Page 1

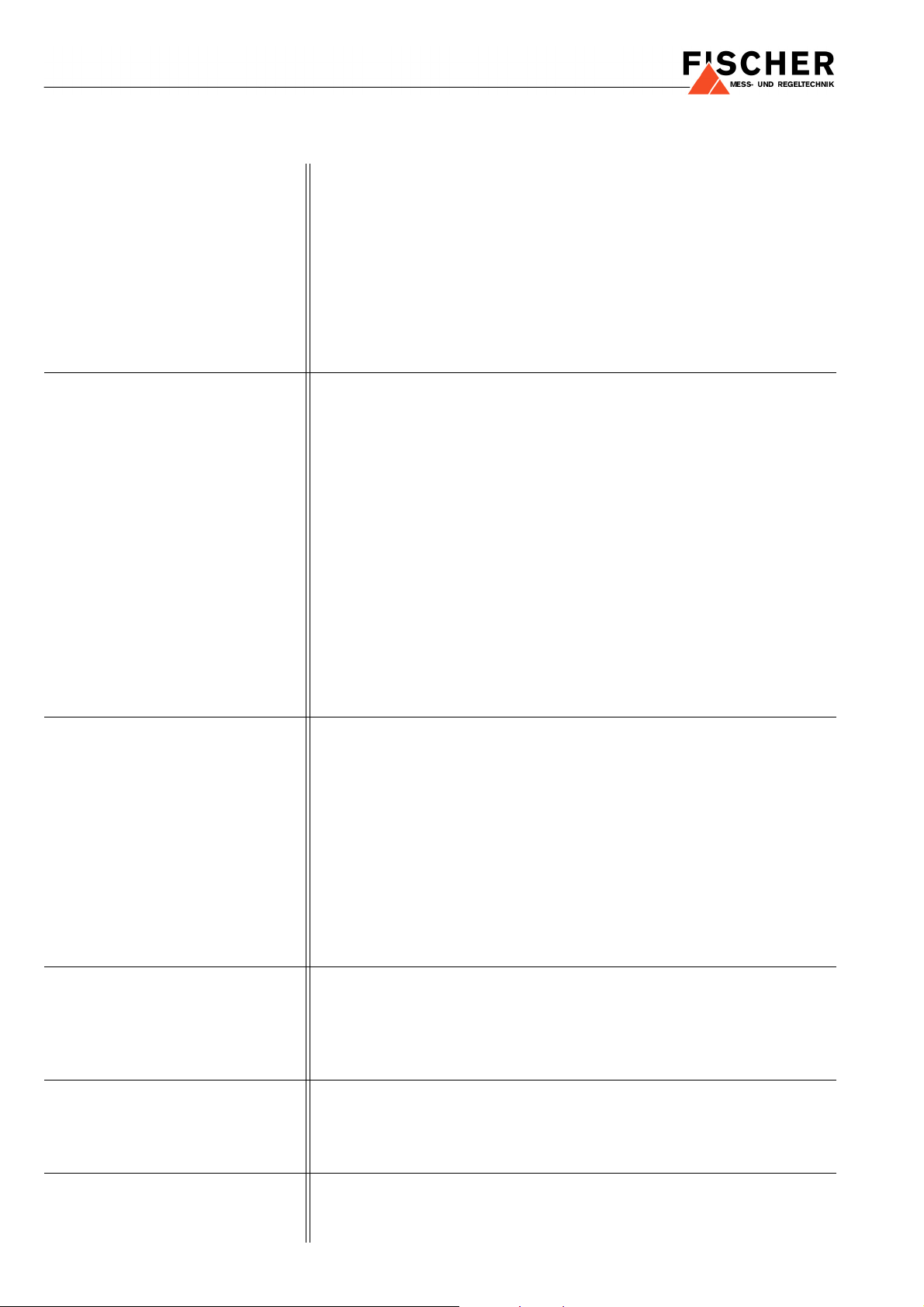

Inductive displacement

transducer

Capsule element

1.

2.

3.

4.

1. Load

2. Load

3. 2 change-over contacts

4. LC-display

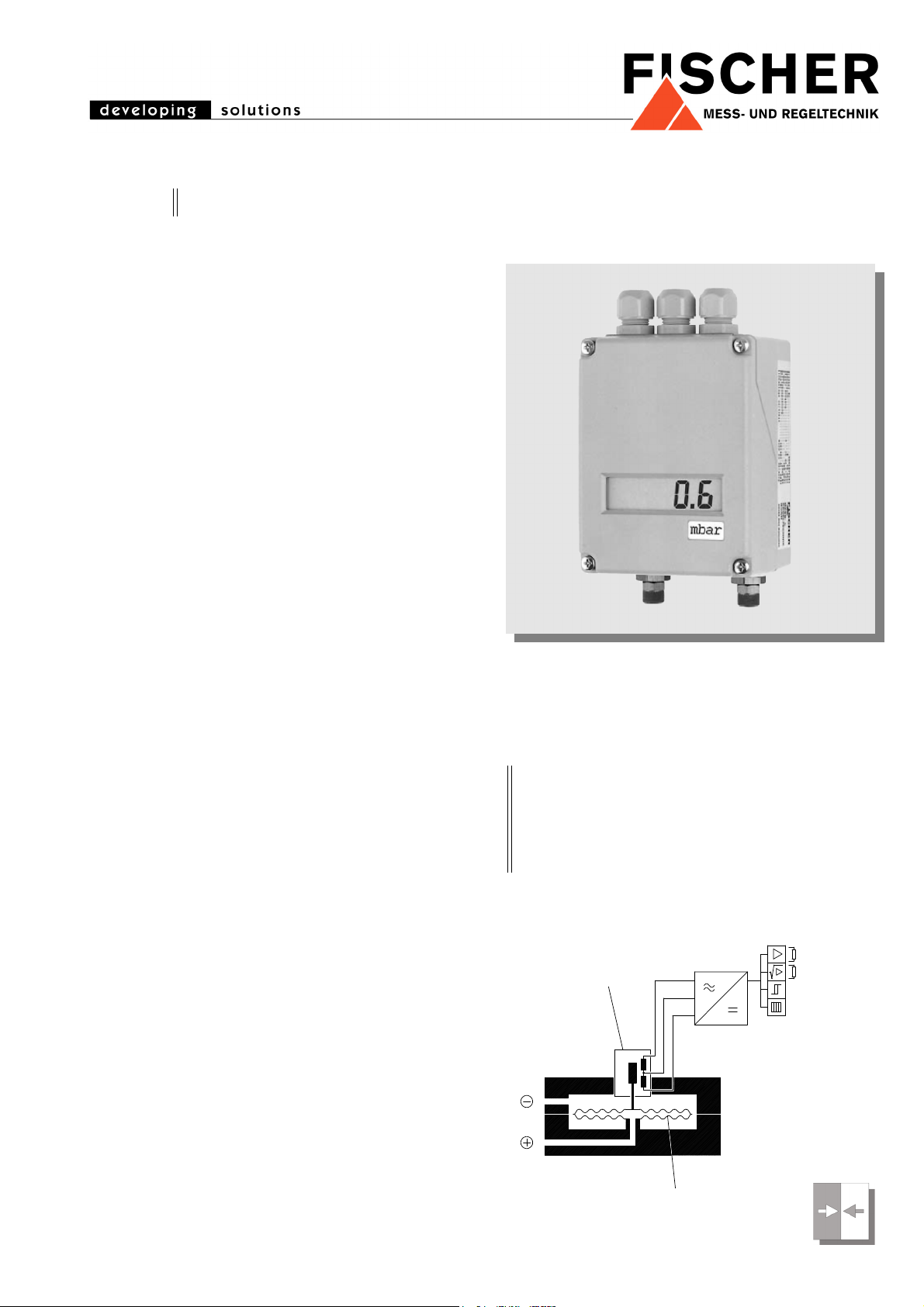

DE50 Differential Pressure Transmitter

Measuring transmitter with limit switching function for overpressure, vacuum

and differential pressure especially for

gaseous media

Range of applications:

• air conditioning technology

• ventilation technology

• environmental engineering

Typical Applications

• continuous ventilating control

• monitoring of exhausters, tapline filters etc.

• chimney draft measurement

• flow and control pressure measurement

• surface technology

3.6.08 DB_GB_DE50.fm

Principles of Operation

The function of this transmitter is based

on a capsule element measuring system

suitable for overpressure-, vacuum- and

differential pressure measurements.

Pressure or differential pressure to be

measured displaces the capsule element and moves hereby the core of inductive displacement transducer. The

electronic amplifier generates an electrical output signal. Different types of electronic converters can be supplied. Apart

from the different operating voltages

output signal can be supplied as current

or voltage signal. Flow rates of gaseous

medium are often measured by measuring differential pressure. In order to obtain a flow proportional measuring value

differential pressure signal has to be

square-root extracted. For those applications transformation electronics are

used which supply square-root extracted output signals.

In addition to analogue output signal potential free relay outputs can be supplied. They can be adjusted to any value

within the measuring range. By means

of a built-in LC-display (option) a local linear indication

of pressure-/differential pressure measuring values is

possible.

Main Features

• high overpressure safety

• maintenance-free due to wear resistant inductive

measuring cell

• rugged design

Functional Scheme

Page 2

Specifications

General

Measuring ranges 0...4mbar to 0...600 mbar (see Ordering Code)

Nominal pressure max. 3 bar (see Ordering Code)

Max. static pressure overpressure safe up to permitted nominal pressure

Measuring accuracy ± 1% FS

Temperature drift 0.5% FS / 10K

Perm. ambient temperature -10°...+60°C

Perm. medium temperature -20°...+70°C

Protection class IP 54 acc. to DIN EN 60529

Electrical

Electrical connections 4/3-wire 4/3-wire 2-wire

Operating voltages 230 V AC 4-wire

115 V AC 4-wire

24 V AC 4-wire

24 V DC 3-wire

Power consumption approx. 3 VA approx. 3 VA ≤ 0,75 W

Output signal 0-20 mA 0-10 V DC 4-20 mA

Apparent ohmic resistance max. 800 Ω > 2 k Ω max. 500 Ω

Current limit approx. 30 mA approx. 30 mA approx. 30 mA

Voltage limit - approx. 12 V DC -

Square-rooted output ± 0.5%

with suppression of leak flow volume 2% set up

Range adjustment approx. 10% FS

Zero point adjustment approx. 10% FS

Measuring Indication /

Switching Sections

Measuring indication 3½ digit LC-Display

Switching point adjustment The digital display can be switched over between the differential pressure

actual value and the switch point adjustments via selector. The display then

indicates the related setpoint value. Setpoint values are adjustable within full

scale range.

Switching point hysteresis approx. 2%

Contact output 1 or 2 potential-free change-over contacts

Load data of contacts

U~

U=

Connection

Electrical Connections internal connector bloc, M16x1.5 connection

plug connections on request

Pressure Connections female thread G¼, threaded hose coupling (al) for 6/8 mm flexible tube,

cutting ring connection (brass) for 6/8/10 mm tube

Materials

Housing diecasted aluminium, varnished

Housing cover ABS, self-extinguishing

Measuring element capsule element of Cu Be 2

Installation

wallmounting vertical, pressure ports downward

any other orientation correction of zero point recommended

= 250 V AC, I~

max.

= 30 V, I=

max.

max.

= 2 A, P=

max.

230 V AC 4-wire

115 V AC 4-wire

24 V AC 4-wire

24 V DC 3-wire

= 2 A, P~

max.

= 250 VA ohmic resistance

max.

= 60 W ohmic resistance

24 V DC

Page 3

Dimensions (all units in mm unless stated otherwise)

Electrical Connections

Operating Voltage

4-wire 230 V AC / 115 V AC / 24 V AC

Operating Voltage

3-wire 24 V DC

Operating Voltage

2-wire 24 V DC

Mounting holes ø

4.5 mm

Cable gland M16 x 1.5

Page 4

Ordering Code

Differential Pressure Transmitter DE50

Measuring range / max. static operating pressure

0– 4 mbar 20 mbar....................................................> 5 2

0– 6 mbar 30 mbar....................................................> 5 3

0– 10 mbar 50 mbar....................................................> 5 4

0– 16 mbar 80 mbar....................................................> 5 5

0– 25 mbar 125 mbar....................................................> 5 6

0– 40 mbar 200 mbar....................................................> 5 7

0– 60 mbar 300 mbar....................................................> 5 8

0–100 mbar 500 mbar....................................................> 5 9

0–160 mbar 800 mbar....................................................> 6 0

0–250 mbar 1200 mbar....................................................> 8 2

0–400 mbar 2000 mbar....................................................> 8 3

0–600 mbar 3000 mbar....................................................> 8 4

– 1 to 5 mbar 30 mbar...........................................> C 3

– 4 to 6 mbar 50 mbar...........................................> 5 0

– 10 to 6 mbar 80 mbar...........................................> 6 3

– 20 to 40 mbar 300 mbar...........................................> 6 8

– 40 to 60 mbar 500 mbar...........................................> 7 0

–100 to 60 mbar 800 mbar...........................................> 7 3

–250 to 150 mbar 2000 mbar...........................................> 7 7

Pressure Connections

Female Thread G ¼.........................................................................> 0 1

Cutting ring connection brass for 6 mm tube ...................................> 2 8

Cutting ring connection brass for 8 mm tube ...................................> 2 9

Cutting ring connection brass for 10 mm tube .................................> 3 0

Screw connection AI for 6 mm flexible tube.....................................> 4 0

Screw connection AI for 8 mm flexible tube.....................................> 4 1

Electrical Output Signal

0–20 mA linear................................................................................................ > A

4–20 mA linear 2-wire, only for 24 V DC

without contacts and square root extraction.................................................... > B

0–10 V DC linear............................................................................................. > C

0–20 mA square-rooted .................................................................................. > E

4–20 mA square-rooted .................................................................................. > F

0–10 V DC square-rooted ............................................................................... > G

4–20 mA linear................................................................................................ > P

Operating Voltage

230 V AC.................................................................................................................. > 1

115 V AC .................................................................................................................. > 2

24 V AC.................................................................................................................... > 4

24 V DC.................................................................................................................... > 9

Indication / Switching Sections

Without indication / without contacts............................................................................... > 0

3½ digit indication / without contacts............................................................................... > 1

3½ digit indication / with 1 potential-free contact ............................................................ > 2

3½ digit indication / with 2 potential-free contacts........................................................... > 5

Electrical Connection

Internal connector bloc...............................................................................................................> E

M12 plug connection..................................................................................................................> M

Technische Änderungen vorbehalten • Subject to change without notice • Changements techniques sous réserve

Loading...

Loading...