FISCHER DS31 Instruction Manual

d e v elopi n g s o l u t i o n s

*09005344* BA_EN_DS31 Rev.A 08/12

*09005344*

Instruction Manual

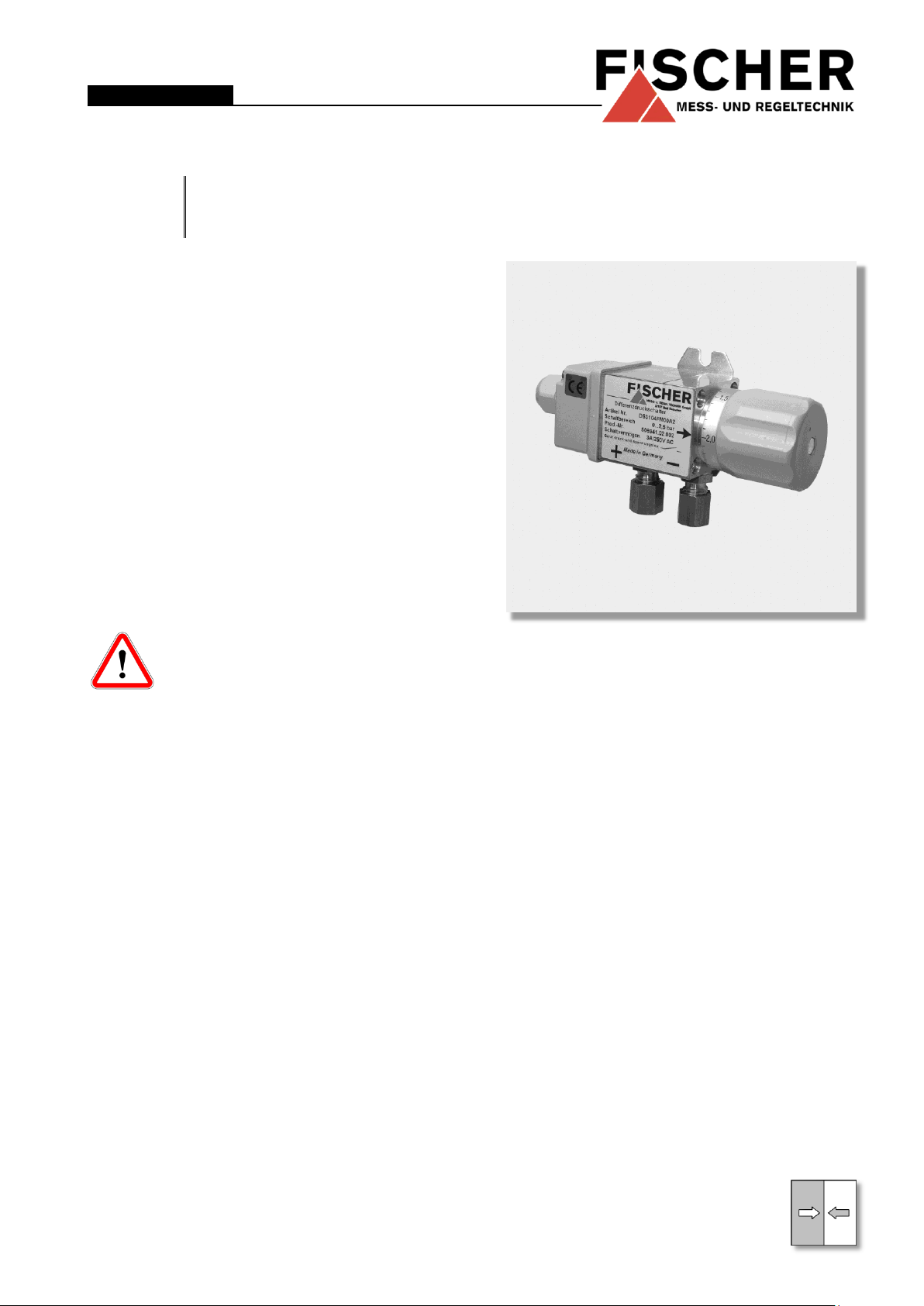

DS31

Differential Pressure Switch

Table of Contents

1 Safety Instructions

2 Intended Applications

3 Product Description and Functions

4 Installation

5 Commissioning

6 Maintenance

7 Transport

8 Service

9 Accessories

10 Disposal

11 Specifications

12 Ordering Code

13 Dimensions

14 CE-Certificate

1 Safety Instructions

1.1 General information

This operating manual contains detailed

information about the installation, operation and maintenance of the instrument.

This information must be observed and

read by the installer, operator and other skilled personnel prior to any installation and commissioning

of the instrument.

This operating manual forms part of the product and

must be kept in the immediate vicinity of the instrument for easy access by the responsible personnel

at any time.

The following chapters, especially the instructions

on installation, commissioning and maintenance

contain important safety information, the noncompliance of which may result in hazards to persons, animals, environment and objects.

1.1 Personnel qualification

Only personnel trained in the installation, commissioning and operation of this product may install

and operate the same.

Skilled personnel are persons who are able to judge

delegated work and possible hazards based on

their technical education, proficiency and experiences, particularly due to their knowledge about the

applicable norms.

1.2 Risks of non-compliance with safety instructions

Non-compliance with these safety instructions, inappropriate use of this product, and/or operation of

this product outside the limits specified for any of its

technical parameters, may result in harm to persons, the environment or the system in which it is

installed.

The producer is not liable for any claims for damages in such circumstances.

1.3 Safety instructions for operators

Safety instructions for the proper use of this product

must be followed. This information must be available at all times to personnel responsible for installation, operation, maintenance and inspection of this

product.

Adequate steps must be taken to prevent the occurrence of hazardous conditions that can be caused

by electric energy and the convertible energy of the

process media and/or improper connection of the

instrument. Detailed information can be found in the

relevant national and/or international rules and regulations.

In Germany DIN EN, UVV apply, for industryspecific applications regulations of DVGW, Ex, GL,

as well as the rules of the local authorities (EVUs in

Germany).

WARNING!

... indicates a possible hazardous situation the non-observance of which

might result in hazards to humans, animals, environment and objects.

NO contact

Operation with

NO contact

(Standard wiring mode)

1.4 Forbidden modifications

Modification or other technical alteration of the device by the customer is not permissible. This also

applies for the use of spare parts. Any eventual

modifications/ variations will be carried out solely by

Fischer Mess- und Regeltechnik GmbH.

1.5 Impermissible operational modes

The operational dependability of the device is guaranteed only if it is used as intended. The device

version must be adapted to the medium used in the

system. The limiting values stated in the technical

data must not be exceeded.

1.6 Safety Considerations during Installation and Maintenance

The safety instructions stated in this manual, existing national regulations on accident prevention and

the internal rules and procedures on working, operation and safety of the operator are to be observed.

It is the responsibility of the operator to ensure that

only authorised and skilled technical personnel carry out any required maintenance, inspection and installation works.

1.7 Explanation of symbols

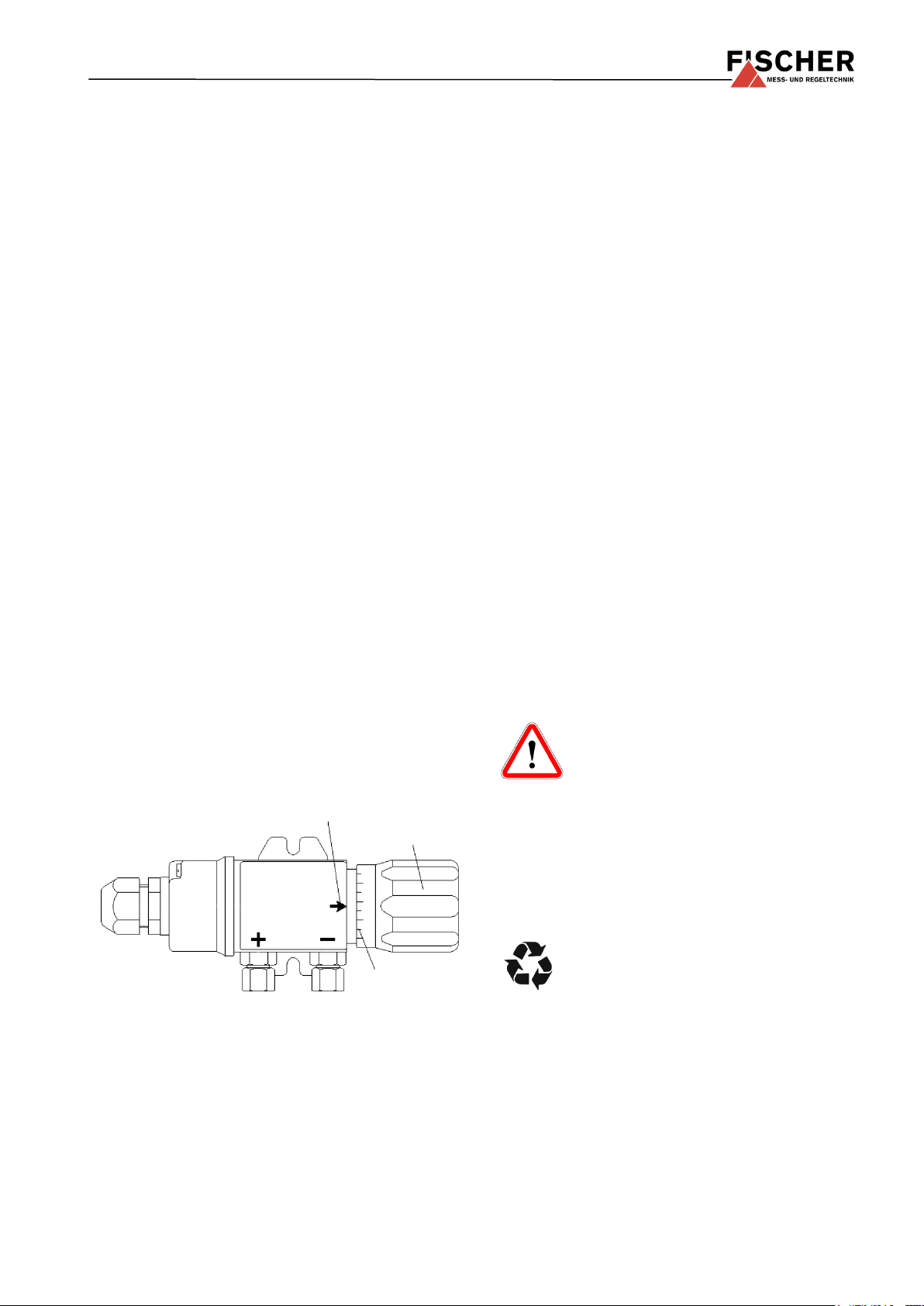

3.2 Principles of Operation

This pressure switch is based on a rugged and uncomplicated diaphragm movement. It is suitable for

monitoring positive / negative gauge and differential

pressure. The operating principle of the system is

identical in all three cases. The monitored pressure

or differential pressure creates an unbalanced force

on the diaphragm. This force moves the diaphragm

system against the force of the range selector

springs. A tappet, which is mounted on the diaphragm, actuates the microswitch.

The setpoint can be adjusted by a scaled handwheel.

4 Installation

4.1 Process Connections

• By authorized personnel only.

• For suitable mechanical fittings only.

• Ensure that the process equipment and pres-

sure lines are at atmospheric pressure before

making pressure connections to the instrument.

• The instrument should be provided with suitable

protection against pressure surges (e.g., snubber or pulsation damper).

• Ensure that the mechanical configuration and

materials of construction of the instrument are

compatible with the process media.

2 Intended Applications

Differential pressure switch for positive / negative

gauge pressure or differential pressure of neutral

media such as industrial water, water for heating

systems, neutral gases and oils. The product must

be used only for applications and under conditions

specified by Fischer Mess- und Regeltechnik

GmbH.

3 Product Description and Functions

3.1 Block Schematic Diagram

• Ensure that process pressure is always less

than the specified safe pressure rating.

4.2 Electrical Connections

• By authorized personnel only.

• Electrical connections must conform to relevant

international, national and local regulations and

norms relating to electrical and instrumentation

installations.

• Switch off electrical power to the plant before

attempting electrical installation work of any

kind.

• Make electrical connections to the instrument

through a suitable fuse.

• Depending on your order the device is supplied

with Normally Open (NO) or Normally Closed

(NC) contact. Standard: NO contact

adjustment knob

arrow marker

scale

5 Commissioning

• Power supply and signal cabling to the instru-

ment must be correctly selected to meet operational requirements, and installed in a way that

does not cause physical stress to the instrument.

• Pressure connections must be ventilated to

avoid measuring failure. If used with water protect instrument against freezing.

• Prior to commissioning pressure connections

must be checked for leaks.

5.1 Pressure Connections

The instruments pressure ports are marked by (+)

and (-) symbols. The pressure applications need to

be installed according to the label.

• Differential pressure measurement:

+ Higher pressure

- Lower pressure

• Pressure measurement:

+ Pressure port

• Negative pressure measurement:

- Negative pressure port

5.2 Shock Pressure Damping

Pulsating pressure on the plant may lead to mechanical wear and disturbances in functional capability. To avoid this we recommend installing absorbers into the pressure lines, e.g.: Capillary coil

MZ401 M.

5.3 Switching Point Adjustment

6 Maintenance

The instrument is inherently maintenance-free.

However, to ensure reliable operation and maxim-

ize the operating life of the instrument, it is recommended that the instrument, its external electrical

and process connections, and external connected

devices be regularly inspected, e.g.:

• Check the switching operation in connection to

follow-up components.

• Check all pressure connections for leak-

tightness.

• Check the electrical connection (screw termi-

nals).

Inspection and test schedules depend on operating

and site conditions. The operating manuals of other

equipment to which the instrument is connected

must be read thoroughly to ensure that all of them

work correctly when connected together.

7 Transport

The product must be protected against shock and

vibration during transport. It must therefore be

properly packed, preferably in the original factory

packaging, whenever it is to be transported.

8 Service

Any defective devices or devices with missing parts

should be returned to Fischer Mess- und Regeltechnik GmbH. For quick service contact our service department.

Remaining medium in and on dismantled

measuring instruments may cause danger to persons, environment and equipment. Take reasonable precautions!

Clean the instrument thoroughly if necessary.

9 Accessories

Not available.

10 Disposal

Protect your environment!

Use the product in accordance with relevant regulations. Please be aware of environmental consequences of disposal at

care accordingly.

the end of the product's life, and take

Loading...

Loading...