FireplaceXtrordinair 2000 36 DV XL Owner's Manual

TM

Tested and Listed by

• Built-In Direct Vent Fireplace

• Natural Gas or Propane

• Residential or Mobile Home

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this manual. For assistance or additional

information consult a qualified installer, service agency, or the gas supplier.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

- Inst allation mus t be perf or m ed by a qualified installer, s er v ic e agenc y or the gas supplier

IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Omni-Test Laboratories, Inc.

Beaver ton, Oregon

R eport # 028- S-20-1

ANSI Z 21.88, CSA 2. 33 MR 8,

CAN/ CGA 2.17-M 91

2000 36 DV XL Owner’s Manual

- September, 2000 -

Installer: After installation give this manual to the home-

owner and explain operation of this fireplace.

$10.00 Copyright 2000, T.I. Part # 93508118

10850 117th Place N.E. Kirkland, WA 98033

2 Safety Precautions

• IF YOU SMELL GAS:

* Do not light any appliance

* Extinguish any open flame

* Do not touch any electrical switch or plug or unplug anything

* Open windows and vacate building

* Call gas supplier from neighbor's house, if not reached, call fire

department

• This unit must be installed by a qualified installer to prevent the possibility of an

explosion. Your dealer will know the requirements in your area and can inform you of

those people considered qualified. The room heater should be inspected before use

and at least annually by a qualified service person. More frequent cleaning may be

required due to excessive lint from carpeting, bedding material, etc.

• The instructions in this manual must be strictly adhered to. Do not use makeshift

methods or compromise in the installation. Improper installation will void the warranty

and safety listing.

Ok

Look for this label:

For LPG only | Pout 11” W.C.

If the label is present, the

heater is equipped for LP

(propane). If the label is

absent, the heater is equipped

for NG (natural gas).

• Contact your local building

officials to obtain a permit

and information on any

installation restrictions or

inspection requirements in

your area. Notify your

insurance company of this

heater as well.

• It is imperative that control

compartments, screens, or

circulating air passageways

of the heater be kept clean

and free of obstructions.

These areas provide the air

necessary for safe

operation.

• This heater is either approved for natural

gas (NG) or for propane (LP). Burning the

incorrect fuel will void the warranty and

safety listing and may cause an extreme

safety hazard. Direct questions about the

type of fuel used to your dealer. Check

the label and flame adjust knob on the

gas control valve.

• If the flame becomes sooty,

dark orange in color, or

extremely tall, do not

operate the heater. Call

your dealer and arrange for

proper servicing.

• Do not operate the heater if

it is not operating properly in

any fashion or if you are

uncertain. Call your dealer

for a full explanation of your

?

heater and what to expect.

• Do not store or use gasoline

or other flammable liquids in

the vicinity of this heater.

Gas

Travis Industries 93508118 270900

• Do not operate if any portion

of the heater was

submerged in water or if any

corrosion occurs.

Safety Precautions 3

• Do not place clothing or

other flammable items on or

near the heater. Because

this heater can be controlled

by a thermostat there is a

possibility of the heater

turning on and igniting any

items placed on or near it.

• The viewing glass should be

opened only for lighting the

pilot or conducting service.

• Any safety screen or guard

removed for servicing must

be replaced prior to

operating the heater.

• Operate the heater

according to the instructions

included in this manual.

• If the main burners do not

start correctly turn the gas

off at the gas control valve

and call your dealer for

service.

• Light the heater using the

built-in piezo igniter. Do not

use matches or any other

external device to light your

heater.

• Never remove, replace,

modify or substitute any part

of the heater unless

instructions are given in this

manual. All other work must

be done by a trained

technician. Don't modify or

replace orifices.

• Allow the heater to cool

before carrying out any

maintenance or cleaning.

• The pilot flame must contact

the thermopile and

thermocouple (see the

illustration to the left). If it

does not, turn the gas

control valve to "OFF" and

call your dealer.

• This unit is not for use with

solid fuel

• Do not place anything inside

the firebox (except the

included fiber logs).

• If the fiber logs become

damaged, replace with

Travis Industries log set.

• Do not touch the hot

surfaces of the heater.

Educate all children of the

danger of a hightemperature heater. Young

children should be

supervised when they are in

the same room as the

heater.

• Instruct everyone in the

house how to shut gas off to

the appliance and at the gas

main shutoff valve. The gas

main shutoff valve is usually

next to the gas meter or

propane tank and requires a

wrench to shut off.

This

Manual

36"

• Do not throw this manual

away. This manual has

important operating and

maintenance instructions

that you will need at a later

time. Always follow the

instructions in this manual.

• Keep all furniture or other

combustible items at least

36" away from the front of

the fireplace (this includes

drapes or doors that may

swing within 36" of the front

of the fireplace).

• Travis Industries, Inc.

grants no warranty,

implied or stated, for

the installation or

maintenance of your

heater, and assumes

no responsibility of any

consequential

damage(s).

Travis Industries 93508118 270900

4 Table of Contents

Introduction

Introduction & Important Information................1

Safety Precautions

Safety Precautions ......................................2

Features & Specifications

Features ....................................................5

Installation Options ......................................5

Heating Specifications ..................................5

Dimensions.................................................5

Installation

Installation Warning......................................6

Packing List................................................6

Additional Items Required for Installation..........6

Installation Overview ....................................6

Fireplace Placement Requirements..................7

Minimum Framing Dimensions ....................7

Clearances ............................................7

Corner Installations.................................8

Raised Fireplaces....................................8

Hearth Requirements....................................9

Facing Requirements....................................10

Facing Over 1" Thick.....................................10

Facing Detail...............................................11

Face Dimensions .........................................12

Rectangular Faces.......................................12

Facing and Hearth Examples..........................13

Mantel Requirements....................................15

Vent Requirements.......................................16

Altitude Considerations ............................16

Clearances ............................................16

Use of 8” Dia. Pipe...................................16

Part Numbers for 6-5/8" Dia. Pipe................16

Vent Installation......................................17

Approved Vent Configurations........................18

Restrictor Position...................................18

Elbows ..................................................18

Measuring Vent Lengths...........................18

Vertical Term. 0,2 or 4 45° Offsets (6-5/8")....19

Hor. Terminations with 6-5/8" Dia. Vent ........20

Vert. Term. with 2 or 3 Elbows (6-5/8" Dia.)....21

Horizontal Terminations with 8” Dia. Vent......22

Vent Termination Requirements ......................23

Gas Line Requirements.................................24

Fuel......................................................24

Gas Line Connection................................24

Gas Inlet Pressure ..................................24

Electrical Connection....................................25

Finalizing the Installation

1 Glass Removal (& installation)......................26

2 Log & Coal Installation................................27

3 Replace the Glass .....................................30

4 Faceplate Installation .................................30

5 Leak Test.................................................30

6 Pilot Adjustment (if necessary).....................30

7 Air Shutter Adjustment (if necessary)............31

8 Check Flame.............................................31

9 Explain Operation to Home-Owner.................31

Operation

Before You Begin.........................................32

Location of Controls .....................................32

Starting The Pilot .........................................33

Starting the Fireplace for the First Time.............34

Turning the Fireplace On and Off.....................34

Adjusting the Flame Height.............................34

Adjusting the Blower Speed............................35

Normal Operating Sounds..............................35

Maintenance

Yearly Service Procedure ..............................36

Troubleshooting Table...................................37

How this Fireplace Works...............................38

What Turns the Main Burners On and Off......38

What Prevents Gas Buildup.......................38

Wiring Diagram ............................................39

Replacement Parts List .................................39

Safety Label

Safety (Listing) Label....................................40

Warranty

Warranty ....................................................41

Optional Equipment

LP Conversion Kit ........................................42

Power Heat Duct..........................................46

Thermostat.................................................52

Remote Control Thermostat............................53

Decorative Refractories (Classic & Brick) .........53

Index

Index.........................................................54

Travis Industries 93508118 270900

Features and Specifications 5

l

n

r

Features:

- Works During Power Outages (millivolt system)

- High Efficiency

- Optional Thermostat or Remote Control

- Realistic "Wood Fire" Look

- Quiet Blower for Effective Heat Distribution

- Convenient Operating Controls

- Variable-Rate Heat Output

Installation Options:

- Residential or Mobile Home

- Straight or Corner Placement

- Flush or Recessed Face

- Raised or Floor Hearth

- Internal or External Chase

- Horizontal or Vertical Vent

- Power Heat Duct

- Low Maintenance

Heating Specifications:

Natural Gas Propane

Approximate Heating Capacity (in square feet)* 1,200 - 2,250 1200 - 2,250

Maximum BTU Input Per Hour 43,000 43,000

Minimum BTU Output on Low (with blowers on) 23,384 20,800

Efficiency** (with blowers on) Up to 79% Up to 80%

AFUE (Annual Fuel Utilization Efficiency) 72 % 73 %

* Heating capacity will vary with floor plan, insulation, use of Power Heat Duct, and outside temperature.

** Efficiency rating is a product thermal efficiency rating determined under continuous operation

independent of installed system.

Dimensions:

Weight: 250 Lbs.

3-1/4"

Power

Heat Vent

Hook-Up

Vent has an

external diameter

of 6-5/8"

25-3/4"*

7-7/8"

7-7/8"*

6-1/4"

connection is made i

the lower right rea

6-3/4"

The electrica

corner.

3-3/4"

1-7/8"

6-1/4"

21-1/2"

23"

26-3/4"

1"

1"

Gas Inlet (on both sides)

35-1/4"

43"*

* Includes the

1/2" stand-offs

1/2" Stand-offs

Nail Down

Plate (used

to secure

the fireplace

to the floor)

40"

19-5/8"*

6-5/8"

Travis Industries 93508118 270900

6 Installation (for qualified installers only)

Installation Warnings:

! Failure to follow all of the requirements may result in property damage, bodily

injury, or even death.

! This heater must be installed by a qualified installer who has gone through a

training program for the installation of direct vent gas appliances.

! This appliance must be installed in accordance with all local codes, if any; if not, in

U.S.A. follow ANSI Z223.1 and NFPA 54(88), in Canada follow B-149.

! In Manufactured or Mobile Homes must confirm with: In USA, Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280; In Canada, CSA Z240.4

and Gas-Equipped Recreational Vehicles and Mobile Housing. This appliance may

be installed in Manufactured Housing only after the home is site located.

! The 36DV is designed to operate on natural gas, or propane (LP).

All exhaust gases must be vented outside the structure of the living-area.

Combustion air is drawn from outside the living-area structure.

! Notify your insurance company before hooking up this fireplace.

! The requirements listed below are divided into sections. All requirements must be

met simultaneously. The order of installation is not rigid – the qualified installer

should follow the procedure best suited for the installation.

Packing List

• Propane Conversion Kit

• Log Set (Log Set & Coals)

• Electrical Connector (3 wires - female molex)

• Flex Tube with Pipe Adapter

• Glass Latch Tool (to un-latch glass frame)

• Arch Covers (for arched faces only)

Installation Overview

See "Power Heat

Vent" in the optional

equipment section.

4-1/2" Min.

Drywall

Additional Items Required

• Faceplate (gold or black) - Includes attachment screws

• Direct Vent (Simpson Dura-Vent Ph. # 800 835-4429)

• Gas Line Equipment (shutoff valve, pipe, etc.)

• Electrical Equipment (min. 18 gauge, grounded line)

See the section

"Vent Requirements"

See the section

"Horizontal Termination

Requirements"

See the

section

"Acceptable

Vent Lengths"

Non-combustible facing

(see the section "Facing

Requirements")

See the section

"Mantel Requirements"

See the section

"Hearth Requirements"

Travis Industries 93508118 270900

See the section "Fireplace

Placement Requirements"

Nail

Down

Plate

See the section

"Gas Line Installation"

Insulation must not fill

the spaces between

the stand-offs

See the section

"Electrical

Connection"

See the section "Minimum

Framing Dimensions"

Installation (for qualified installers only) 7

Fireplace Placement Requirements

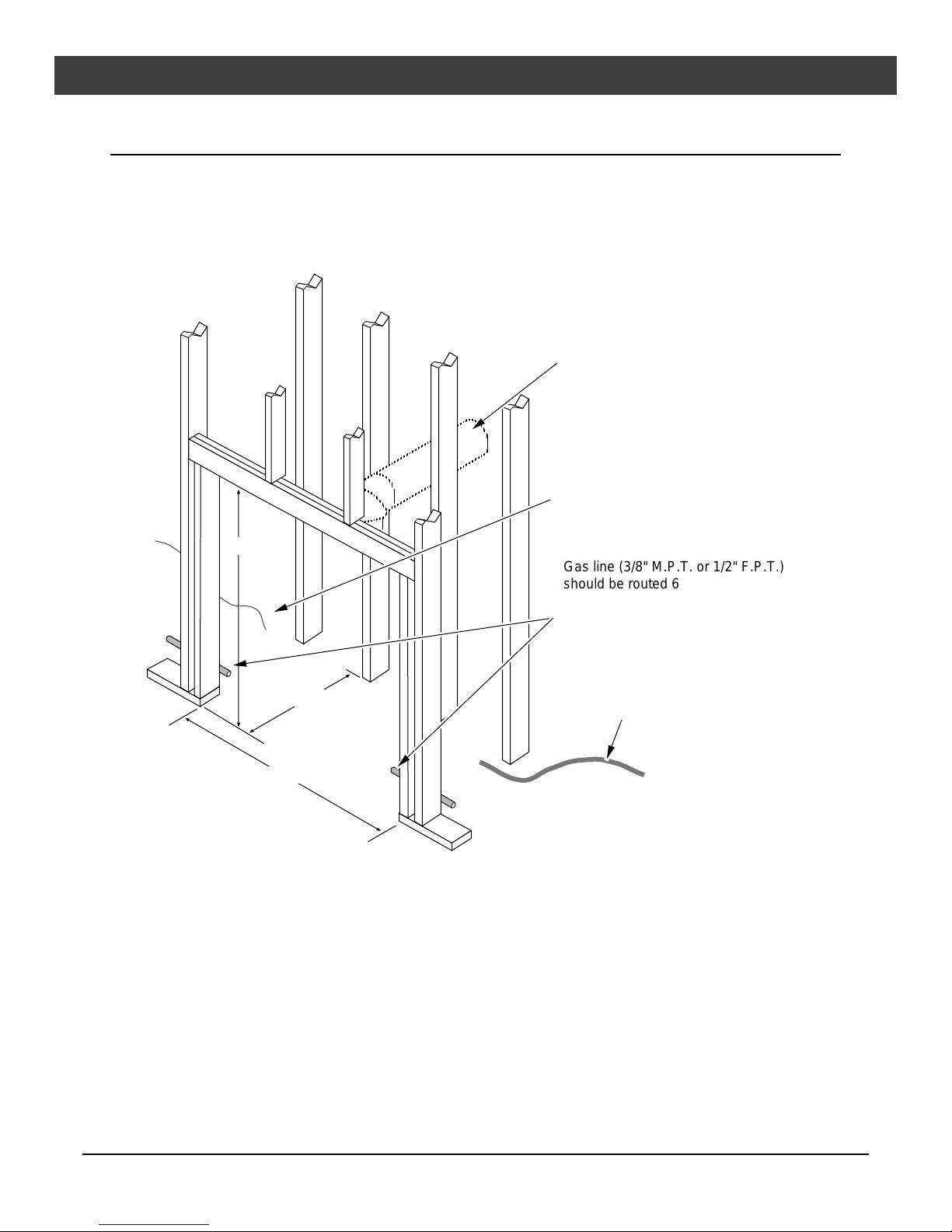

Minimum Framing Dimensions

The 1/2" stand-offs on the back and sides and 6-1/4" stand-offs on the top of the fireplace are

designed to separate the fireplace from the framing members. These stand-offs may contact the

framing members but no material may be placed between the stand-offs.

NOTE: if venting directly to the rear,

make sure there is a min. 8-5/8" space

centered behind the fireplace for the

wall thimble. If a 90° elbow is used

directly off of the fireplace, the thimble

will be centered 51-1/4" above the

base of the fireplace.

If using a remote control or

thermostat, route the wire to a

location near the gas line (include

an extra 3' length for hookup).

46-1/2"

Gas line (3/8" M.P.T. or 1/2" F.P.T.)

should be routed 6-5/8" behind the

framing opening and 1-7/8" above

the base of the fireplace (see "Gas

Line Connection" for details).

19-5/8"

43-1/4"

Route the electrical line to a position

at the right rear of the fireplace.

NOTE: If using the power heat vent,

allow for the duct passage when

framing the enclosure.

• Fireplace must be installed on a level surface capable of supporting the fireplace and vent

• Fireplace must be placed directly on wood or non-combustible surface (not on linoleum or carpet)

• Due to the high temperature of the fireplace, it should be located out of traffic and away from furniture

and draperies.

• This heater may be placed in a bedroom. Please be aware of the large amount of heat this appliance

produces when determining a location.

Clearances

• When installed, walls in front of the fireplace must be a minimum 4-1/2" to the side of the faceplate.

• Fireplace must be placed so that no combustibles are within, or can swing within 36" of the front of the

fireplace (e.g. drapes, doors)

• Fireplace must be placed so the vents below and above the glass do not become blocked

Travis Industries 93508118 270900

8 Installation (for qualified installers only)

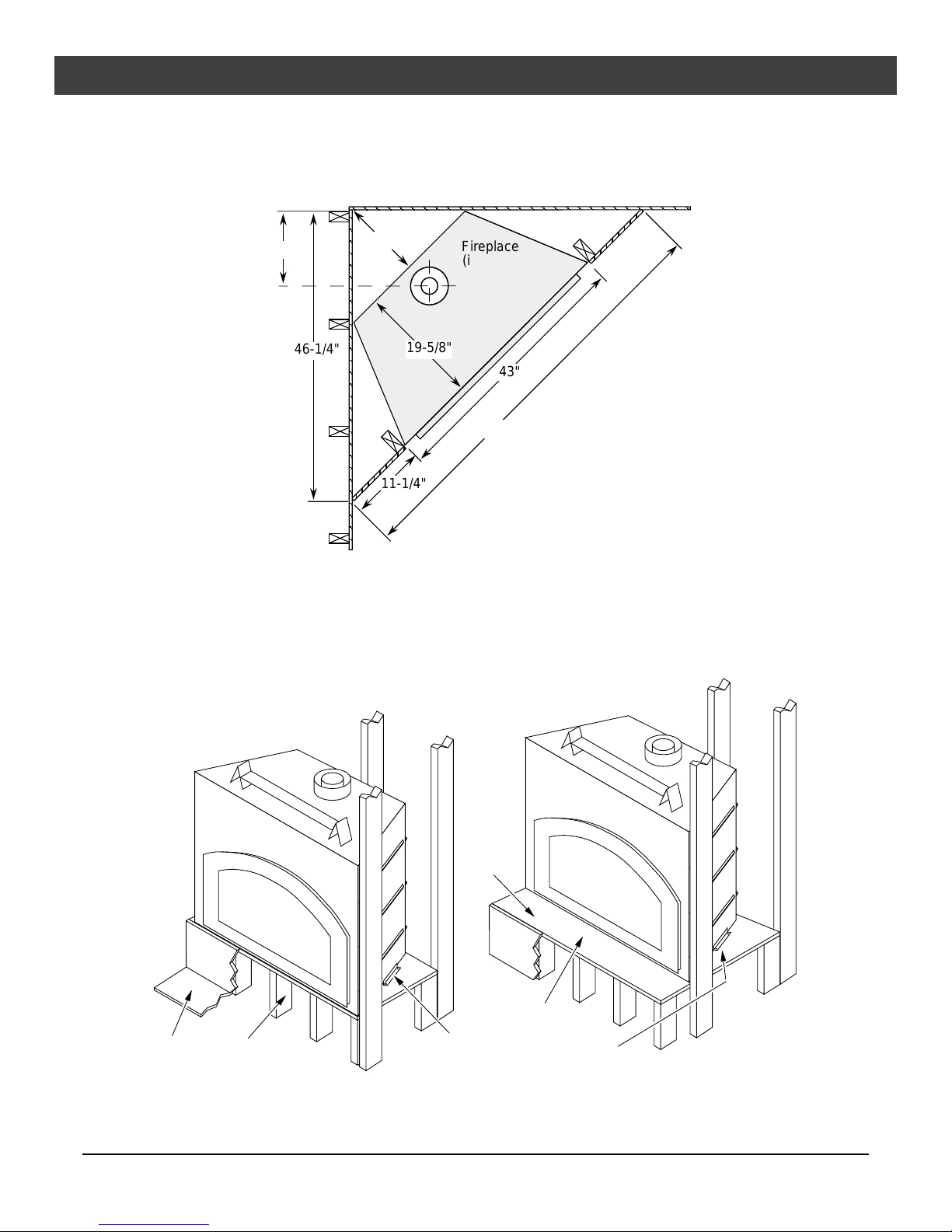

Corner Installations

A typical 45° installation uses the minimum framing dimensions shown in the illustration below (NOTE:

all clearances still apply).

14-1/2"

46-1/4"

12-3/4"

19-5/8"

11-1/4"

Fireplace

(includes

1/2"

standoffs)

43"

65-1/2"

Raised Fireplaces

• The fireplace (and hearth, if desired) may be placed on a platform designed to support the fireplace

(250 Lbs.) and vent.

• The fireplace may not be raised so as to place the ceiling within 24" of the top of the faceplate.

Raised fireplace

Hearth

Raised

Platform

Raised fireplace with

raised hearth.

Raised

Platform

Raised Hearth

Nail the nail down plates to the floor

(or raised platform)

Travis Industries 93508118 270900

Installation (for qualified installers only) 9

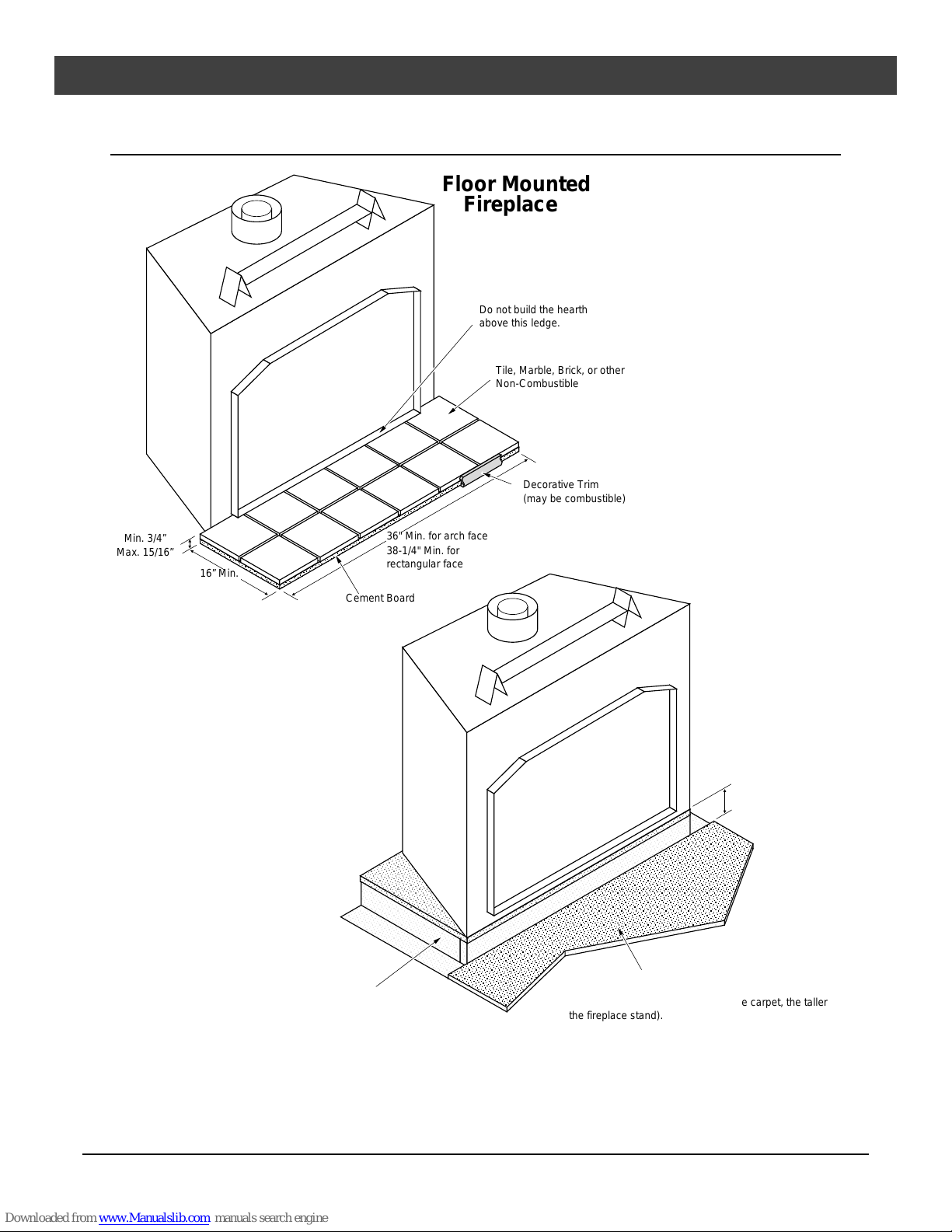

Hearth Requirements

Floor Mounted

Fireplaces

Do not build the hearth

above this ledge.

Tile, Marble, Brick, or other

Non-Combustible

Decorative Trim

(may be combustible)

Min. 3/4”

Max. 15/16”

16” Min.

Cement Board

Raised

Fireplaces

Fireplace Stand

36" Min. for arch face

38-1/4" Min. for

rectangular face

When raised a minimum of

3” off of the floor surface,

no hearth is required.

Make sure to accomodate the floor covering (carpet,

linoleum, flooring, etc.) when determining the height of

the fireplace stand (i.e. the thicker the carpet, the taller

the fireplace stand).

Travis Industries 93508118 270900

10 Installation (for qualified installers only)

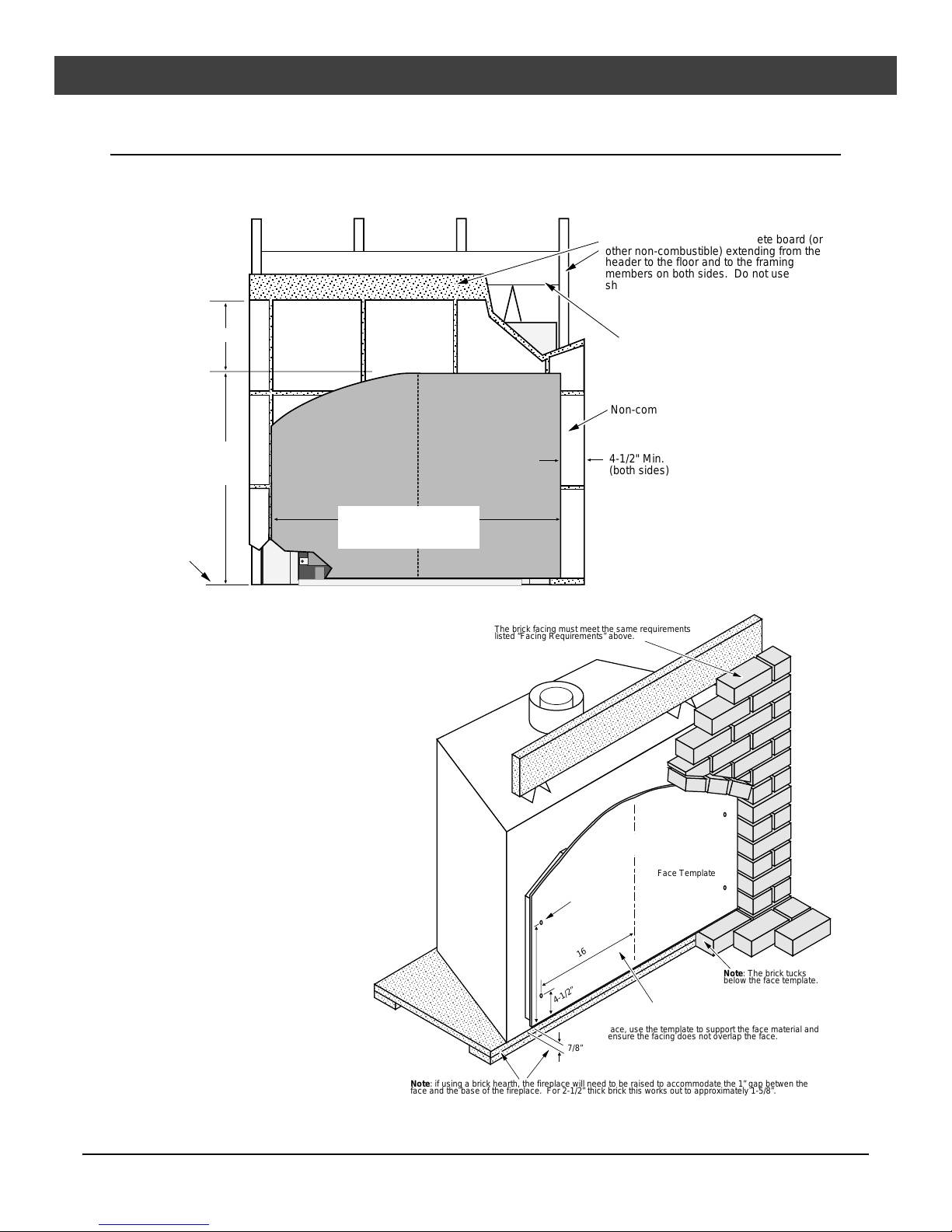

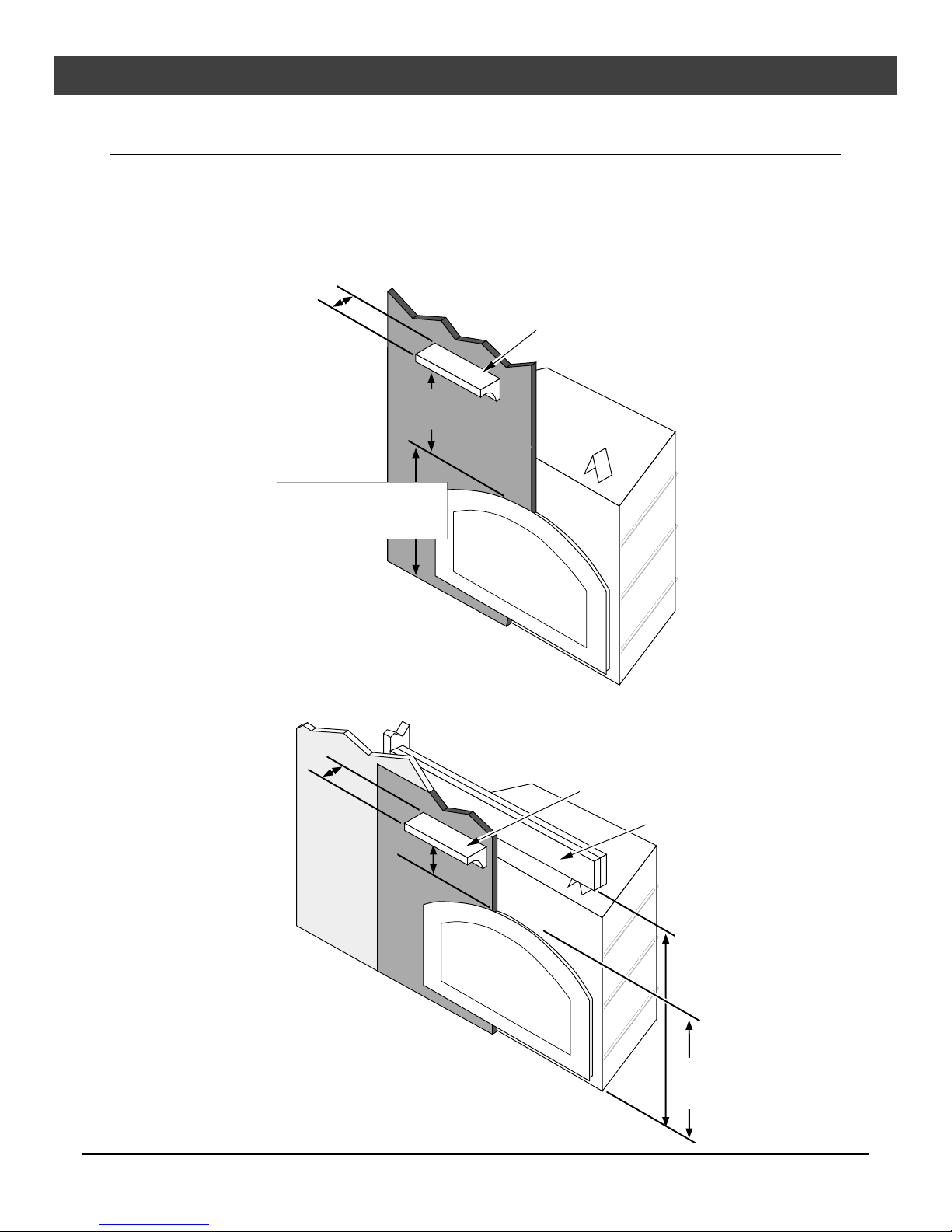

Facing Requirements

NOTE: The combustible area above the facing must not protrude more than 3/4" from the facing. If it

does, it is considered a mantel and must meet the mantel requirements listed in this manual.

The fireplace requires a concrete board (or

other non-combustible) extending from the

header to the floor and to the framing

members on both sides. Do not use

sheetrock, plywood or other combustible.

10" Min.

28-1/2" Rectangular face

30-3/8" Architectural face

30" Arch face

Base of

Fireplace

Facing Over 1"

Thick

• Architectural faces

require a 5/8" gap

above the face for face

installation.

• If the facing material is

over 1" thick (e.g. brick,

river rock), install the

facing around the

perimeter of the face.

You may wish to make a

face template (see the

illustration to the right).

If using an arch face,

you may wish to order

the optional set-up

face:

Arch Set-Up Face

Part # 98500692

• For rectangular faces,

use a piece of plywood

cut to the dimensions

shown on page 12

(add 1/8" to each

dimension).

Arch Face

36" Arch face

38" Rectangular face

36-1/4" Architectural face

Header

Rectangular Face

The brick facing must meet the same requirements

listed “Facing Requirements” above.

Mounting

Holes

19-3/4”

4-1/2”

Note: if using a brick hearth, the fireplace will need to be raised to accommodate the 1” gap betwen the

face and the base of the fireplace. For 2-1/2” thick brick this works out to approximately 1-5/8”.

Non-combustible Facing

4-1/2" Min.

(both sides)

Center

Line

Face Template

16-3/8”

Note: The brick tucks

below the face template.

The face template should be 1/8” larger than the

finished face. Attach the template to the fireplace using

the face attachment screws. Then while building the

face, use the template to support the face material and

ensure the facing does not overlap the face.

7/8”

Travis Industries 93508118 270900

Installation (for qualified installers only) 11

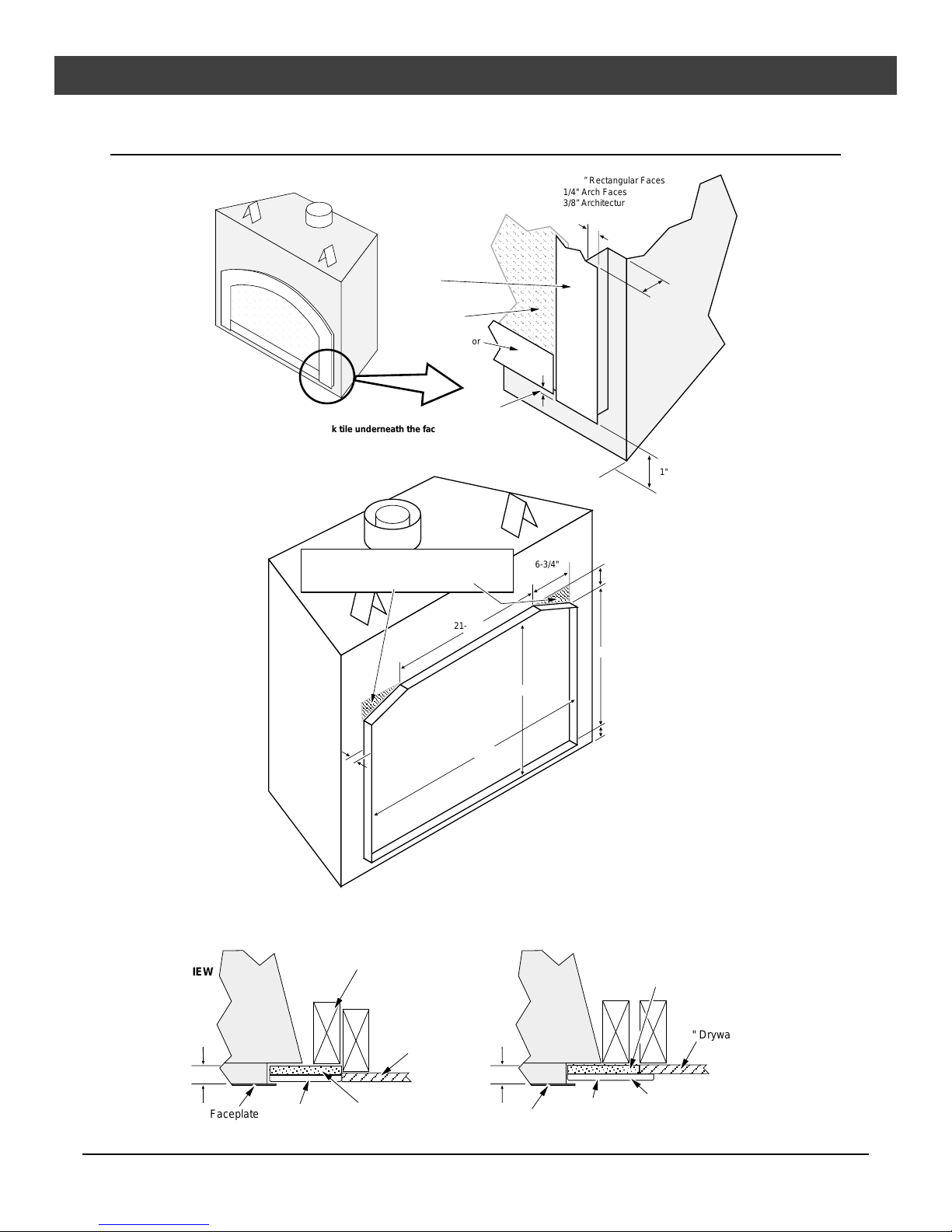

Facing Detail

NOTE:

The overlap is 1-1/2" along

the top of the face.

Face

Glass

Access Door

Air Space

Do not tuck tile underneath the face on the bottom (there

will be a 1/2" air space below the access door). You may

do this on the sides and top, but not on the bottom.

Make sure these shaded areas are faced over

when using the arched face. Rectangular faces

do not require this area to be faced.

21-1/2"

1-3/8” Rectangular Faces

1/4" Arch Faces

3/8” Architectural Faces

1/2"

6-3/4"

1"

1"

3-3/4"

23"

26-3/4"

1"

1"

35-1/4"

• To achieve a facing that is flush with the drywall to the side of the fireplace, recess the framing directly

next to the fireplace. See the illustration below.

TOP

VIEW

1"

Fireplace

Faceplate

3/8" Tile

This 2x4 is recessed 3/8"

to make a flush facing

1/2" Drywall

1/2" Concrete Board

1/2" Concrete Board

Fireplace

1/2" Drywall

1"

3/8" Tile

The tile overlaps the drywall

for an overlap facingFaceplate

Travis Industries 93508118 270900

12 Installation (for qualified installers only)

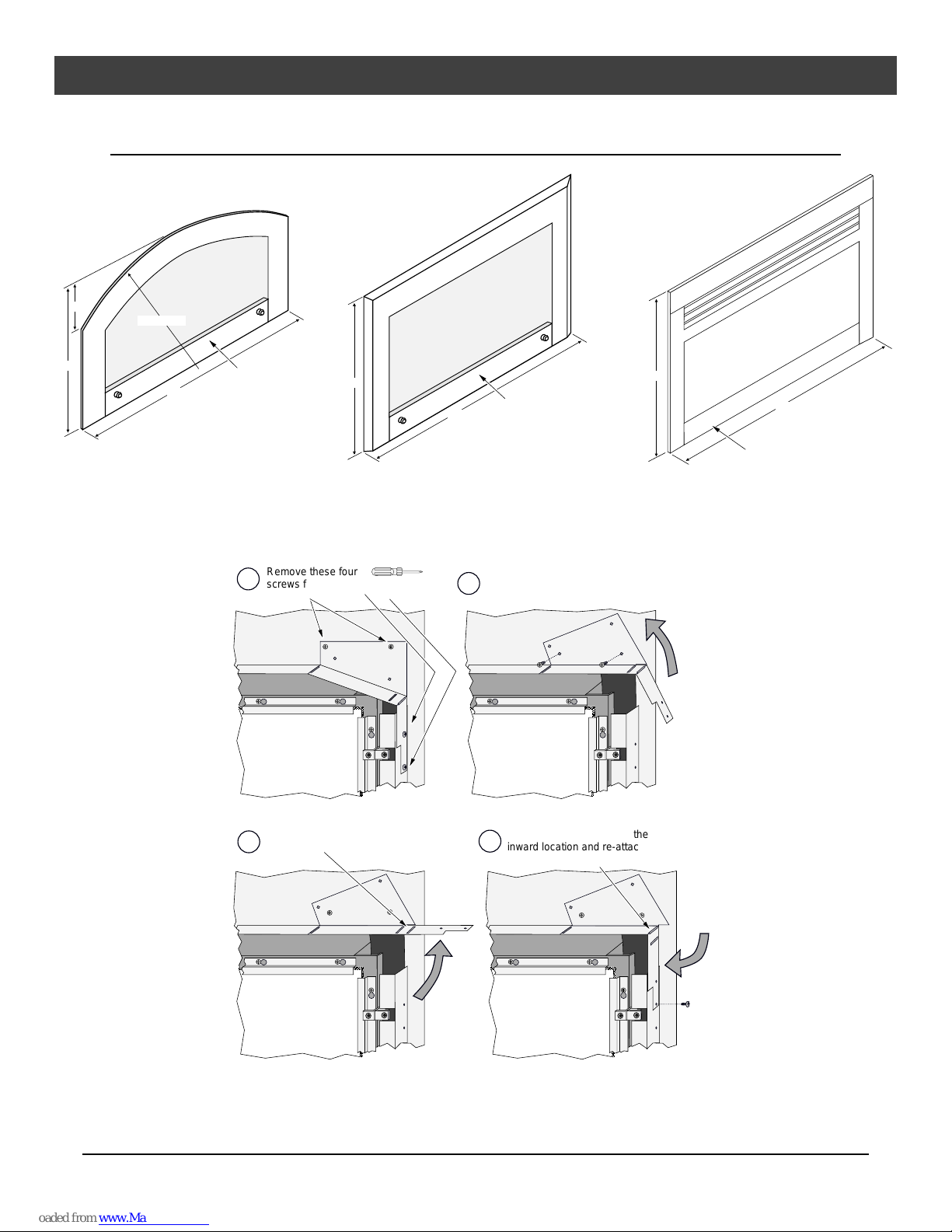

Face Dimensions

Classic Arched

(Gold, Black, or Artisan*)

5"

29"

Radius = 35”

36”

* Artisan faces may vary slightly in size

due to the forging process.

Modifying the Face Angle for Rectangular Faces

If using a rectangular face, adjust the face angles at the top corners of the glass (see the illustration

below).

Access Door

Remove these four

a

screws from the face

angle.

Rectangular Bevel Face

(Black or Gold)

27-1/2”

Phillips

Screwdriver

Access Door

38”

Bend the face angle up and replace

b

the two screws on the upper section.

Architectural Faces

(French Country,

Arts & Crafts,

Art Deco, or Neo-Classical)

29-3/8”

Access Door

36-1/4”

Front of

Fireplace

Glass

Straighten the face angle.

c

Re-bend the face angle at the

d

inward location and re-attach the

lower portion with one screw.

Travis Industries 93508118 270900

Installation (for qualified installers only) 13

Facing and Hearth Examples

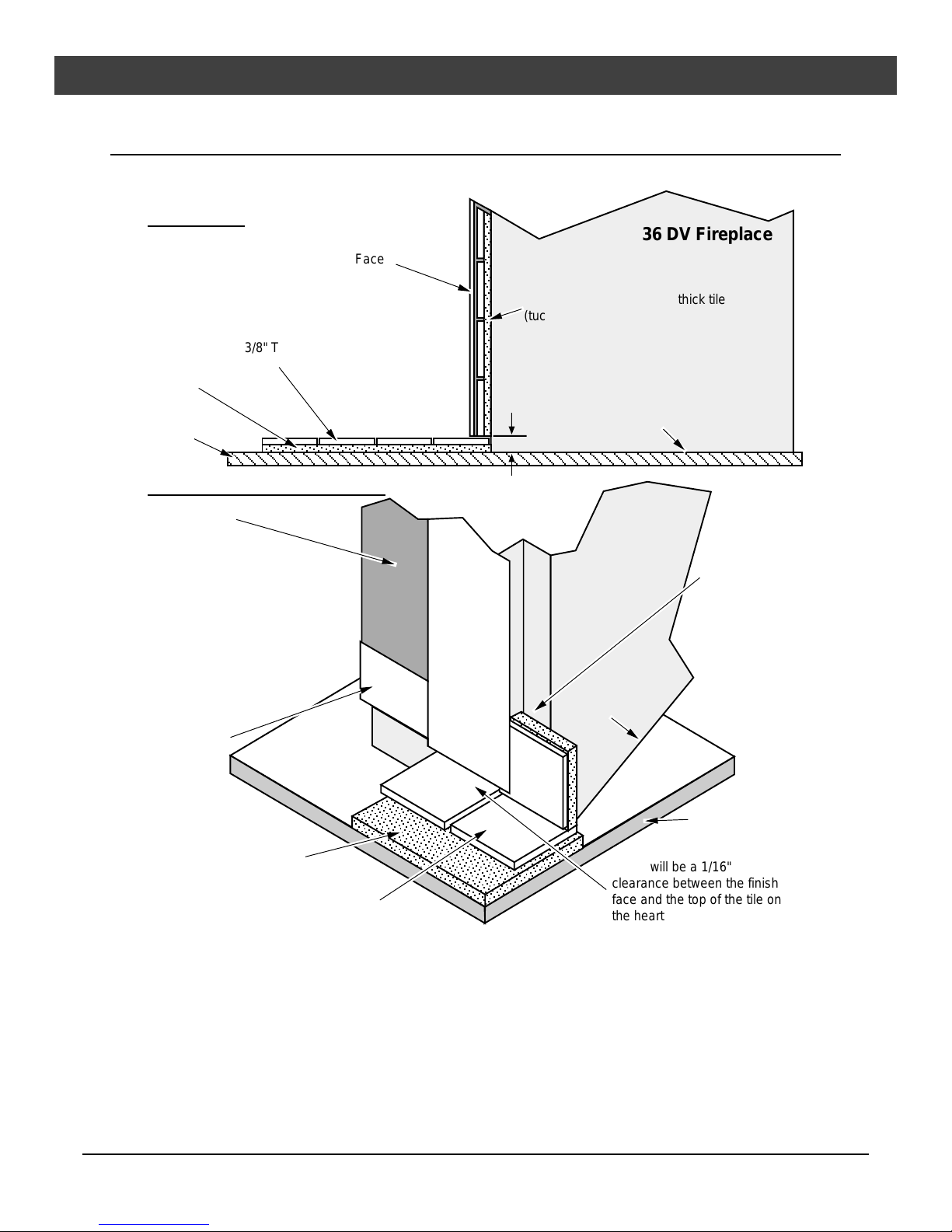

Side View

Face

SUGGESTION:

If using a hearth, make your platform height a

dimension that will accommodate the size tiles

you are using and the 1" between the base of

the fireplace and the bottom of the face.

3/8" Thick

1/2" Cement

Board

Wood Sub

Floor

Tile

Fireplace

1"

2x4 and Plywood Platform

Base of Fireplace

Three-Dimensional View

Access Door

NOTE:

When fully installed, there will be a 1/2"

air space below the access door on the

face. Do not block this space (it is

required for access door opening and

air flow).

Note how the tile facing fits behind

the face on the side and top and

butts up to the face on the bottom.

Face

Side of

Fireplace

1/2" Cement Board

& 3/8" Tile

(tucked behind the

face)

Base of Fireplace

2x4 and

Plywood

Platform

Tile

Cement Board

Travis Industries 93508118 270900

14 Installation (for qualified installers only)

Facing and Hearth Examples (continued)

Side View

36 DV Fireplace

Face

1/2" Cement Board & 3/8" thick tile

(tucked behind the face)

3/8" Thick

1/2" Cement

Board

Wood Sub

Floor

Three-Dimensional View

Face

Tile

1"

Base of Fireplace

NOTE:

When hearth installation is

correctly completed, there will

be a 1/2" air space below the

access door on the face. Do

not block this air space (it is

required for access door

opening and proper air flow).

Access

Door

1/2" Cement

Board

WARNING:

Do not install cement board underneath the fireplace. To do so

would leave a large gap underneath the finish faceplate sides.

3/8" Tile

Side of

Fireplace

Base of

Fireplace

There will be a 1/16"

clearance between the finish

face and the top of the tile on

the hearth.

Note how the

tile facing fits

behind the

face on the

side and top.

Wood Sub Floor

Travis Industries 93508118 270900

Installation (for qualified installers only) 15

Mantel Requirements

• The combustible area above the facing must not protrude more than 3/4" from the facing. If it does, it

is considered a mantel and must meet the mantel requirements listed in this manual.

Combustible Mantels

Non-Combustible

Mantels

Max.

Mantel

Depth is

8”

30" Arch face

28-1/2" Rectangular face

30-3/8” Architectural face

24” Min. Arch Faces

22” Min. Rect. Faces

Combustible Mantel

Non-Combustible mantels must maintain a 12"

clearance to the top of the face and be located

below the header -or- maintain a 24" clearance.

Max.

Mantel

Depth is

8”

Travis Industries 93508118 270900

Min. 12"

Non-Combustible Mantel

Header

46-1/8"

30" Arch face

28-1/2" Rectangular face

30-3/8" Architectural face

16 Installation (for qualified installers only)

Vent Requirements

! The vent must maintain the required clearance to combustible materials to prevent a fire (see

“Clearances” below). Do not fill air spaces with insulation.

! The gas appliance and vent system must be vented directly to the outside of the building, and never

be attached to a chimney serving a separate solid fuel or gas-burning appliance. Each direct vent gas

appliance must use it's own separate vent system.

Altitude Considerations

This heater has been tested at altitudes ranging from sea level to 8,000 feet (2,400 M). In this testing we have

found that the heater, with its standard orifice, burns correctly with just an air shutter adjustment.

! Failure to adjust the air shutter properly may lead to improper combustion which can create a safety hazard.

Consult your dealer or installer if you suspect an improperly adjusted air shutter.

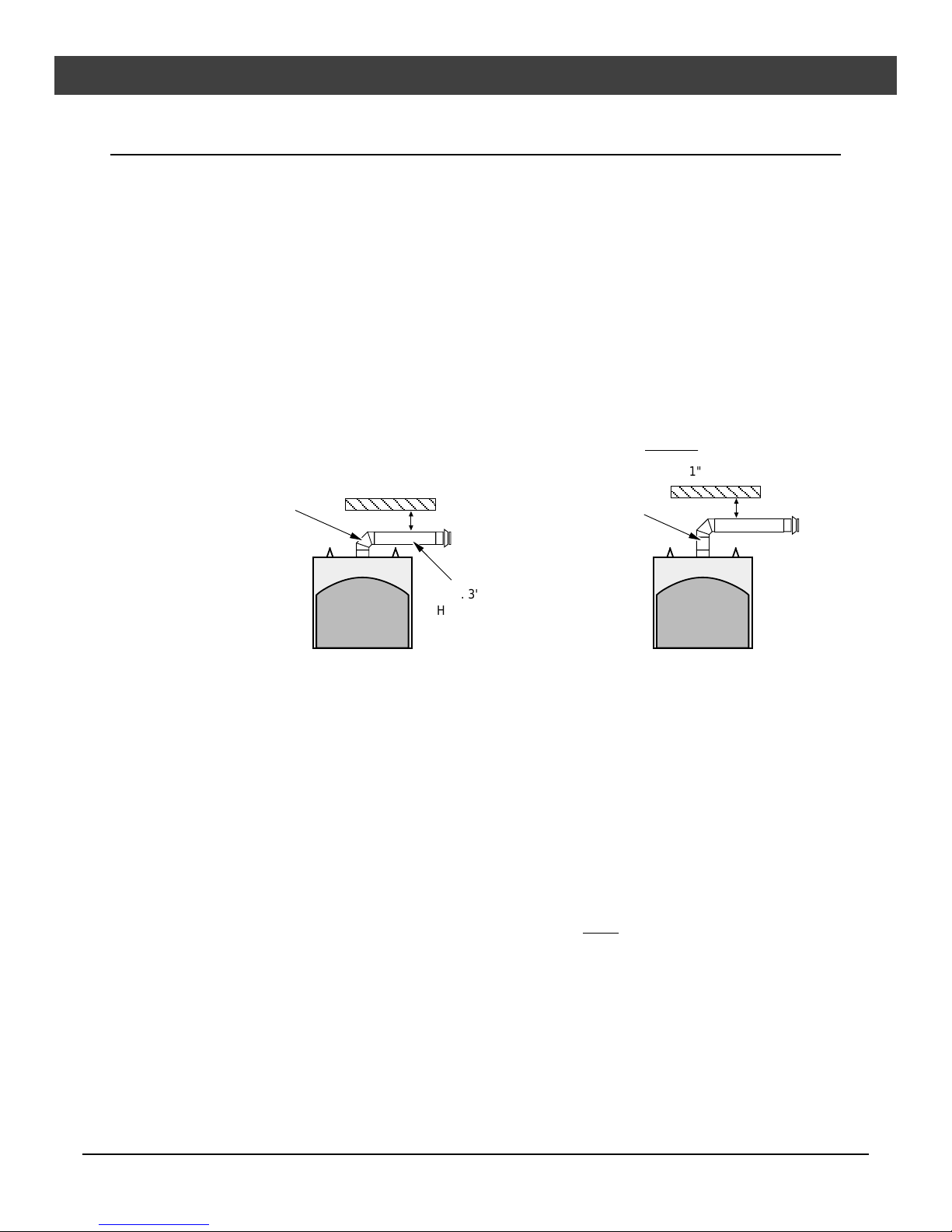

Clearances

Minimum 1” clearance to all combustibles (measured from the outside of the pipe) except for the following:

When using 6-5/8" vent, a

horizontal termination, and

an elbow directly off the

top of the fireplace, a 2"

clearance is required

above the horizontal

sections (1" to the side

and below).

2" Clearance

With any vertical

vent directly off the

fireplace, the

clearance is 1".

Max. 3'

Horizontal

Run

1" Clearance

Use of 8” Diameter Pipe

• Most venting configurations use 6-5/8” diameter vent. To achieve longer horizontal runs (over 12’)

with a horizontal termination, 8” dia. Simpson Duravent type GS Direct Vent may be used. See the

section “Horizontal Terminations using 8” Diameter Vent” for details. Part Numbers are listed below.

Straight Lengths

1208B 6" Pipe Length, Black

1207B 9" Pipe Length, Black

1206B 12" Pipe Length, Black

1204B 24" Pipe Length, Black

1203B 36" Pipe Length, Black

1202B 48" Pipe Length, Black

1211B 11” to 14-5/8" Adjustable Pipe,

Black

Terminations

1284 Horizontal Square Termination

1285 Hor. High Wind Termination

1250 Vinyl Siding Stand-off

Elbows

1245B 45° Elbow, Black

1290B 90° Elbow, Black

Penetration, Support

1242 Wall Firestop

1241 Cathedral Ceiling Support Box

1263 Ceiling Fire-stop

1288 Wall Strap

Adapter (6-5/8” to 8” dia.)

925T DV GS 6-5/8” to 8” Increaser

Part Numbers for 6-5/8” Diameter Vent

• Use Model GS Direct Vent manufactured by Simpson Dura-Vent only . Follow the installation

instructions included with the vent. For the nearest Simpson Dura-Vent supplier, call (800) 835-4429.

Vent part numbers and descriptions are listed below.

Straight Lengths

908B 6" Pipe Length, Black (interior)

907B 9" Pipe Length, Black (interior)

906 12" Pipe Length, Galvanized

906B 12" Pipe Length, Black (interior)

904 24" Pipe Length, Galvanized

904B 24" Pipe Length, Black (interior)

903 36" Pipe Length, Galvanized

903B 36" Pipe Length, Black (interior)

902 48" Pipe Length, Galvanized

902B 48" Pipe Length, Black (interior)

911B 11" to 14 5/8" Adjustable, Black (interior)

Travis Industries 93508118 270900

Vent Terminations

981 Snorkel Termination (36" rise)

(for basement or raised

termination installations)

982 Snorkel Termination (14" rise)

(for basement or raised

termination installations)

984 Horizontal Square Termination

950 Vinyl Siding Stand-off

991 High Wind Vertical

Termination

Elbows

990 90• Elbow

990B 90• Elbow, Black (interior)

Penetration, Support

942 Wall Thimble

941 Cathedral Ceiling Support Box

943 Flashing, 0/12 to 6/12 Roof Pitch

943S Flashing, 7/12 to 12/12 Roof Pitch

953 Storm Collar

963 Ceiling Fire-stop

988 Wall Strap

Installation (for qualified installers only) 17

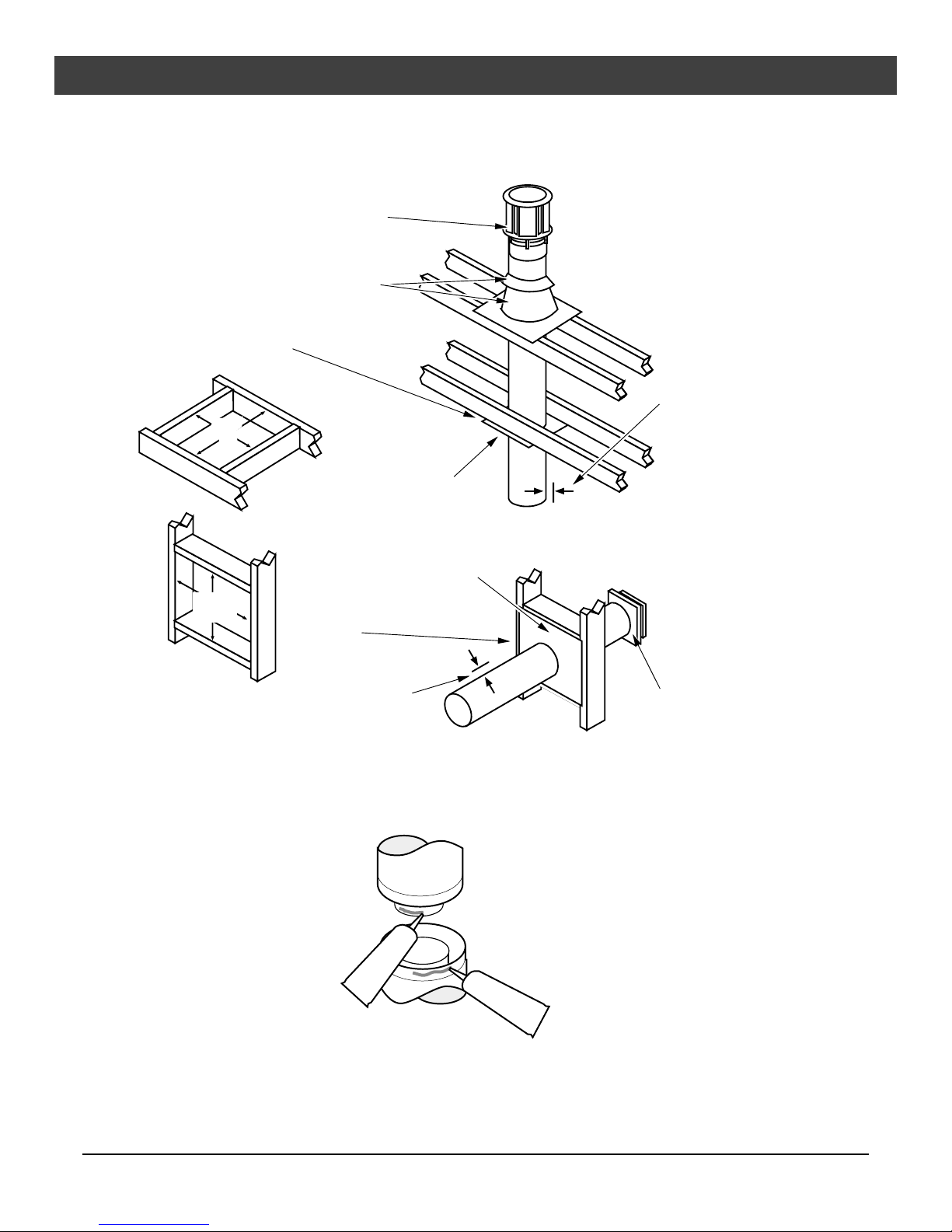

Vent Installation

• In addition to the requirements below, follow the requirements provided with the vent.

Vertical Termination

Use a roof flashing and storm collar

whenever passing through the roof

Use a firestop whenever

passing through a ceiling

8-5/8"

8-5/8"

or

10"

or

10"

Minimum framing

for fire stop

Minimum

Framing for

wall thimble

Use a support box

on exposed vent

Use a firestop whenever

passing through a wall

Vertical Vent

Requirements

Maintain a minimum 1"

clearance from vent to

any combustible

Horizontal Vent

Requirements

Horizontal TerminationMaintain a minimum 1" clearance (2" in

some cases - see "Clearances") from

vent to any combustible

• Apply high-temperature silicone to the inner and outer pipe before assembling the sections (on the

male, upper section). This seals the inner pipe from the outer pipe. Slide the sections together and

turn 1/4 turn until the sections lock in place. Install three metal screws through each joint to lock the

outer section in place (see the instructions included with the vent for further details).

Apply a 1/8" (3 mm)

bead of hightemperature silicone

to the inner and

outer pipe. The

silicone must seal

the inner pipe from

the outer pipe.

Silicone

Silicone

• Horizontal sections require a 1/4" rise every 12" of travel

• Horizontal sections require non-combustible support every three feet (e.g.: plumbing tape)

Travis Industries 93508118 270900

Loading...

Loading...