Page 1

By:

Master Install Guide

CM3 Series - CM4200 – CM1000A

FOR DISTRIBUTION TO AUTHORIZED

COMPUSTAR DEALERS ONLY

- 1 -

04/27/06

Page 2

- 2 -

Page 3

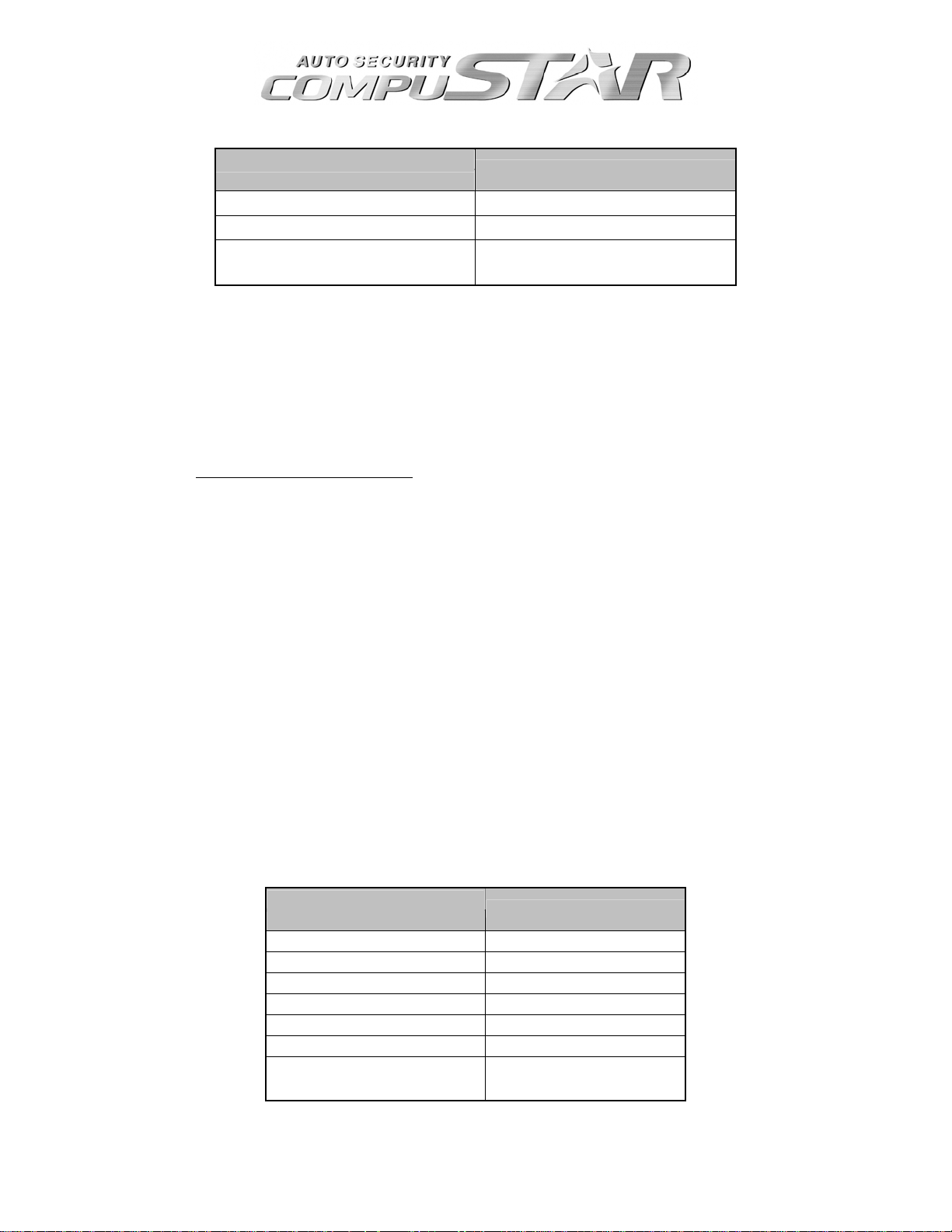

TABLE OF CONTENTS

Install Checklist ..................................................................................Page 4

Remote Programming Procedure

1WAM4R, 1WFM4R, 1W900FM4R, 1WSSR......................Page 7

1WSS4R w/ 2WSSR...............................................................Page 7

1WFM6R ................................................................................Page 8

2WFMR-S, 2WAMR, 2WFMR, 2W900FMR .......................Page 8

2WSSR....................................................................................Page 8

Common Procedures

Antenna Mounting................................................................Page 13

Dip Switch and Jumper Settings...........................................Page 13

The Little Green Loop ..........................................................Page 14

Adjusting Siren Volume .......................................................Page 14

Adjusting Shock Sensor Sensitivity......................................Page 14

Programming Tach/Alternator Sensing ................................Page 14

Diagnosing Remote-Start Problems......................................Page 15

Control Modules

CM3000 ................................................................................Page 19

CM3300 ................................................................................Page 27

CM4200 ................................................................................Page 33

CM1000A .............................................................................Page 39

Option Programming

Four Button Remotes w/ Same Lock/Unlock Button...........Page 45

Four Button Remotes w/ Separate Lock/Unlock Buttons.....Page 45

R500A...................................................................................Page 46

1WFM6R ..............................................................................Page 47

Two-Way Remotes ...............................................................Page 47

CM3-Series Option Programmer..........................................Page 48

Resetting Options to Factory Defaults..................................Page 48

Option Menus........................................................................Page 51

Options Explained In Detail..................................................Page 55

Installation Assistance

FAQ / Trouble Shooting .......................................................Page 63

Common Diagrams...............................................................Page 65

Accessory Manuals...........................................................................Page 75

- 3 -

Page 4

Install Checklist

Please use this checklist to complete the installation of any CompuStar system. These

steps should be done in the order shown.

Prep/Install Module:

Begin preparing the system for installation by removing any wires you are not going to

be using, leave some of the wire in case you need to use it in the future. Then wire up any

relays, etc., and install the control module in the vehicle.

Code Remote:

Code the remote using the remote coding procedure shown in this manual. The remotes

do not come preprogrammed as a result of the modular design of the CompuStar lineup.

Program Tach:

Program tach by tapping the tach learn button located on the back of the control module.

Set Options:

Using the Option Programming section of this manual, set the options of the control

module.

Test:

Test the system by testing and adjusting the shock sensor, testing the remote start process,

and verifying all of the alarm triggers.

- 4 -

Page 5

Remote Programming Procedures

- 5 -

Page 6

- 6 -

Page 7

Remote Programming Procedures

Because the CompuStar systems are modular in design (upgradeable), the remotes Do

Not come pre-programmed from the factory. Listed below are the procedures for

programming the CompuStar transmitters.

Programming for:

1WAM4R (all versions), 1WFM4R (all versions), 1W900FM4R (all versions),

and for programming the 1WSS4R as a standalone remote:

1. Insert the key into the ignition and turn the ignition ON then OFF five times.

2. The fifth time you turn the ignition on, the parking lights will flash once.

3. Tap the Top Left button on the transmitter once. The parking lights will again

flash once to confirm that the remote was coded.

4. After a few seconds, the parking lights will flash twice to signal the ending of

the remote programming mode.

If you have multiple remotes, you can program them all at once by coding the first

remote, then right after getting the confirmation flash, coding the second remote

(you will get another confirmation flash), and then coding the third remote.

Programming for:

1WSS4R, when using it in conjunction with the 2WSSR.

If you plan to use the 2WSSR and the 1WSS4R together, you must program them

at the same time.

1. Pull the positive side of the battery out of the 2WSSR, do not remove the whole

battery as you will need to quickly insert it again.

2. Insert the key into the ignition and turn the ignition ON then OFF five times.

3. The fifth time you turn the ignition on, the parking lights will flash once.

4. Quickly push the positive side of the battery back into the 2WSSR. The parking

lights will flash once to confirm that the remote was coded.

5. Immediately after, tap the Top Left button on the 1WSS4R once. The parking

lights will again flash once to confirm that the remote was coded.

6. After a few seconds, the parking lights will flash twice to signal the ending of

the remote programming mode. Do not press any buttons on either remote, the

2WSSR will still be in the process of synchronizing. As soon as the 2WSSR

chirps once or twice, you are finished and can use the remotes. This should

only take a few seconds.

- 7 -

Page 8

Programming for:

1WFM6R

1. Insert the key into the ignition and turn the ignition ON then OFF five times.

2. The fifth time you turn the ignition on, the parking lights will flash once.

3. Tap the Lock button on the transmitter once. The parking lights will again flash

once to confirm that the remote was coded.

4. After a few seconds, the parking lights will flash twice to signal the ending of

the remote programming mode.

If you have multiple remotes, you can program them all at once by coding the first

remote, then right after getting the confirmation flash, coding the second remote

(you will get another confirmation flash), and then coding the third remote.

Programming for:

2WFMR-S, 2WAMR, 2WFMR, and 2W900FMR

1. Insert the key into the ignition and turn the ignition ON then OFF five times.

2. The fifth time you turn the ignition on, the parking lights will flash once.

3. Tap the ( I ) button on the transmitter once. The parking lights will again flash

once to confirm that the remote was coded.

4. After a few seconds, the parking lights will flash twice to signal the ending of

the remote programming mode.

If you have multiple remotes, you can program them all at once by coding the first

remote, then right after getting the confirmation flash, coding the second remote

(you will get another confirmation flash), and then coding the third remote.

Programming for:

2WSSR

1. Pull the positive side of the battery out of the 2WSSR, do not remove the whole

battery as you will need to quickly insert it again.

2. Insert the key into the ignition and turn the ignition ON then OFF five times.

3. The fifth time you turn the ignition on, the parking lights will flash once.

4. Quickly push the positive side of the battery back into the 2WSSR. The parking

lights will flash once to confirm that the remote was coded.

5. After a few seconds, the parking lights will flash twice to signal the ending of

the remote programming mode. Do not press any buttons on the remote, the

2WSSR will still be in the process of synchronizing. As soon as the 2WSSR

chirps once or twice, you are finished and can use the remote. This should only

take a few seconds.

- 8 -

Page 9

You can only use 1 two-way remote at a time with each install. However, 1 oneway remote can be added to the system.

- 9 -

Page 10

- 10 -

Page 11

Common Procedures

- 11 -

Page 12

- 12 -

Page 13

Antenna Mounting

CompuStar antennas can, in general, be mounted with any orientation. Horizontal or

vertical, doesn’t really matter. Things to consider would be the routing of the antenna

cable, and mounting the antenna a few inches down from the roof and/or tint line. If the

antenna cable is pinched or crimped on its way to the antenna, the system may experience

problems such as; poor range, one-way communication on two-way models, or possibly

no response at all. Metal acts as a natural shield to radio frequency signals so mounting

the antenna close to the roof, or behind some kinds of tint that have metal content to

them, can cause poor performance.

Dipswitch and Jumper Settings

Dipswitch settings for:

CM3000, CM3200, CM3300, and CM4200

1. Dipswitch #1 will select the engine-sensing mode, tach or alternator. The ON

position is for tach sensing (Note: Factory default is tach sensing.) The OFF

position is for alternator sensing.

2. Dipswitch #2 will select the remote start run time. The OFF position will

provide a 15-minute run time for gas vehicles and a 25-minute run time for

diesel vehicles. The ON position will provide a 25-minute run time for gas

vehicles and a 45-minute run time for diesel vehicles.

Jumper settings for:

CM4200

1. Jumper #1- 2nd Ignition 12-volt (+) positive output to the blue wire on

connector 1.

2. Jumper #2- 2nd Accessory 12-volt (+) positive output to the blue wire on

connector 1.

3. Jumper #3- 2

connector 1.

nd

Starter 12-volt (+) positive output to the blue wire on

- 13 -

Page 14

The Little Green Loop

This wire is only present in international models. This jumper wire will determine the

transmission setting. If the jumper wire is not cut the control module will be set for

manual transmission mode. (Note: The factory default is manual transmission. If the

control module is installed in a manual transmission vehicle and the jumper is cut ALL

WARRANTY is void.) When the jumper wire is cut the control module will be set for

automatic transmission mode.

Adjusting Siren Volume

To increase the volume of the siren, cut the black loop of wire located on it. This will

increase the volume of the siren by 3 dB.

Adjusting Shock Sensor Sensitivity

To adjust the sensitivity of the shock sensor, turn the dial located on it. The higher the

number, the higher the sensitivity to impacts to the vehicle. Even a small adjustment to

the dial can make a big difference in the sensitivity. Most vehicles will use a sensitivity

setting below “4”.

Programming Tach / Alternator Sensing

Tach sensing:

When using tach mode on vehicle, the tach signal must be learned to the control

module before vehicle will remote start.

Tach sensing procedure

(To test for tach sensing set digital multi-meter for AC voltage.)

1. Start the vehicle with the key. Allow time for the engine to idle down.

2. At idle the tach wire will test between 1 to 4-volts AC. As the R.P.M.’s

increase the voltage on the meter will increase.

3. While vehicle is at idle, tap the tach learn button. The parking lights will

flash once and siren will chirp once to confirm the control module accepted

the tach signal. If the parking lights flash three times and the siren chirps

three times this is confirmation that the control module did not accept the

tach signal. After two seconds the number of parking light flashes will

indicate the cause of the error.

- 14 -

Page 15

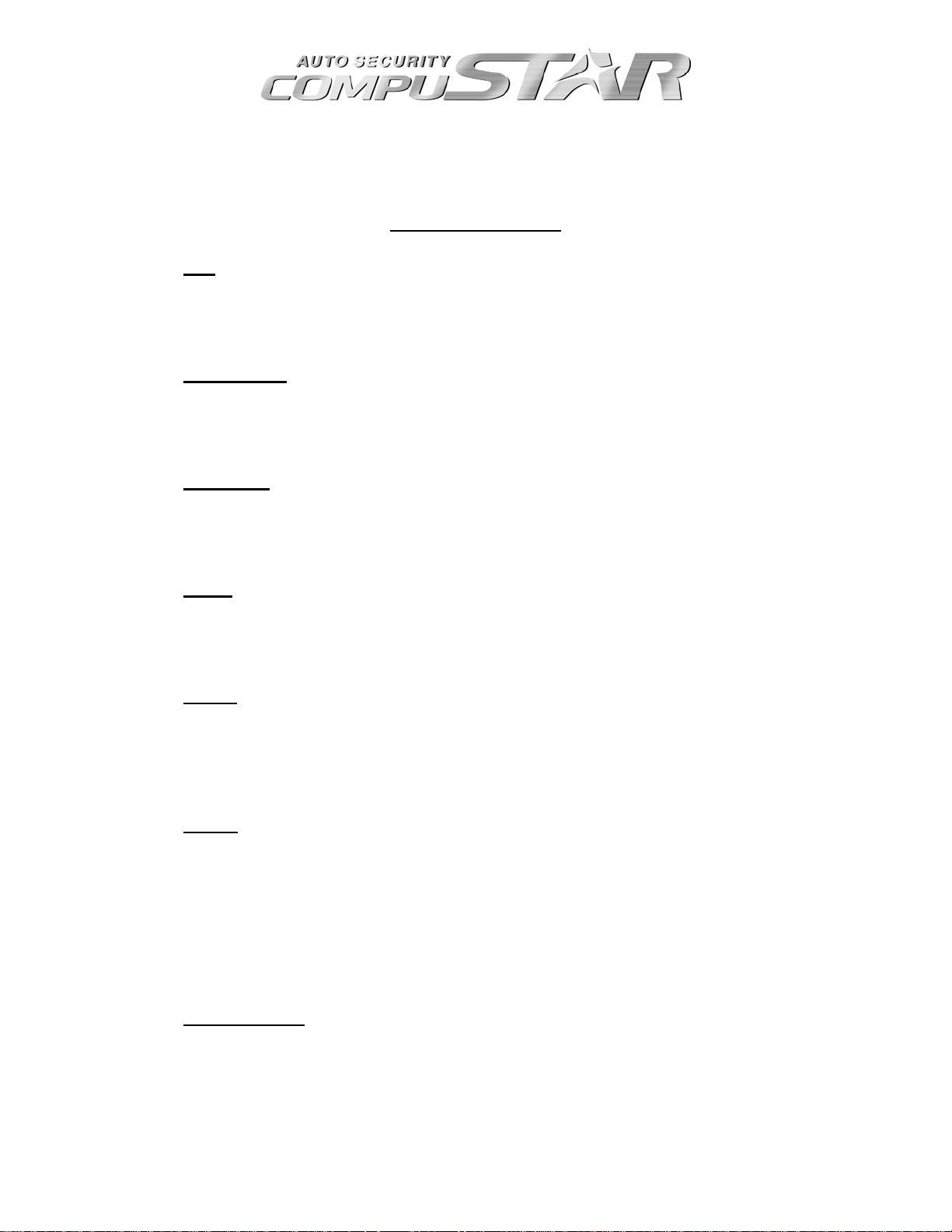

Error Number

(# of times parking lights flash)

1 Dipswitch #1 is on alternator sensing.

2 Key is in the off position.

3

Tach Learning Error Diagnosis

No signal, or the signal is not fast

enough. Find a different wire

Alternator sensing:

This is not voltage sensing. To use alternator sensing the engine sense input,

(yellow/black) must be connected to the stator wire on the alternator. This will be

a small gauge wire.

Alternator sensing procedure

(To test for alternator sensing set digital multi-meter for DC voltage. Alternator is

pre-programmed in the control module and does not require programming. )

1. The stator wire will rest at 0-volts DC while the vehicle is off.

2. Turn the ignition to the run position with the key. The stator wire will test

between 4 to 6-volts DC.

Start the vehicle with the key. While the vehicle is running at idle the stator wire

will test between 12 to 14-volts DC.

Diagnosing Remote Start Problems

If there is a problem auto-starting the vehicle, you will hear three chirps or see three

parking light flashes when you attempt to auto-start it. Wait for 2 seconds and the cause

for the error will be indicated by the number of times the parking lights flash.

Error Number

(# of times parking lights flash)

1 Engine On

2 Key On

3 Door Open

4 Trunk Open

5 Brake On

6 Hood Open

7

(Manual Transmission Only)

Error Reason

Reservation Off

- 15 -

Page 16

- 16 -

Page 17

Control Modules

- 17 -

Page 18

- 18 -

Page 19

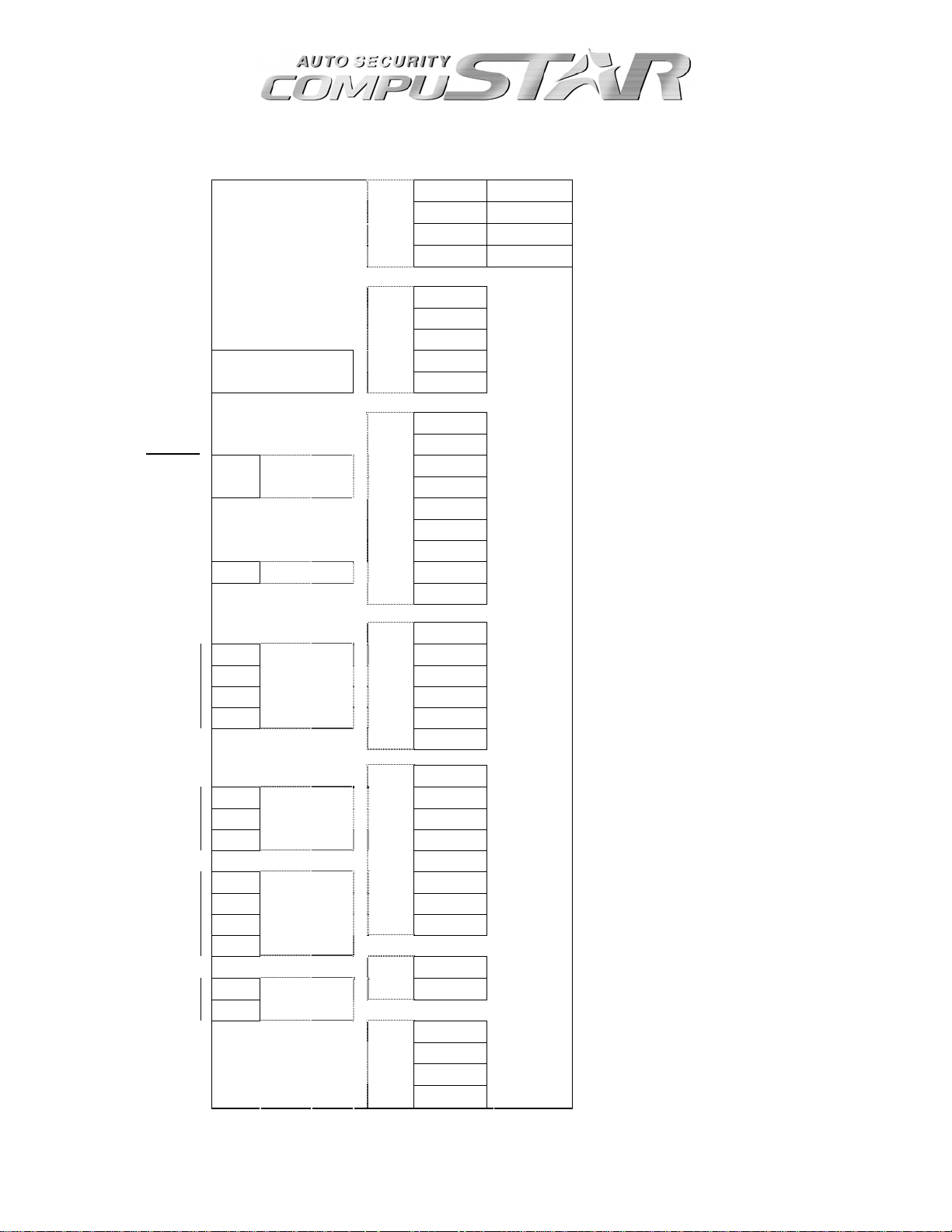

CM3000 Wiring Diagram

1 Red 2 Gr/Wht 1: ( + ) 12v Constant 2: ( + ) Parking Light

3 Red/Wht 4 White 3: ( + ) 12v Constant 4: ( + ) Accessory

5 Violet 6 Yellow 5: ( - ) When Armed 6: ( + ) Starter

1 Gr/Wht ( - ) Parking Lt. Output 250 mA

2 Black ( - ) Status Out (GWR) 250 mA

3 Green ( - ) Ignition Output 250 mA

Cut = Auto 4 Wht/Blk ( - ) Accessory Output 250 mA

Uncut = Manual

1 Lt. Blue ( - ) E-Brake Input

OFF / ON 2 Gray/Bk ( - ) Hood Input

Altenator / Tach DIP 1 3 Lt. Blue/Wh ( + ) Brake Input

15 (25) / 25 (45) DIP 2

Gas (Diesel) 5 Red/Wht ( - ) Door Input

6 Red ( + ) Door Input

7 Brown/Blk ( - ) Glow Plug Input

Tach Switch SW

1 None

Antenna

1 Orange ( - ) Rearm Output 250 mA

Temp Sensor

5 White ( - ) Horn Output 250 mA

Remote Paging

System

1 Black LED ( - )

Optional Sensor

Input

1 Black ( - )

2 White 2nd Stage Shock

3 Red ( + )

Jumper

DIP

CN12

4 ( - ) 2 Violet/Wht ( - ) Trunk Release Output 250 mA

3 ( + ) 3 Orange/Blk ( - ) 2nd Unlock Output 250 mA

2 Tx 4 Blue ( - ) Unlock Output 250 mA

1 Rx

3 ( - ) 2 Orange/Wht ( - ) Disarm Output 250 mA

2 Temp 3 Violet ( - ) Dome Light Supervision 250 mA

1 ( + )

4 LED 6 Yellow ( - ) Auxiliary 1 Output 250 mA

3 ( + ) 7 Yellow/Wht ( - ) Auxiliary 2 Output 250 mA

2 Knock

1 ( - )

2 2nd

1 1st

CN11

CN10

CN9

CN8

CN1

7 Gr/Red 8 Black 7: ( + ) Ignition 8: ( - ) Ground

CN2

4 Violet/Blk ( - ) Trunk Input

CN3

8 Brown/Wht ( + ) Glow Plug Input

CN4

5 Blue/Blk ( - ) Lock Output 250 mA

4 Brown ( + ) Siren Output 250 mA

CN5

CN6

CN7

5 Red/Blk ( - ) Starter Output 250 mA

9 Yellow/Blk Tach / Altenator Input

6 None

8 None

2 Black/Wht LED ( + )

4 Yellow 1st Stage Shock

- 19 -

Page 20

CM-3000 WIRING DETAIL

CONNECTOR 1

Pin 1 Red- Constant 12-volt (+) positive power input for the control module. This wire

must be connected to a constant 12-volt (+) positive source. The proper wire will

test 12-volt (+) positive with the key in the off position, while key is in the on

position and during crank.

Pin 2 Green/White- Parking light (+) positive output. Connect this wire to the (+)

positive parking light wire generally at the parking light switch or behind the fuse

box. The proper wire will test 12-volts (+) positive when the parking light switch is

in the on position.

Pin 3 Red/White- Constant 12-volt (+) positive power input for the starter and accessory

on-board relays. This wire must be connected to a constant 12-volt (+) positive

source. The proper wire will test 12-volts (+) positive with the key in the off

position, while the key is in the on position and during crank

Pin 4 White- Accessory 12-volts (+) positive output. This wire must be connected to the

heater and A/C blower motor wire. The proper wire will test 0-volts with the key in

the off position, 12-volts (+) positive while key is in the on position, 0-volts while

cranking and back to 12-volts (+) positive with the key in the on position

.

Pin 5 Violet- 250mA (-) negative output when armed and remote started. This wire will

provide a (-) negative output when system is locked and armed and during remote

start for anti-grind. (Note: This wire can also be used to trigger after-market L.E.D.

kits and other after-market accessories. Output must be diode isolated when used to

trigger after-market accessories.)

Pin 6 Yellow- Starter 12-volt (+) positive output. This is pre-wired to pin 87a of the

starter interrupt relay. This wire will provide12-volts (+) positive to the vehicles

starter. The proper wire will test 0-volts with the key in the off position, 0-volts

while the key is in the on position and 12-volts (+) positive during crank. (Note:

The vehicle starter wire will need to be cut. The yellow wire from pin 87a on the

starter interrupt relay will go to the starter side of the vehicles starter wire. The

yellow/black wire from pin 30 of the starter interrupt relay will go to the key side of

the vehicles starter wire.)

Pin 7 Green and Red

vehicles ignition to power up all accessories and to trigger remote programming.

The proper wire will test 0-volts with the key in the off position, 12-volts (+)

positive while the key is in the on position and 12-volts (+) positive during crank.

(Note: Red wire is the ignition input for the pre-wired starter kill relay.)

–Ignition output and input. This wire must be connected to the

- 20 -

Page 21

Pin 8 Black- Ground (-) negative input. This wire will connect to chassis ground.

CONNECTOR 2

These outputs can be used to trigger the secondary external pre-wired relay on the main

ignition harness. (I.e.: 2

wire of the relay will give you a 2nd ignition (+) positive output on the blue wire of the

relay.

Pin 1 Green/White- Parking light 250mA (-) negative output. This is an optional output

that will provide a (-) negative output with parking light flash.

Pin 2 Black- Status 250mA (-) negative output. This is an optional output that will

provide a (-) negative output before the ignition is triggered, during remote start and

will shut down after ignition has shut down. (Note: This wire can be used to trigger

factory security interface modules)

Pin 3 Green- 2nd Ignition 250mA (-) negative output. This is an optional output that will

provide a (-) negative output while the ignition is triggered and during remote start.

Pin 4 White/Black- 2nd Accessory 250mA (-) negative output. This is an optional output

that will provide a (-) negative output while the accessory output is triggered.

Pin5 Red/Black- 2nd Starter 250mA (-) negative output. This is an optional output that

will provide a (-) negative output during crank only.

nd

ignition (-) negative output green wire connected to the violet

CONNECTOR 3

Pin 1 Light Blue- Parking brake (-) negative input. This input is required for manual

transmission reservation mode and to trigger the turbo-timer mode. The proper wire

will provide a (-) negative trigger only when parking brake is set. (Note: Turbo

mode is optional.)

Pin 2 Gray/Black- Hood-pin (-) negative input. This input is a safety shut down that will

prevent the vehicle from remote starting and shut down the engine when the hood is

opened. (Note: This wire will also trigger the alarm when the system is armed.)

Pin 3 Light Blue/White

down vehicle when remote started. The proper wire will test 12-volts (+) positive

only when the foot brake is pressed.

- 21 -

- Brake 12-volts (+) positive input. This input is required to shut

Page 22

Pin 4 Violet/Black- Trunk-pin (-) negative input. This is an optional input that will

monitor when the vehicles trunk is opened. (Note: This wire will also trigger the

alarm when the system is armed.)

Pin 5 Red/White- Door trigger (-) negative input. This wire monitors (-) negative trigger

door-pins. The proper wire will provide a (-) negative trigger only when the doors

are opened. (Note: This wire is required for manual transmission remote starts.)

Pin 6 Red

Pin 7 Brown/Black

Pin 8 Brown/White- Glow plug (+) positive input. This wire will delay the starter output

Pin 9 Yellow/Black- Engine sensing input. A tach input or alternator input is required for

- Door trigger (+) positive input. This wire monitors (+) positive trigger door-

pins. The proper wire will provide a (+) positive trigger only when the doors are

opened. (Note: This wire is required for manual transmission remote starts.)

- Glow plug (-) negative input. This wire will delay the starter output

to allow the glow plugs to warm up on diesel engine vehicles. The proper wire will

only provide a (-) negative trigger while the “Wait to Start” light is on.

to allow the glow plugs to warm up on diesel engine vehicles. The proper wire will

only provide a (+) positive trigger while the “Wait to Start” light is on.

the system to sense when the vehicle is running. (Note: Option selected by

dipswitch #1. On=Tach sensing. Off=Alternator sensing.)

CONNECTOR 4

Pin 1 Not used

Pin 2 Violet/White

(-) negative trigger pulse. (Note: Positive trigger trunk release will require a relay.

System will unlock doors and disarm alarm prior to trunk release.)

Pin 3 Orange/Black

output that will provide a (-) negative pulse output for driver’s priority door lock.

(Note: This feature will require additional relays and programming.)

Pin 4 Blue- Unlock 250mA (-) negative output. This wire will provide a (-) negative

pulse output during unlock and disarm. (Note: Positive and reverse polarity will

require additional relays.)

Pin 5 Blue/Black- Lock 250mA (-) negative output. This wire will provide a (-) negative

pulse output during lock and arm. (Note: Positive and reverse polarity will require

additional relays.

- Trunk release 250mA (-) negative output. This wire will provide a

- 2nd Unlock 250mA (-) negative output. This wire is an optional

- 22 -

Page 23

Pin 6 Not used.

CONNECTOR 5

Pin 1 Orange- Factory alarm re-arm 250mA (-) negative output. This is an optional

output that will provide a (-) negative pulse output during lock, after crank and after

ignition shut down.

Pin 2 Orange/White- Factory alarm disarm 250mA (-) negative output. This is an

optional output that will provide a (-) negative pulse output during unlock and

before ignition is turned on.

Pin 3 Violet- Dome light 250mA (-) negative output. This is an optional output that will

provide a 30 second (-) negative output after system is unlocked for dome-light

supervision.

Pin 4 Brown- Siren 12-volt (+) positive output. This wire will provide a 30 or 60 second

(+) positive output for the external siren. (Note: Factory default is 30 seconds.)

Pin 5 White- Horn honk 250mA (-) negative output. This is an optional output that will

provide a 30 or 60 second (-) negative pulse when the alarm is triggered or during

panic.

Pin 6 Yellow- Aux 1- 250mA (-) negative output. This is an optional output that will

provide a pulse, latch or a timed pulse output. (Note: Options programmer is

required to program a timed pulse output.)

Pin 7 Yellow/White- Aux 2- 250mA (-) negative output. This is an optional output that

will provide a pulse, latch or a timed pulse output. (Note: Options programmer is

required to program a timed pulse output.)

Pin 8 Not used.

CONNECTOR 6

(Pre-wired L.E.D.)

Pin 1 Black-L.E.D. - (-) negative output.

Pin 2 Black/White - 3-volt L.E.D. (+) positive output.

- 23 -

Page 24

CONNECTOR 7

(Pre-wired Shock Sensor)

Pin 1 Black

Pin 2 White-Shock sensor 2nd stage (-) negative input. (Instant trigger)

Pin 3 Red

Pin 4 Yellow

-Shock sensor (-) negative ground input.

-Shock sensor 12-volt (+) positive input.

-Shock sensor 1st stage (-) negative input. (Warn away)

CONNECTOR 8

(Optional add on sensors; i.e. proximity)

Pin 1 Gray/White- Optional sensor 1st stage (-) negative input. (Warn away)

Pin 2 Black/White-Optional sensor 2nd stage (-) negative input. (Instant trigger)

CONNECTOR 9

(Pre-wired Remote Paging Sensor or R.P.S.)

Pin 1 Black-R.P.S. sensor (-) negative ground input.

Pin 2 White-R.P.S. sensor (-) negative paging input.

Pin 3 Red

Pin 4 Yellow- R.P.S. sensor 9-volt (+) positive L.E.D. output

-R.P.S. sensor 12-volt (+) positive input.

CONNECTOR 10

(Optional Temperature sensor)

Pin 1 Gray-12-volt (+) positive output. This wire will provide 12-volt (+) positive to

temperature sensor.

Pin 2 Brown-Temp sensor (-) negative input. This wire will activate remote start when

provided a (-) negative input. (Note: If vehicle is remotely started, a (-) negative

input will turn the vehicle off.)

Pin 3 Black

-Temp sensor (-) negative ground output.

- 24 -

Page 25

CONNECTOR 11

(Pre-wired Antenna Cable)

Pin 1 Yellow

Pin 2 White-TX output. This wire transmits signal to remote.

Pin 3 Red

Pin 4 Black

-RX input. This wire receives signal from remote.

-12-volt constant (+) positive input.

- (-) negative ground input.

- 25 -

Page 26

- 26 -

Page 27

CM3300 Wiring Diagram

Brown 1 ( + ) Siren Output

Green/Wh 2 ( + ) Parking Light

Red 3 12v Constant

Green/Wh 1 ( - ) Parking Light 200mA

White 2 ( - ) Horn Output 200mA

Yellow 3 ( - ) Aux 1 Output 200mA

Yellow/Wh 4 ( - ) Aux 2 Output 200mA

Purple 5 ( - ) Starter Kill Output 200mA

Green 6 ( + ) Ignition Input

Purple 7 ( - ) Dome Light Output 200mA

Orange 8 ( - ) Rearm Output 200mA

( - ) 4 Black

( + ) 3 Red Gray/Blk 1 ( - ) Hood Pin Input

Tx Antenna Cable 2 White Purple/Blk 2 ( - ) Trunk Trigger

Rx Anrenna Cable 1 Yellow

Red 4 ( + ) Door Trigger

LED ( - ) 4 Yellow Black/Wh 5 ( - ) Optional Trigger 1

( + ) 3 Red

RPS 2 White

( - ) 1 Black

Purple/Wh 2 ( - ) Trunk Release 200mA

Orange/Blk 3 ( - ) 2nd Unlock Output 200mA

Blue 4 ( - ) Unlock Output 200mA

Blue/Blk 5 ( - ) Lock Output 200mA

Black 1 ( - ) LED

Black 1 ( - )

White 2 2nd Stage Shock Sensor

Red 3 ( + )

CN8

Red/Wh 3 ( - ) Door Trigger

CN7

None 1 ( + ) 12v Constant

CN1

Black 4 Ground

CN2

Orange/Wh 9 ( - ) Disarm Output 200mA

CN3

Gray/Wh 6 ( - ) Optional Trigger 2

CN4

None 6 ( - ) Ground

CN5

Black/Wh 2 ( + ) LED

CN6

Yellow 4 1st Stage Shock Sensor

- 27 -

Page 28

CM-3300 WIRING DETAIL

CONNECTOR 1

Pin 1 Brown- Siren 12-volt (+) positive output. This wire will provide a 30 or 60 second

(+) positive output for the external siren. (Note: Factory default is 30 seconds.)

Pin 2 Green/White- Parking light (+) positive output. Connect this wire to the (+)

positive parking light wire generally at the parking light switch or behind the fuse

box. The proper wire will test 12-volts (+) positive when the parking light switch is

in the on position.

Pin 1 Red- Constant 12-volt (+) positive power input for the control module. This wire

must be connected to a constant 12-volt (+) positive source. The proper wire will

test 12-volt (+) positive with the key in the off position, while key is in the on

position and during crank.

Pin 4 Black- Ground (-) negative input. This wire will connect to chassis ground.

CONNECTOR 2

Pin 1 Green/White- Parking light 250mA (-) negative output. This is an optional output

that will provide a (-) negative output with parking light flash.

Pin 2 White- Horn honk 250mA (-) negative output. This is an optional output that will

provide a 30 or 60 second (-) negative pulse when the alarm is triggered or during

panic.

Pin 3 Yellow- Aux 1- 250mA (-) negative output. This is an optional output that will

provide a pulse, latch or a timed pulse output. (Note: Options programmer is

required to program a timed pulse output.)

Pin 4 Yellow/White

will provide a pulse, latch or a timed pulse output. (Note: Options programmer is

required to program a timed pulse output.)

Pin 5 Violet-

negative output when system is locked and armed. (Note: This wire can also be

used to trigger after-market L.E.D. kits and other after-market accessories. Output

must be diode isolated when used to trigger after-market accessories.)

250mA (-) negative output when armed. This wire will provide a (-)

- Aux 2- 250mA (-) negative output. This is an optional output that

- 28 -

Page 29

Pin 6 Green –Ignition input. This wire must be connected to the vehicles ignition to

trigger remote programming. The proper wire will test 0-volts with the key in the

off position, 12-volts (+) positive while the key is in the on position and 12-volts

(+) positive during crank.

Pin 7 Violet- Dome light 250mA (-) negative output. This is an optional output that will

provide a 30 second (-) negative output after system is unlocked for dome-light

supervision.

Pin 8 Orange

output that will provide a (-) negative pulse output during lock, after crank and after

ignition shut down.

Pin 9 Orange/White- Factory alarm disarm 250mA (-) negative output. This is an

optional output that will provide a (-) negative pulse output during unlock and

before ignition is turned on.

- Factory alarm re-arm 250mA (-) negative output. This is an optional

CONNECTOR 3

Pin 1 Gray/Black- Hood-pin (-) negative input. This is an optional input that will

monitor when the vehicles hood is opened.. (Note: This wire will also trigger alarm

when system is armed.)

.

Pin 2 Violet/Black- Trunk-pin (-) negative input. This is an optional input that will

monitor when the vehicles trunk is opened. (Note: This wire will also trigger alarm

when system is armed.)

Pin 3 Red/White- Door trigger (-) negative input. This wire monitors (-) negative trigger

door-pins. The proper wire will provide a (-) negative trigger only when the doors

are opened.

Pin 4 Red

Pin 5 Black /White- Optional sensor 2

Pin 6 Gray/White- Optional sensor 1

- Door trigger (+) positive input. This wire monitors (+) positive trigger doorpins. The proper wire will provide a (+) positive trigger only when the doors are

opened.

nd

stage (-) negative input. (Instant trigger)

st

stage (-) negative input. (Warn away)

- 29 -

Page 30

CONNECTOR 4

Pin 1 Not used

Pin 2 Violet/White

) negative trigger pulse. (Note: Positive trigger trunk release will require a relay.

System will unlock doors and disarm alarm prior to trunk release.)

Pin 3 Orange/Black- 2nd Unlock 250mA (-) negative output. This wire is an optional

output that will provide a (-) negative pulse output for driver’s priority door lock.

(Note: This feature will require additional relays and programming.)

Pin 4 Blue- Unlock 250mA (-) negative output. This wire will provide a (-) negative

pulse output during unlock and disarm. (Note: Positive and reverse polarity will

require additional relays.)

Pin 5 Blue/Black- Lock 250mA (-) negative output. This wire will provide a (-) negative

pulse output during lock and arm. (Note: Positive and reverse polarity will require

additional relays.

Pin 6 Not used.

- Trunk release 250mA (-) negative output. This wire will provide a (-

CONNECTOR 5

(Pre-wired L.E.D.)

Pin 1 Black-L.E.D. - (-) negative output.

Pin 2 Black/White

- 3-volt L.E.D. (+) positive output.

CONNECTOR 6

(Pre-wired Shock Sensor)

Pin 1 Black-Shock sensor (-) negative ground input.

Pin 2 White

Pin 3 Red

Pin 4 Yellow-Shock sensor 1st stage (-) negative input. (Warn away)

-Shock sensor 2nd stage (-) negative input. (Instant trigger)

-Shock sensor 12-volt (+) positive input.

- 30 -

Page 31

CONNECTOR 7

(Pre-wired Remote Paging Sensor or R.P.S.)

Pin 1 Black

Pin 2 White-R.P.S. sensor (-) negative paging input.

Pin 3 Red

Pin 4 Yellow

-R.P.S. sensor (-) negative ground input.

-R.P.S. sensor 12-volt (+) positive input.

- R.P.S. sensor 9-volt (+) positive L.E.D. output

CONNECTOR 8

(Pre-wired Antenna Cable)

Pin 1 Yellow-RX input. This wire receives signal from remote.

Pin 2 White-TX output. This wire transmits signal to remote.

Pin 3 Red-12-volt constant (+) positive input.

Pin 4 Black- (-) negative ground input.

- 31 -

Page 32

- 32 -

Page 33

CM4200 Wiring Diagram

Cut = Auto 1 Red 2 Gr/Wht 1: ( + ) 12v Constant

Uncut = Manual

5 Blue 6 Yellow 5: ( + ) Output, *JM1 6: ( + ) Starter

OFF / ON

Altenator / Tach DIP 1

15 (25) / 25 (45) DIP 2

Gas (Diesel) 2 Red/Blk ( - ) Starter Output 250 mA

3 Violet ( - ) Output to Sterter Kill 250 mA

JM1

Tach Switch SW CN12

1 Lt. Blue ( - ) E-Brake Input

TX 4 White 2 Gray/Bk ( - ) Hood Input

RX 3 Blue 3 Lt. Blue/Wh ( + ) Brake Input

( - ) 2 Black 4 Violet/Blk ( - ) Trunk Input

( + ) 1 Red

4 ( - ) 7 Brown/Blk ( - ) Glow Plug Input

Antenna

Temp Sensor

3 ( + ) 8 Brown/Wht ( + ) Glow Plug Input

2 Tx

1 Rx

1 None

2 Violet/Wht ( - ) Trunk Release Output 250 mA

3 Orange/Blk ( - ) 2nd Unlock Output 250 mA

3 ( - ) 4 Blue ( - ) Unlock Output 250 mA

2 Temp 5 Blue/Blk ( - ) Lock Output 250 mA

1 ( + )

Jumper

3 Red/Wht 4 White 3: ( + ) 12v Constant 4: ( + ) Accessory

CN1

7 Gr/Red 8 Black 7: ( + ) Ignition 8: ( - ) Ground

DIP

3 2nd Starter 4 Black ( - ) Status Out (GWR) 250 mA

2 2nd Acc 5 Orange ( - ) Rearm Output 250 mA

1 2nd Ign

1 Gr/Wht ( - ) Parking Lt. Output 250 mA

CN2

CN8

6 Orange/Wh ( - ) Disarm Output

CN7

CN3

5 Red/Wht ( - ) Door Input

6 Red ( + ) Door Input

CN11

CN4

CN5

7 White ( - ) Horn Output

9 Yellow/Blk Tach / Altenator Input

6 None

2: ( + ) Parking

Light

* Output of Pin 5 of CN1 is determined by the placement of Jumper JM1.

- 33 -

Page 34

CM-4200 WIRING DETAIL

CONNECTOR 1

Pin 1 Red- Constant 12-volt (+) positive power input for the control module. This wire

must be connected to a constant 12-volt (+) positive source. The proper wire will

test 12-volt (+) positive with the key in the off position, while key is in the on

position and during crank.

Pin 2 Green/White- Parking light (+) positive output. Connect this wire to the (+)

positive parking light wire generally at the parking light switch or behind the fuse

box. The proper wire will test 12-volts (+) positive when the parking light switch is

in the on position.

Pin 3 Red/White- Constant 12-volt (+) positive power input for the starter and accessory

on-board relays. This wire must be connected to a constant 12-volt (+) positive

source. The proper wire will test 12-volts (+) positive with the key in the off

position, while the key is in the on position and during crank

Pin 4 White- Accessory 12-volts (+) positive output. This wire must be connected to the

heater and A/C blower motor wire. The proper wire will test 0-volts with the key in

the off position, 12-volts (+) positive while key is in the on position, 0-volts while

cranking and back to 12-volts (+) positive with the key in the on position

Pin 5 Blue- 2nd Ign., Acc. or Starter 12-volts (+) positive output. This wire is an optional

output that will provide 12-volts (+) positive output. The jumper setting on the

control module will determine the output.

Pin 6 Yellow

starter interrupt relay. This wire provides 12-volts (+) positive to the vehicles

starter. The proper wire will test 0-volts with the key in the off position, 0-volts

while the key is in the on position and 12-volts (+) positive during crank. (Note:

The vehicle starter wire will need to be cut. The yellow wire from pin 87a on the

starter interrupt relay will go to the starter side of the vehicles starter wire. The

yellow/black wire from pin 30 of the starter interrupt relay will go to the key side of

the vehicles starter wire.)

Pin 7 Green and Red –Ignition output and input. This wire must be connected to the

vehicles ignition to power up all accessories and to trigger remote programming.

The proper wire will test 0-volts with the key in the off position, 12-volts (+)

positive while the key is in the on position and 12-volts (+) positive during crank.

(Note: Red wire is the ignition input for the pre-wired starter kill relay.)

Pin 8 Black- Ground (-) negative input. This wire will connect to chassis ground.

- Starter 12-volts (+) positive output. This is pre-wired to pin 87a of the

- 34 -

Page 35

CONNECTOR 2

Pin 1 Green/White

that will provide a (-) negative output with parking light flash.

Pin 2 Red/Black

will provide a (-) negative output during crank only.

Pin 3 Violet- 250mA (-) negative output when locked and remote started. This wire will

provide a (-) negative output when system is locked and armed and during remote

start for anti-grind. (Note: This wire can also be used to trigger after-market L.E.D.

kits and other after-market accessories. Output must be diode isolated when used to

trigger after-market accessories.)

Pin 4 Black- Status 250mA (-) negative output. This is an optional output that will

provide a (-) negative output before the ignition is triggered, during remote start and

will shut down after ignition has shut down. (Note: This wire can be used to trigger

factory security interface modules)

Pin 5 Orange- Factory alarm re-arm 250mA (-) negative output. This is an optional

output that will provide a (-) negative pulse output during lock, after crank and after

ignition shut down.

Pin 6 Orange/White- Factory alarm disarm 250mA (-) negative output. This is an

optional output that will provide a (-) negative pulse output during unlock and

before ignition is turned on.

Pin 7 White- Horn honk 250mA (-) negative output. This is an optional output that will

provide a (-) negative pulse when the door locks are activated and 30 or 60 second

pulse output during panic.

- Parking light 250mA (-) negative output. This is an optional output

- 2nd Starter 250mA (-) negative output. This is an optional output that

CONNECTOR 3

Pin 1 Light Blue

transmission reservation mode and to trigger the turbo-timer mode. The proper wire

will provide a (-) negative trigger only when parking brake is set. (Note: Turbo

mode is optional.)

Pin 2 Gray/Black- Hood-pin (-) negative input. This input is a safety shut down that will

prevent the vehicle from remote starting and shut down the engine when the hood is

opened. (Note: This wire will also trigger the alarm when the system is armed.)

- 35 -

- Parking brake (-) negative input. This input is required for manual

Page 36

Pin 3 Light Blue/White- Brake 12-volts (+) positive input. This input is required to shut

down vehicle when remote started. The proper wire will test 12-volts (+) positive

only when the foot brake is pressed.

Pin 4 Violet/Black- Trunk-pin (-) negative input. This is an optional input that will

monitor when the vehicles trunk is opened. (Note: This wire will also trigger the

alarm when the system is armed.)

Pin 5 Red/White

door-pins. The proper wire will provide a (-) negative trigger only when the doors

are opened. (Note: This wire is required for manual transmission remote starts.)

Pin 6 Red

Pin 7 Brown/Black- Glow plug (-) negative input. This wire will delay the starter output

Pin 8 Brown/White- Glow plug (+) positive input. This wire will delay the starter output

Pin 9 Yellow/Black- Engine sensing input. A tach input or alternator input is required for

- Door trigger (+) positive input. This wire monitors (+) positive trigger door-

pins. The proper wire will provide a (+) positive trigger only when the doors are

opened. (Note: This wire is required for manual transmission remote starts.)

to allow the glow plugs to warm up on diesel engine vehicles. The proper wire will

only provide a (-) negative trigger while the “Wait to Start” light is on.

to allow the glow plugs to warm up on diesel engine vehicles. The proper wire will

only provide a (+) positive trigger while the “Wait to Start” light is on.

the system to sense when the vehicle is running. (Note: Option selected by

dipswitch #1. On=Tach sensing. Off=Alternator sensing.)

- Door trigger (-) negative input. This wire monitors (-) negative trigger

CONNECTOR 4

Pin 1 Not used

Pin 2 Violet/White- Trunk release 250mA (-) negative output. This wire will provide a (-

) negative trigger pulse. (Note: Positive trigger trunk release will require a relay.

System will unlock doors prior to trunk release.)

Pin 3 Orange/Black- 2nd Unlock 250mA (-) negative output. This is an optional output

that will provide a (-) negative pulse output for driver’s priority door lock. (Note:

This feature will require additional relays and programming.)

Pin 4 Blue- Unlock 250mA (-) negative output. This wire will provide a (-) negative

pulse output during unlock. (Note: Positive and reverse polarity will require

additional relays.)

- 36 -

Page 37

Pin 5 Blue/Black- Lock 250mA (-) negative output. This wire will provide a (-) negative

pulse output during lock. (Note: Positive and reverse polarity will require additional

relays.

Pin 6 Not used.

CONNECTOR 5

(Optional Temperature sensor)

Pin 1 Gray-12-volt (+) positive output. This wire will provide 12-volt (+) positive to

temperature sensor.

Pin 2 Brown-Temp sensor (-) negative input. This wire will activate remote start when

provided a (-) negative input. (Note: If vehicle is remotely started, a (-) negative

input will turn the vehicle off.)

Pin 3 Black-Temp sensor (-) negative ground output.

CONNECTOR 6

(Pre-wired Antenna Cable)

Pin 1 Yellow-RX input. This wire receives signal from remote.

Pin 2 White-TX output. This wire transmits signal to remote.

Pin 3 Red

Pin 4 Black

-12-volt constant (+) positive input.

- (-) negative ground input.

CONNECTOR 7

RS 232

Pin 1 Yellow-RX input. This wire receives signal from remote.

Pin 2 Blue-TX output. This wire transmits signal to remote.

Pin 3 Black-(-) negative ground in

Pin 4 Red-12-volt constant (+) positive input.

- 37 -

Page 38

- 38 -

Page 39

Red 1 ( + ) 12V Constant Input

Violet 2

Brown 3 ( + ) Siren Output

Gray 4 ( + ) Trunk Output

Anrenna Wire Black

Lt.Blue/Wh 6 ( + ) Brake Input

Black 1 ( - ) LED

Black 1 ( - )

White 2

Red 3 ( + )

CM1000A Wiring Diagram

CN1

Black 5 Ground

Yellow/Blk 1 Normal Closed

Yellow 2

Yellow/Wh 3 Normal Open

Green/Blk 4 Normal Closed

CN2

Green 5 Common - Lock Output

Green 1 ( + ) Ignition Input

Blue 2 ( - ) Starter Kill Output 250mA

Red/Blk 3 ( - ) Door Trigger

Red 4 ( + ) Door Trigger

CN3

Violet/Blk 5 ( - ) Trunk Trigger

CN4

CN5

Green/Wh 6 Normal Open

Black/Wh 7

Black/Wh 2 ( + ) LED

Yellow 4 1st Stage Shock Sensor

( + ) Parking Light

Output

Common - Unlock

Output

( - ) Optional Sensor

Input

2nd Stage Shock

Sensor

- 39 -

Page 40

CM-1000A WIRING DETAIL

CONNECTOR 1

Pin 1 Red- Constant 12-volts (+) positive power input for the control module. This wire

must be connected to a constant 12-volt (+) positive source. The proper wire will

test 12-volt (+) positive with the key in the off position, while key is in the on

position and during crank.

Pin 2 Violet- Parking light (+) positive output. Connect this wire to the (+) positive

parking light wire generally at the parking light switch or behind the fuse box. The

proper wire will test 12-volts (+) positive when the parking light switch is in the on

position.

Pin 3 Brown- Siren 12-volts (+) positive output. This wire will provide a 30 or 60 second

(+) positive output for the external siren. (Note: Factory default is 30 seconds.)

Pin 4 Gray- Trunk release 12-volts (+) positive output. This wire will provide a (+)

positive trigger pulse. (Note: Negative trigger trunk release will require a relay.

System will unlock doors and disarm alarm prior to trunk release.)

Pin 5 Black- Ground (-) negative input. This wire will connect to chassis ground.

CONNECTOR 2

Pin 1 Yellow/Black- Normally closed pin (87a) of unlock relay. For a positive or

negative unlock system this wire will not be used. For after-market actuators this

wire will go to chassis ground. For reverse polarity this wire will go to the switch

side of the unlock wire of the vehicle. When the factory unlock wire is cut the

switch side will test 12-volts positive when the switch is pressed to unlock.

Pin 2 Yellow

this wire will go to the vehicles unlock wire. For after-market actuators this wire

will go to the unlock wire of the actuator. For reverse polarity this wire will go to

the motor side of the unlock wire of the vehicle.

Pin 3 Yellow/White

system this wire will go to a 12-volts (+) positive source. For a negative unlock

system this wire will go to chassis ground. For after-market actuators this wire will

go to a 12-volts (+) positive source. For reverse polarity this wire will go to a 12volts (+) positive source.

- Common pin (30) of unlock relay. For positive or negative unlock system

- Normally opened pin (87) of unlock relay. For a positive unlock

- 40 -

Page 41

Pin 4 Green/Black- Normally closed pin (87a) of lock relay. For a positive or negative

lock system this wire will not be used. For after-market actuators this wire will go

to chassis ground. For reverse polarity this wire will go to the switch side of the

lock wire of the vehicle. When the factory lock wire is cut the switch side will test

12-volts positive when the switch is pressed to unlock.

Pin 5 Green- Common pin (30) of lock relay. For positive or negative lock system this

wire will go to the vehicles lock wire. For after-market actuators this wire will go to

the lock wire of the actuator. For reverse polarity this wire will go to the motor side

of the lock wire of the vehicle.

Pin 6 Green/White- Normally opened pin (87) of lock relay. For a positive lock system

this wire will go to a 12-volts (+) positive source. For a negative lock system this

wire will go to chassis ground. For after-market actuators this wire will go to a 12volts (+) positive source. For reverse polarity this wire will go to a 12-volts (+)

positive source.

CONNECTOR 3

Pin 1 Green –Ignition input. This wire must be connected to the vehicles ignition to

trigger remote programming. The proper wire will test 0-volts with the key in the

off position, 12-volts (+) positive while the key is in the on position and 12-volts

(+) positive during crank

Pin 2 Blue- 250mA (-) negative output when armed. This wire will provide a (-) negative

output when system is locked and armed. (Note: This wire can also be used to

trigger after-market L.E.D. kits and other after-market accessories. Output must be

diode isolated when used to trigger after-market accessories.)

Pin 3 Red/Black- Door trigger (-) negative input. This wire monitors (-) negative trigger

door-pins. The proper wire will provide a (-) negative trigger only when the doors

are opened.

Pin 4 Red

Pin 5 Violet/Black

- Door trigger (+) positive input. This wire monitors (+) positive trigger doorpins. The proper wire will provide a (+) positive trigger only when the doors are

opened.

- Trunk-pin (-) negative input. This is an optional input that will

monitor when the vehicles trunk is opened. (Note: This wire will also trigger alarm

when system is armed.)

- 41 -

Page 42

Pin 6 Light Blue/White- Brake 12-volts (+) positive input. This input is used for ignition

controlled door locks. The proper wire will test 12-volts (+) positive only when the

foot brake is pressed.

Pin 7 Black /White- Optional sensor (-) negative input. (Instant trigger)

CONNECTOR 4

(Pre-wired L.E.D.)

Pin 1 Black-L.E.D.- (-) negative output.

Pin 2 Black/White

-3-volt L.E.D. (+) positive output.

CONNECTOR 5

(Pre-wired Shock Sensor)

Pin 1 Black-Shock sensor (-) negative ground input.

Pin 2 White-Shock sensor 2nd stage (-) negative input. (Instant trigger)

Pin 3 Red-Shock sensor 12-volt (+) positive input.

Pin 4 Yellow-Shock sensor 1st stage (-) negative input. (Warn away)

- 42 -

Page 43

Option Programming

- 43 -

Page 44

- 44 -

Page 45

Option Programming

1WAM4R, 1WFM4R, 1W900FM4R, and 1WSS4R

With lock and unlock on the same button.

1. Enter programming by pressing:

a. The (lock/unlock) button, and the (start/stop) button

simultaneously until the parking lights flash once. This is Menu 1.

b. The (lock/unlock) button, and the (query) button simultaneously

until the parking lights flash once. This is Menu 2.

2. Tap the (query) button the number of times equal to the option you

would like to change. For example, if it were the 5

menu that you would like to change, you would tap the (query) button

five times. The CompuStar system will flash the parking lights once

each time you tap the (query) button.

3. Wait a few seconds, and the parking lights will flash the number of

times corresponding to the option number you are about to modify. If

the number of times the lights flash does not correspond with the

option you want to change, wait a few seconds and the siren/horn will

sound, signaling that you have exited programming mode. After the

siren/horn sounds, you can retry the process from the beginning.

4. Immediately after the parking lights stop flashing from step 3, press:

a. The (lock/unlock) button for the factory default setting. The

parking lights will flash once.

b. The (start/stop) button for the optional setting. The parking

lights will flash twice.

You will need to perform these steps for each option you would like to change.

th

option in the

1WAM4R, 1WFM4R, 1W900FM4R, and 1WSS4R

With lock and unlock on separate buttons.

1. Enter programming by pressing:

a. The (lock) button, and the (unlock) button simultaneously until

the parking lights flash once. This is Menu 1.

b. The (lock) button, and the (start/stop) button simultaneously

until the parking lights flash once. This is Menu 2.

2. Press the (trunk) button and the (start/stop) button simultaneously until

the parking lights flash, the number of times equal to the option you

would like to change. For example, if it were the 5th option in the

- 45 -

Page 46

menu that you would like to change, you would press the (trunk), and

(start/stop) buttons simultaneously five times.

3. Wait a few seconds, and the parking lights will flash the number of

times corresponding to the option number you are about to modify. If

the number of times the lights flash does not correspond with the

option you want to change, wait a few seconds and the siren/horn will

sound, signaling that you have exited programming mode. After the

siren/horn sounds, you can retry the process from the beginning.

4. Immediately after the parking lights stop flashing from step 3, press:

a. The (lock) button for the factory default setting. The parking

lights will flash once.

b. The (unlock) button for the optional setting. The parking lights

will flash twice.

You will need to perform these steps for each option you would like to change.

R500A (CM1000A)

1. Enter programming by pressing the (trunk) button, and the (siren)

button simultaneously until the parking lights flash once.

2. Tap the (siren) button the number of times equal to the option you

would like to change. For example, if it were the 5th option in the

menu that you would like to change, you would tap the (query) button

five times. The CompuStar system will flash the parking lights once

each time you tap the (siren) button.

3. Wait a few seconds, and the parking lights will flash the number of

times corresponding to the option number you are about to modify. If

the number of times the lights flash does not correspond with the

option you want to change, wait a few seconds and the siren/horn will

sound, signaling that you have exited programming mode. After the

siren/horn sounds, you can retry the process from the beginning.

4. Immediately after the parking lights stop flashing from step 3, press:

a. The (lock) button for the factory default setting. The parking

lights will flash once.

b. The (unlock) button until the parking lights flash, for the

optional setting. The parking lights will flash twice.

You will need to perform these steps for each option you would like to change.

- 46 -

Page 47

1WFM6R

1. Enter programming by pressing:

a. The (trunk) button, and the (start) button simultaneously until

the parking lights flash once. This is Menu 1.

b. The (trunk) button, and the (stop) button simultaneously until

the parking lights flash once. This is Menu 2 .

2. Press the (stop) button until the parking lights flash, the number of

times equal to the option you would like to change. For example, if it

were the 5

would press the (stop) button five times.

5. Wait a few seconds, and the parking lights will flash the number of

times corresponding to the option number you are about to modify. If

the number of times the lights flash does not correspond with the

option you want to change, wait a few seconds and the siren/horn will

sound, signaling that you have exited programming mode. After the

siren/horn sounds, you can retry the process from the beginning.

6. Immediately after the parking lights stop flashing from step 3, press:

a. The (unlock) button for the factory default setting. The parking

b. The (start) button until the parking lights flash, for the optional

You will need to perform these steps for each option you would like to change.

th

option in the menu that you would like to change, you

lights will flash once.

setting. The parking lights will flash twice.

2WFMR-S, 2WAMR, 2WFMR, and 2W900FMR

1. Enter programming by pressing:

c. Button ( I ), and button ( II ) simultaneously until the parking

lights flash once. This is Menu 1.

d. Button ( I ), and button ( IV ) simultaneously until the parking

lights flash once. This is Menu 2.

2. Tap button ( IV ) the number of times equal to the option you would

like to change. For example, if it were the 5

you would like to change, you would tap button ( IV ) five times. The

CompuStar system will flash the parking lights once each time you tap

button ( IV ).

th

option in the menu that

- 47 -

Page 48

3. Wait a few seconds, and the parking lights will flash the number of

times corresponding to the option number you are about to modify. If

the number of times the lights flash does not correspond with the

option you want to change, wait a few seconds and the siren/horn will

sound, signaling that you have exited programming mode. After the

siren/horn sounds, you can retry the process from the beginning.

4. Immediately after the parking lights stop flashing from step 3, press:

a. Button ( I ) for the factory default setting. The parking lights

will flash once.

b. Button ( II ) for the optional setting. The parking lights will

flash twice.

You will need to perform these steps for each option you would like to change.

2WSSR

The 2WSSR programs options just like the other 2-way remotes listed above, but a more

focused approach may be needed. Inherent to the type of technology used in the 2WSSR,

is a noticeably longer delay in the response time. Given the delayed response time, and

that the option programming is a timed process in itself, option programming with this

remote can be a more difficult process if you are not sure of which buttons you need to

press during the process. Another option is the below mentioned Option Programmer,

which eliminates the need for remote option programming altogether.

CM3 Series Option Programmer

The Option Programmer is an installer’s tool used to modify options within the

CompuStar System. This unit plugs into the CompuStar system through the antenna cable

and is powered through this cable as well, therefore requiring no batteries to replace. The

Option Programmer makes it easier to program options available to remote programming

and also makes available some options that the remotes are unable to modify. The Option

Programmer has its own user’s guide in the “Accessory Manuals” section.

Resetting all of Menu #1 or Menu #2

to the factory default settings.

If you are not sure about current programming, you can change everything to the factory

settings and start again.

- 48 -

Page 49

1-Way 4 Button Remotes

With lock and unlock on the same button.

1. Enter programming by pressing:

a. The (lock/unlock) button, and the (start/stop) button

simultaneously until the parking lights flash once. This is

Menu 1.

b. The (lock/unlock) button, and the (query) button

simultaneously until the parking lights flash once. This is

Menu 2.

2. Tap the (trunk) button 3 times, waiting for a parking light flash

between each time.

3. The parking lights will flash three times, signaling that all of the

options have been reset, and that you have exited programming mode.

1-Way 4 Button Remotes

With separate lock and unlock buttons.

1. Enter programming by pressing:

a. The (lock) button, and the (unlock) button simultaneously

until the parking lights flash once. This is Menu 1.

b. The (lock) button, and the (start/stop) button simultaneously

until the parking lights flash once. This is Menu 2.

2. Tap the (start/stop) button 3 times, waiting for a parking light flash

between each time.

3. The parking lights will flash three times, signaling that all of the

options have been reset, and that you have exited programming mode.

R500A (CM1000A)

1. Enter programming by pressing the (trunk) button, and the (siren)

button simultaneously until the parking lights flash once.

2. Tap the (trunk) button three times, waiting for a parking light flash

between each time.

3. The parking lights will flash three times, signaling that all of the

options have been reset, and that you have exited programming mode.

- 49 -

Page 50

1WFM6R

1. Enter programming by pressing:

a. The (trunk) button, and the (start) button simultaneously until

the parking lights flash once. This is Menu 1.

b. The (trunk) button, and the (stop) button simultaneously until

the parking lights flash once. This is Menu 2 .

2. Press the (start) button until the parking lights flash, do this 3 times.

3. The parking lights will flash three times, signaling that all of the

options have been reset, and that you have exited programming mode.

All 2-Way Remotes

1. Enter programming by pressing:

a. Button ( I ), and button ( II ) simultaneously until the parking

lights flash once. This is Menu 1.

b. Button ( I ), and button ( IV ) simultaneously until the

parking lights flash once. This is Menu 2.

2. Tap button ( III ) 3 times, waiting for a parking light flash between

each time.

3. The parking lights will flash three times, signaling that all of the

options have been reset, and that you have exited programming mode.

- 50 -

Page 51

CM3000

Option Menu 1

Feature Option 1 Option 2 Option 3 Option 4

Unlock Before, Start, Lock After

1-1

1-2 Door lock / Unlock Pulse Duration 0.8 sec 2.5 sec

1-3 Crank Time w/ Alternator Sensing 0.8 sec 1.0 sec

1-4 Driver's Priority Unlock OFF ON

1-5 Double Pulse Unlock OFF ON

1-6 Dome Light Factory Rearm OFF ON

1-7 Turbo Mode OFF ON

1-8 Diesel Timer * Glow Plug Wire 18 Sec

1-9 Delayed Door Trigger for Locking OFF 90 Sec Delay

1-11 Valet option for R.P.S. Sensor ON OFF

Start

Option Menu 2

Feature Option 1 Option 2 Option 3 Option 4

OFF ON

2-1

2-2

2-3

2-4 Anti - Jacking OFF ON

2-5 Ignition Controlled Door Locks OFF ON

2-6 Aux 1 Output 0.5 Sec Latch

2-7 Aux 2 Output 0.5 Sec Latch

2-8 Siren Duration 30 Sec 60 Sec

2-9 Channel Expander * OFF ON

2-10

* Denotes Options That Can Only Be Programmed With The Option Programmer V.2

** International Models Only

Cold Start w/ Optional Temp.

Sensor

Timer Start or Minimum Interval

Between Cold Starts

Lock Behavior During Passive

Arming

Passive Arming With Channel

Expander *

OFF ON

3 Hours 1.5 Hours

Passive Locking

OFF ON

Passive Locking

Off

Auto Anti-Jacking** /

No Auto Lock

- 51 -

Auto Anti-Jacking** /

With Auto Lock

Page 52

CM3300

Option Menu 1

Feature Option 1 Option 2 Option 3 Option 4

Unlock Before, Start, Lock After

1-1

1-2 Door lock / Unlock Pulse Duration 0.8 sec 2.5 sec

1-3 Crank Time w/ Alternator Sensing N/A N/A

1-4 Driver's Priority Unlock OFF ON

1-5 Double Pulse Unlock OFF ON

1-6 Dome Light Factory Rearm OFF ON

2-1

2-2

2-3

2-4 Anti - Jacking OFF ON

Cold Start w/ Optional Temp.

Timer Start or Minimum Interval

Lock Behavior During Passive

Start

Option Menu 2

Feature Option 1 Option 2 Option 3 Option 4

Sensor

Between Cold Starts

Arming

N/A N/A

N/A N/A

N/A N/A

Passive Locking

Passive Locking

Off

Auto Anti-Jacking** /

No Auto Lock

Auto Anti-Jacking** /

With Auto Lock

2-5 Ignition Controlled Door Locks OFF ON

2-6 Aux 1 Output 0.5 Sec Latch

2-7 Aux 2 Output 0.5 Sec Latch

2-8 Siren Duration 30 Sec 60 Sec

2-9 Channel Expander * OFF ON

2-10

* Denotes Options That Can Only Be Programmed With The Option Programmer V.2

** International Models Only

Passive Arming With Channel

Expander *

OFF ON

- 52 -

Page 53

CM4200

Option Menu 1

Feature Factory Default Optional

1-1 Unlock Before, Start, Lock After Start OFF ON

1-2 Door lock / Unlock Pulse Duration 0.8 sec 2.5 sec

1-3 Crank Time w/ Alternator Sensing 0.8 sec 1.0 sec

1-4 Driver's Priority Unlock OFF ON

1-5 Double Pulse Unlock OFF ON

1-6 Dome Light Factory Rearm N/A N/A

1-7 Turbo Mode OFF ON

1-8 Diesel Timer * Glow Plug Wire 18 Sec

1-9 Short Pulse Lock / Unlock OFF 0.125 Sec

1-10 Starter Kill Relay Anti-Grind Only Anti Grind + Starter Kill

1-11 Manual Transmission Auto Lock Lock After Reservation

Does Not Lock After

Reservation

1-12 Delayed Door Trigger for Locking OFF 90 Sec Delay

1-13 Factory Style Alarm OFF ON

1-14

2-1 Cold Start w/ Optional Temp. Sensor OFF ON

2-2 Timer Start or Minimum Interval Between Cold Starts 3 Hours 1.5 Hours

2-3 Lock Behavior During Passive Arming Passive Locking Passive Locking Off

2-4 Anti - Jacking N/A N/A

2-5 Ignition Controlled Door Locks OFF ON

* Denotes Options That Can Only Be Programmed With The Option Programmer V.2

Double Pulse Start Input for Use as Slave Unit With OEM

Remotes

Option Menu 2

Feature Factory Default Optional

OFF ON

- 53 -

Page 54

CM1000A

Option Menu 1

Feature Factory Default Optional

1

2

3

4

5

Lock/Unlock Pulse Duration 0.8 sec 4 sec

Application of Pre-Wired Kill Relay Starter Kill Anti-Jacking (Ign Kill)

Door Open Parking Light Indicator Disabled Enabled

30 sec Passive Relock Disabled Enabled

Double Pulse Unlock Disabled Enabled

These option descriptions are for the CM1000A ONLY. They differ from the regular

option menus so much that they need their own section. The full listing of option menu

descriptions immediately follows this page.

1. Lock / Unlock Pulse Duration

This option determines the output duration of the lock and unlock pulses Some Vehicles

do not respond to short lock/unlock pulses.

2. Application of Pre-Wired Kill Relay

This option requires that the starter kill relay be installed in the ignition circuit, rather than

into the starter circuit. With this option turned on, Panic mode will become Anti-Jacking

mode. If Anti-Jacking is activated while the vehicle is running with the key in the ignition,

the siren will sound for 30 seconds. After 30 seconds the system will break the ignition

circuit, thereby disabling the vehicle. The siren will continue to play for 1 more minute.

With this option turned off, when Panic mode is activated, the system will arm, activate

the starter kill, and play the siren for 1.5 minutes.

3. Door Open Parking Light Indicator

With this option enabled, the parking lights will flash if a door is left open while the vehicle

is being armed. This serves as a warning that all of the doors have not been closed.

4. 30 sec Passive Relock

With this option enabled, after disarming the system with the remote, the system will

relock the doors and arm the alarm after 30 seconds if a door has not been opened. At

10 and 20 seconds after the disarm command was given, the siren will chirp once to

indicate that the alarm is about to rearm. At 30 seconds after, the siren will chirp once,

and the system will arm the alarm. If you wish to stop this process, you must open a door

within 30 seconds of disarming the alarm.

5. Double Pulse Unlock

With this option enabled, the unlock wire will perform a double pulse every time the

unlock command is given. Some vehicles require this double pulse to operate the locks

correctly.

- 54 -

Page 55

Options Explained In Detail CM3000-3300-4200

1-1 – Unlock Before, Lock After Starting. Lock After Remote Start.

If enabled, this option will make the system unlock the doors before remote

starting, start the vehicle, then lock the doors after the vehicle starts. It will then

lock the doors again if the remote start run time expires and the vehicle shuts

down. This feature is for vehicles that have factory alarms that need to be

disarmed before remote starting.

1-2 – Door Lock/Unlock Pulse Duration.

This option determines the output duration of the door lock and unlock pulses.

Some vehicles do not respond to short door lock/unlock pulses.

1-3 – Minimum Crank Time When Using Alternator Sensing

This option determines the minimum amount of crank time used when the system

is operating in Alternator Sensing mode. The CompuStar system automatically

increases its crank time if it fails to start during either the first or second attempts.

This is how the CompuStar system will crank under the following conditions:

Option Setting 1st Start Attempt 2nd Start Attempt 3rd Start Attempt

Option 1-3, Factory Setting 0.8 sec 0.9 sec 1.0 sec

Option 1-3, Optional Setting 1.0 sec 1.1 sec 1.2 sec

1-4 – Driver’s Door Priority Unlock

If enabled, this option will cause the system to unlock the driver’s door first, and

if the unlock button is pressed again within 3 seconds, the other doors will unlock.

This option requires additional installation to function; you must isolate the

driver’s door from the rest of the doors.

1-5 – Double Pulse Unlock

If enabled, this option will cause the system to double pulse the unlock output.

This option is used on a majority of Chrysler vehicles. The first unlock pulse

disarms the alarm, and the second pulse unlocks the doors.

1-6 – Dome Light Factory Rearm

If enabled, this option will cause the system to send a pulse to the vehicle through

the dome light wire if:

a. The run time has expired and the vehicle shuts down.

b. The vehicle is shut down manually through the remote.

c. The system is locked and/or armed.

This option can be used to shut down the radio in vehicles where the radio stays

on until the door opens after the ignition has been on. The system will also send

- 55 -

Page 56

the lock and rearm pulses to the vehicle while the dome light output is active. This

will simulate the door being opened and the lock button being pressed, therefore

arming the factory alarm.

1-7 – Turbo Mode

If enabled, this option will allow the system to be put in Turbo mode through the

remote. In Turbo mode, the system will keep the vehicle running until two

minutes after the ignition has been turned to the OFF position, if the emergency

brake wire has been grounded. This feature is useful for vehicles with

turbochargers because it allows the turbo too slowly cool before shutting off the

engine. To use Turbo mode, you must turn on option 1-7, enable Turbo mode on

the remote, and set the emergency brake.

1-8 – Diesel Timer Mode

With this option on the default setting, the CompuStar system will remote start

normally unless it senses input on either the ( + ) or ( - ) glow-plug input wires. If

it senses input on either one of these wires, it will delay the start until the input

goes away. With this option on the optional setting, the system will turn on the

ignition wires then wait 18 seconds before starting. This 18 second delay is

adjustable between 3 and 99 seconds, but only with the CM3 Series Option

Programmer.

1-9 – CM3000:

Delayed Door Trigger for Locking

With this option turned on, the system will ignore the door trigger for 90 seconds

after the lock command has been issued. This will prevent the “door open”

indication on 2-way remotes. If the door is still seen as open after 90 seconds, the

remote will be paged to indicate that the door is still open.

CM4200

Short Pulse Lock/Unlock

With this option enabled, the output duration of the door lock will be reduced

from 0.8 seconds to 0.125 seconds.

1-10 – Starter Kill Relay

With this option on the default setting, the starter kill relay will act as an antigrind circuit only, and will not disable the starter when the system is locked. In

the optional setting, the starter kill relay will act as an anti-grind and starter kill

circuit.

1-11 – CM3000

Valet Option for RPS Sensor

With this option turned off, the RPS sensor will not be activated.

(Continued…)

- 56 -

Page 57

CM4200

Manual Transmission Auto-Lock

With this option on the default setting, the doors will lock right after reservation

mode is set. On the optional setting, the doors will have to be locked with the

remote after reservation mode has been set.

1-12 – CM4200:

Delayed Door Trigger for Locking

With this option turned on, the system will ignore the door trigger for 90 seconds

after the lock command has been issued. This will prevent the “door open”

indication on 2-way remotes. If the door is still seen as open after 90 seconds, the

remote will be paged to indicate that the door is still open.

1-13 – CM4200:

Factory Style Alarm

With this option turned on, the 4200 starter only system will function as a factory

style alarm by monitoring the door trigger and sounding the horn and flashing the

parking lights if the door is opened after the doors have been locked.

1-14 – CM4200:

Double Pulse Start Input

With this option turned on, the ground trigger start input of the temp sensor will

require 2 pulses to initiate the start sequence. This will allow you to install the

system as a slave start unit by tying the start input to the lock wire in the vehicle.

Make sure it is a ground pulse, or flip the polarity with a relay.

2-1 – Cold Start with Temperature Sensor

To use this option, an optional temperature sensor must be installed. With this

option turned on, the system will check the status of the temperature sensor every

1.5 to 3.0 hours, depending on the setting of option 2-2. If the temperature of the

sensor is below the specified start temperature, the system will remote start.

2-2 – Timer Start, or Minimum Interval Between Cold Starts.

This option regulates the start intervals in Cold Start and Timer Start modes. On

the default setting, if Timer mode is activated, the system will remote start every 3

hours. If the optional temperature sensor is installed, and option 2-2 is turned on,

the system will check the status of the temperature sensor every 3 hours. On the

optional setting, if Timer mode is activated, the system will remote start every 1.5

hours. If the optional temperature sensor is installed, and option 2-2 is turned on,

the system will check the status of the temperature sensor every 1.5 hours.

2-3 – Lock Behavior During Passive Arming

With this option on the default setting, the doors will lock once Passive Arming

mode has armed the alarm. With this option on the optional setting, the doors will

remain unlocked even if the system passively arms.

- 57 -

Page 58

2-4 – Anti Jacking

This option requires the starter kill relay to be installed in the ignition circuit

rather than into the starter circuit. With this option set to Option 2, Panic Mode

becomes Anti-Jacking Mode. If Anti-Jacking is activated while the vehicle is

running with the key in the ignition, the siren will sound for 30 seconds then the

system will disconnect the ignition, thereby disabling the vehicle. The siren will

continue to sound for 1 more minute. With this option turned off, when Panic

Mode is activated, the system will arm, activate starter kill, and sound the siren

for 1.5 minutes.

** International models only, with this option set to Option 3, the ignition kill and