Page 1

1 Safety Instructions

1.1 General

This manual contains detailed information about the product, and instructions for its installation, operation and maintenance. Operators

and other technical personnel responsible for the equipment must read this thoroughly before attempting to install or operate this

equipment. A copy of this manual must always be

kept accessible at the place of work for reference

by concerned personnel.

Chapter 1 (sections 1.2 through 1.7) contains general as well as specific safety instructions.

Chapters 2 through 10, covering topics ranging

from intended purpose of the equipment to its final disposal, also include important points relating to safety. Overlooking or ignoring any of these safety points can endanger humans and animals, and possibly cause damage to other equipment.

1.2 Personnel Qualification

Personnel responsible for installation, operation,

maintenance and inspection of this product must

have the qualifications, training and experience

necessary to carry out such work on this type of

equipment.

1.3 Risks of Disregarding Safety Instructions

Disregarding safety instructions, use of this product for purposes for which it is not intended,

and/or operation of this product outside the limits

specified for any of its technical parameters, can

result in harm to persons, the environment, or the

plant on which it is installed. Fischer Mess- und

Regeltechnik GmbH will not be responsible for

consequences in such circumstances.

1.4 Safety Instructions for Operators

Safety instructions for the proper use of this product must be followed. This information must be

available at all times to by personnel responsible

for installation, operation, maintenance and inspection of this product.

Adequate steps must be taken to prevent the

occurrence of hazardous conditions that can be

caused by electric energy and the convertible

energy of the process media. Such conditions

can, for example, be the result of improper

electrical or process connections.

Detailed information is available in relevant published norms (DIN EN, UVW in Germany; and

equivalents in other countries), industrial standards such as DVWG, EG-, GL-, VDE

guidelines, as well as regulations of the

local authorities ( e.g., EVUs in Germany).

# 09005136 26.03.2009 BA_D_DE38_D410

Ins tru ctio n M anu al

D E 3 8

D ig ita l D iffe re ntia l P re ss ure Tra nsm itte r / S witch

DE38D410

Inhalt

1 Safety Instructions .......................................1

2 Intended Applications...................................2

3 Product Description and Functions..............2

4 Installation....................................................2

5 Commissioning ............................................3

6 Maintenance ................................................8

7 Transport......................................................8

8 Service.........................................................8

9 Accessories..................................................8

10 Disposal.......................................................8

11 Specifications...............................................9

12 Dimensions ................................................11

13 CE-Certificate.............................................12

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 2

1.5 Modifications Forbidden

Modification or other technical alteration of the product

is not permissible. This also applies to the use of unauthorized spare parts for repair / maintenance of the

product. Any modifications to this product, if and as necessary, should be done only by Fischer Mess- und Regeltechnik GmbH.

1.6 Operational Restrictions

The operational reliability of the product is guaranteed

only when used for intended purposes. The product

must be selected and configured for use specifically

with defined process media. The limiting values of operating parameters, as given in the product specification

sheet, must never be crossed.

1.7 Safety Considerations during Installation and Maintenance

The safety instructions given in this manual, existing national regulations relating to accident prevention, and

the internal safety rules and procedures of the user organization regarding safety during installation, operation

and servicing must all be followed meticulously.

It is the responsibility of the users to ensure that only

suitably qualified and experienced technical personnel

are used for installation, operation and servicing of this

equipment.

2 Intended Applications

The product includes the functions of sensing, signal

conversion, display, signal transmission, and limit detection of pressure / differential pressure of gases and

liquids. The product must be used only for applications

and under conditions specified by the manufacturer. In

case of uncertainties, the user should consult the manufacturer before installing and using the product.

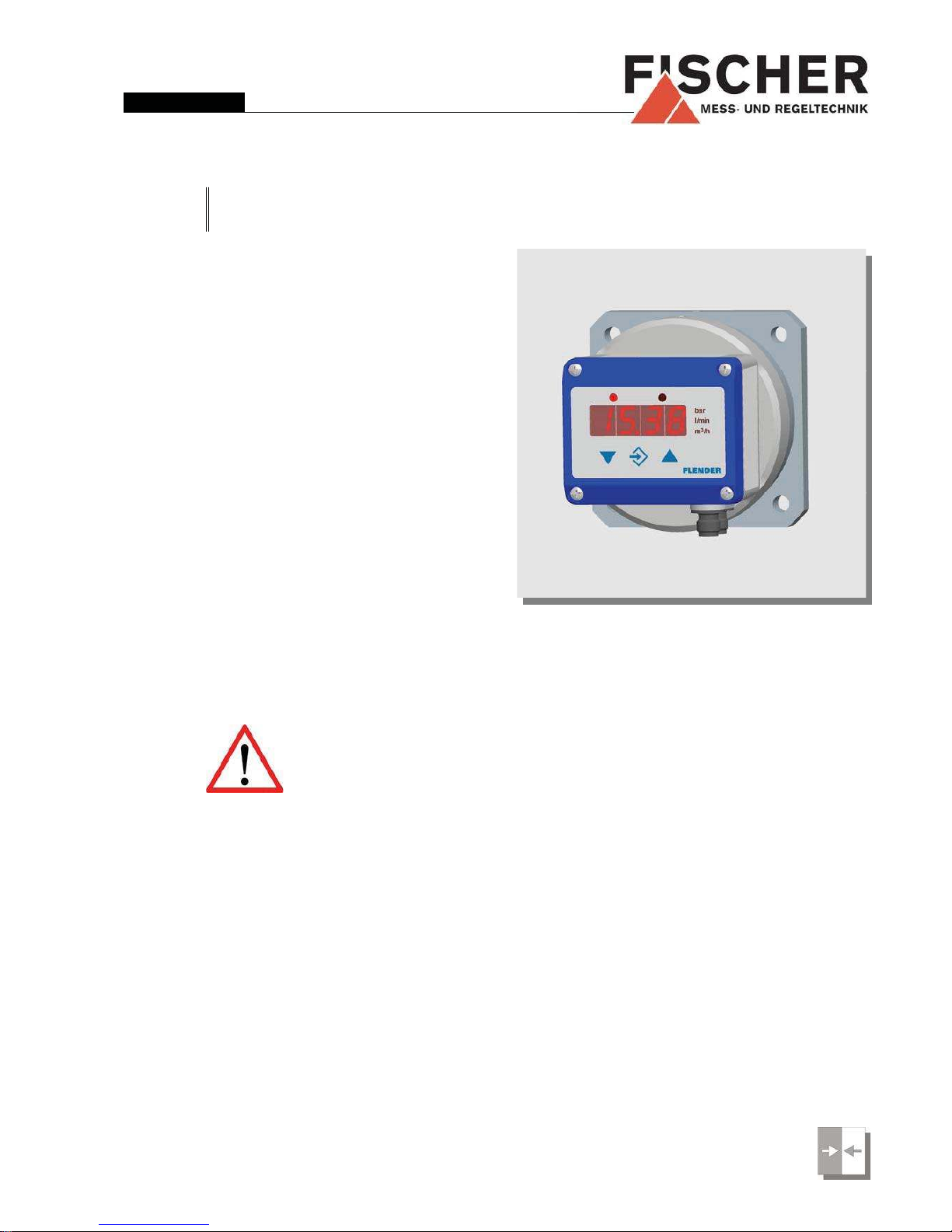

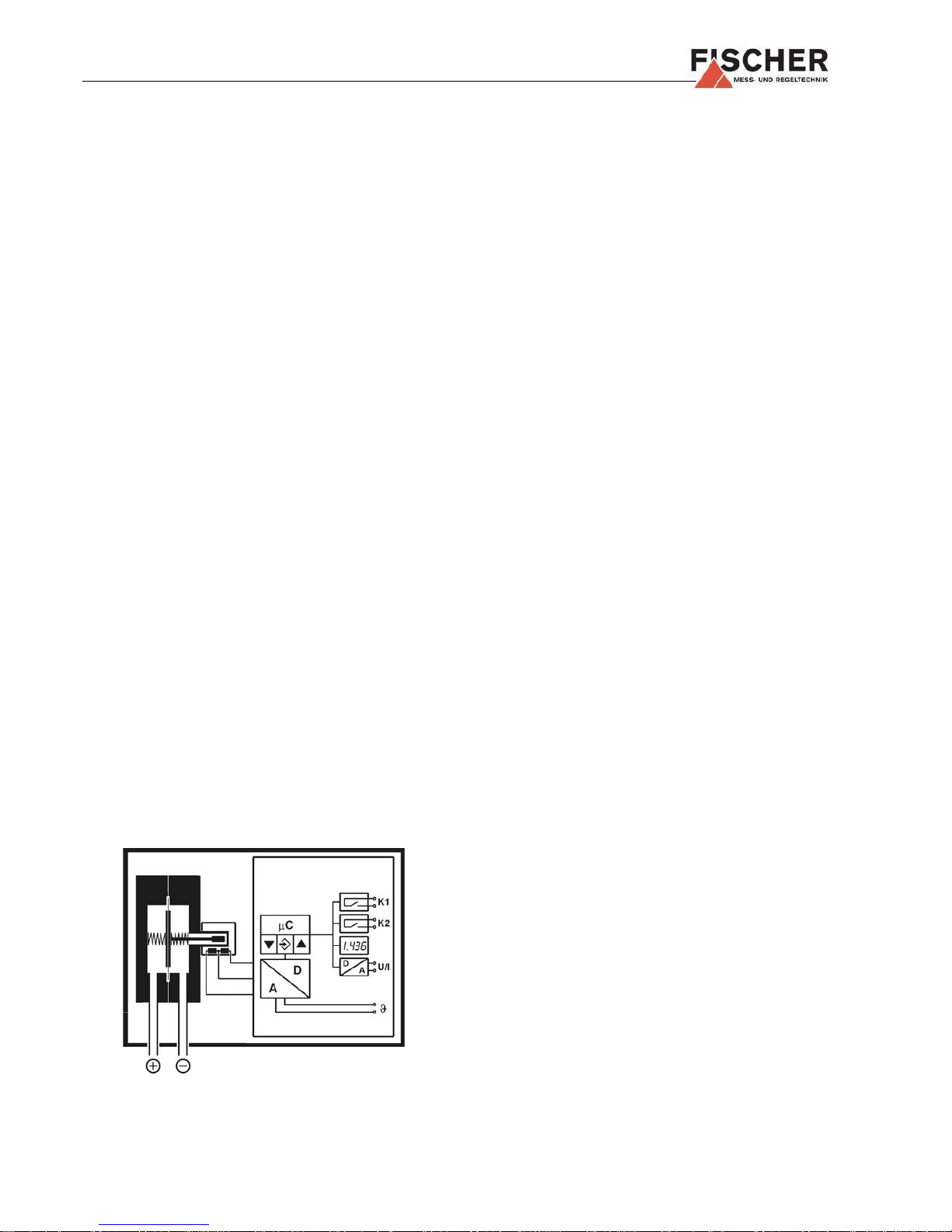

3 Product Description and Functions

3.1 Block Schematic Diagram

3.2 Principles of Operation

The instrument uses a tough, robust sensing diaphragm, which is qualified for over-, low- and differential pressure measurings. The comparative pressures

work on a elastic bedded measuring diaphragm. The diaphragm is at zero position when pressures on either

side of the diaphragm are equal.Inequality of pressures

results in deflecting the diaphragm towards the lower

pressure side until a new equilibrium determined by the

spring power is reached. This deflection is transmitted

by a tappet to the center of a inductive travel sensor.

The integrated electronics analyzes the deflection and

converts it into display, switch contacts and output signal.

4 Installation

The instrument is intended for the assembly on the

base of the Flender circulatory- measurement.

At the installation of the upper part there should be paid

attention to the correct adjustment. The operator must

be able to regulate and read the instrument from a safe

place.

The sealing faces and the O- ring seals must not be damaged!

The instrument is adjustet for a vertical mounting position. Other positions aren't sensibel because of the clearness of reading the digital display.

If the instrument is intended for outdoor application, we

highly recommend using an ade-quate protective housing (or at least a big enough shelter) as permanent

protection against UV-radiation on the membrane keyboard and against exposure of the instrument to rain or

snow.

4.1 Process Connections

Ensure that process equipment and pressure lines

are at atmospheric pressure before making pressure

connections.

The instrument should be provided with suitable pro-

tection against pressure surges (e.g., snubber or

pulsation damper).

Ensure that the mechanical configuration and mate-

rials of construction of the instrument are compatible

with the process media.

Take account of the maximum pressure.

Carefully check the pressure-tightness of all pressu-

re connections before start-up.

4.2 Electrical Connections

Only qualified technicians authorized for this type of

work should undertake installation.

Electrical connections must comply with relevant in-

ternational, national and local regulations and norms

relating to electrical and instrumentation installations.

2

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 3

Switch off electrical power to the plant before at-

tempting electrical installation work of any kind.

Make electrical connections to the transmitter

through a suitable energy-limiting safety device (isolation or zener barrier).

5 Commissioning

Power supply and signal cabling to the transmitter

must be correctly selected to meet operational requirements, and installed in a way that does not cause

physical stress to the instrument.

Pressure lines must have a downward gradient

throughout from the pressure instrument to the process vessel / pipe. This is to prevent formation of air

/ gas pockets (for liquid applications) and liquid plugs

(for air / gas applications). If this continuous downward gradient cannot be provided for any reason,

then suitable water and / or air separation devices

must be inserted into the pressure lines.

Pressure lines must be kept as short as possible and

must not have short bends to avoid measurement

errors induced by pressure line delays.

5.1 Pressure Connections

If the pressure transmitter is subjected to pressure

when it is started up, zero point checking and adjustment is not possible. In such cases, only electrical connections of the instrument should be made, but not the

pressure connections.

5.2 Display

The 3½ digit LED display normally indicates the current

differential pressure. The backlit symbols to the right of

the 3½ digit LED display indicate the unit of pressure

measurement. (Note: the units shown in the illustrations

of this document can be different from those of the actual instrument). The two LED lamps above the 3½ digit

LED display respectively indicate the status of the two

limit relays / solid-state switches

(LED on = relay

contacts closed / solid-state switch on).

While the instrument is in set-up mode, the 3½ digit

LED display either indicates the selected menu option

or a set-up parameter value. The instrument continues

its pressure monitoring functions even while it is in setup mode, except under either of two circumstances.

One is when the limit switching delay time is changed:

the existing delay must time out first. The other is when

the look-up table (for conversion of measured values) is

re-programmed (s. 5.3.7.). In these circumstances, the

output signal value and the limit relay/switch states are

frozen until the changes are finalized.

5.3 Set-up

The instrument has comprehensive set-up options by

means of which it can be optimized for any specific

measuring or control application. This section of the

document provides information and instructions about

each of the set-up parameters.

Depending on the instrument configuration ordered (e.g.: without transmitter signal

output / with voltage signal output / with

current signal output) some of the menu

options may not available. Some set-up

parameters may be consequentially excluded. For

example, if the instrument is ordered without a transmitter output, all signal conversion programming options

are omitted in the set-up menu (s. 5.3.6. Signal Conversion and Transfer Functions).

All instrument settings can be conveniently done from a

PC connected to the instrument through a serial interface adaptor. All set-up parameters can be viewed and

changed on the PC screen. Also, the entire instrument

set-up configuration can be loaded, stored on the PC's

hard disk drive, and printed out for plant / process documentation purposes. Further information about this PC

software is given in the software documentation.

5.3.1 Selecting the Unit of Pressure Measurement

Make the necessary electrical connections (signal, power supply) to the instrument. Its pressure sensor must

be pressure-free (i.e. vented to atmosphere; typically by

disconnecting the pressure line/s).

The current valid unit of measurement is indicated by

one of the back-lighted symbols to the right of the digital

display. To change the unit of measurement, first press

then search for parameter EEEEIIIINNNN using . Next press

again and select another unit of measurement using

or . Then presse again to store the selection, and

EEEEIIIINNNN will appear again in the digital display.

To exit the set-up mode, press

until EEEESSSScccc appears, and

then press

. The current pressure measured value is

indicated again, and the appropriate symbol of the unit

of measurement (to the right of the digital display) is

lighted.

The digital display is limited to a count of

±1999. Therefore, all the available units of

measurement may not be suitable for se-

lection for a given application.

3

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 4

5.3.2 Zero Point Checking and Adjustment

If the instrument has been de-pressurized (vented to atmosphere) and does not indicate precisely zero, note

this non-zero value. Using the set-up parameter OOOOFFFF1111,

you can trim this offset to exactly zero. If the indicated

non-zero value is positive, this value must be entered

and stored as a negative offset value, and vice versa.

If the instrument was in use before zero

setting is done, values of set-up parameters OOOOFFFF1111 and nnnnPPPP would have been previously programmed. In this case, set

both values to zero, read the actual zero

offset, and then use this value for OOOOFFFF1111 for zero point correction, as described in the previous paragraph.

Note: The registered value is a pure number: no decimal point is indicated.

After correcting the zero offset, the pressure connections can be made again.

5.3.3 Damping and Zero Stabilization

If the media is subject to excessive pressure fluctuations, the displayed readings and the transmitter output

signal can be stabilized using the instrument's DDDDAAAAMMMM and

NNNNPPPP set-up parameters.

The set-up parameter DDDDAAAAMMMM has the effect of a pulsation

damper (on the displayed measurements, output signal

and limit detection, - not on the sensor itself!). It adds a

time-constant (averaging filter) in the user selectable

range of 0.0 to 100.0 secs. When the damping is set to

maximum, it took more than 2 minutes to reach the final

value for a full scale pressure jump.

In many cases fluctuating pressure readings do not

cause a problem, except when the plant / equipment is

at zero (differential) pressure condition and readings

fluctuate near about zero value. The set-up parameter

NNNNPPPP is meant to take of this. Its value defines the number

range across zero (similar to the zero offset correction

number), within which the measured value is forced to

zero. If a value of 8 is set for NNNNPPPP any pressure measurement in the range -0.08 to +0.08 bar (or -8 to +8 kPa)

displayed as zero. Only when the actual pressure is

outside this range will the display indicate a non-zero

value. The actual and displayed pressures will agree

starting from double the value of the NNNNPPPP setting (in the

given example: 0.16 bar or 16 kPa).

5.3.4 Output Signal Setting

The transmitter output signal depends primarily on the

measured pressure. However, this signal can be adapted to meet users' application requirements precisely.

The basic pressure range (as marked on the product

identification label) and the type of output signal (voltage or current) always remain unchanged for a particular

instrument unit.

The set-up parameters MMMMAAAA (measuring range starting

point) and MMMMEEEE (measuring range end point) specify the

pressure values between which the measurements are

expected to be. Both values can selected anywhere

within the specified measuring range of the instrument

(e.g., 400 kPa). This user-programmed pressure range

will correspond to the output signal (current or voltage)

range, which will be as specified on the product identification plate: i.e., 0 ... 10V or 4 ... 20 mA.

If MMMMAAAA is lower than MMMMEEEE, the signal is said to have a positive slope: i.e., the output signal increases as the pressu-

re increases. If MMMMEEEE is lower than MMMMAAAA, the output signal

has a negative slope: i.e., the output signal decreases

as the pressure increases.

The difference between the values of MMMMAAAA and MMMMEEEE must be

at least 25% of the specified measuring range of the instrument (100 kPa for 400 kPa instrument example

mentioned above). The software does not permit a

smaller pressure span to be entered (the instrument will

not allow storing of, nor exit from an invalid span).

Note: If you change MMMMAAAA and/or MMMMEEEE the lookup table (s .5.3.6., 5.3.7.) that existed up

to that instant is deleted!

5.3.5 Output Signal Limiting (Namur)

The three set-up parameters ooooGGGG1111, ooooGGGG2222 and ooooEEEErrrr specify

the limits of the signal output current or voltage that are

not to be exceeded, irrespective of the actual pressure.

These limit values have higher priority than the MMMMAAAA and

MMMMEEEE pressure span settings.

These settings serve mainly to prevent control systems

from interpreting brief pressure excursions outside the

measuring range as error / fault events. ooooGGGG1111 sets the

output signal minimum value, and is useful only for a

4 ... 20 mA current signal, because sometimes a value

below 3.8 mA is defined as a sensor fault condition. ooooGGGG22

22

sets the upper signal limit and is valid for either current

or voltage signal (e.g., voltage signal output can be limited at 10.2 V).

An instrument fault condition can be transmitted as an

output signal value set as parameter ooooEEEErrrr. However, it

should be understood that not all instrument fault and

error conditions can be detected and signaled by the

self-diagnostic functions of the instrument.

5.3.6 Signal Conversion and Transfer Functions

In certain cases other process variables are derived

from primary pressure measurement. Examples are

flow rate derived from differential pressure across an

orifice plate, and liquid level derived from hydrostatic

pressure of liquid measured at the bottom of the tank.

Such derivations often involve non-linear transfer functions, while it is necessary for the output signal to be linearly proportional to the derived variable (e.g. liquid volume in a tank in m³, or flow rate in cm/sec).

The set-up parameter FFFF allows the user to select the appropriate signal conversion function from those

4

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 5

available:

FF

FF

= 0: Linear characteristic (default)

FFFF

= 1: Square root extraction

FF

FF

= 2: Horizontal cylindrical tank

FF

FF

= 3...30: Look-up table with 3 to 30 pairs of values

The tables generated by functions FFFF = 0, FFFF = 1 and

FF

FF

= 2 are not visible. For these functions, internal values are used for table computation. These values cannot be modified directly in the table by the user.

For all conversion functions, when the actual pressure

is equal to the MMMMAAAA value, the output signal will be at the

lowest end of its range (0 V, 0 mA or 4 mA). When the

actual pressure is equal to the MMMMEEEE value, the output signal will be at the highest end of its range (10 V or 20

mA). The user can enter only the 1...28 intermediate va-

lues of the look-up table function FFFF = 3....30. The para-

meters MMMMAAAA and MMMMEEEE relate to the start and end values of

the look-up table. A change in either of these parameter

values causes the conversion function to be re-set to

FF

FF

= 0.

Whenever the value of FFFF is changed, the

instrument internally generates a new

look-up table. All previous table values

are deleted and replaced by new linear progression values.

5.3.7 Look-up Table Programming (F = 3..30)

If the value of set-up parameter FFFF is selected equal to or

greater than 3, a sub-menu LLLLIIIInnnn is invoked. Through this

sub-menu all the required look-up table values can be

entered, except the first and last pairs of table values

(respectively corresponding to MMMMAAAA and MMMMEEEE). This submenu has its own entry and exit points, the latter being

the last of the value pairs to be entered. The table is

stored only when the user exits to the sub-menu prompt

LLLLIIIInnnn, by pressing

. If the table is not correctly entered,

the display will indicate EE

EE

rr

rr

rrrr, indicating an error condition. If this happens, it is not possible to exit this submenu mode until the error is corrected.

The table entries consist of 1 to 28 pairs of values. Values IIII00002222 through IIII22229999 (or uuuu00002222 through uuuu22229999) specify the

amplitude of the out the signal output, and the values

PPPP00002222 through PPPP22229999 are the corresponding pressure values.

Entering or changing table values through the instrument's membrane keyboard is a tedious and error-prone method. It should only be used as a stopgap method

when a PC and/or the PC interface module is not

available.

The table is accepted as correct if each output value is

larger than its preceding value. Pressure values can be

steadily increasing or steadily decreasing. However, a

transition from falling to rising pressure values is not

permitted; nor are pressure values allowed to turn back

along the same curve.

5.3.8 Limit Setting

The two limit switching outputs

(relay contacts or

solid-state switches) are each configured by four set-up

parameters:

Switching output 1 is configured by parameters RRRR1111AAAA,

RRRR1111EEEE, RRRR1111DDDD and RRRR1111FFFF .

Switching output 2 is configured by parameters RRRR2222AAAA,

RRRR2222EEEE, RRRR2222DDDD and RRRR2222FFFF.

The turn-on and turn-off points of switching output 1 are

defined respectively by parameters RRRR1111AAAA and RRRR1111EEEE. The va-

lues for these are set in the currently valid unit of measurement (indicated by the lighted symbol to the right of

the digital display).

The two parameters RRRR1111AAAA and RRRR1111EEEE together determine the

logic of switching output 1:

If RRRR1111AAAA is smaller than RRRR1111EEEE, the output turns on when the

measured value exceeds RRRR1111EEEE. It turns off again only

when the measured value falls below RRRR1111AAAA (hysteresis

function).

If RRRR1111AAAA and RRRR1111EEEE have the same value, there is no hysteresis: the switching output turns on when the measured

value exceeds RRRR1111AAAA / RRRR1111EEEE, and turns off again when the

measured value falls below RRRR1111AAAA / RRRR1111EEEE.

If RRRR1111AAAA is larger than RRRR1111EEEE, the switching output turns on

when the measured value falls between RRRR1111AAAA and RRRR1111EEEE:

i.e., when RRRR1111EEEE < measured value < RRRR1111AAAA (window limit

function).

Both parameters can be independently adjusted over

the full measuring range.

If the unit of measurement is changed, the switching

points are changed accordingly. In this event, rounding

error can cause a deviation in the least significant (rightmost) digit.

The value of the set-up parameter RRRR1111DDDD determines the

delay time for switching output 1, after the measured

value reaches the switching point. The delay value can

be selected in the range 0.0 to 100.0 secs. This value

applies equally to turn on and turn off.

The set-up parameter RRRR1111FFFF determines the action of the

switching output. If RRRR1111FFFF = 1, the switching output acts as

normally open (NO) contacts. If RRRR1111FFFF = 2, it acts as nor-

mally closed (NC) contacts.

5.3.9 Password

The last set-up parameter allows a password to be entered. A password value of 001 to 999 can be selected.

A value of 000 disables the password function.

If a password was set previously the digital display indicates PPPPAAAASSSS after EEEESSSScccc is displayed and

is pressed. The

password is then entered, by pressing and then , .

Only then will the set-up menu options be accessible. If

an incorrect password is entered, the display jumps

5

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 6

back to beginning of the menu (i.e., EEEESSSScccc).

New Functions! (as of April 2008)

5.3.10 DD

DD0000

– Display options

This parameter allows smoothing the displayed values

in cases where they are frequently deviating. The filter

function is similar to the dd

ddAAAAMMMM

function, but acts only

upon the display, having no impact on the output signal.

Additionally the display can be turned off partially

(DD

DD0000

= -1, only the setpoint LEDs are driven) or comple-

tely (DD

DD0000

= -2).

5.3.11 rr

rreeeessss

– Reset to default values

This function will reset all parameters to default when

activated. Default values can be defined only by using

the PC interface.

5.3.12 MM

MMAAAAFFFF,,,, MMMMEEEEFFFF,,,, ddddPPPPFFFF

– Free Unit

If the device is configured to have a free third unit

(symbol:

) then the display can be scaled as desired

by using these three parameters.

The measuring range as defined by parameters MMMMAAAA and

MMMMEEEE is rescaled to MMMMAAAAFFFF and MMMMEEEEFFFF. If the table function (FFFF ) is

enabled, table values will be taken into account too.

The ddddPPPPFFFF value controls the position of the decimal point.

5.4 Overview of Set-up Parameters

When the instrument is turned on, it briefly displays the

software version number, and then switches automatically to normal operating mode. Pressing

causes the

set-up menu to be called up, indicated by EEEESSSScccc on the digital display. After that, by pressing repeatedly, each

of the set-up parameters is called up in sequence:

Note: Depending on the version of the instrument that was ordered, some of the individual

parameters might not be available.

PPPPAAAASS

SS

Password input (appears only if password

function has been enabled). Values: 001 to

999

DDDDAAAAMM

MM

Damping (time constant). Range of values

= 0.0 to 100.0 secs

DDDD00

00

Damping (display only), range of values

0..100. Additional: -1 = no digital value and

-2 = display turned off completely.

RRRR1111AA

AA

Switching output 1: turn-off point.

RRRR1111EE

EE

Switching output 1: turn-on point.

RRRR1111DD

DD

Switching output 1: delay. Range of values

= 0.0 to 100.0 sec. This values applies equally

for turn-on and turn-off delays.

RRRR1111FF

FF

Switching output 1 action. If RR

RR1111FFFF

= 1, acts as

NO contacts. If RR

RR1111FFFF

= 2, acts as NC contacts.

RRRR2222AA

AA

Switching output 2: turn-off point.

RRRR2222EE

EE

Switching output 2: turn-on point.

RRRR2222DD

DD

Switching output 2: delay. Range of values

= 0.0 to 100.0 sec. This values applies equally

for turn-on and turn-off delays.

RRRR2222FF

FF

Switching output 2 action. If RR

RR1111FFFF

= 1, acts as

NO contacts. If RR

RR1111FFFF

= 2, acts as NC contacts.

EEEEiiiiNN

NN

Unit of measurement. The selection is indicated by the lighted symbol to the right of the digital display. A particular unit can be selected

only if it can be meaningfully represented

within the basic measuring range of the instrument.

MMMMAA

AA

Measuring range start point. The value of the

measured variable corresponding with the minimum value of the output signal (0 V, 0 mA or

4 mA, depending on the instrument version).

MMMMEE

EE

Measuring range end point. The value of the

measured variable corresponding with the

maximum value of the output signal (10 V or

20 mA, depending on the instrument version).

DDDDPPPPFF

FF

Position of decimal place for free unit.

MMMMAAAAFF

FF

Measuring range start point (displayed value)

for free unit.

MMMMEEEEFF

FF

Measuring range end point (displayed value)

for free unit.

NNNNPP

PP

Zero stabilization. Range = 0 to 100 counts.

The value spans symmetrically around the actual zero point.

OOOOFFFF11

11

Zero offset correction, input 1. Range = -100

to +100 counts.

FF

FF

Signal conversion function. (0 = linear, 1 =

square root, 2 = horizontal cylindrical tank,

3..30 = look-up table)

llllIIIInn

nn

Look-up table entry (sub-menu)

ooooGGGG11

11

Output signal limiting, minimum

OOOOGGGG22

22

Output signal limiting, maximum

OOOOEEEErr

rr

Fault signaling (output signal value on detection of instrument fault).

RRRREEEESS

SS

Reset all values to default. (Default values

can be defined only by using the PC inter-

face.)

----PPPP--

--

Password setting. Permissible password values = 001 to 999. "000" disables password

protection.

6

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 7

If the password is lost, the instrument can be

unlocked only through a serial interfaced PC,

or the instrument has to be sent to the manufacturer for this purpose

If ooooGGGG1111 and OOOOGGGG2222 are both set to "0", the output signal will not be subjected to limiting.

If ooooGGGG1111 is set at the maximum value (11 V

or 21 mA), the output signal can be ad-

justed using OOOOGGGG2222 to any arbitrary value

between zero and maximum value, irrespective of pressure measurement. This feature enables the instrument to be used as a simulated signal

source to test signal lines and other instruments or systems.

5.5 Electrical Connections, Switching Outputs

Switching outputs:

Switching output 1 is configured by parameters RRRR1111AAAA, RRRR1111EEEE,

RRRR1111DDDD, and RRRR1111FFFF.

Switching output 2 is configured by parameters RRRR2222AAAA,

RRRR2222EEEE, RRRR2222DDDD, and RRRR2222FFFF.

Power supply voltage and output signal load:

Nominal supply voltage and the operating supply voltage range are indicated under 11. Specifications.

The maximum output signal loads are indicated under

11. Specifications.

The signal ground line is internally connected to the in-

strument ground, and serves only as an alternative

ground connection for the output signal. This usually increases the noise margin.

5.6 Default parameter (Model C)

Does not apply to replacement instruments of model

B, see thererfore chapter 5.7.

5.7 Default parameter

(instruments as a replacement for model B)

7

Parameter Einstellwert Einhe

BASE MEASURING RANGE

OFFSET-ADJUSTMENT

0

0

1 bar

DAMPING

ZERO WINDOW

DISPLAY OPTION

DISPLAY OF DAMPING

5

100

Display of damping [do>0]

2

s

s

DENOTATION

UNIT

RELAY TRIPPING POINT 1

RELAY SWITCHING POINT 1

DE3802DYYPKD410

l/min

acc. to equipment list

acc. to equipment list

RELAY DECELERATION 1

RELAY FUNCTION 1

RELAY TRIPPING POINT 2

RELAY SWITCHING POINT 2

10

Shutter

acc. to equipment list

acc. to equipment list

s

RELAY DECELERATION 2

RELAY FUNCTION 2

MEASURING RANGE 4 mA at

MEASURING RANGE 20 mA at

10

Shutter

0

acc. to adjustment of oil

density

LINEARISATION

RATE OF FLOW at start

RATE OF FLOW at last

DECIMAL PLACES

0

acc. to equipment list

s

bar

bar

LIMITATION Imin

LIMITATION Imax

LIMITATION Ierror

1

21

21

mA

mA

mA

Parameter Einstellwert Einheit

BASE MEASURING RANGE

OFFSET-ADJUSTMENT

0

0

1 bar

DAMPING

ZERO WINDOW

DISPLAY OPTION

DISPLAY OF DAMPING

5

100

Display of damping [do>0]

2

s

s

DENOTATION

UNIT

RELAY TRIPPING POINT 1

RELAY SWITCHING POINT 1

DE3802DYYPKD410

bar

0

0

RELAY DECELERATION 1

RELAY FUNCTION 1

RELAY TRIPPING POINT 2

RELAY SWITCHING POINT 2

10

Shutter

0

0

s

RELAY DECELERATION 2

RELAY FUNCTION 2

MEASURING RANGE 4 mA at

MEASURING RANGE 20 mA at

10

Shutter

0

1

LINEARISATION

RATE OF FLOW at start

RATE OF FLOW at last

DECIMAL PLACES

0 (straight line)

0

1000

0.000

s

bar

bar

LIMITATION Imin

LIMITATION Imax

LIMITATION Ierror

1

21

21

mA

mA

mA

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 8

6 Maintenance

The instrument is inherently maintenance-free.

However, to ensure reliable operation and maximize the

operating life of the instrument, it is recommended that

the instrument, its external electrical and process connections, and external connected devices be regularly

inspected, e.g.:

Check the display.

Check the switching function in connection with ex-

ternal devices.

Check all pressure connections for leak-tightness.

Check the integrity of all electrical connections of the

instruments.

Inspection and test schedules depend on operating and

site conditions. The operating manuals of other equipment to which the transmitter is connected must be

read thoroughly to ensure that all of them work correctly

when connected together.

7 Transport

The product must be protected against shock and vibration during transport. It must therefore be properly paked, preferably in the original factory packaging whenever it is to be transported.

8 Service

Any defective devices or devices with missing parts

should be retourned to Fischer Mess- und Regeltechnik

GmbH. For quick service contact our service department.

Remaining medium in and on dismantled measuring instruments may cause danger to persons, environment

and equipment. Take reasonable precautions! Clean the

instrument thoroughly if necessary.

9 Assessories

M12 connectors with pre-wired cable lengths

(on request)

PC serial interface adaptor with software:

model EU03.F300

10 Disposal

P rote ct yo u r e n v i ro nm en t! Use the product

in accordance with relevant regulations.

Please be aware of environmental consequences of disposal at the end of the product's life, and take care accordingly.

8

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 9

9

Measuring

range

bar 0-1,000

max. static

operating

pressure

straight line

error (max.)°

bar

%FS

25 bar

2,50%

Straight line

error (typ.)°

Tc span

(max.)°°

Tc span

(typ.)°°

Tc zero point

(max.)°°

%FS

%FS /

10K

0,80%

0,40%

%FS /

10K

%FS /

10K

0,20%

0,50%

°: Straight line error = nonlinearity + hysteresis; at 25°C; pressure within specified range

(characteristic linear, not spreaded)

°°: Pressure within specified range (characteristic linear, not spreaded); compensated temperature range 0 to 60°C

Tc zero point

(typ.)°°

%FS /

10K

0,20%

Operating temp. (ambient) -10 70°C

Operating temp. (media)

Storage temperature

-10 70°C

-20 70°C

Protection class (housing)

Nominal supply voltage

IP 65 acc. to DIN EN 60529

E lectrica l

24 V DC/AC

Operating supply voltage

Output signal

Output signal load

Power consumption

12 32 V DC/AC

4 20 mA square root

For output current RL

(UB - 4 V) / 0,02 A (UB 26V), else RL 1100

Approx. 2 W/VA

Switching contacts

Display

2 sets of programmable voltage free relay contacts: NO or NC

Umax = 32 V DC/AC, Imax = 2 A, Pmax = 64 W/VA

3½ digit. LED

Electrical connections

C o n n e ctio n s

Two round-shell multi-pin connector sockets (M12, male)

Connector 1: 5-pin: power input and analog signal output

Connector 2: 4-pin: relay contacts / solid-state switch outputs

Pressure connections

Materials, housing

at the upper part of the volume flow-measurement

M ate ria ls, M ountin g

Polyamid PA 6.6

Materials, media contact

Mounting

Aluminum hartcoat, VITON®

Rear mounting holes for panel mounting

11 Specifications

11.1 General

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 10

10

11.2 User- specific Data

Differential pressure transmitter DE38D410

Measurement range 0 1 bar

Static operating pressure 25 bar

Diaphragm and sealing of Viton

Pressure chamber Alu/hartcoat

output signal 4-20 mA square rooted, three-wire-system

Operating voltage 24 V DC/AC

3 ½-digit LED display

Display unit: bar, l/min., m³/h

2 voltage free relay contacts

Electrical connection M12-Stecker

Protection class IP65 nach DIN EN 60529

Mounting form as flow control device- top

Flender-works standard W3 5927

Housing cover blue RAL 5005

User-specific membrane keyboard with Flender-Logo

S e ttings:

Input filtering

Relay / switch 1 / 2

0.0 ... 100.0 secs (10 / 90% step response time) for signal output,

display seperated

activation point, de-activation point, response time delay (0.0 ...

100.0 secs), logic (N/O or N/C)

Measurement unit selection

Zero suppression

Setting of oil-density

Zero pressure calibration

bar, l/min, m³/h

0 ... 100 Digits (1)

±100 counts (3)

Output characteristic

Password range

linear, square rooted, horizontal cylindr. tank, table (3...30 entries)

001 ... 999 (000 = password protection disabled)

0,88

0,830

0,890,839

0,900,848

0,910,858

0,920,867

0,930,877

0,940,886

0,950,896

0,960,905

0,970,914

0,980,924

0,990,933

1,000,943

1,010,952

1,020,962

1,030,971

1,040,980

1,050,990

Oil density

differential pressure [bar]

"measuring range

20mA bei 0, xxx bar"

11.3 Programming

Via membrane key switches or by using PC-programming interface (accessory), programming mode can be pas-

word protected.

Notes:

(1): Measured value deviations up to 100 counts symmetric about zero are set to zero. Used for zero drift suppression.

(2): Maximum effective turn-down ratio = 4:1. Only the output signal is affected.

Transfer function is inverted if start value > end value.

(3): Zero calibration setting may change with mounting orientation.

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 11

11

12 Dimensions (all units in mm unless stated otherwise)

Anschlussschema /

Schaltfunktion

view of rear side

rear side

M 12 connector

No. 1

M 12 connector

No. 2

Electrical Connections /

Switching Outputs

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Page 12

12

13 CE- Certificate

Contact: EK Engineering (www.ekeindia.com)

Email: india.eke@gmail.com

Mob: +91-9680966000

Loading...

Loading...