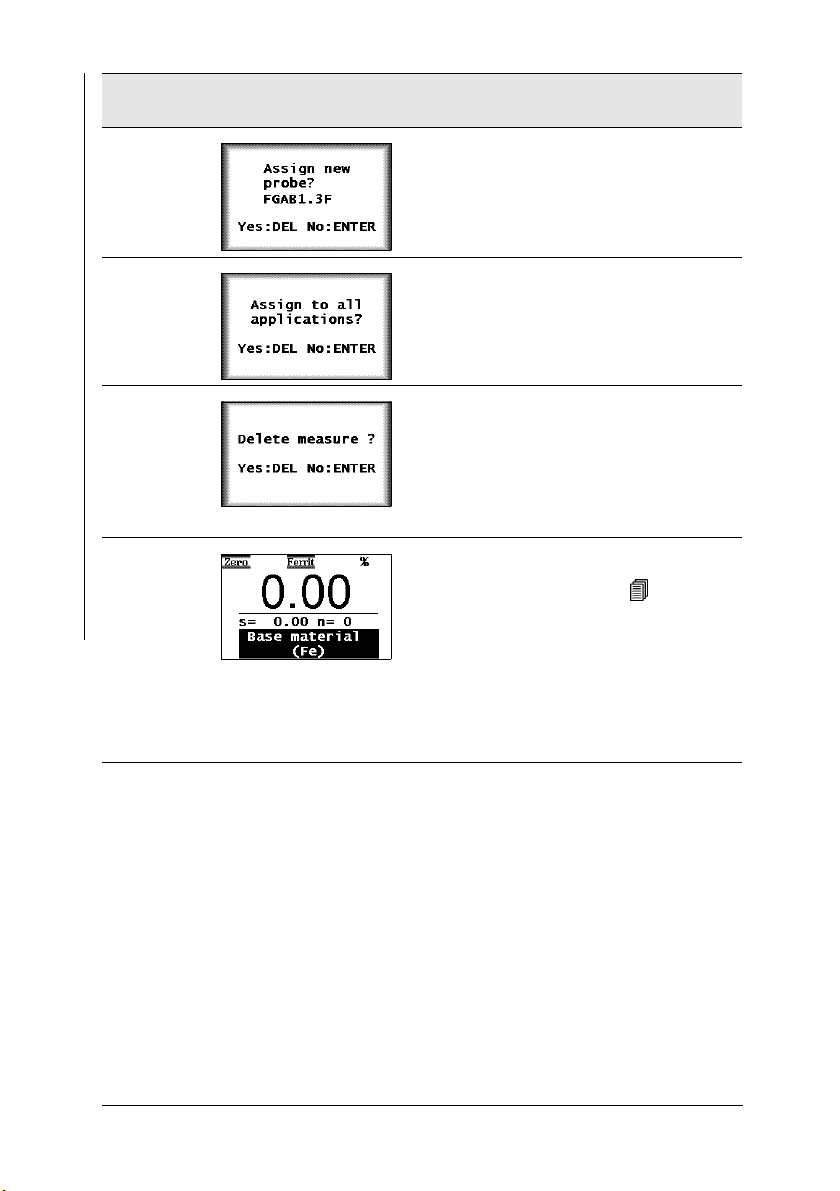

APPL No Use APPL No to start the selection of the

APPL No Use APPL No to start or continue the se-

∧ or ∨

Detail of the LCD

display

Explanation

Application.

[Appl:]: Application number

[sheet:]: Assigned Application designation

(Example; appears only if an Application

designation has been assigned

( 5.5 ‘Assigning Application Designations’, beginning on Page 52). If an Appli-

cation designation has not been assigned,

the following will appear immediately on

the LCD display:

lection of the Application.

[Appl:]: Application number

[n=]: Number of the measurements stored

in the Application

Use the arrow keys to select an Application that has not yet been set up.

Page 46 Operators Manual FERITSCOPE® FMP30

Page 49

Key sequ. /

Action

ENTER if [always ask] is selected from the service

ENTER Use ENTER to start setting up the Applica-

Detail of the LCD

display

Explanation

function Measurement/Unit

( 10.7.5 ‘Unit’, beginning on Page 184),

select the unit of measurement for making

the measurements in the Application at

this point:

Use the arrow keys to select the unit.

[Fe%]: The ferrite content will be measured in ferrite percent.

[FN]: The ferrite content will be measured

in ferrite numbers.

[OK: ENTER]: Use ENTER to confirm the

selection.

tion.

ZERO appears on the LCD display.

[Base material (Fe)]: The measurements

for the normalization should be made on

base.

Applications

ENTER: Cancels the normalization.

Performing the normalization: begin-

Page 68.

ning on

Operators Manual FERITSCOPE® FMP30 Page 47

Page 50

5.2 Selecting the Desired Application

To make ferrite content measurements, a probe must be connected and an Application must be selected that has been set up using the connected probe before

measurements can be made.

Applications

If [Ferrite] flashes on the LCD Display after instrument power-up or

after selecting an Application, an Application has not yet been set

up using the connected probe. It is not possible to make measurements when the display is flashing.

The following options exist if an Application has not yet been set up using the

connected probe:

z Setting up a new Application using the connected probe ( 5.1 ‘Setting Up

an Application’, beginning on Page 45),

z Overwriting an existing Application using the connected probe

( 5.3 ‘Deleting an Application’, beginning on Page 49),

z Connecting a probe that has already been used to set up an Application

( 3.2 ‘Connecting Probes’, beginning on Page 33).

Procedure Selecting an Application

Key sequ. /

Action

APPL No Use APPL No to start the selection of the

Detail of the LCD

display

Explanation

Application.

[Appl:]: Application number

[n=]: Number of the measurements stored

in the Application

∧ or ∨

Page 48 Operators Manual FERITSCOPE® FMP30

Use the arrow keys to select the desired

Application.

Page 51

Key sequ. /

Action

ENTER Use ENTER to confirm the selected Appli-

Detail of the LCD

display

Explanation

cation. The selected Application will be retrieved. The last reading of the last not

closed block is displayed. The instrument

is ready to make measurements.

5.3 Deleting an Application

As long as the restricted operating mode is enabled (indicated by

on the LCD display), the DEL key will not be enabled, i.e., it is

not possible to delete Applications ( 10.6.1 ‘Restricted Operating

Mode’, beginning on Page 171).

When deleting an Application, all readings as well as the normalization and corrective calibration coefficients stored in the Application

will be deleted. Thus, this Application memory is free for a new measuring application.

Applications

Key sequ. /

Action

APPL No Use APPL No to start the selection of the

∧ or ∨

Operators Manual FERITSCOPE® FMP30 Page 49

Detail of the LCD

display

Explanation

Application.

[Appl:]: Application number

[n=]: Number of the measurements stored

in the Application

Use the arrow keys to select the Application to be deleted or leaf through the pages

using CAL +

∨.

Page 52

Key sequ. /

Action

DEL Use DEL to start the deletion process.

Applications

Detail of the LCD

display

Explanation

Pressing DEL again: Deletes the Application.

ENTER: Cancels the deletion.

It is now possible to select a different Ap-

plication ( Page 48) or to set up a new

Application ( Page 45).

5.4 List of Set Up Applications

Key sequ. /

Action

APPL No Use APPL No to start the selection of the

Page 50 Operators Manual FERITSCOPE® FMP30

Detail of the LCD

display

Explanation

Application.

[sheet]: Assigned Application designation

(Example; appears only if an Application

designation has been assigned

( 5.5 ‘Assigning Application Designations’, beginning on Page 52). If an Appli-

cation designation has not been assigned,

the following will appear immediately on

the LCD display:

[Appl:]: Application number

[n=]: Number of the measurements stored

in the Application

Page 53

Key sequ. /

Action

Print Use PRINT to start the printout of the list of

Detail of the LCD

display

Explanation

set up Applications.

The list of set up applications will print if a

printer is connected and switched on

(Fig. 5-1).

It is now possible to select a different Ap-

plication ( Page 48) or to set up a new

Application ( Page 45).

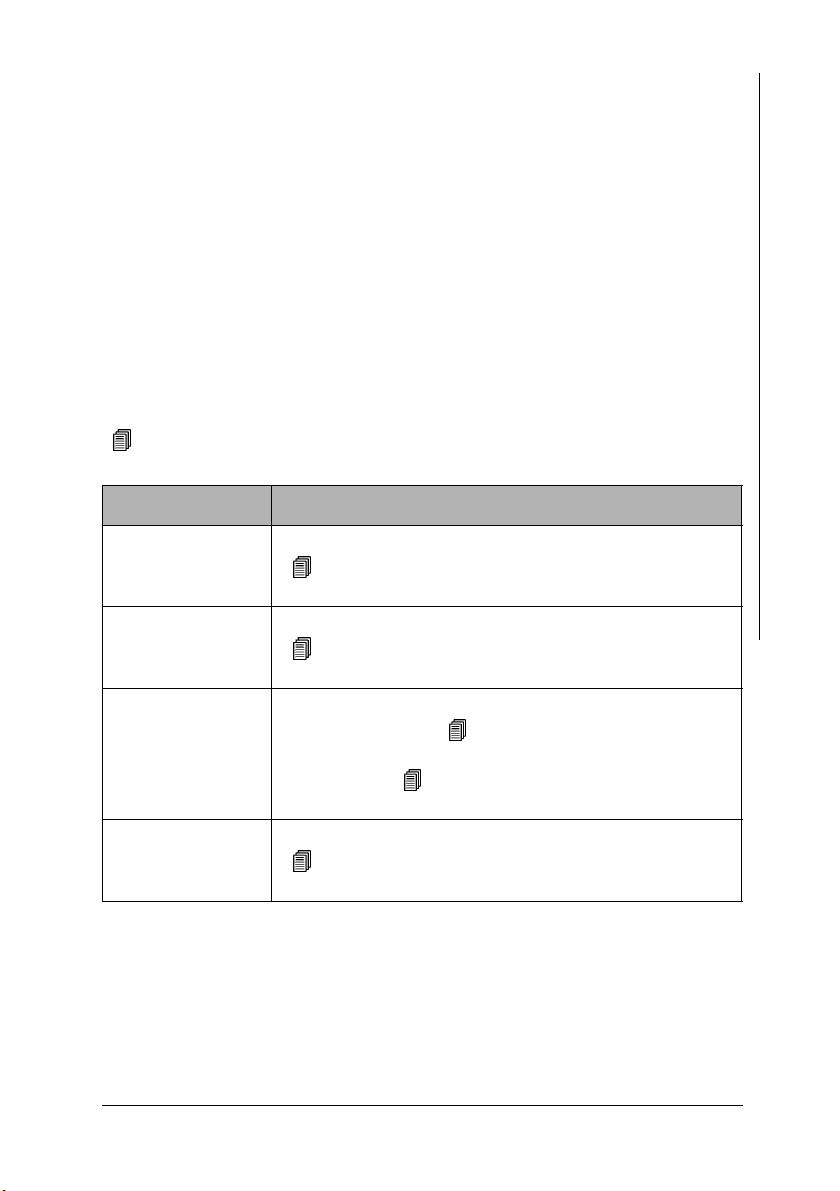

FISCHER FERITSCOPE FMP30 23.07.08

Applications:

0 sheet

FGAB1.3Fe Fe % 23.07.08 n= 7

1 face

FGAB1.3Fe Fe % n= 3

2 level

FGAB1.3Fe Fe % n= 0

Applications

Fig. 5-1 List of set up Applications (Example

Explanations to Fig. 5-1:

FISCHER FERITSCOPE FMP30

2008-07-23 Current date

0, 1, 2 (1st column) Number of the Application

sheet, face ... Application designation (appears only if an Applica-

FGAB1.3Fe ... Short form designation for the probe that has been

Fe% ... Unit (Fe% or FN)

Operators Manual FERITSCOPE® FMP30 Page 51

Instrument type:

tion designation has been assigned ( Page 52).

used to set up the Application.

Page 54

2008-07-23 End of block - Date of the last block closure of this

Application (if no date is shown, the Application does

not contain a closed block!).

n= Number of measurements stored in this Application

Applications

5.5 Assigning Application Designations

A customer-specific designation that can be comprised of a max. of 16 ASCII

characters can be assigned to every Application.

Assigning the Application designation can be carried out in the following manner:

z Use of the optional software MPNAME (the software is available from your

authorized supplier or directly from the Helmut Fischer GmbH Institute for

Electronics and Metrology.)

z Transmitting the command “SAN” via the USB port ( 9.4.2 ‘Control

Commands’, beginning on Page 142)

When making measurements in the matrix measuring mode, each block can be

assigned a designation as well ( Page 115).

Once Application or block designations have been assigned, the

designations appear in the information lines of the LCD display,

where applicable, alternating with the respective numbers. On printouts, the Application or block designation will appear in place of the

Application or block number.

5.6 Application Specific Settings

The following settings apply only to the settings of the open Application, i.e.,

they are Application-specific:

z Settings that are entered after pressing the MENU key.

z Measurement program ( Page 61)

z Unit ( Page 184)

After pressing the MENU key, the following application-specific settings can be

made:

Page 52 Operators Manual FERITSCOPE® FMP30

Page 55

Key sequ. /

Action

Detail of the LCD

display

Explanation

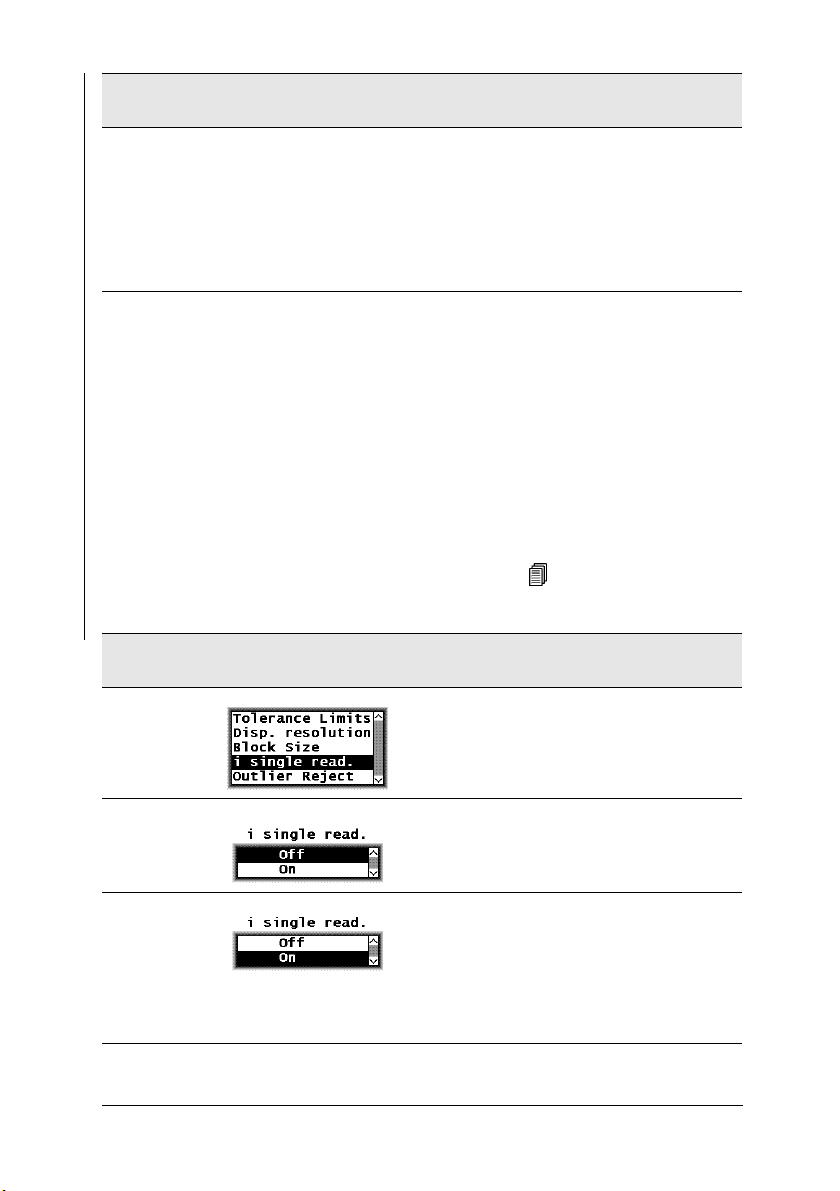

MENU

Selects a menu option by pressing ∧ or ∨:

z Tolerance Limits ( Page 54)

z Measurement display resolution

( Page 56)

z Automatic block size and block creation

( Page 57)

z Number of single readings to be mea-

sured in auto-averaging mode before an

individual value is generated from them

by averaging ( Page 58)

z Outlier rejection ( Page 60)

Pressing ENTER confirms the selection.

Pressing DEL or performing a measurement exits the MENU.

As long as the restricted operating mode is enabled (indicated by

on the LCD display), the MENU key will not be enabled, i.e., it is

not possible to modify these application-specific settings

( 10.6.1 ‘Restricted Operating Mode’, beginning on Page 171)!

Applications

Operators Manual FERITSCOPE® FMP30 Page 53

Page 56

5.6.1 Tolerance Limits

Having the tolerance limits enabled allows for a simple and quick determination

if the measured ferrite contents are within specified limits

( 7.3.5 ‘Measurements With Tolerance Limits Enabled’, beginning on

Page 94).

Applications

Key sequ. /

Action

MENU Use MENU to start Settings.

ENTER Use ENTER to confirm the “tolerance lim-

∧ or ∨

ENTER Use ENTER to confirm the value for the

Detail of the LCD

display

Explanation

its”.

To activate the tolerance limits:

use the arrow keys to select limits “on” or

to deactivate the tolerance limits: Select

limits “off”.

lower specification limit or:

specify a new lower limit by pressing

∧ or

∨.

ENTER

∧ or ∨

Use ENTER to confirm the value for the

upper specification limit or:

specify a new upper limit by pressing

∧ or

∨.

It is also possible to set the upper and lower specification limits by

making a measurement on an object that corresponds approximately to the specification limits to be set.

Page 54 Operators Manual FERITSCOPE® FMP30

Page 57

ENTER Press ENTER to confirm the entry.

The tolerance limits are now set and enabled. Press DEL to return to the measurement screen.

The instrument is ready to make measurements.

Applications

As long as the tolerance limits are enabled,

LCD display.

will appear on the

If the upper and lower specification limits are mixed up when entering the settings, the instrument will automatically select the lower values as the lower specification limit and the higher value as the upper specification limit.

Operators Manual FERITSCOPE® FMP30 Page 55

Page 58

5.6.2 Measurement Display Resolution

The measurement display resolution specifies the resolution for displaying the

readings on the LCD display.

Example: Reading 18.61

Applications

Display with resolution setting “low”:19

Display with resolution setting “standard”: 18.6

Display with resolution setting “high”: 18.61

Resolution 0.0 ...0.999 1.0 ...9.99 10 ...99.99 100 ...999.9 1000 ...9999

low 0.9 9.9 99 999 9999

medium 0.99 9.9 99.9 999 9999

high 999 9.99 99.99 999.9 9999

Key sequ. /

Action

MENU

∨

ENTER

∧ or ∨

ENTER Press ENTER to confirm the selection and

Detail of the LCD

display

Explanation

Use MENU to start Settings and select

“Disp. resolution” using the arrow key

Use ENTER to confirm the selection “Disp.

resolution”.

Use the arrow keys

desired resolution.

return to the menu to enter additional settings.

Press DEL to return to the measurement

screen.

The instrument is ready to make measurements.

∧ or ∨ to select the

∨ .

Page 56 Operators Manual FERITSCOPE® FMP30

Page 59

5.6.3 Automatic Block Size and Block Creation

“Automatic block creation” must be enabled and a block size must be defined for

a certain number of readings to be combined in a block automatically during the

measurement. The block size must be between 2 and 99 ( 7.3.6 ‘Measurements

With a Fixed Block Size’, beginning on Page 94).

Automatic block creation is not available in the matrix measuring

mode.

Applications

Key sequ. /

Action

MENU

∨

ENTER Use ENTER to confirm the selection “Block

∧ or ∨

Enter Press DEL to delete the readings of the

Detail of the LCD

display

Explanation

Use MENU to start Settings.

Press the arrow key ∨, until “Block size” is

highlighted.

size”.

To activate “Block size”:

Use the arrow keys to select Automatic

block result “on” or

to deactivate block size: select Automatic

block result “off”.

open Application.

If measurements have already been made

without a fixed block size, these measurements must be deleted because the subsequent statistical evaluation of the blocks

is correct only if the number of readings is

the same for each block.

When pressing ENTER, the fixed block

size mode will not be enabled.

∧ or ∨

Operators Manual FERITSCOPE® FMP30 Page 57

Use the arrow keys to set the desired block

size.

Page 60

Key sequ. /

Action